Abstract

Research and implementation efforts and investment in the circular economy are rising sharply. With the high stakes associated with achievements in the field, an increasing emphasis on evaluation, transparency and accountability are to be expected. All require high-quality data, methodologies and tools that are able to improve results and to assess and document the implementation processes and outcomes. A challenging key issue in the implementation of a circular economy is ensuring coordination, control and transparency within a network of parties. Traceability models and systems are vital pillars of such an endeavor, but a preliminary search of the available literature revealed a rather unstable and fragmented research field and practice. The objective of this systematic review was to examine those studies discussing traceability models and traceability systems while connecting traceability capacities and outputs to implement the principles of the circular economy. The literature databases were searched on 6 January 2020, with an update for the entire year of 2020. Overall, 49 studies were included. By addressing eight specific research questions, we found that a link between traceability and the circular economy is yet to be established. Sound research and practice documentation are required to establish evidence regarding this connection, including methodologies that are able to support the design and implementation of business- and lifecycle-oriented, value-based traceability models and traceability systems, along with thorough evaluation methods and tools incorporating economic, social and environmental perspectives.

1. Introduction

The circular economy (CE) has been proposed as an approach to an economic system aimed at making the most of the resources we use and minimizing waste [1,2]. The transition to a circular economy has gained prominence on the agendas of policymakers, researchers and practitioners [3,4,5,6] since it is expected to guide society toward the efficient use of resources and to the dissociation of economic growth from environmental impacts [4,7].

However, closing the loop and achieving circularity while assuring social wealth, productivity and economic growth may prove challenging [8,9]. Given the expected and unprecedented requirements in collaboration, communication, coordination and control [10,11] within a network of involved parties, tracking and tracing capabilities will be in high demand.

Traceability has been defined as the ability to identify and trace the history, distribution, location and application of products, parts, materials and services [12]. A traceability system (TS) would record and allow us to follow the trail of production, as products, parts, materials and services originate from suppliers and are processed and ultimately distributed as final products and services [13]. A TS should support both tracking and tracing [14] and span the boundaries of a single entity, allowing for both internal and external traceability [15]. To be able to trace and identify an item in any system, a traceable resource unit [16,17], or similar concept, must be defined.

The dimensions, components and capabilities of a traceability model (TM) and TS are determined by contextual and industry-specific issues, regulatory recommendations and enforcement, along with the many needs and expectations of different stakeholders. The recent ISO standard, BS 8001 [18], is the first to address the understanding and implementation of a CE at an organizational level. The principles needed to achieve a CE are systems-oriented thinking, stewardship, transparency, collaboration, innovation and value optimization, and while the standard does integrate them into business process development, organizations are given full responsibility for choosing CE performance indicators, both internally and for communicating progress to stakeholders [19]. Moreover, the link between a CE, sustainability, social risks and ethical responsibility needs clarification and specific guidance is missing regarding the quantitative assessment of CE performance [19]. The Ellen MacArthur Foundation has already developed indicators that assess the performance of a company or a product in the context of a CE [20]. More recently, a dashboard for selecting core indicators for the quantitative assessment of CE strategies for organizations and product systems was proposed [19]. Indicators can be used to guide and enable the work of different participants, for example, as decision-making tools in design and procurement, internal and external reports, business evaluation and rating, policy development and research [20,21,22].

In realistic terms, it is not feasible to develop advanced TSs that are intended to span organizational and sectoral boundaries in increasingly data- and information-driven and highly knowledge-intensive contexts without using information and communication technologies. Technology is necessary for the identification and characterization of products and processes, along with the capture, analysis, storage and transmission of data and information, as well as for the overall integration and validation of the system [23].

On the one hand, TSs are fundamental, as are TMs that are able to guide and support their development, deployment and evolution. On the other hand, consistency in terms of approach is a key prerequisite for quality in research and implementation efforts and of the subsequent results, particularly those involving system modeling and integration, commanding the use of ontologies able to capture and ensure a common understanding and an explicit formal specification of the terms used in a domain and the relationships among them [24].

Previous work on TMs, TSs and a CE revealed a rather amorphous field of research, even with regard to the shared understanding of key concepts within the same industry, where several definitions of traceability and its classifications, coming from organizations, legislation and research literature, may be found [25]. One review [26] focuses on the origins, principles, advantages and disadvantages, modeling and implementation of a CE at different levels, without addressing traceability or tracking. A recent systematic review on supply chain management in global supply chains (GSC) [27] addresses GSC configurations, governance mechanisms and the dimensions of sustainability outcomes, but not traceability. A strand of research on the life-cycle assessment (LCA) component of products [28] highlights the pressing need for a socio-economic LCA methodology, including indicators, allowing to complement the more traditional vision of the production, use and disposal of products.

A limited search of available literature revealed that there are currently no systematic reviews on TMs or TSs that are able to support a circular, life-cycle perspective of product design, use and disposal toward a transition to a CE. Therefore, a systematic review (SR) was deemed necessary to identify and review those proposals and implementations of TMs and TSs that would promote and support the transition to a CE.

2. Research Questions

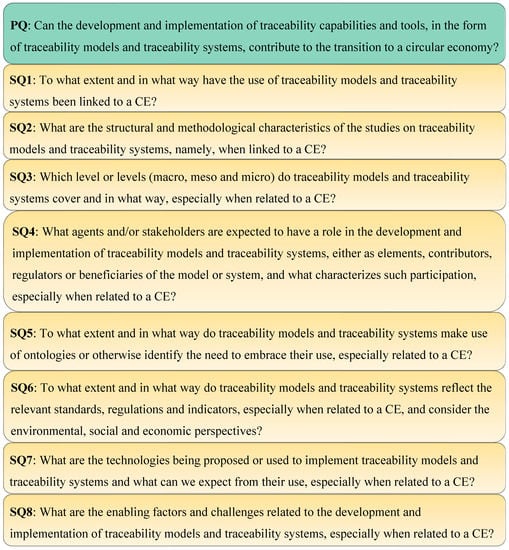

We set a primary question (PQ) and eight secondary questions (SQ) to guide the development of this SR (Figure 1).

Figure 1.

The primary question (PQ) and secondary questions (SQ) of the SR.

3. Eligibility Criteria

The SR included studies where the population consists of traceable entities (e.g., specifications, products, packaging, processes). Traceable entities could be expressed differently depending on the context addressed, the objective sought and the disciplinary perspective of the study.

The SR encompassed studies proposing or assessing TMs and studies conceptualizing, discussing the implementation, or assessing the TSs or components of TSs: (1) broadly presented as a means to support the implementation of the principles of a CE; (2) narrowly presented as a means to improve those issues revolving around the modeling, registration, retrieval, and general management of data and information on traceable entities, with an explicit or implicit mention of a contribution to the principles of a CE. Comparators would consist of other traditional approaches, including frameworks or technological advances that proposed to improve aspects such as collaboration, coordination and transparency in supply chains, intra- or inter- organizations, or performance, such as in safety, quality, sustainability, or circularity-related initiatives, but where traceability may not be considered as essential to the aspects being addressed as outcomes of the intervention.

The SR included studies on TMs and TSs independent of the implementation industry/context, namely: (1) studies addressing the micro, the meso- and the macro-levels [29], along with studies dealing with different layers and different variable types; (2) studies identifying contextual drivers of and barriers to the implementation of TMs and TSs, especially when discussing an impact on the implementation of a CE.

Outcomes sought included: (1) contributions to the implementation of a CE, either as declared by the authors or identified by the reviewers, based on the relevant literature [18,19,20]; (2) contributions to the characteristics of data and information on traceable entities—e.g., accuracy, objectivity, relevance, accessibility, richness, timeliness, authorship, verifiability, scalability.

