Assessing Durability Properties and Economic Potential of Shellfish Aquaculture Waste in the Construction Industry: A Circular Economy Perspective

Abstract

:1. Introduction

- Environmental problems: these wastes can produce odors due to the decomposition of organic matter or of salts contained in the shells, emitting gases such as H2S, NH3 (ammonia) and organic compounds such as amine [11].

- Economic problems: pollution and odors have an economic impact on tourism given that aquaculture enterprises are located on seashores with heavy tourism [12].

- Health problems: illegal dumping of these wastes attracts biological vectors such as rats and mosquitoes in nearby populations [13].

- Social problems: currently, there are few economic and effective solutions for managing shell waste, which has led to the proliferation of illegal waste dumping near populated areas [14]. The foul odors and contamination from dumping have led to protests and complaints from neighboring communities [15].

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Product Durability Tests

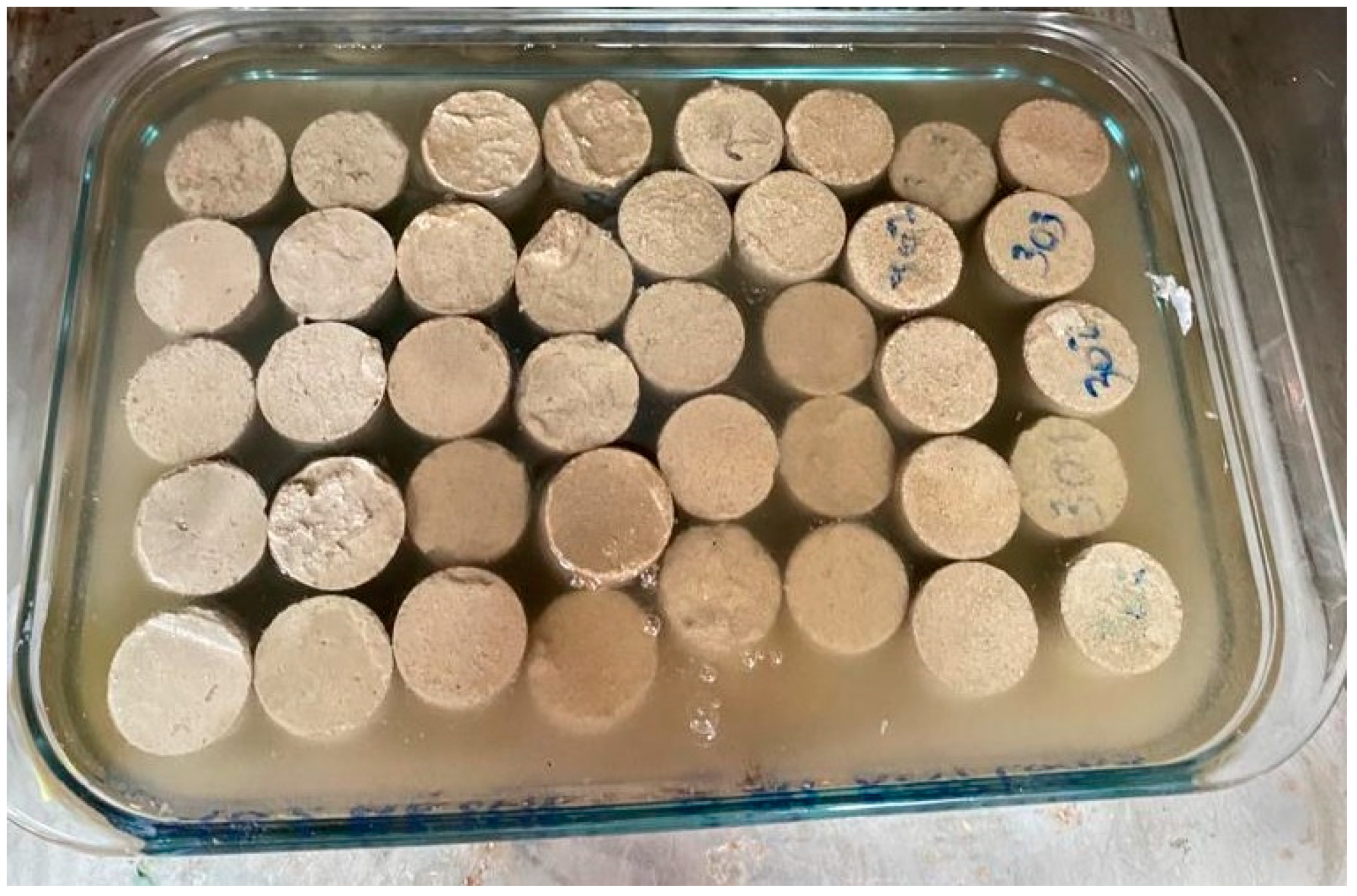

- Resistance to Acid Attack

- Resistance to Sulfate Attack

- Resistance to Freeze-Thaw Cycles

2.2.2. Economic Analysis

- Benefits/Savings Related to The Use of CaCO3—Construction

- Scallop Shell Generation Potential and Disposal Cost—Aquaculture

- Modified Payback Period

- Circular Economy—Construction and Aquaculture

3. Results and Discussion

3.1. Durability

3.1.1. Initial Properties

