Abstract

Excessive dependence on fossil fuels increases GHG emissions and carbon levels in the atmosphere, leading to climatic changes. This phenomenon can be reversed by capturing the carbon via “carbon capture and storage” (CCS) or “carbon capture and utilize” (CCU) technologies. In CCS methods, the captured carbon is stored in natural sinks (e.g., oceans), whereas, in CCU methods, the carbon is converted into useful products. Among CCU methods, the biological conversion of CO2 () into value-added chemicals has gained great attention. This review focuses on providing an overview of the recent advances in CO2 utilization technology with a focus on the . The theoretical background and technical drivers, challenges, and setbacks of upscaling and commercialization of are critically discussed with implications for future improvements. The is increasingly attracting the attention of researchers and industrialists for its capacity to operate under low CO2 concentrations and in the presence of impurities (common conditions in industrial flue gases)—among other numerous advantages. While upscaling algae-based has operational and financial challenges, bioconversion via bacteria and genetically engineered cyanobacterial seems promising due to their efficiency and flexibility.

1. Introduction

Greenhouse gas emissions (GHGs) into the atmosphere frequently result in a financial burden and a hazard to the environment due to their significant role in climate change. The marketed amine technique used to lower CO2 emissions into the environment has a low capacity, significant corrosive properties, and a high energy requirement. Deep saltwater aquifer CO2 injection has little economic value (net cost), and newer experiments have revealed problems with injectivity and caused seismicity. The current capacity of carbon capture, utilization, and storage (CCUS) technologies stands at 111 mtpa [1], but this capacity should be increased by 100-fold by 2040 to achieve the recommended global two-degree scenario’ (2DS). CO2 contributes to 77% of GHGs, making it the main gas that requires reduction to achieve the claimed 2DS. The concentration of CO2 has progressively increased in the atmosphere from 277 ppm in 1750 to almost 419 ppm in March 2022 [2,3] ful effects on human health that, when prolonged, can be fatal. These conditions include chronic inflammation, kidney failure, bone atrophy, and loss of cognitive function [4].

Utilization vs. storage is considered a new addition to CCUS technologies. The new direction is to substitute “storage” with “utilization” of carbon to produce useful end-products. There have been limited trials to use CO2 in food production, chemical processes, and enhanced oil recovery, among others. Yet, there exists an urgent need to explore cost-effective alternatives to remove CO2 from industrial flue gases and, even better, convert it into added-value products with low environmental impacts. It is imperative that developing cost and energy-effective technology for CCS is a prerequisite to reducing GHG emissions and meeting the target emission limit. Reports show that limited attempts have been conducted to employ CO2 in food production and other chemical processes [5,6,7]. The only practical process for CO2 utilization is the enhanced oil recovery process. Such an application has been acknowledged for several decades to have considerable economic value and is thus commercially viable. Exploring and finding alternative cost-effective processes to utilize CO2 and other industrial wastes is of high priority. The low concentration (4–8%) of CO2 in flue gas, high concentration of O2 (13–15%), and wide range of temperatures are the main challenges for its utilization.

Recently, the biological conversion of CO2 (bioconversion of CO2, ) into value-added chemicals has gained great attention. The includes state-of-the-art technologies that convert CO2 into chemicals and/or biofuels in liquid, gaseous, and solid-state while minimizing their environmental impact. In such processes, CO2 undergoes biological conversion in a fermentation process where carbonaceous gases are used as the main substrate for bacterial growth [8,9]. Bioconversion processes could be used to convert a wide range of feedstocks such as SynGAS, gasses produced from the gasification of municipal solid waste, industrial wastes, biomass, agricultural wastes, and industrial off-gases [10,11,12]. into stable added-value products is economically feasible as it does not require pure CO2 or the separation and compression of gasses.

can occur via two pathways: biomineralization, where CO2 is converted into stable carbonate mineral, and bioconversion, where CO2 is converted into biomaterial or biofuel. Biomineralization is generally considered to be a silicate weathering process referring to the ability of silicate to lock up huge amounts of carbon in the form of limestone rocks, such as wollastonite (CaSiO3), serpentine (Mg3Si2O5(OH)4), and olivine (Mg2SiO4) [13]. The biomineralization process occurs via a series of reactions that includes the dissolution of CO2 gas in water-producing carbonic acid. The carbonic acid dissociates afterward into bicarbonate and carbonate ions that react with divalent metal-producing minerals. , on the other hand, is based on the use of acidogenic bacteria to convert CO2 and/or CO gases to a wide variety of added-value products. The use of acidogenic bacteria in processes provides several advantages compared with established CCS in terms of chemical utilization and production cost. During the gas fermentation process, the microorganisms metabolize CO2 and CO as the main growing substrate producing liquid ethanol as a catabolic activity product. Other chemicals, such as acetic acid and butanol, were identified within the products. Acidogenic bacteria are capable of converting CO2 gas into methane, methanol, ethanol, and butanol. Other research works showed the to fuels as well as other marketable chemicals using specific types of bacteria [8,9]. The microbes transport the gas inside the cell membrane and enter the metabolic pathways where several thousand chemical reactions take place. Recently, the technology has matured enough to the degree that large-scale production of ethanol from gas has been demonstrated commercially by three companies, Coskata Inc., INEOS Bio, and LanzaTech. All of these companies demonstrated scalable pilot and demonstration plants.

Several studies have reported and proved the technical feasibility of microbial fermentation, converting CO2 and CO to liquid biofuels and chemicals [14]. The produced biomaterial or biofuels can be recovered using well-established distillation technology. Handler, Shonnard [15] studied the advantages of reducing GHGs via biological conversion into ethanol through the use of acetogenic bacteria from steel mill wastes. The study showed that the bioconversion of these wastes to ethanol decreased GHG emission by 60% compared with fossil gasoline. The study concluded that employing gas bioconversion technology could be a promising next-generation biofuel alternative that satisfies fuel standards with a significant decrease in GHG emissions.

While processes can produce high added-value products at a competitive production cost to gasoline, different challenges are still facing this technology, including the Identification of suitable types of bacteria that can be used in at various concentrations, different temperatures, and pH conditions, Optimization of the key parameters (initial concentration of CO2, pH, inoculum size, and temperature) for the selected bacterial, the Provision of guidelines and operational procedures for optimal growth and maximum chemical production, Investigation of the influence of the bacterial growth kinetics, process hydrodynamic (gas and liquid flow rates), CO2 mass transfer rate on the performance of the bioconversion process, Evaluating the number of different products produced from each bacteria under different operating conditions, and Design a unique, scalable gas fermentation process that effectively converts GHG into chemical and biofuels. Therefore, this paper aims to provide an overview of the recent advances in CO2 utilization technology with a focus on . In addition to providing a theoretical background and technical drivers, the challenges and setbacks of upscaling and commercialization of such technology are critically discussed with implications for future improvements.

2. Sources of CO2

The combustion of fossil fuels in diverse sectors, such as electricity generation, transportation, and industry, is the primary and most substantial (80%) source of CO2 emissions worldwide [16]. This is due to the significant reliance on fossil fuels for energy generation [17]. In actuality, energy generation accounts for roughly 73% of GHG emissions, which are dispersed among 24% of industry, 17% of buildings, 16% of transportation, and around 16% of other applications [18]. Because the global energy demand is predicted to rise by more than 50% between 2020 and 2030, the emission of GHGs is expected to increase dramatically [19]. Accordingly, into biofuel has gained great attention in order to decrease the level of CO2 in the atmosphere and convert a huge amount of waste gases into added-value products. In addition, the reproduction of biofuels to substitute fossil fuels for energy generation (electricity or transportation) can have a considerable impact on GHG emissions. This can be attributed to several factors, including population growth, higher productivity, new products, economic growth, and urbanization.

Agriculture, forestry, and land use are the second greatest sources of CO2 emissions into the atmosphere, accounting for approximately 18% of total GHG emissions [20]. It is worth noting that an overall decrease in GHG emissions has been lately observed; it was hypothetically attributed to social restrictions and economic fallback associated with COVID-19 [21]. A study that included 69 countries, 50 US states, and 30 Chinese provinces (representing 85% of the world population and 97% of global CO2 emissions) estimated the decrease in the daily CO2 emissions to be 17% in April 2020, compared with the mean levels in 2019. Specifically, in China, one of the largest GHG emitters. The observed post-lockdown emissions are about 36% lower than expected levels, with a generally decreasing trend [22]. Despite those observations, the level of atmospheric carbon remains excessively high, and remediation actions are highly needed. Recent projection of the CO2 emissions was summarized by Elmobarak et al. [23].

