The Implementation of a Binary Blend of Waste Glass Powder and Coal Bottom Ash as a Partial Cement Replacement toward More Sustainable Mortar Production

Abstract

1. Introduction

2. Materials and Methods

2.1. The Raw Materials

2.1.1. Cement

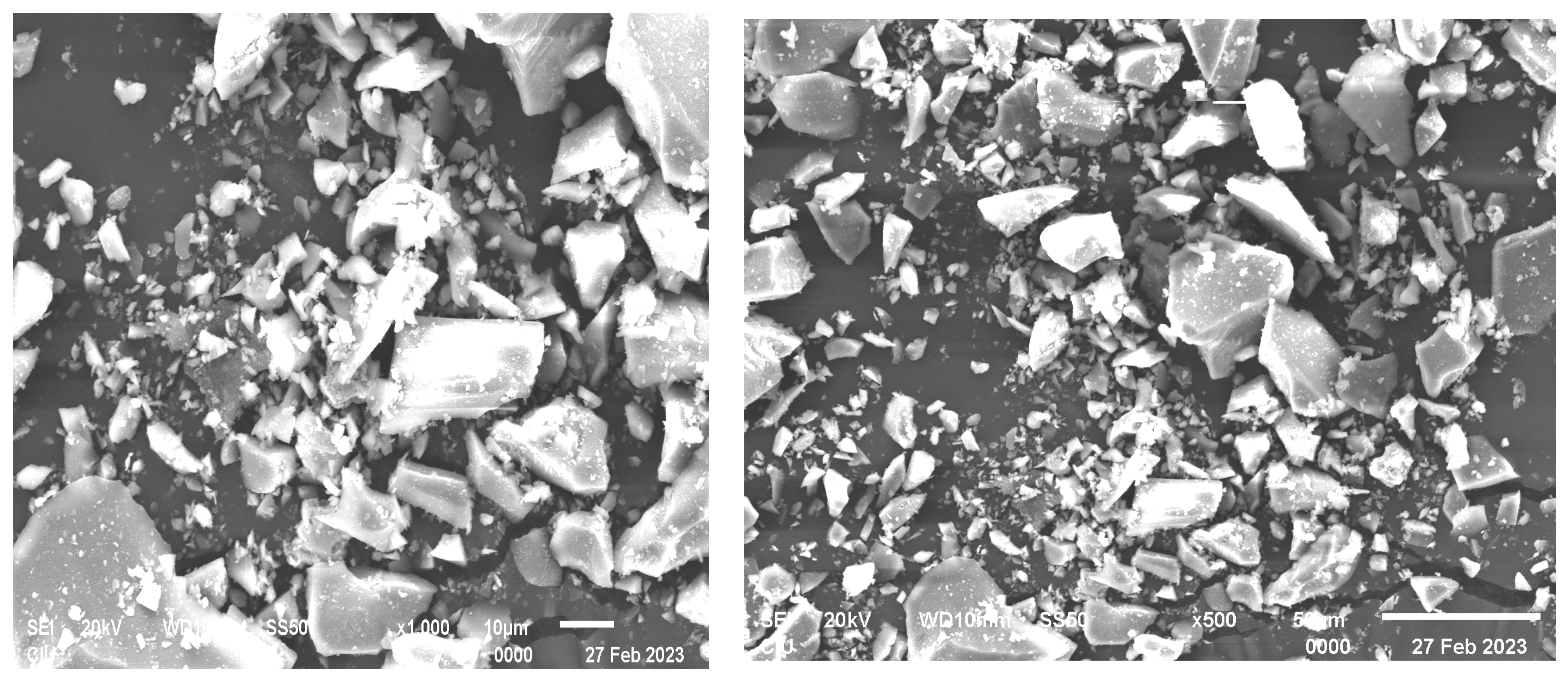

2.1.2. Waste Glass Powder

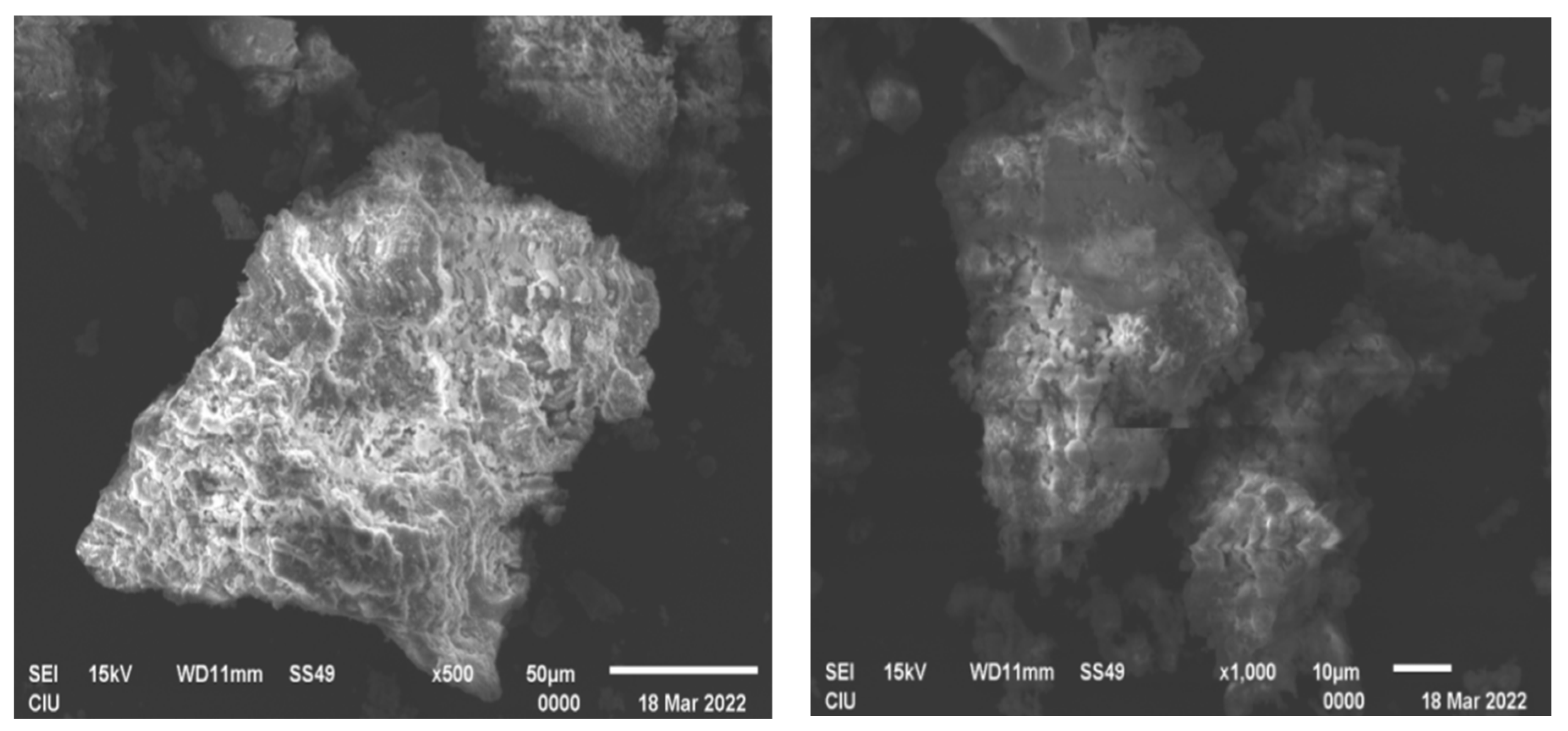

2.1.3. Coal Bottom Ash

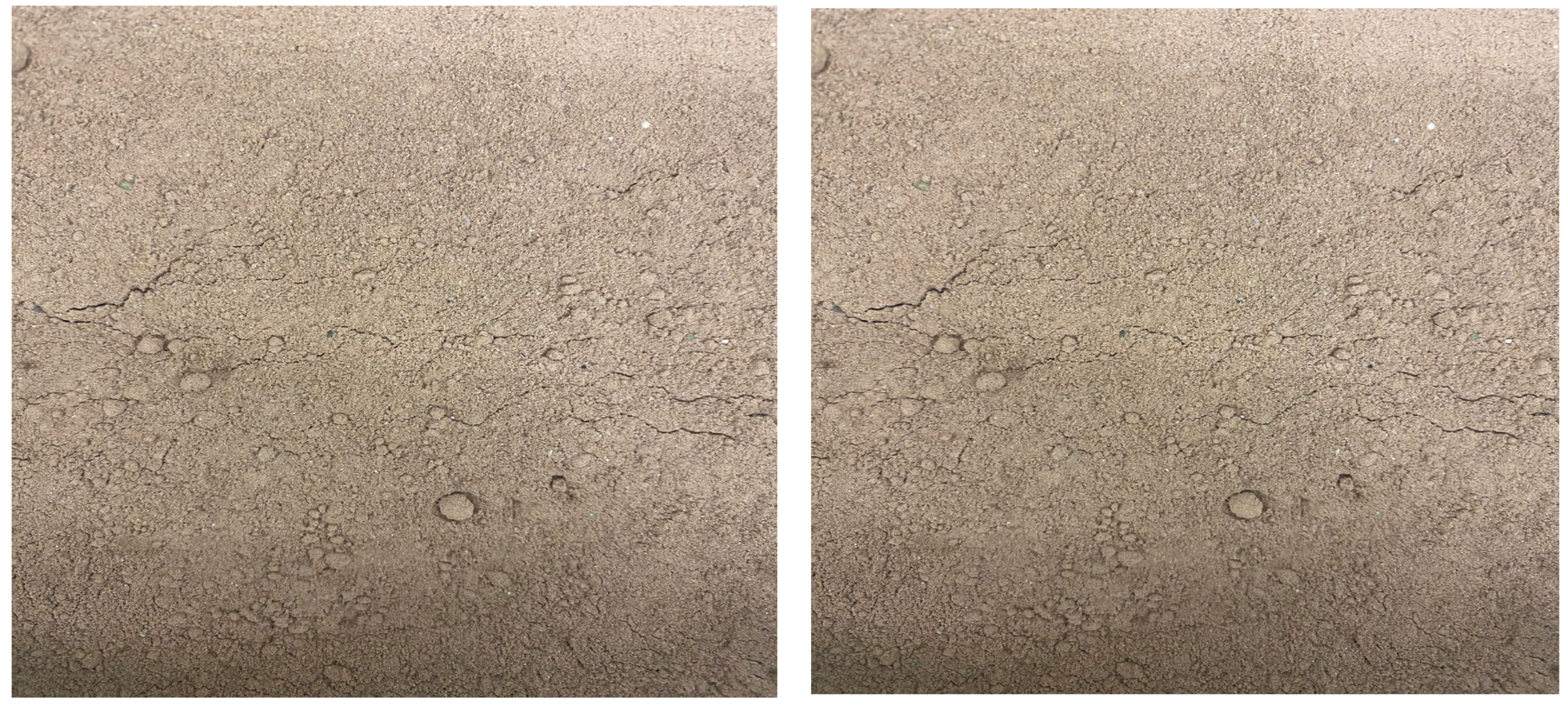

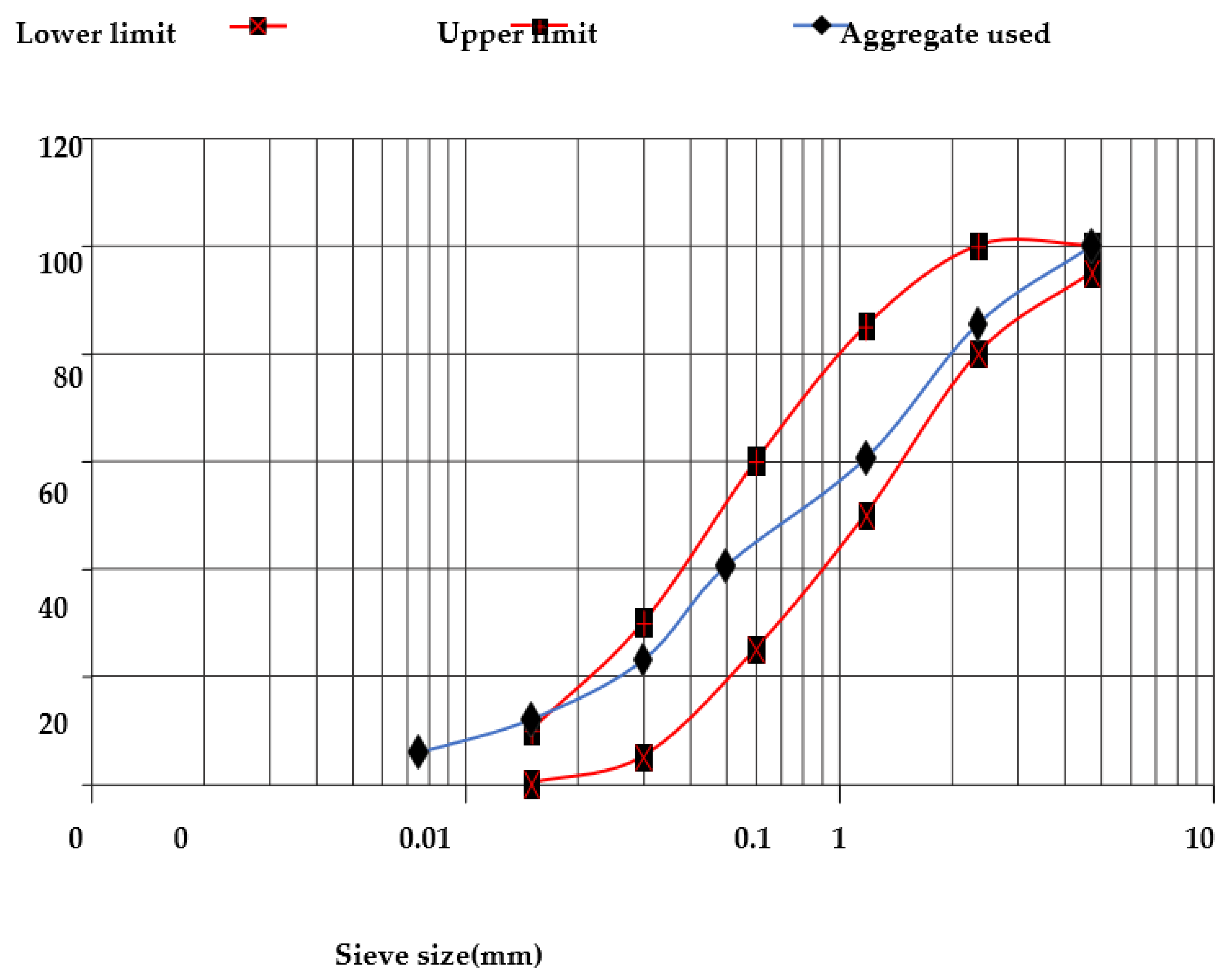

2.1.4. Fine Aggregate

