Characterization of Physicochemical and Mechanical Properties of Dumped Municipal Solid Waste in Sri Lanka as Affected by the Climate Zone and Dumping Age

Abstract

:1. Introduction

2. Materials and Methods

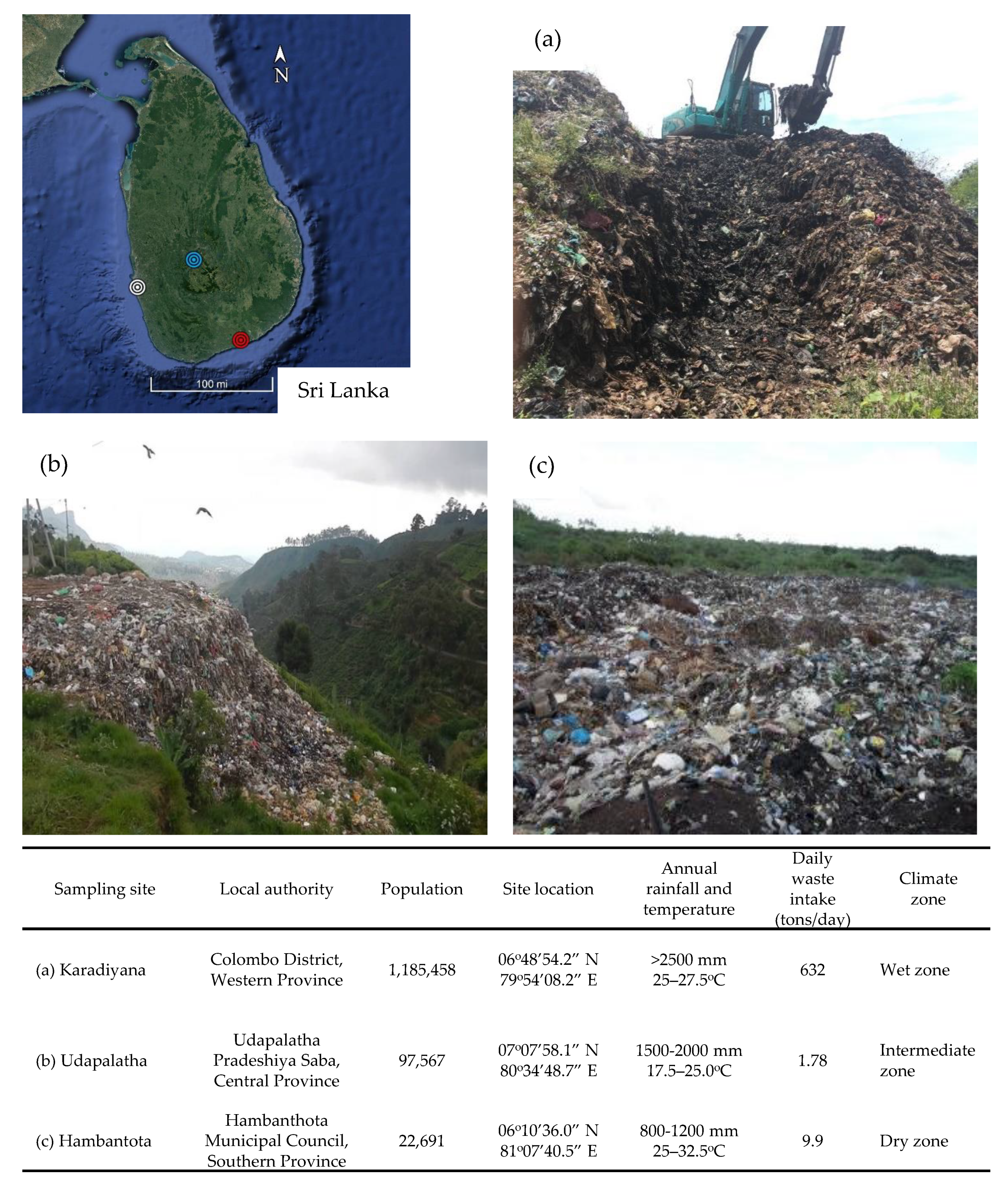

2.1. Sampling Locations

2.2. Waste Composition and Physicochemical Properties

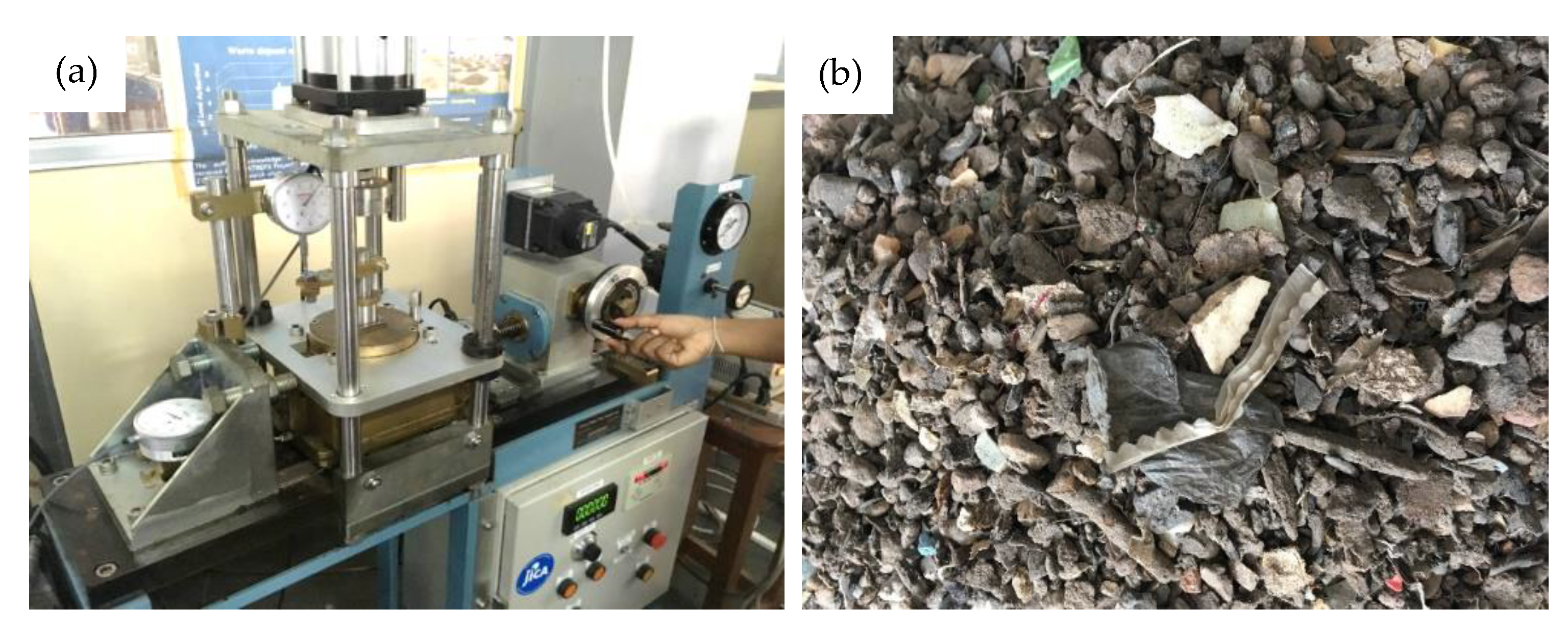

2.3. Compaction and Direct Shear Tests

