Assessment of Emissions and Energy Consumption for Construction Machinery in Earthwork Activities by Incorporating Real-World Measurement and Discrete-Event Simulation

Abstract

:1. Introduction

1.1. Literature Review

1.2. Objectives of the Present Work

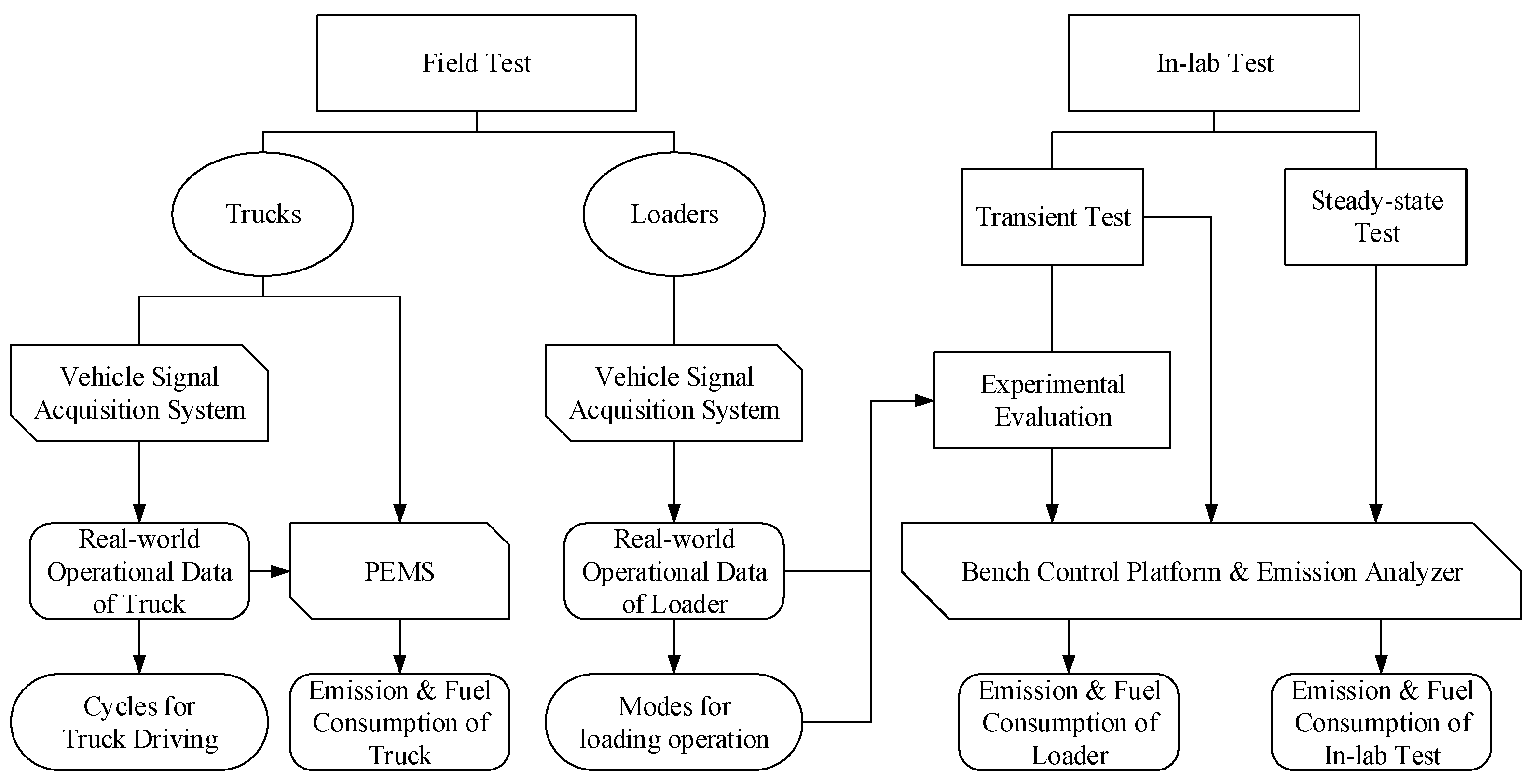

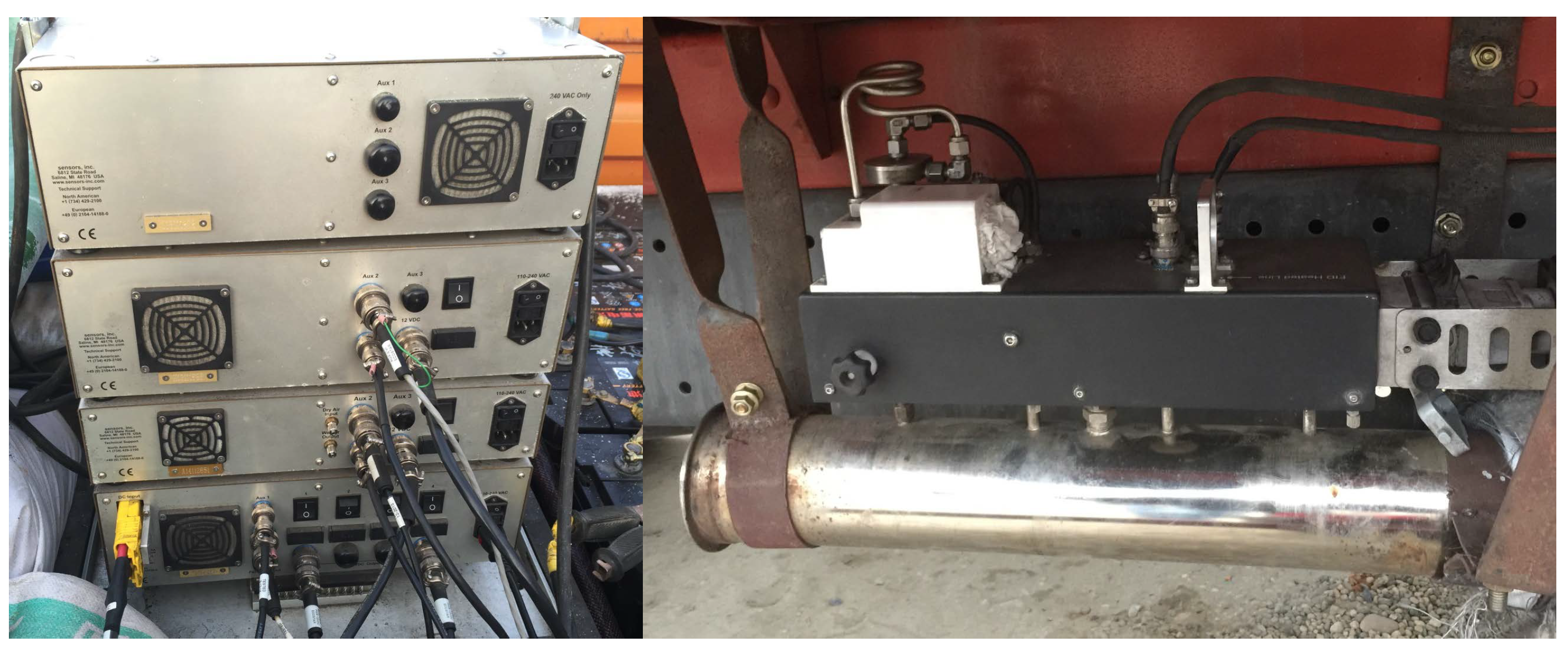

- On-board operational data were measured from equipment (two wheel loaders and two dump trucks) utilized in the earthwork activities of an urban construction site in China. In-lab engine experiments were also conducted to investigate the emission levels and fuel consumption associated with different typical operating conditions.

- Based on measurement data, different operational cycles for wheel loaders and working modes for dump trucks are categorized. Thus, the power-specific and time-based emission factors and fuel consumption for these duty cycles are discussed.

- The emission factors and fuel use levels were integrated into a DES framework to assess and optimize an earthmoving project with the objective of minimizing overall tail-out emissions and fuel consumption.

