Experimental Research on a Lightweight Miniature Wankel Compressor for a Vapor Compression Refrigeration System in Aerospace

Abstract

1. Introduction

2. Development of a Lightweight Miniature Wankel Compressor

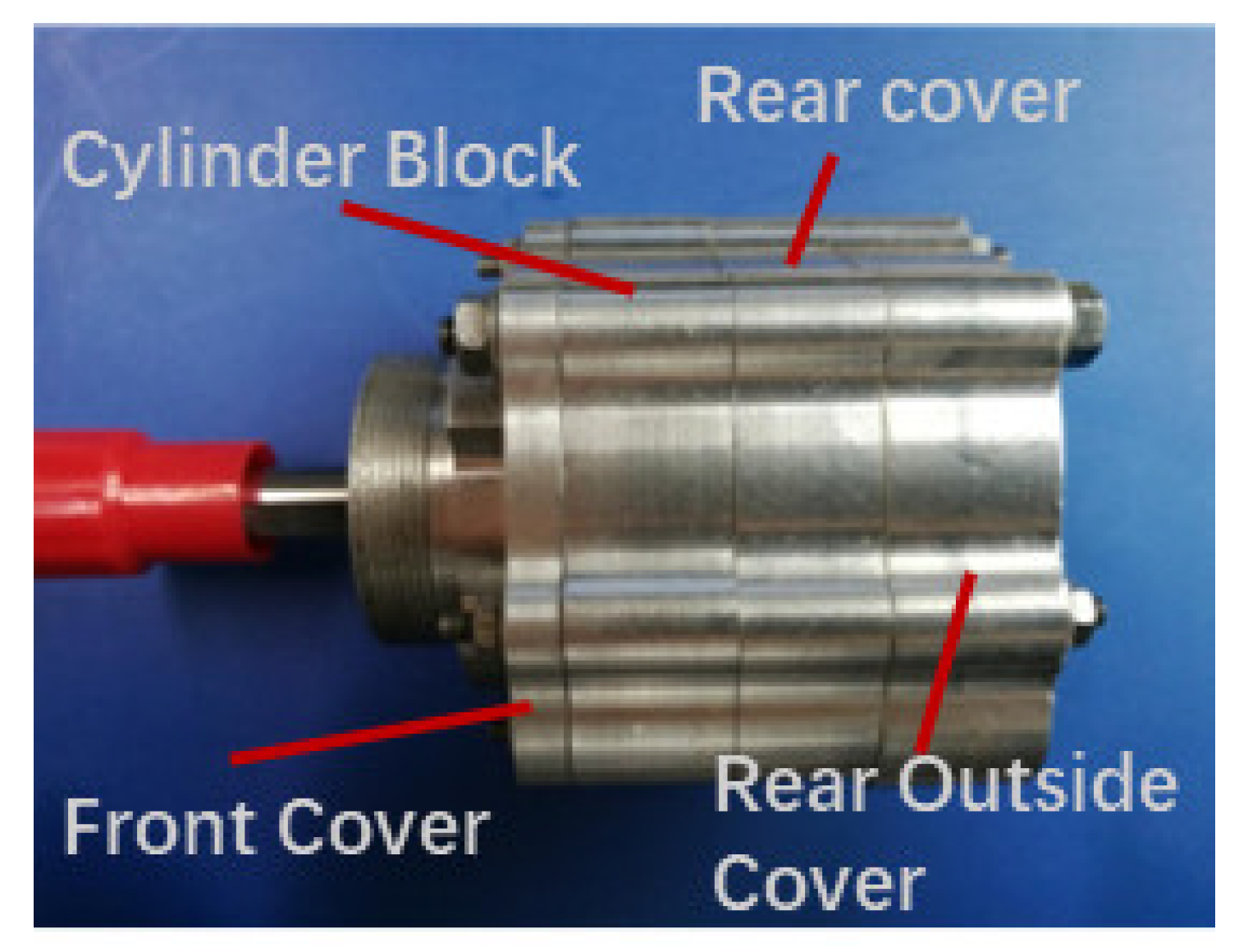

2.1. The Structure Design

2.2. The Parts Material

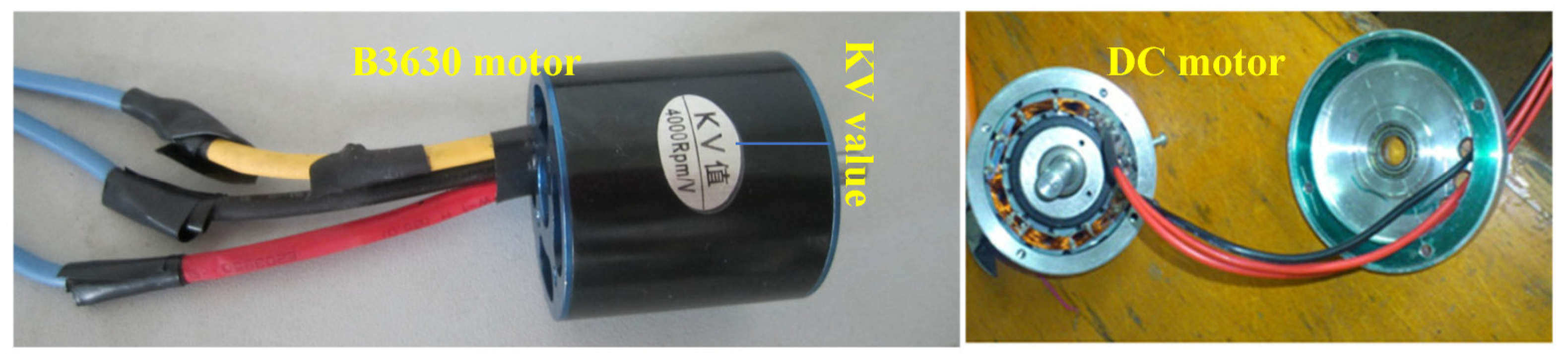

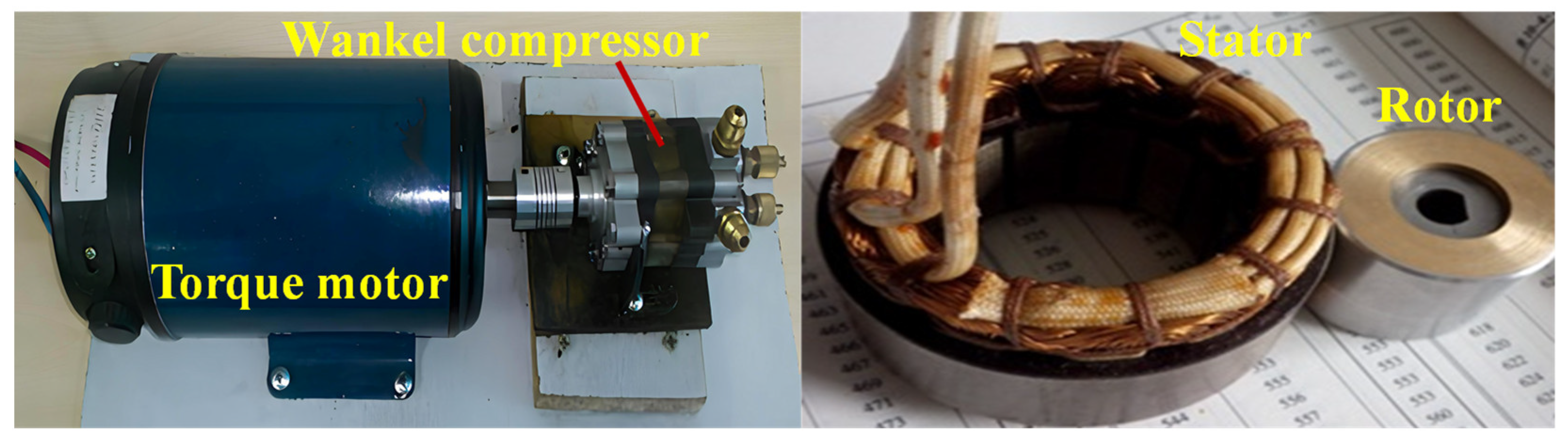