3. Results and Discussion

3.1. Waste Composition and Particle Size Distribution

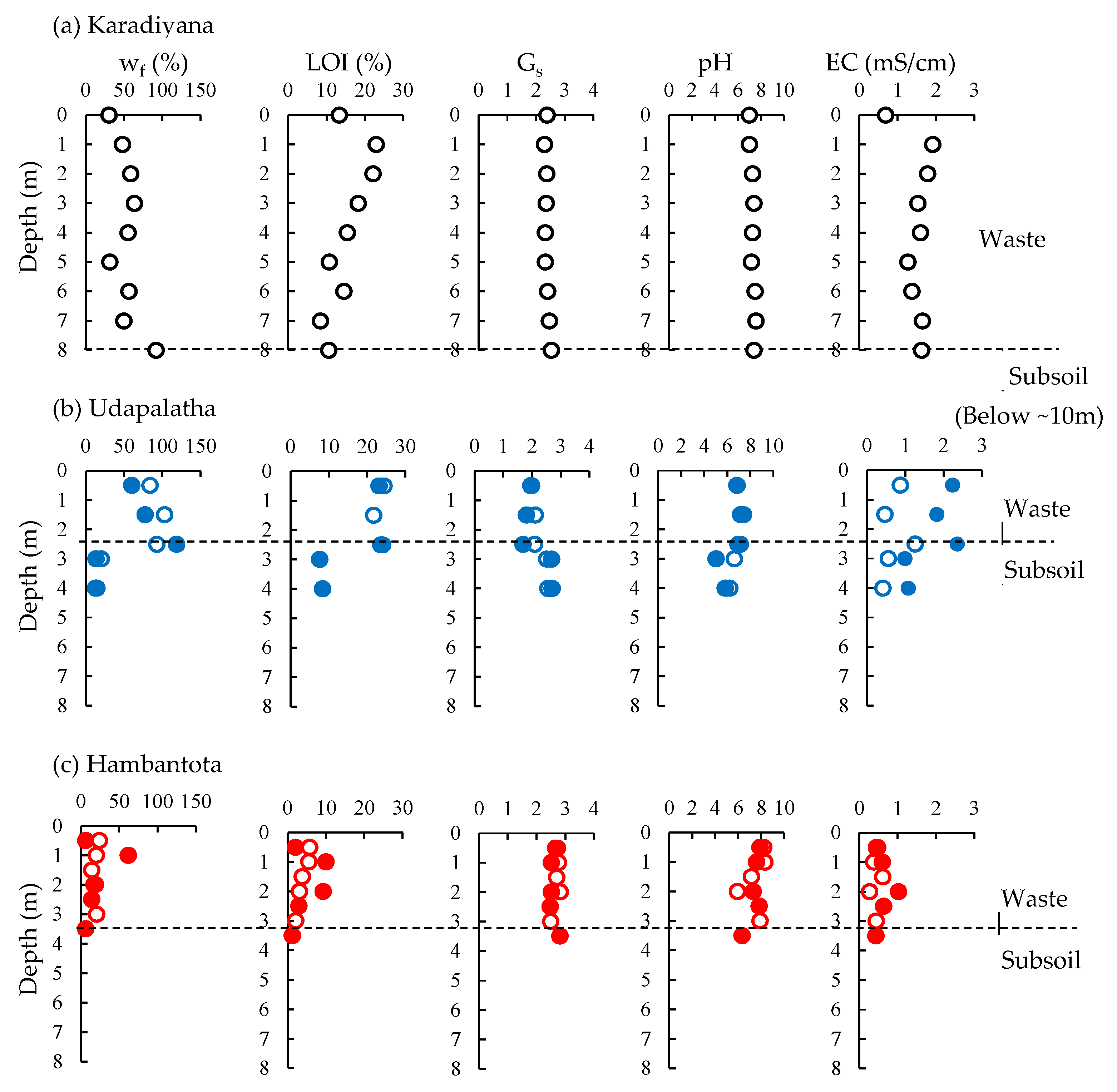

3.2. Physicochemical Properties

3.3. Mechanical Properties of Tested Samples

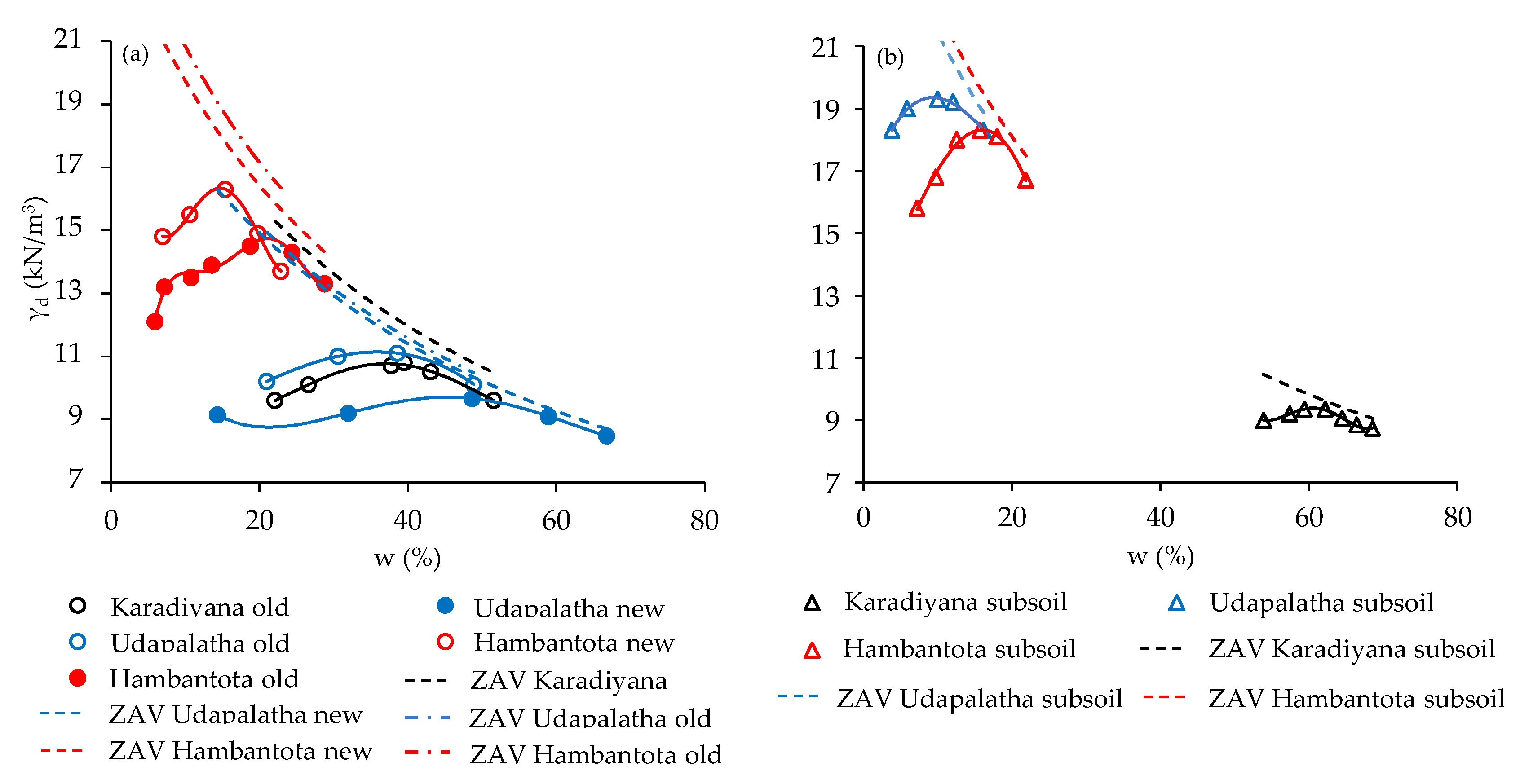

3.3.1. Compaction Properties

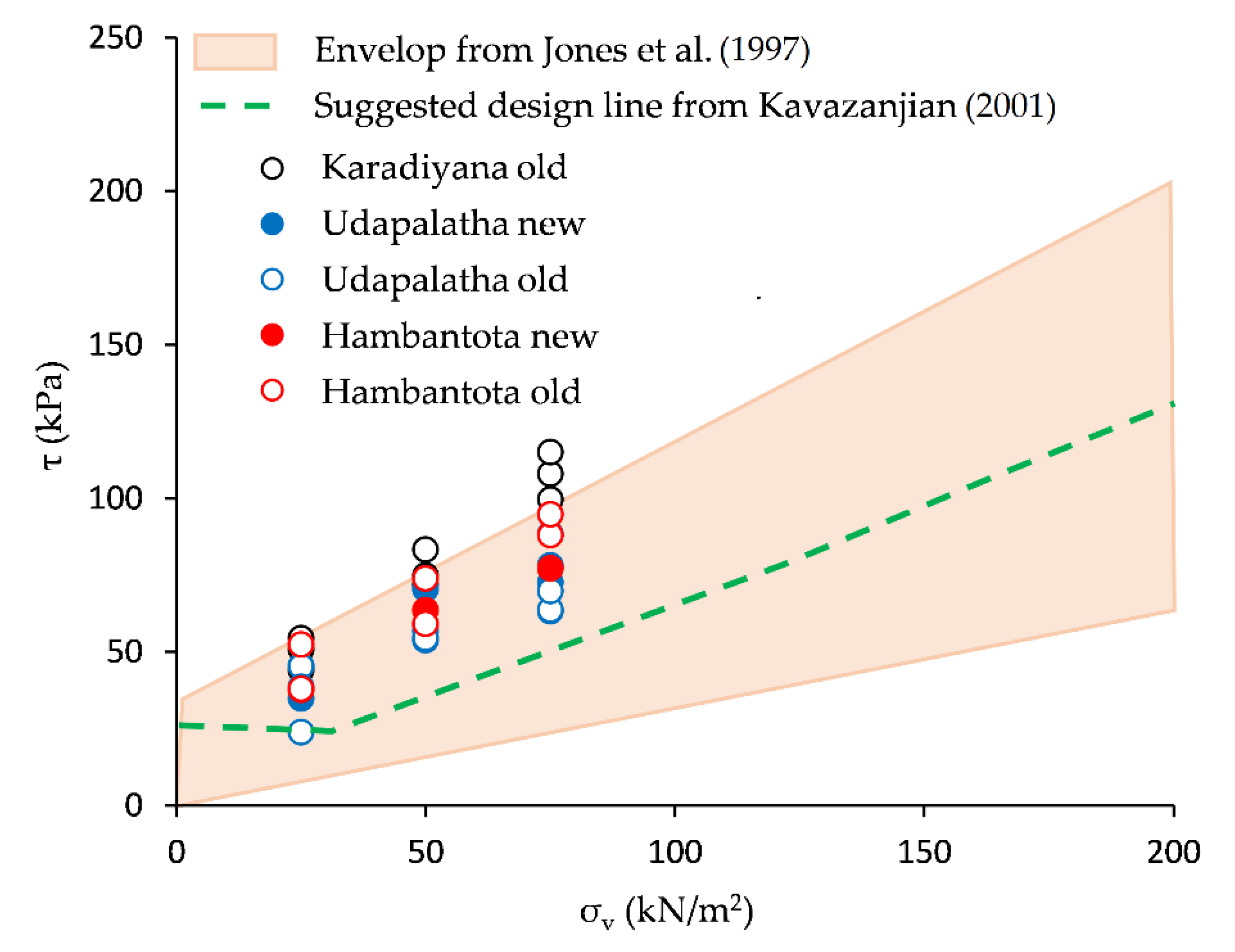

3.3.2. Shear Strength

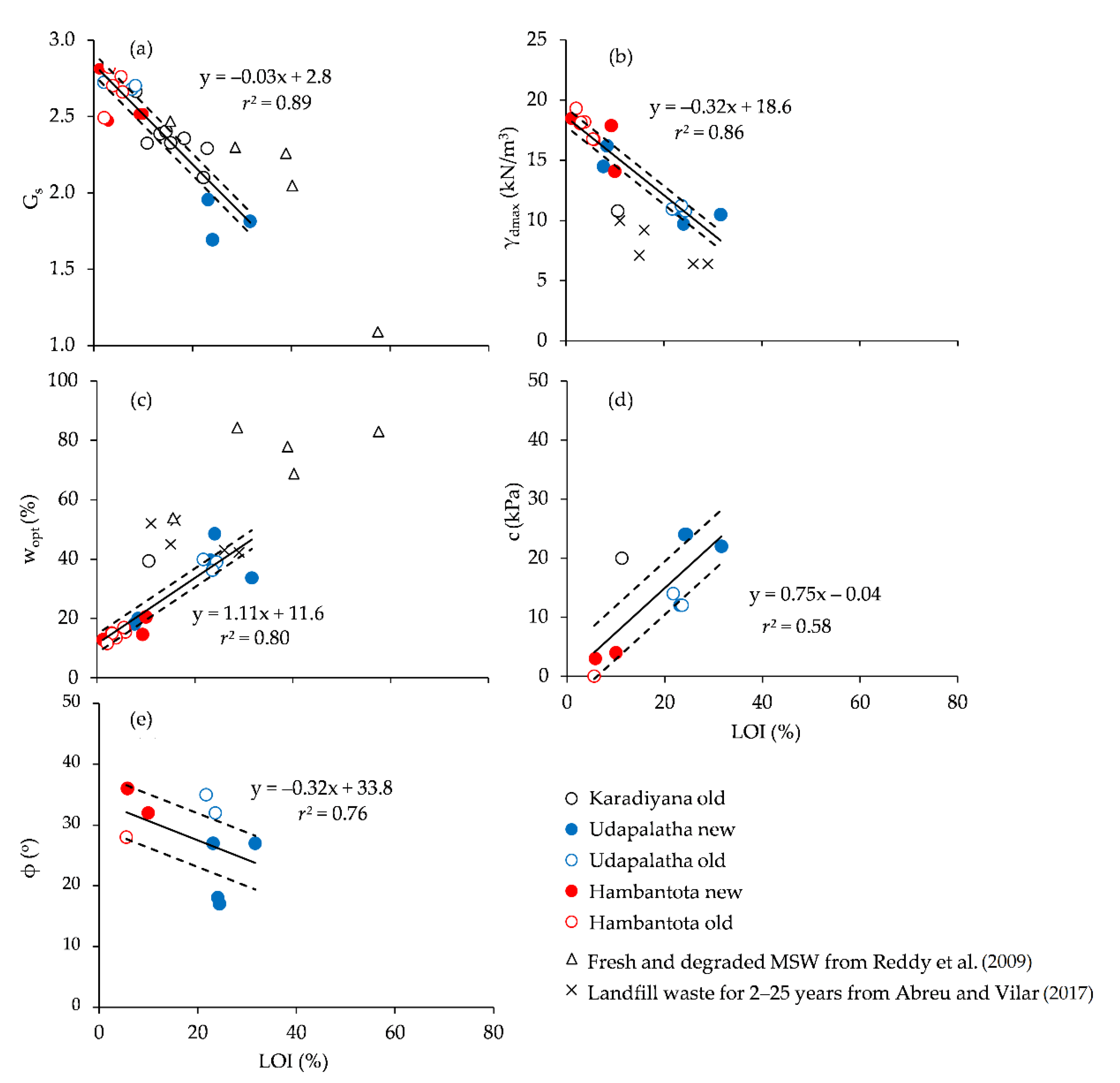

3.3.3. Links between Physicochemical and Mechanical Parameters

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fernando, R.L.S. Solid waste management of local governments in the Western Province of Sri Lanka: An implementation analysis. Waste Manag. 2019, 84, 194–203. [Google Scholar] [CrossRef]

- Falamaki, A.; Eskandari, M.; Khodayari, S.; Forouzeshfar, I.; Ghaedsharaf, A.; Baneshi, Z. Laboratory simulation of aeration on municipal solid waste from Barmshoor Landfill. Int. J. Civ. Eng. 2019, 17, 897–906. [Google Scholar] [CrossRef]

- UNDP. Sustainable Urbanization Strategy: UNDP’s Support to Sustainable, Inclusive and Resilient Cities in the Developing World. 2016. Available online: https://www.undp.org/publications/sustainable-urbanization-strategy#modal-publication-download (accessed on 14 March 2022).

