Prediction and Application of the Height of Water-Conducting Fracture Zone in the Composite Roof: A Case Study of Jinxinda Coal Mine

Abstract

1. Introduction

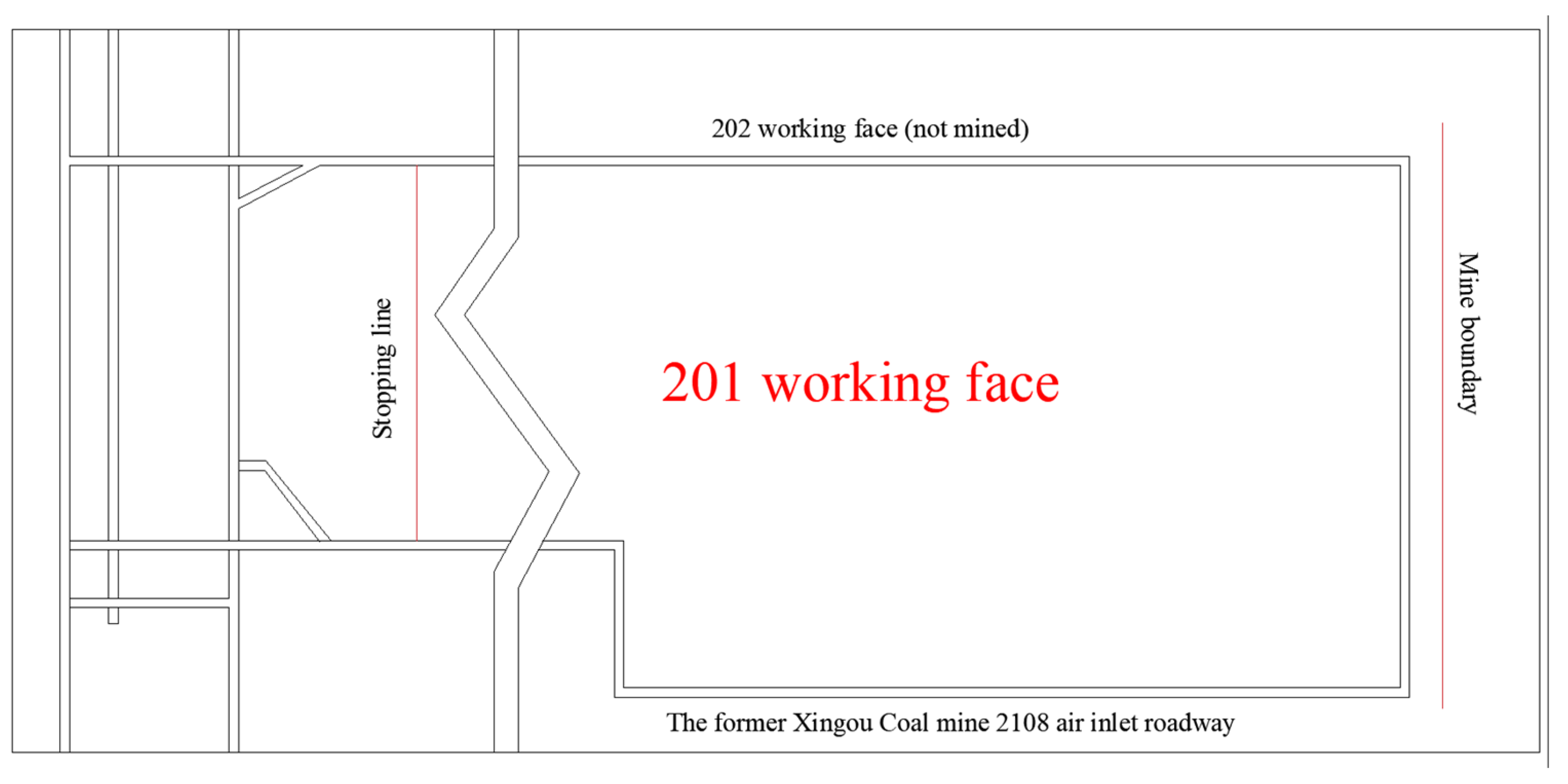

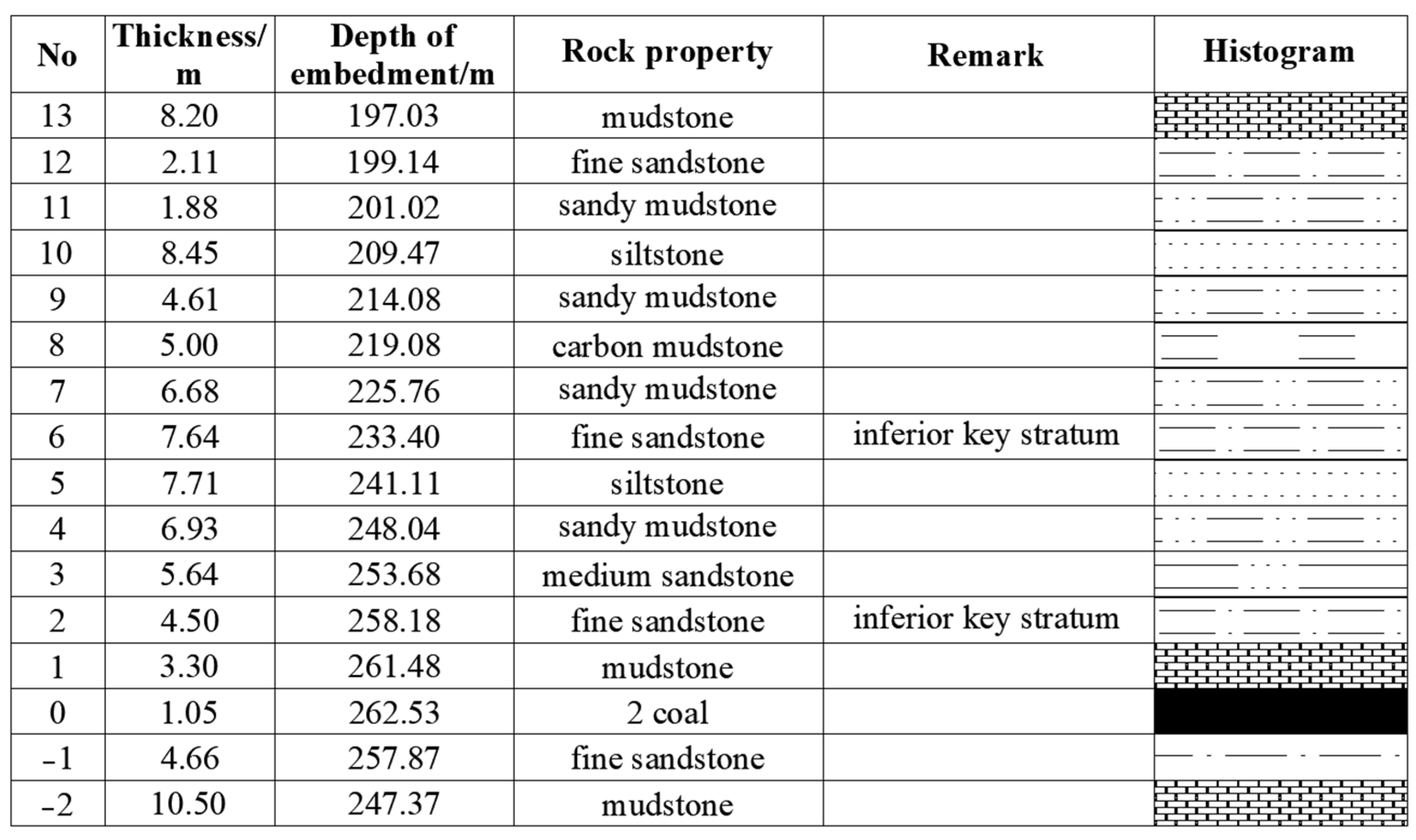

2. Overview of the Working Face