2.3. Motor Selection

2.4. Lightweight Compressor Development

3. Performance Experiment and Analysis

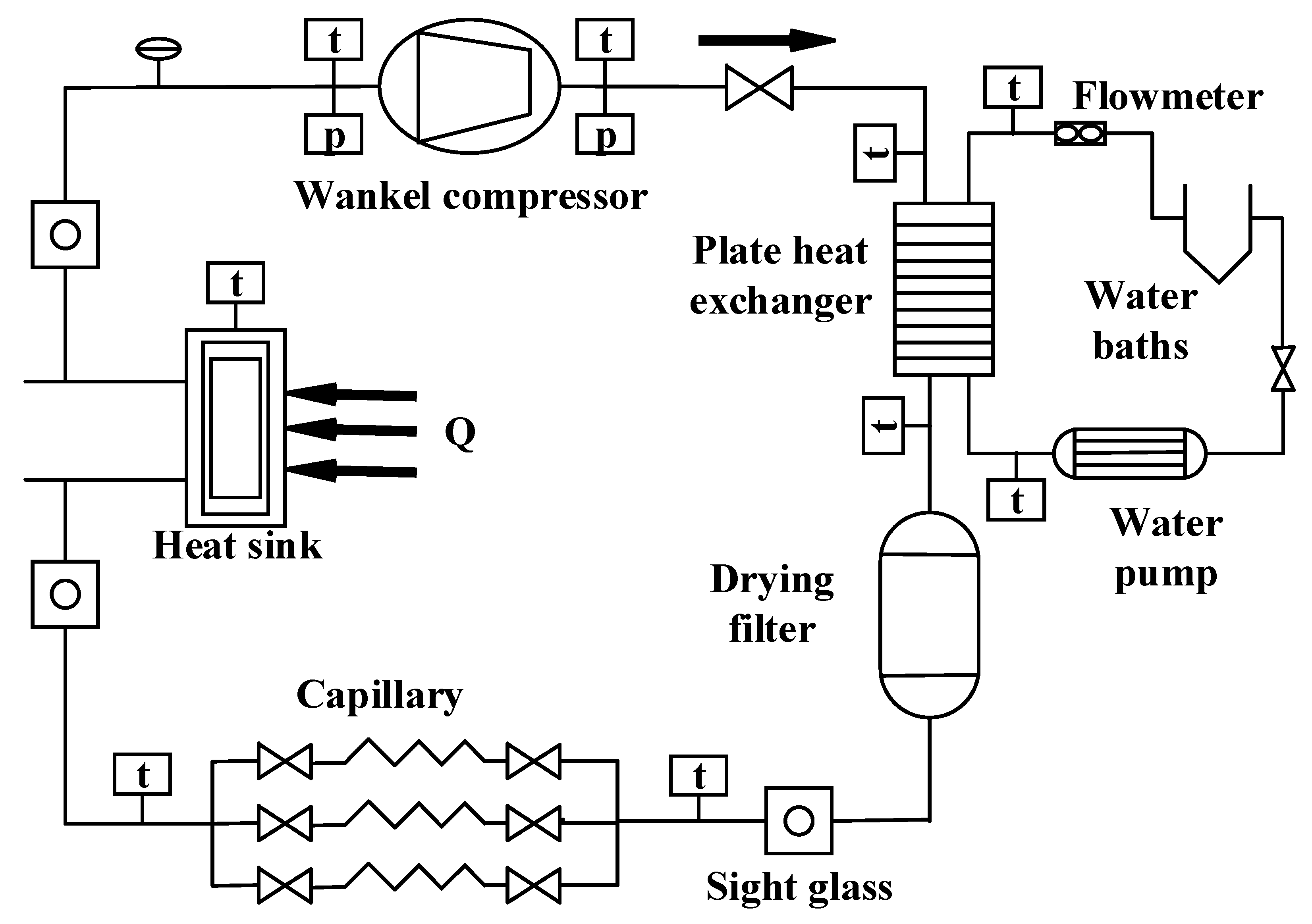

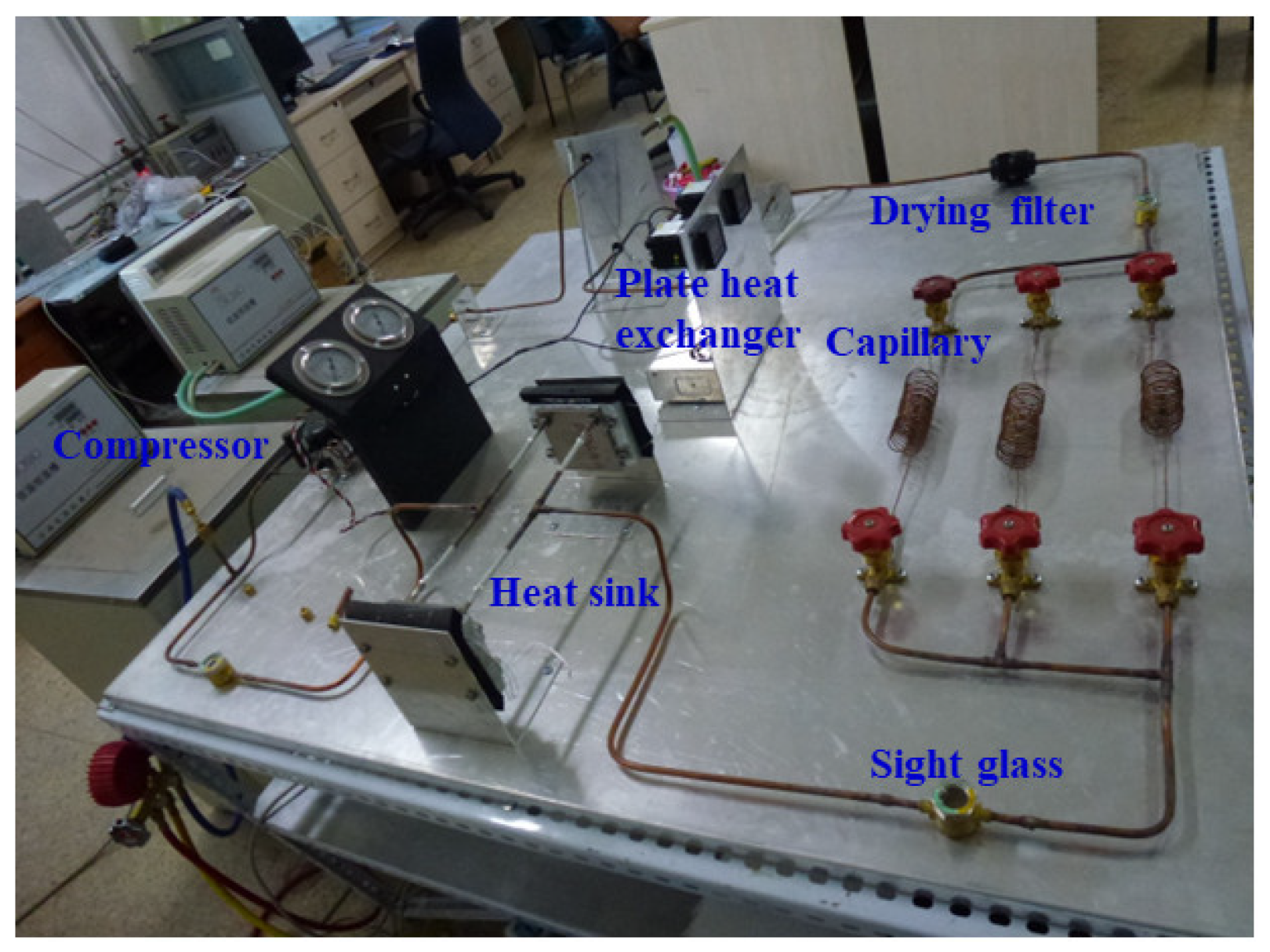

3.1. Experimental System

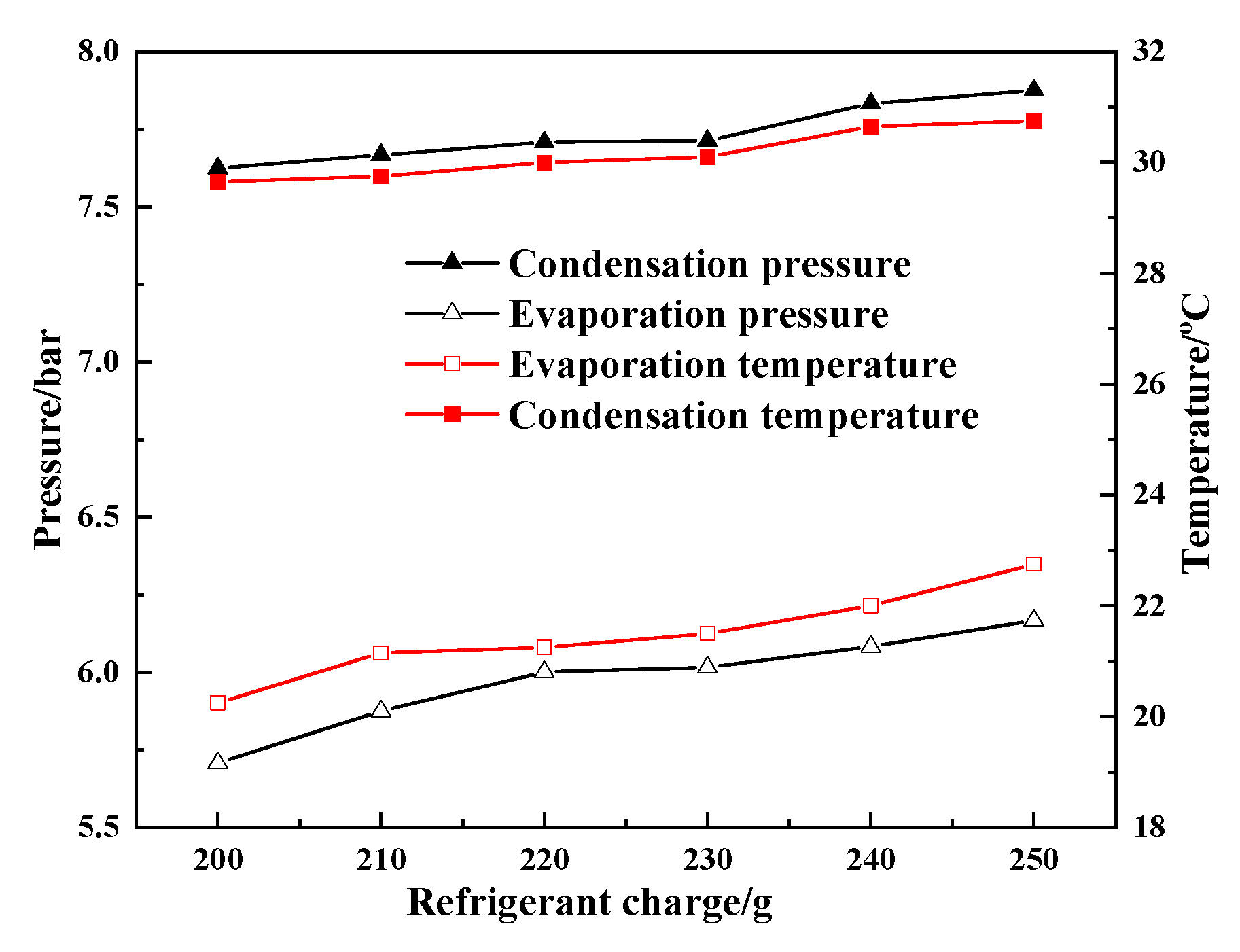

3.2. Influence of Refrigerant Charge on Compressor Performance

3.2.1. Evaporation Pressure and Condensation Pressure