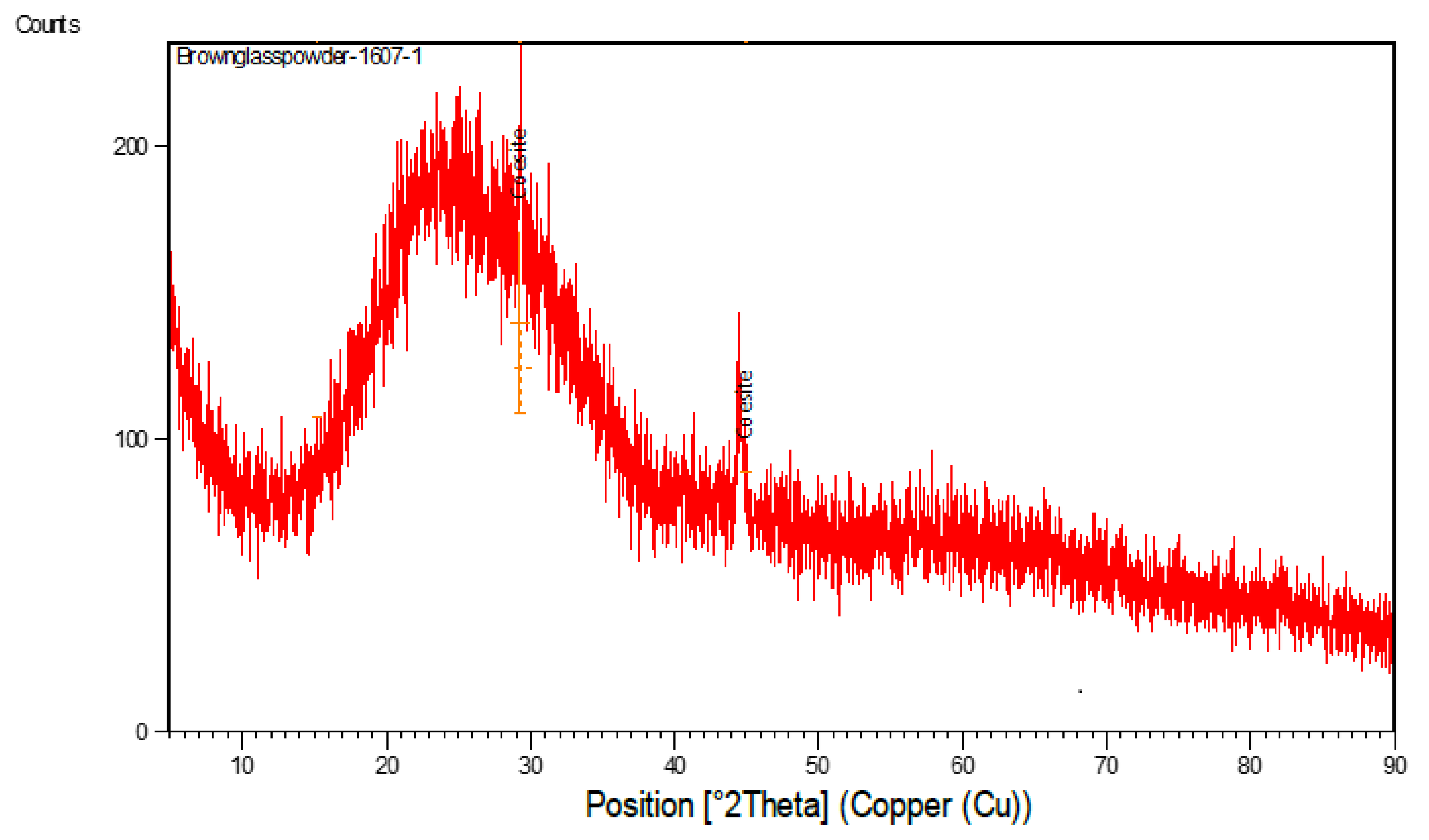

2.1.5. XRD, Elemental Composition of Waste Glass Powder

2.2. Methods

2.2.1. Mix Proportions

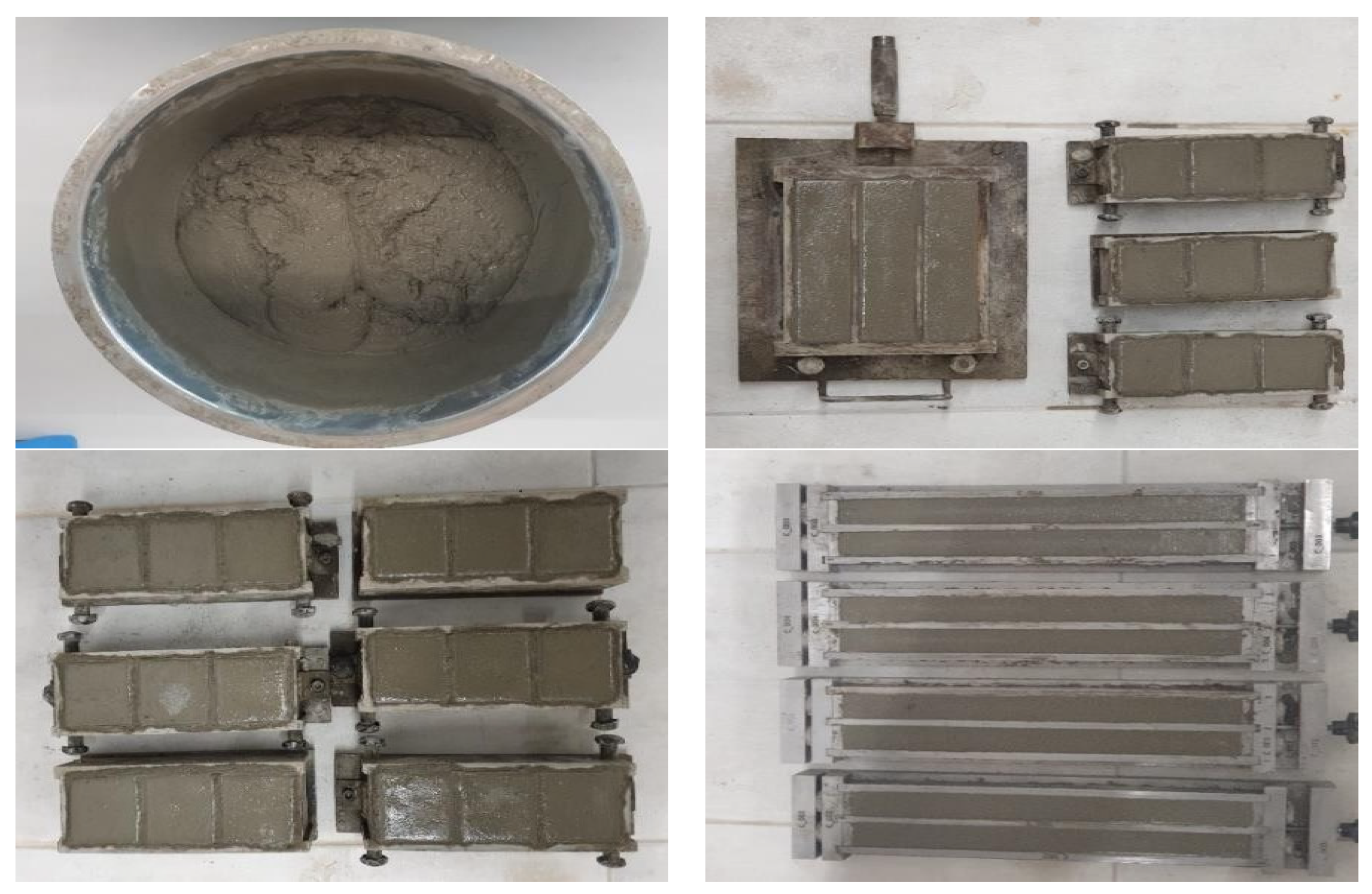

2.2.2. Specimen Preparation

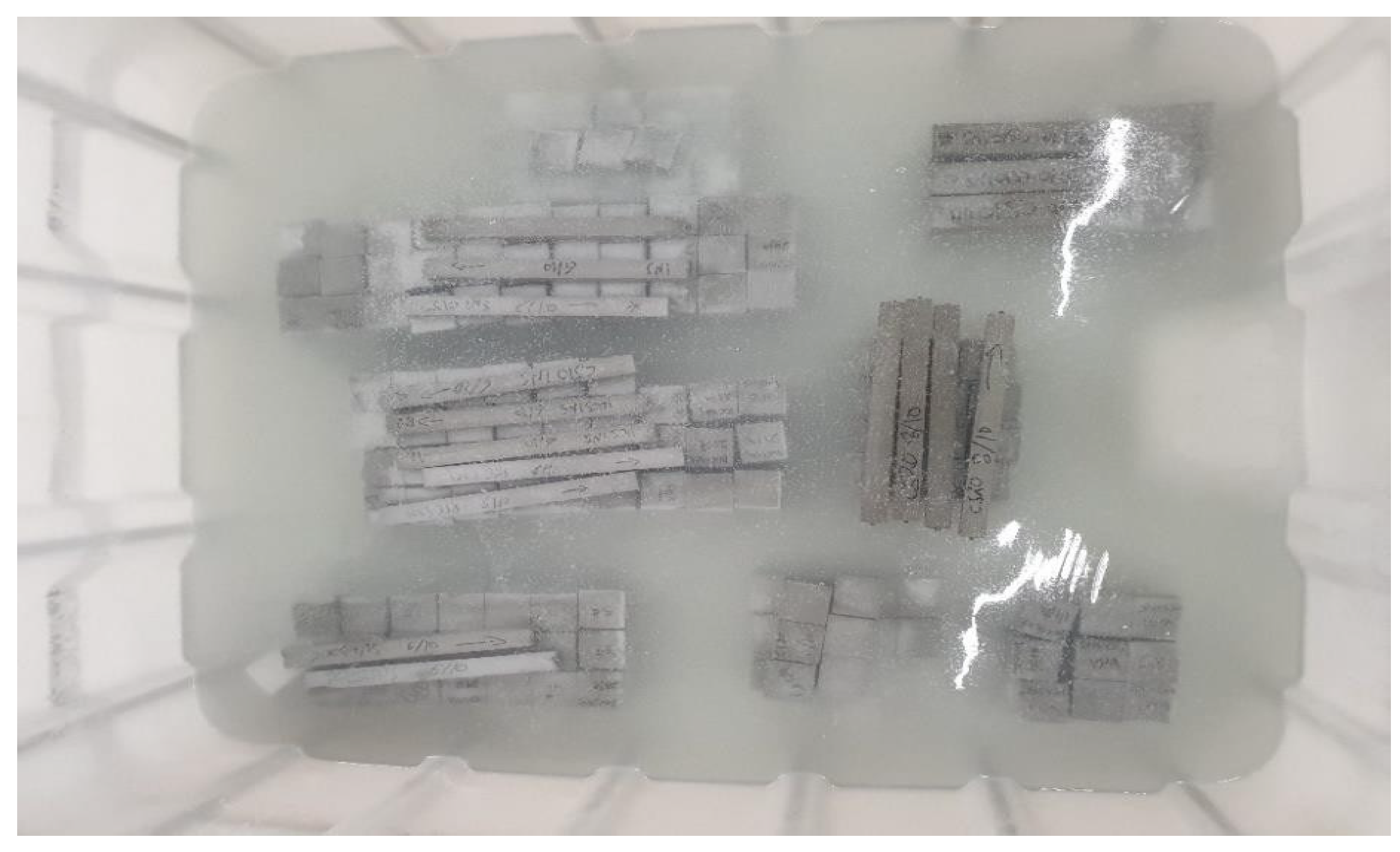

2.2.3. Curing

2.2.4. Flowability

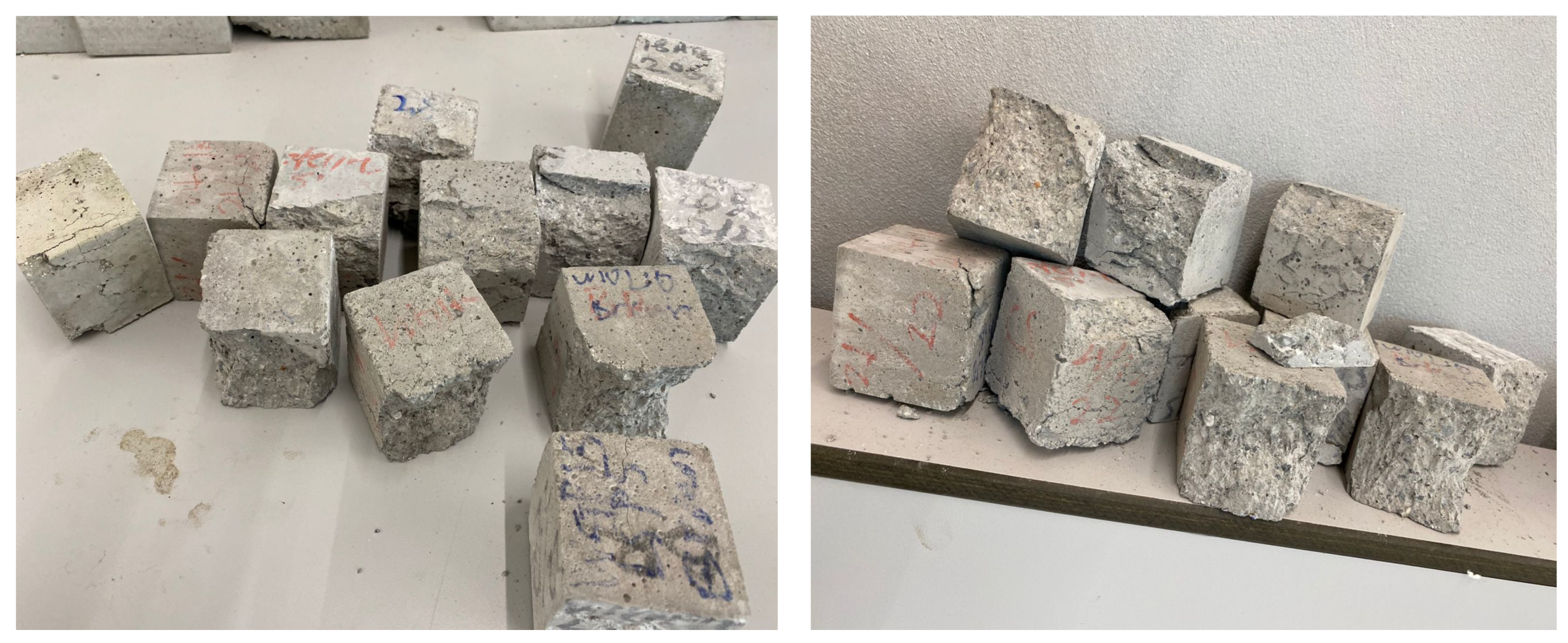

2.2.5. Compressive Strength

- The bottom and upper platens of the compressive strength machine were cleaned to have uniform contact with the placed specimen.