- Balasooriya, B.L.C.B.; Priyankara, N.H.; Alagiyawanna, A.M.N.; Dayanthi, W.K.C.N. Waste amount and composition survey (WACS) in Galle and Hambantota municipal councils. In Proceedings of the 3rd International Symposium on Advances in Civil and Environmental Engineering Practices for Sustainable Development (ACEPS 2015), Galle, Sri Lanka, 9 March 2015; pp. 240–247. [Google Scholar]

- Iqbal, M.R.; Hashimoto, K.; Tachibana, S.; Kawamoto, K. Geotechnical properties of sludge blended with crushed concrete and incineration ash. Int. J. GEOMATE 2019, 57, 116–123. [Google Scholar]

- Asadi, M.; Shariatmadari, N.; Karimpour-Fard, M.; Noorzad, A. Validation of hyperbolic model by the results of triaxial and direct shear tests of municipal solid waste. Geotech. Geol. Eng. 2017, 35, 2003–2015. [Google Scholar] [CrossRef]

- Zhao, Y.R.; Xie, Q.; Wang, G.L.; Zhang, Y.J.; Zhang, Y.X.; Su, W. A study of shear strength properties of municipal solid waste in Chongqing landfill, China. Environ. Sci. Pollut. Res. 2014, 21, 12605–12615. [Google Scholar] [CrossRef]

- Chen, Y.-M.; Zhan, O.L.T. Environmental geotechnics related to landfills of municipal solid wastes. In Advances in Environmental Geotechnics, Proceedings of the International Symposium on Geoenvironmental Engineering—IGSE 2009, Hangzhou, China, 7–11 September 2009; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Singh, M.K.; Sharma, J.S.; Fleming, I.R. Shear strength testing of intact and recompacted samples of municipal solid waste. Can. Geotech. J. 2009, 46, 1133–1145. [Google Scholar] [CrossRef]

- Zhan, T.L.T.; Chen, Y.M.; Ling, W.A. Shear strength characterization of municipal solid waste at the Suzhou landfill, China. Eng. Geol. 2008, 97, 97–111. [Google Scholar] [CrossRef]

- Reddy, K.R.; Hettiarachchi, H.; Gangathulasi, J.; Bogner, J.E. Geotechnical properties of municipal solid waste at different phases of biodegradation. Waste Manag. 2011, 31, 2275–2286. [Google Scholar] [CrossRef]

- Stark, T.D.; Huvaj-Sarihan, N.; Li, G. Shear strength of municipal solid waste for stability analyses. Environ. Geol. 2008, 57, 1911–1923. [Google Scholar] [CrossRef]

- Jayaweera, M.; Gunawardana, B.; Gunawardana, M.; Karunawardena, A.; Dias, V.; Premasiri, S.; Dissanayake, J.; Manatunge, J.; Wijeratne, N.; Karunarathne, D.; et al. Management of municipal solid waste open dumps immediately after the collapse: An integrated approach from Meethotamulla open dump, Sri Lanka. Waste Manag. 2019, 95, 227–240. [Google Scholar] [CrossRef]

- Basnayake, B.F.A.; Popuri, S.; Visvanathan, C.; Jayatilake, A.; Weerasoori, I.; Ariyawansha, R.T.K. Concerted initiative for planned management of municipal solid waste in target provinces in Sri Lanka. J. Mater. Cycles Waste Manag. 2018, 21, 691–704. [Google Scholar] [CrossRef]

- ASTM D5231-92(2016); Standard Test Method for Determination of the Composition of Unprocessed Municipal Solid Waste. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM C136/C136M-19; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D854-14; Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D7348-13; Standard Test Methods for Loss on Ignition (LOI) of Solid Combustion Residues. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM D4318-17e1; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D4972-19; Standard Test Methods for pH of Soils. ASTM International: West Conshohocken, PA, USA, 2019.

- JGS 0212-2009; Test Method for Electric Conductivity of Suspended Soils. Japan Geotechnical Society: Tokyo, Japan, 2009.

- Ministry of the Environment. Report on the Investigation of Actual Condition of Municipal Solid Waste Treatment in Japan. Ministry of the Environment: Tokyo, Japan, 2020. Available online: https://www.env.go.jp/recycle/waste_tech/ippan/index.html (accessed on 14 March 2022). (In Japanese)

- JICA. Data Collection Survey on Solid Waste Management in Democratic Socialist Republic of Sri Lanka; JICA, Kokusai Kogyo Co.: Tokyo, Japan, 2016.

- Gunarathne, A.D.N.; Tennakoon, T.P.Y.C.; Weragoda, J.R. Challenges and opportunities for the recycling industry in developing countries: The case of Sri Lanka. J. Mater. Cycles Waste Manag. 2018, 21, 181–190. [Google Scholar] [CrossRef]

- Reddy, K.R.; Hettiarachchi, H.; Parakalla, N.S.; Gangathulasi, J.; Bogner, J.E. Geotechnical properties of fresh municipal solid waste at Orchard Hills Landfill, USA. Waste Manag. 2009, 29, 952–959. [Google Scholar] [CrossRef]

- Kurian, J.; Esakku, S.; Nagendran, R.; Visvanathan, C. A decision making tool for dumpsite rehabilitation in developing countrie. In Proceedings of the Tenth International Waste Management and Landfill Symposium (Sardinia 2005), Cagliari, Italy, 3–7 October 2005. [Google Scholar]

- Zekkos, D.P.; Bray, J.D.; Kavazanjian, E.; Matasovic, N.; Rathje, E.; Riemer, M.; Stokoe, K.H. Framework for the estimation of MSW unit weight profile. In Proceedings of the Tenth International Waste Management and Landfill Symposium (Sardinia 2005), Cagliari, Italy, 3–7 October 2005. [Google Scholar]

- Stoltz, G.; Gourc, J.P.; Oxarango, L. Characterisation of the physico-mechanical parameters of MSW. Waste Manag. 2010, 30, 1439–1449. [Google Scholar] [CrossRef]