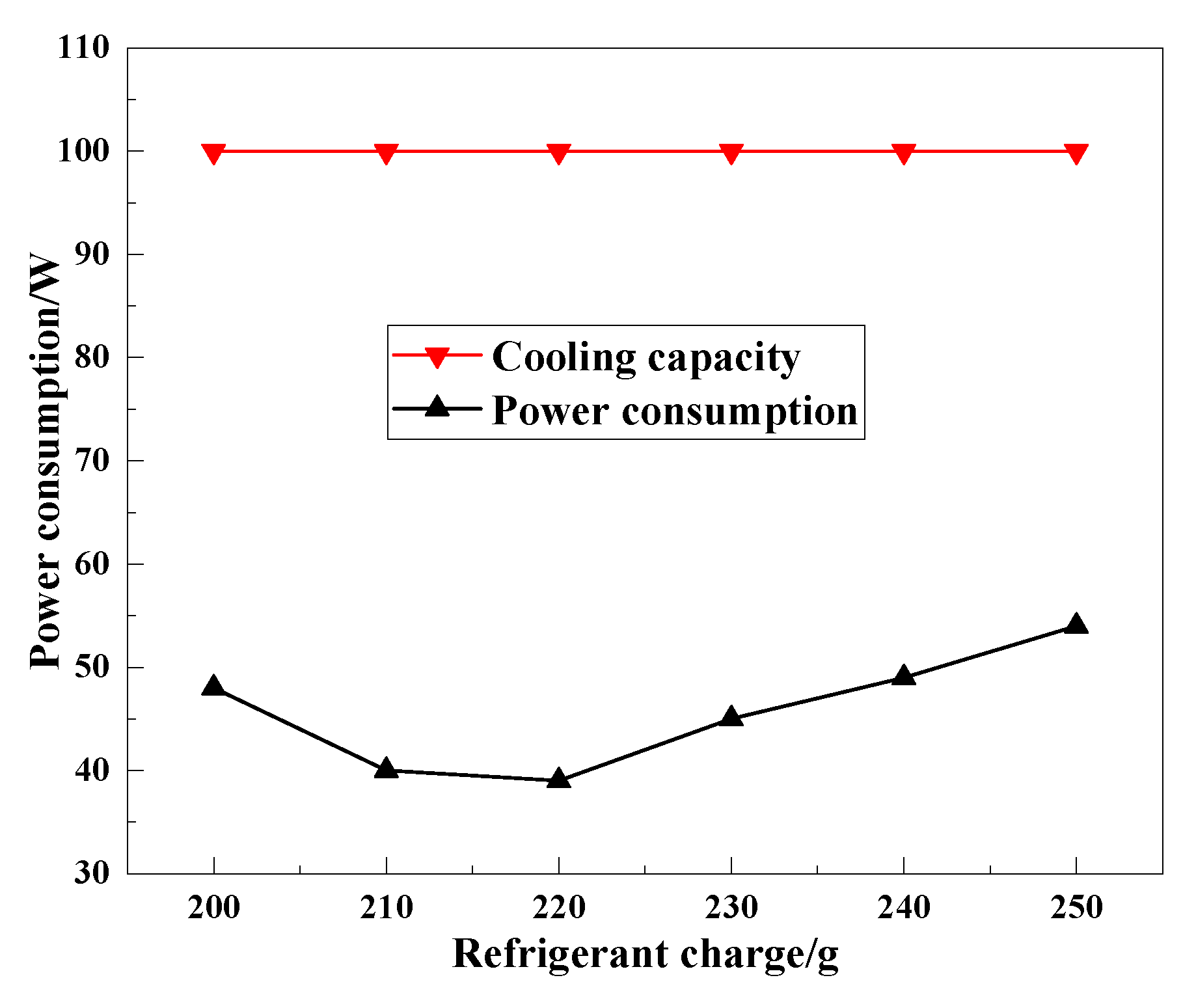

3.2.2. Compressor Power Consumption

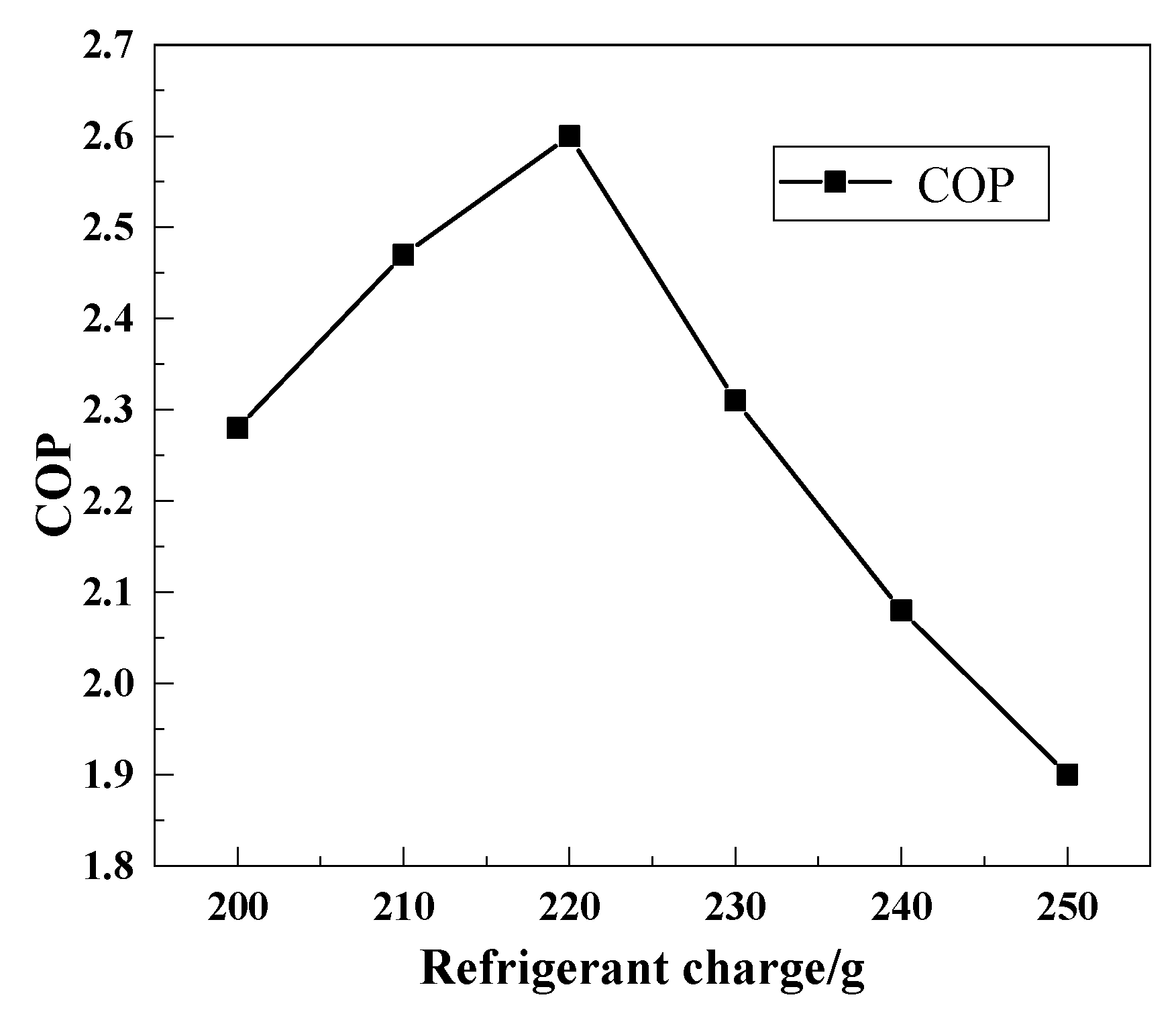

3.2.3. COP

3.3. Influence of Rotational Speed on Compressor Performance

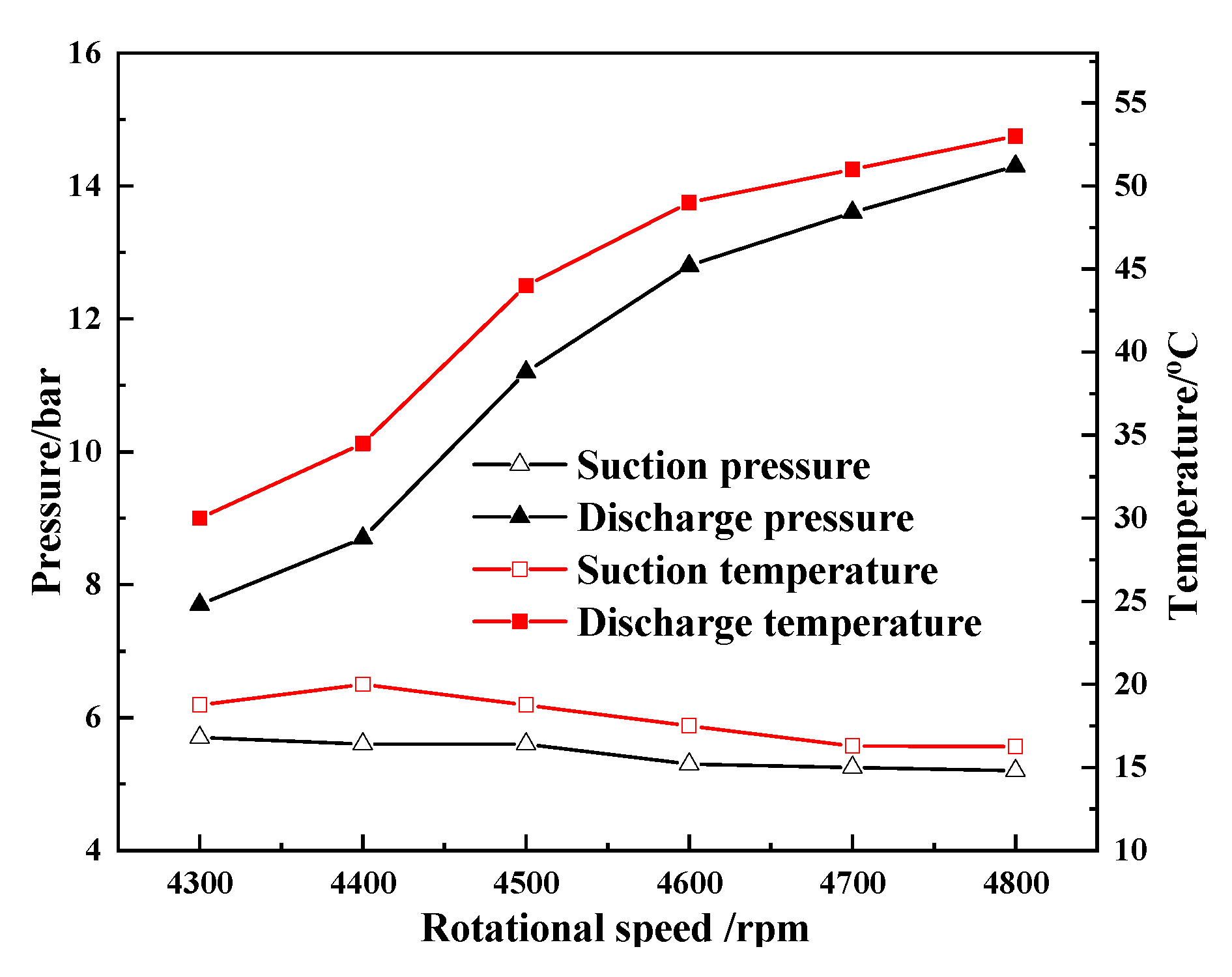

3.3.1. Suction and Discharge Temperature and Pressure of Compressor

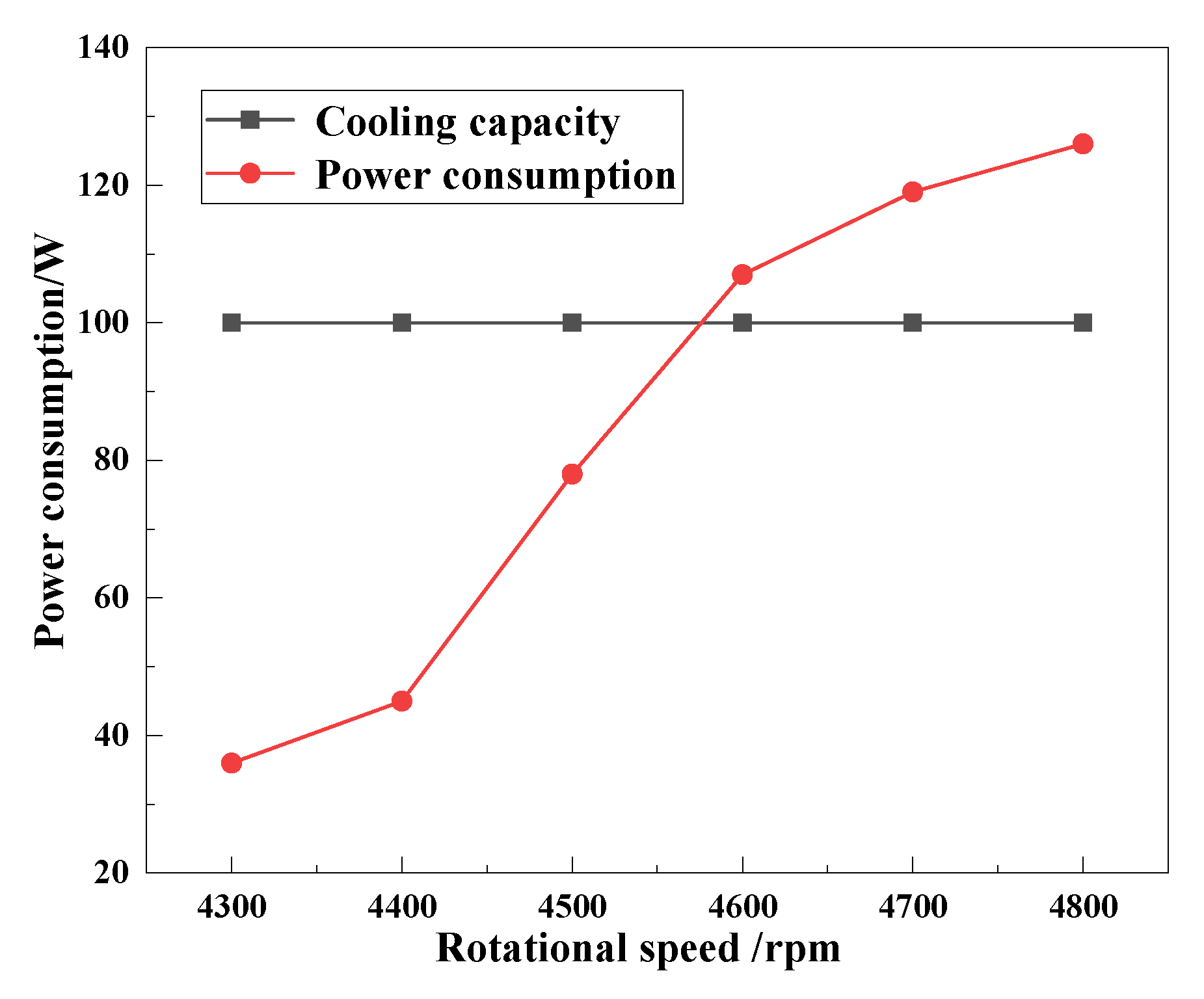