Furthermore, the SR included all types of studies, namely, quantitative and qualitative research, conceptual and empirical studies; it set no time or industry limitations; it also considered publications made in English, Portuguese, Spanish, Italian and French. Moreover, the SR excluded those literature reviews, systematic reviews and studies that did not meet research and professional standards. Finally, the review did not include basic research on technology and process innovation that was disconnected from industry applications.

4. Methods

A population, intervention, comparator, context and outcome (PICCO) framework was used to develop and combine subject headings and keywords, to help with screening and selecting the studies and analyzing, synthesizing and reporting the results. A protocol that was compliant with PRISMA-P (Preferred Reporting Items for Systematic Reviews and Meta-Analysis Protocols) was developed a priori [30]. PRISMA was used to report the SR [31]. The PRISMA 2020 Checklist as well as the PRISMA 2020 for Abstracts Checklist can be found, respectively, in Tables S1 and S2, located in the Supplementary materials.

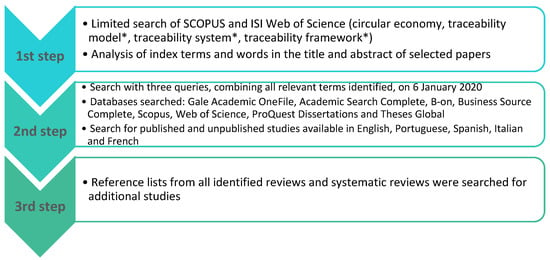

A three-step search strategy was followed, aiming to find both published and unpublished studies (Figure 2). Three queries were finally established for the SR, allowing us to capture studies addressing the primary themes (the circular economy, track and trace, traceability tools, traceability methods) and extending the search to concepts closely related or tantamount to CEs that were in use before the current surge of interest in this topic (reduce, reuse, recycle, circularity, upcycling), as well as to the field of ontologies, when related to the circular economy and industrial symbiosis (see Appendix A for the full queries).

Figure 2.

Three-step search strategy used in the SR.

The selection process evolved in two phases. In the screening phase, the titles and abstracts of all identified studies were screened by two reviewers. In the eligibility phase, the retained studies were assessed by two reviewers through full-text reading. A discussion was conducted to resolve disagreements. Rayyan QCRI [32] was used to help manage the review process.

Data of significance to the primary and the secondary questions and the study methods were collated by two independent reviewers. The extraction forms were validated by the review team prior to utilization, to ensure acceptability and study validity.

It was anticipated that a significant part of the included studies would be descriptive and qualitative in nature and that those studies reporting on results from implementations would be based on observational data. Therefore, the direct applicability of standardized tools for the assessment of methodological validity of studies considered for inclusion in systematic reviews and meta-syntheses was expected to be low; consequently, a custom-made framework based on a multi-dimensional concept of quality in research was used to examine the quality of any studies under consideration.

A narrative synthesis oriented to answering the primary and the secondary questions of the SR was carried out. In the face of the high volume of data extracted, additional consensual categories within the group of reviewers, not previewed in the protocol, were introduced to help synthesize and take meaning from the results. In this phase, no filtering of the primary studies involving the application of additional exclusion criteria was conducted.

5. Results

5.1. Study Selection

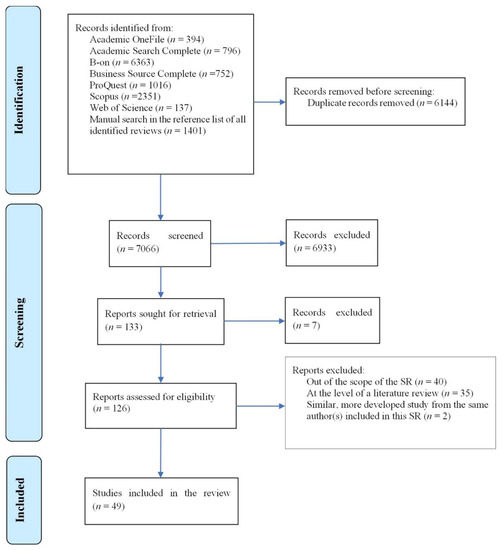

The results of the search and selection processes are presented in Figure 3. A total of 13,210 potentially relevant articles were identified in the literature search, which was conducted on 6 January 2020. Of those, 6144 were duplicates. From the remaining 7066 records, 6933 were excluded after the title and abstract assessments. Subsequently, 84 were excluded after full-text analysis as they did not meet the inclusion criteria, or did not comply with the quality requirements. The remaining 49 studies entered the data collection phase. By the time we began drafting the report, a search update had been conducted for the entire year of 2020 and three additional studies were brought to the discussion.

Figure 3.

PRISMA flow diagram of the study selection and inclusion processes.

The complete extraction tables are available from the authors.

5.2. General Characteristics of the Included Studies

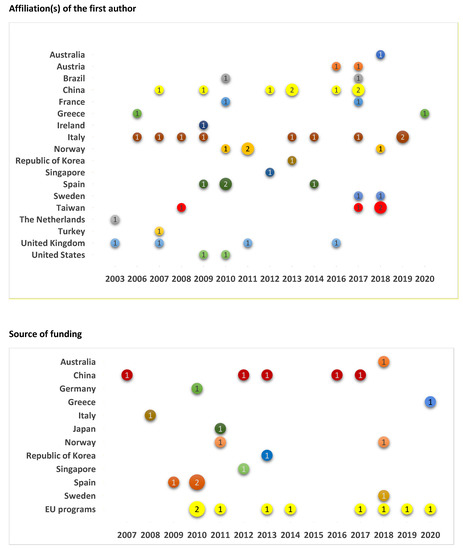

Description data on the general characteristics of all the included studies and study numbers within the SR are presented in Table 1. Dates of publication ranged from 2003 to 2020 and all studies were published in English. When assessed according to the affiliation(s) of the first author, thirty studies were conducted in Europe, fifteen in Asia, four in the US, and one in Oceania. Twenty-three studies declared a source of funding, namely: nine were funded, at least in part, by a European Union (EU) entity or program; eighteen were funded by a national public body, complemented in some cases by other support. Table 1 and Figure 4 provide information on the study characteristics, including author(s), title, country of study and source of funding.

Table 1.

Study characteristics.

Figure 4.

A view showing the country of study and source of funding of all the included studies, arranged by year.

5.3. Methodological Options of the Included Studies

Only five of the included studies stated the research questions explicitly, and always in a very generic way. Eighteen studies described a methodology, research design/methods or approach outline. For many of the other studies, it was possible to elicit steps or phases from the way in which the authors described their work. Only in three studies was there a clear mention of recognizable research methods covering the entire study: design research [55], “design research method, case study, emulation experiment method, and cost-benefit analysis” [56] (p. 96), and trials [66].

Regarding the main areas of research, as declared by the authors or collected by the reviewers from the study introduction/background, it was possible to classify the studies according to eleven main themes (Table 2).

Table 2.

Main areas of research of all included studies.

Twenty studies were classified as reporting on traceability models (TMs) or modeling traceability and thirty-one were classified as reporting on traceability systems (TSs) or the components of traceability systems (Table 3). Two studies [38,48] were classified as belonging to both groups, based on the information available in the studies.

Table 3.

Classification of the included studies.

Stages documented in the studies on traceability systems included conceptual work, design proposals, technology development, implementation and evaluation; in a number of cases, this is evaluated through simulation (Table 4).

Table 4.

Developmental stages reported by the studies on traceability systems.