3. Approaches to Reduce CO2 Emission

The most well-known technique to reduce CO2 emissions is to reduce the use of fossil fuels by either (1) decreasing the demand for energy or (2) using alternative (clean) sources of energy such as solar, wind, geothermal, nuclear, and biomass [24]. Another approach is to substitute materials with a high carbon-to-hydrogen ratio (C/H) with ones having a low C/H. For instance, coal and oil are replaced with natural gas [24]. Yet, the current share of natural gas does not exceed 30% of total fossil fuel energy consumption [25]. Another promising alternative is carbon capture and utilization. Although the captured CO2 can be stored in natural sinks, its utilization in the form of a new product would have different economic benefits [26].

Carbon capture and storage (CCS) is a term used to describe a group of methods used in capturing CO2 from large stationary industrial plants [26]. CCS consists of three steps: capturing, transporting, and then storing CO2 [27]. It is accomplished through the use of solid porous materials such as zeolites, metal–organic frameworks, or hybrid ultra-materials for absorption or adsorption [28]. The captured CO2 is then stored in appropriate geological structures (e.g., depleted oil and gas reservoirs, saline aquifers, coal beds, etc.) or deep oceans [29].

Several CCS pilot projects are now operational or under construction across the world, including the Gorgon facility in Australia, a CCS project in China, and European CCS infrastructure [30]. However, until this date, the proposed processes do not meet the requirements for commercialization and upscaling to address the huge emissions of CO2 around the world [27]. Drawbacks such as high energy consumption, transportation challenges, and the leakage of stored CO2 into the atmosphere still need further research and improvements [31]. CO2 utilization is another alternative to CO2 capture. This alternative provides two paths for carbon utilization: Direct use of CO2 in reservoirs for intense crude oil extraction or enhanced oil recovery (EOR) [32] and indirect use by converting the CO2 into chemical products or fuels [33]. As such, CCU methods not only reduce atmospheric CO2 levels but also provide economically valuable and environmentally clean products [34,35].

4. Conventional CO2 Reduction Processes

Carbon capture methods (CCS and CCU) are classified into three main types depending on the state and the type of combustion of carbon upon capturing [36]:

- Pre-combustion: whereby CO2 is extracted from fossil fuels before they are burned [37].

- Oxyfuel combustion: whereby pure oxygen (instead of air) is used to combust fossil fuels, producing only CO2 and water vapor. The latter is separated from the CO2 via condensation, and pure CO2 is collected and used in many ways [38]. Formic acid and its esters, formamides, methanol, dimethyl carbonate, alkylene carbonates, carbamic acid esters, lactones, carboxylic acids, and polycarbonates are a few examples of the products that can be made using it as a feedstock [39].

- by CO2 is captured from the flue gases after fuel combustion [40] sed on various mechanical and chemical processes (e.g., absorption, adsorption, membrane separation) and bio-chemical means [24]. Among those, chemical absorption into an aqueous amine solution is the most promising [41].

5. Chemical CO2 Capturing Methods

This section summarizes the most common chemical CO2-capturing technology.

5.1. Absorption

CO2 Absorption is a solvent-based method where CO2 is captured using aqueous solutions, such as monoethanolamine (MEA), diamines and tertiary amines, aqueous ammonia, amino acid salts, ionic liquids, and deep eutectic solvents [42,43] CO2 is captured when the gas stream containing the CO2 is brought into contact with these solvents [44]. Some of these solvents absorb the CO2 chemically, while others do it physically [45].

The solvents are then regenerated and reused by breaking the CO2–solvent bond by increasing the temperature or lowering the pressure [46]. Alkanolamine aqueous solutions are the most used solvents. However, these solvents have some drawbacks, such as high corrosion rates, high energy consumption, amine degradation, and a large footprint. To overcome these problems, the use of ionic liquids as solvents has been lately gaining attention due to inherent structure tunability, good affinity to CO2, and low volatility [44]. For CO2 capture, the most mature and close to large-scale applications are absorption processes [43]. In the following paragraphs, physical and chemical absorption will be further investigated.

5.1.1. Physical Absorption

This process does not depend on any chemical reactions but relies on the solubility of CO2 in the used solvents [47]. Several well-established industrial technologies are based on physical absorption, including Rectisol, Purisol, and Fluor. One of the main differences between these technologies is the solvent used. For example, the Rectisol Process uses methanol as solvent, whereas the Purisol Process uses Nmethylpyrrolidone. Each of the marketed processes has its advantages and drawbacks. For instance, Rectisol provides a less corrosive process even in the presence of sulfur, while Purisol is known for its low energy consumption. In comparison, Fluor operates at very high partial pressures (above 60 Psig) [48].

The capture of CO2 through physical absorption is guaranteed by van der Waals forces occurring between CO2 and the solvent; this implies that the regeneration of the solvents is easy upon a moderate decrease in pressure or increase in temperature [47]. This process follows Henry’s law: the higher the partial pressure of CO2 and the lower the temperature, the higher the absorption efficiency [46]. Therefore, for gas streams with CO2 partial pressures <15 vol%, such as those from natural gas and coal-fired power plants, physical absorption is not advantageous [43].

5.1.2. Chemical Absorption

As its name indicates, chemical absorption requires CO2 to react with the solvents to form a weakly bonded intermediate compound. The chemical solvent is then regenerated by thermally breaking these bonds. Primary, secondary, and ternary Alkanolamines, such as Monoethanolamine (MEA), diethanolamine (DEA), and N-methyl diethanolamine (MDEA), respectively, have been used as solvents. As the order of the Alkanolamine increases, its reactivity with CO2 increases, but also, each Alkanolamine presents specific benefits.

In comparison to physical absorption, chemical absorption has a higher CO2 capture rate, because the presence of chemical reactions increases the mass transfer of CO2 from the treated gases to the solvents [43]. Chemical absorption is considered the most mature technology for CO2 capturing [46]. For instance, according to the International Energy Agency- Greenhouse Gas Division (IEAGHG), chemical absorption with MEA solvents scored 9 on the technology readiness level (TRL). This implies that the technology to completely ready for commercialization [43].

In contrast to physical absorption, chemical absorption operates at low CO2 partial pressures. Therefore, it can be used in capturing CO2 from flue gases with low CO2 concentrations. In summary, the main advantages of this process are (1) high capturing efficiency capturing of CO2, (2) advanced maturity level, and (3) low cost. Naturally, the process has a few drawbacks, including (1) amine degradation due to the presence of SO2, NO2, and O2 in the flue gases, (2) high energy requirements for solvents regeneration, (3) high corrosion rates, and (4) a large footprint [46].

5.1.3. Adsorption

Adsorption is the use of solid sorbents to capture CO2. In contrast to absorption, adsorption takes place only at the surface of the sorbents [49]. The used adsorbents can then be regenerated in a desorption process by thermal or pressure modulation with lower energy requirements compared to absorption [49]. The selection of the adsorbent depends on several criteria, such as adsorption capacity, selectivity of adsorbent for CO2, ease of regeneration of adsorbed CO2, and stability of adsorbent after several adsorption/desorption cycles.

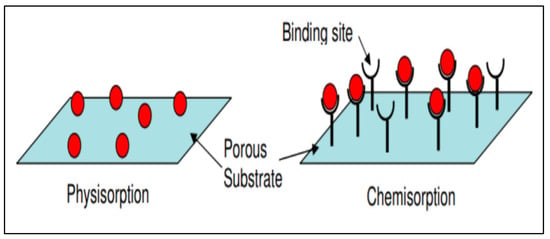

There are two types of adsorption based on the mechanism followed for the capture of CO2 (Figure 1). The first one is chemical adsorption (chemisorption), where the exchange of molecules between the sorbent and adsorbent takes place under chemical reactions, resulting in covalent bonds [50].

In comparison, physical adsorption (physisorption) is the connection of CO2 molecules to the adsorbent surface by van der Waals forces and/or electrostatic interactions. Porous physisorbents have shown favorable CO2 adsorption capacity. They are categorized into carbonaceous and non-carbonaceous [51]. The former include activated carbon, ordered porous carbon, and graphene [52]. Non-carbonaceous sorbents include a variety of materials such as silica, zeolites, hybrid ultra-materials (HUMs), and metal–organic frameworks (MOFs) [28,52,53].

Figure 1.

Representation of Physical and Chemical Adsorption [54].

From an industrial perspective, various adsorption-based systems have been developed, including pressure swing adsorption (PSA), temperature swing adsorption (TSA), electric swing adsorption (ESA), and vacuum swing adsorption (VSA)—with TSA and PSA being the most common [55,56,57]. In TSA, CO2 is used as a purge gas and is exposed directly to the adsorbent [50]. The main drawback of this method is the high energy requirements for adsorbent regeneration [24]. In comparison, VSA has the advantage of low-energy consumption, which makes it attractive for further development and optimization research. Furthermore, with post-combustion capture applications, VSA is more financially feasible than PSA, which requires pressurizing the outlet CO2, leading to a major increase in the operational cost [50].