- The mortar was placed at the approximate center of the bottom platen of the machine. The sides of the specimens facing the upper and bottom platens of the machine were the ones in contact with plane surfaces of the mold.

- The load rate of the machine was kept at 1 kN/s.

- When the samples were crushed, the machine automatically calculated their compressive strength.

2.2.6. Flexural Strength

2.2.7. Water Absorption

- The concrete samples were oven-dried for 72 h at 105 ± 5 °C to attain a consistent density after the exact curing days. Samples were weighed after drying.

- Subsequently, the specimens were immersed in water for 28 days.

- Specimens were weighed again after 28 days to ascertain water absorption according to water absorption =

- where Dw = dry weight of the specimen, and Ww = wet weight of the specimen. After the failure of the specimen, the machine provided its flexural strength.

2.2.8. Sulfuric Acid Resistance

2.2.9. Fire Resistance

- Subsequently, specimens were transferred to the furnace chamber. To ensure consistent heat dispersion, a buffer in both the materials and the vents was kept.

- With a heating rate of 9 °C/min, the temperature was raised from 25 °C to the desired target degree, and it was maintained there for two hours.

- The furnace was turned off, and the specimens were allowed to naturally cool inside the furnace for 24 h.

- Concrete specimens that had been cooled were examined for latent strength.

2.2.10. Drying Shrinkage

- The normal drying equipment rod’s length was measured to establish a reference.

- The samples were then removed from the curing chambers for measurement. Their length was compared to a standard close to ten times to preserve the test’s accuracy.

- Tests were performed on each specimen 1, 3, 7, 14, 21, and 28 days after casting.

- A change in length and percentage change in length were then measured for each specimen.