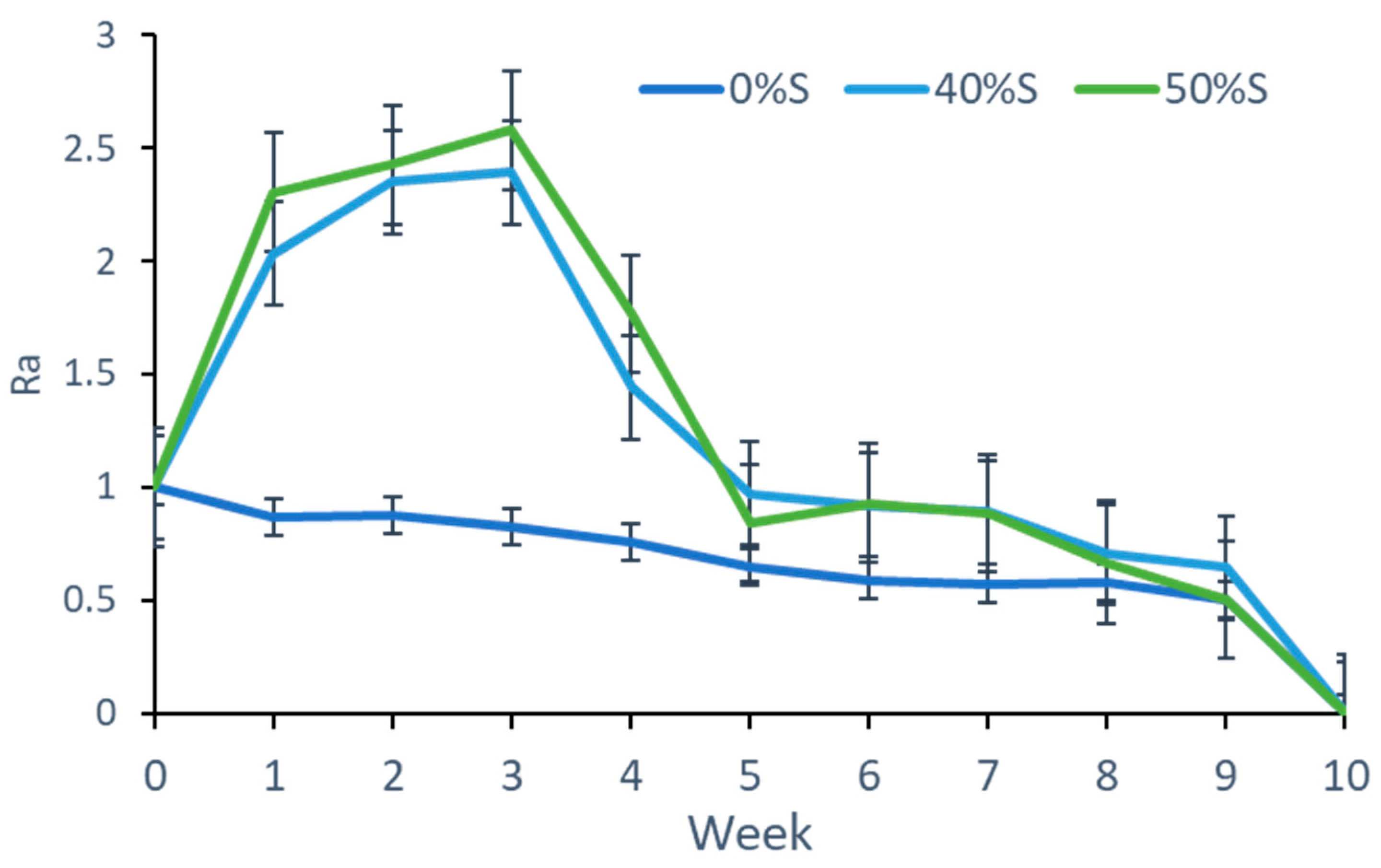

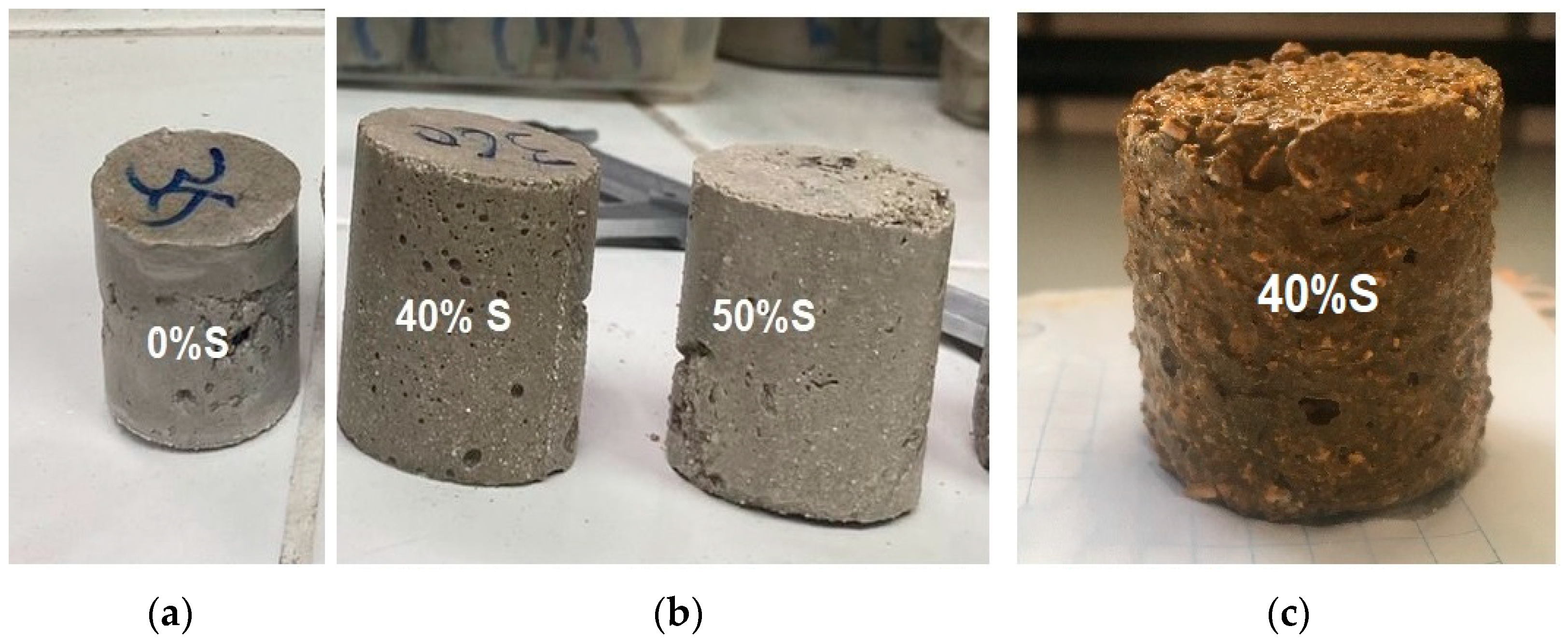

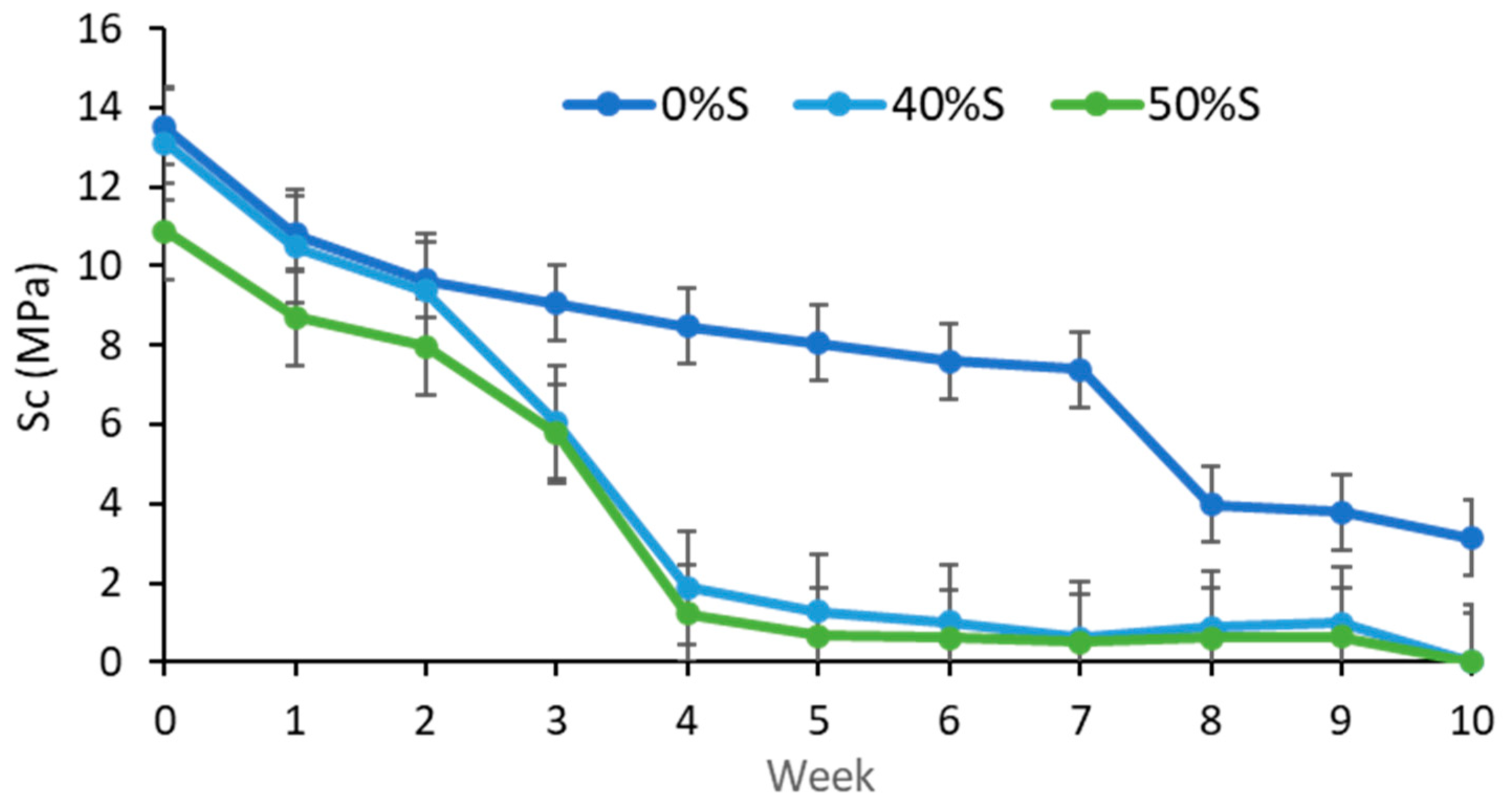

3.1.2. Acid Attack

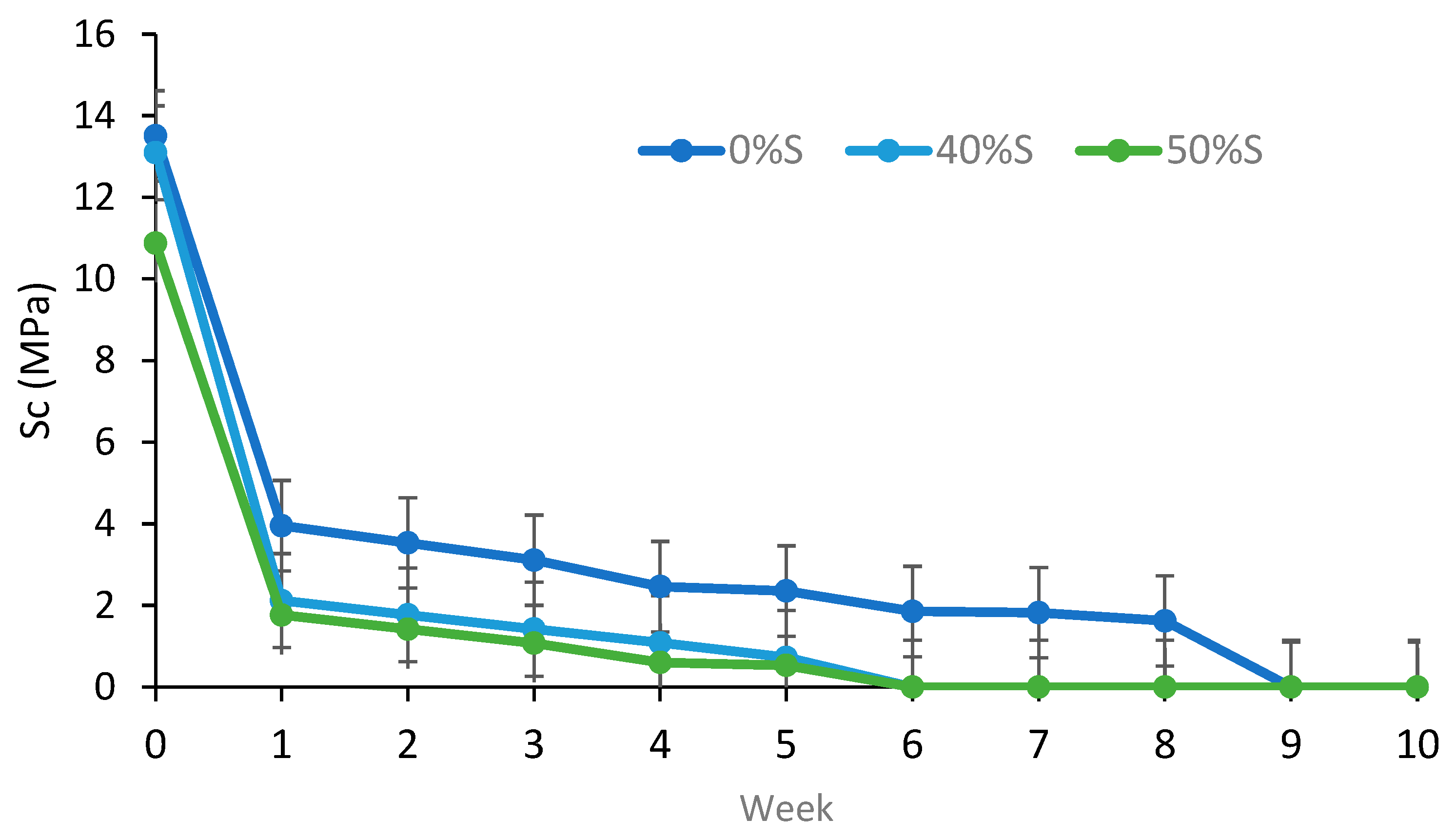

3.1.3. Sulfate Attack

3.1.4. Resistance to Freeze-Thaw

3.2. Economic Analysis

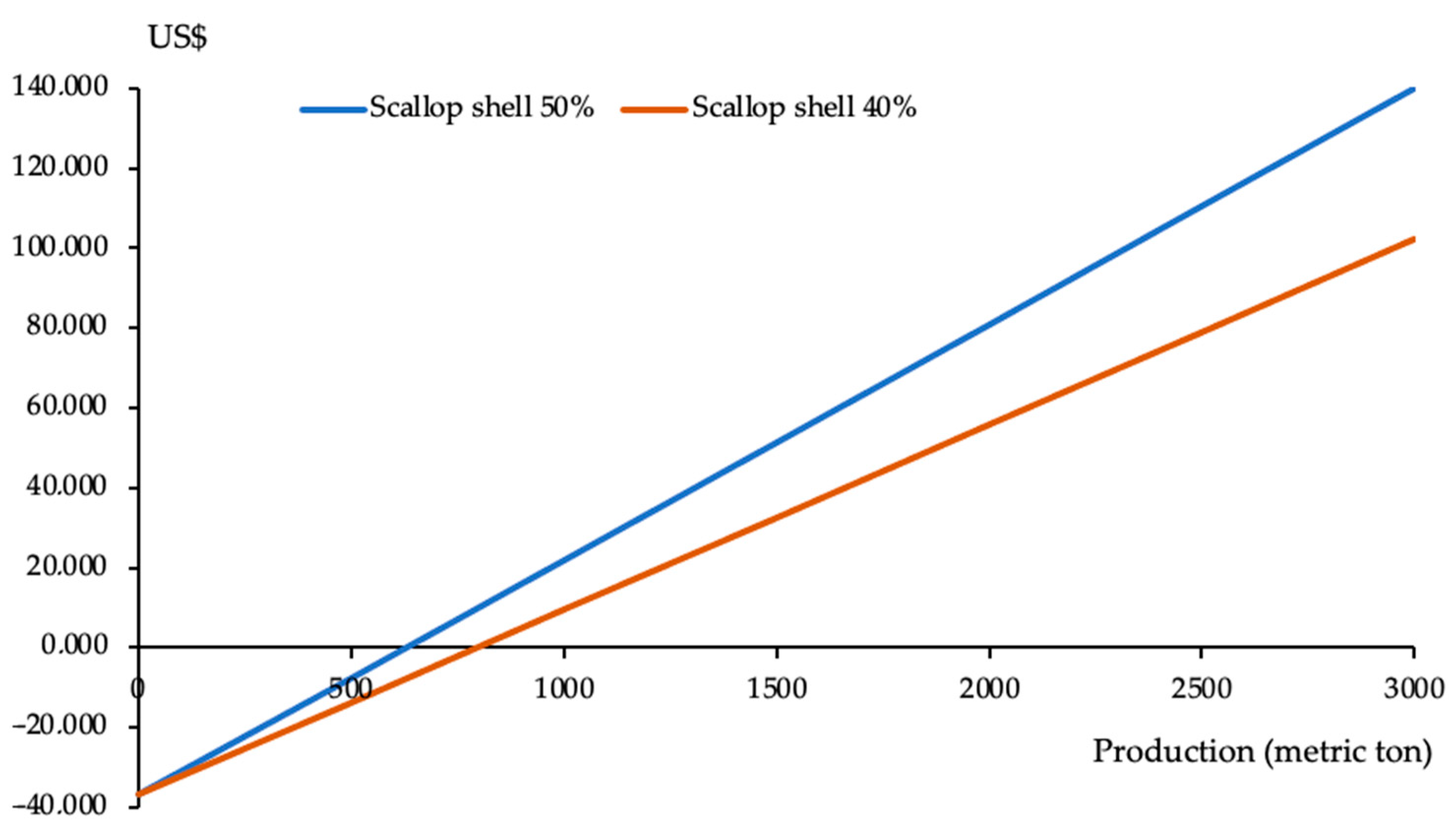

3.2.1. Benefits/Savings Related to the Use of CaCO3—Construction

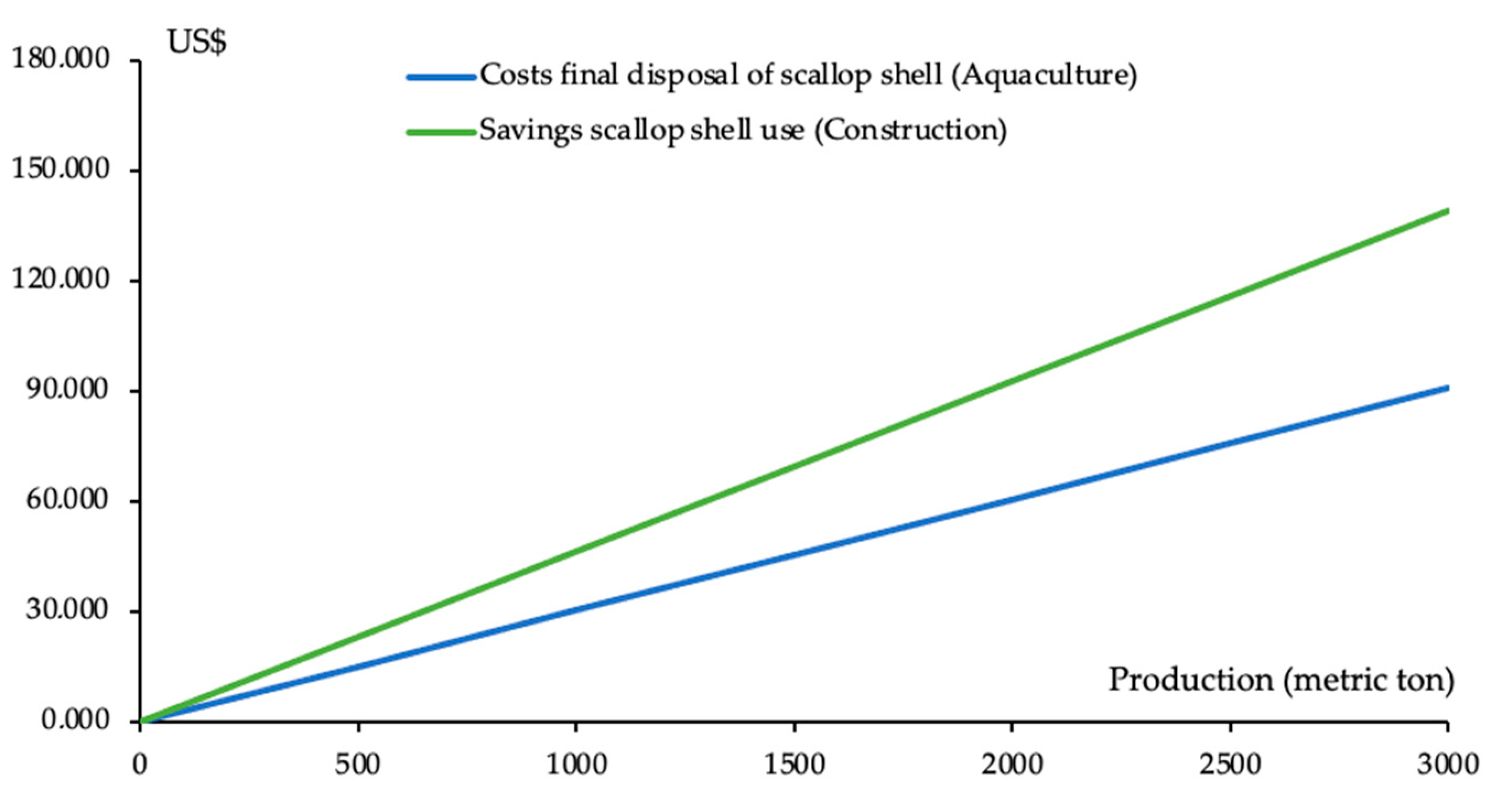

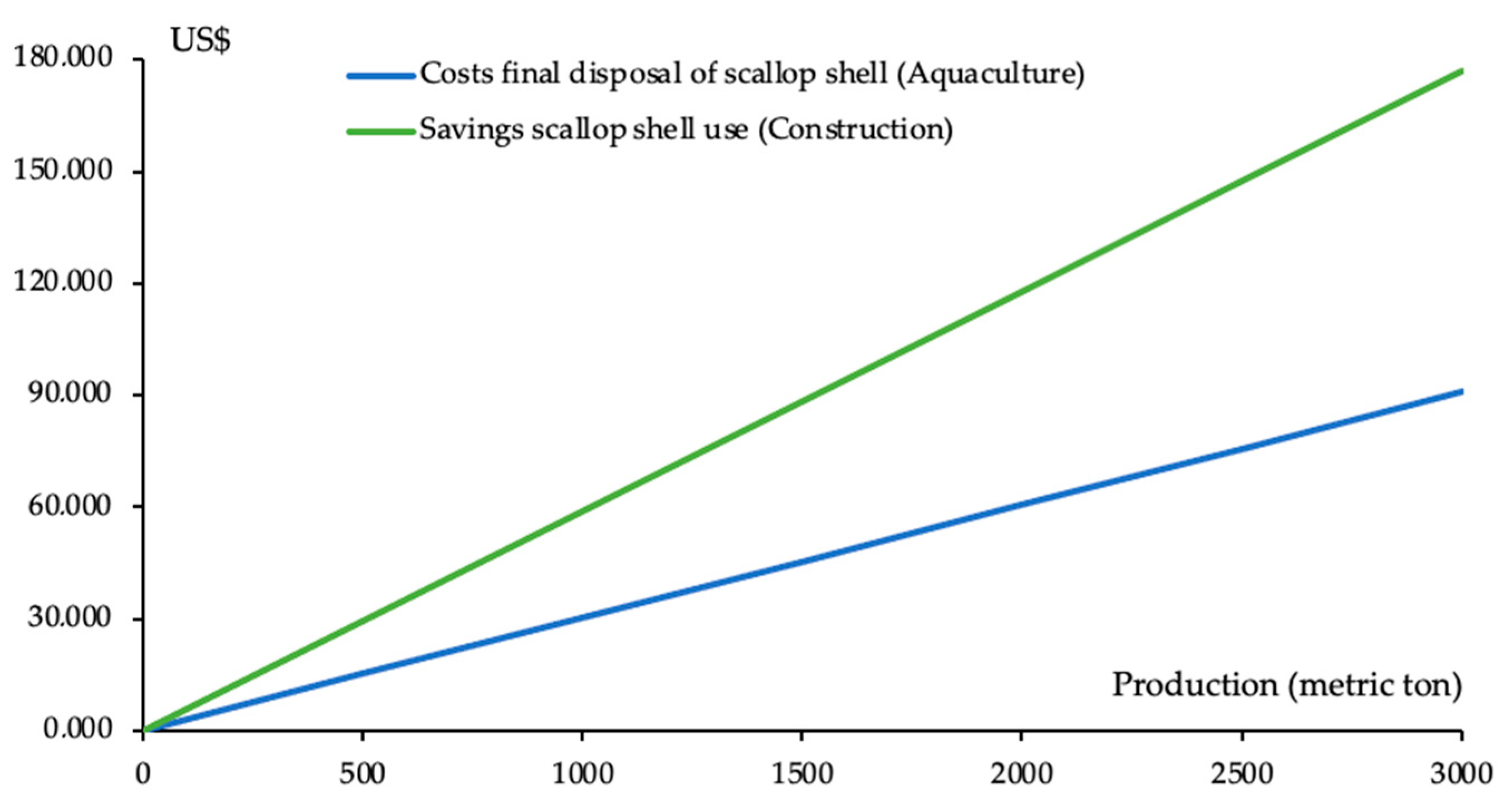

3.2.2. Scallop Shell Generation Potential and Disposal Cost—Aquaculture

3.2.3. Modified Payback Period

3.2.4. Benefits/Savings Related to the Use of CaCO3—Construction

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Secher, A.Q.; Collin, C.; Linnet, A. Construction Product Declarations and Sustainable Development