Abstract

When organic practices may have negative environmental effects, understanding the trade-offs between the economic and environmental outcomes of organic agriculture is essential in its promotion. This paper examines whether organic rice was planted in Japanese rice farms using the combined application of a multi-objective genetic algorithm and life cycle assessment. A modeled farm with 30 hectares (ha) of paddy fields is constructed using information from an agricultural management handbook. The planted crops considered are environmentally friendly rice with reduced use of chemical fertilizers and synthetic pesticides, organic rice, conventional wheat, and conventional soybeans. A bio-economic farm model with both economic and environmental objectives is created. The Pareto-optimal solutions indicate that the planted area of organic rice is 2.3 ha, at best, in the modeled farm. The cultivation of organic rice is likely to be constrained compared with that of environmentally friendly rice, and even though it produces an increase in income, it does not necessarily exert positive effects on the environment. The findings suggest that when organic farming has negative impacts, countermeasures against problems that emerge through its practice should be included in the essential requirements for subsidization.

1. Introduction

Despite potentially lower yields, the premiums paid for the produce of organic agriculture can make it significantly more profitable than conventional agriculture [1]. Furthermore, in most cases, organic agriculture is more environmentally friendly than conventional agriculture because organic farming systems may employ agronomic, biological, and mechanical methods in place of chemical inputs [2,3]. For example, organic agriculture can improve various environmental indicators such as carbon, nitrogen, water footprints, and soil organic carbon [4,5]. Public health might also be influenced by the positive environmental effects of organic cultivation [6]. Consequently, the promotion of organic agriculture helps contribute to the establishment of economically and environmentally sustainable farming systems. However, organic agriculture can also have some negative environmental effects, such as nitrogen pollution resulting from the overuse of animal manure and increased methane emissions from paddy fields because of organic fertilization [3,7]. For this reason, the trade-offs between the economic and environmental outcomes of organic agriculture should be considered in its promotion.

Combining both economic and agroecological models into a single analytical framework, bio-economic farm models can analyze these trade-offs between economic and environmental objectives [8]. However, before optimizing these bio-economic farm models, life cycle assessment (LCA), which can help quantify the environmental impacts of a product [9], is usually required to formulate environmental performance for agricultural production [10]. To construct these bio-economic optimization models, mathematical programming, especially linear programming focusing on a single objective (e.g., income maximization), has often been employed [11,12]. However, because realistic decision making always depends on more than a single factor, multi-objective optimization is a better way forward [13].

Consequently, evolutionary approaches such as multi-objective genetic algorithms (MOGAs) have become the primary tools to solve real-world multi-objective problems [14]. In recent studies, MOGAs have been applied to bio-economic farm models with multiple objectives to be optimized [10]. Although classical multi-objective optimization methods that work according to preference-based strategies may provide subjective solutions to the user, MOGAs have the advantage that they do not require the user to prioritize, scale, or weigh objectives [14,15]. Therefore, MOGAs are better techniques for building realistic bio-economic farm models for organic agriculture including conflicting objectives.

To assess the trade-offs between economic and environmental performance in organic farming, many studies have applied bio-economic farm models [16,17,18,19,20,21,22,23,24,25,26,27,28]. As discussed by Janssen and van Ittersum [11] and Reidsma et al. [12], mathematical programming with a single economic objective has been the most popular technique in these studies (e.g., [16]), although a few models have simultaneously addressed both economic and environmental objectives [19,21,22,26]. However, although these have focused on a range of organic crop and livestock production systems, in relation to organic rice, which is the key organic cereal in Asia [29], few studies have employed bio-economic farm models. Although Delmotte et al. [30] have evaluated organic rice farming in France using a regional bio-economic model, bio-economic approaches considering the trade-offs between economic and environmental outcomes to assess organic rice farming in Asian countries have not been conducted at the farm level.

In Japan, organic certification has been conducted by the Japanese Agricultural Standard (JAS) system since 1999 [31]. In 2020, the total area of organic farmland under JAS organic certification was 12,027 hectares (ha) (including 3062 ha of paddy fields), which accounted for 0.3% of the total cultivated area (some 4397 thousand ha) [32]. At present, Japanese organic rice production remains very small, but Japan, as a country where rice is the staple food, has sufficient capacity to increase supply, given the potential demand for organic rice in the future. To promote environmental protection activities such as preventing global warming and conserving biodiversity, direct payments for environmentally friendly agriculture in Japan support farming practices aimed at reducing or ceasing the use of chemical fertilizers and synthetic pesticides [33]. Under these direct payments, the inputs of chemical fertilizers and synthetic pesticides must be ≤ 50% of the conventional level in the region [33], for which supported farmers can receive 8000–120,000 JPY/ha [33]. The subsidy for organic farming is the largest (120,000 JPY/ha), and 20,000 JPY/ha is added to the subsidy when supported farmers practice an effective way of sequestering carbon in the soils (e.g., manure application) along with soil diagnostics [33]. In 2020, the total supported area was 80,789 ha (including 10,986 ha of organic farming) [34].

This paper examines whether organic rice was planted in Japanese rice farms using a bio-economic farm model and the combined application of MOGA and LCA. This approach has proved useful in maximizing economic objectives and minimizing environmental objectives simultaneously (e.g., [35,36]). Given that organic rice farming is not necessarily positive for environmental mitigation [37], this is vital for better understanding the trade-offs between economic and environmental outcomes in its promotion. It is conjectured that the planted area of organic rice is likely to be limited when its production does not create a win–win situation for both economic and environmental aspects.

2. Materials and Methods

2.1. Direct Payments for Environmentally Friendly Agriculture in the Shiga Region

The Shiga region, which is in the central part of Japan and includes the country’s largest lake (Lake Biwa), was the location of Japan’s first direct payments for environmentally friendly agriculture at the prefecture level in 2004 [38]. In 2020, the total supported area in Shiga was the second largest (12,978 ha including 346 ha of organic farming) in Japan, whereas its subsidized area for rice was the largest (12,622 ha) in Japan [34], with approximately 40% of the total cultivated area of rice in this region allocated to environmentally friendly rice production [39]. The supported farmers have primarily produced environmentally friendly rice with the reduced use of chemical fertilizers and synthetic pesticides in conjunction with integrated pest management, mechanical weeding of paddy field dikes, and prolonged midseason drainage in exchange for a payment of 40,000 JPY/ha [38,39,40]. With environmentally friendly rice production, farmers must have complied with requirements that the frequency of the use of synthetic pesticides based on active ingredients (a.i.) is ≤ 7 and that the nitrogen input from chemical fertilizers is ≤ 40 kg N/ha [41].

2.2. Farm Modeling

In this paper, the modeled farm was based on a large-scale family-run rice farm in the Shiga region using information from an agricultural management handbook [42], modified using personal communication with a representative in Shiga Prefecture [43]. Shiga Prefecture [42] described such a rice farm as one of the agricultural management entities that play a key role in the region’s crop production. Because farmers who produce environmentally friendly rice with the reduced use of chemical fertilizers and synthetic pesticides have a strong interest in providing consumers with safe and secure crops [44], they are likely to hold a typically positive attitude about organic farming. Therefore, it was assumed that environmentally friendly rice and/or organic rice were produced in the modeled farm. In the Shiga region, the main soil types of paddy fields are gley soils (53.5%) and gray lowland soils (30.7%) [45]. For the climatic conditions in Otsu (prefectural capital), the climate normals (1991–2020) of annual mean temperature and annual precipitation were 15.1 degrees Celsius and 1566.6 mm, respectively [46]. However, Shiga Prefecture [42] did not include information on the soils and climatic conditions of the modeled farm.

Table 1 details the characteristics of the modeled farm. The modeled farm had 30 ha of paddy fields. The planted crops were environmentally friendly rice, organic rice, conventional wheat, and conventional soybeans. Environmentally friendly rice had four varieties. However, organic rice included only an early variety 2, which was a dominant variety for organic rice cultivation in the Shiga region [43]. The cropping patterns included repeated cultivation of rice every year and a two-year rotation of three crops (environmentally friendly rice, conventional wheat, and conventional soybeans). Because organic rice must be continuously cropped to maintain organic certification, it was excluded from the crop rotation. The main labor force was two family members, with temporary workers employed for the mechanical weeding of paddy field dikes to avoid labor shortages [38]. Most operations were practiced by family and temporary workers, but several operations were entrusted to others.

Table 1.

Characteristics of the modeled farm.