6. Advances in State-Of-The-Art

The current methods used for the reduction of GHG are mainly based on chemical sequestration, which requires a considerable amount of energy in addition to being low efficiency. High costs (50–100 USD/t CO2 captured), techno-economic uncertainty, and the absence of viable material substitutes for liquid amine-based CCS methods to date have all impeded the adoption of these technologies. Therefore, the search for safe and cost-effective technologies for CO2 capturing and, if possible, converting those to valuable products has gained global attention. Bioconversion methods (biological sequestration) that mimic the conversion of CO2 in biological processes into stable added-value products are economically feasible as they do not require CO2 purification or separation. Recently, genetic engineering and microbial mutation techniques have been applied to gas-fermenting organisms, making it feasible for gases (CO2/CO) to be used as the carbon source for the commercial production of energy-dense biofuels and high-added-value chemicals. Velmurugan & Incharoensakdi [58] have reported the modification of Synechococcus elongatus to produce ethanol from CO2 and water. Joule unlimited has patented a cyanobacterial engineered strain for the production of bioethanol [59]. Ramachandriya et al. [60] utilized renewable hydrogen combined with acetogenic bacteria to convert CO2 from large point sources into fuels and chemicals. Other types of bacteria, including Clostridium carboxidivorans and Clostridium ragsdalei, were successfully used for the bioconversion of CO2 and H2 into ethanol, along with acetic acid, n-butanol, and n-hexanol. Out of these two bacteria, Clostridium carboxidivorans showed high ethanol production potential with a yield of 66.5% when it was fed gas consisting of 75% H2 and the balance CO2. The metabolic pathway of acetogenic can be altered by variations in operational conditions, feed stream, and nutrient composition. In addition, the selectivity and robustness of the bioconversion process, along with its catalyst flexibility and development potential, are high and promising. The process can be modified and optimized using an acetogen bacteria capable of fermenting CO and/or CO2 and H2 into acetyl-CoA (Reactions 1 and 2) and forming various products such as acetic acid, ethanol, butanol, and 2,3-Butanediol. The acetogenic bacteria that can produce ethanol, butanol, and hexanol are generally described as “solventogenic”, while acetogens utilizing CO as a substrate are referred to as “carboxydotrophic”. Acetogenic also includes bacteria that can fix the gaseous CO2 following the Wood–Ljungdahl pathway in the presence of an organic energy source. The bacteria will utilize several fermentation kinetics via the reductive acetyl-CoA pathway to achieve the target CO2 reduction and product generation [61]. The reductive acetyl-CoA pathway was characterized by Wood and Ljungdahl in 1966 (defined as the Wood–Ljungdahl pathway) after employing Clostridium thermoaceticum for the production of acetate from CO2 gas.

The novelty of is based on controlling and altering the reaction mechanism, operating conditions, and feed and nutrient composition to maximize the depletion of CO and CO2 within the well-defined metabolic pathways. The target acidogenic bacteria group would be the mesophilic organisms ranging from 30 to 40 °C. This would require no additional heating during the gas fermentation, especially during summertime. The mechanism, kinetics, and reaction rate for synthetic and actual CO/CO2 gases can be optimized to suit the industrial waste conditions. It is known that the productivity of these bacteria is greatly affected by temperature, operational parameters such as pH, gas pressure, the presence of inhibitors, microbial nutrients, and the presence of hydrogen. In this context, can be applied in different gas fermentation processes with modified operational parameters to establish optimal cell growth and maximum gas utilization. This would enable a better understanding of the fermentation kinetics and identify the limitation of substrate utilization to complete the utilization of the GHG via the metabolic pathway as a priority and promote the cells to produce high-added value chemicals as a main metabolic product as a second priority.

Cotter et al. [62] reported that factors slowing the growth of the acidogenic bacteria increase the depletion rate of the gas substrate. Consequently, for successful , the routes to induce the reaction mechanism toward high growth, as well as maximum gas uptake, should be considered via exposing the bacteria to a limited nutrient environment for a short time and/or changing the operational conditions. In more depth, increasing the NADH (nicotinamide adenine dinucleotide) concentration which favors product formation via NADH-dependent pathways as well as the level of ATP (adenosine triphosphate), would be a condition to enhance the process performance. The ATP limitation usually takes place in anaerobic fermentation resulting in lowering the cell concentration. According to Cotter et al. [62], this would, expectably, enhance gas depletion and product formation. An additional innovative idea that can be used is utilizing the heavy metals available in wastewater treatment in the gas fermentation since it contains essential metals for bacteria growth, such as Ni2+, Zn2+, . Saxena andTannerand [63] reported that Ni2+, Zn2+, and enhance the production of ethanol from a gas substrate because it increases the catalytic activities of key Wood–Ljungdahl pathway metalloenzymes. Potentially, replacing the freshwater addition (completely or partially) with wastewater containing the essential materials for bacteria growth will achieve a major milestone in reducing the negative impact of wastewater.

The low gas mass transfer into the liquid phase is one of the biggest challenges that faces the . Mass transfer is limited by many factors, as reported by Yasin et al. [64]. Novel green additives, such as ionic polymers and special types of surfactants can be used to enhance the mass transfer of the gas and promote the production process.

Parallel to the development of gas fermentation chemistry and kinetics, the improvements to the process would focus on the best fermenter design that meets the basic requirement of bacterial growth, gas consumption, and production capacity. One of the key developments of bioreactor design is improving the transfer of gas into the fermentation medium while reducing the gas–liquid mass transfer-resistant without complicating the process scale-up and, eventually, the operation costs. The design should be targeted to maximize the gas transfer by finding the optimal operating pressure, internal fluid flow, and optimal impellers and implementing a microbubble to achieve the highest volumetric mass transfer resistance (kLa) per unit power input. Ungerman and Heindeland Heindel [65] evaluated the power demand and gas–liquid volumetric mass transfer rates (kLa) of eleven impeller schemes in a continuously stirred tank reactor of a carbon monoxide–water system, applicable to syngas fermentation. The study concluded that a Rushton-type turbine impeller with a D/T ratio of 0.35 exhibits the highest kLa under all conditions. Bioreactors, such as continuously stirred tank reactors (CSTRs) and bubble columns, should be investigated to study the effect of reactor configuration and internal accessories in maximizing the process performance. The optimal gas flow rate versus the optimal value of volumetric mass transfer resistance should be determined and connected to the kinetic and microbial consumption of the gas. Although the majority of published work on syngas fermentation and CO2 bioconversion has been carried out using bench-top scale continuous stirred tank reactors (CSTRs) [66,67], the current industrial demonstration processes use bubble column, gas lift, trickle-bed, immobilized cell, and microbubble reactors [68,69,70,71]. Kundiyana [72] demonstrated the scale-up of gas fermentation in a 100 L pilot scale fermenter. One interesting design is a patented immobilized hollow fiber membrane. This patent is quite interesting since it provides direct contact between the gas and the microbial cells without the need for gas transfer into the liquid phase.

Integration of the with industries such as natural gas and oil refinery platform is another challenge that still requires further investigation. The integration will allow the process to utilize excess heat from natural gas and petroleum process and be used in various places where there is a high demand for heat utilization. For example, in downstream processing, the distillation unit would require large amounts of heat. Traditionally heat requirements for distillation technology can contribute up to 50% of the total energy demand. By heat integration, a considerable amount of operating costs can be decreased by a substantial amount.

7. Biological Processes

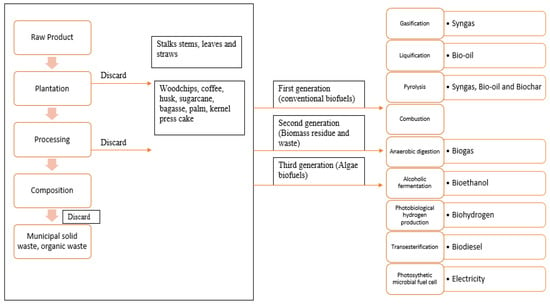

relies on living microorganisms (e.g., bacteria, algae, plant cells, etc.) to capture CO2 and convert it into other valuable products [31,73,74,75]. These products can be used as building blocks for more advanced components in the chemical industry as an alternative for fossil fuel-based products [76]. As such, the does not only mitigate CO2 released into the atmosphere, but it also produces fossil fuel replacements [2,16]. Adopting this approach on a global scale would provide 6–9% of global primary energy needs and is capable of reducing GHG emissions by more than 10% [77]. Currently, only 18% of the energy consumed globally comes from renewable sources, of which bioenergy has the highest share (14%) [78]. Future projections imply that biogas applications would count for 25% of all bioenergy produced worldwide. Figure 2 summarizes the various types of biofuels that could be produced via with their production methods.

Figure 2.

The different generations of Biofuels and their Production Methods.

The example shown in Table 1 is increasingly attracting research and industrial interests as an alternative to (well-established) chemical and physical processes because it is an environmentally friendly process [79]; it is easier to operate and can be achieved under ambient conditions. Biological processes are cheaper and more flexible, and some microorganisms can utilize CO2 in flue gases with concentrations as low as 4%. The biological processes do not require a high-purity CO2 environment, as microorganisms can capture and utilize CO2 even in the presence of SO2 and NOx [31,80]. The biological conversion of CO2 can be employed via different methods, as will be discussed in the following sections.