2.2.11. Microstructure

3. Results and Discussions

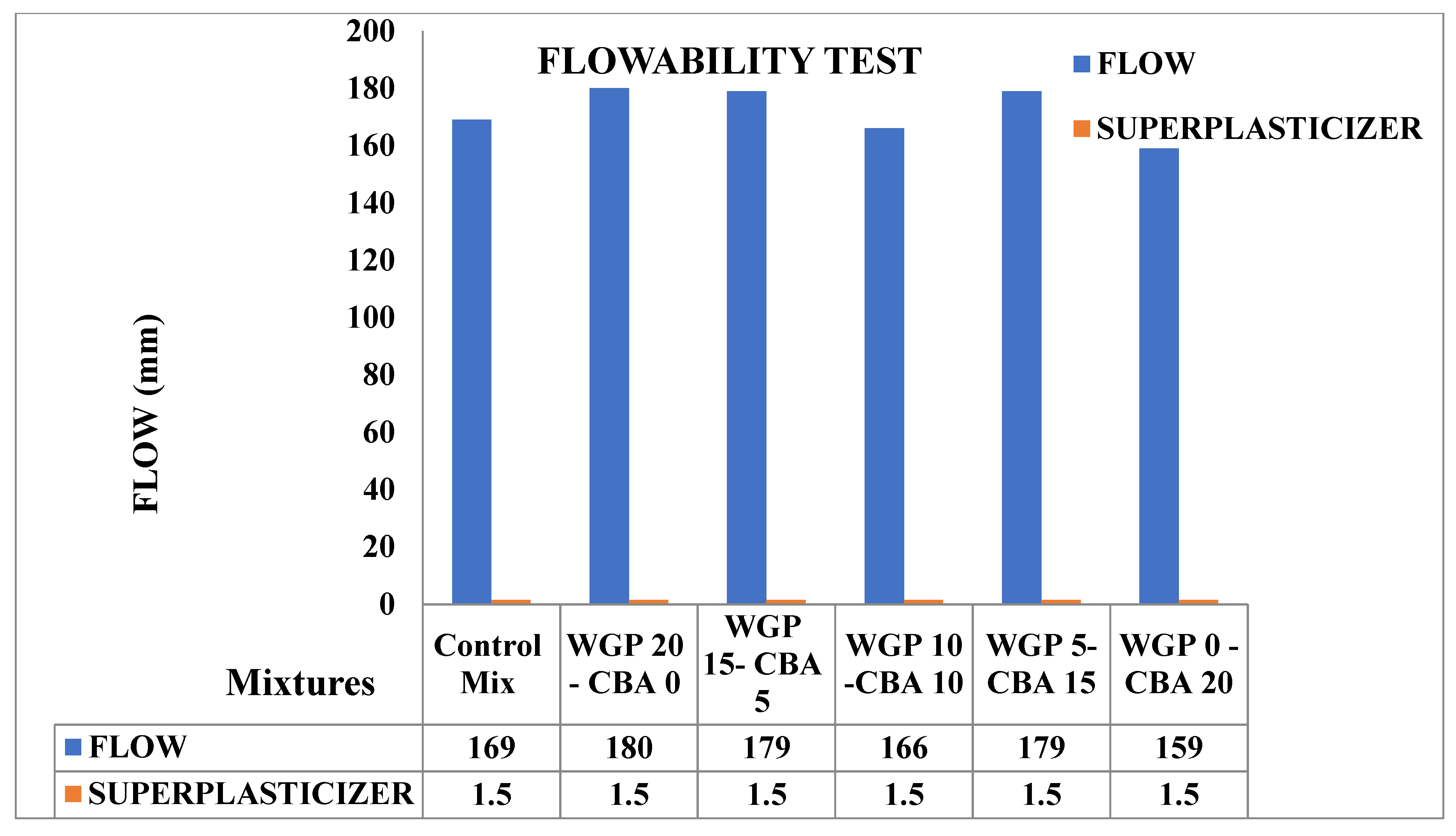

3.1. Flowability

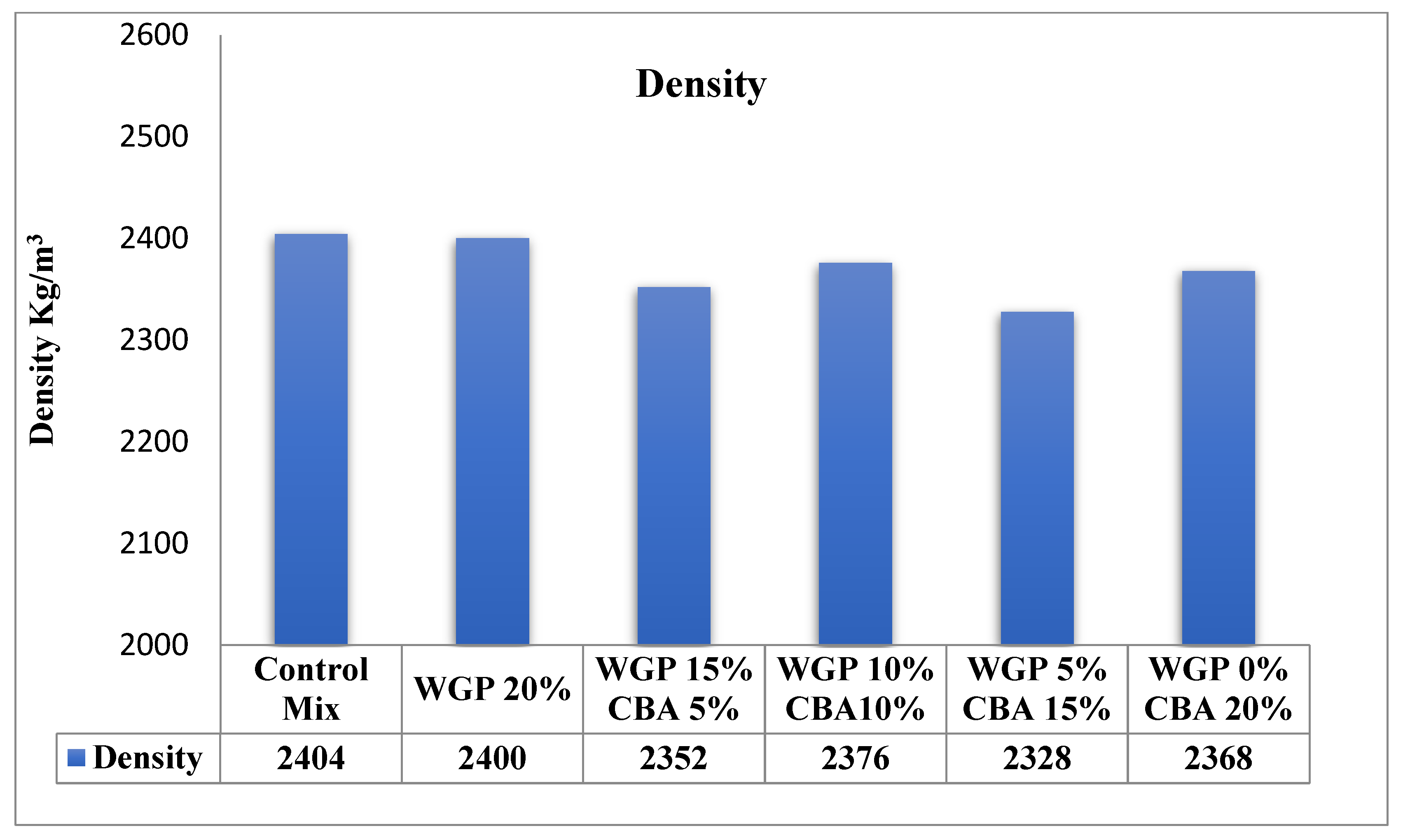

3.2. Density

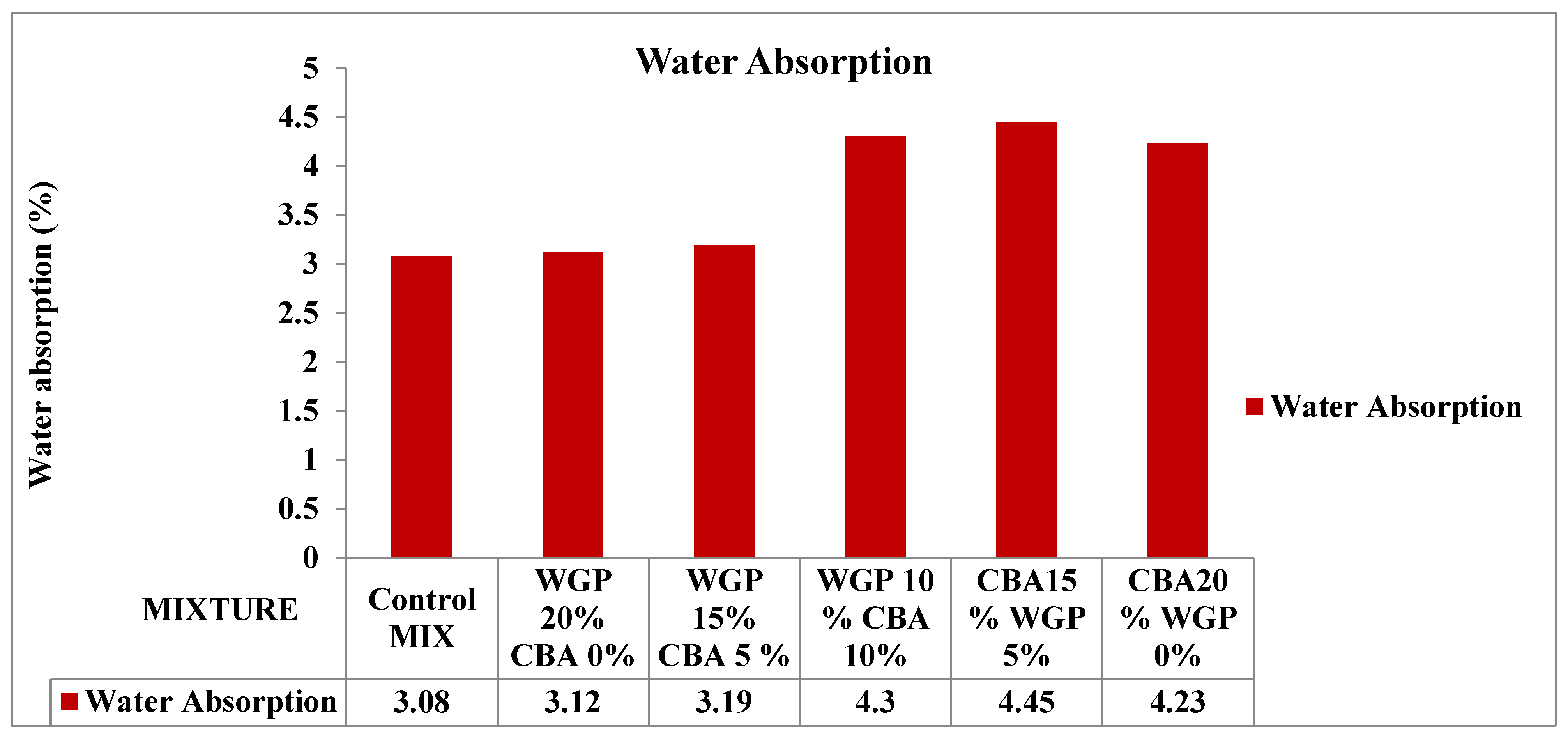

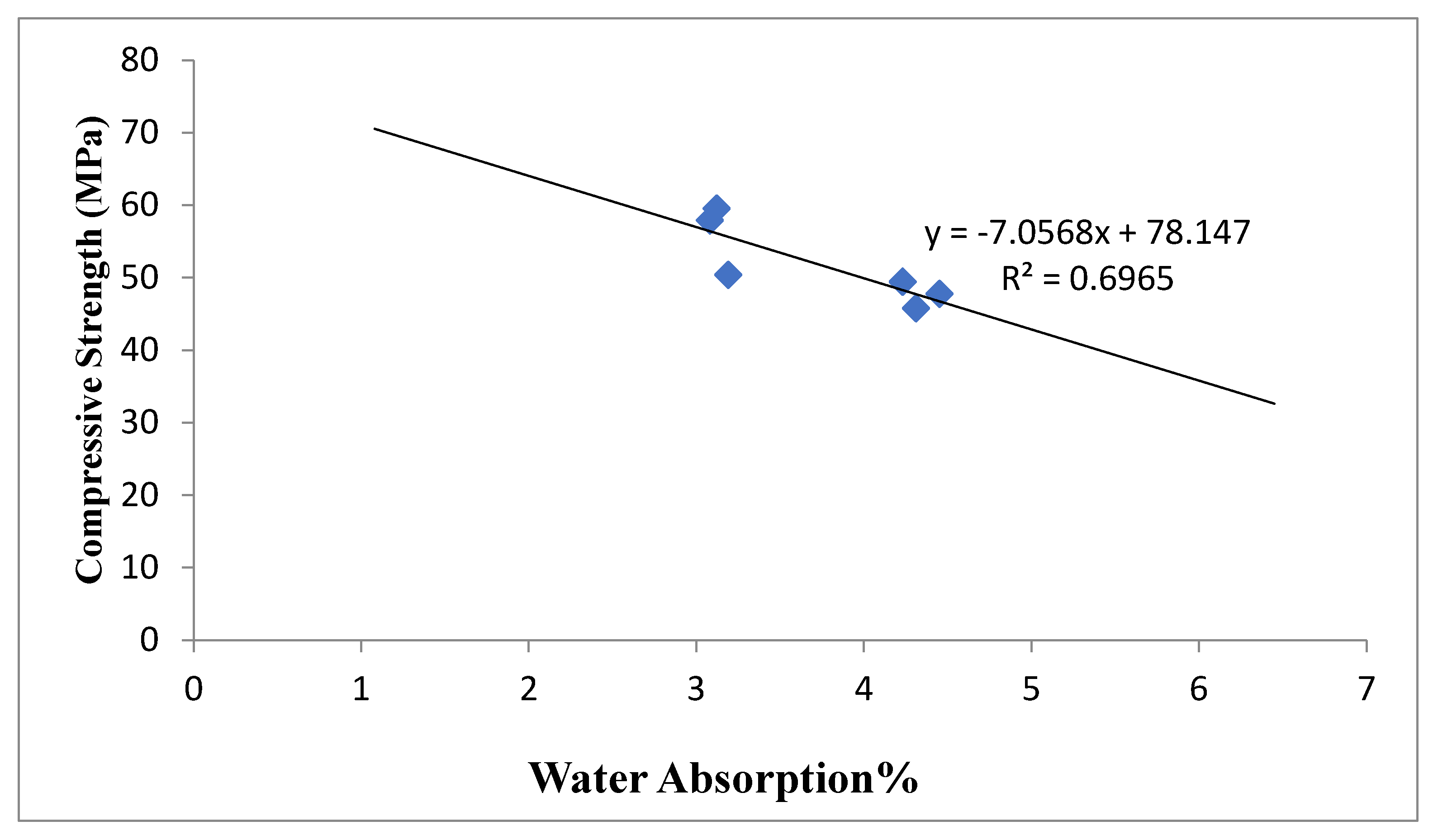

3.3. Absorption of Water

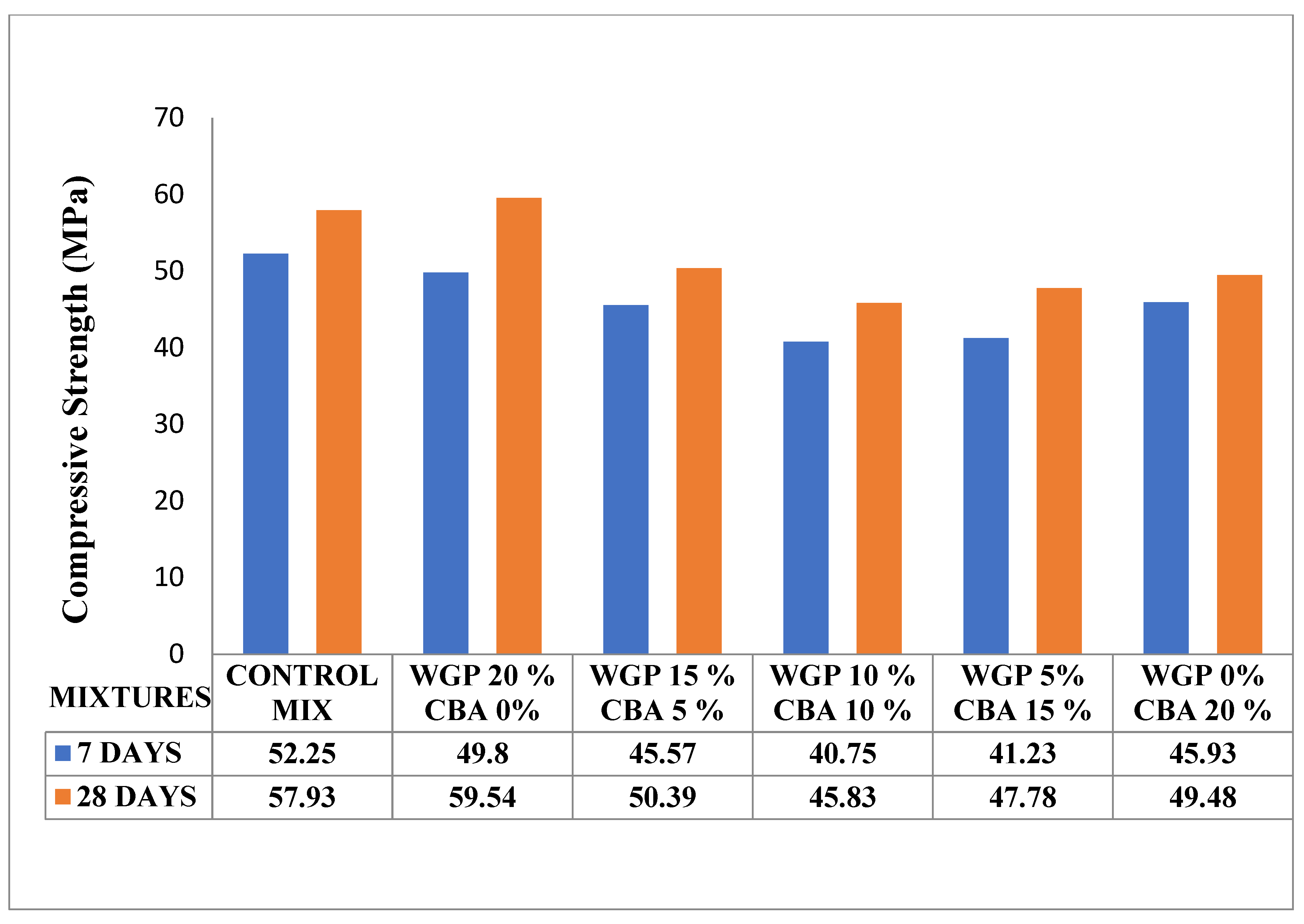

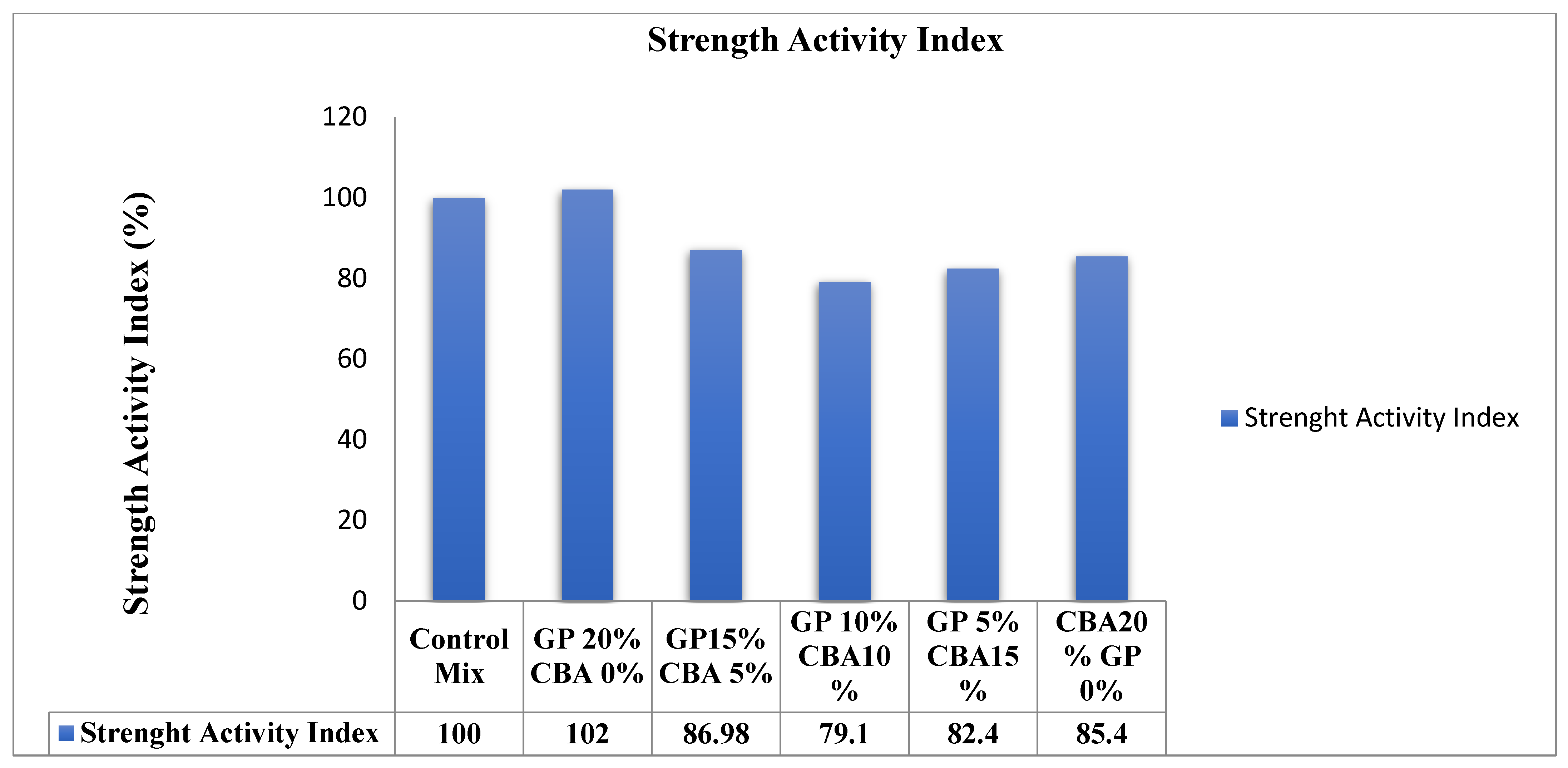

3.4. Compressive Strength

- As a result, of the chemical change in the cement particles, heat was generated, which may have increased the chemical reaction (pozzolanic) activities of GP particles [65].

- By increasing hydration processes due to its strong pozzolanic activity, WGP can improve the rapid strengthening of cement-based materials, from 3 to 7 days.

- In mortar/concrete, a small proportion of glass powder acting or used as filler helps to reduce the total void in the mortar [66].

- The compressive strength of concrete comprises coal bottom ash, which is used to partially substitute cement in concrete or mortar, resulting in a slightly lower compressive strength than conventional concrete [67].

- The porosity of the moist paste affects the strength contributions of concretes. The porosity is thus governed by the water/cement ratio and the cracks that present at the interface of its aggregates and hydrated paste.

- Coal bottom ash, on the other hand, can also be used as a filler, helping to reduce voids in mortar or concrete [68].

