Multicriteria Decision-Making Tools for the Selection of Biomasses as Supplementary Cementitious Materials

Abstract

1. Introduction

2. Materials and Methods

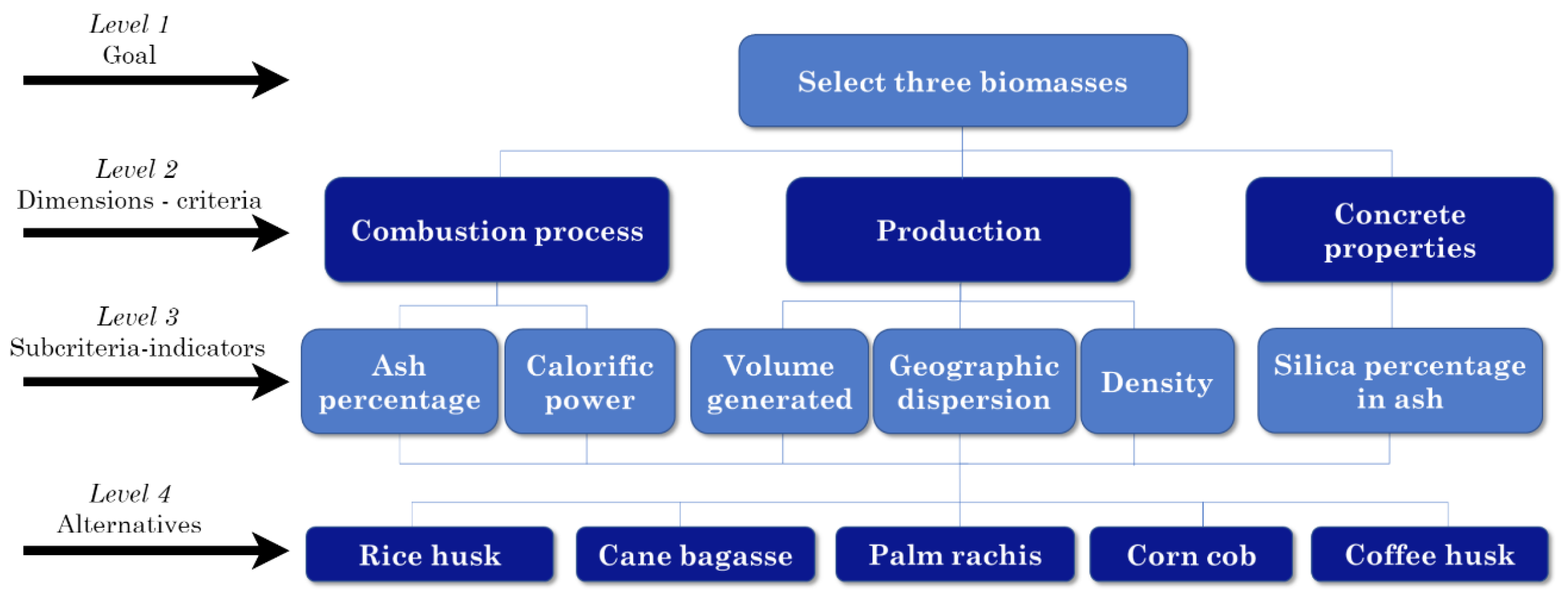

- Stage 1: Criteria (dimensions), sub-criteria (indicators), and alternatives selection.

- Stage 2: Definition of the criteria and sub-criteria weights.