5.4. Traceable Entities

Most of the studies did not define, were unclear, or were rather vague in the way that they reported on traceable entities (Table 5). Within the group of studies reporting on TMs, only two studies clearly identified traceable artifacts (in SW product lines) [38] and product knowledge during design and manufacturing phases [75] as the entities to be traced, and only four studies accounted for the different granularity or different nature of the entity to be tracked/traced along the production process [59] or supply chain [45,62,64]. Within the group of studies reporting on TSs, only eight studies explicitly approached the concept, and two studies went further by accounting for different granularity or the different natures of the entities to be tracked/traced along the supply chain [44] or the production process [50].

Table 5.

Traceable entities/units, as addressed by the included studies.

5.5. Interventions as Proposals on Traceability Models and Traceability Systems

5.5.1. Studies on Traceability Models or Modeling Traceability

Content and Dimensions of the Interventions

From the twenty studies in this group, five developed some sort of data/information model, eight modeled traceability infrastructures, frameworks, or frameworks with tracking capabilities, three developed modeling methodologies or models for information analysis and management in supply chains, two developed ontologies for supporting traceability, one was dedicated to modeling closed-loop product information tracking and feedback, and one discussed a methodology for managing the relevant aspects specific to traceability (Table 6).

Table 6.

Intervention within studies reporting on traceability models or modeling traceability.

All the studies in this group mentioned actors in the process or stakeholders of the overall effort and intended results, most of the time giving scant detail (Table 7).

Table 7.

Actors or stakeholders mentioned when developing traceability models or modeling traceability.

None of the studies in this group addressed the costs of the intervention or measures of workload, such as the time required to deploy the intervention.

Requirements

Nine of the studies in this group addressed the requirements and criteria for design and implementation while developing their proposals, most of the time giving scant detail: user requirements and basic requirements [36], framework requirements [38], traceability requirements using use-case diagrams [45,52], industry-related basic requirements from case studies such as the registration of lot numbers consumed by production and the registration of process variables on batch level [59], legal requirements [60], (non-functional) requirements that are loosely defined [67], criteria for the implementation of chain traceability [69], and information model requirements [73]. A study considered that basic chain traceability requirements were directly covered by EPCIS Events [58], another followed the TraceFood Framework developed during another project [62].

Standards and Regulations

Only nine of the twenty studies in this group reported having brought international and global initiatives and systems, regulations and standards to their research (Table 8).

Table 8.

International initiatives, regulations and standards mentioned or used when developing traceability models or modeling traceability.

Ontologies

The development of new ontologies for the food traceability domain was focal in two studies, the Food Track and Trace ontology (FTTO) [51], and the MESCO ontology [60]. A study developed an IoT-aware ontology concept model (IoTCM) and a “prototypical ontology” (OBLTP) as part of IoT system modeling [55] (p. 73). Another study employed the Bunge–Wand–Weber (BWW) ontology to formalize a holon [75]. Two studies acknowledged the need for more research in this area, given that the lack of standardized semantics or a common framework to share information is one of the major barriers to sharing information [45] and that generic ontologies are not directly usable in the traceability domain, because they do not contain domain-specific concept definitions [64]. The use of appropriate ontologies to permit automated reasoning [63] and for achieving effective universal data exchange [58] was also discussed.

Technologies

Methods and tools for information and knowledge modeling, classification, standardization, processes and business modeling, software and systems development, connection and identification, and communication and interoperability lead the discussion on technologies adopted in most of the twenty studies in this group (Table 9; the detailed extraction table is available from the authors).

Table 9.

Methods and tools used when developing traceability models or modeling traceability.

5.5.2. Studies on Traceability Systems or the Components of Traceability Systems

Content and Dimensions of the Interventions

From the thirty-one studies in this group, eighteen proposed traceability or/and tracking systems, two discussed traceability services or the components of traceability systems, five made proposals where a traceability/tracking capability was a component/module of a larger system, four proposed methodologies by which to analyze, and sometimes improve, traceability systems or part of a system, one addressed critical criteria when implementing electronic chain traceability in a supply chain and another discussed the experiences and lessons learned from developing an RFID-based traceability system (Table 10).

Table 10.

Intervention within studies reporting on traceability systems or components of traceability systems.

All the studies in this group mentioned actors in the process or stakeholders of the intended results, most of the time with scant detail (Table 11).

Table 11.

Actors or stakeholders mentioned when developing traceability systems or components of traceability systems.

Only six of the thirty-one studies identified some sort of implementation costs, namely, the cost per tag of passive and active RFID, and the cost of barcodes and GPS [34]; the cost of RFID tags, addressing two possible solutions for its reduction [47]; the cost of building an IoT-based CPS (cyber-physical system), including the cost of an RFID reader and tagging [56]; the cost of RFID tags and their use in combination with a QR code [57]; the cost of RFID tags and the cost of system maintenance, including the marginal cost, which was difficult to estimate [66]; the cost of implementing an RFID system, including hardware, middleware and service cost [74].

Only four studies in this group addressed the measures of time required to implement and/or test their solution. The duration of some specific activities for a feasibility study was reported without addressing the total time needed for the deployment of the system [34]. The time required to run the pilots in one study was reported but the duration of the umbrella project was unclear [35]; all related process activities were identified and the time to perform them was measured before and after the system implementation. Numerous key performance indicators (KPIs) were used to quantify the benefits obtained in term of time savings after the introduction of the new system in the selected processes. Another study indicated that the completion of their project and of their traceability system was planned within six months, then three months were taken up in the definition of processes and data, with four months to design and create the application [42]. The reduction/elimination of time gained from the implementation of an IoT system framework was discussed in one study; nevertheless, the time required to implement the model on a testbed platform was not provided [56].

Requirements

Eleven of the studies in this group addressed the requirements and criteria for design and implementation as: traceability system with “minimal requirements” [37] (p. 115), traceability framework requirements [38], functional requirements [40], users’ requirements and “performance requirements for RCBTS” [47] (p. 317), essential RFID traceability requirements drawn from earlier studies and an industry survey [49], basic requirements of the international standard ISO 22005 [53], “some of the requirements of the DS” (Discovery Service) [54] (p. 481); users’ requirements using use case diagrams [61], “eight requirements” proposed by others “for an EPCDS system” [70] (p. 575), high-level requirements, functional requirements, and technology-specific requirements for the RFID system [78]. One study addressed business and technical requirements over text [79].

Standards and Regulations

Fifteen of the thirty-one studies in this group reported having brought international and global initiatives and systems, regulations and standards to their research (see Table 12).

Table 12.

International initiatives, regulations and standards mentioned or used when developing traceability systems or the components of traceability systems.

Ontologies

None of the studies in this group either discussed or developed ontologies. One study mentioned that the “IoT-aware ontology model concept model” had been previously developed and published [56] (p. 18).

Technologies

In the face of the high volume and the diversity of data extracted, proposals on methods and technologies were systematized into five main topics, according to the objective sought and the implemented function (Table 13). Three of them are directly related to primary functions expected from a TS: methods and technologies aimed at the identification of traceable resources and the capture of related information, such as RFID devices, wireless sensor networks (WSNs) and their software (topic A); middleware technologies, e.g., database management systems and application servers, and middleware software, which is able to store and process traceability data and information (topic B); methods and technologies aimed at traceability data output, user access and human-system interaction (topic C). Two of the topics are related to support and parallel functions: methods and technologies aimed at advancing specific aspects related to TSs and services, such as performance, security, trust, interoperability, networking and communications, aggregation, efficient discovery services (topic D); methods and technologies aimed at deploying business-related services and features, built over traceability capabilities and technology (topic E). Detailed coverage of all the tools, techniques and technological options is not feasible; therefore, most of the salient aspects reported below should act as entry points for the detailed information presented in the complete extraction table (available from the authors on request) and the corresponding studies.

Table 13.

Main topics of methods and technologies, according to the objective sought and the implemented function, in the group of studies addressing traceability systems or the components of traceability systems.