Table 2 lists the primary operational differences between environmentally friendly and organic rice production. Environmentally friendly rice was produced based on the reduced use of chemical fertilizers and synthetic pesticides in conjunction with integrated pest management, mechanical weeding of paddy field dikes, and prolonged midseason drainage. Organic rice was cultivated in accordance with organic certification standards, including no use of chemical inputs and soil improvements such as manure application (without soil diagnostics). Here, cow manure application was adopted to improve organic paddy soils and provide organic rice with nutrients. In environmentally friendly rice production, this technique was not practiced because manure application was not obligated for the certification [41]. The direct payments for environmentally friendly rice and organic rice were 40,000 and 120,000 JPY/ha, respectively [40].

Table 2.

Primary operational differences between environmentally friendly and organic rice production.

2.3. LCA Methodology

2.3.1. Goal and Scope Definition

The goal of this LCA was to identify environmental indicators for the bio-economic farm model. The functional unit, which enables different systems to be treated as functionally equivalent [9], was defined as 1 ha of farmland area because the variables of crop production for the bio-economic farm model were referenced to an area-based unit.

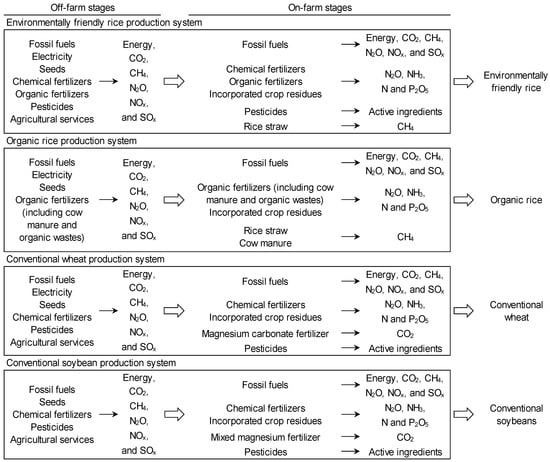

Figure 1 illustrates a simplified flowchart of the crop production systems in the modeled farm. These systems comprised on- and off-farm stages. As with Masuda [38], the system boundaries were set to cradle-to-farm gate. In the on-farm stages, all farm works from operations before seeding/transplanting to drying, processing, and shipping for harvested crops were considered, but any operations after shipping such as transportation were not included. In the LCA calculations, the main causes of environmental impacts for rice, wheat, and soybeans were considered [38,47], but several environmental factors were not evaluated. Farm capital and common inputs in the modeled farm were not included because they did not affect the decisions of crop selection in the bio-economic farm model. Biological nitrogen fixation was also excluded because it was not considered in Japan’s greenhouse gas inventory report [48]. Soil carbon sequestration was not assessed because Shiga Prefecture [42] had no information on soil characteristics for the modeled farm. When multiple outputs were yielded in a product system, environmental impacts should be partitioned into different products [9]. However, because each crop production system had a single output, allocation was not applied.

Figure 1.

Simplified flowchart of the crop production systems in the modeled farm. A frame border of each system shows the system boundary of LCA.

The environmental indicators considered were energy consumption (EC), global warming potential (GWP), acidification potential (AP), eutrophication potential (EP), and pesticide use (PU). EC, GWP, AP, and EP are the main environmental concerns in Japanese rice production [37,47].

2.3.2. Input and Output Data

As shown in Table 3, the input and output data on the crop production systems were collected. Unless otherwise noted, these data were obtained from Shiga Prefecture [42] and through personal communication with a representative in Shiga Prefecture [43].

Table 3.

Input and output data on the crop production systems (per ha).

The inputs for the off-farm stages related to indirect environmental impacts were fossil fuels, electricity, seeds, chemical fertilizers, organic fertilizers, pesticides, and agricultural services. Except for electricity in kilowatt-hours (kWh), the cost data of all inputs were collected. For environmentally friendly rice production, the cost of organic/inorganic compound fertilizer was divided between chemical and organic fertilizers depending on their nitrogen content. However, a small amount of chemical fertilizers included in nursery soils was excluded because it was difficult to identify the cost attributable to chemical fertilizers in the cost of nursery soils. For organic rice production, because the rice bran and soybean wastes used for the control of weeds can also return nutrients to the soil, they were included in organic fertilizers. However, the cost of soybean wastes generated in the modeled farm was deemed zero.

In the on-farm stages, fossil fuels, fertilizers, incorporated crop residues, pesticides, and organic matter were identified as the direct inputs contributing to the environmental impacts. Furthermore, crop yield data as the outputs were collected. The types of fossil fuels directly consumed were diesel oil, kerosene, gasoline, premixed fuel, and motor oil. The inputs of diesel oil, kerosene, gasoline, and premixed fuel were obtained by aggregating each type of fuel consumption used in different farm works excluding entrusted operations. For motor oil, its total use was applied. The constituents of fertilizer application were nitrogen (N), phosphorus pentoxide (P2O5), and dolomite. The N input data for the chemical and organic fertilizers were collected separately because of differences in the NH3 emission coefficients. The inputs of N, P2O5, and dolomite were calculated by multiplying the fertilizer application rates by their content rates. The N and P2O5 content rates were derived from Shiga Prefecture [45] for cow manure, AAFS [49] for rice bran, the Ministry of Education, Culture, Sports, Science and Technology of Japan [50] and Ogawa et al. [51] for soybean wastes, and personal communication with a representative in Shiga Prefecture [43] for the rest. The dolomite content rates of magnesium carbonate fertilizer for conventional wheat and mixed magnesium fertilizer for conventional soybeans were from GIO and MOE [48].

All crop residues generated were assumed incorporated into the soil. The crop yields on an actual weight basis were converted into the outputs of crop residues (husks, stems and leaves, stubbles, and roots) on a dry matter basis [50,51]. The N and P2O5 inputs of crop residues were calculated by multiplying the dry matter yields of crop residues by the nutrient content rates on a dry matter basis [51]. The direct inputs of pesticides were based on the weight of active ingredients. To quantify the active ingredients contained in pesticides, the Safety Data Sheets were obtained from the pesticide makers’ websites [52,53,54,55,56,57,58,59,60].

Rice straw and cow manure were assumed to affect the direct CH4 emissions from the paddy fields [48]. The organic carbon input of rice straw was calculated by multiplying the dry matter yield by the carbon content rate on a dry matter basis [45,51]. For organic rice production, the upper value (20 t/ha) of cow manure that was applicable to paddy fields was used for soil improvement and nutrient supply [61]. The amount of organic carbon in cow manure application was calculated by multiplying the dry matter weight by the carbon percentage on a dry matter basis [45].

In this LCA, the crop yield data were used for calculating the outputs of crop residues. Considering the effects of a decline in yield caused by prolonged midseason drainage, the yield of environmentally friendly rice was assumed to be 96.2% [62] of the described value in Shiga Prefecture [42]. The yields of organic rice, conventional wheat, and conventional soybeans were from Shiga Prefecture [42], as described.

2.3.3. Energy Consumption and Environmental Load Emissions

Indirectly consumed energy on a net calorific value basis and emitted environmental loads (CO2, CH4, N2O, NOx, and SOx) in the off-farm stages were calculated using the embodied global energy and air-emission coefficients (per million JPY) based on the purchaser price for household consumption expenditures or the producer price in the input–output tables [63]. Of these coefficients, the CH4 and N2O emission coefficients on a CO2 equivalence basis were recalculated in terms of CH4 and N2O, respectively, by dividing them by the early CO2-equivalence factors (21 for CH4 and 310 for N2O) [64,65]. For electricity, the coefficients per unit of money were converted into per kWh [63,66].

In the direct use of fossil fuels, energy, CO2, CH4, N2O, NOx, and SOx were considered. Directly consumed energy on a net calorific value basis for each fuel type was calculated using 95% of the gross calorific coefficient [48,67]. The emission coefficients of greenhouse gases (CO2, CH4, and N2O) and acidifying pollutants (NOx and SOx) for each fuel type were derived from Japan’s greenhouse gas inventory report [48,68] and the NIAES’s LCA manual [69], respectively. However, given the lack of data, the NOx and SOx emissions from motor oil were calculated based on the emission coefficients of fuel oil B, which has similar coefficients for energy and CO2 as motor oil [48].