3.3.2. Compressor Power Consumption

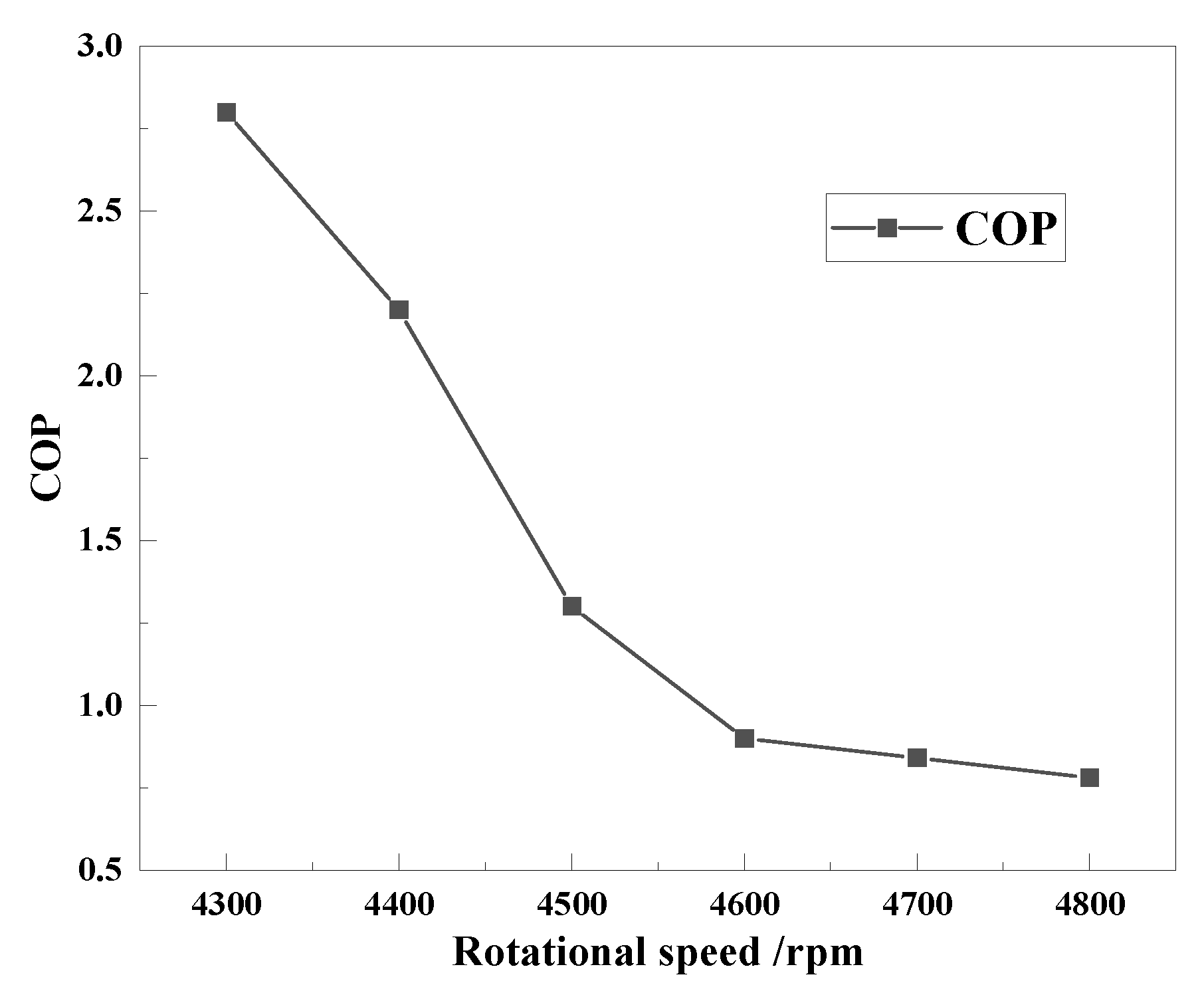

3.3.3. COP

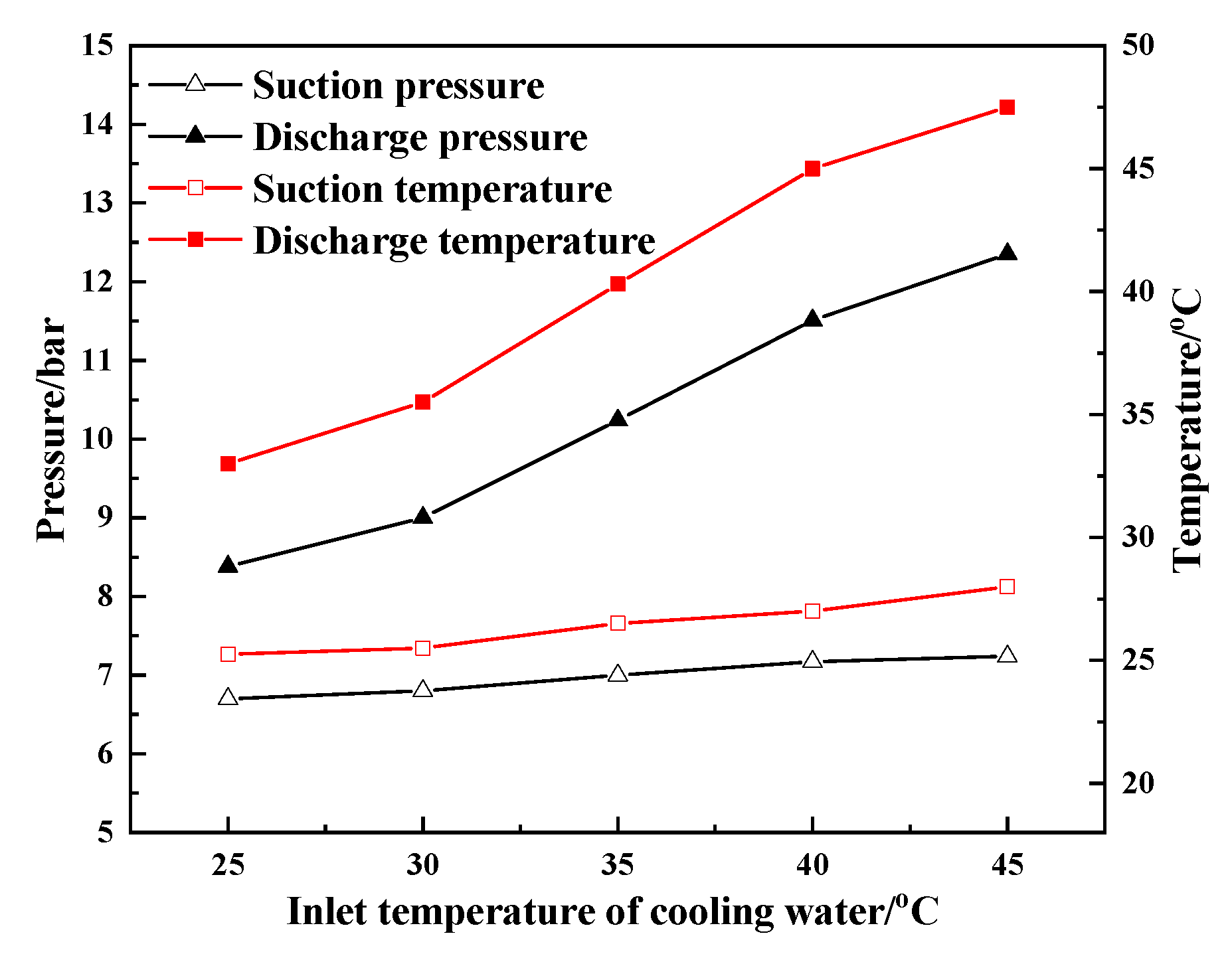

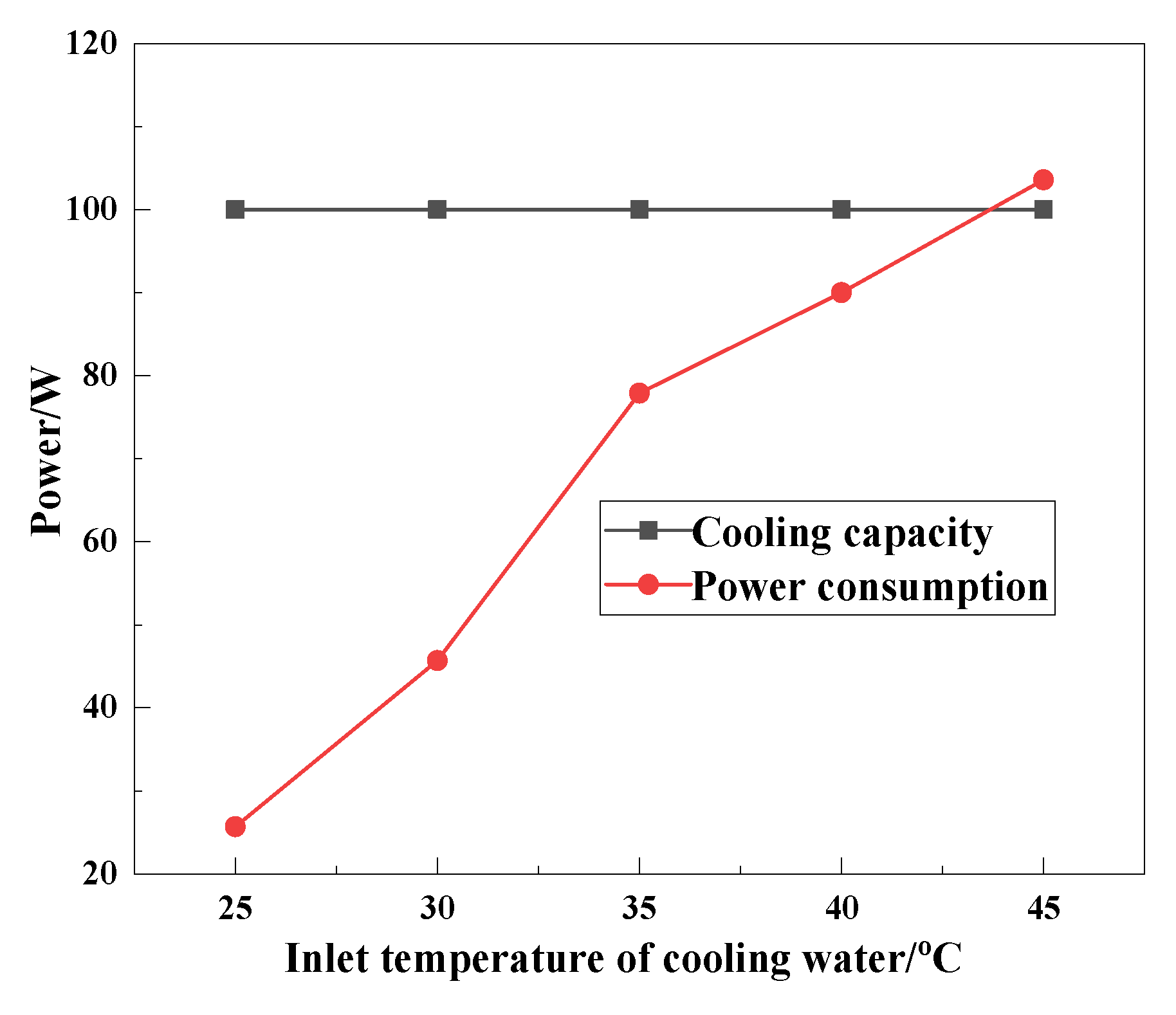

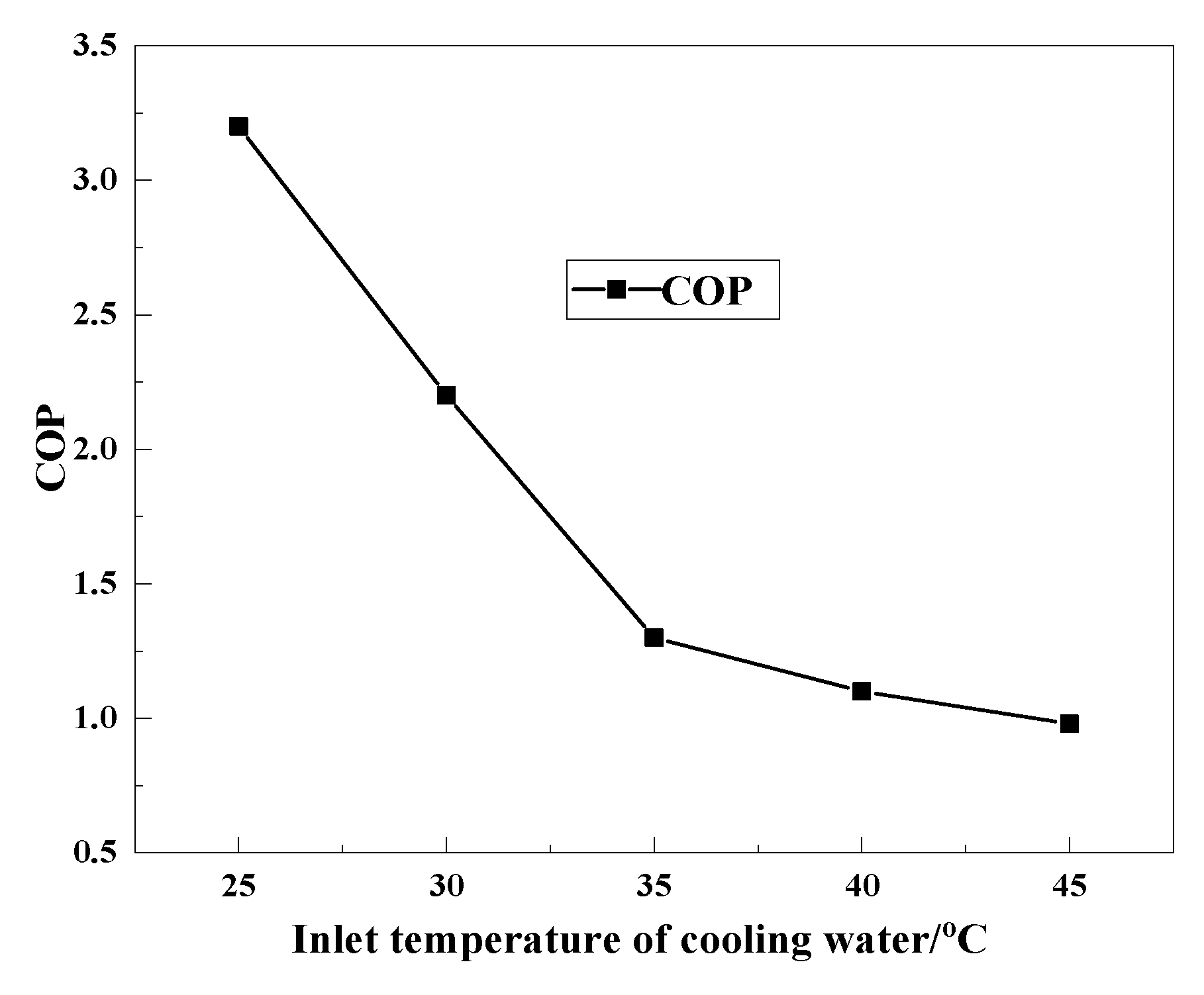

3.4. The Effect of Cooling Water Temperature on Compressor Performance

3.4.1. Suction and Discharge Temperature of the Compressor

3.4.2. Compressor Power Consumption

3.4.3. COP

3.5. Reliability Life Test

4. Conclusions

- (1)

- According to the working principle of the Wankel compressor and the requirements of the miniature refrigeration system, research on a lightweight, miniature, hermetic Wankel compressor has been carried out. The assembled compressor, without housing and motor, had a diameter of 65 mm, height of 85 mm and weight of 340.2 g.

- (2)

- The optimal refrigerant charge of the system was 220 g under a cooling capacity of 100 W. The minimum power consumption was achieved at approximately 40 W and the maximum COP was 2.5.

- (3)

- When the rotational speed was at 4300 rpm, the power consumption was 35 W and the maximum COP was 2.8. An increase in the rotational speed led to a decrease in the evaporation temperature and COP. When the rotational speed increased from 4300 rpm to 4800 rpm, the COP dropped sharply from 2.8 to 0.8.

- (4)

- When the inlet temperature of the cooling water was 25 °C, the maximum COP was obtained at approximately 3.2. To improve the COP, the inlet temperature of the cooling water should not be too high.