Most studies addressed topic A in detail, with the overwhelming presence of RFID technologies. Roughly two-thirds of the studies addressed topic B and about two-thirds addressed topic C, sometimes giving very little detail. Systems based on the SQL language were the most commonly used as the main database management systems. Web services and APIs (application programming interfaces) were often mentioned and employed. User-system interaction, user access and data output were frequently mentioned but little in the way of detail was usually available regarding implementation, beyond brief mentions of the internet and web browsers. PDA (personal digital assistant) hardware was discussed in some studies.

Sixteen studies were deemed as addressing topic D, most of the time contributing to other topics as well, while introducing innovation in those aspects related to traceability systems and services. Most studies addressed business-related services and features built in over traceability capabilities and technology (topic E). Ten of the thirty-one studies in this group were deemed as addressing all the five topics, at different levels of detail.

5.6. Comparators

We went beyond the strict definition of a comparator and researched any mention of, or effort to compare with, other studies and products (Table 14). Roughly half of the studies did not compare with other studies or products.

Table 14.

Mention of, or effort to compare to, other studies and products by studies reporting on traceability systems or components of traceability systems.

5.7. Context

5.7.1. Studies Reporting Traceability Models or Modeling Traceability

Information on the industries addressed and levels and connections between the levels considered are reported in Table 15.

Table 15.

Industries addressed and the levels and connections between levels, as considered by studies reporting on traceability models or modeling traceability.

Fourteen out of twenty studies emphasized enablers and motivators more directly related to their work, namely: standardization initiatives; regulations from governments; business- and market-related motivators; identifying and addressing the needs, expectations, motivations and limitations of diverse stakeholders; technological aspects (details on Table 16).

Table 16.

Enablers/motivators and challenges reported by studies on traceability models or modeling traceability.

Sixteen in twenty studies discussed challenges more directly related to their work, namely: the many faces of heterogeneity; security and privacy issues [36]; standards; semantics inconsistencies; ontology-related issues; difficulties in identification and evaluation of existing conditions before the development of a traceability framework; limitations of modeling methods; technology limitations; issues related to business and markets; governmental intervention and regulatory bodies’ mandates (details on Table 16).

5.7.2. Studies Reporting on Traceability Systems or the Components of Traceability Systems

Information on the industries addressed and levels and connections between levels considered are reported in Table 17.

Table 17.

Industries addressed and levels and connections between levels considered by studies reporting on the traceability systems or the components of traceability systems.

Twenty-six out of thirty-one studies emphasized those enablers and motivators more directly related to their work, including: business- and market-related issues; needs, expectations, the motivations and limitations of diverse stakeholders; increasing pressure from regulators; global standards; technological aspects; environment-related motivations. One study presented a formalized, systematic analysis based on critical criteria when implementing traceability [44], while another identified critical success factors and described lessons learned in detail [46] (see details in Table 18).

Table 18.

Enablers/motivators and challenges reported by studies on traceability systems or the components of traceability systems.

Twenty-two out of thirty-one studies discussed challenges more directly related to their work, namely: technology challenges and limitations; business- and market-related issues; the limitations of the models and methods used; problems posed by standards (details in Table 18).

5.8. Outcomes of the Interventions

We searched for and analyzed both the quantitative and qualitative measures of a contribution to a CE and of a contribution to improving critical characteristics of data and information on traceable entities, such as accuracy, objectivity, relevance, accessibility, richness, timeliness, authorship, verifiability, and scalability, which would betoken the quality of a tracking/tracing solution.

None of the included studies planned for or declared the outcomes of the intervention explicitly related to a circular economy. Brief related mentions could be found in both groups (Table 19). In the same way, none of the studies included in the SR planned for or declared the outcomes of the intervention that were directly related to the critical characteristics of data and information available on traceable entities, even if the aim of most studies was obviously related to them. Discussions were generically focused on the capacity for improved information exchange and access to information, not on the specific characteristics of data and the information available on traceable entities or proving the effectiveness of a proposal through a positive impact on them. However, brief mentions could be found in both groups (Table 19).

Table 19.

Mentions related to the sought outcomes in included studies.

6. Discussion

This review set out to examine a possible relationship between the development and implementation of TMs and TSs and a transition to a CE as documented in the literature. Overall, 49 studies were admitted to the SR. Three additional studies published during 2020 were also brought into the discussion.

6.1. To What Extent and in What Way Have the Use of Traceability Models and Traceability Systems Been Linked to a CE?

While the literature contained many interventions meeting the broad study criteria, it became immediately apparent that the link between traceability and the CE, involving the development of TMs and TSs, was rudimentary, both in terms of the number of studies and the soundness of the means used to document a connection or measuring an effect.

In fact, only one study referred explicitly to the CE, while introducing a technological solution aiming to provide tracking information [81]. However, the study only reported early conceptual work, with no mention of any CE principles or indicators under consideration.

The only study providing data on the environmental impacts of production in a network of companies aimed to establish a link between traceability and environmental sustainability [80], and used those indicators mentioned in the literature as adequate for the quantitative assessment of CE strategies [19]. No before-and-after assessment of an environmental impact was available, but qualitative and quantitative results, as assessed by the reviewers, suggest a capacity for improvement in all CE principles [18].

Qualitative evidence for TMs highlighted the capacity to create value by transforming information into knowledge throughout all phases of a product’s lifecycle [63], the expected improvement in systems’ integration along the supply chain [67] and the impact of clearly defining product information requirements on end-of-life decisions [73]. For TSs, empirical qualitative evidence included the better use of materials and products [34,72,74,79], improved coordination across a supply chain [34,35,56,68], the potential for improving energy management [37], the better management of equipment and components from production to end-of-life, including dangerous materials and waste [43], and the ability to support forward and reverse logistics in supply chains [49].

As for the impact on the quality of data and information available on traceable entities, the general focus was on the capacity for improved information exchange and access to information, even if it was not based on quantitative evidence, nor on the specific characteristics of data and information available, proving the effectiveness of a proposal through a positive impact on them. Only one study proposed a group of measures for a before-and-after effectiveness analysis that included an item linked to information management [61].

A move toward the proposal or use of evaluation methods was found in recent studies, within feasibility studies, case studies, experiments or tests of prototypes. They sought to prove the cost-effectiveness of a secure track and trace system [70], proposed criteria for an RFID-based traceability system evaluation [47], addressed the costs and benefits of a crankshaft traceability and tracking RFID-based system [74], developed an approach to predict traceability performance in agriculture food supply chains [40], developed evaluation methods and conducted experimental evaluations of an IoT-based cyber-physical system prototype [56], and validated the effectiveness of a Web-based platform for eco-sustainable supply chain management with tracing capabilities, while contributing to overcoming the lack of quantitative tools to support companies, along with monitoring and improving the environmental impact along the production chain [80].

6.2. What Are the Structural and Methodological Characteristics of the Studies on Traceability Models and Traceability Systems, Namely, When Linked to a CE?

Structural conditions, such as the resources available, regulations in place, pressure from stakeholders, and sectoral dynamics may influence the implementation of TSs [82] and research in this area [35,82]. In 2004, an exemplary study found that in beef supply chains, the European Union and Japan were leading the trend toward the adoption of mandatory traceability, as a response to the BSE (bovine spongiform encephalopathy) crisis, while the US had not adopted mandatory TSs, although several voluntary systems were in operation and new systems were being developed [83]. The results of this SR seem to confirm and extend part of those findings to other sectors. Between January 2003 and January 2020, thirty of the forty-nine included studies were conducted in Europe, eight in China and only two in the United States. Either through European Union entities and programs or national public bodies, public European money funded fifteen of the twenty-three studies that have declared a source of funding, while five studies were funded by Chinese national public bodies and no study declared having received funding from US-based bodies, public or private. Moreover, we observed more than a decade of investment and reports from projects addressing the several development stages, including pilots in different countries. However, considering the small number of cases and other peculiarities, we need to be careful when drawing conclusions in this regard. For example, temporal information was generically missing, as we only had access to publication dates, hindering our comparisons and conclusions regarding technological options, the challenges and limitations involved in implementation, and achievements in different countries.

