Investigating the Rheological Properties of Styrene-Butadiene-Styrene-Based High-Viscosity Modified Asphalt Using Carbon Nanotubes

Abstract

1. Introduction

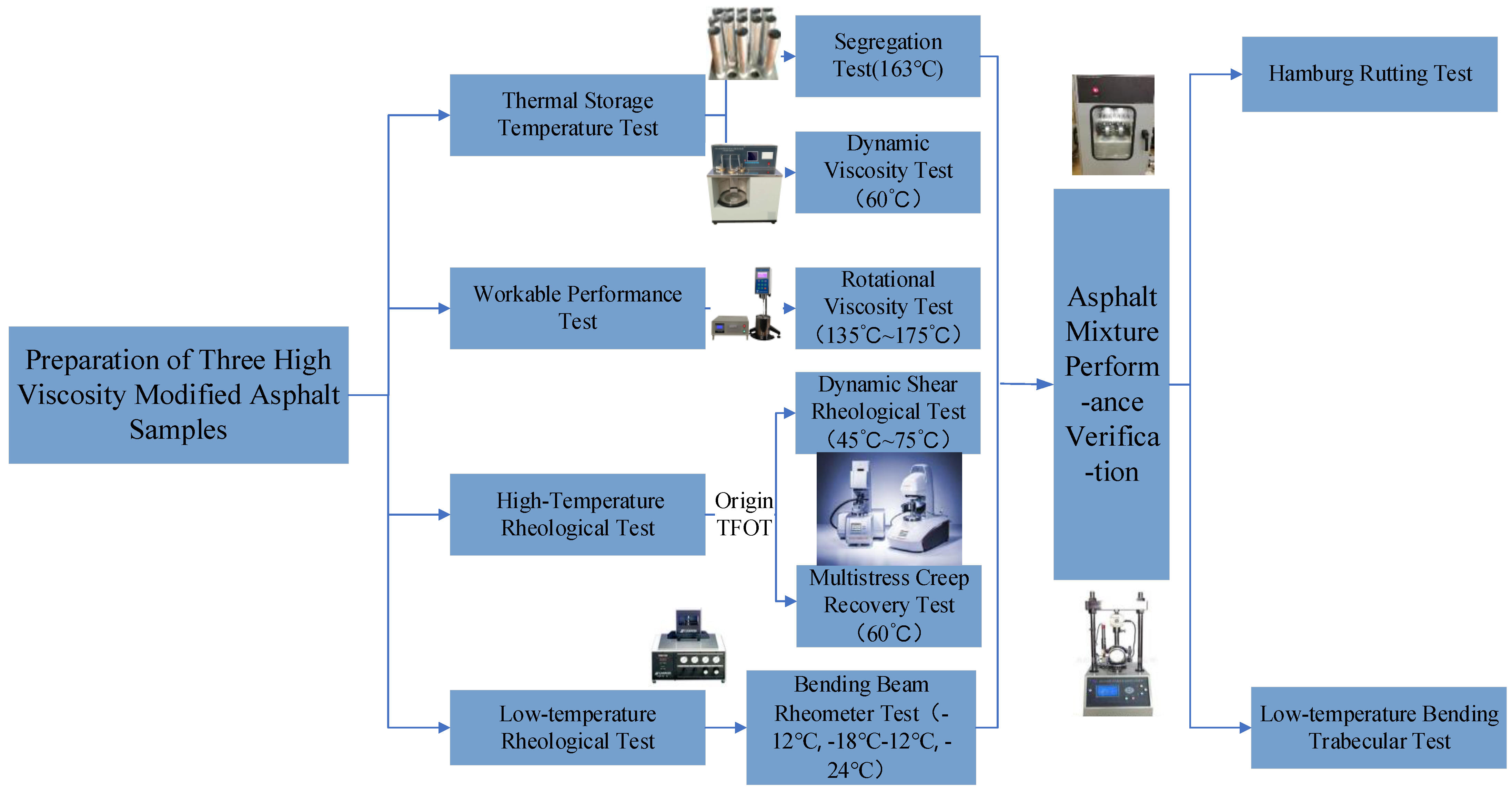

2. Materials and Methods

2.1. Raw Materials and Preparation of HVMA Samples