Goals for Small and Medium Construction Enterprises. Procedia CIRP 2018, 69, 54–58. [Google Scholar] [CrossRef]

- Ingrao, C.; Arcidiacono, C.; Bezama, A.; Ioppolo, G.; Winans, K.; Koutinas, A.; Schmid, A.G. Virtual Special Issue on sustainability issues of by-product and waste management systems to produce building material commodities. Resour. Conserv. Recycl. 2017, 126, A4–A5. [Google Scholar] [CrossRef]

- Alawneh, R.; Mohamed Ghazali, F.E.; Ali, H.; Asif, M. Assessing the contribution of water and energy efficiency in green buildings to achieve United Nations Sustainable Development Goals in Jordan. Build. Environ. 2018, 146, 119–132. [Google Scholar] [CrossRef]

- Qin, G.; Zhang, P.; Wang, Y. Investigating an assessment model of system oil leakage considering failure dependence. Environ. Sci. Pollut. Res. 2020, 27, 40075–40087. [Google Scholar] [CrossRef] [PubMed]

- UNEP. One Planet Network. Available online: https://www.unenvironment.org/explore-topics/resource-efficiency/what-we-do/one-planet-network (accessed on 2 June 2021).

- Şahin, O.; İlcan, H.; Ateşli, A.T.; Kul, A.; Yıldırım, G.; Şahmaran, M. Construction and demolition waste-based geopolymers suited for use in 3-dimensional additive manufacturing. Cem. Concr. Compos. 2021, 121, 104088. [Google Scholar] [CrossRef]

- Pasternak, G.; Ormeno-Cano, N.; Rutkowski, P. Recycled waste polypropylene composite ceramic membranes for extended lifetime of microbial fuel cells. Chem. Eng. J. 2021, 425, 130707. [Google Scholar] [CrossRef]