3. Analysis of Overburden Rock Stability Characteristics of the Working Face

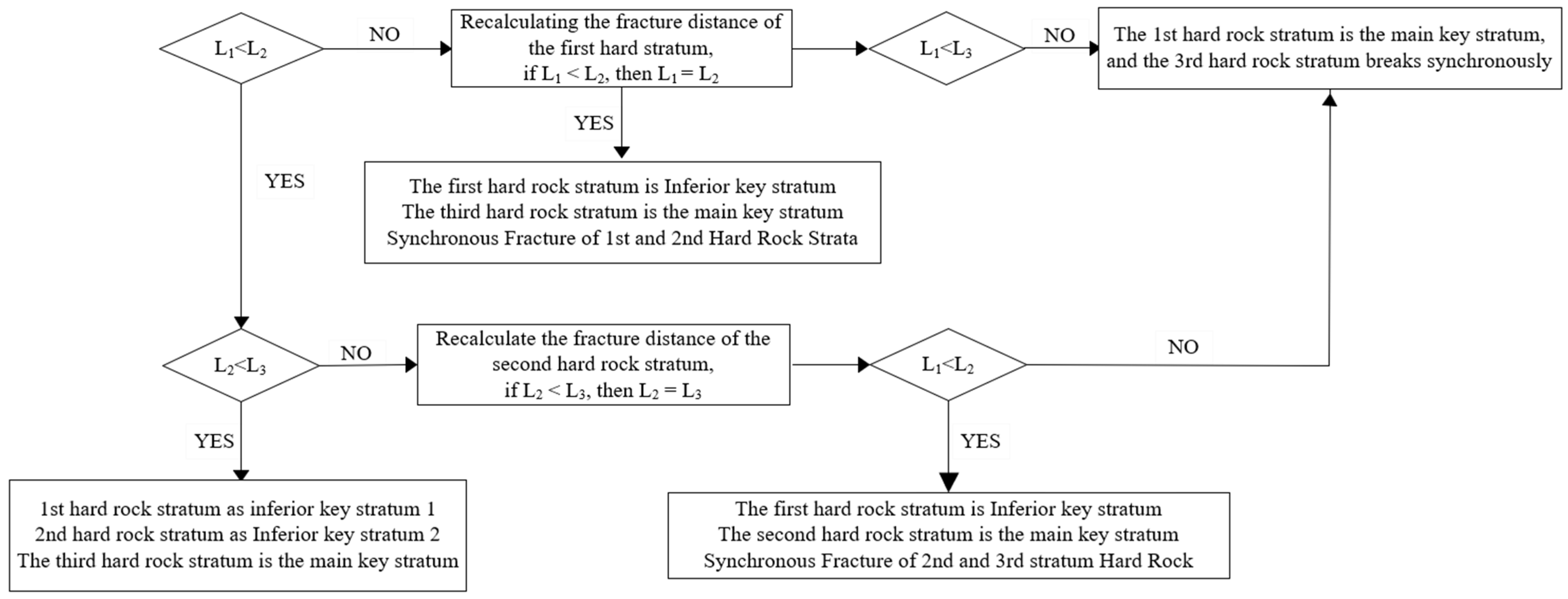

3.1. Key Strata Characteristics and Discrimination Method

3.2. Stability Analysis of Overburden of the Working Face

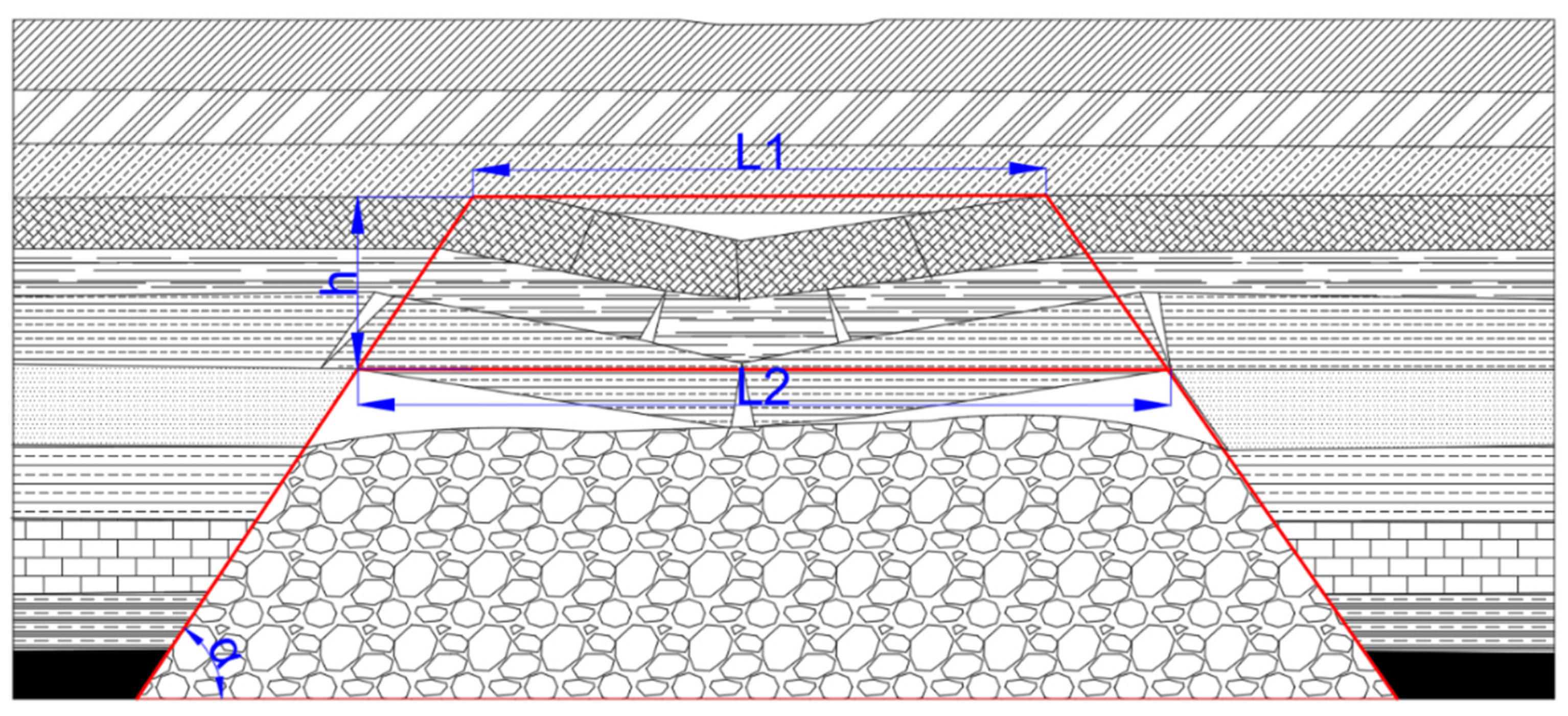