Environmental loads from nutrient inputs in farmland included N2O and NH3 emitted into the air and N and P2O5 leached into water. The N2O–N emission coefficients to nitrogen inputs were 0.31% for fertilization in rice production, 0.62% for fertilization in wheat and soybean production, and 1% for crop residue incorporation [48]. The NH3–N emission coefficients to nitrogen inputs were 4–8% for chemical fertilizers [70], 2% for organic fertilizers [71], and 0.9% for crop residues [72]. The outflow rates to N and P2O5 inputs were 30% [48] and 0.6% [73], respectively. Furthermore, in conventional wheat and soybean production, CO2 emissions from dolomite fertilizers were considered. The CO2–C emission coefficient to dolomite inputs was 13% [48].

Direct CH4 emissions from irrigated rice production were calculated using the following equation estimated under the conditions of a fast drainage rate, intermittent drainage, and the Tokai–Kinki regions (including the Shiga region): , where DCE is the amount of CH4–C emitted directly from paddy fields (kg CH4–C/ha/year) and TOM is the total of organic matter such as rice straw and cow manure (kg C/ha/year) [48,74]. Furthermore, to reflect the suppressive effect on CH4 emissions based on prolonged midseason drainage, the CH4 emissions for environmentally friendly rice production were assumed to be 69.5% of the calculated values [62]. Finally, the CH4 emissions from paddy fields were 143.4–160.6 kg CH4/ha/year for environmentally friendly rice production and 394.1 kg CH4/ha/year for organic rice production.

Following GIO and MOE [48], which provided the CH4 emission factors for Japanese paddy fields from compost and incorporated rice straw, the organic carbon inputs of rice straw and cow manure were used in the CH4 calculations. The organic carbon inputs of all organic fertilizers (including organic/inorganic compound fertilizers) except cow manure were excluded because the organic carbon contents of several fertilizers such as organic/inorganic compound fertilizers and grained 100% organic fertilizer were unclear. Given that the actual weights (0.6 t/ha for environmentally friendly rice and 2.2 t/ha for organic rice) of all organic fertilizers except cow manure were considerably less than that (20 t/ha) of cow manure, this approach is unlikely to have a significant impact on the calculated values of CH4. Because Itoh et al. [62] reported that the GWP of N2O emissions at most sites was much smaller than that of CH4 emissions, the negative effects on N2O emissions of prolonged midseason drainage were not considered.

The coefficients for calculating energy consumption and environmental load emissions are detailed in Table S1 (Supplementary Material).

2.3.4. Impact Assessment

This LCA had five environmental impact categories. EC was aggregated on a net calorific value basis. In the GWP calculation for one hundred years, the CO2-equivalence factors of CO2, CH4, and N2O were 1, 28, and 265, respectively [75]. AP was characterized using the SO2-equivalence factors: 0.7 of NOx, 1 of SOx, and 1.88 of NH3 [9]. For EP, the PO4-equivalence factors for NOx, NH3, N, and P2O5 were 0.13, 0.35, 0.42, and 1.34, respectively [9]. Because the toxicity characterization methods [9,76] did not cover all the toxic substances that were applied in the modeled farm, PU was expressed as the total weight of active ingredients [16,17]. Given that PU does not reflect different toxic levels of active ingredients, it can be technically regarded as an environmental externality indicator or a resource use indicator [16] rather than an environmental impact indicator. To identify how each environmental objective affects the decisions of crop selection in multi-objective optimization, these environmental impacts were not integrated into a single environmental impact index.

2.4. Crop Incomes and Labor Inputs of the Modeled Farm

Crop income (per ha), defined as the difference between the total crop revenue including subsidies and the total variable cost, corresponded to the coefficient of an economic objective function in the bio-economic farm model. Each type of crop revenue was calculated by multiplying the crop yield (Table 3) by the unit price [42]. The production of environmentally friendly and organic rice and conventional wheat and soybeans was supported by direct payments for environmentally friendly agriculture [33,40] and farming income stabilization measures [77,78], respectively. The total variable cost for each crop comprised the costs of LCA inputs (energy, seeds, fertilizers, pesticides, and agricultural services), other production materials, crop insurance, sales commission, shipping, and organic certification [42,43].

Furthermore, to calculate the net farm income of the modeled farm, the data on fixed and common costs, which were excluded in the LCA evaluation, were also collected. The fixed costs included depreciation and repair expenses for agricultural machines and facilities, motor vehicles and transport equipment, and farm implements used across multiple years [42,79]. The common costs comprised the costs of rented farmland, land improvement and water use, taxes and dues, and social insurance [42]. To construct the coefficients for the labor constraints in the bio-economic farm model, the operation-by-operation working hours per ha of family workers and temporary workers were aggregated by term [42,43]. Entrusted operations were excluded from the labor constraints.

2.5. Multi-Objective Optimization Model

2.5.1. Bio-Economic Farm Model with Multiple Objectives

In this paper, a bio-economic farm model with multiple objectives was built by appending environmental objectives to a classical linear programming model with an economic objective. The environmental objectives corresponded to the environmental impact categories (EC, GWP, AP, EP, and PU) of LCA. Therefore, the bio-economic farm model is a multi-objective optimization model with six objectives.

Many optimization procedures have been developed to solve multi-objective optimization problems [15]. In this paper, a MOGA, which is the most popular heuristic approach to multi-objective optimization problems [14], was applied for solving the multi-objective bio-economic farm model.

2.5.2. Multi-Objective Genetic Algorithm

When solving multi-objective optimization problems, a perfect multi-objective solution that simultaneously optimizes each objective function is almost impossible [14]. Therefore, a set of solutions that cannot be improved with respect to any objective without worsening at least one other objective is investigated in multi-objective optimization [14]. These solutions are known as Pareto-optimal solutions, and the frontier formed by these solutions is then a Pareto frontier [15].

Genetic algorithms (GAs), being search and optimization techniques based on the mechanics of natural selection and natural genetics [15,80], are well suited for solving multi-objective optimization problems [14]. GAs work with the coding of the parameter set and include three operators, namely, reproduction, crossover, and mutation [80]. The reproduction operator makes duplicates of good solutions and eliminates bad solutions in a population [15]. Because the reproduction operator cannot create any new solutions in the population, crossover and mutation operators yield new solutions [15]. The crossover operator recombines together good substrings from two good strings, and the mutation operator alters a string locally [15]. The GA circulative procedure through these operators is continued until the termination criterion is satisfied [15].

2.5.3. Model Formulation

The MOGA-based bio-economic farm model has one economic objective to be maximized and five environmental objectives to be minimized under the constraints of land use, labor inputs, and nonnegativity. The multi-objective optimization problem for the modeled farm is expressed as follows (Supplementary Material, Table S2):

subject to

where xi is the planted area (ha) of the ith crop; yj is the jth input (hours) of temporary workers; zk is the input (hours) of temporary workers in the kth term; TCI (JPY), TEC (GJ), TGWP (kg CO2 eq.), TAP (kg SO2 eq.), TEP (kg PO4 eq.), and TPU (kg a.i.) are the total values of crop income, EC, GWP, AP, EP, and PU, respectively; cinci, eci, gwpi, api, epi, and pui are the coefficients per ha of crop income, EC, GWP, AP, EP, and PU for the ith crop, respectively; labik is the labor input coefficient (hours/ha) for the ith crop in the kth term; and flabk is the maximum possible input (hours) of family labor in the kth term. The subscript i is the type of planted crop: environmentally friendly rice (an early variety 1, i = 1; an early variety 2, i = 2; a medium variety, i = 3; and a late variety, i = 4), organic rice (an early variety 2, i = 5), conventional wheat (a medium variety, i = 6), and conventional soybeans (a medium variety, i = 7 and a late variety, i = 8). The subscript j refers to the inputs of temporary workers in early June (j = 1), early July (j = 2), late July (j = 3), mid-August (j = 4), and late September (j = 5). Because every month was divided into early, middle, and late terms, Equation (10) includes 36 functions (k = 1, …, 36).

Equations (1)–(6) are the objective functions. In Equation (1), TCI to be maximized is calculated by subtracting the total wage of temporary workers from the total crop income. Therefore, TCI technically indicates the sum of family earnings and fixed and common farming costs. The hourly wage coefficient (1500 JPY/hour) of temporary workers was from Shiga Prefecture [42]. Given the use of MATLAB, Equation (1) is multiplied by –1 to convert the maximization problem into a minimization problem [81]. For Equations (2)–(6) to be minimized, these environmental coefficients were derived from the results of the LCA.