- (5)

- The reliability life test was carried out for 600 h. This reliability life test proved the reliability of the Wankel compressor.

- (6)

- The compressor was developed to solve the problem of high heat dissipation in spacecraft. Compressor performance optimization under the microgravity and high vacuum environment shall be the focus of future research.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liang, K.; Li, Z.; Chen, M.; Jiang, H. Comparisons between heat pipe, thermoelectric system, and vapour compression refrigeration system for electronics cooling. Appl. Therm. Eng. 2019, 146, 260–267. [Google Scholar] [CrossRef]

- Trutassanawin, S.; Groll, E.A. Review of Refrigeration Technologies for High Heat Dissipation Electronics Cooling. In Proceedings of the International Refrigeration and Air Conditioning Conference at Purdue University, West Lafayette, IN, USA, 12–15 July 2004. [Google Scholar]

- Possamai, F.; Lilie, D.E.B.; Zimmermannn, A.J.P.; Mongia, R. Miniature Vapor Compression System. In Proceedings of the International Refrigeration and Air Conditioning Conference, West Lafayette, IN, USA, 14–17 July 2008; p. 963. [Google Scholar]

- Jeong, S. How difficult is it to make a micro refrigerator? Int. J. Refrig. 2004, 27, 309–313. [Google Scholar] [CrossRef]

- Trutassanawin, S.; Groll, E.A.; Garimella, S.V.; Cremaschi, L. Experimental Investigation of a Miniature-Scale Refrigeration System for Electronics Cooling. IEEE Trans. Compon. Packag. Technol. 2006, 29, 678–687. [Google Scholar] [CrossRef]

- Davies, G.F.; Eames, I.W.; Bailey, P.; Dadd, M.; Janiszewski, A.; Stone, R.; Maidment, G.; Agnew, B. Cooling microprocessors using vapor compression refrigeration. In Proceedings of the 12th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Las Vegas, NV, USA, 2–5 June 2010; pp. 1–8. [Google Scholar]

- Trutassanawin, S. A Miniature-Scale Refrigeration System for Electronics Cooling. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2006. [Google Scholar]

- Sathe, A.A.; Groll, E.A.; Garimella, S.V. Experimental evaluation of a miniature rotary compressor for application in electronics cooling. In Proceedings of the International Compressor Engineering Conference, West Lafayette, IN, USA, 14–17 July 2008; p. 1115. [Google Scholar]

- Wu, Z.; Du, R. Design and experimental study of a miniature vapor compression refrigeration system for electronics cooling. Appl. Therm. Eng. 2011, 31, 385–390. [Google Scholar] [CrossRef]

- Sathe, A.A.; Groll, E.A.; Garimella, S.V. Optimization of electrostatically actuated miniature compressors for electronics cooling. Int. J. Refrig. 2009, 32, 1517–1525. [Google Scholar] [CrossRef]

- Bradshaw, C.R.; Groll, E.A.; Garimella, S.V. A comprehensive model of a miniature-scale linear compressor for electronics cooling. Int. J. Refrig. 2011, 34, 63–73. [Google Scholar] [CrossRef]

- Bradshaw, C.R.; Groll, E.A.; Garimella, S.V. Linear compressors for electronics cooling: Energy recovery and its benefits. Int. J. Refrig. 2013, 36, 2007–2013. [Google Scholar] [CrossRef]

- Liang, K. A review of linear compressors for refrigeration. Int. J. Refrig. 2017, 84, 253–273. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Ziviani, D.; Braun, J.E.; Groll, E.A. Experimental Validation and Analysis of a Dynamic Model for Linear Compressors. In Proceedings of the 24th International Compressor Engineering Conference at Purdue, West Lafayette, IN, USA, 9–12 July 2018. [Google Scholar]

- Zhang, X.Y.; Ziviani, D.; Braun, J.E.; Groll, E.A. Theoretical analysis of dynamic characteristics in linear compressors. Int. J. Refrig. 2020, 109, 114–127. [Google Scholar] [CrossRef]

- Heppner, J.D.; Walther, D.C.; Pisano, A.P. The design of ARCTIC: A rotary compressor thermally insulated μcooler. Sens. Actuators A Phys. 2007, 134, 47–56. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, W. Effects of leakage and friction on the miniaturization of a Wankel compressor. Front. Energy 2011, 5, 83–92. [Google Scholar] [CrossRef]

- Wu, Y.T.; Ma, C.F.; Zhong, X.H. Development and experimental investigation of a miniature-scale refrigeration system. Energy Convers. Manag. 2010, 51, 81–88. [Google Scholar] [CrossRef]

| Item | Parameter | Item | Parameter |

|---|---|---|---|

| Rated voltage | DC 24 V | Continuous running time | ≥5000 h |

| Current | 1–5 A | Cooling capacity | ≥100 W |

| Weight | ≤500 g | Maximum compression ratio | 3.5 |

| Maximum exhaust temperature | 130 °C |

| Part | Pre-Optimization Quality/g | Optimized Quality/g | Amount of Change/g |

|---|---|---|---|

| Eccentric shaft | 39.3 | 39.3 | 0 |

| Triangular rotor | 46.1 | 46.1 | 0 |

| Cylinder | 142.6 | 61.4 | −81.2 |

| Front cover | 137.0 | 59.0 | −78.0 |

| Back cover | 146.5 | 63.1 | −83.4 |

| Rear outer cover | 71.2 | 71.2 | 0 |

| Item | First | Second | Third |

|---|---|---|---|

| Housing material | 45 steel | 45 steel | duralumin |

| Housing thickness | 8 mm | 4 mm | 4 mm |

| Coupling | yes | yes | no |

| Compressor weight | 3.925 kg | 2.855 kg | 1.490 kg |

| Compressor length | 240 mm | 190 mm | 155 mm |

| Components | Parameters |

|---|---|

| Heat sink | Channel width: 2 mm; Overall pressure drop: 1.68 × 104 Pa Heat exchange length: 0.777 m |

| Compressor | Generating radius: 18 mm; Eccentricity: 3 mm |

| Plate heat exchanger | Type: Brazed plate type; Heat transfer coefficient: 2500 W/m2·K Pressure Range: 3.0 MPa; Temperature range: −160~300 °C |

| Capillary | Material: Red copper; Inside diameter: 0.64 × 1 mm; Calculated length: 2.75 m |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhi, R.; Ma, R.; Zhang, D.; Wu, Y. Experimental Research on a Lightweight Miniature Wankel Compressor for a Vapor Compression Refrigeration System in Aerospace. Sustainability 2023, 15, 8826. https://doi.org/10.3390/su15118826

Zhi R, Ma R, Zhang D, Wu Y. Experimental Research on a Lightweight Miniature Wankel Compressor for a Vapor Compression Refrigeration System in Aerospace. Sustainability. 2023; 15(11):8826. https://doi.org/10.3390/su15118826

Chicago/Turabian StyleZhi, Ruiping, Rui Ma, Delou Zhang, and Yuting Wu. 2023. "Experimental Research on a Lightweight Miniature Wankel Compressor for a Vapor Compression Refrigeration System in Aerospace" Sustainability 15, no. 11: 8826. https://doi.org/10.3390/su15118826

APA StyleZhi, R., Ma, R., Zhang, D., & Wu, Y. (2023). Experimental Research on a Lightweight Miniature Wankel Compressor for a Vapor Compression Refrigeration System in Aerospace. Sustainability, 15(11), 8826. https://doi.org/10.3390/su15118826