4. Theoretical Analysis of the Development Height of Water-Conducting Fracture Zone

4.1. Hard Rock Fracture Analysis

4.2. Soft Rock Strata Fracture Analysis

4.3. Prediction of the Development Height of Water-Conducting Fracture Zone

5. Numerical Simulation of Fracture Evolution in Composite Roof

5.1. Establishment of Numerical Model

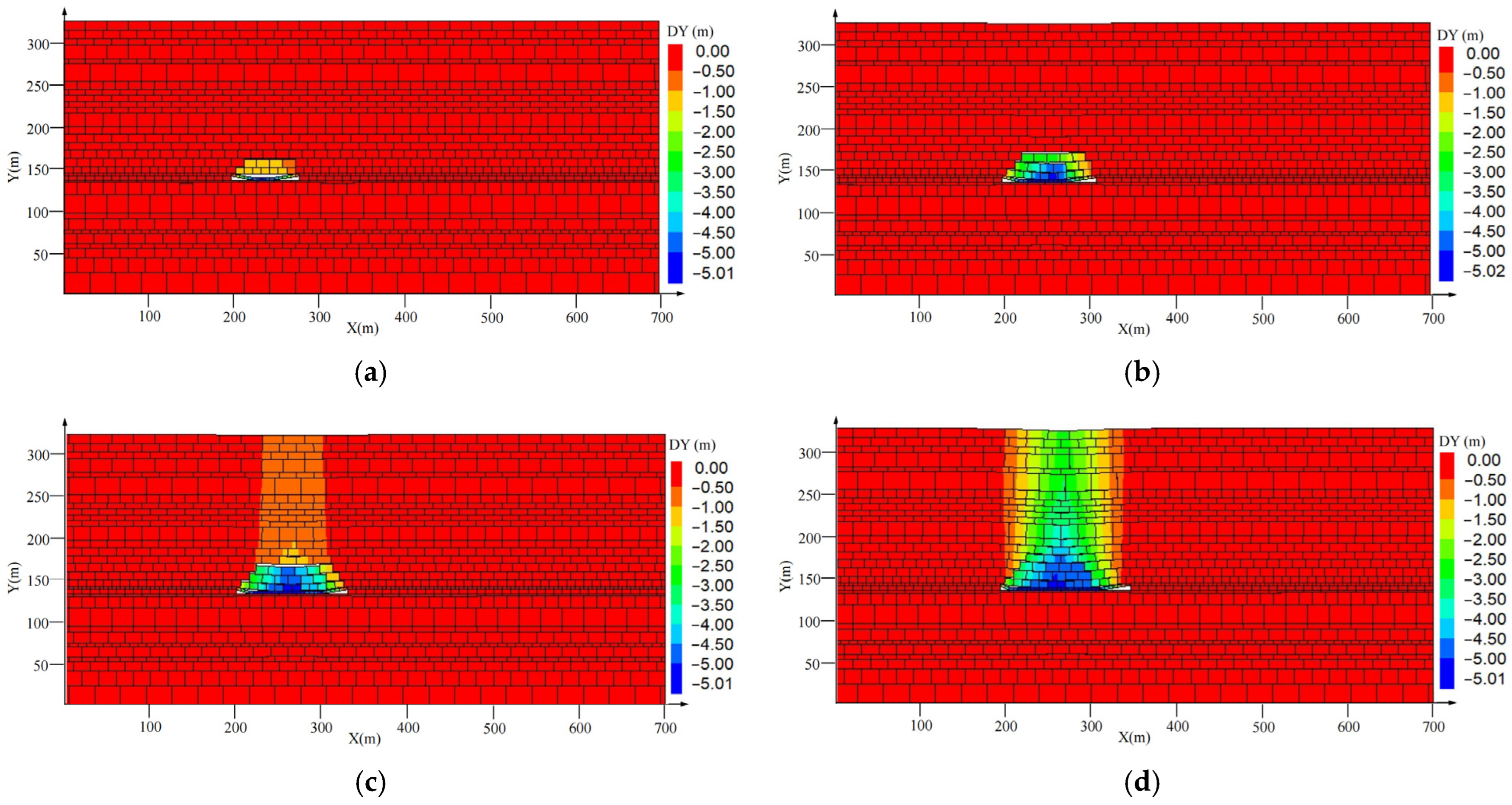

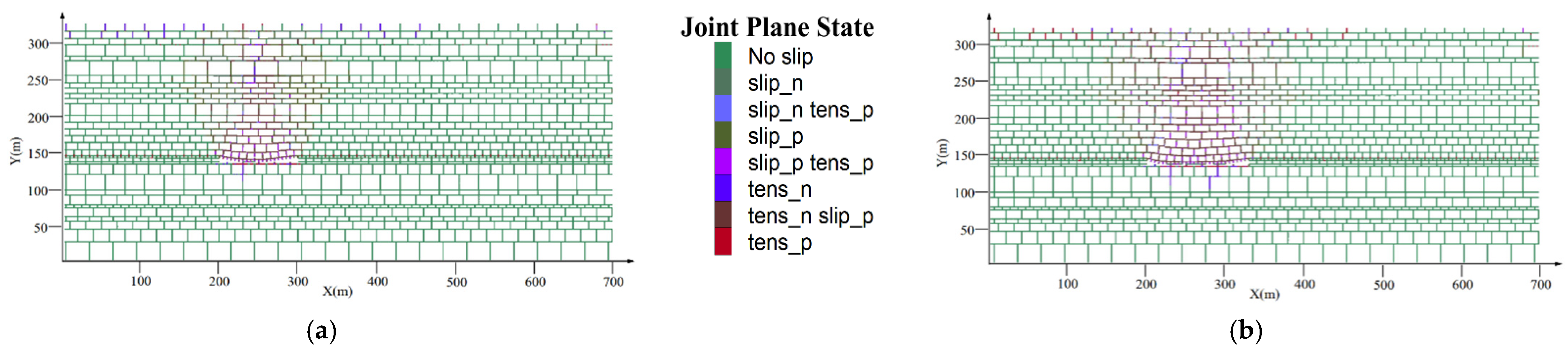

5.2. Analysis of Simulation Results of Fracture Evolution in Composite Roof

6. The 201 Working Face Water Disaster Assessment and Prevention Plan