Equations (7)–(9) represent three cropping patterns in the modeled farm. Equation (7) imposes the constraint that the sum of the planted areas of environmentally friendly rice, organic rice, and conventional wheat corresponds to the total farmland area (30 ha) of the modeled farm because there is an overlap in the growing seasons between rice cultivated in April–October and wheat raised in October–June [42]. Equation (8) decides whether environmentally friendly rice cultivation is converted into conventional wheat production. Equation (9) shows that the succeeding crop of conventional wheat is conventional soybeans (planted in June–December) [42]. To avoid the adoption of fallowing, Equations (7) and (9) have equality signs. These constraints yield the following solutions for the variables. The total area of environmentally friendly rice is equal to the sum of the area cropped continuously every year and the area cultivated in the first year for the two-year rotation of three crops. The area of organic rice is organically planted every year. The areas of conventional wheat and conventional soybeans denote these cropping areas in the second year for the two-year rotation of three crops.

Equations (10)–(15) provide the labor input constraints. Equation (10) means that, in each term, the total labor input for crop production cannot exceed the total labor supply of family members and temporary workers. The labor input coefficients were derived from Shiga Prefecture [42] and personal communication with a representative in Shiga Prefecture [43]. Given that the available labor input per family worker is 59.5 h per week, the maximum possible labor inputs from two family workers are assumed to be 158.7 h per term in February, 170 h per term in a month with 30 days, and 175.7 h per term in a month with 31 days [38,42]. Equations (11)–(15) represent the constraints that the temporary workers engage in only mechanical weeding of paddy field dikes in early June, early July, late July, mid-August, and late September, respectively. The labor input coefficients (hours/ha) of mechanical weeding for paddy field dikes (4 for rice, 5 for wheat, and 2.5 for soybeans) were from Shiga Prefecture [42]. Finally, Equations (16) and (17) are the nonnegativity constraints for xi and yj, respectively.

Growing rice for family consumption was not considered in the MOGA-based bio-economic farm model, although such small amounts of consumption can be managed by introducing and/or modifying constraints in an optimization model. Because a large-scale rice farm was assumed in this paper, this handling did not have a major effect on the optimized results.

In this paper, MATLAB Version R2022a, including the Global Optimization Toolbox [81], was used for building the MOGA-based bio-economic farm model. The solver of “gamultiobj” created a set of solution points on the Pareto front based on a controlled elitist GA, which is a variant of a nondominated sorting GA (NSGA-II) [15,81]. The options for “gamultiobj” were not changed. However, for reproducibility, the random number generator was set to default. Furthermore, the standard linear programming model based on TCI maximization was also performed to compare with the MOGA results.

3. Results

3.1. Economic Performance of the Modeled Farm

Table 4 provides the crop incomes and labor inputs of the modeled farm. The crop incomes (thousand JPY/ha) were 635–824 for environmentally friendly rice, 1319 for organic rice, and 790–896 (per year) for the two-year rotation of the three crops. The labor inputs (hours/ha) were 111.8–120.4 for environmentally friendly rice, 142.6 for organic rice, and 97.2–101.5 (per year) for the two-year rotation of the three crops. Over the three cropping patterns, organic rice production yielded the highest crop income but demanded the largest labor input. The total annual cost of fixed and common inputs used for calculating the net farm income based on the MOGA results was 19,399 thousand JPY.

Table 4.

Crop incomes and labor inputs of the modeled farm.

3.2. Environmental Performance of the Modeled Farm

Table 5 details the LCA results for the various crop production systems. The EC, GWP, AP, EP, and PU per ha for environmentally friendly rice were 36.0–39.6 GJ, 7808–8055 kg CO2 eq., 17.5–17.7 kg SO2 eq., 18.9–19.8 kg PO4 eq., and 1.6 kg a.i., respectively. The impacts per ha of organic rice were 30.2 GJ for EC, 13,857 kg CO2 eq. for GWP, 19.1 kg SO2 eq. for AP, 36.6 kg PO4 eq. for EP, and 0 kg a.i. for PU. For the two-year rotation of the three crops, the annual values per ha of EC, GWP, AP, EP, and PU were 46.6–48.4 GJ, 7507–7631 kg CO2 eq., 33.7–33.8 kg SO2 eq., 34.9–35.3 kg PO4 eq., and 2.9 kg a.i., respectively. In a comparison of the three cropping patterns, given the poorer results for GWP and EP, organic rice production did not necessarily involve any environmental advantage.

Table 5.

LCA results of the crop production systems (per ha).

To identify environmental hotspots for the various crop production systems, contribution analysis, which calculates the overall contribution to the results of various factors [9], was performed across all environmental impact categories except PU. For EC (fossil fuels and fertilizers), AP (fertilizers and fossil fuels), and EP (fertilizers and crop residues), the top two contributors were the same for each crop. However, for GWP, the largest contributor for environmentally friendly rice and organic rice was direct CH4 emissions from paddy fields, whereas that for conventional wheat and conventional soybeans was fertilizers.

3.3. MOGA Results

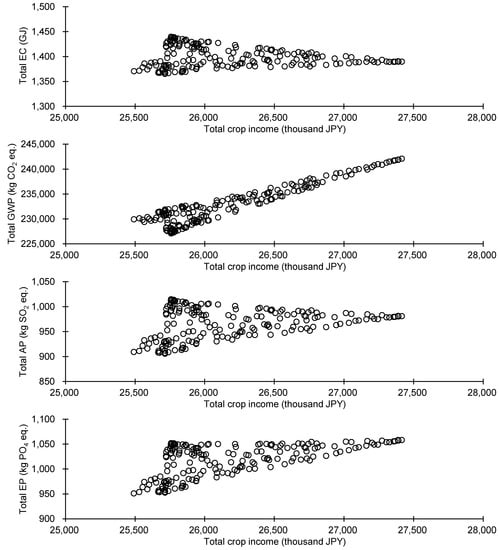

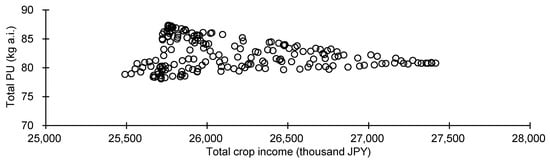

Figure 2 depicts the Pareto fronts between total crop income and each environmental indicator based on the MOGA results. Each environmental objective was compared with the economic objective, which was the most important concern for farmers. The number of Pareto-optimal solutions was 188. The optimum values of total crop income, total EC, total GWP, total AP, total EP, and total PU were in the ranges of 25,491–27,416 thousand JPY, 1365–1440 GJ, 227,117–242,098 kg CO2 eq., 906–1015 kg SO2 eq., 951–1058 kg PO4 eq., and 78.1–87.4 kg a.i., respectively. Using the scatter plots, it appears that an increase in total crop income increased GWP, AP, and EP but decreased EC and PU. Table S3 (Supplementary Material) provides information on all Pareto points.

Figure 2.

Pareto fronts between total crop income and each environmental indicator based on the MOGA results. Negative values of total crop income from Equation (1) were converted into positive values. EC—energy consumption; GWP—global warming potential; AP—acidification potential; EP—eutrophication potential; PU—pesticide use.

Table 6 describes the best Pareto point for each objective based on the MOGA results. The results for minimum total EC, minimum total AP, and minimum total PU represent an identical Pareto-optimal solution. Because organic rice production yielded the highest crop income across three cropping patterns (Table 4), the standard linear programming model based on income maximization provides the largest area (6.6 ha) of organic rice in the optimized results. Conversely, the cultivation of organic rice, which did not necessarily contribute to environmental mitigation (Table 5), was limited in the MOGA results affected by environmental objectives in addition to the economic objective. The MOGA results demonstrate that in the modeled farm, the planted area of organic rice was 2.3 ha at best even though income maximization was emphasized. When any of the minimized environmental objectives were of importance, organic rice was very lowly cultivated (0.3 ha or less).

Table 6.

Best Pareto point for each objective based on the MOGA results.

4. Discussion

4.1. Comparison of Economic and Environmental Outcomes between Organic and Environmentally Friendly Rice

It is known that organic farming often has higher labor costs because of various additional works (e.g., mechanical pest control in farm operations), but nonetheless remains economically competitive with conventional agriculture when organic price premiums are applied [1]. These characteristics of organic farming were also found in a comparison between organic rice and environmentally friendly rice with the reduced use of chemical fertilizers and synthetic pesticides (Table 4). Because the organic price premium more than made up for the decrease in yield, crop income (1319 thousand JPY/ha) for organic rice was much higher than that (635–824 thousand JPY/ha) for environmentally friendly rice. By contrast, given the practices of many weed control systems (Table 2), the labor input (142.6 h/ha) for organic rice was larger than that (111.8–120.4 h/ha) for environmentally friendly rice. Thus, although the modeled farm provided an economic advantage with the cultivation of organic rice, given limitations with the labor input, environmentally friendly rice could not be replaced entirely with organic rice (Table 6).