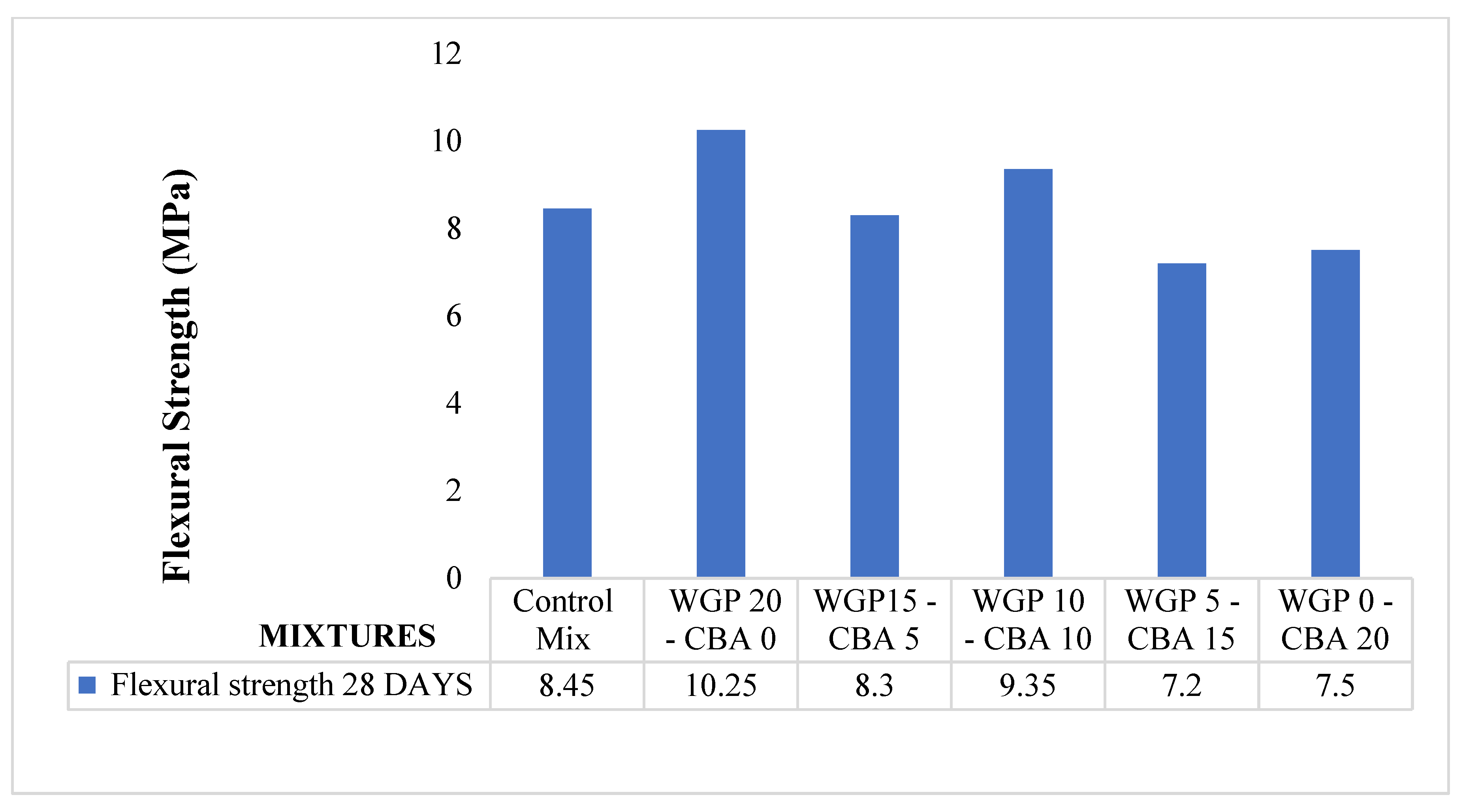

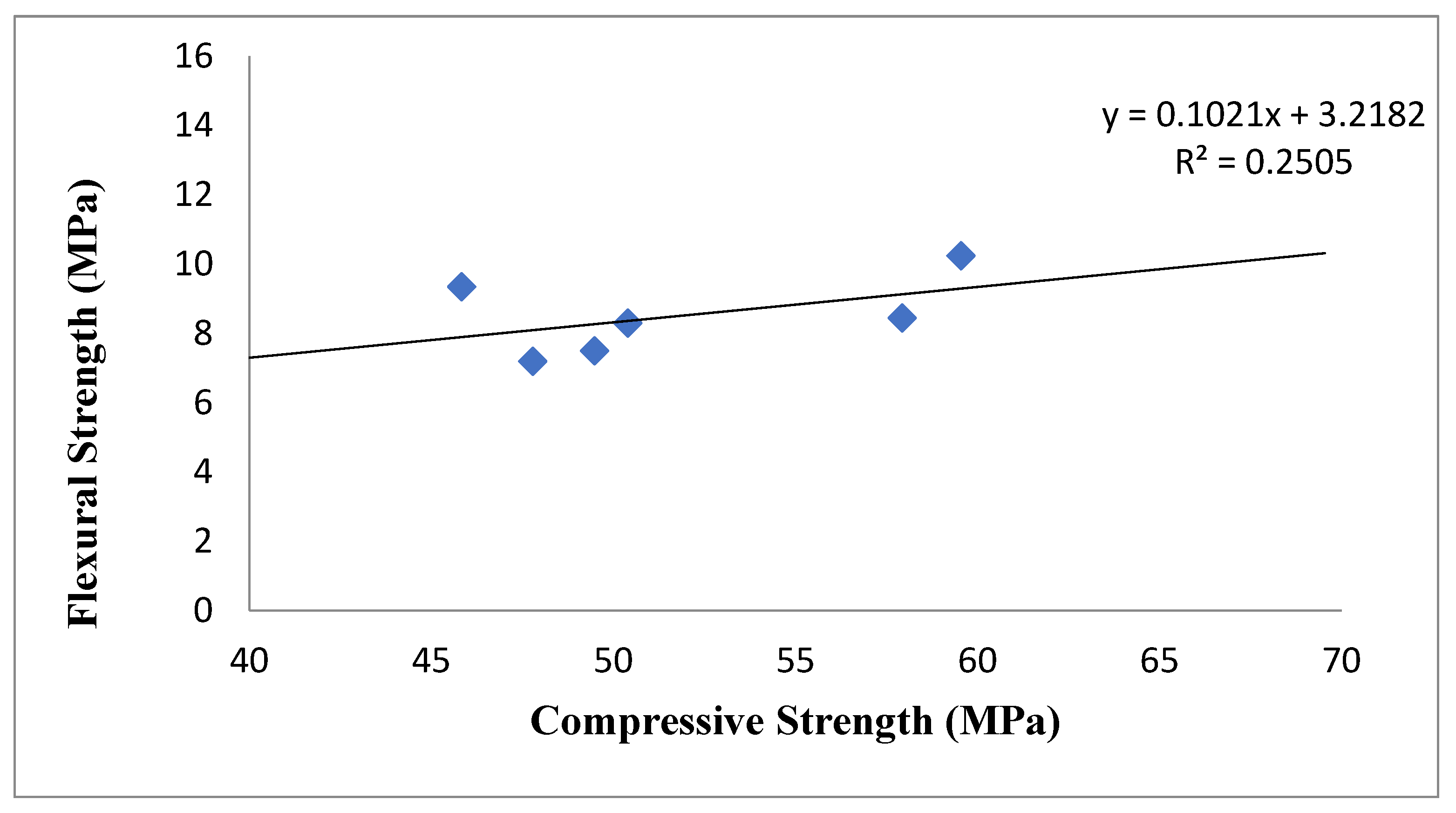

3.5. Flexural Strength

- Using WGP as a partial substitution of cement up to 20% reinforced the flexural strength of concrete because glass powder particles have an angular structure that makes it harder for concrete or mortar to resist bending.

- Furthermore, when the portion of CBA in the mix increased, the flexural strength of concrete decreased. It worth noting that 10% WGP and 10% CBA have greater strength compared to the control mix. It has been demonstrated experimentally that a 10% cement substitution with coal bottom ash is optimal.

- Variations in the shape of coal bottom ash concrete led to a reduction in aggregate evaluation as the coal bottom ash mix ratios increased. This signifies the concrete’s cracked section contains coal bottom ash aggregates.

- It was established that the reduction in the flexural strength of coal bottom ash concrete could be attributed to the splitting of the bottom ash concrete, which happens rapidly compared to conventional aggregate, which has difficulty penetrating.

- The flexural strength test on the effect of coal bottom ash in concrete revealed that flexural strength decreases when natural fine aggregate has been substituted with coal bottom ash concrete [70].