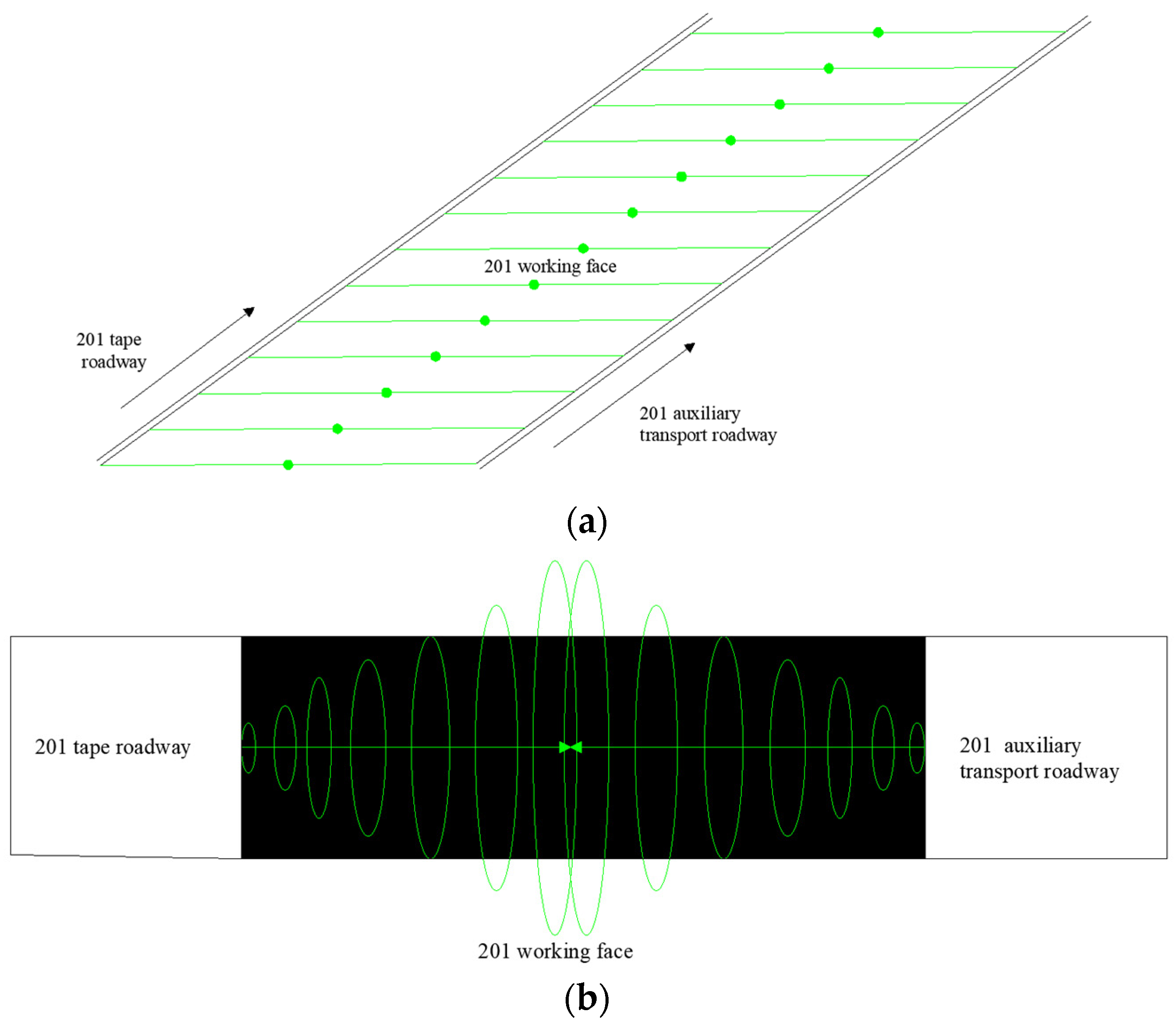

6.1. Analysis of Geophysical Anomaly Area of Working Face

6.2. The 201 Working Face Water Disaster Assessment and Exploration and Drainage Plan for Geophysical Anomaly Area

7. Discussion

- (1)