2.2. Thermal Storage Temperature Test

2.3. Workable Performance Test

2.4. High-Temperature Rheological Test

2.4.1. Frequency Sweep Test

2.4.2. High-Temperature Performance Test

2.5. Low-Temperature Rheological Test

2.6. Asphalt Mixture Performance Test

2.6.1. Hamburg Rutting Test

2.6.2. Low-Temperature Bending Beam Test

3. Results

3.1. Thermal Storage Temperature Test Result

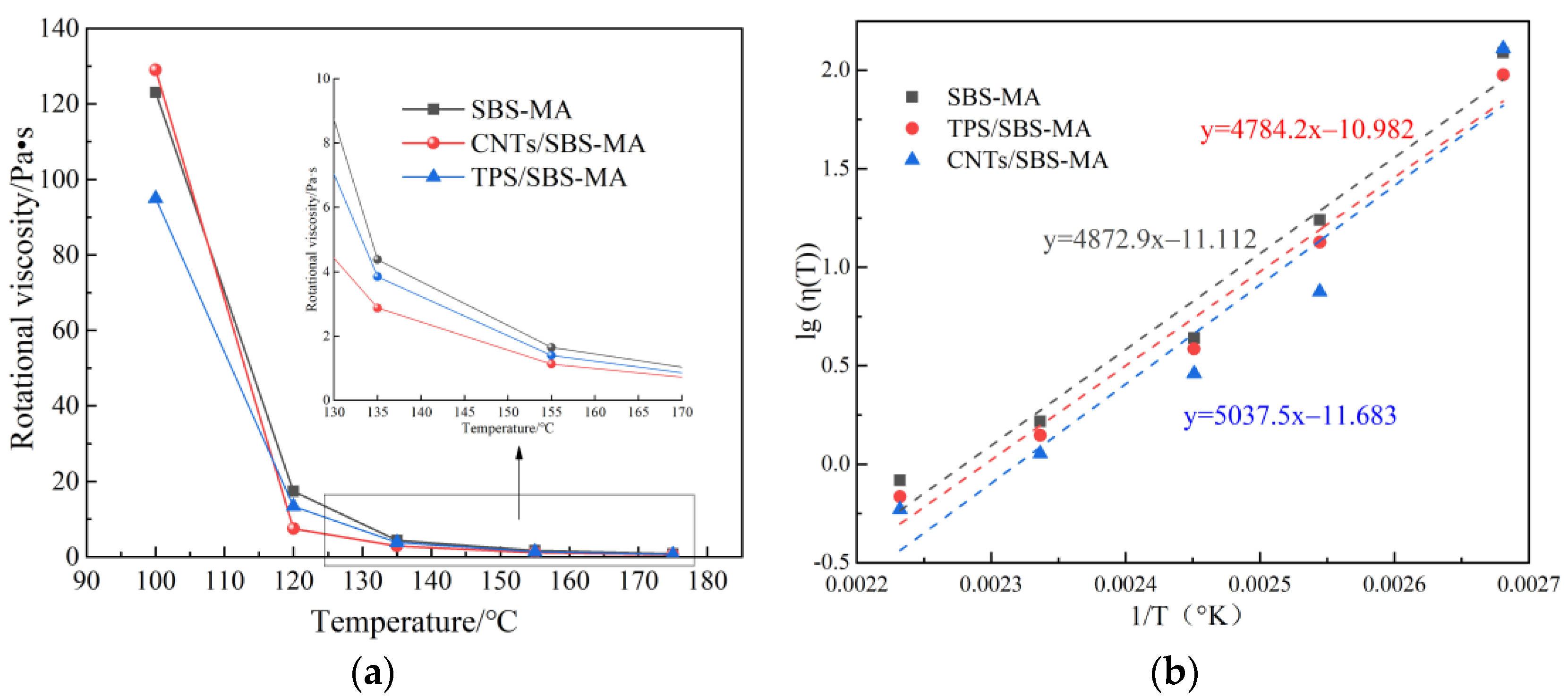

3.2. Workability Test Result

3.3. High-Temperature Rheological Test Result