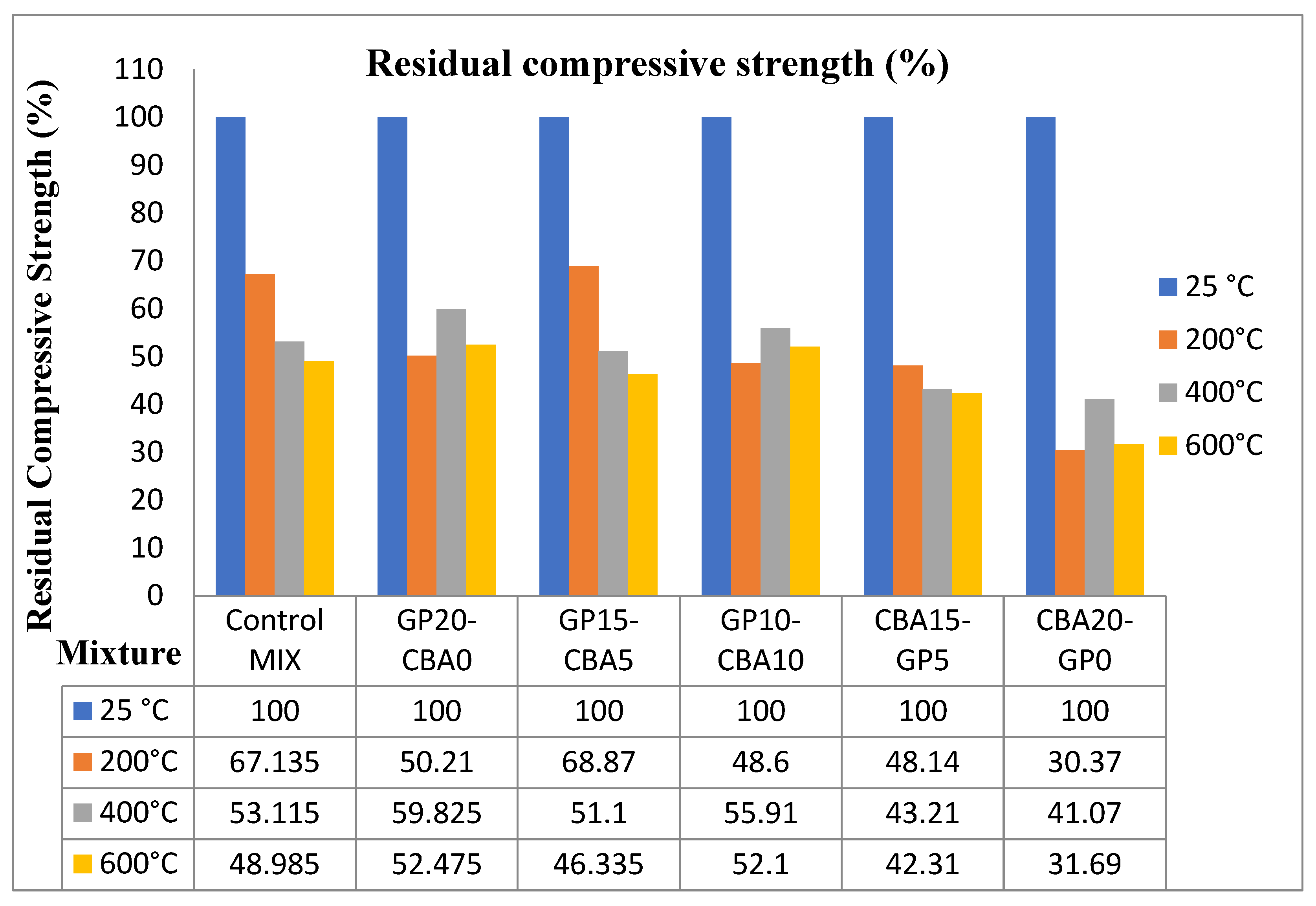

3.6. Fire Resistance

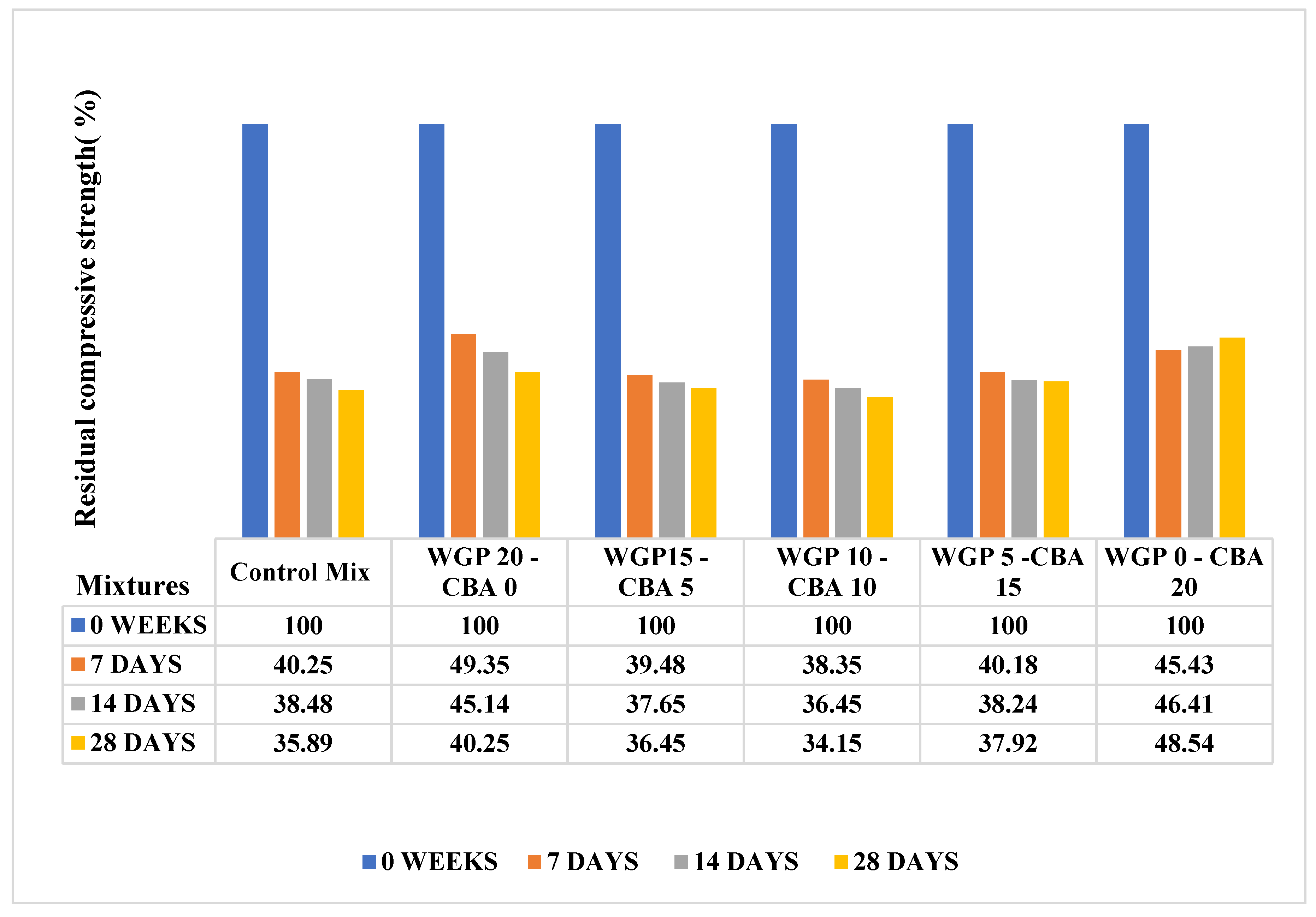

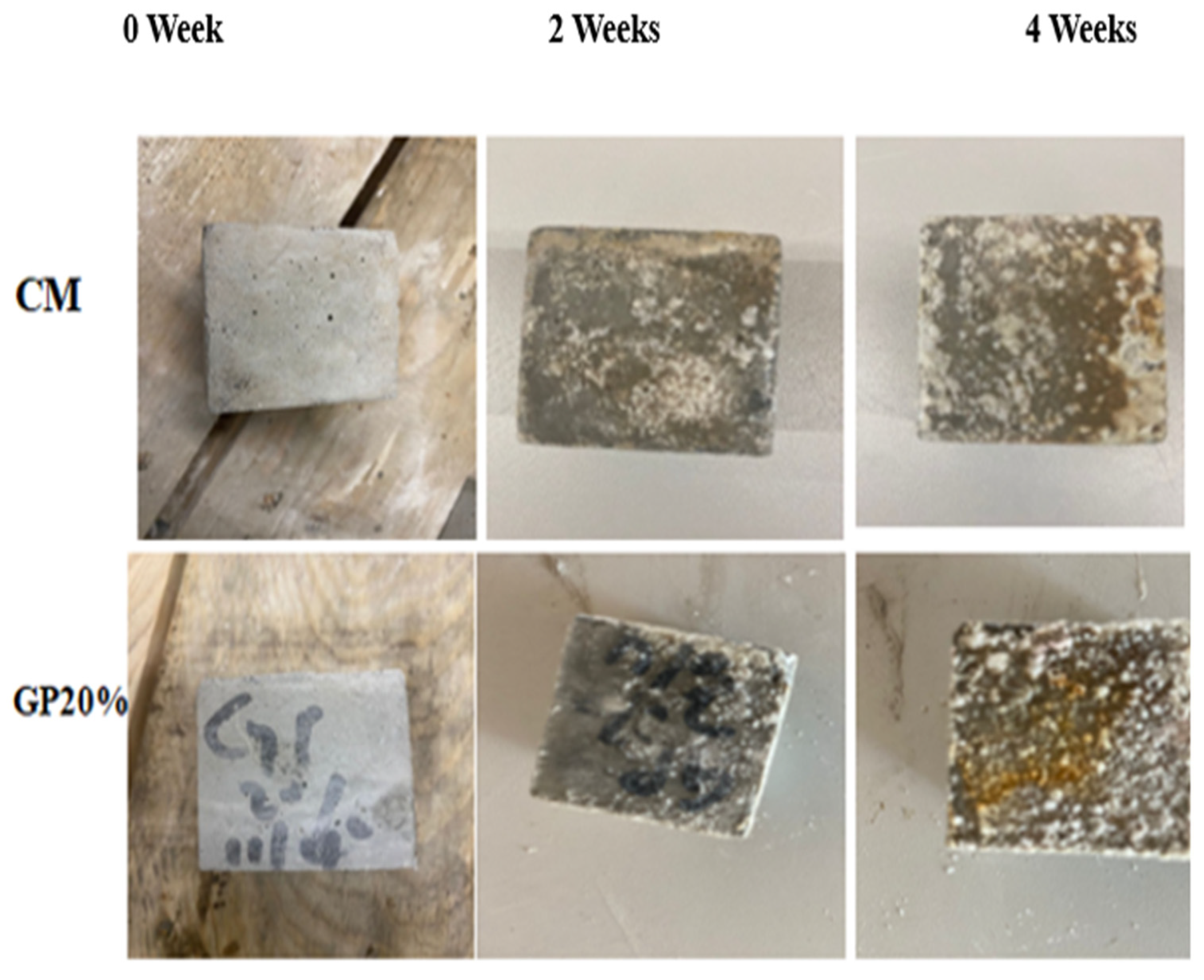

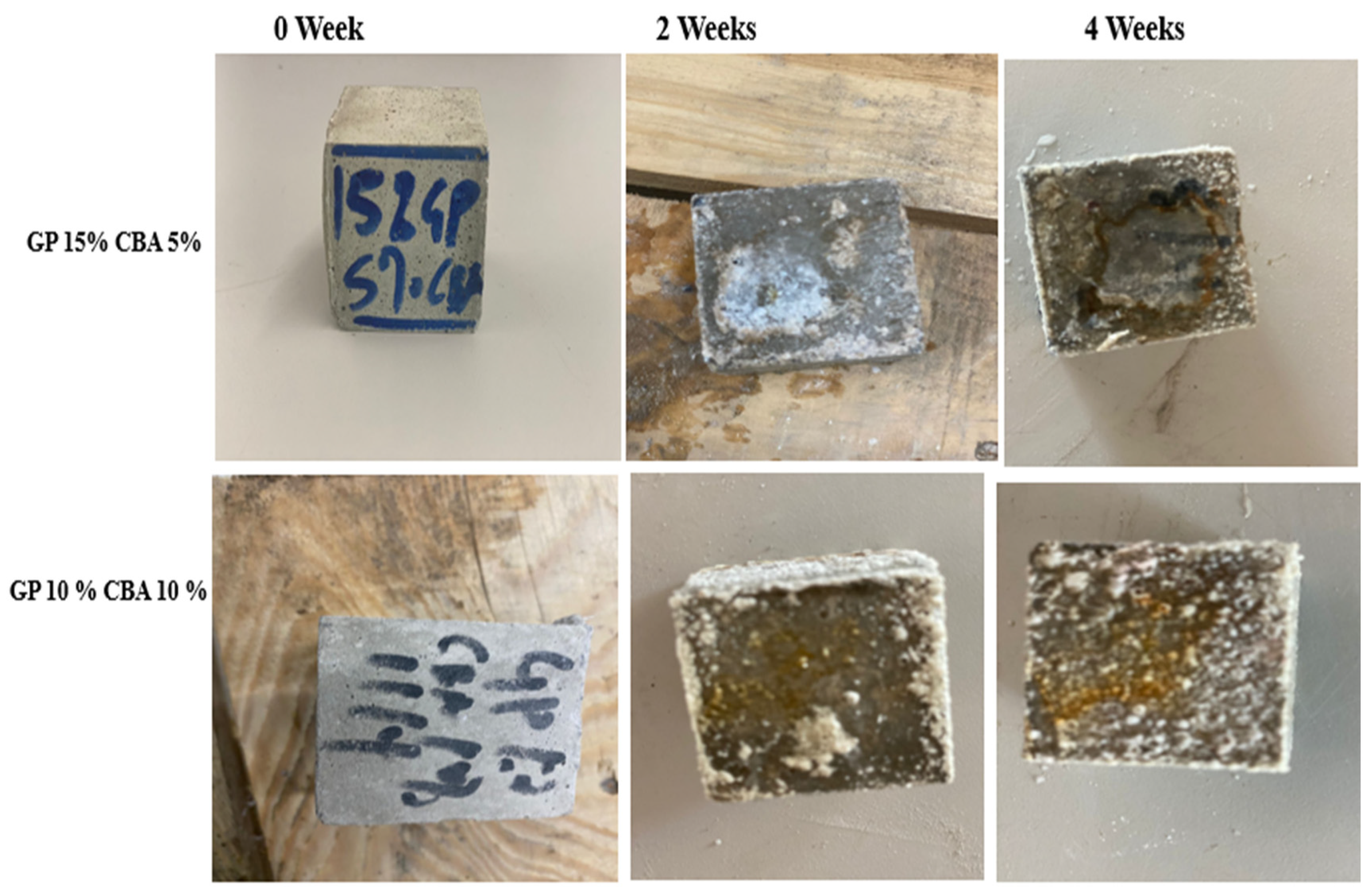

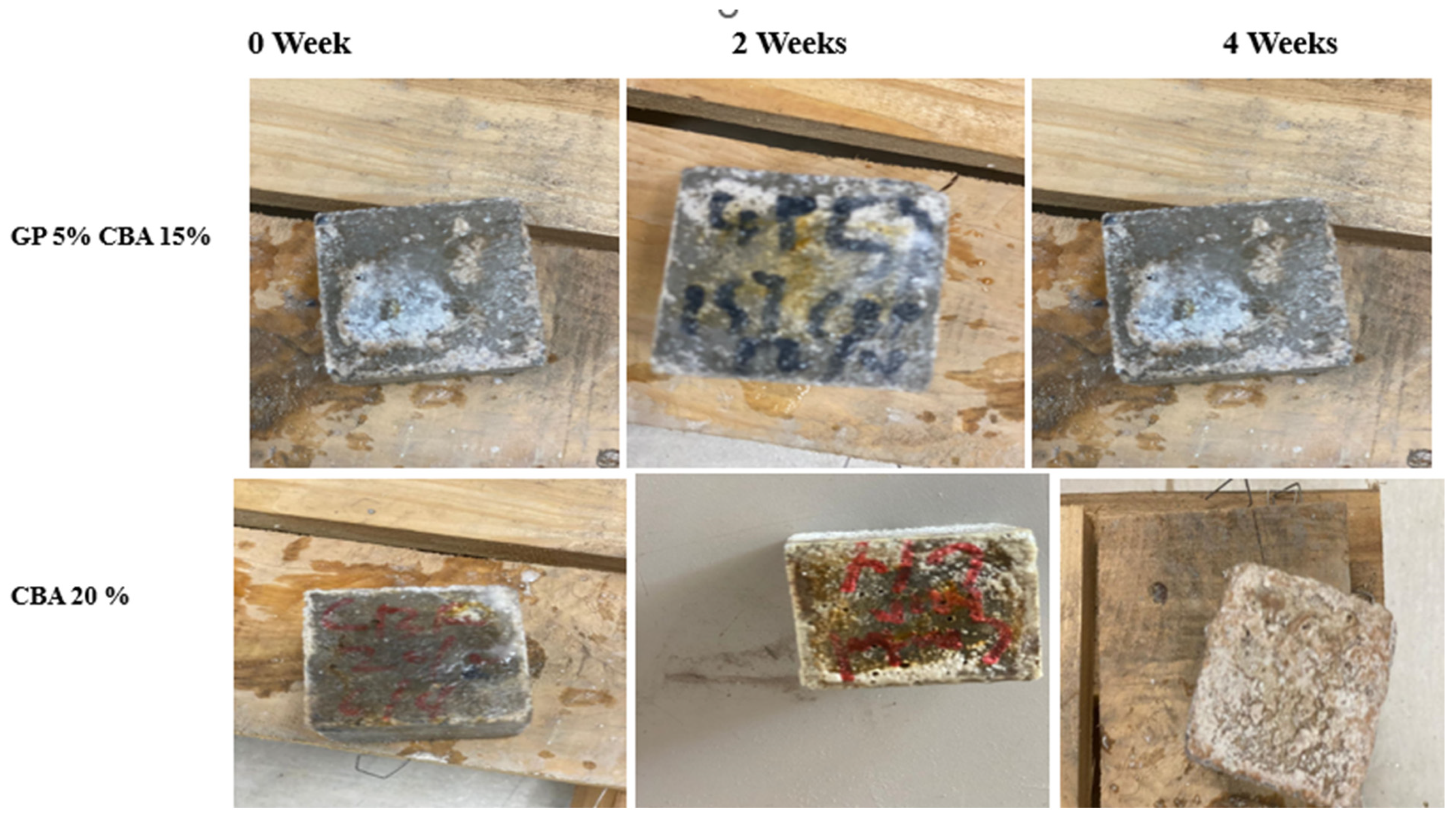

3.7. Sulfuric Acid Attack

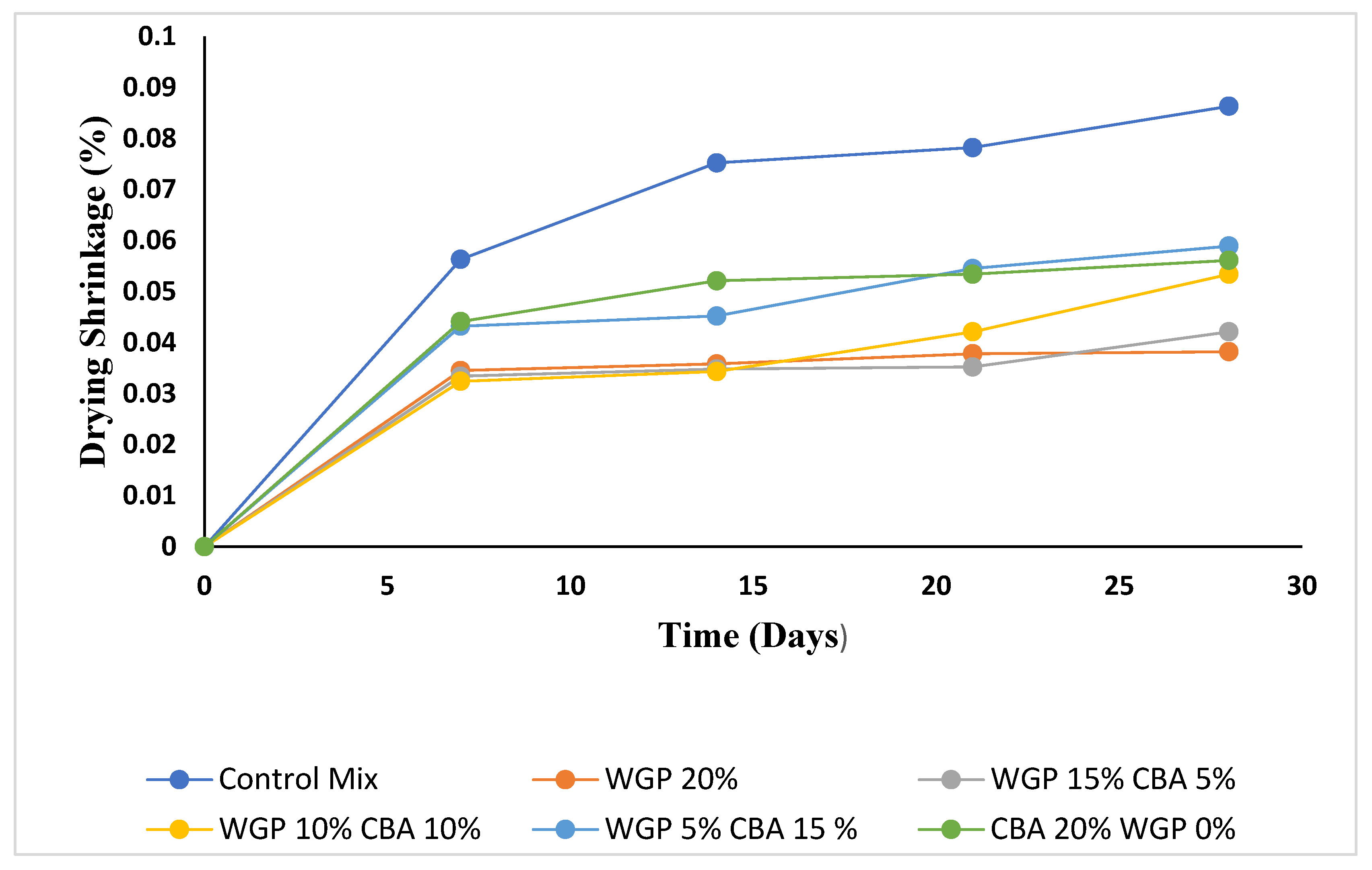

3.8. Dry Shrinkage

- The cementitious interaction of WGP and CBA results in array pore modification which exhibits drying shrinkage.