- Numerical simulation: The development law of vertical displacement and fracture during mining is analyzed. Due to the space limitation, the fracture development law is not analyzed from the perspective of stress, and this part is not sufficiently detailed. In the follow-up study, the mining process will be comprehensively analyzed.

- (2)

- On-site monitoring: Due to space constraints, the monitoring data and analysis process of the transient electromagnetic method are not discussed, and neither are the drilling plan and other contents. In later research, this part of content will be focused on.

8. Conclusions

- (1)

- Based on the theory of elasticity, key strata theory, and thin plate theory, the initial breaking step distance, periodic breaking step distance, and the maximum height of the water-conducting fracture zone of the 201 working face are, respectively, 25.4 m, 14.6 m, and 35.72 m, which are basically consistent with the field measured results.

- (2)

- The migration and fracture evolution laws of mining-induced overburden are analyzed using discrete element software simulation. The simulation results show that the development of water-conducting fractures in the overlying strata is closely related to the movement of the fracture structure of the key strata. The basic roof with a thickness of 4.50 m and the fine sandstone with a thickness of 7.64 m are the two inferior key strata close to the 201 working face, and the height of the water-conducting fracture zone is finally stable at 36 m.

- (3)

- According to the detection results of the transient electromagnetic method in the 201 mining working face, nine abnormal areas were explored, and the abnormal areas were verified by drilling. The results show that there is no water disaster in the geophysical anomaly area but indicate that miners should improve their observations of the roof change after mining in the working face; pay attention to see the working face water flow situation; and if there is a problem or flood situation, confirm and eliminate the flood before organizing mining.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fan, L.M.; Ma, X.D.; Jiang, Z.Q.; Sun, K.; Ji, R.J. Review and thirty years prospect of research on water-preserved coal mining. Coal Sci. Technol. 2019, 47, 1–30. [Google Scholar] [CrossRef]

- Li, L.P.; Jia, C.; Sun, Z.Z.; Liu, H.L.; Cheng, S. Research status and development trend of major engineering disaster prevention and control technology in deep underground. J. Cent. South Univ. Sci. Technol. 2021, 52, 2539–2556. [Google Scholar]

- Zhang, P.S.; Xu, S.A.; Guo, L.Q.; Wu, R.X. Prospect and progress of deformation and failure monitoring technology of surrounding rock in stope. Coal Sci. Technol. 2020, 48, 14–48. [Google Scholar] [CrossRef]

- Lai, X.P.; Zhang, X.D.; Shan, P.F.; Cui, F.; Liu, B.W.; Bai, R. Study on development law of water-conducting fractures in overlying strata of three soft coal seam mining under thick loose layers. Chin. J. Rock Mech. Eng. 2021, 40, 1739–1750. [Google Scholar] [CrossRef]

- Yang, G.Y.; Chen, C.; Gao, S.L.; Feng, B. Study on the height of water flowing fractured zone based on analytic hierarchy process and fuzzy clustering analysis method. J. Min. Saf. Eng. 2015, 32, 206–212. [Google Scholar] [CrossRef]

- Shi, L.Q.; Xin, H.Q.; Zhai, P.H.; Li, S.C.; Liu, T.B.; Yan, Y.; Wei, W.X. Calculating the height of water flowing fracture zone in deep mining. J. China Univ. Min. Technol. 2012, 41, 37–41. [Google Scholar]

- Xu, J.L.; Qian, M.G. Study on the influence of key strata movement on subsidence. J. China Coal Soc. 2000, 25, 122–126. [Google Scholar] [CrossRef]

- Wang, H.B.; Zhang, Y.; Pang, Y.H.; Zhang, C.L. Evolution of the Height of overburden fracture zone based on stage characteristics of surface subsidence. J. China Univ. Min. Technol. 2022, 51, 24–34. [Google Scholar] [CrossRef]

- Han, P.H.; Zhang, C.; Ren, Z.P.; He, X.; Jia, S. The influence of advance speed on overburden movement characteristics in longwall coal mining: Insight from theoretical analysis and physical simulation. J. Geophys. Eng. 2021, 18, 163–176. [Google Scholar] [CrossRef]