Meier et al. [82] reported that, in many cases, organic agricultural products have lower environmental impacts per unit area than conventional agricultural products. However, such findings were not necessarily applicable to organic rice production. For example, Hokazono and Hayashi [37], in a comparison of the environmental impacts of conventional, environmentally friendly, and organic rice from a five-year on-farm trial in Japan, found that organic rice has both positive and negative effects on environmental mitigation on a unit area basis. A comparison of the LCA results between organic rice and environmentally friendly rice also indicated that organic rice provides environmental advantages for the impacts per ha of EC and PU, but environmental disadvantages for those of GWP, AP, and EP (Table 5).

The EC results supported the perception that organic farming usually reduces energy consumption per unit area [2]. Compared with that (36.0–39.6 GJ/ha) for environmentally friendly rice, improvement in the EC (30.2 GJ/ha) for organic rice resulted from the zero use of chemical fertilizers and synthetic pesticides. In organic rice production, the avoidance of chemical fertilizers contributed to a significant reduction in energy demands for fertilizer inputs. Obviously, the energy input of synthetic pesticides was zero. However, a part of these energy reductions was offset by energy use derived from the production and application of organic fertilizers and fossil fuel combustion for weed control in paddy fields.

Organic rice delivered the best environmental performance for the PU (0 kg a.i./ha) because synthetic pesticide application is prohibited in organic farming. Compared with synthetic pesticide inputs (2.4–3.3 kg a.i./ha) for conventional rice in the Shiga region [83], environmentally friendly rice provided lower PU (1.6 kg a.i./ha). Note that given the limited data availability, the weight of active ingredients served as the indicator of PU [16,17]. However, to evaluate better the environmental and ecological impacts of agrichemicals in rice production, toxicity characterization would be better where possible (e.g., [84]).

By contrast, the GWP (13,857 kg CO2 eq./ha) for organic rice was considerably worse than that (7808–8055 kg CO2 eq./ha) for environmentally friendly rice. This was caused by a huge increase in direct CH4 emissions from organic paddy fields, which were calculated based on organic carbon inputs and midseason drainage manners [48,62,74]. Because cow manure, in addition to rice straw, was applied in organic paddy fields, the total organic carbon input (5165 kg C/ha) of organic rice was much larger than that (2652–2983 kg C/ha) of environmentally friendly rice. Furthermore, unlike environmentally friendly rice production, prolonged midseason drainage, useful for reducing direct CH4 emissions from paddy fields [62], was not practiced in organic rice production because it was not included in the essential requirements for the payment of the subsidy for organic agriculture [40].

The AP and EP (19.1 kg SO2 eq./ha and 36.6 kg PO4 eq./ha, respectively) for organic rice were also higher than those (17.5–17.7 kg SO2 eq./ha and 18.9–19.8 kg PO4 eq./ha, respectively) for environmentally friendly rice. The main reason for these degradations is that huge amounts of nutrient components were used in organic rice production. It is noteworthy that cow manure supplied more than half of the nutrient inputs (56% for N and 57% for P2O5) from the organic materials. Organic rice had a dramatically worsening EP because of the nutrient outflows derived from cow manure. Notably, nitrogen that easily leached with water substantially affected the increase in the EP. These results suggested that zero use of chemical fertilizers does not necessarily achieve low-input nutrient management in organic farmland.

In this paper, environmentally friendly rice with the reduced use of chemical inputs and prolonged midseason drainage was compared with organic rice. Because this approach might lead to unfair conclusions regarding the environmental impacts (especially GWP, AP, and EP) for organic rice, the validity of a comparison between organic rice and environmentally friendly rice was discussed by reviewing previous LCA studies that compared organic rice and conventional rice. Hokazono and Hayashi [37] found that GWP, AP, and EP per ha for organic rice, which needed large quantities of organic fertilizers and higher amounts of fossil fuels for mechanical fieldwork, were greater than those for conventional rice. Aguilera et al. [85] indicated that area-based GWP for organic rice had poorer environmental performance than that for conventional rice because of increased CH4 emissions by the incorporation of rice straw and manure. Hokazono and Hayashi [86] showed that continuous organic rice production, which applies a large amount of P2O5 from organic fertilizers, had an environmental disadvantage for land-oriented EP compared with continuous conventional rice production. These previous studies suggested that compared with conventional rice cultivation, organic rice farming is not always a low-input farming system and has possible negative environmental impacts because of intensive nutrient management. The implications obtained through this study showed similarity to those of previous LCA studies that compared organic rice and conventional rice.

4.2. Policy Implication for Organic Rice Farming

Compared with other cropping patterns, organic rice production had an advantage in the economic objective, but not necessarily in the environmental objectives. Although it should be kept in mind that the LCA framework did not include environmental mitigation measures (e.g., soil carbon sequestration), it had the worst effects on GWP and EP of all the cropping patterns. Given these findings, it is difficult to promote organic rice farming with the aim of environmental improvement. Even when intended to provide higher incomes, as shown in Table 6, the planted area of organic rice is likely to be constrained in terms of mitigating environmental degradation. At present, when farmers receive a subsidy for organic rice farming under the direct payments for environmentally friendly agriculture, they do not need to address any environmental measures that are not included in the organic JAS system [33,40]. However, to enhance not only the economic sustainability but also the environmental sustainability of organic rice production, some mitigation measures for the environment, especially GWP and EP, should be included in the essential requirements for its payment.

Prolonged midseason drainage practiced in environmentally friendly rice production is an effective way to reduce GWP because it can suppress direct CH4 emissions from paddy fields [62]. Although farmers can easily introduce prolonged midseason drainage [40], given the risk of yield reduction [62], it is difficult for them to adopt this technique initially without at least some incentive. Therefore, when prolonged midseason drainage is required, a monetary mechanism making up for the reduction in yield should be included in the direct payments for organic rice farming.

In the modeled farm, the application rate of cow manure, which was the main source of carbon and nutrients in organic rice production, was equal to the maximum amount (20 t/ha) of Shiga’s organic matter application standards [42,61]. Cow manure (3 JPY/kg) was available at a lower cost than grained 100% organic fertilizer (99.5 JPY/kg) [42], although these nutrient components were different. Because there is no information on the soil characteristics for the modeled farm [42], whether the nutrient input levels are appropriate is unclear. However, if the excessive use of cow manure is a concern, an effective solution is making it mandatory for farmers to monitor soil nutrient conditions using soil diagnostics when subsidizing organic rice farming. The appropriate use of cow manure is useful for reducing not only CH4 emissions but also nutrient losses. However, at present, in direct payments for environmentally friendly agriculture, the implementation of soil diagnostics is just one of the requirements for payment of an additional subsidy for organic farming, given soil carbon sequestration practices, such as manure applications, but is not mandatory [33].

Alternatively, because livestock manure applied to paddy fields is a significant factor in soil carbon sequestration [87], any saving may diminish the carbon sink effect. However, the benefit of soil carbon sequestration could be offset by the stimulation of CH4 emissions through cow manure application [88]. The reduced use of cow manure leads to decreasing the range of on-farm pollutant emissions to the air (CH4, N2O, and NH3) and water (N and P2O5) in the LCA framework (Figure 1). Therefore, saving cow manure based on soil diagnostics should improve the overall environmental impacts of organic rice, even though the positive effect on carbon sinks is less.

From the perspective of the Pareto-optimal solutions, farmers have difficulty adopting organic rice because of the risk of environmental degradation, but they might expand its planted area when several environmental problems are mitigated by the direct payments amended as mentioned above. However, in practice, they will not actively expand the planted area of organic rice unless its production brings an increased economic advantage, which is their main objective. Given that organic rice production remains very small in Japan [32], some measures for enhancing organic price premiums and developing organic food markets should be required to promote the practical application of organic rice in addition to these environmental policy improvements.