- Zhou, Z.; Hu, J.; Li, F.; Zhang, J.; Lei, M. Elastic Modulus Prediction Model of Foamed Concrete Based on the Walsh Formula. Appl. Sci. 2022, 12, 5142. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhang, J.; Gong, C. Automatic detection method of tunnel lining multi-defects via an enhanced You Only Look Once network. Comput.-Aided Civ. Infrastruct. Eng. 2022, 37, 762–780. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Hasaniyah, M.W.; Zeyad, A.M.; Yusuf, M.O. Properties of concrete containing recycled seashells as cement partial replacement: A review. J. Clean. Prod. 2019, 237, 117723. [Google Scholar] [CrossRef]

- Eziefula, U.G.; Ezeh, J.C.; Eziefula, B.I. Properties of seashell aggregate concrete: A review. Constr. Build. Mater. 2018, 192, 287–300. [Google Scholar] [CrossRef]

- Kwon, H.B.; Lee, C.W.; Jun, B.S.; Yun, J.D.; Weon, S.Y.; & Koopman, B. Recycling waste oyster shells for eutrophication control. Resour. Conserv. Recycl. 2004, 41, 75–82. [Google Scholar] [CrossRef]

- Felipe-Sesé, M.; Eliche-Quesada, D.; Corpas-Iglesias, F.A. The use of solid residues derived from different industrial activities to obtain calcium silicates for use as insulating construction materials. Ceram. Int. 2011, 37, 3019–3028. [Google Scholar] [CrossRef]

- La voz de Galicia. Los Conserveros Plantean la Posibilidad de Verter Concha de Mejillón en el Mar. Available online: https://www.lavozdegalicia.es/noticia/arousa/2000/08/25/conserveros-plantean-posibilidad-verter-concha-mejillon-mar/0003_169074.htm (accessed on 2 June 2021).