- Guo, W.B.; Yang, W.Q.; Ma, Z.B.; Wen, P.; Liu, X.; Bai, E.H. Stability criterion of overburden structure above goaf under building load and its application. J. China Coal Soc. 2022, 47, 2207–2217. [Google Scholar] [CrossRef]

- Guo, S.; Tai, Y.; Wang, Z.W.; Shi, B.W.; Yang, K. Fracture characteristics of basic roof and mechanism of strata behavior in a pillarless working face. J. Geophys. Eng. 2021, 18, 875–889. [Google Scholar] [CrossRef]

- Zuo, J.P.; Yu, M.L.; Sun, Y.J.; Wu, G.S. Analysis of Fracture Mode Transformation Mechanism and Mechanical Model with Different Thickness Rock Strata. J. China Coal Soc. 2022, 1–18. [Google Scholar] [CrossRef]

- Yuan, F.; Ma, Z.K.; Tang, C.A.; Wang, S.J.; Guo, H.Y. Movement of overburden with different mining thickness and response characteristics of surrounding rock under multi-key layer structure. Coal Sci. Technol. 2022, 50, 211–218. [Google Scholar] [CrossRef]

- Liu, S.C.; Liu, X.M.; Jiang, Z.H.; Xing, T.; Chen, M.Z. Research on Electrical Prediction for Evaluating Water Conducting Fracture Zones in Coal Seam Floor. J. Rock Mech. Eng. 2009, 28, 348–356. [Google Scholar]

- Wang, F.; Tu, S.; Zhang, C.; Zhang, Y.W.; Bai, Q.S. Evolution mechanism of water-flowing zones and control technology for longwall mining in shallow coal seams beneath gully topography. Environ. Earth Sci. 2016, 75, 1309. [Google Scholar] [CrossRef]

- Zhu, W.B.; Wang, X.Z.; Kong, X.; Liu, W.T. Study of mechanism of stope water inrush caused by water accumulation in overburden separation areas. Chin. J. Rock Mech. Eng. 2009, 28, 306–311. [Google Scholar]

- Zhou, H.W.; Zhang, T.; Xue, D.J.; Xue, J.H. Evolution of mining-induced crack network in overburden strata of longwall face. J. China Coal Soc. 2011, 36, 1957–1962. [Google Scholar] [CrossRef]

- Hou, E.K.; Yuan, F.; Wang, S.M.; Xie, X.S.; Wu, B.H. Seismic identification and development characteristics of water conducting fissure zone in goaf. J. China Coal Soc. 2023, 48, 414–429. [Google Scholar] [CrossRef]

- Zhou, Y.; Yu, X.Y. Study of the Evolution of Water-Conducting Fracture Zones in Overlying Rock of a Fully Mechanized Caving Face in Gently Inclined Extra-Thick Coal Seams. Appl. Sci. 2022, 12, 9057. [Google Scholar] [CrossRef]

- Gao, W.; Li, Y.C.; He, Q.Y. Determination of Fractured Water-Conducting Zone Height Based on Microseismic Monitoring: A Case Study in Weiqiang Coalmine, Shaanxi, China. Sustainability 2022, 14, 8385. [Google Scholar] [CrossRef]

- Qian, M.G.; Miao, X.X.; Xu, J.L. Theoretical Study of key stratum in ground control. J. China Coal Soc. 1996, 3, 2–7. [Google Scholar]

- Qian, M.G.; Xu, J.L. Behaviors of strata movement in coal mining. J. China Coal Soc. 2019, 44, 973–984. [Google Scholar] [CrossRef]

- Miao, X.X.; Chen, R.H.; Pu, H.; Qian, M.G. Analysis of breakage and collapse of thick key strata around coal face. Chin. J. Rock Mech. Eng. 2005, 8, 1289–1295. [Google Scholar]

- Qian, M.G.; Miao, X.X.; Xu, J.L. Key Strata Theory in Ground Control; China University of Mining and Technology Press: Xuzhou, China, 2003. [Google Scholar]

- Li, Y.; Yang, T.H.; Song, W.D.; Yu, L. Movement Law and Discriminant Method of Key Strata Breakage Based on Microseismic Monitoring. Shock. Vib. 2019, 2019, 865289. [Google Scholar] [CrossRef]

| Advancing Distance/m | Development Rule of Water-Conducting Fracture | Height of Water-Conducting Fracture/m |

|---|---|---|

| 10 | The direct roof collapsed, the basic roof was stable, and the water-conducting fracture zone did not develop upward. | 3.30 |

| 20 | The direct roof collapsed, the basic roof was stable, and the water-conducting fracture zone did not develop upward. | 3.30 |

| 30 | The basic roof was broken, and the water-carrying fracture zone developed upward to the fourth stratum. | 13.44 |

| 60 | The basic roof was broken, and the water-carrying fracture zone developed upward to the fifth stratum. | 28.08 |

| 100 | The water-conducting fracture zone continues to develop to the sixth stratum and still is stable | 35.72 |