4.3. Limitations

The analysis has several limitations that are attributable to the use of an agricultural management handbook [42] and static modeling of a large-scale family-run rice farm. First, the large-scale family-run rice farm that was formulated as the MOGA-based bio-economic farm model was just one of the farm types in the Shiga region. Given that, in practice, many rice farms with different farming characteristics such as part-time farm households and community-based farm cooperatives exist in the region, the applicability of the findings to them should be carefully considered. Data collection based on a sample survey will be required in future studies. Second, the results obtained depended on the data from Shiga Prefecture [42] and the present farming environment. Note that changes in the assumed conditions (e.g., fluctuations in agricultural product prices) can vary the optimized results. Third, the analysis did not include significant effects on changes in the soil parameters. For example, soybean cultivation in a paddy–upland rotation system significantly influences soil nitrogen availability and soil carbon storage [89,90]. Because the continuous application of cow manure improves soil fertility in paddy fields, it leads to a reduction in nutrient inputs in the long term [45]. However, the changes in the soil conditions that affect environmental impacts, in addition to the productivity and profitability of crops, were not considered. Finally, soil conditions for the modeled farm were unclear, and the MOGA-based bio-economic farm model was static. When long-term on-farm trials to produce organic rice by combining the continuing use of a large amount of cow manure with controls on direct CH4 emissions from paddy fields are conducted in Japan, they will provide interesting findings on variations in soil conditions.

5. Conclusions

In this paper, to assess organic rice farming in Japan, a bio-economic farm model, including both economic and environmental objectives, was built through the combined application of MOGA and LCA. In the bio-economic analysis, LCA was used for formulating the environmental objectives, and MOGA was applied for solving the multi-objective optimization problem. The MOGA-based optimization results show that the cultivation of organic rice is likely to be limited because compared with environmentally friendly rice with the reduced use of chemical fertilizers and synthetic pesticides, while it increases income, it does not necessarily improve the environment.

Given the environmental hotspots identified by LCA, the worsening environmental impacts of organic rice, especially global warming and eutrophication, were mainly caused by the heavy use of cow manure and the absence of a countermeasure for the direct CH4 emissions from paddy fields. Therefore, mitigation measures against these problems, such as appropriate soil nutrient management, based on soil diagnostics and CH4 emission control through prolonged midseason drainage should be included in the essential requirements for subsidizing organic rice production.

Even though there is scope for further research into overcoming several limitations of this study, the findings suggest that when an economic benefit derived from organic practices can be largely offset or canceled out by some environmental concern, organic agriculture should be promoted carefully. This implication is useful for organic farmers and policymakers on organic agriculture. Furthermore, when there are trade-offs between economic and environmental objectives in organic rice farming, farmers need to choose a compromise solution. This paper confirms that a MOGA that can provide many options for decision makers is a useful technique for solving a multi-objective optimization problem for a bio-economic farm model.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/su151310059/s1, Table S1: Coefficients for calculating energy consumption and environmental load emissions; Table S2: Objective functions and constraints for the MOGA-based bio-economic farm model; Table S3: Pareto points based on the MOGA results.

Funding

This work was supported by the Japan Society for the Promotion of Science KAKENHI (grant numbers: JP20K06260 and JP22H02441).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The corresponding author will provide the data that support the findings of this study on reasonable request.

Conflicts of Interest

The author declares no conflict of interest.

References

- Crowder, D.W.; Reganold, J.P. Financial competitiveness of organic agriculture on a global scale. Proc. Natl. Acad. Sci. USA 2015, 112, 7611–7616. [Google Scholar] [CrossRef] [PubMed]

- Gomiero, T.; Paoletti, M.G.; Pimentel, D. Energy and environmental issues in organic and conventional agriculture. Crit. Rev. Plant Sci. 2008, 27, 239–254. [Google Scholar] [CrossRef]

- World Bank. Agriculture Investment Sourcebook: Agriculture and Rural Development; World Bank: Washington, DC, USA, 2005. [Google Scholar]

- Arunrat, N.; Sereenonchai, S.; Chaowiwat, W.; Wang, C.; Hatano, R. Carbon, nitrogen and water footprints of organic rice and conventional rice production over 4 years of cultivation: A case study in the lower North of Thailand. Agronomy 2022, 12, 380. [Google Scholar] [CrossRef]

- Arunrat, N.; Sereenonchai, S.; Wang, C. Carbon footprint and predicting the impact of climate change on carbon sequestration ecosystem services of organic rice farming and conventional rice farming: A case study in Phichit province, Thailand. J. Environ. Manag. 2021, 289, 112458. [Google Scholar] [CrossRef]

- Johansson, E.; Hussain, A.; Kuktaite, R.; Andersson, S.C.; Olsson, M.E. Contribution of organically grown crops to human health. Int. J. Environ. Res. Public Health 2014, 11, 3870–3893. [Google Scholar] [CrossRef]

- Scialabba, N.E.-H.; Müller-Lindenlauf, M. Organic agriculture and climate change. Renew. Agric. Food Syst. 2010, 25, 158–169. [Google Scholar] [CrossRef]

- Ruben, R.; Moll, H.; Kuyvenhoven, A. Integrating agricultural research and policy analysis: Analytical framework and policy applications for bio-economic modelling. Agric. Syst. 1998, 58, 331–349. [Google Scholar] [CrossRef]

- Guinée, J.B. (Ed.) Handbook on Life Cycle Assessment: Operational Guide to the ISO Standards; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2002. [Google Scholar]

- Heidari, M.D.; Turner, I.; Ardestani-Jaafari, A.; Pelletier, N. Operations research for environmental assessment of crop-livestock production systems. Agric. Syst. 2021, 193, 103208. [Google Scholar] [CrossRef]

- Janssen, S.; van Ittersum, M.K. Assessing farm innovations and responses to policies: A review of bio-economic farm models. Agric. Syst. 2007, 94, 622–636. [Google Scholar] [CrossRef]

- Reidsma, P.; Janssen, S.; Jansen, J.; van Ittersum, M.K. On the development and use of farm models for policy impact assessment in the European Union—A review. Agric. Syst. 2018, 159, 111–125. [Google Scholar] [CrossRef]

- Castro, L.M.; Härtl, F.; Ochoa, S.; Calvas, B.; Izquierdo, L.; Knoke, T. Integrated bio-economic models as tools to support land-use decision making: A review of potential and limitations. J. Bioecon. 2018, 20, 183–211. [Google Scholar] [CrossRef]

- Konak, A.; Coit, D.W.; Smith, A.E. Multi-objective optimization using genetic algorithms: A tutorial. Reliab. Eng. Syst. Saf. 2006, 91, 992–1007. [Google Scholar] [CrossRef]

- Deb, K. Multi-Objective Optimization Using Evolutionary Algorithms; Wiley: Chichester, UK, 2001. [Google Scholar]

- Acs, S.; Berentsen, P.B.M.; de Wolf, M.; Huirne, R.B.M. Comparison of conventional and organic arable farming systems in the Netherlands by means of bio-economic modelling. Biol. Agric. Hortic. 2007, 24, 341–361. [Google Scholar] [CrossRef]

- Acs, S.; Berentsen, P.B.M.; Huirne, R.B.M. Conversion to organic arable farming in The Netherlands: A dynamic linear programming analysis. Agric. Syst. 2007, 94, 405–415. [Google Scholar] [CrossRef]

- Dupré, M.; Blazy, J.-M.; Michels, T.; Le Gal, P.-Y. Supporting policymakers in designing agricultural policy instruments: A participatory approach with a regional bioeconomic model in La Réunion (France). Land Use Policy 2021, 100, 105128. [Google Scholar] [CrossRef]

- Emamzadeh, S.M.; Forghani, M.A.; Karnema, A.; Darbandi, S. Determining an optimum pattern of mixed planting from organic and non-organic crops with regard to economic and environmental indicators: A case study of cucumber in Kerman, Iran. Inf. Process. Agric. 2016, 3, 207–214. [Google Scholar] [CrossRef]

- Gaudino, S.; Reidsma, P.; Kanellopoulos, A.; Sacco, D.; van Ittersum, M.K. Integrated assessment of the EU’s greening reform and feed self-sufficiency scenarios on dairy farms in Piemonte, Italy. Agriculture 2018, 8, 137. [Google Scholar] [CrossRef]

- Groot, J.C.J.; Oomen, G.J.M.; Rossing, W.A.H. Multi-objective optimization and design of farming systems. Agric. Syst. 2012, 110, 63–77. [Google Scholar] [CrossRef]

- Liang, Y.; Hui, C.W.; You, F. Multi-objective economic-resource-production optimization of sustainable organic mixed farming systems with nutrient recycling. J. Clean. Prod. 2018, 196, 304–330. [Google Scholar] [CrossRef]

- Moriondo, M.; Pacini, C.; Trombi, G.; Vazzana, C.; Bindi, M. Sustainability of dairy farming system in Tuscany in a changing climate. Eur. J. Agron. 2010, 32, 80–90. [Google Scholar] [CrossRef]