As for the methodological aspects, the fact that only five of the forty-nine studies somehow stated research questions, that only eighteen described a methodology or research design/methods, and nineteen missed a definition or were unclear about a traceable entity signaled the paucity of studies quantifying results from evaluation activities or benchmarking to similar work. In fact, over half of the thirty-one studies reporting on TSs did not identify a study with which they could compare, were unclear or were not explicit about it.

Traceability, tracking, and traceability-related concepts were those topics more frequently discussed as the fundaments of a study, followed by RFID methods and tools. A group of studies [36,43,63,72,73,75,80,81] based their research on environment and lifecycle management areas, while only one referred explicitly to the CE [81].

Most studies addressed a design phase, while roughly half of them performed some sort of implementation and a little over two-fifths proposed or performed some sort of evaluation, in many cases described as feasibility studies. We found no evidence of a real-life large uptake of methods or tools as a result of the studies included in this SR, but a study proposing a web-based platform able to trace suppliers and related processes in order to improve decision-making regarding environmental sustainability in a real supply chain stood out [80].

The studies could be gathered in two groups, one composed of studies reporting on TMs or modeling traceability, and the other composed of studies reporting on TSs or the components of TSs. Within the first group, we found studies that had developed some sort of data/information model, modeled traceability infrastructures or frameworks, or frameworks with tracking capabilities, developed modeling methodologies or models for information analysis and management, modeled closed-loop product information tracking and feedback, developed ontologies, and discussed a methodology for managing aspects specific to traceability. Within the second group, we found studies that had developed traceability or/and tracking systems, discussed traceability services or the components of traceability systems, made proposals wherein traceability/tracking capabilities were a component/module of a larger system, proposed methodologies to analyze and sometimes improve a traceability system or part of it, addressed critical criteria when implementing electronic chain traceability, and discussed the experiences and lessons learned from developing RFID-based traceability systems.

We found a scant number of studies identifying the implementation costs and addressing the time required to implement and/or test a solution in the group of thirty-one studies reporting on TSs or components of TSs. These are aspects in need of consideration, given the many barriers to be overcome in order to promote awareness and companies’ investments in these systems and to see them as more of an opportunity than as an expense, especially when SMEs are involved [35,84,85].

6.3. Which Level or Levels Do Traceability Models and Traceability Systems Cover and in What Way, Especially When Related to a CE?

Transitioning to a circular economy calls for intervention at the micro-level, with single companies not only embedding CE principles into their strategic management, operations and production, but also at the meso-level, fostering collaboration among companies, such as in supply chains and eco-industrial parks, and at the macro level, involving local communities, regions, and countries [86].

Through our SR we found that most studies on TMs focused on the supply chain, with a few detailing the material and information flows [58,65,69] and elaborating on the merging of products and product information through the entire lifecycle of the product [36]. Only two studies [55,63] embraced the multilevel and multidimensional modeling of the supply chain and of the entities being processed explicitly. As for TSs, while most studies also favored the supply chain level, a group of them discussed interventions at the company level, with an eventual future extension being given to the value chain, conditioned to the many limitations and challenges identified.

In both groups, over half of the studies focused on the food sector. In other industries, a more recent move was identified, confirming the need for tools able to foster and support better decision-making, control and accountability in complex industries dealing with great economic, environmental and social pressures, such as electrical and electronic equipment [43,55], energy [34,66], automotive parts [74], aircraft and air travel [46,72], construction [78], plastics [81], and the textile and apparel sector [45].

6.4. What Agents or Stakeholders Are Expected to Have a Role in the Development and Implementation of Traceability Models and Traceability Systems, Especially When Related to a CE?

Stakeholder engagement and participation, through cooperative design (co-design) and cooperative production (co-production) are increasingly used to achieve better systems, goods and services. For the provider, that implies identifying, profiling, and bringing them in to processes that, traditionally, were mostly closed to outside entities.

Regarding this SR, all studies on TMs and TSs named actors in the development process or stakeholders of the intended results but, most of the time, these were identified in a generic way. In many cases, stakeholders who had no direct intervention in the study were listed as beneficiaries in an abstract of the results. In other cases, stakeholders were named according to the generic role they played in the supply chain. A small group of studies on TMs and TSs named regulatory, monitoring, auditing and law enforcement entities and directives, which might be particularly important within a transition to a CE [87]. Government agencies may play a significant role while increasing by many times the complexity of the systems, elevating requirements such as data sharing, the confidentiality of information, governance and regulatory compliance [77].

A few studies required collaboration between external services, such as experts from different companies, researchers and consultants, especially regarding RFID technology, and members of the company’s staff, such as the management information system team and operations staff that were brought together to lead a project [46], the production managers and the product safety and quality managers participating in a case study [50] and company employees brought in to identify parts of the operating system [75].

Some studies reported having run interviews [34,35,42,44,47,75], questionnaires [62,65], visits to companies [46], a workshop with field workers [77] and a panel of experts [50] to obtain information or test methods. We were unable to draw conclusions regarding a connection with the establishment of any kinds of requirements, as the overlap between the set of studies employing those techniques to obtain information prior to or during development efforts and the set of studies stating requirements in the group of those reporting on TMs or TSs narrowed to one study [47].

6.5. To What Extent and In What Way Are Ontologies Being Used, Especially When Related to a CE?

Some of the reasons to develop an ontology are the need to make domain assumptions explicit and to share a common understanding of the structure of information among people or software agents [24]. These are tenets of traceability in any field while representing basic requirements for effective and efficient sharing of information and knowledge on traceable entities.

Therefore, it was noteworthy that, within the group of studies addressing TMs, only eight developed or used ontologies, or at least identified the need to embrace their use. In the group of studies reporting on TSs, only one study [56] mentioned the use of an IoT-aware ontology model, developed to support the research and published elsewhere [55].

The shortage of tools able to support the tracking of requirements for and the evaluation of ontologies across all stages of their development and use [24] could be one of the reasons for the scarce results. When small and medium enterprises (SMEs) are involved, the complexity of the effort and the resources needed may be a deterrent. Many times, they are not perceived as a priority [88]. Other aspects found through this that SR included the limitations of existing ontologies to extend them to traceability domains [51,64], the use of generic- versus domain-specific ontologies [60], and the guidance and leniency provided by regulations and global standards [60].

In the food industry, where traceability has been directly linked with important requirements of the sector, such as food quality and safety, parameters must be followed along the entire supply chain; we found that ontologies could play a fundamental role, assisting with the modeling of knowledge of interest and addressing many of the problems concerning data standards and data interchanges in the existing infrastructures [60]. Considering the expected increase in complexity entailed in planning, operating, managing and evaluating activities in a circular economy, with the involvement of different sectors and stakeholders, we expect a similarly important role to be played by ontologies. A primary, essential step to overcome this challenge is to identify the necessary data and information to be gathered, shared and managed at each stage of the product lifecycle, in order to assure circular pathways [63,73]. In fact, ontologies and ontological frameworks have been identified as technologies that are needed to explore data and information in the context of circular manufacturing, namely, in the field of industrial symbiosis [89].