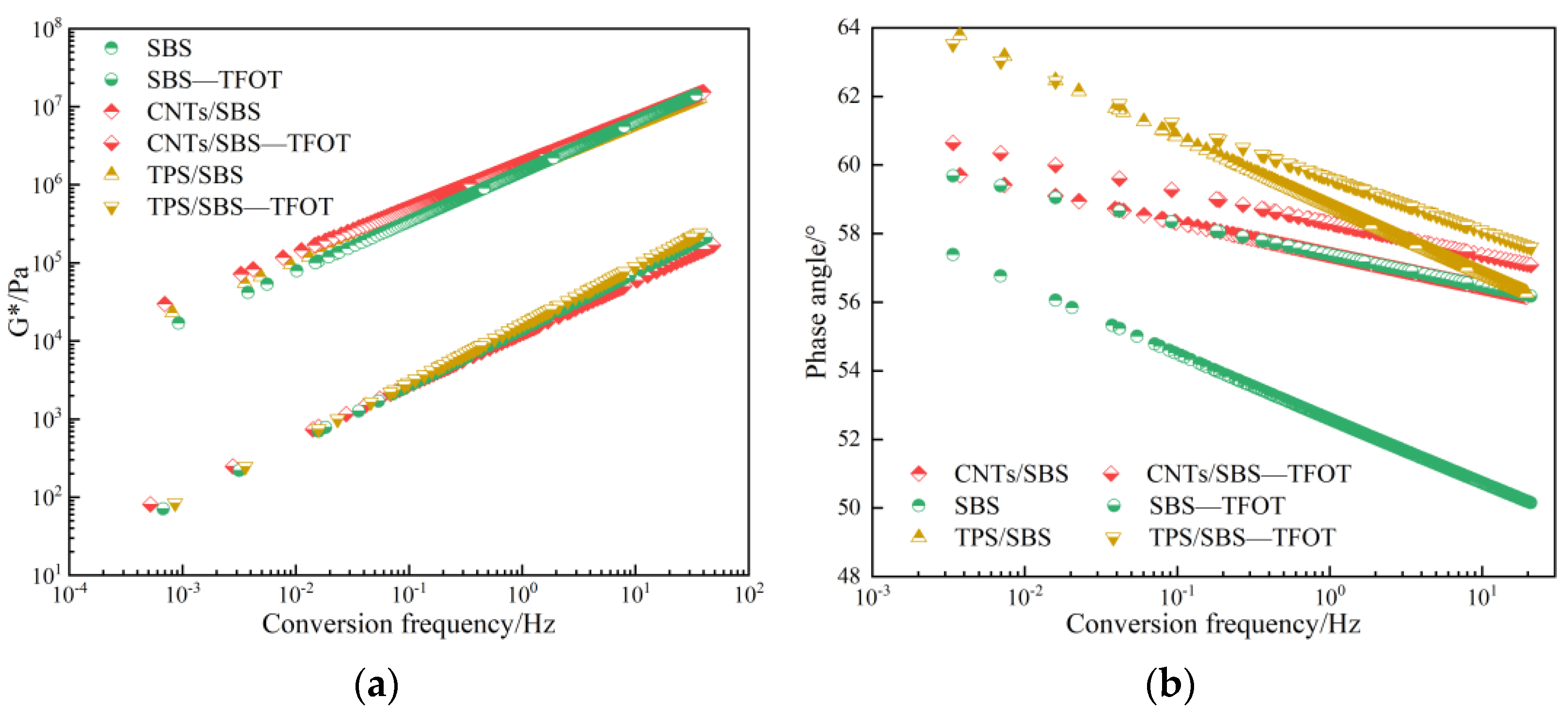

3.3.1. Frequency Sweep Experiment

3.3.2. High-Temperature Performance

3.4. Low-Temperature Rheological Test Result

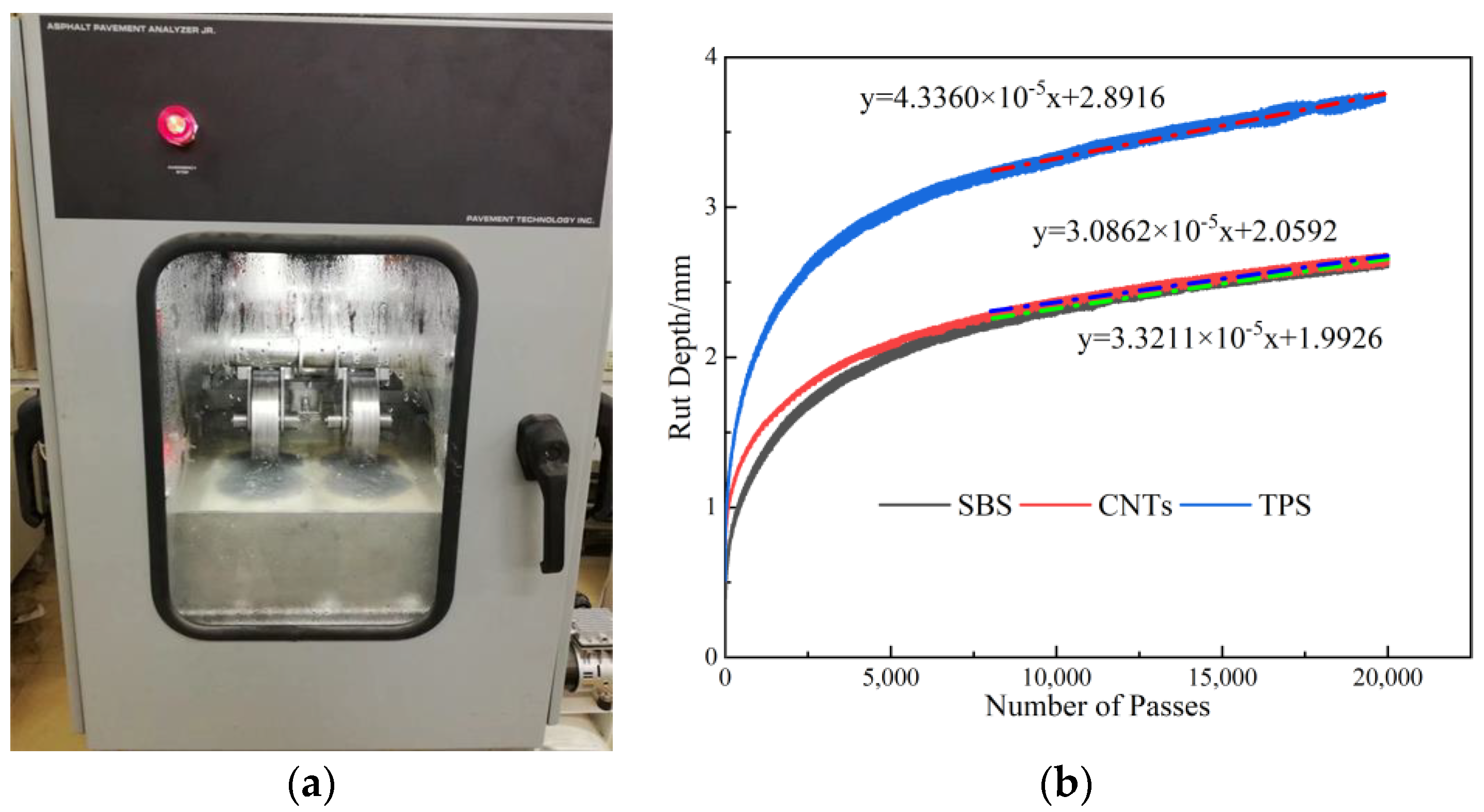

3.5. Asphalt Mixture Performance Test Result

4. Conclusions

- (1)