- The quantity of lime required for a quick hydration rate, which lowers dry shrinkage, is reduced by replacing cement with WGP and CBA.

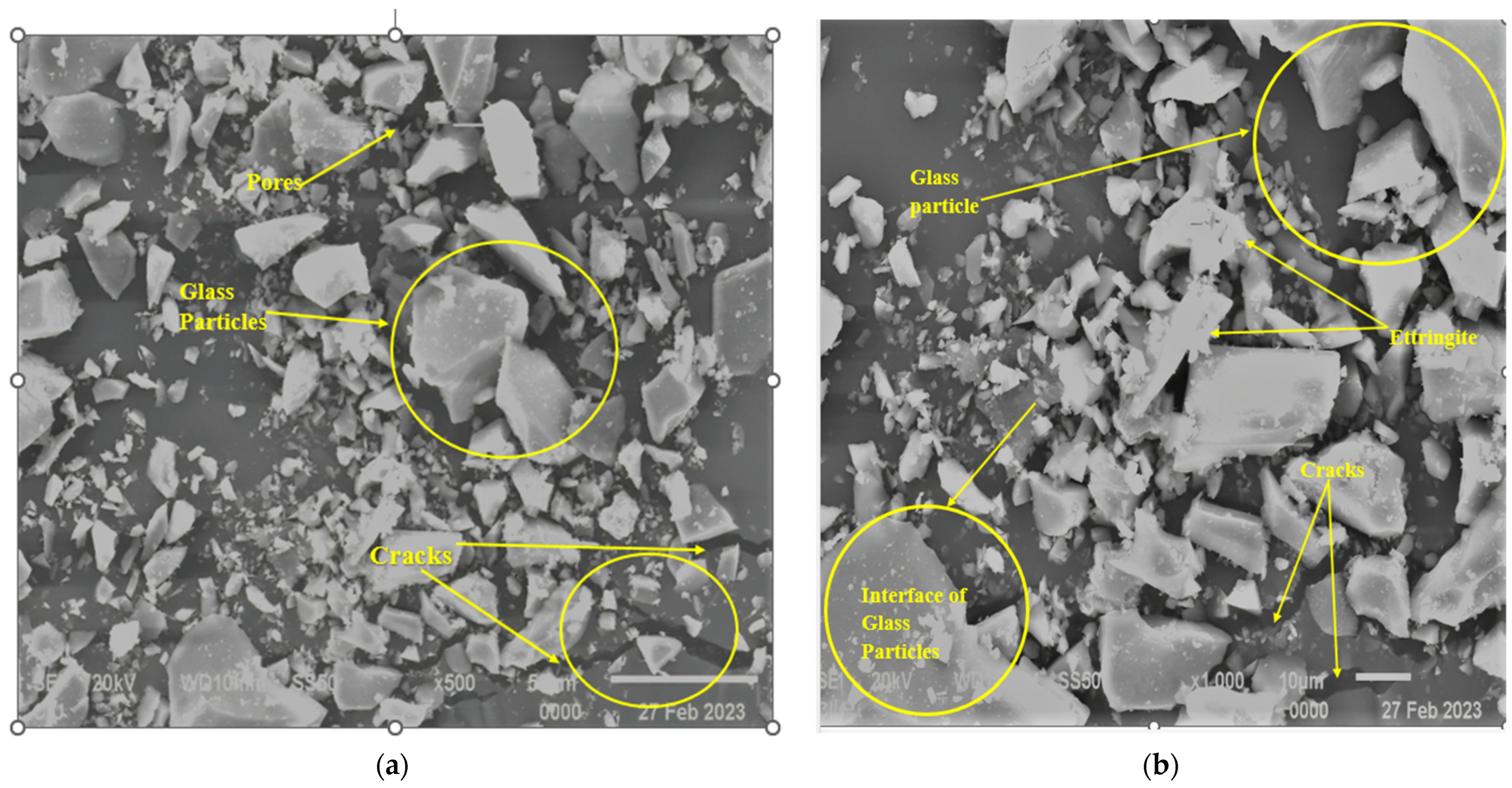

3.9. SEM Analysis

4. Conclusions

- Flowability observation shows the workability of the samples enhanced as the glass powder content replacing cement expand. WGP of 20% has the highest flowability because of its lightweight surface area which leads to an increase in flow. The improvement in mortar flow with the influence of waste glass powder may be the effect of glass material, which is cleaner in nature. The maximum improvement was reached at the supplementation of 20% of glass powder.

- The flowability outcome indicates that the effect of coal bottom ash as an alternative for cement improves the flow value of specimens.

- The compressive strength test demonstrates that the development of the compressive strength continues with age. At a fixed water cement ratio of 0.35, substituting 20% of the cement with WGP enhances the compressive strength of the mortar.

- Flexural strength exhibits a different pattern than compressive strength because the flexural strength of CM diminishes more than that of WGP, and it is also observed that 10% WGP and 10% CBA increases flexural strength compared to the control mix.

- At three different temperatures (200, 400, and 600 °C), mortar modified with GP and CBA shows significant resistance to fire. At 200 °C, a development in residual compressive strength was observed approximately 400 and 600 °C, and the hydrating activity of the raw binders’ particles became less intense. Due to their heat insulation capabilities, which minimize heat conduction between cement and aggregate at 600 °C, WGP and CBA blends produced an unexpected outcome in terms of residual strength.

- The research reveals that WGP and CBA are more resistant to sulfuric acid assault than the control mixture, which lost considerable mass and strength and suffered considerable surface degradation. Because of their characteristics, CBA particles increase overall performance by preventing acid from penetrating deep into the system. After exposure to the acidic medium, a mixture of WGP and CBA in the mortar exhibited a noteworthy performance.

- Due to their significant surface area and pozzolanic activity rate, 15% CBA and 5% WGP were found to have the highest autogenous shrinkage across all ages. This was followed by 20% CBA. The research found that 20% WGP lessened drying shrinkage by reducing hydration rate, heat loss, and water loss across all ages.

- Additionally, SEM analysis confirmed that incorporating WGP and CBA into cement mortar enhanced porosity. In contrast, the combination of WGP and CBA was shown to be quite beneficial in improving the ITZ and obtaining a denser and more compacted microstructure.

5. Future Recommendations

- Investigating the influence of glass powder or coal bottom ash as a cement substitute on structural steel in an attempt to decide the long-term sustainability of glass powder and coal bottom ash use in offshore construction.

- Investigating the impact of combining glass powder with other supplementary cementitious materials as a partial cement substitute on the properties and behaviors of various concrete mixtures.

- From an environmental standpoint, coal bottom ash utilization in cement-based composites should be increased. Recently, it was noted that natural aggregate supplies are progressively diminishing and that commercially cost-effective quarries are getting harder to find in some countries. As a result, the use of recycled or by-product aggregates as an alternative to natural aggregates is recommended, especially since the development of new quarries may have adverse impacts on the ecosystem. It is advantageous to utilize coal bottom ash in place of conventional aggregates because of its sustainable application and the preservation of natural resources.

- Additional research should be conducted along the lines of enhanced utilization of coal bottom ash in addition to implementing the integration of coal bottom ash into building structures that might benefit from the unique properties of coal bottom ash.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yakut, A. Preliminary Seismic Performance Assessment Procedure for Existing Rc Buildings. Eng. Struct. 2004, 26, 1447–1461. [Google Scholar] [CrossRef]

- Kumar, S.; Aleem, G.M.A.; Dinesh, S. Application of geopolymer concrete. Int. Res. J. Eng. Technol. 2015, 2, 96–99. [Google Scholar]

- Imam, A.; Kumar, V.; Srivastava, V. Review study towards the Effect of Silica Fume on the fresh and hardened properties of concrete. Adv. Concr. Constr. 2018, 6, 145. [Google Scholar]

- Aliabdo, A.A.; Abd Elmoaty, M.; Auda, E.M. Reuse of waste marble dust in the production of cement and concrete. Constr. Build. Mater. 2014, 50, 28–41. [Google Scholar] [CrossRef]

- Aruntaş, H.Y.; Gürü, M.; Dayı, M.; Tekin, İ. Utilization of waste marble dust as an additive in cement production. Mater. Des. 2010, 31, 4039–4042. [Google Scholar] [CrossRef]

- Danish, A.; Mosaberpanah, M.A.; Salim, M.U.; Fediuk, R.; Rashid, M.F.; Waqas, R.M. Reusing marble and granite dust as cement replacement in cementitious composites: A review on sustainability benefits and critical challenges. J. Build. Eng. 2021, 44, 102600. [Google Scholar] [CrossRef]

- de Sensale, G.R. Strength development of concrete with rice-husk ash. Cem. Concr. Compos. 2006, 28, 158–160. [Google Scholar] [CrossRef]

- Salim, M.U.; Mosaberpanah, M.A. Mechanical and durability properties of high-performance mortar containing binary mixes of cenosphere and waste glass powder under different curing regimes. J. Mater. Res. Technol. 2021, 13, 602–617. [Google Scholar] [CrossRef]

- Elaqra, H.A.; Abou Haloub, M.A.; Rustom, R.N. Effect of new mixing method of glass powder as cement replacement on the mechanical behavior of concrete. Constr. Build. Mater. 2019, 203, 75–82. [Google Scholar] [CrossRef]

- Khan, M.N.A.; Liaqat, N.; Ahmed, I.; Basit, A.; Umar, M.; Khan, M.A. Effect of brick dust on strength and workability of concrete. IOP Conf. Ser. Mater. Sci. Eng. 2018, 414, 012005. [Google Scholar] [CrossRef]

- Tiwari, V.; Shukla, A.; Bose, A. Acoustic properties of cenosphere reinforced cement and asphalt concrete. Appl. Acoust. 2004, 65, 263–275. [Google Scholar] [CrossRef]

- IEA. Tracking Industrial Energy Efficiency and CO2 Emissions; OECD: Paris, France; IEA: Paris, France, 2007; pp. 1–321. [Google Scholar]

- Rashed, A.M. Recycled Waste Glass as Fine Aggregate Replacement in Cementitious Materials Based on Portland cement. Constr. Build. Mater. 2014, 72, 340–357. [Google Scholar] [CrossRef]

- Sobolev, K.; Türker, P.; Soboleva, S.; Iscioglu, G. Utilization of waste glass in ECO-cement: Strength properties and microstructural observations. Waste Manag. 2007, 27, 971–976. [Google Scholar] [CrossRef] [PubMed]

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Özkılıç, Y.O.; Al Dughaishi, H.; Alosta, M.; Sabri, M.M.; Alkhatib, F.; Milad, A. Concrete containing waste glass as an environmentally friendly aggregate: A review on fresh and mechanical characteristics. Materials 2022, 15, 6222. [Google Scholar] [CrossRef]

- Afshinnia, K.; Rangaraju, P.R. Impact of Combined Use of Ground Glass Powder and Crushed Glass Aggregate on Selected Properties of Portland Cement Concrete. Constr. Build. Mater. 2016, 117, 263–272. [Google Scholar] [CrossRef]

- Shi, C.; Zheng, K. A review on the use of waste glasses in the production of cement and concrete. Resour. Conserv. Recycl. 2007, 52, 234–247. [Google Scholar] [CrossRef]

- Jiang, X.; Xiao, R.; Bai, Y.; Huang, B.; Ma, Y. Influence of waste glass powder as a supplementary cementitious material (SCM) on physical and mechanical properties of cement paste under high temperatures. J. Clean. Prod. 2022, 340, 130778. [Google Scholar] [CrossRef]

- Bilondi, M.P.; Toufigh, M.M.; Toufigh, V. Experimental investigation of using a recycled glass powder-based geopolymer to improve the mechanical behavior of clay soils. Constr. Build. Mater. 2018, 170, 302–313. [Google Scholar] [CrossRef]

- Tan, K.H.; Du, H. Use of waste glass as sand in mortar: Part I—Fresh, mechanical and durability properties. Cem. Concr. Compos. 2013, 35, 109–117. [Google Scholar] [CrossRef]

- Xiao, R.; Polaczyk, P.; Zhang, M.; Jiang, X.; Zhang, Y.; Huang, B.; Hu, W. Evaluation of Glass Powder-Based Geopolymer Stabilized Road Bases Containing Recycled Waste Glass Aggregate. Transp. Res. Rec. J. Transp. Res. Board 2020, 2674, 22–32. [Google Scholar] [CrossRef]

- Wang, Y.; Ke, G. The research on the fineness modulus and fractal dimension of waste glass powder with different grinding time. Appl. Mech. Mater. 2014, 638–640, 1465–1471. [Google Scholar]

- Taha, B.; Nounu, G. Utilizing waste recycled glass as sand/cement replacement in concrete. J. Mater. Civ. Eng. 2009, 21, 709–721. [Google Scholar] [CrossRef]

- Letelier, V.; Henríquez-Jara, B.I.; Manosalva, M.; Moriconi, G. Combined use of waste concrete and glass as a replacement for mortar raw materials. Waste Manag. 2019, 94, 107–119. [Google Scholar] [CrossRef] [PubMed]

- C-09; Committee Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2013.