In the meantime, new studies on less widely reported industries have been published recently [90] and the area is poised to evolve rapidly in response to new needs, with ontologies becoming more descriptive and providing more contextual detail, supporting alternative views of the world and, thus, use by inhomogeneous user communities [91].

6.6. Do Traceability Models and Traceability Systems Reflect the Relevant Standards, Regulation and Indicators, and Consider Environmental, Social and Economic Perspectives, Especially When Related to a CE?

Standards represent the refined, consensual knowledge of individuals with expertise in specific subjects who are knowledgeable on the working conditions and the needs of the organizations they represent. Together with legislation, regulations and vetted indicators, they provide guidance to all kinds of organizations and to those monitoring, evaluating and endorsing, or not endorsing, their actions [92,93]. Therefore, they should be considered from the point of inception when engaging in initiatives as consequential as the deployment of internal and external TSs.

The results from our study show that only about half of the included studies declared that they had brought international and global initiatives and systems, regulations and standards to their research and that only a few of those did actually provide a detailed discussion on the topic, both in the group of those reporting on TMs and those reporting on TSs. Standards for markup languages and information modeling were those areas more frequently proposed for use within the first group, many times when in connection with feasibility studies or proposals for scenario validation, while scant references were made to GS1 standards and initiatives, ISO standards, EU directives and sector-related initiatives. Among the studies reporting on TSs, GS1 standards and initiatives were those areas more frequently named, followed by the standards for markup languages, web services, and information exchange between software systems and security, while scant references were made to ISO standards, EU directives and sector-related initiatives.

Global standards and initiatives facilitate the deployment of traceability systems and participants’ collaboration by allowing developers and organizations to focus more on how to use the information than on how to obtain that information [94]. EPCglobal has provided interrelated standards for hardware, software and data interfaces, together with core services, in order to support an open supply chain. However, in practical terms, they fall short of supporting the needs of track and trace services as only elementary-level services were defined [49]. The situation is somehow reflected by included studies published between 2010 and 2013, regarding the effort and time required from companies and developers to implement real-life RFID-based TSs, even when embracing the standards, and concerns regarding the security aspects being underserved by global initiatives [70]. Additionally, we found studies proposing generic RFID traceability services with embedded algorithms that would allow the multiple aggregation of products into containers and would work efficiently by invoking EPCISs in parallel [49], discovery services to automatically obtain a supply network [54], a relay policy for EPCDS and a secure track and trace system based on the EPCglobal network, where the EPCDS is semi-trusted [70]. The latter amount to a challenge for developers while trying to provide new functionalities and services without modifying the architecture of the standard EPCglobal network [70].

No mention was found to the BS 8001 [18]. Only one study [80] referred to the use of an indicator related to the environmental impact of a supply chain, the climate change indicator, which was linked to the flow of goods between the actors involved in the supply chain, and the use of a social impact indicator, the human toxicity indicator, judged as being significant for the specific context of this study.

6.7. What Are the Technologies Being Proposed or Used to Implement Traceability Models and Traceability Systems and What Can We Expect from Their Use, Especially When Related to a CE?

Solutions based on information technologies are being implemented by companies of all sizes to reduce the complexity associated with tracking and tracing, to gain access to highly connected value chains and to rip the benefits of massive volumes of high-quality data on virtually any aspect of their businesses.

How to deploy technological solutions in a cost-effective way, in particular those involving RFID devices, how to access meaningful, business-oriented information from huge volumes of real-time data, and how to integrate this system into the company processes are some of the key questions to be solved [23]. The studies included in this SR somehow reflect a quest for answers.

Within the group of those papers reporting on TMs or modeling traceability, UML, XML ebXM and EPCglobal tools were the technologies most frequently proposed or used. Tools for the development and evaluation of ontologies and tools specific to process modeling, such as Petri nets and BPMN tools, were seldom found.

Within the group of those reporting on TSs, a significant number of studies proposed or used RFID technologies, an option in part driven by efforts to lower costs and improve performance. Still, the number of those still dealing with technological and contextual challenges related to their use was still quite large, with studies pointing out the immaturity of the technologies and difficulties in implementing them in real, oftentimes dynamic, conditions [35,71,74,78,79,80], with difficulties in attaching tags to certain materials and living animals [41], high implementation costs [47,57,66,71], the need for research in terms of accuracy improvement for active RFID [34], the sustainability of RFID systems [46] and the need for new software services and data structures, enabling the ripping of benefits from the data gathered by tags and sensors [74].

We have also identified a recent emphasis on distributed solutions, both in terms of TSs coordination and of the technological options made when implementing them, with many studies proposing flexible, modular solutions supported by web services and systems and resorting to the cloud for development tools, processing times and services, and distributed databases technology, such as blockchain. All three of the studies from 2020 that were subsequently reviewed outside the main set of included papers discussed blockchain-based solutions [95,96,97]. Nevertheless, all the reviewed studies proposing the use of blockchain were mostly conceptual, with no traceability capabilities that were either simulated or implemented in real settings. The general claim was in terms of transparency in the supply chain, proving the authenticity, reliability, integrity, and validity of the final products and of the elements that compose the whole supply chain, but without proving anything besides the integrity and authorship of data supported by blockchain. Research is needed to ascertain companies’ willingness to embrace the technological options that they may perceive not only as less secure in terms of data handling but also as having embedded characteristics that expose too much of the unique characteristics of their manufacturing processes. A recent systematic review [98] identified, among other issues, the need for further examination of the benefits and challenges of blockchain technologies in terms of the circular economy and sustainable development.

The scant detail provided by most studies regarding the technological options for user-system interaction, user access to traceability information, and traceability data output may be a sign of the low technology readiness level (TRL) of many proposals. The information available on interface validation with end-users was meager, and if tests have been performed the user’s appreciation remained mostly unclear. Together with the scant information found regarding efforts to collect and characterize working conditions and users’ needs, preferences and limitations and considering the challenges experienced in field tests reported by many of the reviewed studies, all justify a strong call for research and investment in these areas, in line with recent initiatives [99].

Many studies on TSs or the components of TSs aimed at advancing specific aspects related to TSs and services, proposing methods and tools for integrating data from diverse sources and with diverse characteristics [35,68,79], integrating auto-ID technology in manufacturing and business processes [34], developing traceability services able to overcome the limitations of standards [49,54,70], tackling evaluation and proof of results by embedding measuring capabilities for efficiency gained from the traceability function [40], or deploying a testbed platform to conduct the experimental evaluation and cost-benefit analysis of a prototype system [56], advancing research on security in terms of track and trace for RFID-enabled supply chains [70], and proposing technology-based solutions to address eco-sustainability concerns [80,81].

Most studies included in this group identified business-related services and features built regarding traceability capabilities and technology, with a small group addressing eco-sustainability concerns and tackling lifecycle management and closed-loop arrangements [43,72,80,81].

6.8. What Are the Enabling Factors and the Challenges Related to the Development and Implementation of Traceability Models and Traceability Systems, Especially When Related to a CE?

Technological aspects related to methods, software and hardware, business- and market-related issues, regulations and guidelines aspects, standardization and classification in its multiple dimensions and needs, expectations, motivations, and limitations of diverse stakeholders typify important enablers and motivators identified by the studies addressing TMs and modeling traceability. The latter are particularly relevant in this fundamental phase of any development initiative, in the face of the huge challenges posed by high heterogeneity environments [36,38,45,52,55,67,69], the absence or non-consideration of standards in an industry [51,59], semantic inconsistencies and the lack of agreement on a concept’s meaning and the relationship between terms exacerbated by current enterprise information systems [51,63], and the limitations of ontology-based approaches [75], even in sectors with many years of experience in traceability implementation [51]. The limitations of modeling methods, including the identification and evaluation of existing conditions [63,65], and the inability to model information flows [52] and IoT systems [55] further hamper the design phase. Business- and market-related issues, particularly when SMEs are involved [45,62,69,76], technology pitfalls and limitations [64,69,75], security and privacy concerns [36], issues related to governmental intervention, and regulatory bodies’ mandates, especially regarding cross-border trade [77] are other factors demanding holistic approaches early in the modeling phase.