7.1. Bacteria-Based Processes

using bacteria as a catalyst is a long-known process that dates back to the early 1900s [81]. Previously, was constrained by the scarcity of microorganisms and the low profit margin of the end products. However, there has recently been an increase in research to improve and advance bacterial-based technology. Both aerobic and anaerobic bacteria grew autotrophically on gas components and followed a specific pathway to produce fuels and chemicals from inorganic waste gases [82,83]. Closed and open photobioreactors were used as advanced biological technologies for [84]. However, the open system was not suggested for such applications due to its low energy efficiency (3%), uneven light distribution, evaporative losses, and restricted CO2 diffusion [85]. On the other hand, microorganisms can process the independent from light in what is known as dark carbon fixation, and this was highly recommended. In terms of technology, dark carbon fixation could be a cheap way to turn CO2 into chemical building blocks [86]. Chemolithoautotrophic organisms, for example, can use the carbon in CO2 as an energy source to undertake redox processes and convert it to various compounds [87]. Mishra et al. [88] used Halomonas stevensii (H. stevensii) bacteria to convert atmospheric CO2 into fatty alcohols (Dodecanol, Tetradecanol, and Pentadecanol). The H. stevensii bacteria were isolated from Sambhar Salt Lake samples and cultivated before seeding. The effects of different parameters, such as CO2 inlet concentration, temperature, PH, and energy sources, were analyzed (through batch experiments) to determine optimum operational conditions. The maximum biomass productivity was found at 15% (v/v) CO2 (equivalent to 1.12 g/L), which is a common concentration in flue gases. The optimum values of the remaining parameters were found to be: 0.5 M salts concentration, pH 8, and 37 °C.

Liu et al. [30] investigated the ability of three different strains of Alkalibaculum bacchi (CP11T, CP13, and CP15) to convert syngas (as carbon source) to ethanol and acetic acid. The bacteria were isolated from livestock-impacted soil and incubated under anaerobic conditions at 37 °C and pH 8 in batch-fed bottles. The syngas was supplied once daily to the fermenter under a pressure of 2.39 bar. All three strains were able to convert the CO2 from syngas to acetic acid and ethanol. CP15 strain had the maximum cell growth and ethanol production of 0.21 g/L and 1.7 g/L, respectively. Yet, larger-scale experiments are needed to prove the up-scalability of this method.

Ho et al. [89] produced biofuel from using Scenedesmus obliquus CNW-N (S. obliquus CNW-N) photosynthetic microorganisms. The S. obliquus CNW-N strain was isolated from freshwater in southern Taiwan and was then cultivated and inoculated before being placed in a one-liter glass vessel photobioreactor (PBR). An external source of light with a 60 mol/ m2 s light intensity was used to illuminate the PBR. Several growth indicators, such as maximum cell concentration, maximum specific growth rate, and overall biomass production, were used to track the system performance. It was found that 10% CO2 is the most suitable concentration for S. obliquus CNW-N strain, resulting in biomass productivity of 292 mg/L.d, lipid productivity of 79 mg/L.d (equivalent to 39% per dry weight), and CO2 consumption rate of 550 mg/L.d. The process was further enhanced in another study by increasing the light intensity to 420 µmol/m2.s and applying nitrogen starvation to promote lipid and carbohydrate accumulation [89]. As a result, the maximum productivity of biomass, lipid, and carbohydrate increased to 1421, 841 and 140 mg/L.d, respectively; also, the CO2 consumption rate reached 1420.6 mg/L.d.

Several other bacteria have been proven efficient in converting CO2 into valuable products. For instance, some homoacetogens (e.g., Clostridium ljungdahlii, Clostridium autoethanogenum, Eubacterium limosum, and Moorella thermoacetica, etc.) can metabolize carbon into acetate under anaerobic conditions [90,91]. Bacteria like Escherichia coli can be genetically modified to convert CO2 [92].

Microorganisms that grow in highly salinized environments exhibited preserve cell integrity due to the generation of osmolytes [93]. The generated osmolytes provide the microorganisms with protection against stress factors making them multi-functional agents for effective . Czech et al. [93] showed that the formation of osmolytes Ectoine (2-methyl-1,4,5,6-tetrahydropyrimidine-4-carboxylic acid) acts as a protective hydro-layer on cell surfaces and strengthens hydrogen bonds in aqueous solutions. Ectoine is therefore regarded as a very powerful stabilizer of nucleic acids, cell membranes, proteins, DNA–protein complexes, and proteins. The conserved gene cluster ect ABC encodes three distinct enzymes for the ectoine: l-2,4-diaminobutyric acid (DABA) transaminase (EctB), DABA acetyltransferase (EctA), and ectoine synthase (EctC) play an important role in the to added-value products [84].

Different aerobic methanotrophs (M. alcaliphilum, M. buryatense, M. kenyense or M. japanense) have been identified to develop ectoine and contribute the to C1 products. For example, M. alcaliphilum showed an excellent methanotrophic performance with ectoine-specific yields of 230 ± 20 mg gdcw−1 [94].

7.2. Cyanobacteria-Based Process

Cyanobacteria are defined as a type of prokaryotes (creatures with no characteristic nucleolus) that utilize photons to transfer electrons. Cyanobacteria transfer electrons from water to CO molecules to convert them into valuable products [95]. Some genetically modified cyanobacteria can directly convert CO2 into target products. This is achieved by manipulating the metabolomics-guided strain of cyanobacteria to (1) redirect carbon flow from CO2 toward the desired product and (2) improve the CO2 uptake rate [96]. However, before their employment in on a big scale, a number of inherited issues such as delayed growth, uneven carbon distribution, unbalanced reducing power generation, and an imbalance between growth and biosynthesis must be rectified. Sun et al. [97] recently demonstrated that choosing fast-growing cyanobacteria along with multiplex artificial small RNA cofactor enhancement under optimized sensing protocol would result in enhanced . This is because the growth defect caused by blocking essential and carbon re-direction using rhythmical cultivation would be avoided. The common bacterial and cyanobacterial species employed for are summarized in Table 1. (Yu et al. [98], Zahra et al. [99] have used Synechocystis sp. PCC6803 to convert CO2 into acetone (36 mg/L), Ethanol (5.5 g/L), Ethylene (171 µg/L per day), and fatty acids (197 mg/L). Additionally, it was experimentally proven that Synechococcus elongatus sp. PCC 7942 can convert CO2 to 2,3 Butanediol (2.4 g/L), 1-Butanol (30 mg/L), and Isobutanol (450 mg/L). Savakis et al. [95] achieved the direct production of glycerol from the genetically engineered Synechocystis sp. PCC6803. The introduction of phosphoglycerol phosphatase 2 from Saccharomyces cerevisiae into Synechocystis sp. PCC6803 resulted in a mutant strain named Synechocystis PSA002. The modified strain produced up to 11.6 mM in 17 days after inoculation. Although glycerol is known to be toxic for Synechocystis, the new strain Synechocystis PSA002 showed tolerance at concentrations higher than 1250 mM.

Similarly, Hirokawa et al. [100] showed that genetically enhanced Synechococcus elongatus PCC 7942 can convert CO2 into 1,3-propanediol (1,3-PDO), following a synthetic metabolic pathway of a four-step reaction. They studied the effect of CO2 concentration via an aeration experiment. They found that glycerol concentrations were about five folds higher under 1% and 3% CO2 compared to ambient air conditions: 13.14 mM at 1%, 12.62 mM at 3%, and 2.50 mM in ambient air. The production of 1,3-PDO at ambient air, 1% CO2, and 3% CO2 were found to be 1.88 mM, 3.25 mM, and 3.79 mM, respectively. These results indicate that production increases with CO2 level; however, further increases in CO2 concentration (beyond 3%) led to growth inhibition. The highest concentration of 1,3-PDO and glycerol were achieved on the 14th day of culture (under 3% CO2): to be 288 mg/L and 1.16 g/L, respectively. Candidatus accumulibacter phosphatis (CAP) and Synechococcus leopoliensis cyanobacteria were employed for the to biofuels, H2, and ethanol. The experimental work focused on shifting the biological process into dark anaerobic conditions where hydrogenase-mediated H2 formation reaction takes place. The involves the formation of ethanol from biomass waste [101]. The experiment was effective in demonstrating the cyclic turnover of carbon, but more research was needed to produce fuel on a wide scale.

To attain improved , Shahid et al. [102] investigated optimizing the growth conditions for a newly identified filamentous cyanobacterium, Plectonema terebrans BERC10. Optimized conditions (T ≈ 32 ± 2 °C, and pH 10.0–11.0) achieved higher biomass productivity of 140 mg L−1 d−1 (dried mass) and of 250 mg L−1 day−1. The produced biomass is rich in carbohydrates (58.68 mgg−1d−1) and lipids (39.25 mgg−1d−1). Because of these characteristics, Plectonema terebrans BERC10 is a good candidate for to biofuels and bioproducts.