- Omran, A.; Tagnit-Hamou, A. Performance of glass-powder concrete in field applications. Constr. Build. Mater. 2016, 109, 84–95. [Google Scholar] [CrossRef]

- Zeybek, Ö.; Özkılıç, Y.O.; Karalar, M.; Çelik, A.İ.; Qaidi, S.; Ahmad, J.; Burduhos-Nergis, D.P. Influence of replacing cement with waste glass on mechanical properties of concrete. Materials 2022, 15, 7513. [Google Scholar] [CrossRef]

- Özkılıç, Y.O.; Çelik, A.İ.; Ufuk, T.U.; Karalar, M.; Deifalla, A.; Alomayri, T.; Althoey, F. The use of Crushed Recycled Glass for Alkali Activated Fly Ash Based Geopolymer Concrete and Prediction of Its Capacity. J. Mater. Res. Technol. 2023, 11, 8267–8281. [Google Scholar] [CrossRef]

- Çelik, A.İ.; Ufuk, T.U.; Bahrami, A.; Karalar, M.; Mydin, M.A.; Alomayri, T.; Özkılıç, Y.O. Use of Waste Glass Powder toward more Sustainable Geopolymer Concrete. J. Mater. Res. Technol. 2023, 12, 8533–8546. [Google Scholar] [CrossRef]

- Cheriaf, M.J.; Rocha, C.; Pera, J. Pozzolanic properties of pulverized coal combustion bottom ash. Cem. Concr. Res. 1999, 29, 1387–1391. [Google Scholar] [CrossRef]

- Zainal Abidin, N.E.; Wan Ibrahim, M.H.; Jamaluddin, N.; Kamaruddin, K.; Hamzah, A.F. The effect of bottom ash on fresh characteristic, compressive strength and water absorption of self-compacting concrete. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2014; Volume 660, pp. 145–151. [Google Scholar]

- Abubakar, A.U.; Baharudin, K.S. Properties of Concrete using Tanjung Bin Power Plant Coal Bottom Ash and Fly ash. Int. J. Sustain. Constr. Eng. Technol. 2012, 3, 56–69. [Google Scholar]

- Marto, A.; Tan, C.S. Properties of coal bottom ash from power plants in Malaysia and its suitability as geotechnical engineering material. J. Teknol. 2016, 78, 1–10. [Google Scholar] [CrossRef]

- Tiwari, M.; Sahu, S.K.; Bhangare, R.C.; Ajamal, P.Y.; Pandit, G.G. Elemental Characterization of Coal, Fly Ash and bottom ash using an energy dispersive Xray fluorescence technique. Appl. Radiat. Isot. 2014, 90, 53–57. [Google Scholar] [CrossRef]

- Singh, M.; Siddique, R. Properties of concrete containing high volume of coal bottom ash as fine aggregate. J. Clean. Prod. 2014, 91, 269–278. [Google Scholar] [CrossRef]

- Ngoc Minh, V.T.; Pham, V.H.; Tung, V.H.; Tung, C.T.; Phuong, N.T.H. Firing-Associated Recycling of Coal-Fired Power Plant Fly Ash. J. Anal. Methods Chem. 2023, 2023, 8597376. [Google Scholar] [CrossRef] [PubMed]

- Hamada, H.; Alattar, A.; Tayeh, B.; Yahaya, F.; Adesina, A. Sustainable application of coal bottom ash as fine aggregates in concrete: A comprehensive review. Case Stud. Constr. Mater. 2022, 16, e01109. [Google Scholar] [CrossRef]

- Karalar, M.; Bilir, T.; Çavuşlu, M.; Özkiliç, Y.O.; Sabri, M.M. Use of recycled coal bottom ash in reinforced concrete beams as replacement for aggregate. Front. Mater. 2022, 9, 1064604. [Google Scholar] [CrossRef]

- Casanova, S.; Silva, R.V.; de Brito, J.; Pereira, M.F.C. Mortars with alkali-activated municipal solid waste incinerator bottom ash and fine recycled aggregates. J. Clean. Prod. 2021, 289, 125707. [Google Scholar] [CrossRef]

- Aramraks, T. Experimental study of concrete mix with bottom ash as fine aggregate in Thailand. In Symposium on Infrastructure Development and the Environment; 2006; pp. 1–5. [Google Scholar]

- Aggarwal, P.; Aggarwal, Y.; Gupta, S.M. Effect of Bottom Ash as Replacement of Fine. Asian J. Civ. Eng. (Build. Hous.) 2007, 8, 49–62. [Google Scholar] [CrossRef]

- Raju, R.; Paul, M.M.; Aboobacker, K.A. Strength Performance of concrete using bottom ash as fine aggregate. Int. J. Res. Eng. Technol. 2014, 2, 111–112. [Google Scholar]

- Ramzihannan, N.; Shahidan, I.R.S.; Maarof, M.Z.; Ali, N. Physical and Chemical Properties of Coal Bottom Ash (CBA) from Tanjung Bin Power Plant. IOP Conf. Ser. Mater. Sci. Eng. 2016, 160, 12056. [Google Scholar]

- ASTM C150/C150M-21; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- ASTM C33/C33M-18; Standard Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2018. [CrossRef]

- ASTMC136/C136M-19; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C128-15; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2015. [CrossRef]

- ASTMC270-19a; Standard Specification for Mortar for Unit Masonry. ASTM International: West Conshohocken, PA, USA, 2019. [CrossRef]

- ASTM C305-20; Standard Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortar of Plastic Consistency. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- ASTM C511-21; Standard Specification for Mixing Roms, Moist Rooms, and Water Storage Tanks Used in the Testing of Hydraulic Cement and Concrete. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- ASTM C1437-20; Standard Test Method for Flow of Hydraulic Cement Mortar. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- ASTMC109-21; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50 mm] Cube Specimens). ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- ASTM C348-21; Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C642-13; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- ASTM C267-20; Standard Test Methods for Chemical Resistance of Mortars, Grouts, and Monolithic Surfacing’s and Polymer Concretes. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- ASTM E119-20; Standard Test Methods for Fire Tests of Building Construction and Materials. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- Bar, B.; Hoseinian, S.B.; Beygi, M.A. shrinkage of concrete stored in natural environments. Cem. Concr. Compos 2003, 25, 19–29. [Google Scholar] [CrossRef]

- ASTM C596-18; Standard Test Method for Drying Shrinkage of Mortar Containing Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2018.

- Ramachandran, V.S. Concrete Admixture Handbook: PROPERTIES, Science and Technology; William Andrew: Norwich, NY, USA, 1996. [Google Scholar]

- Daniel, D.G. Factors influencing concrete workability. In Significance of Tests and Properties of Concrete and Concrete-Making Materials; ASTM International: West Conshohocken, PA, USA, 2006. [Google Scholar]

- Jiang, X.; Xiao, R.; Ma, Y.; Zhang, M.; Bai, Y.; Huang, B. Influence of waste glass powder on the physico-mechanical properties and microstructures of fly ash-based geopolymer paste after exposure to high temperatures. Constr. Build. Mater. 2020, 262, 120579. [Google Scholar] [CrossRef]

- Torkittikul, P.; Nochaiya, T.; Wongkeo, W.; Chaipanich, A. Utilization of coal bottom ash to improve thermal insulation of construction material. J. Mater. Cycles Waste Manag. 2017, 19, 305–317. [Google Scholar] [CrossRef]

- Patel, D.; Shrivastava, R.; Tiwari, R.P.; Yadav, R.K. Properties of cement mortar in substitution with waste fine glass powder and environmental impact study. J. Build. Eng. 2020, 27, 100940. [Google Scholar] [CrossRef]

- Zhao, J.; Li, S. Study on processability, compressive strength, drying shrinkage and evolution mechanisms of microstructures of alkali-activated slag-glass powder cementitious material. Constr. Build. Mater. 2022, 344, 128196. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Y.; Su, Y.; He, X.; Strnadel, B. Preparation of waste glass powder by different grinding methods and its utilization in cement-based materials. Adv. Powder Technol. 2022, 33, 103690. [Google Scholar] [CrossRef]

- Chindasiriphan, P.; Meenyut, B.; Orasutthikul, S.; Jongvivatsakul, P.; Tangchirapat, W. Influences of high-volume coal bottom ash as cement and fine aggregate replacements on strength and heat evolution of eco-friendly high-strength concrete. J. Build. Eng. 2023, 65, 105791. [Google Scholar] [CrossRef]

- Nakararoj, N.; Tran, T.N.; Sukontasukkul, P.; Attachaiyawuth, A.; Tangchirapat, W.; Ban, C.C.; Rattanachu, P.; Jaturapitakkul, C. Effects of High-Volume bottom ash on Strength, Shrinkage, and creep of High-Strength recycled concrete aggregate. Constr. Build. Mater. 2022, 356, 129233. [Google Scholar] [CrossRef]

- Ganesan, H.; Sachdeva, A.; Petrounias, P.; Lampropoulou, P.; Sharma, P.K.; Kumar, A. Impact of Fine Slag Aggregates on the Final Durability of Coal Bottom Ash to Produce Sustainable Concrete. Sustainability 2023, 15, 6076. [Google Scholar] [CrossRef]

- ASTM C618-19; Standard Specification for Coal Fly and Raw or Calcined Natural Pozzolan for use in Concrete. ASTM International: West Conshohocken, PA, USA, 2019.

- Singh, A.; Zhou, Y.; Gupta, V.; Sharma, R. Sustainable use of different size fractions of municipal solid waste incinerator bottom ash and recycled fine aggregates in cement mortar. Case Stud. Constr. Mater. 2022, 17, e01434. [Google Scholar] [CrossRef]

- Aygörmez, Y. Sulfate and chloride resistance of bottom ASH doped slag-based geopolymer composites. Sigma 2023, 41, 288–301. [Google Scholar] [CrossRef]

- Mansour, M.A.; Ismail, M.H.B.; Imran Latif, Q.B.A.; Alshalif, A.F.; Milad, A.; Bargi, W.A.A. A systematic review of the concrete durability incorporating recycled glass. Sustainability 2023, 15, 3568. [Google Scholar] [CrossRef]

- Bai, Y.; Darcy, F.; Basheer, P.A. Strength and drying shrinkage properties of concrete containing furnace bottom ash as fine aggregate. Constr. Build. Mater. 2005, 19, 691–697. [Google Scholar] [CrossRef]

| Properties | Value |

|---|---|

| Specific gravity (SSD) | 2.66 |

| Moisture absorption (%) | 1.32 |

| Bulk density (Kg/m³) | 1728 |

| Loss bulk density (Kg/m³) | 1576 |

| Fineness modulus | 2.79 |

| Moisture content (%) | 0.1 |

| Nomenclature | Cement (%) | WGP (%) | CBA (%) |

|---|---|---|---|

| Control Mix | 100 | 0 | 0 |

| WGP 20%-CBA 0% | 80 | 20 | 0 |

| WGP 15%-CBA 5% | 80 | 15 | 5 |

| WGP 10%-CBA 10% | 80 | 10 | 10 |

| WGP 5%-CBA 15% | 80 | 5 | 5 |

| WGP 0%-CBA 20% | 80 | 0 | 20 |

| Mix ID | W/B | Cement (Kg/m³) | Sand (Kg/m³) | Water (Kg/m³) | GP (Kg/m³) | CBA (Kg/m³) | SP (Kg/m³) |

|---|---|---|---|---|---|---|---|

| CM | 0.35 | 684 | 1538 | 239 | 0 | 0 | 10.26 |

| WGP20-CBA 0 | 0.35 | 547.2 | 1538 | 239 | 136.8 | 0 | 10.26 |

| WGP15-CBA 5 | 0.35 | 547.2 | 1538 | 239 | 102.6 | 34.2 | 10.26 |

| WGP10-CBA10 | 0.35 | 547.2 | 1538 | 239 | 68.4 | 68.4 | 10.26 |

| WGP5-CBA 15 | 0.35 | 547.2 | 1538 | 239 | 34.2 | 102.6 | 10.26 |

| WGP0-CBA20 | 0.35 | 547.2 | 1538 | 239 | 0 | 136.8 | 10.26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Babajide Olabimtan, S.; Mosaberpanah, M.A. The Implementation of a Binary Blend of Waste Glass Powder and Coal Bottom Ash as a Partial Cement Replacement toward More Sustainable Mortar Production. Sustainability 2023, 15, 8776. https://doi.org/10.3390/su15118776

Babajide Olabimtan S, Mosaberpanah MA. The Implementation of a Binary Blend of Waste Glass Powder and Coal Bottom Ash as a Partial Cement Replacement toward More Sustainable Mortar Production. Sustainability. 2023; 15(11):8776. https://doi.org/10.3390/su15118776

Chicago/Turabian StyleBabajide Olabimtan, Stephen, and Mohammad Ali Mosaberpanah. 2023. "The Implementation of a Binary Blend of Waste Glass Powder and Coal Bottom Ash as a Partial Cement Replacement toward More Sustainable Mortar Production" Sustainability 15, no. 11: 8776. https://doi.org/10.3390/su15118776

APA StyleBabajide Olabimtan, S., & Mosaberpanah, M. A. (2023). The Implementation of a Binary Blend of Waste Glass Powder and Coal Bottom Ash as a Partial Cement Replacement toward More Sustainable Mortar Production. Sustainability, 15(11), 8776. https://doi.org/10.3390/su15118776