- Stage 3: Aggregation

- Stage 4: Results analysis

3. Results and Discussion

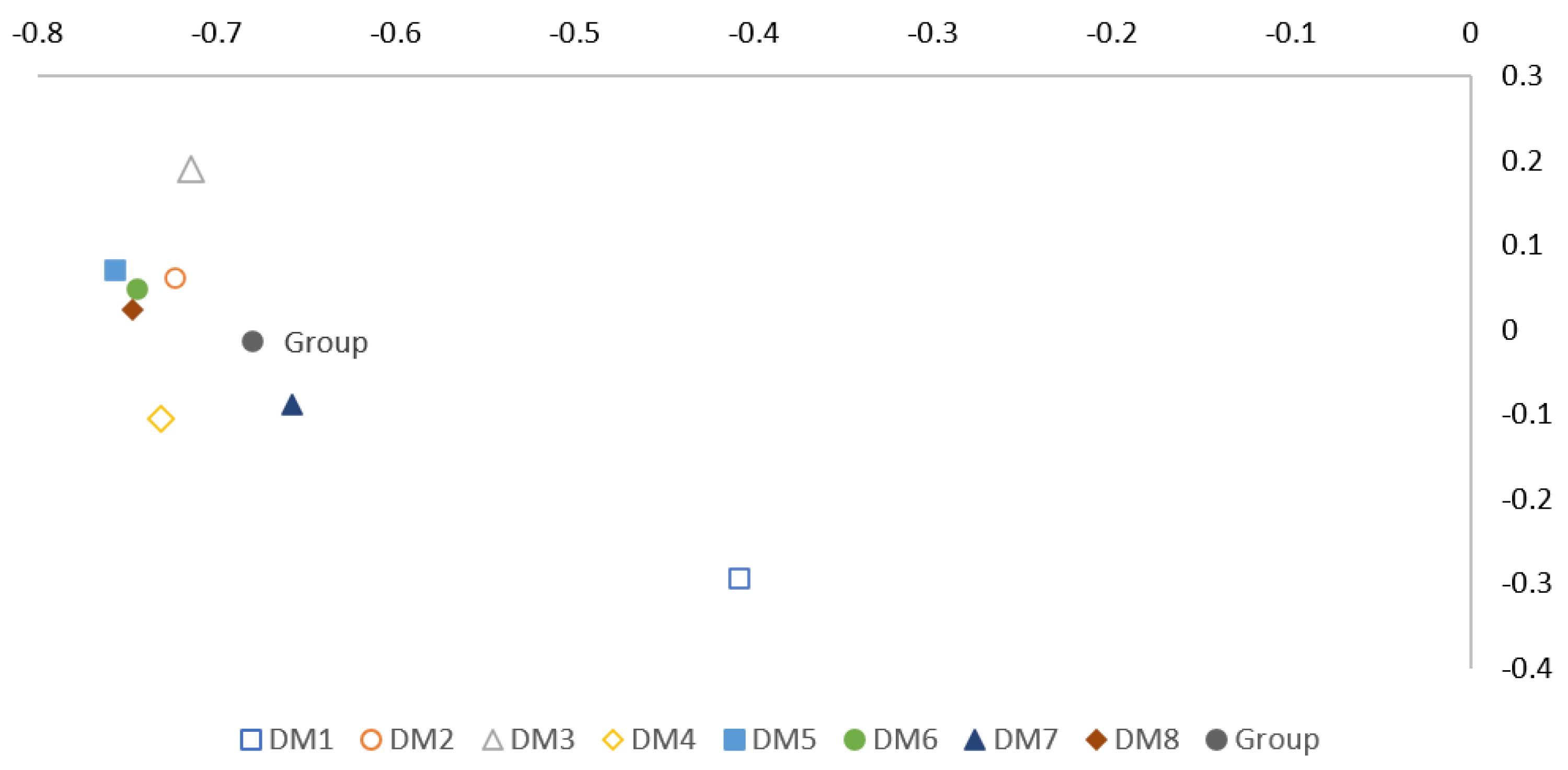

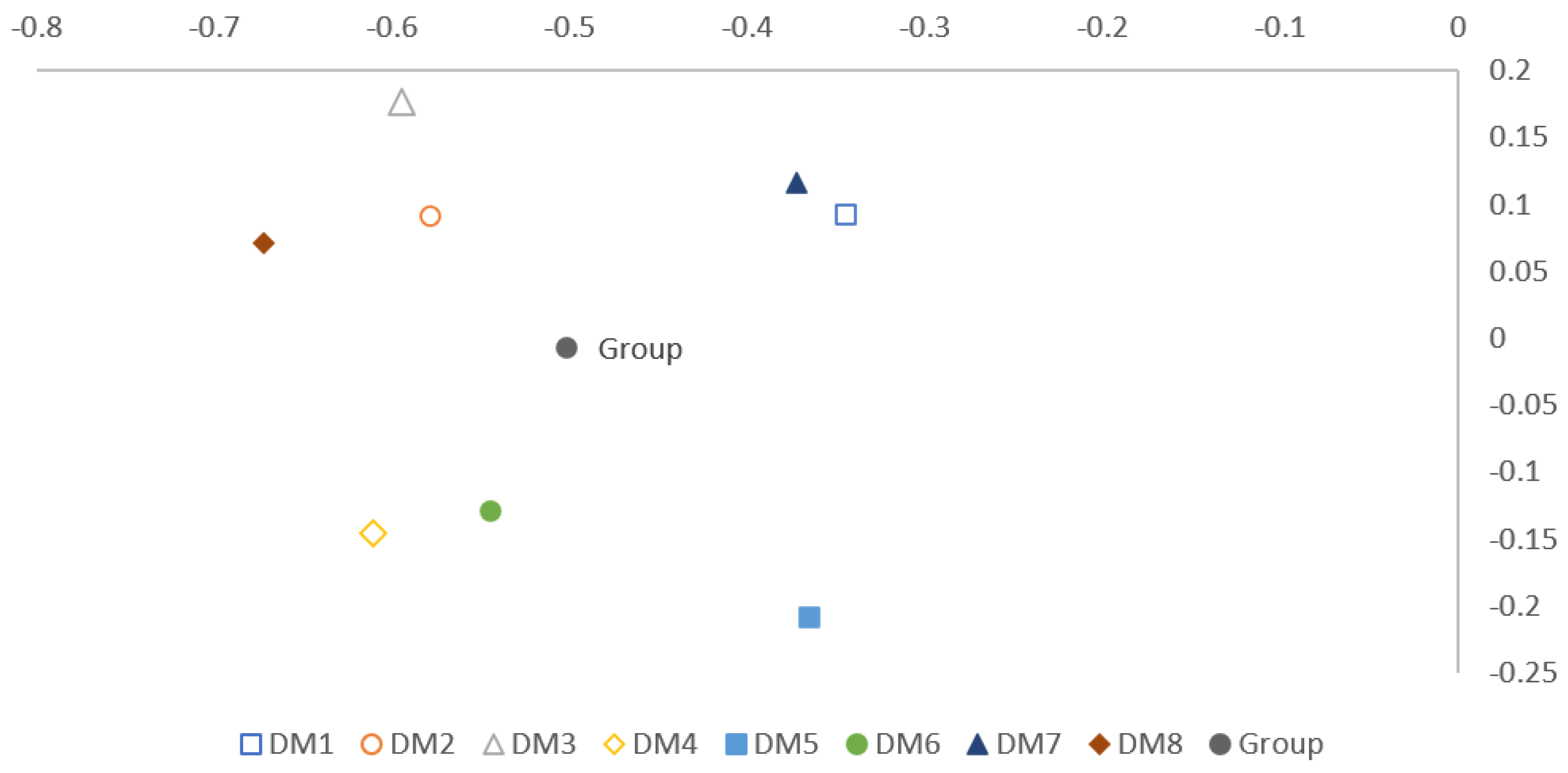

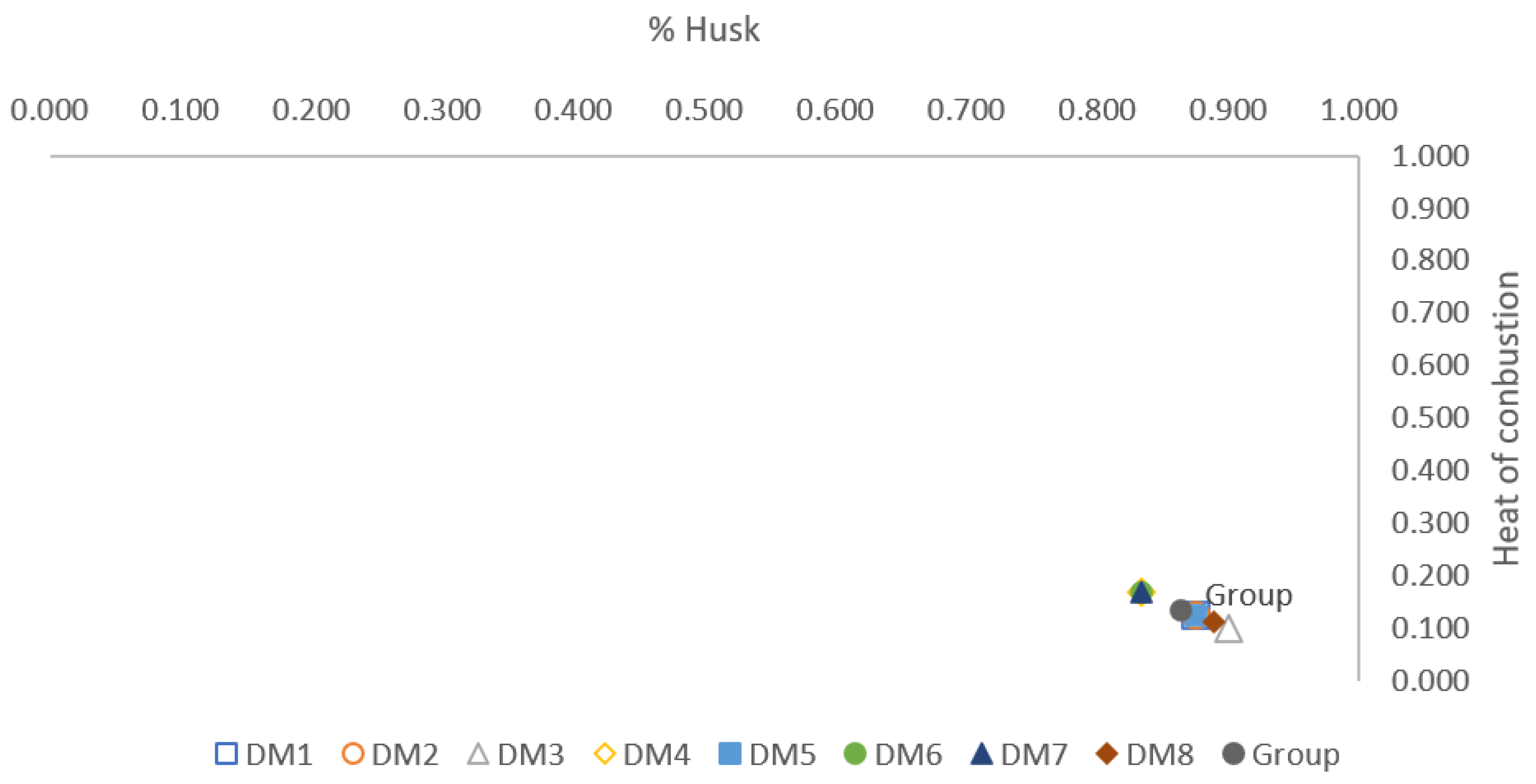

3.1. Analysis of Expert Judgments

3.2. Biomass Selection

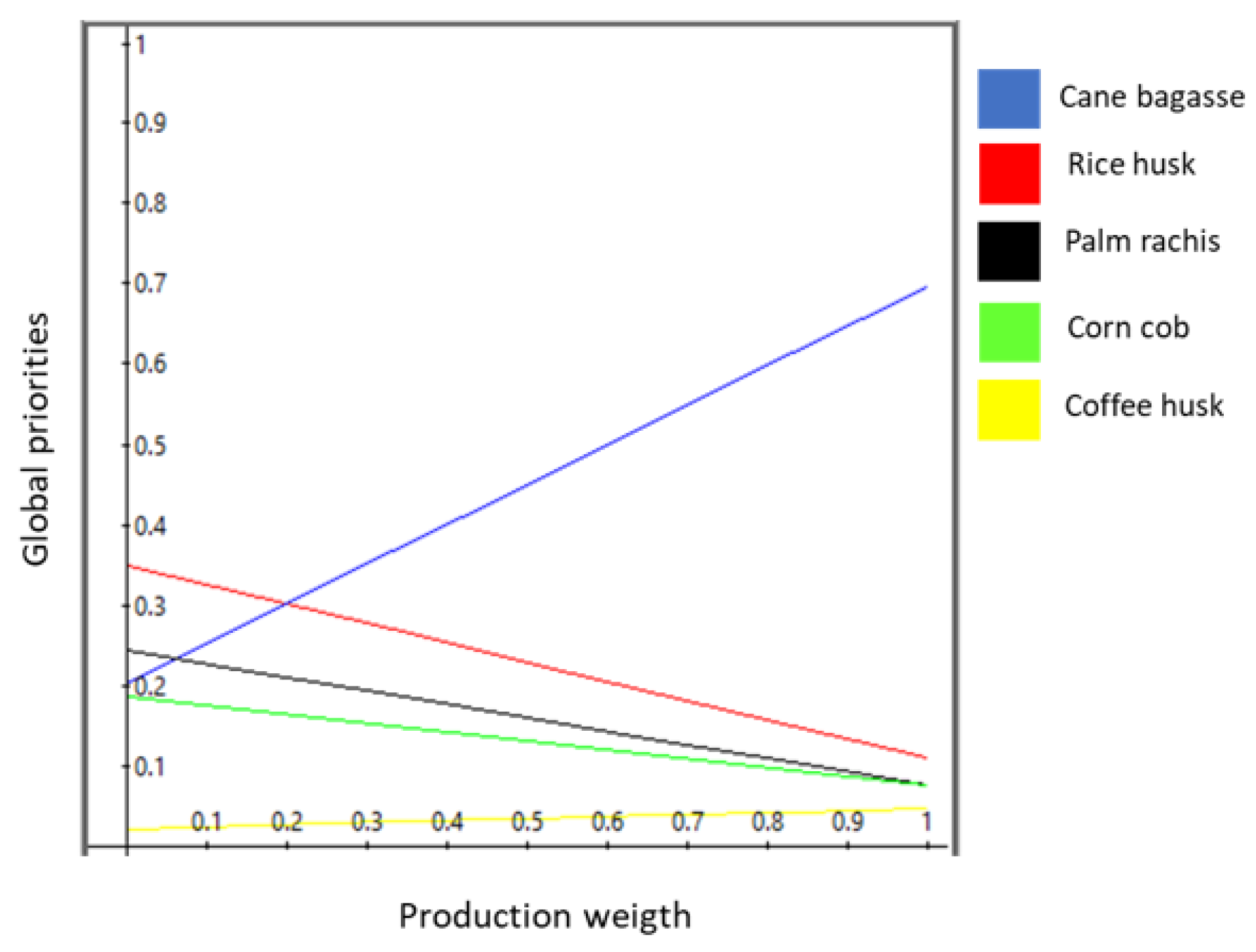

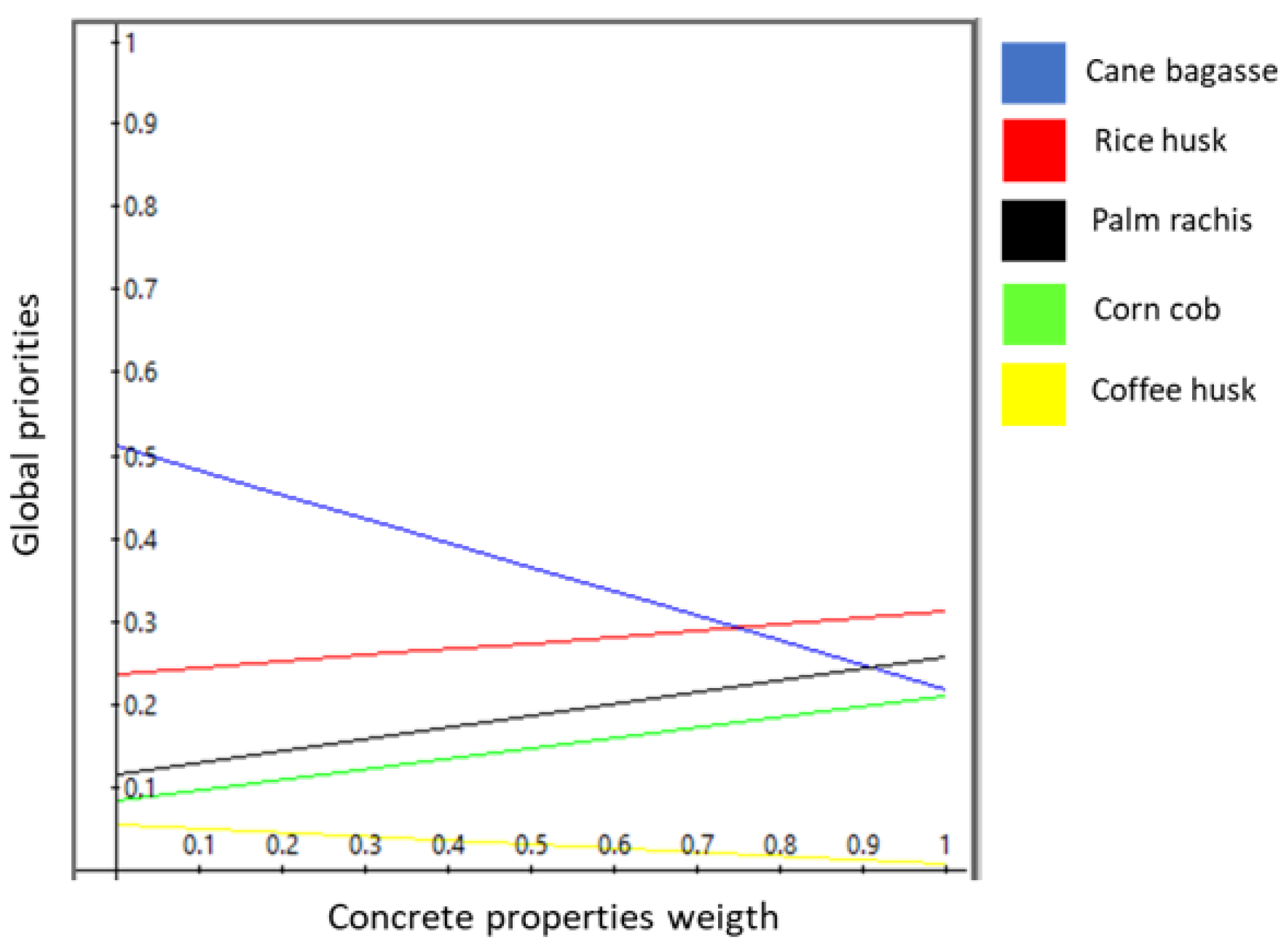

3.3. Sensitivity Analysis

Evaluation of Alternative Scenarios

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Sources of Information for the Candidate Biomasses in the Different Criteria

| Biomass | Ash Percentage | Volume Generated | Density | Calorific Power | Silica Percentage in Ash | Sources |

|---|---|---|---|---|---|---|