| Strata | Bulk Modulus /GPa | Shear Modulus /GPa | Density /kg·m−3 | Cohesion /MPa | Tensile Strength /MPa | Internal Friction Angle/° | Dilatancy Angle /° |

|---|---|---|---|---|---|---|---|

| Medium sandstone | 16.7 | 7.7 | 2700 | 5.6 | 3.5 | 29 | 15 |

| Mudstone | 10 | 4.62 | 2750 | 3.76 | 3 | 32 | 15 |

| Siltstone | 14.2 | 6.5 | 2520 | 4.36 | 3.2 | 34 | 15 |

| Coal | 5.2 | 2.78 | 2100 | 2.4 | 1.28 | 25 | 15 |

| Fine sandstone | 6.57 | 4.53 | 2750 | 5.9 | 3.9 | 38 | 15 |

| Strata | Normal Stiffness /GPa | Shear Stiffness /GPa | Cohesion /MPa | Tensile Strength /MPa | Internal Friction Angle/° |

|---|---|---|---|---|---|

| Medium sandstone | 60.0 | 45.0 | 0.61 | 10.4 | 10 |

| Mudstone | 53.2 | 54.2 | 0.46 | 5.5 | 13 |

| Siltstone | 54.0 | 63.2 | 0.63 | 9.2 | 18 |

| coal | 3.2 | 3.4 | 0.13 | 2.3 | 10 |

| Fine sandstone | 87.7 | 85.3 | 0.91 | 17.9 | 27 |

| Detect Roadway | Abnormal Area Number | Location of the Abnormal Area | Distance of the Abnormal Point from the Roadway Location (m) | Explanation of the Cause of the Anomaly | Note |

|---|---|---|---|---|---|

| 201 auxiliary transport roadway | YCQ-1 | 590–640 | 60–100 | The apparent resistivity value is relatively low, and it is speculated that there may be water in the coal seam cracks. | Iron pipes are hanging on the right side of the roadway, and the iron anchor net, bolt, and pallet support are on the left side. |

| YCQ-2 | 910–950 | 55–100 | The abnormal area is located in the empty roadway and is similar to YC08, which is presumed to be water in the low-lying area of the empty roadway or water in the seam cracks. | ||

| YCQ-3 | 1420–1450 | 50–90 | The range of abnormal areas is small, and it is presumed that there may be water in the coal seam cracks. | ||

| YCQ-4 | 1720–1755 | 45–80 | The apparent resistivity of the abnormal area is relatively low and the range is small, and it is located in an empty roadway. It is presumed that there is water accumulation in the low-lying area of the empty roadway or water in the seam cracks. | ||

| YCQ-5 | 2140–2165 | 5–95 | The abnormal area has a low apparent resistivity value and is close to the auxiliary transport roadway. It is presumed that there may be water in coal seam cracks or tectonic fractures. | ||

| YCQ-6 | 2200–2245 | 60–110 | The apparent resistivity value of the abnormal area is relatively low, adjacent to fault F2, and located in the empty roadway. It is speculated that there may be water in the fault cracks or water in the low-lying area of the empty roadway. | ||

| 201 tape roadway | YCQ-7 | 765–815 | 45–95 | The apparent resistance value of the abnormal area is low, and the range is large. It is speculated that there may be water in the fault cracks. | The inside of the roadway is laid with iron belt supports. |

| YCQ-8 | 840–920 | 45–100 | The apparent resistivity of the abnormal area is low and has a large range, and is close to YC02, which is speculated to indicate that there may be water in the structural fracture. | ||

| YCQ-9 | 970–1075 | 40–100 | The abnormal area has a low apparent resistivity value and a large range and is located in the empty roadway. It is guessed that there may be water in the low-lying area or iron tools stacked in the empty roadway. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Xing, W.; Duan, Y.; Qin, T.; Hou, X. Prediction and Application of the Height of Water-Conducting Fracture Zone in the Composite Roof: A Case Study of Jinxinda Coal Mine. Sustainability 2023, 15, 9003. https://doi.org/10.3390/su15119003

Zhang G, Xing W, Duan Y, Qin T, Hou X. Prediction and Application of the Height of Water-Conducting Fracture Zone in the Composite Roof: A Case Study of Jinxinda Coal Mine. Sustainability. 2023; 15(11):9003. https://doi.org/10.3390/su15119003

Chicago/Turabian StyleZhang, Guohua, Wenyan Xing, Yanwei Duan, Tao Qin, and Xiangang Hou. 2023. "Prediction and Application of the Height of Water-Conducting Fracture Zone in the Composite Roof: A Case Study of Jinxinda Coal Mine" Sustainability 15, no. 11: 9003. https://doi.org/10.3390/su15119003

APA StyleZhang, G., Xing, W., Duan, Y., Qin, T., & Hou, X. (2023). Prediction and Application of the Height of Water-Conducting Fracture Zone in the Composite Roof: A Case Study of Jinxinda Coal Mine. Sustainability, 15(11), 9003. https://doi.org/10.3390/su15119003