Table 1.

Common bacteria and cyanobacteria species used for .

Table 1.

Common bacteria and cyanobacteria species used for .

| Species | Type | Initial CO2 Concentration in the Feed (% v/v) | % CO2 Removal | Fixation Rate (g L−1 d−1) | Products (Concentrations) | Source |

|---|---|---|---|---|---|---|

| H. stevensii | Bacteria | 5–15 (±1) | 98 | 0.174–0.218 g L−1 d−1 | Dodecanol, Tetradecanol, Pentadecanol | [88] |

| Alkalibaculum bacchi | Bacteria | 15–30 | - | - | Ethanol (1.7 g/L) | [30] |

| Scenedesmus obliquus CNW-N | Bacteria | 2.5% | 840.6–1435.90 | Carbohydrate (1420.6 mg/L d), Lipid (840.6 mg/ L d) | [103] | |

| Synechocystis sp. PCC6803 | Cyanobacteria | - | - | - | Acetone (36 mg/L), Ethanol (5.5 g/L), Ethylene (171 µg/L per day), Fatty acids (197 mg/L) | [98,99] |

| Synechococcus elongatus sp. PCC 7942 | Cyanobacteria | - | - | - | 2,3 Butanediol (2.4 g/L), 1-Butanol (30 mg/L), Isobutanol (450 mg/L) | [98] |

| Scenedesmus sp. | Bacteria | 7% | 85% | Biodiesel | [104] | |

| Chlorococcum littorale | Green Algae | 5% | - | - | Biomass | [105] |

| Synechococcus elongatus | Cyanobacteria | 0.04 to 60% | - | - | [106] | |

| Chlorella sp. | Bacteria | 0.04 to 11.6% | 60% | Biogas | [107] | |

| Genetically modified Acetobacterium woodii | Bacteria | 15–60% | 99% | Acetate (50 g/L) | [77] | |

| Acetoanaerobium noterae | Bacteria | 25–60% | 95.4% (conversion to acetate 34%) | 2.7% | Acetate (0.3 g/L) and CH4 > 95% | [108] |

| Clostridium ljungdahlii | Bacteria | - | - | - | Acetate: (1.68 g/L/d) | [109] |

| Tetraselmis suecica | Bacteria | 0.04–30% | 96.89 mg L−1 d−1 | Organic acid | [110] |

7.3. Algae-Based Process

Using algae for the bioconversion of CO2 has multiple benefits. Generally, algae growth requires basic and abundant elements such as light, sugar, CO2, etc. Algae biosystems are considered non-toxic and can easily grow almost anywhere, even in harsh environments, which makes them a very attractive solution for CO2 conversion [76]. According to a recent study, 1 kg of algae can fix 1.83 kg of CO2, and some algae species can use COx and NOx as nutritional fluxes in addition to CO2 [111]. These findings make microalgae an effective technology. Yet, algae-based conversion has its own challenges. Algae need sufficient exposure to light to grow; this constitutes a major hurdle for real-scale applications, which would require excessively large surface areas [112]. In addition, operational costs might be prohibitive, requiring an extensive techno-economic assessment before implementing any algae-based biofuel project [113].

The three types of microalgae are photoautotrophic (which assimilates inorganic carbon and uses light as an energy source), heterotrophic (which accepts organic carbon whether or not there is light), and mixotrophic (which assimilates both inorganic and organic carbon) [114]. Because they can grow on a larger variety of substrates and do not require as much irradiation, mixotrophic microalgae hold more promise for widespread application. Such strength allows for greater flexibility in carbon assimilation [115]. Operational conditions such as pH, CO2 concentration, the presence of other gases and temperature have a direct effect on algal growth and CO2 biofixation. The pH of the growth medium can have a significant impact on the enzymes involved and the ions absorbed by microalgal cells [114]. Given that HCO−3 absorption causes a high pH level (>9), the optimal microalgal culture should have the ability to absorb HCO−3 as the main source of dissolved inorganic carbon in these conditions. Although most microalgal strains cannot grow well at CO2 concentrations above 5% [116], only a few species of chlorophyte could withstand high CO2 concentrations above 60% [115,117].

The microalgal candidates with the highest CO2 tolerance and pH levels are Chlorella vulgaris, Synechococcus sp., Anabaena cylindrical, and Spirulina platensis species. Because it can catalyze the conversion of CO2 into bicarbonate and protons, carbonic anhydrase (CA) in microalgal species has recently attracted more attention as an enzymatic promoter. Anabaena cylindrical and Spirulina platensis frequently contain CA [118].

7.3.1. Prospective of Algae in Process

In most cases, the use of algae for is paired with wastewater treatment in what’s known as an Algae-based wastewater treatment process [119]. Algae can be regarded as an effective treatment procedure due to its great ability to absorb nutrients and pollutants from wastewater [79]. Algae can remove nitrogen, phosphate, and other contaminants from water while absorbing CO2 from the atmosphere or flue gases during the photosynthetic process, helping to reduce GHGs [120,121,122]. Therefore, by utilizing algae for wastewater treatment and CO2 capture, we can achieve dual benefits of environmental sustainability and resource recovery.

Generally, algae is cultivated in wastewater either in open ponds or closed photobioreactors (PBRs). These systems provide favorable conditions for algae growth, including sunlight, temperature control, and nutrient supply [123,124,125]. Algae in the cultivation system consume nutrients, such as nitrogen and phosphorus, from the wastewater as they grow. This helps in removing these pollutants from the water. As the algae photosynthesize, they release oxygen into the water, which improves its quality and supports aerobic conditions. Once the algae have absorbed nutrients and pollutants, they can be separated from the treated wastewater using sedimentation, filtration, or other methods [126,127]. The clean water can then be discharged or subjected to further treatment if needed.

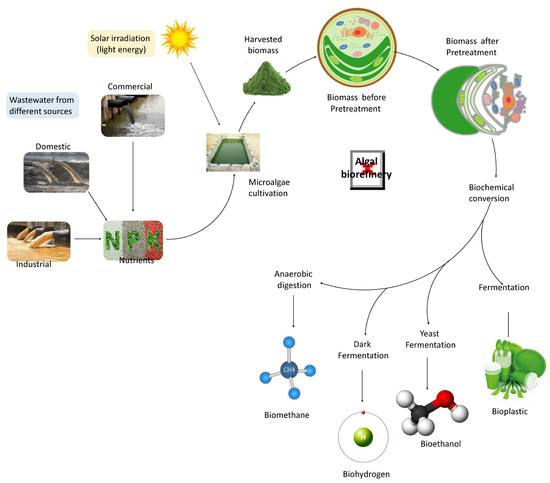

To achieve high algae growth, the PBRs should have a controlled environment of wastewater or a mixture of wastewater and CO2-rich flue gases from industrial sources [128]. Algae can absorb CO2 during photosynthesis. By exposing them to CO2-rich air or gas streams, such as those produced by power plants or industrial facilities, the algae capture and incorporate the CO2 into their biomass. The harvested algae biomass can be processed to extract valuable products, such as biofuels, bioplastics, or animal feed. Figure 3 illustrates the different pathways used for processing algae after and wastewater treatment. This utilization provides economic value while sequestering the captured CO2 within the biomass [129]. Therefore, the benefits of using algae for wastewater treatment, and can be summarized as follows:

Figure 3.

Pathways used for processing of algae after and wastewater treatment. Printed with permission from [130].

- High nutrient removal: algae efficiently remove nutrients like nitrogen and phosphorus, helping to mitigate water pollution and prevent eutrophication in water bodies.

- Effective carbon sequestration: algae capture and store CO2, reducing greenhouse gas emissions and contributing to climate change mitigation efforts.

- Renewable resources: the harvested algal biomass can be utilized for the production of various valuable products, contributing to the development of a sustainable bioeconomy.

- Energy-efficient: algae-based wastewater treatment and CO2 capture systems can operate with low energy requirements compared to traditional treatment processes or other carbon capture technologies.

- Potential for decentralized systems: algae cultivation systems can be implemented at different scales, allowing for localized wastewater treatment and CO2 capture in areas with limited infrastructure.

It is important to note that while algae-based solutions show promise, there are still challenges to address, such as optimizing cultivation methods, scaling up production, and ensuring economic viability. Ongoing research and development efforts are aimed at further improving the efficiency and effectiveness of algae-based wastewater treatment and CO2 capture systems.