| Cane bagasse | X | [5,39,40,41,42] | ||||

| X | X | [43,44,45,46,47] | ||||

| X | [46] | |||||

| X | [48] | |||||

| X | [45,49] | |||||

| Coffee husk | X | X | [45,46] | |||

| X | [46] | |||||

| X | [50] | |||||

| X | [51] | |||||

| Corn cob | X | X | [52,53] | |||

| X | X | [54] | ||||

| X | [55] | |||||

| X | X | X | [56] | |||

| X | [57] | |||||

| X | [58] | |||||

| X | [51] | |||||

| Palm rachis | X | X | [45] | |||

| X | [59] | |||||

| X | X | X | [48,60] | |||

| X | [61] | |||||

| X | [48,51] | |||||

| X | X | [62] | ||||

| Rice husk | X | [63] | ||||

| X | X | X | [64] | |||

| X | [65] | |||||

| X | [66,67] | |||||

| X | [51,66] | |||||

| X | [68] |

References

- Poudyal, L.; Adhikari, K. Environmental Sustainability in Cement Industry: An Integrated Approach for Green and Economical Cement Production. Resour. Environ. Sustain. 2021, 4, 100024. [Google Scholar] [CrossRef]

- Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-Efficient Cements: Potential Economically Viable Solutions for a Low-CO2 Cement-Based Materials Industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- González-Kunz, R.N.; Pineda, P.; Bras, A.; Morillas, L. Plant Biomass Ashes in Cement-Based Building Materials. Feasibility as Eco-Efficient Structural Mortars and Grouts. Sustain. Cities Soc. 2017, 31, 151–172. [Google Scholar] [CrossRef]