1.3. Document Organization

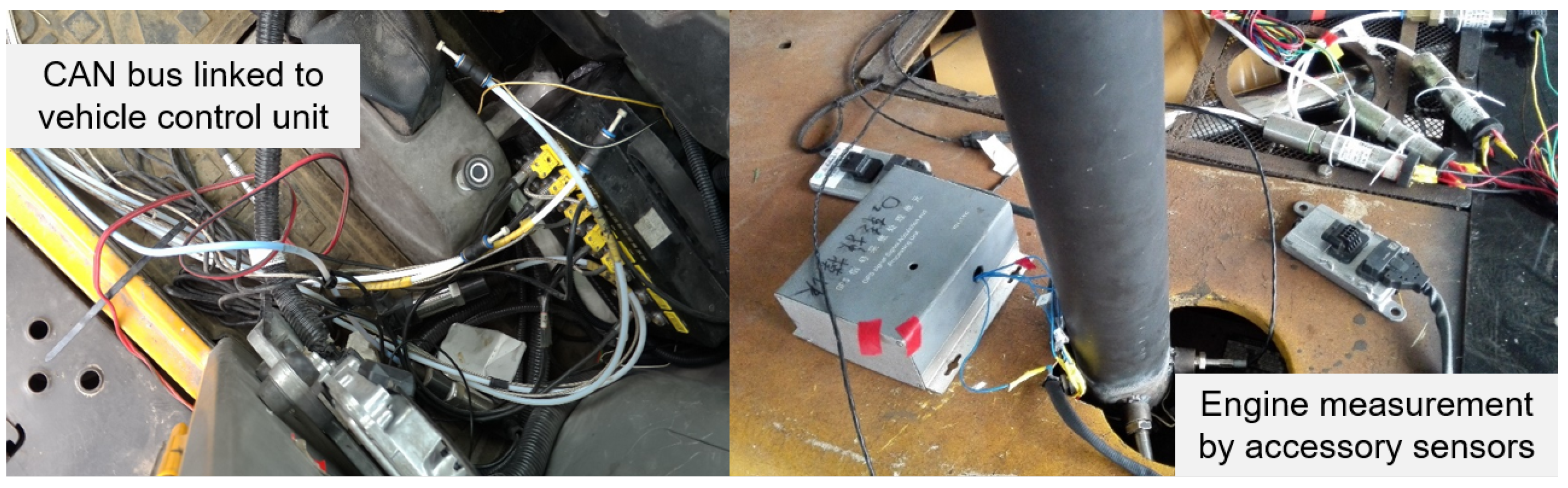

2. Experiments and Data Collection

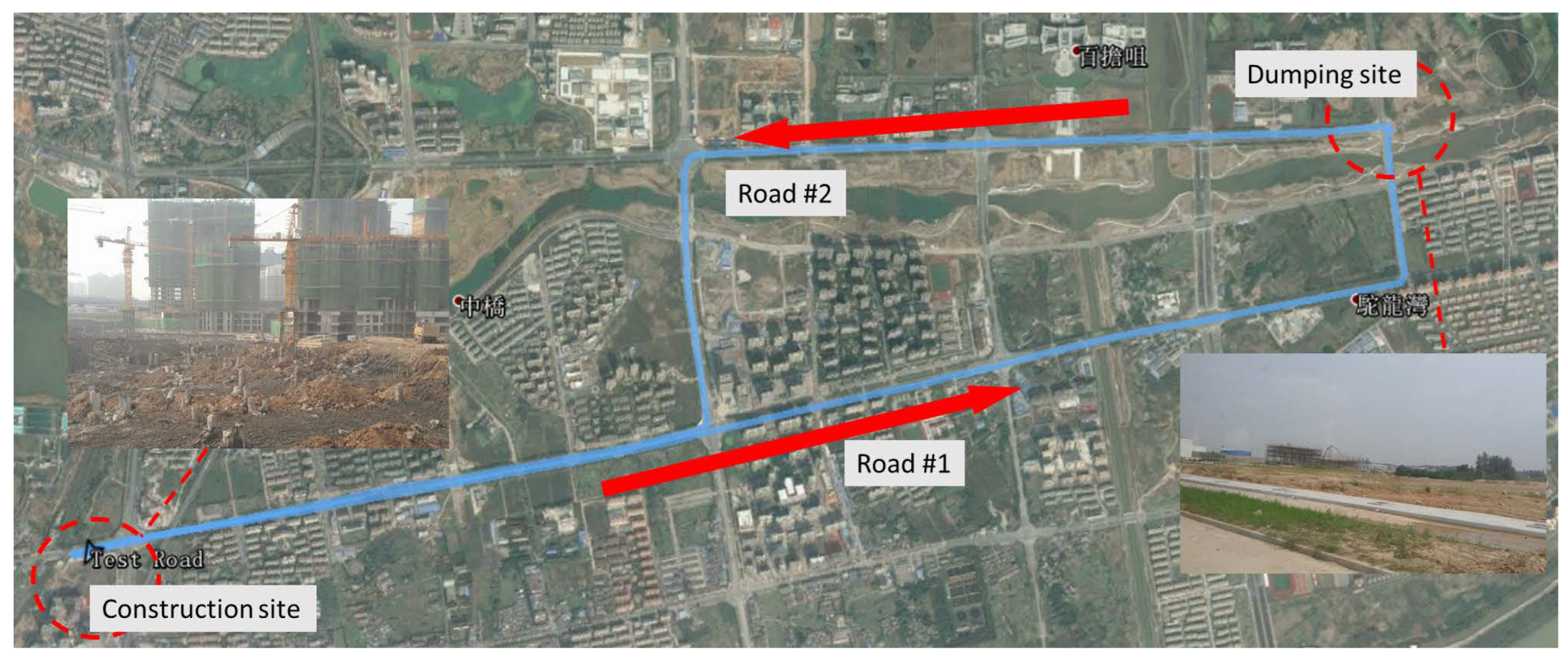

2.1. Field Test

2.2. In-Lab Test

3. Emission Factors of Duty Cycles

3.1. Emission Factors

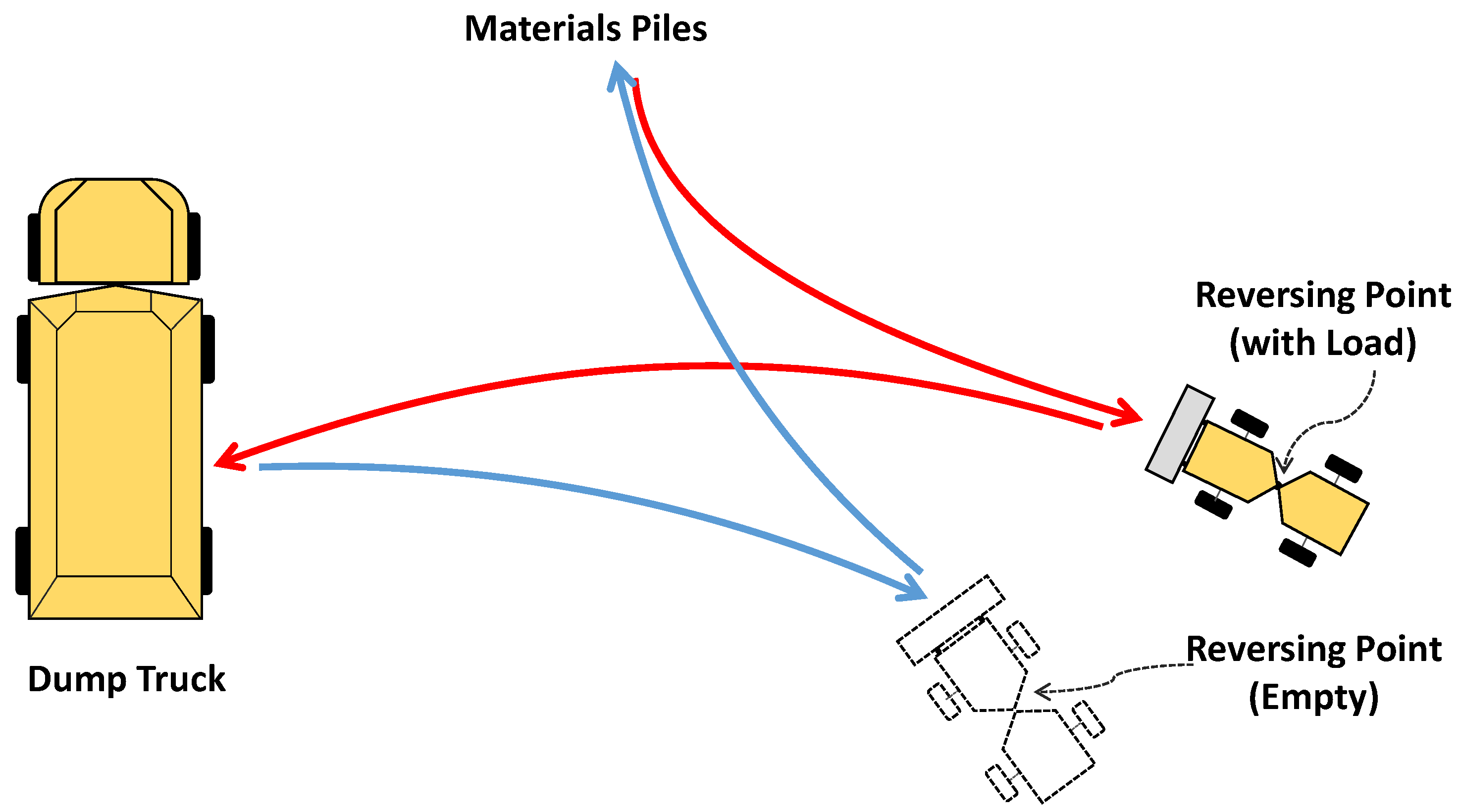

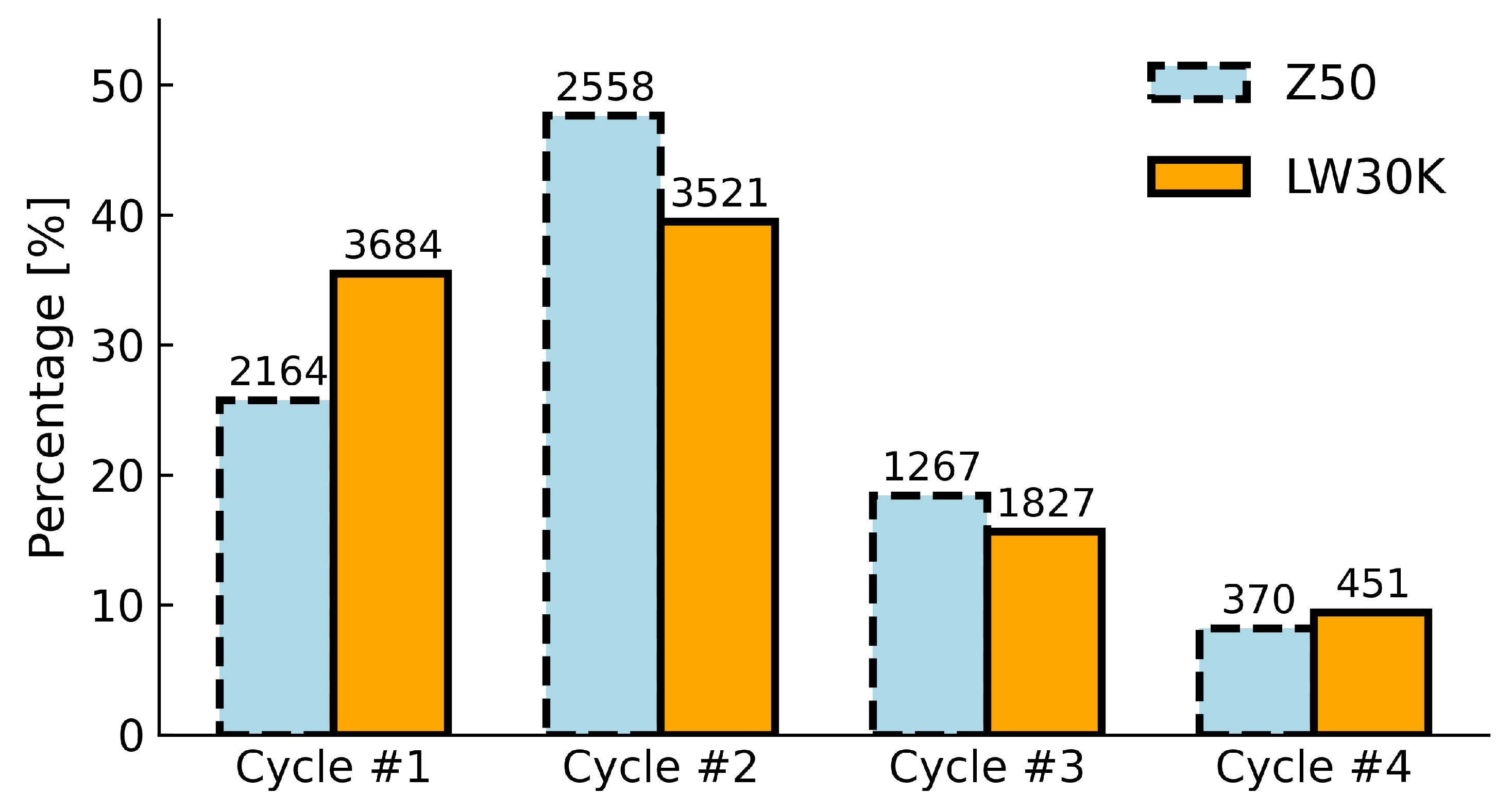

3.2. Operational Cycles of Wheel Loaders

3.3. Working Modes of Dump Trucks

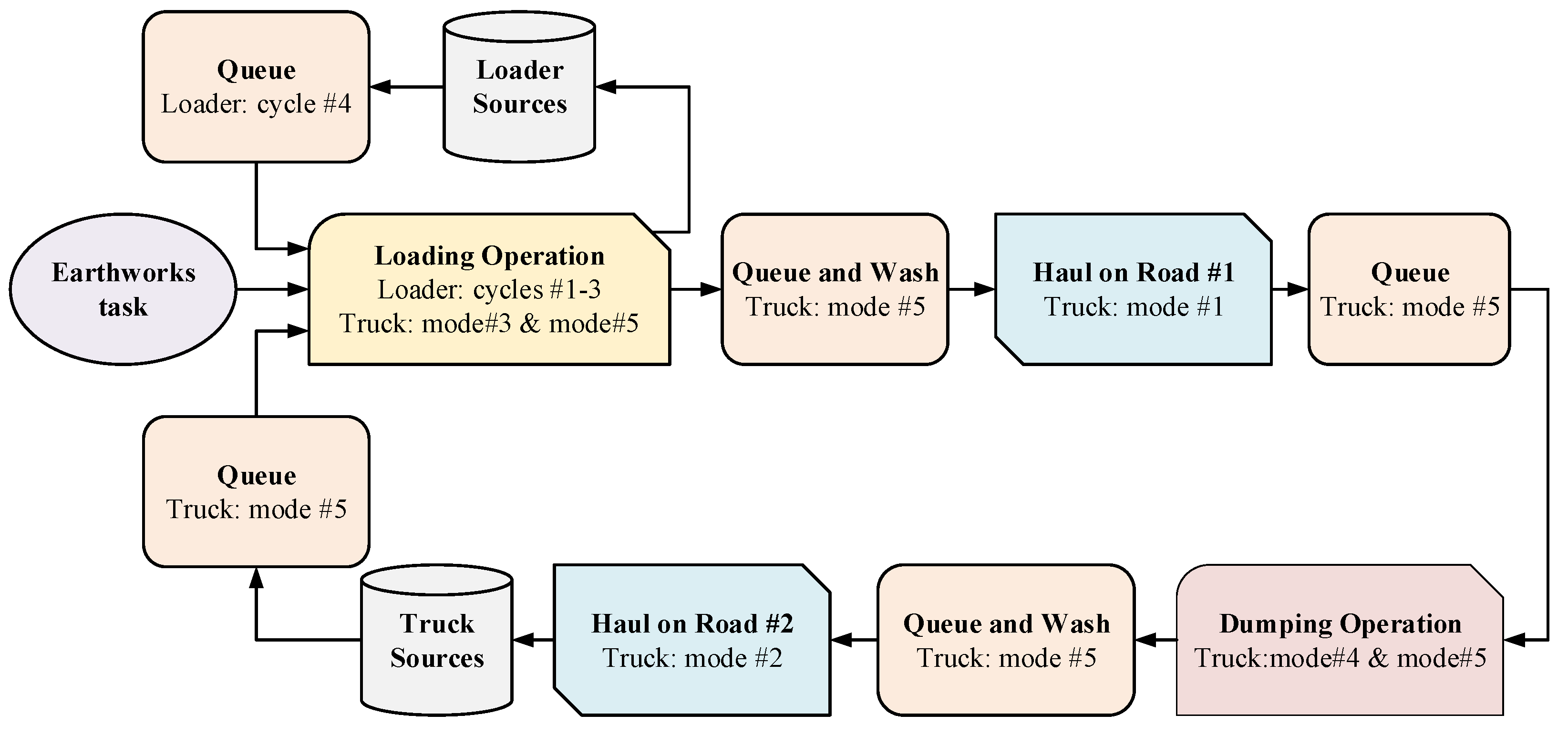

- Mode #1

- The fully loaded truck drives from the construction site to the dump site on Road 1;

- Mode #2

- The empty truck drives from the dump site to the construction site on Road 2;

- Mode #3

- The truck moves on the construction site, but excluding the idle stations;

- Mode #4

- The truck works in the dump site, but excluding the idling;

- Mode #5

- All the idle stations in both sites include waiting in the queue and being loaded by a loader.