As for studies dealing with TSs, the broad enablers and motivators found by the SR were business- and market-related issues, environmental-related motivations, technological aspects, needs, expectations, the motivations and limitations of stakeholders, including regulators and governments, and the limitations and potential of existing standards. Factors deterring the implementation of traceability in a fish supply chain were analyzed and the critical criteria were described in detail for the planning and implementation phases, with motivation being identified as the most critical criterion in both phases [44]. In an aircraft engineering company, the implementation of an RFID project allowed the researchers to systematize four groups of critical success factors, namely, strong organizational motivation, implementation process efficiency, effective cost control and effective university–industry interaction [46]. Challenges identified by this SR also relate mostly to business- and market-related issues, as well as technology drawbacks and limitations. Problems posed by the standards [49,56,70,79] and limitations of models and methods to measure and prove an impact were identified; namely, when establishing the real value of traceability beyond the obligatory duty [42], developing analytical models [46] and establishing the link between traceability and the environmental sustainability assessment of supply chains [80].

6.9. Limitations of the Included Studies

The studies included in this SR presented some methodological weaknesses, the more prominent being the considerable number of studies that did not define or that were unclear about a traceable entity/unit, which is a fundamental element when modeling traceability or developing a traceability system, considering the downstream implications and challenges arising therefrom; the large number of studies missing a clear declaration of indicators able to measure and communicate an effect, a situation that is even more critical when the effect itself is not clearly identified because a definition of objectives is also missing; and the high number of studies that did not state their a priori objectives and/or research question and a research design/methodology. All these limitations not only had implications when trying to demonstrate results or benchmark against similar studies but also an impact on the ability of those trying to review the work in a systematic way. Ill-structured studies, where important information is missing, and ill-placed or misreported data slow down the review work considerably and may give rise to misunderstandings, interpretative subjectivity and an inability to perform comparative work.

The related limitations were the lack of rigor when defining the title and the keywords of a study, as observed in some cases where concepts used in the title and/or as keywords could not be found in the main text, and vice versa.

The absence of a chronological date that could be related to methodological and technological options and the work that was conducted was also a limitation of most studies, as only the publication date was available. Given the fast pace of technological development, this factor is relevant, especially where comparative work is involved and considering that a systematic review is supposed to provide updated guidance for future studies.

Lastly, a limited investment in positioning the research was observed, with some studies barely describing a theoretical background, including the main research field and a definition of the key concepts, as well as the context of application.

6.10. Limitations of the Review

This SR has some limitations. First, the search was undertaken in January 2020, being nearly 18 months old by the time we started drafting the report, due to the extensive work involved in data analysis and systematization and the work constraints experienced during parts of 2020 and 2021. To overcome this limitation, the databases were searched for studies from January 2020 to December 2020, using a query reflecting the core of this review: ALL ((“circular economy”) AND (“traceability system*” OR “traceability model*”)). The studies that met the inclusion criteria (n = 3) were reviewed and introduced in the discussion. However, we did not evaluate their methodological quality; therefore, these findings need to be treated with caution.

Second, the search was limited to articles published in the languages spoken by the research group members, and only papers published in English were finally included. The exclusion of papers in other languages could cause limited access to studies with significant findings related to our aim that were developed in different business, cultural and socio-economic contexts. Such is the case of papers eventually published in Chinese, given that, according to our findings, China is home to many initiatives in this field and public agencies have been funding related research.

Third, despite all the methodological tools and controls implemented and the rigorous approach followed, a degree of subjectivity was subjacent to the analysis and the categorization of information, particularly in some dimensions. Filling in the several extraction and categorization tables was quite complex, also due to the structuring and reporting options of many studies, particularly in terms of the implementation and evaluation phases.

Finally, due to the variations in outputs and outcomes assessed across the included studies, the scant number of studies focusing on the same or similar interventions and the different characteristics of traceability entities and contexts, it was not viable to crosscheck data from the included studies in detail or to perform a deep context–mechanisms–outcome (CMO) [100] analysis.

7. Conclusions

This review has demonstrated that the link between traceability and the circular economy, when assessed by published research and practice demonstrating the impact of the development of traceability models and traceability systems, is yet to be established. In fact, only one study reporting early conceptual work referred explicitly to the CE, with no mention of any CE principles or indicators under consideration. Qualitative evidence for TMs highlighted the capacity to create value by transforming information into knowledge throughout all phases of a product’s lifecycle, the expected improvement in systems’ integration along the supply chain, and the impact of clearly defining product information requirements regarding end-of-life decisions. For TSs, empirical qualitative evidence included the better use of materials and products, improved coordination across a supply chain, the potential for improving energy management, the better management of equipment and components from production to end-of-life and the ability to support forward and reverse logistics in supply chains. As for the impact on the quality of data and information available, our focus was on the capacity for improved information exchange and access to information, even if it was not based on quantitative evidence, and not on the specific characteristics of the data and information available on traceable entities and on proving a positive impact on them.

We conclude that sound research and practice documentation are required to establish evidence and foster the uptake of traceability systems and services by all the stakeholders. We found gaps in all the areas reviewed, signaling great research and innovation opportunities, especially connected to the CE. Circularity brings a new layer to a multi-disciplinary, multi-level and already very complex field, and calls for renewed efforts regarding conceptual approaches and research methods, data and process modeling, evaluation methodologies, economic and financial modeling, funding models and mechanisms, requirements engineering, the development and evaluation of ontologies, the development and appraisal of regulations, standards and indicators, and a broad spectrum of technological methods and tools. Based on our results, we defend the hypothesis that a deep understanding of the implementation context and of contextual dimensions, including the human factor, is of paramount importance and deserves considerably more research and investment.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/su14095469/s1, Table S1: PRISMA 2020 Checklist; Table S2: PRISMA 2020 for Abstracts Checklist.

Author Contributions

S.S.: conceptualization, methodology, investigation, data curation, writing—original draft preparation, reviewing and editing, visualization, validation, and approving the final version of the manuscript. A.R.: collaboration in conceptualization, investigation, data curation, including data import and preparation on the Rayyan platform, visualization, writing—reviewing and editing, validation, and approving the final version of the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research was partially funded by the FCT—Foundation for Science and Technology, Portugal, grant numbers UIDB/04058/2020 and UIDP/04058/2020.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The complete extraction tables are available from the corresponding author.

Acknowledgments

We acknowledge the contribution of our colleague Victor Moutinho, who co-screened a batch of titles and abstracts during the exploratory stage of the search for studies in electronic databases. We acknowledge the support of the GOVCOPP—Research Unit in Governance, Competitiveness and Public Policies.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript, to keep the exact formulation used in the included studies from where the text has been extracted:

| ATF | AMPLE Traceability Framework |

| BPMN | Business Process Modeling and Notation |

| CE | Circular Economy |

| CPS | Cyber-Physical System |

| ebXML | Electronic Business XML |

| EPC | Electronic Product Code |

| EPCIS | EPC Information Services |

| EPCDS | EPC Discovery Services |

| EU | European Union |

| GPS | Global Positioning System |

| GSC | Global Supply Chain |

| GS1 | Global Standards 1 |

| IoT | Internet of Things |

| ISO | International Organization for Standardization |

| LCA | Life Cycle Assessment |

| LNG | Liquefied Natural Gas |

| MESCO | Meat Supply Chain Ontology |

| PL | Production Logistics |

| QR | Quick Response |

| RCBTS | RFID-based Cattle/Beef Traceability System |

| RFID | Radio Frequency Identification |

| SC | Supply Chain |

| SCM | Supply Chain Management |

| SME | Small and Medium Enterprises |

| SOAP | Simple Object Access Protocol |

| SQL | Structured Query Language |

| SR | Systematic Review |

| SW | Software |

| TM | Traceability Model |

| TMs | Traceability Models |

| TS | Traceability System |

| TSs | Traceability Systems |

| UML | Unified Modelling Language |

| XML | Extensible Markup Language |

| Acronyms | |

| QCRI | Qatar Computing Research Institute |

Appendix A

- First query: Search string on Scopus.