- The analysis of the segregation softening point and viscosity test revealed that CNTs/SBS-HVMA had higher storage stability and better workability than the other two asphalts.

- (2)

- DSR frequency sweep and MSCR tests revealed that CNT addition improved the anti-aging performance of SBS-HVMA, played a short fiber reinforcement role between the asphalt and the SBS, increased the bond strength of the asphalt system, and enhanced the high-temperature deformation resistance of the asphalt.

- (3)

- BBR and low-temperature trabecular bending rheological tests revealed that CNT addition had little effect on the low-temperature properties and improved the high-temperature properties of the asphalt. The asphalt and asphalt mixture still exhibited good low-temperature crack resistance.

- (4)

- The Hamburg rutting test revealed that the high-temperature rutting resistance of CNTs/SBS-HVMA was 7% and 28%, respectively, higher than those of SBS-HVVMA and TPS/SBS-HVMA, respectively. This shows that CNT addition improved the high-temperature performance of the asphalt mixture while reducing the amount of modifier in SBS-HVMA.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kiselev, A.; Zhang, H.; Liu, Z. The effect of two-phase mixing on the functional and mechanical properties of TPS/SBS-modified porous asphalt concrete. Constr. Build. Mater. 2021, 270, 121841. [Google Scholar] [CrossRef]

- Chen, M.; Geng, J.; Xia, C.; He, L.; Liu, Z. A review of phase structure of SBS modified asphalt: Affecting factors, analytical methods, phase models and improvements. Constr. Build. Mater. 2021, 294, 123610. [Google Scholar] [CrossRef]

- Wen, G.; Zhang, Y.; Zhang, Y.; Sun, K.; Fan, Y. Rheological characterization of storage stable SBS-modified asphalts. Polym. Test. 2002, 21, 295–302. [Google Scholar] [CrossRef]

- Lu, X.; Isacsson, U. Rheological characterization of styrene-butadiene-styrene copolymer modified bitumens. Constr. Build. Mater. 1997, 11, 23–32. [Google Scholar] [CrossRef]

- Fawcett, A.; McNally, T. Polystyrene and asphaltene micelles within blends with a bitumen of an SBS block copolymer and styrene and butadiene homopolymers. Colloid Polym. Sci. 2003, 281, 203–213. [Google Scholar] [CrossRef]

- Zhai, F.; Feng, Y.; Li, Z.; Xie, Y.; Ge, J.; Wang, H.; Qiu, W.; Feng, W. 4D Printed untethered self-propelling soft robot with tactile perception: Rolling, racing, and exploring. Matter 2021, 4, 3313–3326. [Google Scholar] [CrossRef]

- Li, Y.; Tan, Y.; Meng, L. Application study on high modulus asphalt concrete in bridge pavement. Adv. Mater. Res. 2011, 243–249, 4244–4247. [Google Scholar] [CrossRef]

- Jiao, Y.; Zhang, Y.; Fu, L.; Guo, M.; Zhang, L. Influence of crumb rubber and tafpack super on performances of SBS modified porous asphalt mixtures. Road Mater. Pavement Des. 2019, 20, S196–S216. [Google Scholar] [CrossRef]

- Shuo, G.; Yuzhi, L.; Ping, Z. Research on road performance of SBS and TPS composite modified asphalt mixture. Sino-Foreign Highw. 2013, 33, 216–218. [Google Scholar]