4. Discrete-Event Simulation

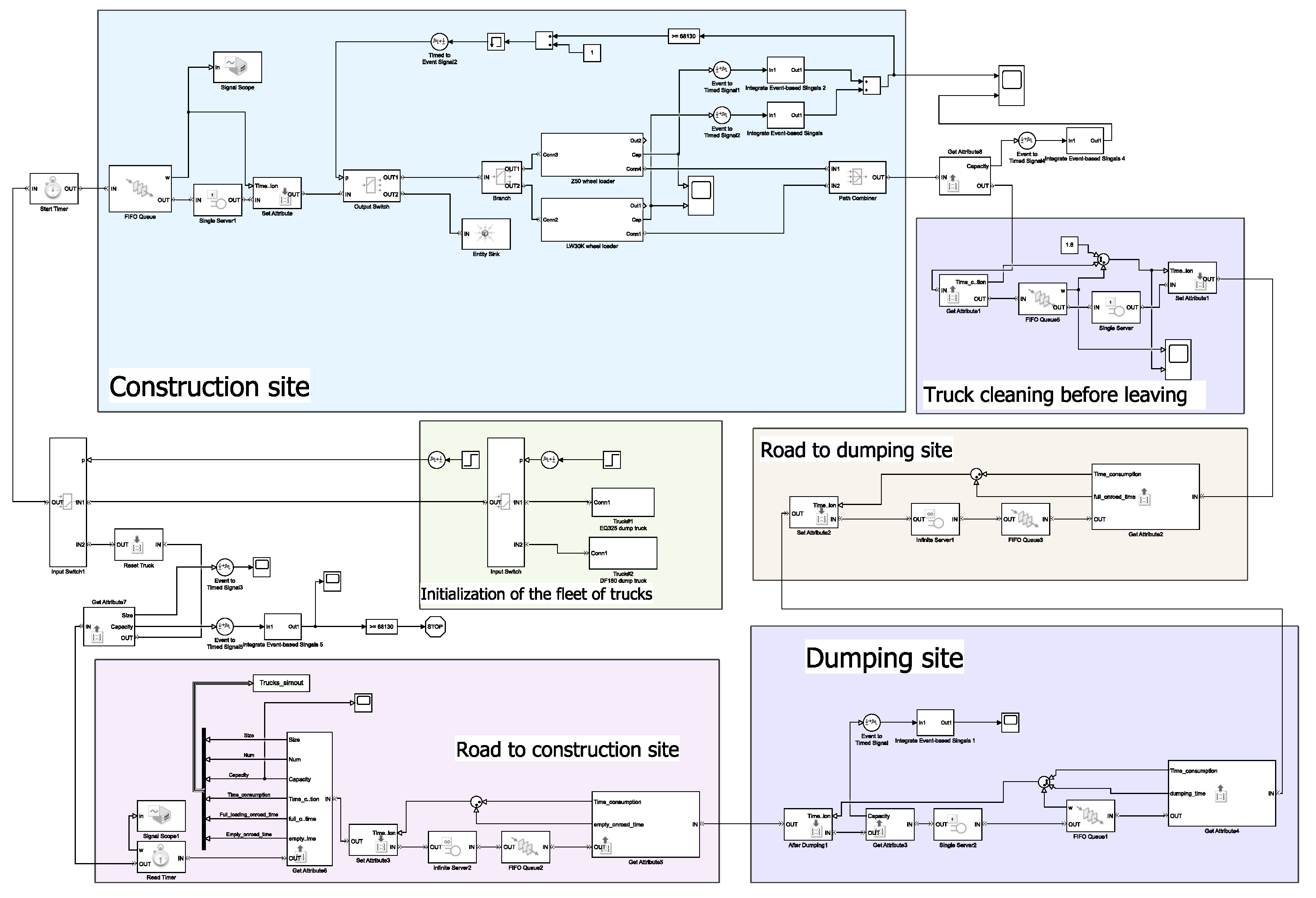

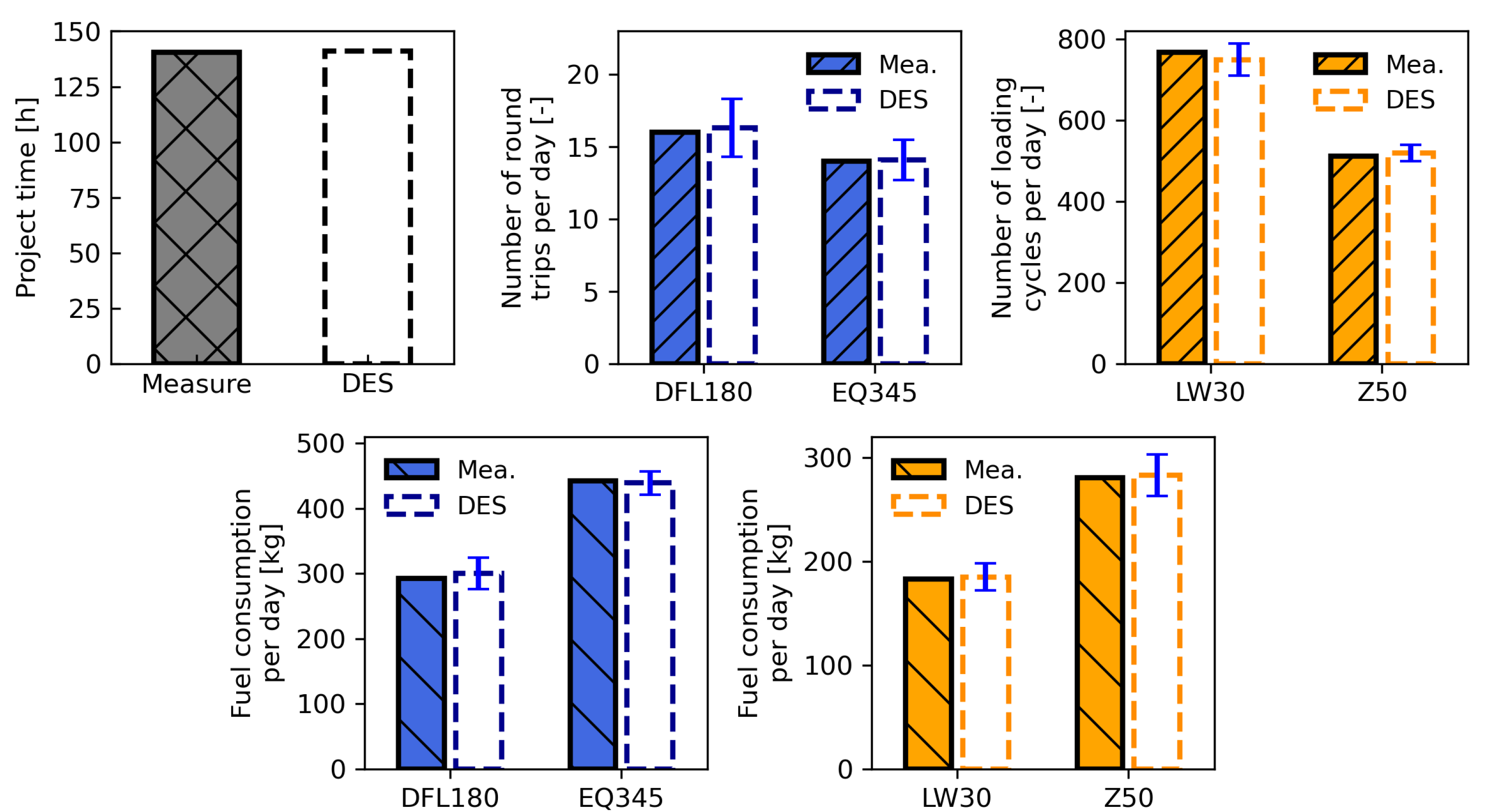

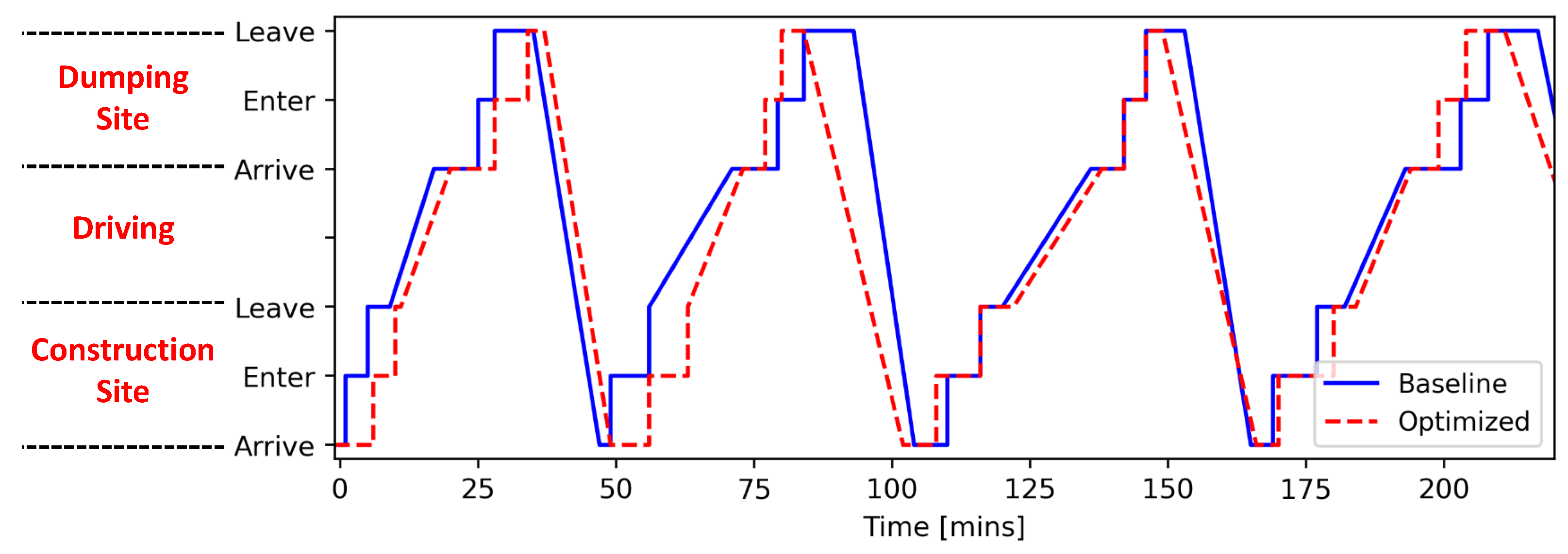

4.1. Earthwork Project and Simulation

- Initialization module for the truck and loader fleets.

- Earth loading module in the constructions site: empty trucks arrive and wait in the queue, while the loaders are the servers.

- Earth dumping module in the dumping site: loaded trucks arrive and wait in the queue, while the two dumping positions are the servers.

- Truck washing module in the construction site and dumping area: loaded trucks arrive and wait in the queue; one washing server is set in the module.

- Truck driving module: working modes for different driving scenarios.

4.2. Quantification of Emissions and Fuel Consumption

4.3. Optimized Equipment Fleet Schedule for Emission Reduction

5. Discussion and Recommendations

6. Conclusions

- There are significant differences between the real-world measured emissions and relevant legislative test cycle results. This indicates that the test duty cycles applied in emission certification cannot fully represent the real-world operating conditions of the construction equipment.

- Compared to the high-load operating conditions, wheel loaders operating between 45% and 70% power efficiency can reduce half of their power-specific NOx emissions and around 6% of their fuel consumption. Moreover, the LW30 wheel loader with a smaller power rating is more likely to work in the high-load conditions.

- In contrast to the loaders, the emission variability among different work modes of trucks are not significant. Although the upgraded emission control system reduced most pollutants of the EQ345 trucks, the after-treatment system also demands more energy supply, thereby increasing fuel consumption and CO2 emission.

- The comparison of power-specific emission factors shows that the loaders’ emissions and fuel consumption were lower than that of the trucks. Moreover, the construction equipment with a higher engine power rating also had better emission and fuel performances.

- Based on the validated DES, it can be found that about 80 tons of fuel were used for the earthwork activities in this project, with 302 tons of greenhouse gases emitted into the urban atmosphere.