- Stoltz, G.; Tinet, A.-J.; Staub, M.J.; Oxarango, L.; Gourc, J.-P. Moisture retention properties of municipal solid waste in relation to compression. J. Geotech. Geoenviron. Eng. 2012, 138, 535–543. [Google Scholar] [CrossRef]

- Stoltz, G.; Gourc, J.P.; Oxarango, L. Liquid and gas permeabilities of unsaturated municipal solid waste under compression. J. Contam. Hydrol. 2010, 118, 27–42. [Google Scholar] [CrossRef]

- Ramaiah, B.J.; Ramana, G.V.; Datta, M. Mechanical characterization of municipal solid waste from two waste dumps at Delhi, India. Waste Manag. 2017, 68, 275–291. [Google Scholar] [CrossRef]

- Gabr, M.A.; Hossain, M.S.; Barlaz, M.A. Shear strength parameters of municipal solid waste. J. Geotech. Geoenviron. Eng. 2007, 133, 478–484. [Google Scholar] [CrossRef]

- Machado, S.L.; Karimpour-Fard, M.; Shariatmadari, N.; Carvalho, M.F.; do Nascimento, J.C. Evaluation of the geotechnical properties of MSW in two Brazilian landfills. Waste Manag. 2010, 30, 2579–2591. [Google Scholar] [CrossRef] [Green Version]

- Machado, S.L.; Vilar, O.M.; Carvalho, M.F. Constitutive model for long term municipal solid waste mechanical behavior. Comput. Geotech. 2008, 35, 775–790. [Google Scholar] [CrossRef]

- Machado, S.L.; Carvalho, M.F.; Vilar, O.M. Constitutive model for municipal solid waste. J. Geotech. Geoenviron. Eng. 2002, 128, 940–951. [Google Scholar] [CrossRef]

- Maheshi, D.; Steven, V.P.; Karel, V.A. Environmental and economic assessment of ‘open waste dump’ mining in Sri Lanka. Resour. Conserv. Recycl. 2015, 102, 67–79. [Google Scholar] [CrossRef]

- The World‘s 50 Biggest Dumpsites, Waste Atlas Report 2014. D-WASTE.com. Available online: https://www.nswai.org/docs/World’s%20Fifty%20biggest%20dumpsites,Waste%20Atlas%202014.pdf (accessed on 14 March 2022).

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Woerden, F.V. (Eds.) What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; World Bank Group: Washington, WA, USA, 2018; Available online: https://openknowledge.worldbank.org/handle/10986/30317 (accessed on 14 March 2022).

- Alahacoon, N.; Edirisinghe, M. Spatial Variability of Rainfall Trends in Sri Lanka from 1989 to 2019 as an Indication of Climate Change. ISPRS Int. J. Geo-Inf. 2021, 10, 84. [Google Scholar] [CrossRef]

- Piumali, A.B.K.T.; Saito, T.; Priyankara, N.H.; Alagiyawanna, A.M.N.; Kawamoto, K. Characterization of physical, chemical, and compaction properties for buried municipal solid waste at three dumping sites in Sri Lanka. In Proceedings of the Seventh International Conference on GEOMATE, Tsu, Japan, 21–24 November 2017. [Google Scholar]

- Marasinghe, M. Policy evolution of solid waste management in Sri Lanka. J. Fac. Soc. Sci. Humanit. 2018, 7, 39–47. [Google Scholar]

- Nawagamuwa, U.P.; Thirojan, J. Determination of the age of municipal solid waste through soil tests. J. Inst. Eng. Sri Lanka 2020, 53, 53–62. [Google Scholar] [CrossRef]

- Dixon, N.; Langer, U. Development of a MSW classification system for the evaluation of mechanical properties. Waste Manag. 2006, 26, 220–232. [Google Scholar] [CrossRef] [Green Version]

- ASTM D698-12e2; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12 400 ft-lbf/ft3 (600 kN-m/m3)). ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM D3080/D3080M-11; Standard Test Method for Direct Shear Test of Soils under Consolidated Drained Conditions. ASTM International: West Conshohocken, PA, USA, 2011.

- Abreu, A.E.S.; Vilar, O.M. Influence of composition and degradation on the shear strength of municipal solid waste. Waste Manag. 2017, 68, 263–274. [Google Scholar] [CrossRef]

- Caicedo, B.; Yamin, L.; Giraldo, E.; Coronado, O. Geomechanical properties of municipal solid waste in Doña Juana sanitary landfill. In Proceedings of the Fourth International Congress on Environmental Geotechnics (4th ICEG), Rio de Janeiro, Brazil, 11–15 August 2002. [Google Scholar]

- Harris, J.M.; Shafer, A.L.; DeGroff, W.; Hater, G.R.; Gabr, M.; Barlaz, M.A. Shear strength of degraded reconsitituted municipal solid waste. Geotech. Test. J. 2006, 29, 141–148. [Google Scholar]

- Das, B.M.; Sivakugan, N. Fundamentals of Geotechnical Engineering, 5th ed.; Cengage Learning: Boston, MA, USA, 2016; pp. 247–254. [Google Scholar]

- Kavazanjian, E. Mechanical properties of municipal solid waste. In Proceedings of the Eighth International Waste Management and Landfill Symposium (Sardinia 2001), Cagliari, Italy, 1–5 October 2001; pp. 415–424. [Google Scholar]