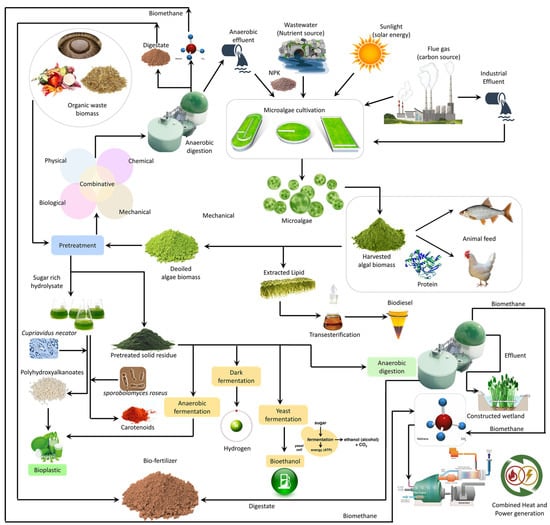

7.3.2. Added Values from the Using Algae

Algae can be converted into various value-added products through different processes, including biofuels, nutritional supplements, food ingredients, cosmetics, personal care products, bioplastics, fertilizers, and soil conditioners [131,132]. Figure 4 shows the different options used to convert algae to added-value products. The conversion of algae into biofuel is a promising area of research and development in the field of renewable energy [133]. The algal biomass generated algae-based wastewater treatment process can then be processed to extract and convert the energy-rich compounds into biofuels. The most common types of biofuels derived from algae are biodiesel and bioethanol [134,135,136]. The process of converting algae into biofuel involves the cultivation of algae in large-scale cultivation systems (e.g., open ponds, closed PBRs, or raceway ponds). Once the algae have reached a certain density or desired growth stage, they are harvested. Harvesting methods include mechanical filtration, centrifugation, flocculation, or flotation. After harvesting, the algae biomass is separated from the water through dewatering processes. This step reduces the water content and concentrates the algae biomass. The lipid-rich algae strains are processed to extract the oils, which can be converted into biodiesel. Extraction methods include solvent extraction, mechanical pressing, or cell disruption techniques. In the case of biodiesel production, the extracted oils are subjected to a chemical process called transesterification. Transesterification involves reacting the oils with an alcohol (such as methanol) and a catalyst (such as sodium hydroxide or potassium hydroxide) to produce biodiesel and glycerol as a byproduct. The biodiesel is further purified through processes such as washing, drying, and filtering to remove impurities and ensure its quality meets the required standards [134,137,138].

Figure 4.

Options to convert algae to added-value products. Printed with permission from [130].

For bioethanol production, the algae biomass can be subjected to fermentation processes, where enzymes or microorganisms convert the carbohydrates present in the algae into ethanol. The ethanol can then be distilled and purified. It is worth noting that the conversion of algae to biofuel is still a developing technology, and there are ongoing research efforts to improve efficiency, scalability, and cost-effectiveness. Challenges include optimizing algae cultivation and harvesting techniques, increasing lipid or carbohydrate content in algae strains, and reducing the overall production costs [139,140,141]. However, algae biofuels have the potential to provide a sustainable and renewable energy source while also helping to mitigate greenhouse gas emissions. Algae-based nutritional supplements offer a wide range of essential nutrients, including proteins, vitamins (such as B vitamins and vitamin C), minerals (such as iron, calcium, and magnesium), antioxidants, and omega-3 fatty acids. These supplements are often consumed in the form of capsules, tablets, powders, or as ingredients in functional foods and beverages [142,143].

Algae can also be converted into nutritional supplements due to their rich nutrient content. Algae-based nutritional supplements are often derived from specific types of algae, such as spirulina and chlorella, which are known for their high protein, vitamin, and mineral content. After cultivation, harvesting, and drying, the algae biomass undergoes additional processing, including grinding or milling the dried biomass into a fine powder to improve its texture and facilitate mixing with other ingredients. Then, the algae powder is combined with other ingredients to enhance its nutritional profile or improve the taste. This can include adding vitamins, minerals, antioxidants, or natural flavorings. Stringent quality control measures are implemented to ensure the safety, purity, and potency of the algae-based supplement. This involves testing for contaminants, verifying nutrient content, and adhering to regulatory guidelines [144,145]. It is important to note that while algae-based nutritional supplements can provide valuable nutrients, it is recommended to consult with a healthcare professional or registered dietitian before adding them to your diet to ensure they align with your specific nutritional needs and any existing health conditions.

The algae-based food ingredients are formulated and incorporated into various food products. This can involve blending the algae ingredients with other ingredients, such as flour, oils, or binders, to create functional food components or finished food products. The nutritional value and potential functional properties make algae a good material for the production of food ingredients. The cultivated dry algal biomass is milled or ground into a fine powder to improve its texture and facilitate incorporation into food products. Then, depending on the desired food ingredient, specific compounds may be extracted from the algae biomass [146]. For example, proteins, pigments, or polysaccharides can be isolated using appropriate extraction techniques [142,147,148]. The extracted compounds may undergo further refining and purification steps to enhance their quality, remove impurities, and concentrate the desired components. The most commonly used nutritional compound extracted from algae is omega-3 fatty acids and pigments. Algae oil can be extracted and used as a plant-based alternative to fish oil in various food applications, including dressings, sauces, or supplements [149,150]. Some algae contain pigments like chlorophyll, carotenoids, or phycocyanins, which can be extracted and used as natural food colorants or additives.

Algae can be used as a feedstock for the production of bioplastics, which are environmentally friendly alternatives to traditional petroleum-based plastics [151]. Algae-based bioplastics offer several advantages over conventional plastics derived from fossil fuels. They are renewable, biodegradable, and have a reduced carbon footprint. It is important to note that the specific conversion processes for algae-to-bioplastic production can vary depending on the target biopolymer and the specific algae species being utilized [152,153]. Additionally, research and development efforts are ongoing to optimize the efficiency, scalability, and cost-effectiveness of algae-based bioplastic production [154]. The conversion of harvested algae into bioplastics involves biomass processing to extract the key components that can be used for bioplastic production. This typically involves steps such as drying, milling, and cell disruption to break down the algae cells and release their contents. The extracted components of interest from the algae biomass, such as lipids or carbohydrates, are further isolated and purified. Different extraction methods may be employed depending on the specific target component. The extracted components are then subjected to a polymerization process to convert them into biopolymers. For example, lipids can be converted into polyhydroxyalkanoates (PHAs) through fermentation or other enzymatic processes, while carbohydrates can be converted into polylactic acid (PLA) through fermentation and subsequent chemical processes [154,155]. The biopolymers produced from algae are further processed to form bioplastic materials. This can involve techniques such as extrusion, injection molding, or film casting, depending on the desired form and application of the bioplastic. However, it is worth mentioning that algae-based bioplastics are still in the early stages of commercialization, and there are challenges to overcome, including cost competitiveness, scalability, and ensuring consistent quality [153,156,157]. Nonetheless, the potential of algae as a sustainable feedstock for bioplastic production makes it an area of active research and development in the quest for more eco-friendly plastic alternatives.

Algae can be converted into fertilizers and soil conditioners due to their nutrient content and ability to improve soil health [158,159,160]. The collected algae biomass is typically dried to remove excess moisture. Various drying methods, such as sun drying or mechanical drying, can be employed. Once dried, the algae biomass may undergo additional processing steps, such as grinding or milling, to create a fine powder or flakes. Algae are rich in nutrients, including nitrogen, phosphorus, potassium, and micronutrients. Dried algae biomass can be further processed to extract these nutrients. This may involve techniques such as solvent extraction, mechanical pressing, or enzymatic hydrolysis [161]. The extracted nutrients from algae are formulated and blended with other organic or inorganic materials, such as compost, manure, or mineral fertilizers. This step allows for the customization of the nutrient composition and ensures a balanced fertilizer or soil conditioner product. The blended mixture can be pelletized or granulated to create uniform-sized particles for easier application and handling. This process involves agglomerating the mixture under pressure or with the help of binding agents. Stringent quality control measures are implemented to ensure the safety, purity, and nutrient content of algae-based fertilizers or soil conditioners. This includes testing for contaminants, verifying nutrient levels, and complying with regulatory guidelines.

Algae-based fertilizers and soil conditioners offer several benefits. They provide essential nutrients to plants, improving their growth and productivity [159,162]. Algae-based products can enhance soil fertility, structure, and water retention capacity. Additionally, they can contribute to sustainable agriculture by reducing the reliance on synthetic fertilizers and minimizing nutrient runoff, which can lead to water pollution [163]. It is worth noting that the specific conversion processes and formulations for algae-based fertilizers and soil conditioners can vary depending on factors such as the type of algae, target nutrient composition, and application requirements [164,165]. Additionally, regulatory standards and local agricultural practices should be considered during the development and use of these products.

7.4. H2-Based Process

H2-based has been proposed to uptake CO2 and convert it into CH4 using H2 mostly produced via water electrolysis, resulting in a novel technology known as power-to-gas (P2G) [166]. Waste heat recovery systems and/or energy from renewable energy sources, such as solar and wind, is primarily used to produce the necessary electricity needed to produce H2 via water electrolysis [167]. Keeping electricity in the form of CH4 can make future energy storage and distribution easier [168]. As a result, many countries in Europe and the United States regard P2G technology as the best way to generate renewable transportation fuel from surplus electricity [169,170]. Methanogen is the primary metabolic entity responsible for in the presence of H2 to produce CH4 [171]. According to the substrates they use for metabolism, methanogens are divided into three groups: hydrogenotrophic methanogens, homoacetogens, and acetoclastic methanogens. Table 2 summarizes these methanogenic species.