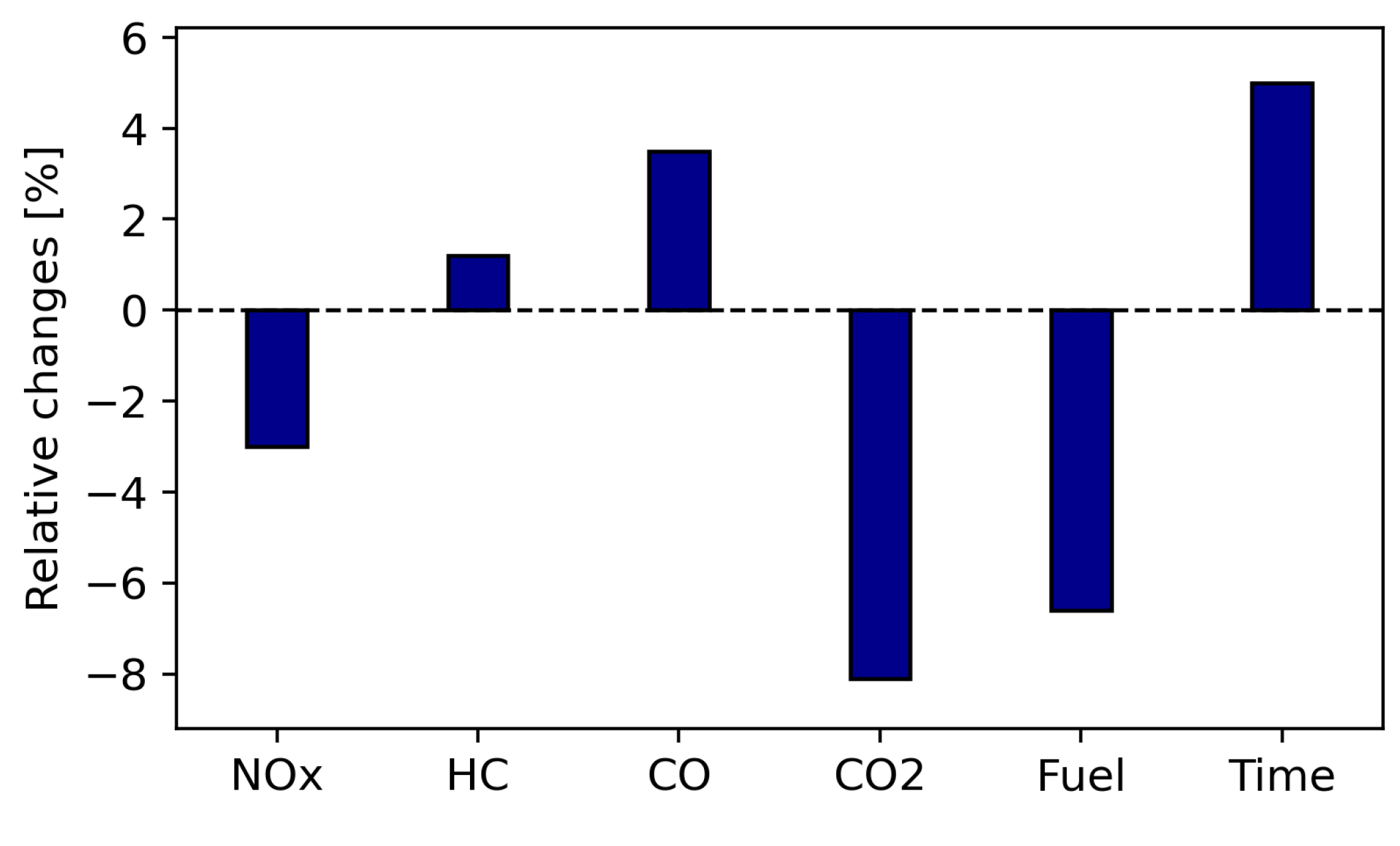

- Using a genetic algorithm, the equipment fleet planning was optimized to develop more sustainable earthwork operations. The optimized equipment fleet schedule increased the number of high-power equipment, especially for dump trucks. Compared with the baseline case, with a 5.2% increase in project time consumption, the most remarkable improvement was the reduction of greenhouse gas emissions and fuel use by 8.1% and 6.6%, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| HD | Heavy-duty |

| NOx | Nitrogen oxides |

| HC | Hydrocarbon |

| CO | Carbon monoxide |

| PM | Particulate matter |

| EPA | Environmental Protection Agency |

| OBD | On-board diagnostics |

| GPS | Global positioning system |

| FPGA | Field-programmable gate array |

| CAN | Controller area network |

| PEMS | Portable emissions measurement system |

| rpm | Revolutions per minute |

| DES | Discrete-event simulation |

| SCR | Selective catalytic reduction |

| EGR | Exhaust gas recirculation |

| ECU | Engine control unit |

| CR | Common-rail system |

| NRTC | Nonroad transient cycle |

| ESC | European stationary cycle |

| ETC | European transient cycle |

| SS | Steady-state |

| RW | Real-world |

Appendix A. Emission Standards Referred to in This Study

| Emission Standard | Engine Power (kW) | NOx + HC (g/kWh) | CO (g/kWh) | PM (g/kWh) |

|---|---|---|---|---|

| Nonroad Stage III | 130 ≤ P ≤ 560 | 4.0 | 3.5 | 0.2 |

| 75 ≤ P ≤ 130 | 4.0 | 5.0 | 0.3 |

| Emission Standard | Test Cycle | NOx (g/kWh) | HC (g/kWh) | CO (g/kWh) | PM (g/kWh) |

|---|---|---|---|---|---|

| Stage IV | ESC | 3.5 | 0.46 | 1.5 | 0.02 |

| ETC | 3.5 | - | 4.0 | 0.03 | |

| Stage V | ESC | 2.0 | 0.46 | 1.5 | 0.02 |

| ETC | 2.0 | - | 4.0 | 0.03 |

Appendix B. Illustration of SimEvents Model

Appendix C. Optimization Based on SimEvents Model

References

- Lewis, P.; Rasdorf, W.; Frey, H.C.; Pang, S.H.; Kim, K. Requirements and incentives for reducing construction vehicle emissions and comparison of nonroad diesel engine emissions data sources. J. Constr. Eng. Manag. 2009, 135, 341–351. [Google Scholar] [CrossRef]

- Chen, C.; Zhu, Z.; Hammad, A. Critical Review and Road Map of Automated Methods for Earthmoving Equipment Productivity Monitoring. J. Comput. Civ. Eng. 2022, 36, 03122001. [Google Scholar] [CrossRef]

- Beltrami, D.; Iora, P.; Tribioli, L.; Uberti, S. Electrification of Compact Off-Highway Vehicles—Overview of the Current State of the Art and Trends. Energies 2021, 14, 5565. [Google Scholar] [CrossRef]

- Frey, H.C.; Rasdorf, W.; Lewis, P. Comprehensive Field Study of Fuel Use and Emissions of Nonroad Diesel Construction Equipment. Transp. Res. Rec. 2010, 2158, 69–76. [Google Scholar] [CrossRef]

- European Commission. Proposal for a Regulation of the European Parliament and of the Council on Requirements Relating to Emission Limits and Type-Approval for Internal Combustion Engines for Nonroad Mobile Machinery; European Commission: Brussels, Belgium, 2014. [Google Scholar]

- Ministry of Ecology and Environment of China. Limits and Measurement Methods for Exhaust Pollutants from Diesel Engines of Nonroad Mobile Machinery (III, IV); Ministry of Ecology and Environment: Beijing, China, 2014. [Google Scholar]

- Ministry of Ecology and Environment of China. Limits and Measurement Methods for Exhaust Pollutants from Compression Ignition and Gas Fuelled Positive Ignition Engines of Vehicles (II, IV, V); Ministry of Ecology and Environment: Beijing, China, 2007. [Google Scholar]

- Tu, R.; Li, T.; Meng, C.; Chen, J.; Sheng, Z.; Xie, Y.; Xie, F.; Yang, F.; Chen, H.; Li, Y.; et al. Real-world emissions of construction mobile machines and comparison to a nonroad emission model. Sci. Total Environ. 2021, 771, 145365. [Google Scholar] [CrossRef]

- Giakoumis, E.G. Driving and Engine Cycles; Springer: Berlin/Heidelberg, Germany, 2017; Volume 1. [Google Scholar]

- Sepasgozar, S.M.E.; Blair, J. Measuring nonroad diesel emissions in the construction industry: A synopsis of the literature. Int. J. Constr. Manag. 2021, 21, 582–597. [Google Scholar] [CrossRef]

- Ullman, T.L.; Webb, C.C.; Jackson, C.C.; Doorlag, M.H. Nonroad Engine Activity Analysis and Transient Cycle Generation. SAE Trans. 1999, 108, 176–186. [Google Scholar]

- Samulski, M.J.; Jackson, C.C. Effects of Steady-State and Transient Operation on Exhaust Emissions from Nonroad and Highway Diesel Engines. SAE Trans. 1998, 107, 2068–2080. [Google Scholar]

- Desouza, C.; Marsh, D.; Beevers, S.; Molden, N.; Green, D. Real-world emissions from nonroad mobile machinery in London. Atmos. Environ. 2020, 223, 117301. [Google Scholar] [CrossRef]