- Zhang, F.; Hu, C. Preparation and properties of high viscosity modified asphalt. Polym. Compos. 2017, 38, 936–946. [Google Scholar] [CrossRef]

- Liang, M.; Xin, X.; Fan, W.; Wang, H.; Ren, S.; Shi, J. Effects of polymerized sulfur on rheological properties, morphology and stability of SBS modified asphalt. Constr. Build. Mater. 2017, 150, 860–871. [Google Scholar] [CrossRef]

- Zani, L.; Giustozzi, F.; Harvey, J. Effect of storage stability on chemical and rheological properties of polymer-modified asphalt binders for road pavement construction. Constr. Build. Mater. 2017, 145, 326–335. [Google Scholar] [CrossRef]

- Qu, L.; Gao, Y.; Yao, H.; Cao, D.; Pei, G.; He, B.; Duan, K.; Zhou, W. Preparation and Performance Analysis of High-Viscosity and Elastic Recovery Modified Asphalt Binder. Adv. Civ. Eng. 2019, 2019, 6070685. [Google Scholar] [CrossRef]

- Shi, J.; Zhao, P.; Fan, W.; Yang, Z.; Lin, Y.; Ouyang, J. Facile preparation and application performance evaluation of SBS/C9 petroleum resin blends as modifier for high viscosity asphalt. Constr. Build. Mater. 2020, 262, 120073. [Google Scholar] [CrossRef]

- Goli, A.; Ziari, H.; Amini, A. Influence of carbon nanotubes on performance properties and storage stability of SBS modified asphalt binders. J. Mater. Civ. Eng. 2017, 29, 04017070. [Google Scholar] [CrossRef]

- Wang, P.; Dong, Z.J.; Tan, Y.Q.; Liu, Z.Y. Effect of multi-walled carbon nanotubes on the performance of styrene–butadiene–styrene copolymer modified asphalt. Mater. Struct. 2017, 50, 17. [Google Scholar] [CrossRef]

- Tsantilis, L.; Dalmazzo, D.; Baglieri, O.; Santagata, E. Effect of SBS molecular structure on the rheological properties of ternary nanomodified bituminous binders. Constr. Build. Mater. 2019, 222, 183–192. [Google Scholar] [CrossRef]

- Xin, X.; Yao, Z.; Shi, J.; Liang, M.; Jiang, H.; Zhang, J.; Zhang, X.; Yao, K. Rheological properties, microstructure and aging resistance of asphalt modified with CNTs/PE composites. Constr. Build. Mater. 2020, 262, 120100. [Google Scholar] [CrossRef]

- Zhai, F.; Feng, Y.; Zhou, K.; Wang, L.; Zheng, Z.; Feng, W. Graphene-based chiral liquid crystal materials for optical applications. J. Mater. Chem. C 2018, 7, 2146–2171. [Google Scholar] [CrossRef]

- Wang, R.; Yue, M.; Xiong, Y.; Yue, J. Experimental study on mechanism, aging, rheology and fatigue performance of carbon nanomaterial/SBS-modified asphalt binders. Constr. Build. Mater. 2021, 268, 121189. [Google Scholar] [CrossRef]

- Ashish, P.K.; Singh, D. High- and Intermediate-Temperature Performance of Asphalt Binder Containing Carbon Nanotube Using Different Rheological Approaches. J. Mater. Civ. Eng. 2017, 30, 04017254. [Google Scholar] [CrossRef]

- Ziari, H.; Farahani, H.; Goli, A.; Galooyak, S.S. The investigation of the impact of carbon nano tube on bitumen and HMA performance. Pet. Sci. Technol. 2014, 32, 2102–2108. [Google Scholar] [CrossRef]