- Jones, R.; Taylor, D.; Dixon, N. Shear strength of waste and its use in landfill stability analysis. In British Geoenvironmental Engineering Conference; British Geotechnical Society: Cardiff, UK, 1997; pp. 343–350. [Google Scholar]

| Sample Location | Age | Depth | Description | wf | γd, In-situ | Atterberg Limits | Gs | pH | EC | LOI | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (Year) | (m) | (%) | (kN m−3) | wL (%) | wP (%) | IP | (mS cm−1) | (%) | ||||

| Karadiyana site | ||||||||||||

| Old | >20 | 0.0–2.0 | Blackish dumped waste | 45.5 | - | - | - | - | 2.26 | 7.1 | 1.46 | 19.5 |

| 2.0–4.0 | 59.0 | - | - | - | - | 2.26 | 7.3 | 1.63 | 18.7 | |||

| 4.0–6.0 | 47.8 | - | - | - | - | 2.35 | 7.3 | 1.41 | 13.6 | |||

| 6.0–8.0 | 65.9 | 4.68 | 68.2 | 54.3 | 13.9 | 2.66 | 7.5 | 1.55 | 11.2 | |||

| Original soil | - | 2.0–3.0 | Peaty soil | 137 | 5.04 | 54.2 | 36.1 | 18.1 | 2.42 | 6.5 | 5.37 | 20.9 |

| Udapalatha site | ||||||||||||

| New | <3 | 0.0–1.0 | Blackish dumped waste with fine sand | 60.2 | 6.41 | NM * | NM * | NP ** | 1.96 | 6.9 | 2.24 | 23.1 |

| 1.0–2.0 | Blackish dumped waste with clay and sand | 77.7 | 7.03 | NM * | NM * | NP ** | 1.81 | 7.2 | 1.83 | 31.6 | ||

| 2.0–2.75 | Blackish dumped waste with fine sand | 119 | - | NM * | NM * | NP ** | 1.69 | 6.9 | 2.36 | 24.0 | ||

| Old | 7–11 | 0.0–1.0 | Black, dumped waste | 83.8 | 5.31 | NM * | NM * | NP ** | 1.99 | 6.8 | 0.88 | 24.4 |

| 1.0–2.0 | 103 | 5.17 | NM * | NM * | NP ** | 2.12 | 7.4 | 0.47 | 21.7 | |||

| 2.0–3.0 | 93 | 4.56 | NM * | NM * | NP ** | 2.1 | 7.1 | 1.26 | 23.6 | |||

| Subsoil | - | 1.0–2.0 | Brown, medium to fine sand with gravel | 12 | - | - | - | - | 2.54 | 6 | 0.04 | 2.07 |

| Hambantota site | ||||||||||||

| New | <1 | 0.5–1.0 | Blackish dumped waste with clay and sand | 61.9 | 7.8 | 25.7 | NM * | - | 2.52 | 7.6 | 0.6 | 9.96 |

| Old (pit 1) | 7–8 | 0.0–0.5 | Blackish dumped waste with clay and sand | 17.8 | 10.4 | - | - | - | 2.64 | 7.3 | 0.236 | 7.10 |

| 0.5–1.0 | 36.2 | 10.3 | - | - | - | 2.72 | 7.3 | 0.308 | 7.44 | |||

| Old (pit 2) | 0.0–0.5 | 24.1 | 12.1 | 29.5 | NM * | - | 2.66 | 8.2 | 0.48 | 5.78 | ||

| 0.5–1.0 | 19.9 | 8.45 | 30.6 | 15.5 | 15.1 | 2.76 | 8.3 | 0.38 | 5.50 | |||

| Subsoil | - | 1.0–2.0 | Gray, weathered silty sandy clay | 18.6 | - | 24.8 | 22.9 | 1.89 | 2.67 | 7.5 | 0.07 | 3.44 |

| Karadiyana [42] | 1 | 1–2 | - | - | - | 61.7 | 36.8 | 24.9 | 1.73 | - | - | 72–80 |

| 2 | 1–2 | - | - | - | 50.3 | 36.0 | 15.6 | 1.66 | - | - | ||

| 7–10 | 1–3 | - | - | - | 20.4 | 15.9 | 4.5 | 1.84 | - | - | 35–44 | |

| Jaffna [42] | 10–13 | - | - | - | 18.5 | 16.1 | 2.4 | 2.08 | - | - | 18–23 | |

| 13–15 | - | - | - | 20.5 | 15.5 | 4.0 | 2.24 | - | - | |||

| Material | Karadiyana Old | Udapalatha New | Udapalatha Old | Hambantota New | Hambantota Old |

|---|---|---|---|---|---|

| Paper | 0.6 | 0.1 | 1.7 | 0.0 | 0.0 |

| Plastic | 5.4 | 3.2 | 2.3 | 0.0 | 0.0 |

| Vinyl | 5.2 | 7.7 | 6.8 | 3.6 | 8.8 |

| Glass, ceramic, and metal | 4.0 | 6.7 | 5.9 | 3.3 | 3.4 |

| Leather and rubber | 1.4 | 0.1 | 2.8 | 0.0 | 0.0 |

| Textile | 1.9 | 1.0 | 4.6 | 1.1 | 0.4 |

| Grass and wood | 13.8 | 10.8 | 6.5 | 0.6 | 4.5 |

| Cementitious material | 3.0 | 13.4 | 4.2 | 0.0 | 0.0 |

| Gravel (>9.50 mm) | 8.3 | 5.7 | 9.0 | 17.5 | 8.2 |

| Residues (2.0–4.75 mm) | 33.2 | 17.1 | 21.6 | 31.5 | 30.7 |

| Residues (<2.0 mm) | 22.9 | 34.3 | 34.6 | 42.4 | 44.0 |

| Others | 0.4 | 0.0 | 0.0 | 0.0 | 0.0 |

| Total | 100 | 100 | 100 | 100 | 100 |

| Sample Details (Age after Dumping) | Depth | Compaction | Direct Shear Stress | Shear Strength Parameters * | Measured SD Range (%) | Reference | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| (m) | wopt (%) | γdmax (kN m−3) | τ (kN m−2) | c (kN m−2) | ϕ (o) | |||||

| σv = 25 kPa | σv = 50 kPa | σv = 75 kPa | ||||||||

| Karadiyana site | ||||||||||

| Old (>20 years) | 6.0–8.0 | 39.3 | 10.8 | 53.7 | 74.8 | 98.1 | 35 | 48 | 15 | This study |