- Mosnier, C.; Duclos, A.; Agabriel, J.; Gac, A. What prospective scenarios for 2035 will be compatible with reduced impact of French beef and dairy farm on climate change? Agric. Syst. 2017, 157, 193–201. [Google Scholar] [CrossRef]

- Schuler, J.; Sattler, C.; Helmecke, A.; Zander, P.; Uthes, S.; Bachinger, J.; Stein-Bachinger, K. The economic efficiency of conservation measures for amphibians in organic farming—Results from bio-economic modelling. J. Environ. Manag. 2013, 114, 404–413. [Google Scholar] [CrossRef] [PubMed]

- Van Calker, K.J.; Berentsen, P.B.M.; Giesen, G.W.J.; Huirne, R.B.M. Maximising sustainability of Dutch dairy farming systems for different stakeholders: A modelling approach. Ecol. Econ. 2008, 65, 407–419. [Google Scholar] [CrossRef]

- Veysset, P.; Lherm, M.; Bébin, D. Productive, environmental and economic performances assessments of organic and conventional suckler cattle farming systems. Org. Agric. 2011, 1, 1–16. [Google Scholar] [CrossRef]

- Viaggi, D.; Raggi, M.; Gomez y Paloma, S. Modelling and interpreting the impact of policy and price scenarios on farm-household sustainability: Farming systems vs. result-driven clustering. Environ. Modell. Softw. 2013, 43, 96–108. [Google Scholar] [CrossRef]

- Willer, H.; Trávníček, J.; Meier, C.; Schlatter, B. (Eds.) The World of Organic Agriculture: Statistics and Emerging Trends 2021; Research Institute of Organic Agriculture FiBL: Frick, Switzerland; IFOAM—Organics International: Bonn, Germany, 2021. [Google Scholar]

- Delmotte, S.; Couderc, V.; Mouret, J.-C.; Lopez-Ridaura, S.; Barbier, J.-M.; Hossard, L. From stakeholders narratives to modelling plausible future agricultural systems. Integrated assessment of scenarios for Camargue, Southern France. Eur. J. Agron. 2017, 82, 292–307. [Google Scholar] [CrossRef]

- Current Situation and Policy on Organic Agriculture in Japan. Available online: https://www.maff.go.jp/e/policies/env/sustainagri/attach/pdf/organicagri-1.pdf (accessed on 6 January 2022).

- Authorized Business Operators, Grading Results, and Farmland Areas for Organic Foods. Available online: https://www.maff.go.jp/j/jas/jas_kikaku/yuuki_old_jigyosya_jisseki_hojyo.html (accessed on 29 July 2022). (In Japanese)

- Direct Payments for Environmentally Friendly Agriculture. Available online: https://www.maff.go.jp/e/policies/env/sustainagri/directpay.html (accessed on 11 January 2022).

- The Implementation Status of Direct Payments for Environmentally Friendly Agriculture in 2020. Available online: https://www.maff.go.jp/j/seisan/kankyo/kakyou_chokubarai/other/attach/pdf/r2jisshi-3.pdf (accessed on 6 January 2022). (In Japanese)

- Khoshnevisan, B.; Bolandnazar, E.; Shamshirband, S.; Shariati, H.M.; Anuar, N.B.; Kiah, M.L.M. Decreasing environmental impacts of cropping systems using life cycle assessment (LCA) and multi-objective genetic algorithm. J. Clean. Prod. 2015, 86, 67–77. [Google Scholar] [CrossRef]

- Mousavi-Avval, S.H.; Rafiee, S.; Sharifi, M.; Hosseinpour, S.; Notarnicola, B.; Tassielli, G.; Renzulli, P.A. Application of multi-objective genetic algorithms for optimization of energy, economics and environmental life cycle assessment in oilseed production. J. Clean. Prod. 2017, 140, 804–815. [Google Scholar] [CrossRef]

- Hokazono, S.; Hayashi, K. Variability in environmental impacts during conversion from conventional to organic farming: A comparison among three rice production systems in Japan. J. Clean. Prod. 2012, 28, 101–112. [Google Scholar] [CrossRef]

- Masuda, K. Optimization model for mitigating global warming at the farm scale: An application to Japanese rice farms. Sustainability 2016, 8, 593. [Google Scholar] [CrossRef]

- Final Assessment Report: Direct Payments for Environmentally Friendly Agriculture in Shiga Prefecture. Available online: https://www.pref.shiga.lg.jp/file/attachment/5143820.pdf (accessed on 16 September 2020). (In Japanese).

- Shiga Prefecture. Outlines of the Direct Payments for Environmentally Friendly Agriculture in 2020 (Shiga Prefecture’s Version); Shiga Prefecture: Otsu, Japan, 2020. (In Japanese) [Google Scholar]

- Shiga Prefecture. Outlines of the Certification System for Environmentally Friendly Agricultural Products; Shiga Prefecture: Otsu, Japan, 2021. (In Japanese) [Google Scholar]

- Shiga Prefecture. Handbook on Agricultural Management; Shiga Prefecture: Otsu, Japan, 2018. (In Japanese) [Google Scholar]

- Shiga Prefecture; (Shiga Prefecture, Otsu, Japan). Personal communication, 2021–2022.

- Kurosawa, M.; Tezuka, T. Awareness of farmers approaching the sustainable agriculture to improve regional environment: Case study of environmentally conscious agriculture in Shiga Prefecture. J. Rural Plan. Assoc. 2005, 24, 61–66, (In Japanese with English Abstract). [Google Scholar] [CrossRef]

- Shiga Prefecture. Technical Guide on Soil Improvement; Shiga Prefecture: Otsu, Japan, 1997. (In Japanese) [Google Scholar]

- Climate Normals (1991–2020) in Otsu. Available online: https://www.data.jma.go.jp/obd/stats/etrn/view/nml_amd_ym.php?prec_no=60&block_no=0586 (accessed on 12 June 2023). (In Japanese)

- Masuda, K. Eco-efficiency assessment of intensive rice production in Japan: Joint application of life cycle assessment and data envelopment analysis. Sustainability 2019, 11, 5368. [Google Scholar] [CrossRef]

- Greenhouse Gas Inventory Office of Japan (GIO); Ministry of the Environment, Japan (MOE) (Eds.) National Greenhouse Gas Inventory Report of Japan 2021; National Institute for Environmental Studies: Tsukuba, Japan, 2021.

- Association of Agriculture and Forestry Statistics (AAFS) (Ed.) Pocket Directory of Fertilizers 2019/2020; AAFS: Tokyo, Japan, 2021. (In Japanese) [Google Scholar]

- Food Composition Database. Available online: https://fooddb.mext.go.jp/ (accessed on 16 July 2021). (In Japanese)

- Ogawa, K.; Takeuchi, Y.; Katayama, M. Biomass production and the amounts of absorbed inorganic elements by crops in arable lands in Hokkaido, and its evaluation. Res. Bull. Hokkaido Natl. Agric. Exp. Stn. 1988, 149, 57–91, (In Japanese with English Abstract). [Google Scholar]

- Official Website of Bayer CropScience K.K. Available online: https://cropscience.bayer.jp/ja/home/ (accessed on 4 June 2021). (In Japanese).

- Official Website of Hokko Chemical Industry Co., Ltd. Available online: https://www.hokkochem.co.jp/ (accessed on 4 June 2021). (In Japanese).

- Official Website of Kumiai Chemical Industry Co., Ltd. Available online: https://www.kumiai-chem.co.jp/ (accessed on 4 June 2021). (In Japanese).

- Official Website of Kyoyu Agri Co., Ltd. Available online: https://www.kyoyu-agri.co.jp/ (accessed on 4 June 2021). (In Japanese).

- Official Website of MARUWA Biochemical Co., Ltd. Available online: https://www.mbc-g.co.jp/ (accessed on 4 June 2021). (In Japanese).

- Official Website of Mitsui Chemicals Agro, Inc. Available online: https://www.mitsui-agro.com/ (accessed on 4 June 2021). (In Japanese).

- Official Website of Nippon Soda Co., Ltd. Available online: https://www.nippon-soda.co.jp/ (accessed on 4 June 2021). (In Japanese).

- I-Nouryoku (Sumitomo Chemical Co., Ltd.). Available online: https://www.i-nouryoku.com/index.html (accessed on 4 June 2021). (In Japanese).

- Official Website of Syngenta Japan K.K. Available online: https://www.syngenta.co.jp/ (accessed on 4 June 2021). (In Japanese).