- Endale, S.A.; Taffese, W.Z.; Vo, D.H.; Yehualaw, M.D. Rice Husk Ash in Concrete. Sustainability 2023, 15, 137. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Toledo Filho, R.D.; Tavares, L.M.; Fairbairn, E.M.R. Experimental Characterization of Binary and Ternary Blended-Cement Concretes Containing Ultrafine Residual Rice Husk and Sugar Cane Bagasse Ashes. Constr. Build. Mater. 2012, 29, 641–646. [Google Scholar] [CrossRef]

- Aprianti, S.E. A Huge Number of Artificial Waste Material Can Be Supplementary Cementitious Material (SCM) for Concrete Production—A Review Part II. J. Clean. Prod. 2017, 142, 4178–4194. [Google Scholar] [CrossRef]

- Thomas, B.S.; Yang, J.; Mo, K.H.; Abdalla, J.A.; Hawileh, R.A.; Ariyachandra, E. Biomass Ashes from Agricultural Wastes as Supplementary Cementitious Materials or Aggregate Replacement in Cement/Geopolymer Concrete: A Comprehensive Review. J. Build. Eng. 2021, 40, 102332. [Google Scholar] [CrossRef]

- Luhar, S.; Cheng, T.W.; Luhar, I. Incorporation of Natural Waste from Agricultural and Aquacultural Farming as Supplementary Materials with Green Concrete: A Review. Compos. B Eng. 2019, 175, 107076. [Google Scholar] [CrossRef]

- Zyoud, S.H.; Fuchs-Hanusch, D. A Bibliometric-Based Survey on AHP and TOPSIS Techniques. Expert Syst. Appl. 2017, 78, 158–181. [Google Scholar] [CrossRef]

- Vlachokostas, C.; Michailidou, A.V.; Achillas, C. Multi-Criteria Decision Analysis towards Promoting Waste-to-Energy Management Strategies: A Critical Review. Renew. Sustain. Energy Rev. 2021, 138, 110563. [Google Scholar] [CrossRef]

- Huang, I.B.; Keisler, J.; Linkov, I. Multi-Criteria Decision Analysis in Environmental Sciences: Ten Years of Applications and Trends. Sci. Total Environ. 2011, 409, 3578–3594. [Google Scholar] [CrossRef] [PubMed]

- Zavadskas, E.K.; Antuchevičienė, J.; Kapliński, O. Multi-Criteria Decision Making in Civil Engineering: Part I—A State-of-the-Art Survey. Eng. Struct. Technol. 2016, 7, 103–113. [Google Scholar] [CrossRef]

- Rashid, K.; Farooq, S.; Mahmood, A.; Iftikhar, S.; Ahmad, A. Moving towards Resource Conservation by Automated Prioritization of Concrete Mix Design. Constr. Build. Mater. 2020, 236, 117586. [Google Scholar] [CrossRef]

- Papić, M.; Garabinović, D. Overview of the Application of Multi Criteria Decision Making Methods on Issues Regarding Biomass. In Proceedings of the 32nd International Congress on Process Engineering, Procesing ’19, Belgrade, Serbia, 30 May 2019; pp. 235–242. [Google Scholar]

- Zavadskas, E.K.; Antuchevičienė, J.; Kaplinski, O. Multi-Criteria Decision Making in Civil Engineering. Part II—Applications. Eng. Struct. Technol. 2016, 7, 151–167. [Google Scholar] [CrossRef]

- Tramarico, C.L.; Mizuno, D.; Salomon, V.A.P.; Marins, F.A.S. Analytic Hierarchy Process and Supply Chain Management: A Bibliometric Study. Procedia Comput. Sci. 2015, 55, 441–450. [Google Scholar] [CrossRef]

- Goulart Coelho, L.M.; Lange, L.C.; Coelho, H.M.G. Multi-Criteria Decision Making to Support Waste Management: A Critical Review of Current Practices and Methods. Waste Manag. Res. 2017, 35, 3–28. [Google Scholar] [CrossRef]

- Ho, W.; Ma, X. The State-of-the-Art Integrations and Applications of the Analytic Hierarchy Process. Eur. J. Oper. Res. 2018, 267, 399–414. [Google Scholar] [CrossRef]

- Jato-Espino, D.; Castillo-Lopez, E.; Rodriguez-Hernandez, J.; Canteras-Jordana, J.C. A Review of Application of Multi-Criteria Decision Making Methods in Construction. Autom. Constr. 2014, 45, 151–162. [Google Scholar] [CrossRef]

- Rashid, K.; Hameed, R.; Ahmad, H.A.; Razzaq, A.; Ahmad, M.; Mahmood, A. Analytical Framework for Value Added Utilization of Glass Waste in Concrete: Mechanical and Environmental Performance. Waste Manag. 2018, 79, 312–323. [Google Scholar] [CrossRef]

- Praveenkumar, S.; Sankarasubramanian, G.; Sindhu, S. Selecting Optimized Mix Proportion of Bagasse Ash Blended High Performance Concrete Using Analytical Hierarchy Process (AHP). Comput. Concr. 2019, 23, 459–470. [Google Scholar] [CrossRef]

- Akadiri, P.O.; Olomolaiye, P.O.; Chinyio, E.A. Multi-Criteria Evaluation Model for the Selection of Sustainable Materials for Building Projects. Autom. Constr. 2013, 30, 113–125. [Google Scholar] [CrossRef]

- Aghazadeh, E.; Yildirim, H.; Kuruoglu, M. A Hybrid Fuzzy MCDM Methodology for Optimal Structural System Selection Compatible with Sustainable Materials in Mass-Housing Projects. Sustainability 2022, 14, 13559. [Google Scholar] [CrossRef]

- Do, J.Y.; Kim, D.K. AHP-Based Evaluation Model for Optimal Selection Process of Patching Materials for Concrete Repair: Focused on Quantitative Requirements. Int. J. Concr. Struct. Mater. 2012, 6, 87–100. [Google Scholar] [CrossRef]

- Pinto, S.R.; de Bem, D.H.; Rebmann, M.S.; de Medeiros, M.H.F. Application of the Analytic Hierarchy Process (AHP) to Select High Performance Concretes. Rev. IBRACON Estrut. Mater. 2021, 14, 1–15. [Google Scholar] [CrossRef]