| Original soil | 2.0–3.0 | 62.1 | 9.3 | - | - | - | - | - | ||

| Udapalatha site | ||||||||||

| New (<3 years) | 0.0–1.0 | 39.7 | 10.9 | 34.9 | 53.9 | 63.3 | 20 | 31 | ||

| 1.0–2.0 | 33.7 | 10.5 | 45.4 | 70.4 | 78.2 | 26 | 38 | |||

| 2.0–2.75 | 48.6 | 9.7 | 45.4 | 56.8 | 72.7 | 30 | 30 | |||

| Old (7–11 years) | 0.0–1.0 | 39.0 | 10.8 | 23.8 | 54.5 | 63.7 | 23 | 29 | ||

| 1.0–2.0 | 39.9 | 11.1 | 45.3 | 58.9 | 88.4 | 13 | 44 | |||

| 2.0–3.0 | 36.2 | 11.3 | 38.6 | 54.4 | 69.8 | 24 | 32 | |||

| Subsoil | 1.0–2.0 | 11.0 | 19.3 | - | - | - | - | - | ||

| Hambantota site | ||||||||||

| New (<1 year) | 0.5–1.0 | 20.5 | 14.1 | 37.6 | 63.5 | 77.2 | 24 | 35 | ||

| Old (pit 1) (7–11 years) | 0.0–0.5 | 13.4 | 17.3 | - | - | - | - | - | ||

| 0.5–1.0 | 16.1 | 16.3 | - | - | - | - | - | |||

| Old (pit 2) (7–11 years) | 0.0–0.5 | 15.4 | 16.8 | 38.0 | 59.2 | 88.1 | 11.7 | 45.1 | ||

| 0.5–1.0 | 17.0 | 16.8 | 52.4 | 73.9 | 94.7 | 31.3 | 40.3 | |||

| Subsoil | 1.0–2.0 | 16.6 | 18.3 | - | - | - | - | - | ||

| The literature | ||||||||||

| (Sri Lanka: Wet climate zone) | ||||||||||

| Karadiyana (<1 year) | 1–2 | 46 | 9.60 | - | - | - | 10.5 | 56 | 15 | [42] |

| Karadiyana (<2 years) | 1–2 | 47 | 9.15 | - | - | - | 15.1 | 49.5 | 15 | |

| (Sri Lanka: Dry climate zone) | ||||||||||

| Jaffna (7–10 years) | 1–3 | 20.3 | 15.2 | - | - | - | 27.6 | 28 | 15 | |

| Jaffna (10–13 years) | 1–3 | 16.7 | 15.6 | - | - | - | 34.0 | 41.5 | 15 | [42] |

| Jaffna (13–15 years) | 1–3 | 16.5 | 15.4 | - | - | - | 17.7 | 44 | 15 | |

| (Other regions) | ||||||||||

| Fresh Landfill | - | 70 | 4.10 | 180 | 240 | 560 | 31–64 | 26–30 | 15 | [13] |

| Landfills (<1 years) | - | 67 | 10.0 | 13 | 56 | 117 | 23 | 24 | 15 | [46] |

| Landfill (<2 years) | - | - | 11–17 | - | - | - | 9–14 | 20–29 | 10 | [47] |

| Landfill (12–34 years) | - | - | 12.6–15.8 | - | - | - | 14 | 36 | 5 | [9] |

| Landfill (2–25 years) | 1–9 | 39–52.3 | 5.1–10.1 | 50 | 100 | 250 | 4.4–13.7 | 22–30 | 15 | [48] |

| Parameters | Gs | LOI (%) | pH | EC (mS cm−1) | γdmax (kN m−3) | wopt (%) | c (kN m−2) | ϕ (o) | No. of Samples |

|---|---|---|---|---|---|---|---|---|---|

| Gs | 1 | −0.89 | 0.64 | −0.70 | 0.70 | −0.68 | −0.47 | 0.91 | 17 |

| LOI | 1 | −0.68 | 0.61 | −0.86 | 0.80 | 0.58 | −0.76 | 20 | |

| pH | 1 | −0.51 | 0.71 | −0.69 | −0.18 | 0.89 | 20 | ||

| EC | 1 | −0.78 | 0.78 | 0.45 | −0.85 | 20 | |||

| γd, max | 1 | −0.97 | −0.31 | 0.81 | 12 | ||||

| wopt | 1 | 0.30 | −0.79 | 12 | |||||

| c | 1 | −0.46 | 9 | ||||||

| ϕ | 1 | 9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iqbal, M.R.; Piumali, A.B.K.T.; Priyankara, N.H.; Alagiyawanna, A.M.N.; Kurukulasuriya, L.C.; Kawamoto, K. Characterization of Physicochemical and Mechanical Properties of Dumped Municipal Solid Waste in Sri Lanka as Affected by the Climate Zone and Dumping Age. Sustainability 2022, 14, 4706. https://doi.org/10.3390/su14084706

Iqbal MR, Piumali ABKT, Priyankara NH, Alagiyawanna AMN, Kurukulasuriya LC, Kawamoto K. Characterization of Physicochemical and Mechanical Properties of Dumped Municipal Solid Waste in Sri Lanka as Affected by the Climate Zone and Dumping Age. Sustainability. 2022; 14(8):4706. https://doi.org/10.3390/su14084706

Chicago/Turabian StyleIqbal, Muhammad Rashid, Abeywickrama Bamunusin Kankanamge Thilini Piumali, Nadeej Hansaraj Priyankara, Alagiyawanna Mohottalalage Nayana Alagiyawanna, Laksiri Chandana Kurukulasuriya, and Ken Kawamoto. 2022. "Characterization of Physicochemical and Mechanical Properties of Dumped Municipal Solid Waste in Sri Lanka as Affected by the Climate Zone and Dumping Age" Sustainability 14, no. 8: 4706. https://doi.org/10.3390/su14084706

APA StyleIqbal, M. R., Piumali, A. B. K. T., Priyankara, N. H., Alagiyawanna, A. M. N., Kurukulasuriya, L. C., & Kawamoto, K. (2022). Characterization of Physicochemical and Mechanical Properties of Dumped Municipal Solid Waste in Sri Lanka as Affected by the Climate Zone and Dumping Age. Sustainability, 14(8), 4706. https://doi.org/10.3390/su14084706