Scopus: ALL ((“circular economy”) AND (trace* OR track* OR tracing) AND (model* OR framework* OR “traceability system*” OR identifier* OR “traceable resource unit” OR descriptor*) AND (indicator* OR metric* OR measure* OR method* OR scale* OR standard*)).

- Second query: Search string on Scopus.

Scopus: TITLE-ABS-KEY (“circular economy” OR (reduc* AND reus* AND recycl*) OR circularit* OR upcycl*) AND ALL ((trace* OR track* OR tracing) AND (model* OR framework* OR “traceability system*” OR identifier* OR “traceable resource unit” OR descriptor*) AND (indicator* OR metric* OR measure* OR method* OR scale* OR standard*)).

- Third query: Search string on Scopus.

Scopus: TITLE-ABS-KEY ((“circular economy” OR “industrial symbiosis”) AND ontolog*).

References

- Ellen MacArthur Foundation (EMF). Completing the picture: How the circular economy tackles climate change. Ellen MacArthur Found. Mater. Econ. 2019, 3, 1–62. [Google Scholar]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- EMF. Towards the circular economy: An economic and business rationale for an accelerated transition. Ellen MacArthur Found. Rethink. Futur. 2013, 1, 1–98. [Google Scholar]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- EU Circular Cooperation Hub. Strategic Research and Innovation Agenda on Circular Economy—CICERONE. 2020. Available online: https://cicerone-h2020.eu/wp-content/uploads/2020/09/Circular-Economy-SRIA-2020.pdf (accessed on 14 May 2021).

- INEC & ORÉE. Major Circular Economy Networks in Europe. Available online: https://institut-economie-circulaire.fr/wp-content/uploads/2020/03/majorcirculareconomynetworks.pdf (accessed on 14 May 2021).

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2018, 135, 190–201. [Google Scholar] [CrossRef]

- Hahladakis, J.N.; Iacovidou, I. An overview of the challenges and trade-offs in closing the loop of post-consumer plastic waste (PCPW): Focus on recycling. J. Hazard. Mater. 2019, 380, 120887. [Google Scholar] [CrossRef] [PubMed]

- Johansson, N.; Henriksson, M. Circular economy running in circles? A discourse analysis of shifts in ideas of circularity in Swedish environmental policy. Sustain. Prod. Consum. 2020, 23, 148–156. [Google Scholar] [CrossRef]

- Junestrand, S. Towards a Circular Economy in the Built Environment: Blockchain as a Solution for Supply Chain Transparency. Available online: https://medium.com/@stefanjunestrand/towards-a-circular-economy-in-the-built-environment-blockchain-as-a-solution-for-supply-chain-79027a584123 (accessed on 28 April 2018).

- Pishchulov, G.V.; Richter, K.K.; Pakhomova, N.V.; Tsenzharik, M.K. A circular economy perspective on sustainable supply chain management: An updated survey. J. Econ. Stud. 2018, 34, 267–297. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO 9000:2015(en) Quality management systems—Fundamentals and vocabulary. Geneva Int. Organ. Stand. 2015, 4, 53. [Google Scholar]

- Global Traceability Standard (GS1). GS1’s Framework for the Design of Interoperable Traceability Systems for Supply Chains. 2017. Available online: https://www.gs1.org/sites/default/files/docs/traceability/GS1_Global_Traceability_Standard_i2.pdf (accessed on 28 April 2018).

- Bosona, T.; Gebresenbet, G. Food traceability as an integral part of logistics management in food and agricultural supply chain. Food Control 2013, 33, 32–48. [Google Scholar] [CrossRef]

- GS1. GS1 Standards Document—Business Process and System Requirements for Full Supply Chain Traceability. Global Traceability Standard. 2012. Available online: https://www.gs1.org/docs/traceability/Global_Traceability_Standard.pdf (accessed on 28 April 2018).

- Kim, H.M.; Fox, M.S.; Gruninger, M. Ontology of quality for enterprise modelling. In Proceedings of the 4th IEEE Workshop on Enabling Technologies: Infrastructure for Collaborative Enterprises (WET ICE ’95), Berkeley Springs, WV, USA, 20–22 April 1995; pp. 105–116. [Google Scholar]

- Moe, T. Traceability in food manufacturing can range from in-house traceability in production plants to traceability in whole or part of the production chain from raw material to consumer. Trends Food Sci. Technol. 1998, 9, 211–214. [Google Scholar] [CrossRef]

- BS 8001:2017; Framework for Implementing the Principles of the Circular Economy in Organizations—Guide. British Standards Institution (BSI): London, UK, 2017.

- Pauliuk, S. Critical appraisal of the circular economy standard BS 8001: 2017 and a dashboard of quantitative system indicators for its implementation in organizations. Resour. Conserv. Recycl. 2018, 129, 81–92. [Google Scholar] [CrossRef]

- EMF (Ellen MacArthur Foundation). Circularity Indicators: An Approach to measuring Circularity—Project Overview. 2015. Available online: https://emf.thirdlight.com/link/yybss1obhtdv-ub419h/@/preview/1?o (accessed on 28 April 2018).

- Behrens, A.; Taranic, I.; Rizos, V. Resource Efficiency Indicators for Policy-Making—CEPS Working Document. 2015. Available online: http://aei.pitt.edu/69666/1/WD415.pdf (accessed on 28 April 2018).

- EASAC. Indicators for a circular economy. EASAC Policy Rep. 2016, 30, 1–43. [Google Scholar]

- Sánchez, B.B.; Alcarria, R.; Martín, D.; Robles, T. TF4SM: A framework for developing traceability solutions in small manufacturing companies. Sensors 2015, 15, 29478–29510. [Google Scholar] [CrossRef] [PubMed]

- Neuhaus, F.; Vizedom, A.; Baclawski, K.; Bennett, M.; Dean, M.; Denny, M.; Grüninger, M.; Hashemi, A.; Longstreth, T.; Obrst, L.; et al. Towards ontology evaluation across the life cycle: The ontology summit 2013. Appl. Ontol. 2013, 8, 179–194. [Google Scholar] [CrossRef]

- Aung, M.M.; Chang, Y.S. Traceability in a food supply chain: Safety and quality perspectives. Food Control 2014, 39, 172–184. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Koberg, E.; Longoni, A. A systematic review of sustainable supply chain management in global supply chains. J. Clean. Prod. 2019, 207, 1084–1098. [Google Scholar] [CrossRef]

- Benoît, C.; Norris, G.A.; Valdivia, S.; Ciroth, A.; Moberg, A.; Bos, U.; Prakash, S.; Ugaya, C.; Beck, T. The guidelines for social life cycle assessment of products: Just in time! Int. J. Life Cycle Assess. 2010, 15, 156–163. [Google Scholar] [CrossRef]

- Mhatre, P.; Panchal, R.; Singh, A.; Bibyan, S. A systematic literature review on the circular economy initiatives in the European Union. Sustain. Prod. Consum. 2021, 26, 187–202. [Google Scholar] [CrossRef]