- Ziari, H.; Rahim-of, K.; Fazilati, M.; Goli, A.; Farahani, H. Evaluation of different conditions on the mixing bitumen and carbon nano-tube. Int. J. Civ. Environ. Eng. 2012, 12, 12–53. [Google Scholar]

- Amirkhanian, A.N.; Xiao, F.; Amirkhanian, S.N. Evaluation of high temperature rheological characteristics of asphalt binder with carbon nano particles. J. Test. Eval. 2010, 39, 1–9. [Google Scholar]

- Amirkhanian, A.N.; Xiao, F.; Amirkhanian, S.N. Characterization of unaged asphalt binder modified with carbon nano particles. Int. J. Pavement Res. Technol. 2011, 4, 281–286. [Google Scholar]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- Zhang, D.; Birgisson, B.; Luo, X.; Onifade, I. A new short-term aging model for asphalt binders based on rheological activation energy. Mater. Struct. 2019, 52, 68. [Google Scholar] [CrossRef]

- Hasan, M.R.M.; You, Z.; Yang, X.; Heiden, P.A. Quantification of physicochemical properties, activation energy, and temperature susceptibility of foamed asphalt binders. Constr. Build. Mater. 2017, 153, 557–568. [Google Scholar] [CrossRef]

- Sun, D.; Lin, T.; Zhu, X.; Cao, L. Calculation and evaluation of activation energy as a self-healing indication of asphalt mastic. Constr. Build. Mater. 2015, 95, 431–436. [Google Scholar] [CrossRef]

- Wang, T.; Lin, J.T.; Pang, L.; Lei, M.; Jenkins, K.; Wu, S.P. Study on the Viscoelastic Performance of Asphalt Mixture Based on Dynamic Modulus. Adv. Mater. Res. 2013, 753–755, 728–733. [Google Scholar] [CrossRef]

- Yang, P.; Cui, H.Z.; Wang, W.L. Visco-Elasticity of Asphalt Mixture under Broad Temperature and Frequency. Adv. Mater. Res. 2013, 838–841, 156–161. [Google Scholar] [CrossRef]

- Haq, M.; Ahmad, N.; Nasir, M.A.; Hafeez, M.; Rafi, J.; Zaidi, S.B.A.; Haroon, W. Carbon Nanotubes (CNTs) in Asphalt Binder: Homogeneous Dispersion and Performance Enhancement. Appl. Sci. 2018, 8, 2651. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, A.; Zhang, W.; Zhang, Y. Research on high temperature performance of asphalt pavement on in-service expressway based on Hamburg rutting test. Zhongwai Highw. 2020, 40, 68–72. [Google Scholar]

- Qiao, X.B.; Li, X.M.; Wei, D.B. Research on Rubber/SBS Modified Asphalt by MSCR Test. Adv. Mater. Res. 2012, 557–559, 1066–1069. [Google Scholar] [CrossRef]

- Ma, L.J.; Chen, H.B.; Zhang, J.Y. Research on Crack Resistance Evaluation of Asphalt Mixture at Low Temperature. Adv. Mater. Res. 2013, 753–755, 668–672. [Google Scholar] [CrossRef]

- Yang, L.Y.; Tan, Y.Q.; Dong, Y.M.; Li, E.G. Rutting Resistance Property of Warm Recycled Asphalt Mixture. Appl. Mech. Mater. 2012, 204–208, 3749–3753. [Google Scholar] [CrossRef]

| Index | Test Result | Technical Requirement |

|---|---|---|

| Penetration (25 °C, 100 g, 5 s), 0.1 mm | 75.6 | 60–80 |

| Penetration Index | −1.25 | −1.5–+1.0 |

| Softening point, °C | 46.5 | ≥46 |

| Ductility (10 °C), cm | 55 | ≥20 |

| Dynamic viscosity (60 °C), Pa·s | 204 | ≥180 |

| Index | SBS-HVMA | TPS/SBS-HVMA | CNTs/SBS-HVMA |

|---|---|---|---|

| Penetration (25 °C, 100 g, 5 s), 0.1 mm | 42.5 | 48.3 | 45.5 |

| Softening point, °C | 92.8 | 90.3 | 93.4 |

| Ductility, cm | 28.4 | 36 | 28.8 |

| Dynamic viscosity (60 °C), Pa·s | 134,500 | 108,000 | 160,000 |

| Sieve Size (mm) | Passing Percentage of Each Sieve Hole (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | |

| Composite gradation | 100 | 93.8 | 62.5 | 29.7 | 19.1 | 16.1 | 14.2 | 12.9 | 11.2 | 9.9 |

| SMA specification grading upper limit | 100 | 100 | 75.0 | 34.0 | 26.0 | 24.0 | 20.0 | 16.0 | 15.0 | 12.0 |

| SMA specification grading lower limit | 100 | 90.0 | 50.0 | 20.0 | 15.0 | 14.0 | 12.0 | 10.0 | 9.0 | 8.0 |

| SMA norm gradation median | 100 | 95.0 | 62.5 | 27.0 | 20.5 | 19.0 | 16.0 | 13.0 | 12.0 | 10.0 |

| Asphalt Type | Fit Equation | R2 | Activation Energy E/(kJ/mol) | Lg A | A |

|---|---|---|---|---|---|

| SBS-HVMA | y = 4872.9x − 11.112 | 0.972 | 93.302 | −11.112 | 1.493 × 10−5 |

| TPS/SBS-HVMA | y = 4784.2x − 10.982 | 0.976 | 91.604 | −10.982 | 1.701 × 10−5 |

| CNTs/SBS-HVMA | y = 5037.5x − 11.683 | 0.929 | 96.454 | −11.683 | 8.437 × 10−6 |

| Types of Asphalt Mixtures | Maximum Rut Depth/mm | Creep Slope |

|---|---|---|

| SBS-HVMA | 2.674 | 3.3211 × 10−5 |

| CNTs/SBS-HVMA | 2.687 | 3.0862 × 10−5 |

| TPS/SBS-HVMA | 3.768 | 4.3360 × 10−5 |

| Types of Asphalt Mixtures | Flexural Tensile Strength RB/MPa | Failure Strain εB/με | Bending Stiffness Modulus SB/MPa |

|---|---|---|---|

| SBS-HVMA | 8.065 | 3714.4 | 2171.4 |

| CNTs/SBS-HVMA | 8.092 | 3517.5 | 2300.5 |

| TPS/SBS-HVMA | 10.527 | 4646.3 | 2265.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Huang, Z.; Wang, H.; Yang, Z.; Zhang, T. Investigating the Rheological Properties of Styrene-Butadiene-Styrene-Based High-Viscosity Modified Asphalt Using Carbon Nanotubes. Sustainability 2023, 15, 71. https://doi.org/10.3390/su15010071

Chen J, Huang Z, Wang H, Yang Z, Zhang T. Investigating the Rheological Properties of Styrene-Butadiene-Styrene-Based High-Viscosity Modified Asphalt Using Carbon Nanotubes. Sustainability. 2023; 15(1):71. https://doi.org/10.3390/su15010071

Chicago/Turabian StyleChen, Jiangcai, Zhenfu Huang, Haipeng Wang, Zhenxing Yang, and Tao Zhang. 2023. "Investigating the Rheological Properties of Styrene-Butadiene-Styrene-Based High-Viscosity Modified Asphalt Using Carbon Nanotubes" Sustainability 15, no. 1: 71. https://doi.org/10.3390/su15010071

APA StyleChen, J., Huang, Z., Wang, H., Yang, Z., & Zhang, T. (2023). Investigating the Rheological Properties of Styrene-Butadiene-Styrene-Based High-Viscosity Modified Asphalt Using Carbon Nanotubes. Sustainability, 15(1), 71. https://doi.org/10.3390/su15010071