- Heidari, B.; Marr, L.C. Real-time emissions from construction equipment compared with model predictions. J. Air Waste Manag. Assoc. 2015, 65, 115–125. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Chow, J.C.; Kohl, S.D.; Percy, K.E.; Legge, A.H.; Watson, J.G. Real-world emission factors for Caterpillar 797B heavy haulers during mining operations. Particuology 2016, 28, 22–30. [Google Scholar] [CrossRef]

- Wang, F.; Li, Z.; Zhang, K.; Di, B.; Hu, B. An overview of nonroad equipment emissions in China. Atmos. Environ. 2016, 132, 283–289. [Google Scholar] [CrossRef]

- Bie, P.; Ji, L.; Cui, H.; Li, G.; Liu, S.; Yuan, Y.; He, K.; Liu, H. A review and evaluation of nonroad diesel mobile machinery emission control in China. J. Environ. Sci. 2022. [Google Scholar] [CrossRef]

- Tan, D.; Tan, J.; Peng, D.; Fu, M.; Zhang, H.; Yin, H.; Ding, Y. Study on real-world power-based emission factors from typical construction machinery. Sci. Total. Environ. 2021, 799, 149436. [Google Scholar] [CrossRef]

- AbouRizk, S. Role of Simulation in Construction Engineering and Management. J. Constr. Eng. Manag. 2010, 136, 1140–1153. [Google Scholar] [CrossRef]

- Jabri, A.; Zayed, T. Agent-based modeling and simulation of earthmoving operations. Autom. Constr. 2017, 81, 210–223. [Google Scholar] [CrossRef] [Green Version]

- González, V.; Echaveguren, T. Exploring the environmental modeling of road construction operations using discrete-event simulation. Autom. Constr. 2012, 24, 100–110. [Google Scholar] [CrossRef]

- Liu, B.; Yang, B.; Xiao, J.; Zhu, D.; Zhang, B.; Wang, Z.; Dong, M. Review of Optimization Dynamically Applied in the Construction and the Application Potential of ICT. Sustainability 2021, 13, 5478. [Google Scholar] [CrossRef]

- Ahn, C.R.; Lee, S. Importance of Operational Efficiency to Achieve Energy Efficiency and Exhaust Emission Reduction of Construction Operations. J. Constr. Eng. Manag. 2013, 139, 404–413. [Google Scholar] [CrossRef]

- Ozcan-Deniz, G.; Zhu, Y. Multi-objective optimization of greenhouse gas emissions in highway construction projects. Sustain. Cities Soc. 2017, 28, 162–171. [Google Scholar] [CrossRef] [Green Version]

- Gwak, H.S.; Seo, J.; Lee, D.E. Optimal cut-fill pairing and sequencing method in earthwork operation. Autom. Constr. 2018, 87, 60–73. [Google Scholar] [CrossRef]

- Zhang, H. Discrete-Event Simulation for Estimating Emissions from Construction Processes. J. Manag. Eng. 2015, 31, 04014034. [Google Scholar] [CrossRef]

- Lewis, P.; Frey, H.C.; Rasdorf, W. Development and Use of Emissions Inventories for Construction Vehicles. Transp. Res. Rec. 2009, 2123, 46–53. [Google Scholar] [CrossRef]

- U.S. Environmental Protection Agency. User’s Guide for the Final NONROAD 2005 Model EPA420-R-05-013; Environmental Protection Agency: Washington, DC, USA, 2014. [Google Scholar]

- Ministry of Ecology and Environment of China. Revision on Limits and Measurement Methods for Exhaust Pollutants from Diesel Engines of Nonroad Mobile Machinery (III, IV); Ministry of Ecology and Environment: Beijing, China, 2020. [Google Scholar]

- Hong, B.; Ma, X. Path planning for wheel loaders: A discrete optimization approach. In Proceedings of the 2017 IEEE 20th International Conference on Intelligent Transportation Systems (ITSC), Yokohama, Japan, 16–19 October 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Hong, B.; Ma, X. Path optimization for a wheel loader considering construction site terrain. In Proceedings of the 2018 IEEE Intelligent Vehicles Symposium (IV), Changshu, China, 26–30 June 2018; pp. 2098–2103. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw-Hill Series in Mechanical Engineering; McGraw-Hill Education: New York, NY, USA, 1989. [Google Scholar]

- MathWorks. SimEvents Toolbox: User’s Guide(R2020a), MathWorks: Natick, MA, USA, 2020.

- Faber, P.; Drewnick, F.; Borrmann, S. Aerosol particle and trace gas emissions from earthworks, road construction, and asphalt paving in Germany: Emission factors and influence on local air quality. Atmos. Environ. 2015, 122, 662–671. [Google Scholar] [CrossRef]

- Luo, Q.; Huang, L.; Xue, X.; Chen, Z.; Zhou, F.; Wei, L.; Hua, J. Occupational health risk assessment based on dust exposure during earthwork construction. J. Build. Eng. 2021, 44, 103186. [Google Scholar] [CrossRef]

- Mendoza, J.; de-la Bandera, I.; Álvarez Merino, C.S.; Khatib, E.J.; Alonso, J.; Casalderrey-Díaz, S.; Barco, R. 5G for Construction: Use Cases and Solutions. Electronics 2021, 10, 1713. [Google Scholar] [CrossRef]

| Type: Wheel Loader | LW30 | Z50 |

| Operation Weight (kg) | 10,600 | 16,600 |

| Bucket Capacity (m3) | 1.8 | 4.5 |

| Rated Load (kg) | 3200 | 5000 |

| Max. Breakout Force (kN) | 100 | 190 |

| Engine Rated Power | 92 kW @2300 rpm | 162 kW @2000 rpm |

| Fuel Type | Diesel | Diesel |

| Emission Control Devices | CR, EGR | CR, SCR |

| Emission Standard | Nonroad Stage III | Nonroad Stage III |

| Type: Dump Truck | DFL180 | EQ345 |

| Curb Weight (kg) | 12,000 | 22,000 |

| Dump Container Size (cm) | 540 × 250 × 120 | 835 × 250 × 125 |

| Rated Load (kg) | 25,000 | 40,000 |

| Max. Speed (km/h) | 85 | 90 |

| Engine Rated Power | 228 kW @2200 rpm | 385 KW @2500 rpm |

| Fuel Type | Diesel | Biodiesel & Diesel |

| Emission Control Devices | CR, SCR | CR, SCR, DPF |

| Emission Standard | Stage IV | Stage V |

| Operational Cycles | Power Efficiency | Operating Characteristics |

|---|---|---|

| Cycle #1 | Full load, fast moving and loading, extreme conditions. | |

| Cycle #2 | Full load, normal moving and loading speed. | |

| Cycle #3 | Half or less load, trivial and small work. | |

| Cycle #4 | Idle or other low efficiency movement. |

| LW30K Wheel Loader | ||||||||||

| NOx | HC | CO | CO2 | Fuel | ||||||

| g/kWh | g/h | g/kWh | g/h | g/kWh | g/h | g/kWh | kg/h | g/kWh | kg/h | |

| SS a | 3.73 | - | 0.22 | - | 0.95 | - | 769.99 | - | 261.81 | - |

| NRTC | 3.97 | - | 0.31 | - | 1.64 | - | 802.17 | - | 287.45 | - |

| RW b | 5.56 | 306.9 | 0.21 | 11.6 | 1.08 | 59.6 | 845.12 | 46.7 | 301.56 | 16.6 |

| Cycle #1 c | 4.64 | 320.2 | 0.20 | 13.8 | 1.24 | 85.6 | 864.14 | 59.6 | 279.67 | 19.3 |

| Cycle #2 | 4.28 | 216.6 | 0.24 | 12.1 | 0.94 | 47.6 | 781.97 | 39.6 | 306.43 | 15.5 |

| Cycle #3 | 3.53 | 97.4 | 0.23 | 6.3 | 0.84 | 23.2 | 846.24 | 23.4 | 234.19 | 6.5 |