Table 2.

Methanogenic species associated with H2-based process.

Hydrogenotrophic methanogens use H2 or other chemicals in and the production of CH4. In such a process, hydrogenotrophic methanogens such as Methanosarcina spp. metabolize H2 as electron donors to reduce CO2 to CH4. As hydrogenotrophic methanogens are more robust to ammonia inhibition than acetoclastic methanogens, high ammonia nitrogen levels (5500 mg/L) were found to have a favorable impact on the conversion of CO2 into CH4 by these organisms [172]. Therefore, under conditions of high ammonia, hydrogenotrophic methanogens may be essential for high . On the other hand, to acetate using homoacetogens follows the Wood–Ljungdahl pathway is an indirect method of conversion.

H2-based have shown a lot of promise for the utilization of CO2 to produce CH4 concentration. However, the primary obstacles to the widespread of such technology are the low H2 gas-to-liquid mass transfer, insufficient gas–liquid contact time, and pH variation. Wu et al. [170] have proposed strategies to achieve high efficiency and fine consequent output gas quality.

8. The Current and Future Trends of the

The current and future trends of the research and technological development of have received a lot of attention in recent years. Table 3 presents the challenges associated with with the proposed mitigation procedure. In addition to the biological technologies discussed above, artificial photosynthesis and artificial biological membranes are being investigated [17,173,174]. Researchers are actively striving to improve the efficiency of these microbes by improving their metabolic pathways using genetic engineering techniques [175,176]. Electrochemical methods have also emerged as promising pathways [177]. Microbial electro-synthesis and electro-reduction are being investigated as methods of converting CO2 into valuable goods using renewable electricity. Electrochemical approaches can help to make compounds like methane, ethylene, and formate from CO2, providing a more sustainable approach to carbon capture and utilization (CCU) [178]. Inspired by natural photosynthesis, researchers are creating artificial photosynthetic technologies that use sunlight to transform CO2 into energy-rich molecules. Catalysts and photoactive materials are employed in these systems to capture and transform solar energy into chemical energy, which is then used to drive the bioconversion of CO2 into fuels and chemicals. Artificial photosynthesis has enormous potential for long-term , but more research is needed to enhance efficiency and scalability.

Table 3.

Challenges associated with the and the proposed mitigation procedure.

Future trends in include advances in genetic engineering techniques, which will be critical in the future [179]. Table 4 presents the future trends of the with their maturity status. Engineering synthetic metabolic pathways, improving enzyme performance, and expanding the capacity for CO2 uptake will allow scientists to build and improve microorganisms. This will result in more efficient and specialized microbes capable of converting CO2 into desirable compounds. Synthetic biology will aid in the development of new biological systems capable of effective CO2 conversion. Synthetic organisms with custom-designed metabolic pathways would convert CO2 into a variety of compounds. This method will allow the creation of customized microbes that are optimized for various CO2 conversion processes. Bioreactor design and optimization advances will boost CO2 efficiency and scalability.

Table 4.

Future trends of the with their maturity status.

While some technologies for into biofuels and other biobased compounds are highly researched and sophisticated, others are still in their early stages. Every existing or new technology has limitations, technical problems, and barriers to commercialization. The viability of these technologies will also be determined by their social acceptance. Most CO2-fixing microorganisms are sensitive to greater CO2 concentrations. A CO2 concentration of more than 5% has a negative impact on their growth rate. As a result, future studies will concentrate on finding suitable and efficient candidate strains of these bacteria that can uptake high concentrations of CO2 to efficiently fix it into biomass. The characterization of such distinct strains using multiomics could reveal the molecular mechanisms behind the desirable features. Following genetic/metabolic engineering and breeding operations, these strains will be economically viable production strains.

Another recent advancement in is the development of microfluid, which has contributed to the development of artificial biological membranes [195]. It was reported that energy generation is a critical component of such self-sustaining systems [196]. The ATP production in these light-driven artificial organelles (synthetic liposomes) employing ATP-synthase and bacteriorhodopsin has made significant progress in this context [197]. Thus, light-powered self-sustaining artificial bioreactors for CO2 fixation are conceivable, and more research is needed in this area. Miller et al. [198] have demonstrated the successful integration of a synthetic CO2-fixing pathway via crotonyl-CoA/ethylmalonyl-CoA/hydroxybutyryl-CoA (CETCH) and photosynthetic membranes within water-in-oil droplets and developed a chloroplast that is energized by light. They have recommended further integrating more natural processes.

9. The Techno-Economic Assessment (TEA) of Technologies

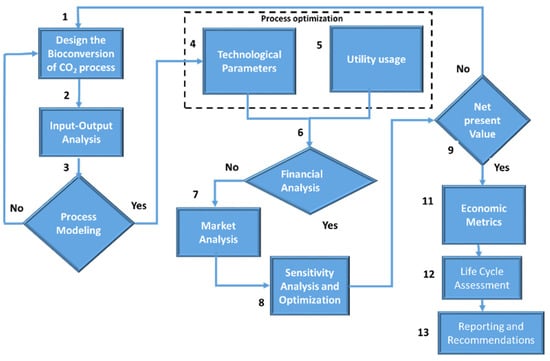

The techno-economic assessment (TEA) of any technology is essential to analyze its economic viability, competitiveness, and environmental impact. Figure 5 presents the steps used in the techno-economic assessment of . The TEA includes evaluating capital investment, operational expenses, yield and productivity, product market value, environmental effect, and risk evaluation. In addition, technological and economic issues should be included in this TEA to establish the possibility of processes becoming commercially competitive and sustainable. The capital investment, which comprises the costs of CO2 capture and usage infrastructure, equipment, facilities, and alterations one of the important components of the TEA of technology. The size of the facility and the technologies used have a considerable impact on capital investment. Furthermore, the expenses of CO2 collection technology, such as absorption or adsorption systems, must be considered. Raw materials, utilities, labor, maintenance, and waste management are all examples of operational costs. The selection of microorganisms, growing media, and growth conditions can all affect raw material costs. Another important element is the energy consumption of the process, especially in energy-intensive methods like electrochemical bioconversion. Optimizing the process might reduce the energy requirements, and employing CO2 as a low-cost feedstock can assist in lowering operational expenses. The output and productivity of the process are critical concerns. The efficiency with which CO2 is converted into target products such as biofuels or chemicals influences the overall process economics. Higher yields and productivity result in increased product output, which can help to minimize unit costs. yield and productivity can be increased via genetic engineering, metabolic pathway modification, and process management methods. TEA entails determining the market value and demand for products. The financial potential of the process is determined by the market price of biofuels, chemicals, or other useful molecules. The competitiveness of products in comparison to conventional alternatives is critical. Technological breakthroughs, government policies, and market demand, among other things, can all have an impact on market value. A critical component of TEA for is assessing the environmental impact.

Figure 5.

Steps used in the techno-economic assessment of the .

Life cycle analyses (LCAs) are used to calculate the environmental impact of the bioconversion process, encompassing the upstream and downstream stages. Evaluating the carbon footprint, water usage, and other environmental indicators aids in understanding the technology’s long-term viability and potential for carbon footprint reduction. The environmental benefits of , such as reduced GHG emissions and promotion of circular economy concepts, may contribute to its economic feasibility. Sensitivity analysis is included in TEA to analyze the impact of uncertainty on the overall economics of . Raw material prices, energy costs, government policies, and market volatility can all have an impact on the process’s profitability. Risk assessment and mitigation measures are critical for determining the economic sustainability of the technology under various scenarios and identifying potential risks and uncertainties. TEA sheds light on the scalability and commercialization prospects of . It aids in determining the ideal plant size, production capacity, and potential cost savings with scale. The TEA also takes into account the legal framework, intellectual property considerations, and market dynamics to assess the technology’s commercialization prospects. The TEA results in the development of a scale-up plan as well as the identification of potential barriers and possibilities. could have advantages over other technologies due to their ability to operate at atmospheric conditions and with low-carbon concentration feedstock. Several biotechnology providers have worked on developing processes for -to-chemicals. However, most of these works were limited to the experimental stage. For that reason, assessing the potential of to be implemented on an industrial scale remains economically challenged.

The techno-economic studies on have yielded several key findings:

- ➢

- Economic Viability: processes, such as microbial fermentation or enzymatic catalysis, have the potential to be economically viable compared to traditional carbon-intensive processes [194,199].

- ➢

- Cost Reduction: optimizing the process conditions, improving catalysts or enzyme efficiencies, and scaling up production would produce a cost-effective process.