- Rashid, K.; Razzaq, A.; Ahmad, M.; Rashid, T.; Tariq, S. Experimental and Analytical Selection of Sustainable Recycled Concrete with Ceramic Waste Aggregate. Constr. Build. Mater. 2017, 154, 829–840. [Google Scholar] [CrossRef]

- Rashid, K.; Yazdanbakhsh, A.; Rehman, M.U. Sustainable Selection of the Concrete Incorporating Recycled Tire Aggregate to Be Used as Medium to Low Strength Material. J. Clean. Prod. 2019, 224, 396–410. [Google Scholar] [CrossRef]

- Rashid, K.; Rehman, M.U.; de Brito, J.; Ghafoor, H. Multi-Criteria Optimization of Recycled Aggregate Concrete Mixes. J. Clean. Prod. 2020, 276, 124316. [Google Scholar] [CrossRef]

- Ishizaka, A.; Labib, A. Review of the Main Developments in the Analytic Hierarchy Process. Expert Syst. Appl. 2011, 38, 14336–14345. [Google Scholar] [CrossRef]

- Aprianti, E.; Shafigh, P.; Bahri, S.; Nodeh, J. Supplementary Cementitious Materials Origin from Agricultural Wastes—A Review. Constr. Build. Mater. 2015, 74, 176–187. [Google Scholar] [CrossRef]

- Saaty, T.L. The Modern Science of Multicriteria Decision Making and Its Practical Applications: The AHP/ANP Approach. Oper. Res. 2013, 61, 1101–1118. [Google Scholar] [CrossRef]

- Aguarón, J.; Moreno-Jiménez, J.M. The Geometric Consistency Index: Approximated Thresholds. Eur. J. Oper. Res. 2003, 147, 137–145. [Google Scholar] [CrossRef]

- Escobar, M.T.; Aguarón, J.; Moreno-Jiménez, J.M. A Note on AHP Group Consistency for the Row Geometric Mean Priorization Procedure. Eur. J. Oper. Res. 2004, 153, 318–322. [Google Scholar] [CrossRef]

- Devernay, F.; Pollard, T. Irene-DM Sammon Mapping in Python. Available online: https://github.com/tompollard/sammon (accessed on 5 April 2022).

- Frías, M.; Villar, E.; Savastano, H. Brazilian Sugar Cane Bagasse Ashes from the Cogeneration Industry as Active Pozzolans for Cement Manufacture. Cem. Concr. Compos. 2011, 33, 490–496. [Google Scholar] [CrossRef]

- Condon, E.; Golden, B.; Wasil, E. Visualizing Group Decisions in the Analytic Hierarchy Process. Comput. Oper. Res. 2003, 30, 1435–1445. [Google Scholar] [CrossRef]

- Camacho, C.; Álvarez, G.; Villegas, J.G. Mathematical Model for the Tactical Planning of the Supply Chain of Supplementary Cementitious Materials. In Engineering for Transformation: 2022 Libro IC ExpoIngenieria; Aristizabal, R., Vieira, S., Flórez, S., Gómez Botero, M., Correa, M., Eds.; Fondo Editorial EIA: Medellín, Colombia, 2022; Volume 1. [Google Scholar]

- López, J.F. Desarrollo de Un Concreto Sostenible de Alta Resistencia Mediante El Uso de Ceniza de Cascarilla de Arroz Como Material Cementante Suplementario; Instituto Tecnológico Metropolitano: Medellín, Colombia, 2020. [Google Scholar]

- Calligaris, G.A.; Franco, M.K.K.D.; Aldrige, L.P.; Rodrigues, M.S.; Beraldo, A.L.; Yokaichiya, F.; Turrillas, X.; Cardoso, L.P. Assessing the Pozzolanic Activity of Cements with Added Sugar Cane Straw Ash by Synchrotron X-Ray Diffraction and Rietveld Analysis. Constr. Build. Mater. 2015, 98, 44–50. [Google Scholar] [CrossRef]

- Ganesan, K.; Rajagopal, K.; Thangavel, K. Evaluation of Bagasse Ash as Supplementary Cementitious Material. Cem. Concr. Compos. 2007, 29, 515–524. [Google Scholar] [CrossRef]

- De Soares, M.M.N.S.; Garcia, D.C.S.; Figueiredo, R.B.; Aguilar, M.T.P.; Cetlin, P.R. Comparing the Pozzolanic Behavior of Sugar Cane Bagasse Ash to Amorphous and Crystalline SiO2. Cem. Concr. Compos. 2016, 71, 20–25. [Google Scholar] [CrossRef]

- Villar-Cociña, E.; Rojas, M.F.; Morales, E.V. Sugar Cane Wastes as Pozzolanic Materials: Application of Mathematical Model. ACI Mater. J. 2008, 105, 258–264. [Google Scholar] [CrossRef]

- Granados, D.A.; Velásquez, H.I.; Chejne, F. Energetic and Exergetic Evaluation of Residual Biomass in a Torrefaction Process. Energy 2014, 74, 181–189. [Google Scholar] [CrossRef]

- Granados, D.A.; Ruiz, R.A.; Vega, L.Y.; Chejne, F. Study of Reactivity Reduction in Sugarcane Bagasse as Consequence of a Torrefaction Process. Energy 2017, 139, 818–827. [Google Scholar] [CrossRef]

- Marrugo, G.; Valdés, C.F.; Chejne, F. Characterization of Colombian Agroindustrial Biomass Residues as Energy Resources. Energy Fuels 2016, 30, 8386–8398. [Google Scholar] [CrossRef]

- Marrugo, G.; Valdés, C.F.; Gómez, C.; Chejne, F. Pelletizing of Colombian Agro-Industrial Biomasses with Crude Glycerol. Renew. Energy 2019, 134, 558–568. [Google Scholar] [CrossRef]

- Montoya, J.I.; Valdés, C.; Chejne, F.; Gómez, C.A.; Blanco, A.; Marrugo, G.; Osorio, J.; Castillo, E.; Aristóbulo, J.; Acero, J. Bio-Oil Production from Colombian Bagasse by Fast Pyrolysis in a Fluidized Bed: An Experimental Study. J. Anal. Appl. Pyrolysis 2015, 112, 379–387. [Google Scholar] [CrossRef]

- Montoya, J.; Valdés, C.; Chaquea, H.; Pecha, M.B.; Chejne, F. Surplus Electricity Production and LCOE Estimation in Colombian Palm Oil Mills Using Empty Fresh Bunches (EFB) as Fuel. Energy 2020, 202, 117713. [Google Scholar] [CrossRef]

- DANE Encuesta Nacional Agropecuaria (ENA) 2019. 2020. Available online: https://www.dane.gov.co/index.php/estadisticas-por-tema/agropecuario/encuesta-nacional-agropecuaria-ena (accessed on 10 February 2022).