| Cycle #4 | 8.67 | 123.1 | 0.19 | 2.7 | 1.46 | 12.8 | 649.47 | 9.2 | 196.57 | 2.8 |

| Z50 Wheel Loader | ||||||||||

| NOx | HC | CO | CO2 | Fuel | ||||||

| g/kWh | g/h | g/kWh | g/h | g/kWh | g/h | g/kWh | kg/h | g/kWh | kg/h | |

| SS a | 3.9 | - | 0.15 | - | 1.23 | - | 780.17 | - | 263.55 | - |

| NRTC | 4.07 | - | 0.27 | - | 1.84 | - | 813.42 | - | 277.45 | - |

| RW b | 4.34 | 421.8 | 0.32 | 31.1 | 1.73 | 168.2 | 821.51 | 79.9 | 262.54 | 25.5 |

| Cycle #1 c | 5.37 | 652.5 | 0.37 | 45.0 | 1.92 | 233.3 | 792.17 | 96.2 | 246.21 | 29.9 |

| Cycle #2 | 3.93 | 318.3 | 0.31 | 25.1 | 1.67 | 135.3 | 821.06 | 66.5 | 276.42 | 22.4 |

| Cycle #3 | 3.01 | 195.0 | 0.29 | 18.8 | 1.59 | 103.0 | 783.78 | 50.8 | 221.36 | 14.3 |

| Cycle #4 | 10.31 | 334.0 | 0.20 | 6.5 | 2.33 | 43.1 | 402.34 | 13.0 | 174.14 | 5.6 |

| DFL180 Dump Truck | ||||||||||

| NOx | HC | CO | CO2 | Fuel | ||||||

| g/kWh | g/h | g/kWh | g/h | g/kWh | g/h | g/kWh | kg/h | g/kWh | kg/h | |

| ESC a | 2.7 | - | 0.22 | - | 1.69 | - | 646.79 | - | 201.34 | - |

| ETC b | 3.39 | - | 0.24 | - | 1.65 | - | 702.61 | - | 209.54 | - |

| RW c | 3.74 | 502.7 | 0.27 | 36.3 | 1.98 | 266.1 | 754.31 | 99.4 | 200.11 | 26.9 |

| Mode #1 d | 3.07 | 490.4 | 0.28 | 44.7 | 1.87 | 298.7 | 784.49 | 129.6 | 199.19 | 31.8 |

| Mode #2 | 3.58 | 546.3 | 0.29 | 44.3 | 2.18 | 332.6 | 752.49 | 103.0 | 194.74 | 29.7 |

| Mode #3 | 3.78 | 447.5 | 0.33 | 39.1 | 2.30 | 272.3 | 824.92 | 81.4 | 215.26 | 25.5 |

| Mode #4 | 4.19 | 478.6 | 0.24 | 27.4 | 2.56 | 292.4 | 745.97 | 68.2 | 209.7 | 24.0 |

| Mode #5 | 5.09 | 77.6 | 0.44 | 6.7 | 3.71 | 41.2 | 737.12 | 8.7 | 229.7 | 3.5 |

| EQ345 Dump Truck | ||||||||||

| NOx | HC | CO | CO2 | Fuel | ||||||

| g/kWh | g/h | g/kWh | g/h | g/kWh | g/h | g/kWh | kg/h | g/kWh | kg/h | |

| ESC a | 1.95 | - | 0.32 | - | 1.94 | - | 592.94 | - | 213.57 | - |

| ETC b | 2.01 | - | 0.41 | - | 1.26 | - | 603.09 | - | 224.85 | - |

| RW c | 2.18 | 389.9 | 0.29 | 50.8 | 1.95 | 341.8 | 616.41 | 166.2 | 229.46 | 40.2 |

| Mode #1 d | 2.25 | 403.3 | 0.21 | 37.6 | 1.45 | 259.5 | 613.19 | 158.8 | 204.21 | 36.5 |

| Mode #2 | 2.15 | 411.0 | 0.31 | 59.3 | 1.08 | 206.6 | 734.41 | 201.2 | 199.09 | 38.1 |

| Mode #3 | 1.85 | 385.9 | 0.59 | 123.2 | 1.86 | 388.4 | 609.72 | 173.6 | 229.14 | 47.8 |

| Mode #4 | 2.23 | 392.5 | 0.61 | 107.6 | 1.82 | 320.9 | 668.37 | 189.3 | 212.32 | 37.4 |

| Mode #5 | 2.79 | 64.2 | 0.87 | 20.1 | 2.31 | 53.3 | 596.65 | 8.6 | 228.32 | 3.2 |

| Equipment | Duty Cycles | Time Distributions |

|---|---|---|

| LW30 wheel loader | Cycle #1 | Normal (47.7, 4.3) |

| Cycle #2 | Normal (61.1, 3.2) | |

| Cycle #3 | Lognormal (2.92, 0.81) | |

| Cycle #4 | – | |

| Z50 wheel loader | Cycle #1 | Normal (45.7, 4.3) |

| Cycle #2 | Normal (59.3, 4.2) | |

| Cycle #3 | Lognormal (2.46, 0.92) | |

| Cycle #4 | – | |

| DFL180 dump truck | Hauling (Mode #1) | Uniform (13.14, 16.83) |

| Returning (Mode #2) | Uniform (10.75, 12.57) | |

| Loading (Mode #3) | Normal (6.19, 2.27) for LW30 | |

| Normal (4.75, 1.31) for Z50 | ||

| Dumping (Mode #4) | Normal (4.19, 0.71) | |

| Waiting or Idle (Mode #5) | – | |

| EQ345 dump truck | Hauling (Mode #1) | Uniform (14.85, 19.67) |

| Returning (Mode #2) | Uniform (13.46, 15.71) | |

| Loading (Mode #3) | Normal (8.37, 1.89) for LW30 | |

| Normal (7.64, 1.63) for Z50 | ||

| Dumping (Mode #4) | Normal (4.74, 0.82) | |

| Waiting or Idle (Mode #5) | – |

| LW30 | Z50 | DFL180 | EQ345 | Total | |

|---|---|---|---|---|---|

| NOx (kg) | 43.30 | 59.52 | 70.93 | 55.01 | 1071.34 |

| HC (kg) | 1.64 | 4.39 | 5.12 | 7.17 | 100.12 |

| CO (kg) | 8.41 | 23.73 | 37.55 | 48.23 | 675.39 |

| CO2 (ton) | 6.59 | 11.27 | 13.26 | 23.42 | 302.69 |

| Fuel (ton) | 2.34 | 3.60 | 3.80 | 5.67 | 80.03 |

| LW30 | Z50 | DFL180 | EQ345 | |

|---|---|---|---|---|

| Baseline | 2 | 2 | 8 | 6 |

| Optimized | 1 | 3 | 3 | 9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, B.; Lü, L. Assessment of Emissions and Energy Consumption for Construction Machinery in Earthwork Activities by Incorporating Real-World Measurement and Discrete-Event Simulation. Sustainability 2022, 14, 5326. https://doi.org/10.3390/su14095326

Hong B, Lü L. Assessment of Emissions and Energy Consumption for Construction Machinery in Earthwork Activities by Incorporating Real-World Measurement and Discrete-Event Simulation. Sustainability. 2022; 14(9):5326. https://doi.org/10.3390/su14095326

Chicago/Turabian StyleHong, Beichuan, and Lin Lü. 2022. "Assessment of Emissions and Energy Consumption for Construction Machinery in Earthwork Activities by Incorporating Real-World Measurement and Discrete-Event Simulation" Sustainability 14, no. 9: 5326. https://doi.org/10.3390/su14095326

APA StyleHong, B., & Lü, L. (2022). Assessment of Emissions and Energy Consumption for Construction Machinery in Earthwork Activities by Incorporating Real-World Measurement and Discrete-Event Simulation. Sustainability, 14(9), 5326. https://doi.org/10.3390/su14095326