- Shiga Prefecture. Technical Guide on Environmentally Friendly Agriculture; Shiga Prefecture: Otsu, Japan, 2010. (In Japanese) [Google Scholar]

- Itoh, M.; Sudo, S.; Mori, S.; Saito, H.; Yoshida, T.; Shiratori, Y.; Suga, S.; Yoshikawa, N.; Suzue, Y.; Mizukami, H.; et al. Mitigation of methane emissions from paddy fields by prolonging midseason drainage. Agric. Ecosyst. Environ. 2011, 141, 359–372. [Google Scholar] [CrossRef]

- Nansai, K.; Kondo, Y.; Kagawa, S.; Suh, S.; Nakajima, K.; Inaba, R.; Tohno, S. Estimates of embodied global energy and air-emission intensities of Japanese products for building a Japanese input–output life cycle assessment database with a global system boundary. Environ. Sci. Technol. 2012, 46, 9146–9154. [Google Scholar] [CrossRef]

- Greenhouse Gas Inventory Office of Japan (Ed.) National Greenhouse Gas Inventory Report of Japan; National Institute for Environmental Studies: Tsukuba, Japan, 2013. [Google Scholar]

- Estimation Methods of Sectoral Energy Consumption and Greenhouse Gas Emissions Based on 2005 Input–Output Tables, Revised Edition (August 2013). Available online: http://www.cger.nies.go.jp/publications/report/d031/jpn/pdf/6/3EID2005_Method_jp.pdf (accessed on 3 August 2021). (In Japanese)

- 2005 Input–Output Tables for Japan. Available online: https://www.e-stat.go.jp/stat-search/files?page=1&layout=datalist&toukei=00200603&tstat=000001026283&cycle=0&tclass1val=0 (accessed on 3 August 2021). (In Japanese)

- International Energy Agency (IEA). Energy Statistics Manual; IEA Publications: Paris, France, 2005.

- Kainou, K. Recommendation of Draft Revised Standard Calorific Value and Carbon Emission Factor for Fossil Fuel Energy Sources in Japan: 2013 FY Revised Standard Calorific Value and Carbon Emission Factor, Revised Edition (January 2016) (RIETI Discussion Paper Series 14-J-047); Research Institute of Economy, Trade and Industry: Tokyo, Japan, 2016. (In Japanese)

- National Institute for Agro-Environmental Sciences (NIAES) (Ed.) Manual for Life Cycle Assessment of Agricultural Practices in Japan; NIAES: Tsukuba, Japan, 2003. (In Japanese)

- Asman, W.A.H. Ammonia Emission in Europe: Updated Emission and Emission Variations (Report No. 228471008); National Institute of Public Health and Environmental Protection: Bilthoven, The Netherlands, 1992.

- AMAFE Joint Research Team (Ed.) User Manual of Decision Support System for Application of Manure and Fertilizer to Grassland and Forage Corn Field Based on Nutrient Recycling (AMAFE 2006); AMAFE Joint Research Team: Kitahiroshima, Japan, 2006. (In Japanese) [Google Scholar]

- Mannheim, T.; Braschkat, J.; Marschner, H. Ammonia emissions from senescing plants and during decomposition of crop residues. J. Plant Nutr. Soil Sci. 1997, 160, 125–132, (In German with English Abstract). [Google Scholar]

- Mishima, S.; Itahashi, S.; Kimura, R.; Inoue, T. Trends of phosphate fertilizer demand and phosphate balance in farmland soils in Japan. Soil Sci. Plant Nutr. 2003, 49, 39–45. [Google Scholar] [CrossRef]

- Katayanagi, N.; Fumoto, T.; Hayano, M.; Takata, Y.; Kuwagata, T.; Shirato, Y.; Sawano, S.; Kajiura, M.; Sudo, S.; Ishigooka, Y.; et al. Development of a method for estimating total CH4 emission from rice paddies in Japan using the DNDC-Rice model. Sci. Total Environ. 2016, 547, 429–440. [Google Scholar] [CrossRef]

- Stocker, T.F.; Qin, D.; Plattner, G.-K.; Tignor, M.; Allen, S.K.; Boschung, J.; Nauels, A.; Xia, Y.; Bex, V.; Midgley, P.M. (Eds.) Climate Change 2013: The Physical Science Basis; Cambridge University Press: New York, NY, USA, 2013. [Google Scholar]

- Rosenbaum, R.K.; Bachmann, T.M.; Gold, L.S.; Huijbregts, M.A.J.; Jolliet, O.; Juraske, R.; Koehler, A.; Larsen, H.F.; MacLeod, M.; Margni, M.; et al. USEtox—The UNEP-SETAC toxicity model: Recommended characterisation factors for human toxicity and freshwater ecotoxicity in life cycle impact assessment. Int. J. Life Cycle Assess. 2008, 13, 532–546. [Google Scholar] [CrossRef]

- Ministry of Agriculture, Forestry and Fisheries of Japan (MAFF). Summary of Farming Income Stabilization Measures in 2020; MAFF: Tokyo, Japan, 2020. (In Japanese)

- Shiga Prefecture. On the Shiga Prefecture’s Subsidies for Developing Crop Production Areas in 2020; Shiga Prefecture: Otsu, Japan, 2020. (In Japanese) [Google Scholar]

- Japan Agricultural Mechanization Association (JAMA). Handbook on Agricultural Machinery and Facilities (2015/2016); JAMA: Tokyo, Japan, 2015. (In Japanese) [Google Scholar]

- Goldberg, D.E. Genetic Algorithms in Search, Optimization, and Machine Learning; Addison-Wesley: Reading, MA, USA, 1989. [Google Scholar]

- Global Optimization Toolbox. Available online: https://www.mathworks.com/help/gads/ (accessed on 31 March 2022).

- Meier, M.S.; Stoessel, F.; Jungbluth, N.; Juraske, R.; Schader, C.; Stolze, M. Environmental impacts of organic and conventional agricultural products—Are the differences captured by life cycle assessment? J. Environ. Manag. 2015, 149, 193–208. [Google Scholar] [CrossRef]

- Hasukawa, H.; Shibahara, F.; Komai, S.; Mizutani, S.; Oobayashi, H.; Fujii, Y.; Sudo, M. Reductions in outflow loads during paddy rice cropping period by environment-conscious agricultural practice. Bull. Shiga Prefect. Agric. Technol. Promot. Cent. 2009, 48, 1–21, (In Japanese with English Abstract). [Google Scholar]

- He, X.; Qiao, Y.; Liang, L.; Knudsen, M.T.; Martin, F. Environmental life cycle assessment of long-term organic rice production in subtropical China. J. Clean. Prod. 2018, 176, 880–888. [Google Scholar] [CrossRef]

- Aguilera, E.; Guzmán, G.; Alonso, A. Greenhouse gas emissions from conventional and organic cropping systems in Spain. I. Herbaceous crops. Agron. Sustain. Dev. 2015, 35, 713–724. [Google Scholar] [CrossRef]

- Hokazono, S.; Hayashi, K. Life cycle assessment of organic paddy rotation systems using land- and product-based indicators: A case study in Japan. Int. J. Life Cycle Assess. 2015, 20, 1061–1075. [Google Scholar] [CrossRef]

- Rui, W.; Zhang, W. Effect size and duration of recommended management practices on carbon sequestration in paddy field in Yangtze Delta Plain of China: A meta-analysis. Agric. Ecosyst. Environ. 2010, 135, 199–205. [Google Scholar] [CrossRef]

- Zhou, M.; Zhu, B.; Wang, S.; Zhu, X.; Vereecken, H.; Brüggemann, N. Stimulation of N2O emission by manure application to agricultural soils may largely offset carbon benefits: A global meta-analysis. Glob. Chang. Biol. 2017, 23, 4068–4083. [Google Scholar] [CrossRef]

- Hasukawa, H.; Inoda, Y.; Toritsuka, S.; Sudo, S.; Oura, N.; Sano, T.; Shirato, Y.; Yanai, J. Effect of paddy-upland rotation system on the net greenhouse gas balance as the sum of methane and nitrous oxide emissions and soil carbon storage: A case in western Japan. Agriculture 2021, 11, 52. [Google Scholar] [CrossRef]

- Takakai, F.; Nakagawa, S.; Sato, K.; Kon, K.; Sato, T.; Kaneta, Y. Net greenhouse gas budget and soil carbon storage in a field with paddy-upland rotation with different history of manure application. Agriculture 2017, 7, 49. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).