- Dorado, H.F. Uso de Subproductos de La Industria de Café y Caña de Azúcar Como Fundente y Formador de Poros En La Manufactura de Ladrillos de Arcilla Roja. 2015. Available online: https://bibliotecadigital.univalle.edu.co/bitstream/handle/10893/9908/CB-0529086.pdf?sequence=1 (accessed on 22 March 2022).

- Ministerio de Agricultura y Desarrollo Rural Área, Producción y Rendimiento Nacional Por Cultivo. Available online: https://www.agronet.gov.co/estadistica/Paginas/home.aspx?cod=1 (accessed on 18 May 2022).

- Biswas, B.; Pandey, N.; Bisht, Y.; Singh, R.; Kumar, J.; Bhaskar, T. Pyrolysis of Agricultural Biomass Residues: Comparative Study of Corn Cob, Wheat Straw, Rice Straw and Rice Husk. Bioresour. Technol. 2017, 237, 57–63. [Google Scholar] [CrossRef]

- Intani, K.; Latif, S.; Cao, Z.; Müller, J. Characterisation of Biochar from Maize Residues Produced in a Self-Purging Pyrolysis Reactor. Bioresour. Technol. 2018, 265, 224–235. [Google Scholar] [CrossRef]

- Memon, S.A.; Khan, M.K. Ash Blended Cement Composites: Eco-Friendly and Sustainable Option for Utilization of Corncob Ash. J. Clean. Prod. 2018, 175, 442–455. [Google Scholar] [CrossRef]

- Olonade, K.A.; Jaji, M.B.; Adekitan, O.A. Experimental Comparison of Selected Pozzolanic Materials. Afr. J. Sci. Technol. Innov. Dev. 2017, 9, 381–385. [Google Scholar] [CrossRef]

- Siddiqi, H.; Bal, M.; Kumari, U.; Meikap, B.C. In-Depth Physiochemical Characterization and Detailed Thermo-Kinetic Study of Biomass Wastes to Analyze Its Energy Potential. Renew. Energy 2020, 148, 756–771. [Google Scholar] [CrossRef]

- Suwanmaneechot, P.; Nochaiya, T.; Julphunthong, P. Improvement, Characterization and Use of Waste Corn Cob Ash in Cement-Based Materials. IOP Conf. Ser. Mater. Sci. Eng. 2015, 103, 012023. [Google Scholar] [CrossRef]

- Zhang, Y.; Ghaly, A.E.; Li, B. Physical Properties of Corn Residues. Am. J. Biochem. Biotechnol. 2012, 8, 44–53. [Google Scholar] [CrossRef]

- Ayu, R.S.; Khalina, A.; Harmaen, A.S.; Zaman, K.; Isma, T.; Liu, Q.; Ilyas, R.A.; Lee, C.H. Characterization Study of Empty Fruit Bunch (EFB) Fibers Reinforcement in Poly(Butylene) Succinate (PBS)/Starch/Glycerol Composite Sheet. Polymers 2020, 12, 1571. [Google Scholar] [CrossRef] [PubMed]

- Solarte Toro, J.C. Oil Palm Rachis Gasification for Synthesis Gas Production. Master’s Thesis, Universidad Nacional de Colombia, Bogota, Colombia, 2017. [Google Scholar]

- Yoo, H.M.; Seo, Y.C.; Park, S.W.; Kang, J.J.; Choi, H.S.; Oh, C.H. Removal Effect of Ash and Metallic Species by Washing from Empty Fruit Bunch Byproducts in Palm Mills on Pyrolytic Characteristics to Produce Bio-Crude Oil. Waste Biomass Valorization 2018, 9, 491–502. [Google Scholar] [CrossRef]

- Urueta, J.C.; Urbina, J.; Weber, A.; Bula, A.; Sanjuán, M.E.; Verdeza, A.; Lenis, Y.; Hernandez, I.N.; Perez, J.D. Valoración Energética de Los Residuos Del Proceso de Extracción de Aceite de Palma Africana Mediante Gasificación. 2017. Available online: https://docplayer.es/87359585-Valoracion-energetica-de-los-residuos-del-proceso-de-extraccion-de-aceite-de-palma-africana-mediante-gasificacion.html (accessed on 14 February 2022).

- Alvarez, J.; Lopez, G.; Amutio, M.; Bilbao, J.; Olazar, M. Bio-Oil Production from Rice Husk Fast Pyrolysis in a Conical Spouted Bed Reactor. Fuel 2014, 128, 162–169. [Google Scholar] [CrossRef]

- Chen, G.; Du, G.; Ma, W.; Yan, B.; Wang, Z.; Gao, W. Production of Amorphous Rice Husk Ash in a 500 KW Fluidized Bed Combustor. Fuel 2015, 144, 214–221. [Google Scholar] [CrossRef]

- Madhiyanon, T.; Lapirattanakun, A.; Sathitruangsak, P.; Soponronnarit, S. A Novel Cyclonic Fluidized-Bed Combustor (ψ-FBC): Combustion and Thermal Efficiency, Temperature Distributions, Combustion Intensity, and Emission of Pollutants. Combust. Flame 2006, 146, 232–245. [Google Scholar] [CrossRef]