- ➢

- Feedstock Availability: the availability and cost of capturing the CO2 as feedstock significantly impact the economic feasibility of

- ➢

- Market Potential: evaluations of the proposed technologies should consider the dynamics of the market, including demand, pricing, competition, and regulatory frameworks.

- ➢

- Value-Added Products: the potential and revenue of any is highly correlated to the final product (biofuels, chemicals, polymers, and pharmaceuticals).

- ➢

- Process Optimization: the importance of process optimization to achieve feasible technology was emphasized. Practices such as strain engineering, metabolic pathway optimization, and fermentation conditions would have a direct impact on the process economy.

- ➢

- Scale-Up Challenges: scaling up any processes from laboratory to industrial scale poses challenges. There is an urgent need for robust and efficient bioreactor systems, optimal process design, and cost-effective downstream processing to achieve economic feasibility at larger scales.

- ➢

- Policy Support: supportive policies, such as carbon pricing mechanisms, renewable energy standards, and incentives for CO2 utilization technologies, are key factors in enhancing the economic viability of projects.

10. Conclusions

processes that include bacteria, algae, and H2-based approaches have emerged as promising strategies for reducing greenhouse gas emissions and producing valuable products through the conversion of CO2 into biomass, fuels, chemicals, and other added-value compounds. Microorganisms such as bacteria, archaea, and algae are used in the microbial conversion process to transform CO2 into usable chemicals. Bacteria-based technologies have shown considerable promise in converting CO2 into usable chemicals by utilizing the metabolic capabilities of diverse bacteria species. Cyanobacteria, in particular, show great potential because they can photosynthesise, fix atmospheric CO2, and make biofuels, chemicals, and high-value substances. However, enhancing the efficiency and scalability of these processes for large-scale applications remains a difficulty. Because of their potential to efficiently trap CO2 and convert it into biomass and biofuels, algae-based systems have shown various advantages, including fast growth rates, a diverse biochemical makeup, and the ability to clean wastewater. Algae have a high potential for since they can be grown in a variety of conditions, including open ponds and photobioreactors, and can contribute to the economy. Algae-based processes not only sequestrate carbon but also produce biofuels (e.g., biodiesel and bioethanol) and high-value compounds (e.g., pigments, omega-3 fatty acids, and bioactive), which can substitute fossil fuels, reducing reliance on nonrenewable resources and have applications in the food, pharmaceutical, and cosmetics industries. This would result in new revenue streams and economic potential. H2-based combine hydrogen with CO2 to create useful compounds and fuels. However, hydrogen source availability and sustainability remain critical factors for its economic viability and wider implementation. The future trends of focus on improving process efficiency, productivity, and scalability. Advances in genetic engineering, metabolic engineering, and synthetic biology are enabling the design and optimization of microorganisms for enhanced . Furthermore, the integration of technologies with renewable energy sources and carbon capture and storage systems holds significant potential for achieving carbon neutrality and creating a circular carbon economy. Techno-economic assessment (TEA) of highlighted the importance of continued research, technological advancements, supportive policies, and collaborative efforts to further develop and commercialize such technologies to achieve a more sustainable and circular economy.

Author Contributions

All authors contributed equally to this review. All authors have read and agreed to the published version of the manuscript.

Funding

The authors acknowledge the financial support from Qatar University and QAFCO-Qatar. (Fund number QUEX-CENG-QAFCO-20/21-1). The statements made herein are solely the responsibility of the authors. Open Access funding is provided by the Qatar National Library.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets generated during and/or analyzed during the current study are available upon request.

Conflicts of Interest

The authors have no relevant financial or non-financial interest to disclose.

References

- Sowiżdżał, A.; Starczewska, M.; Papiernik, B. Future Technology Mix—Enhanced Geothermal System (EGS) and Carbon Capture, Utilization, and Storage (CCUS)—An Overview of Selected Projects as an Example for Future Investments in Poland. Energies 2022, 15, 3505. [Google Scholar] [CrossRef]

- Anwar, M.; Fayyaz, A.; Sohail, N.; Khokhar, M.; Baqar, M.; Yasar, A.; Rasool, K.; Nazir, A.; Raja, M.; Rehan, M.; et al. CO2 utilization: Turning greenhouse gas into fuels and valuable products. J. Environ. Manag. 2020, 260, 110059. [Google Scholar] [CrossRef] [PubMed]

- Salehizadeh, H.; Yan, N.; Farnood, R. Recent advances in microbial CO2 fixation and conversion to value-added products. Chem. Eng. J. 2020, 390, 124584. [Google Scholar] [CrossRef]

- Bierwirth, P. Carbon Dioxide Toxicity and Climate Change: A Major Unapprehended Risk for Human Health; ResearchGate: Berlin, Germany, 2019. [Google Scholar]

- Bonfim-Rocha, L.; Silva, A.B.; de Faria, S.H.B.; Vieira, M.F.; de Souza, M. Production of Sodium Bicarbonate from CO2 Reuse Processes: A Brief Review. Int. J. Chem. React. Eng. 2019, 18, 20180318. [Google Scholar] [CrossRef]

- Esposito, E.; Dellamuzia, L.; Moretti, U.; Fuoco, A.; Giorno, L.; Jansen, J.C. Simultaneous production of biomethane and food grade CO2 from biogas: An industrial case study. Energy Environ. Sci. 2018, 12, 281–289. [Google Scholar] [CrossRef]

- Zhang, Z.; Pan, S.Y.; Li, H.; Cai, J.; Olabi, A.G.; Anthony, E.J.; Manovic, V. Recent advances in carbon dioxide utilization. Renew. Sustain. Energy Rev. 2020, 125, 109799. [Google Scholar] [CrossRef]

- Riegler, P.; Chrusciel, T.; Mayer, A.; Doll, K.; Weuster-Botz, D. Reversible retrofitting of a stirred-tank bioreactor for gas-lift operation to perform synthesis gas fermentation studies. Biochem. Eng. J. 2018, 141, 89–101. [Google Scholar] [CrossRef]

- Stoll, I.K.; Boukis, N.; Sauer, J. Syngas Fermentation to Alcohols: Reactor Technology and Application Perspective. Chem. Ing. Tech. 2020, 92, 125–136. [Google Scholar] [CrossRef]

- He, Y.; Kennes, C.; Lens, P.N. Enhanced solventogenesis in syngas bioconversion: Role of process parameters and thermodynamics. Chemosphere 2022, 299, 134425. [Google Scholar] [CrossRef]

- Mathews, S.L.; Epps, M.J.; Blackburn, R.K.; Goshe, M.B.; Grunden, A.M.; Dunn, R.R. Public questions spur the discovery of new bacterial species associated with lignin bioconversion of industrial waste. R. Soc. Open Sci. 2019, 6, 180748. [Google Scholar] [CrossRef]

- Chilakamarry, C.R.; Sakinah, A.M.; Zularisam, A.; Sirohi, R.; Khilji, I.A.; Ahmad, N.; Pandey, A. Advances in solid-state fermentation for bioconversion of agricultural wastes to value-added products: Opportunities and challenges. Bioresour. Technol. 2021, 343, 126065. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Hu, X.; Wang, Y.; Jiang, N. A critical review of biomineralization in environmental geotechnics: Applications, trends, and perspectives. Biogeotechnics 2023, 1, 100003. [Google Scholar] [CrossRef]

- Sun, X.; Atiyeh, H.K.; Huhnke, R.L.; Tanner, R.S. Syngas fermentation process development for production of biofuels and chemicals: A review. Bioresour. Technol. Rep. 2019, 7, 100279. [Google Scholar] [CrossRef]

- Handler, R.M.; Shonnard, D.R.; Griffing, E.M.; Lai, A.; Palou-Rivera, I. Life Cycle Assessments of Ethanol Production via Gas Fermentation: Anticipated Greenhouse Gas Emissions for Cellulosic and Waste Gas Feedstocks. Ind. Eng. Chem. Res. 2015, 55, 3253–3261. [Google Scholar] [CrossRef]

- Barati, B.; Zafar, F.F.; Qian, L.; Wang, S.; Abomohra, A.E.-F. Bioenergy characteristics of microalgae under elevated carbon dioxide. Fuel 2022, 321, 123958. [Google Scholar] [CrossRef]

- Zhao, T.-T.; Feng, G.-H.; Chen, W.; Song, Y.-F.; Dong, X.; Li, G.-H.; Zhang, H.-J.; Wei, W. Artificial bioconversion of carbon dioxide. Chin. J. Catal. 2019, 40, 1421–1437. [Google Scholar] [CrossRef]

- Ritchie, H.; Roser, M.; Rosado, P. Energy; Our World in Data: Oxford, UK, 2022. [Google Scholar]

- Andrae, A.S. Hypotheses for primary energy use, electricity use and CO2 emissions of global computing and its shares of the total between 2020 and 2030. WSEAS Trans. Power Syst. 2020, 15, 4. [Google Scholar]