- Martínez, J.D.; Pineda, T.; López, J.P.; Betancur, M. Assessment of the Rice Husk Lean-Combustion in a Bubbling Fluidized Bed for the Production of Amorphous Silica-Rich Ash. Energy 2011, 36, 3846–3854. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, S.; Yang, H.; Shao, J.; Chen, Y.; Feng, Y.; Wang, X.; Chen, H. Effects of Hydrofluoric Acid Pre-Deashing of Rice Husk on Physicochemical Properties and CO2 Adsorption Performance of Nitrogen-Enriched Biochar. Energy 2015, 91, 903–910. [Google Scholar] [CrossRef]

- Cruz, E.; Antonio, M.; Mena, L.; Antonio, O. Caracterización Energética de La Cascarilla de Arroz Para Su Aplicación En La Generación de Energía Termoeléctrica, Escuela Politécnica Nacional. 2010. Available online: https://bibdigital.epn.edu.ec/bitstream/15000/2058/1/CD-2863.pdf#:~:text=El%20presente%20proyecto%20de%20titulaci%C3%B3n%20contiene%20la%20caracterizaci%C3%B3n,como%20biocombustible%20en%20la%20generaci%C3%B3n%20de%20energ%C3%ADa%20termoel%C3%A9ctrica (accessed on 16 February 2022).

| Criteria | Sub-Criteria (Units) | Definition |

|---|---|---|

| Combustion process | Ash percentage (p/p) | SCM efficiency after the biomass combustion process. If a first biomass has a higher ash percentage than a second one, the former will have a higher preference. |

| Calorific power (MJ/kg) | Chemical energy of a material made of carbon, hydrogen, sulfur, oxygen, and nitrogen released from a combustion process. If a first biomass has a higher calorific value than a second one, the former will have a higher preference. | |

| Production | Volume generated (t/year) | Tons of biomass generated per year in Colombia. If a first biomass has a greater volume generated than a second one, the former will have a higher preference. |

| Geographic dispersion | Estimates how concentrated or dispersed the biomass generation is across Colombia. If a first biomass is more geographically concentrated than a second one, the latter will have a higher preference. | |

| Density (kg/m3) | Relation between the weight and the volume of the waste. If a first biomass has a higher density than a second one, the former will have a higher preference. | |

| Concrete properties | Silica percentage (%) | Silica content in biomass ash after the combustion process. If a first biomass has a higher silica percentage than a second one, the former will have a higher preference |

| % Ash (p/p) bs | Calorific Power (MJ/Kg) | Volume Generated (Millions of t/year) | Density (Kg/m3) | % Silica in Ash | |

|---|---|---|---|---|---|

| Cane Bagasse | 4.46 | 15.87 | 9.45 | 90.00 | 65.66 * |

| Coffee husk | 2.60 | 15.77 * | 0.10 | 245.00 | 2.31 |

| Rice husk | 18.20 * | 15.30 * | 0.30 | 1495.00 * | 93.60 |

| Corn cob | 2.55 * | 16.64 * | 0.25 | 318.14 * | 62.80 * |

| Palm rachis | 6.43 | 17.20 | 0.42 | 980.00 * | 77.03 |

| Decision Makers (DM) | Aggregated Group Weights | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| DM1 | DM2 | DM3 | DM4 | DM5 | DM6 | DM7 | DM8 | |||

| Dimensions-criteria | Combustion process | 0.33 | 0.09 | 0.06 | 0.15 | 0.08 | 0.07 | 0.11 | 0.33 | 0.15 |

| Production | 0.33 | 0.17 | 0.13 | 0.38 | 0.16 | 0.28 | 0.19 | 0.60 | 0.29 | |

| Concrete properties | 0.33 | 0.74 | 0.81 | 0.47 | 0.76 | 0.65 | 0.70 | 0.07 | 0.56 | |

| Combustion process | Ash percentage | 0.88 | 0.88 | 0.90 | 0.83 | 0.88 | 0.83 | 0.83 | 0.89 | 0.13 |

| Subcriteria | Calorific power | 0.12 | 0.12 | 0.10 | 0.17 | 0.12 | 0.17 | 0.17 | 0.11 | 0.02 |

| Production | Volume generated | 0.33 | 0.71 | 0.80 | 0.60 | 0.73 | 0.71 | 0.58 | 0.70 | 0.19 |

| Subcriteria | Geographic dispersion | 0.33 | 0.20 | 0.10 | 0.32 | 0.21 | 0.22 | 0.28 | 0.24 | 0.07 |

| Density | 0.33 | 0.09 | 0.10 | 0.08 | 0.06 | 0.07 | 0.14 | 0.06 | 0.03 | |

| Scenario | Sub-Criteria Weights | Global Priorities | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Combustion Process | Production | |||||||||

| % Ash | Calorific Power | Volume Generated | Geographic Dispersion | Density | Cane Bagasse | Rice Husk | Palm Rachis | Corn Cob | Coffee Husk | |

| Baseline | 0.13 | 0.02 | 0.19 | 0.07 | 0.03 | 0.35 | 0.28 | 0.19 | 0.15 | 0.03 |

| 1 | 0.13 | 0.02 | 0.21 | 0.06 | 0.02 | 0.36 | 0.27 | 0.19 | 0.15 | 0.03 |

| 2 | 0.13 | 0.02 | 0.19 | 0.07 | 0.03 | 0.34 | 0.28 | 0.20 | 0.15 | 0.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Álvarez-López, G.; Múnera, A.M.; Villegas, J.G. Multicriteria Decision-Making Tools for the Selection of Biomasses as Supplementary Cementitious Materials. Sustainability 2023, 15, 10031. https://doi.org/10.3390/su151310031

Álvarez-López G, Múnera AM, Villegas JG. Multicriteria Decision-Making Tools for the Selection of Biomasses as Supplementary Cementitious Materials. Sustainability. 2023; 15(13):10031. https://doi.org/10.3390/su151310031

Chicago/Turabian StyleÁlvarez-López, Germán, Alejandra María Múnera, and Juan G. Villegas. 2023. "Multicriteria Decision-Making Tools for the Selection of Biomasses as Supplementary Cementitious Materials" Sustainability 15, no. 13: 10031. https://doi.org/10.3390/su151310031

APA StyleÁlvarez-López, G., Múnera, A. M., & Villegas, J. G. (2023). Multicriteria Decision-Making Tools for the Selection of Biomasses as Supplementary Cementitious Materials. Sustainability, 15(13), 10031. https://doi.org/10.3390/su151310031