- La voz de Galicia. Eliminan un Vertido a la Ría Causado por un Depósito de Concha de Mejillón. Available online: https://www.lavozdegalicia.es/noticia/arousa/2020/04/26/eliminan-vertido-ria-causado-deposito-concha-mejillon/0003_202004A26C10993.htm (accessed on 2 June 2021).

- Ngii, E.; Mustika, W.; Sukri, A.S.; Balaka, R.; Sriyani, R.; Welendo, L. The effect of clamshells partial substitution of coarse aggregates on the mechanical properties of shellfish concrete (Berang). IOP Conf. Ser. Earth Environ. Sci. 2020, 419, 12064. [Google Scholar] [CrossRef]

- Ndoke, P.N.; Ndoke, P. Performance of Palm Kernel Shells as a Partial replacement for Coarse Aggregate in Asphalt Concrete. Leonardo Electron. J. Pract. Technol. 2006, 9, 145–152. Available online: https://www.researchgate.net/profile/Peter-Ndoke/publication/26449133_Performance_of_Palm_Kernel_Shells_as_a_Partial_replacement_for_Coarse_Aggregate_in_Asphalt_Concrete/links/0a85e536f94d5d1f70000000/Performance-of-Palm-Kernel-Shells-as-a-Partial-replacement-for-Coarse-Aggregate-in-Asphalt-Concrete.pdf?_sg%5B0%5D=started_experiment_milestone&origin=journalDetail (accessed on 28 April 2022).

- Richardson, A.E.; Fuller, T. Sea shells used as partial aggregate replacement in concrete. Struct. Surv. 2013, 31, 347–354. [Google Scholar] [CrossRef]

- Seo, J.H.; Park, S.M.; Yang, B.J.; Jang, J.G. Calcined oyster shell powder as an expansive additive in cement mortar. Materials 2019, 12, 1322. [Google Scholar] [CrossRef] [Green Version]

- Talha Zaid, S.; Ghorpade, V.G.; Pradesh Anantapur, A.; Pradesh, A. Experimental Investigation of Snail Shell Ash (SSA) as Partial Repalacement of Ordinary Portland Cement in Concrete. Int. J. Eng. Res. 2014, 3, 2278-0181. [Google Scholar]

- Umoh, A.A.; Ujene, A.O. Improving the strength performance of high volume periwinkle shell ash blended cement concrete with sodium nitrate as accelerator. JCEST 2015, 6, 18–22. [Google Scholar] [CrossRef] [Green Version]

- Sickels-Taves, L.B.; Sheehan, M.S. The Lost Art of Tabby Redefined: Preserving Oglethorpe’s Architectural Legacy, 1st ed.; Architectural Conservation Press: Southfield, MI, USA, 1999; pp. 1–200. [Google Scholar]

- Asaoka, S.; Yamamoto, T.; Kondo, S.; Hayakawa, S. Removal of hydrogen sulfide using crushed oyster shell from pore water to remediate organically enriched coastal marine sediments. Bioresour. Technol. 2009, 100, 4127–4132. [Google Scholar] [CrossRef] [Green Version]

- Bolan, N.S.; Adriano, D.C.; Curtin, D. Soil acidification and liming interactions with nutrient and heavy metal transformation and bioavailability. Adv. Agron. 2003, 78, 5–272. [Google Scholar]

- Lee, C.H.; Lee, D.K.; Ali, M.A.; Kim, P.J. Effects of oyster shell on soil chemical and biological properties and cabbage productivity as a liming material. Waste Manag. 2008, 28, 2702–2708. [Google Scholar] [CrossRef] [PubMed]

- Bozbaş, S.K.; Boz, Y. Low-cost biosorbent: Anadara inaequivalvis shells for removal of Pb(II) and Cu(II) from aqueous solution. Process Saf. Environ. Prot. 2016, 103, 144–152. [Google Scholar] [CrossRef]

- Du, Y.; Lian, F.; Zhu, L. Biosorption of divalent Pb, Cd and Zn on aragonite and calcite mollusk shells. Environ. Pollut. 2011, 159, 1763–1768. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Chen, J.; Clark, M.; Yu, Y. Adsorption of copper to different biogenic oyster shell structures. Appl. Surf. Sci. 2014, 311, 264–272. [Google Scholar] [CrossRef]

- Kaewdaeng, S.; Sintuya, P.; Nirunsin, R. Biodiesel production using calcium oxide from river snail shell ash as catalyst. Energy Procedia 2017, 138, 937–942. [Google Scholar] [CrossRef]

- Boro, J.; Thakur, A.J.; Deka, D. Solid oxide derived from waste shells of Turbonilla striatula as a renewable catalyst for biodiesel production. Fuel Process. Technol. 2011, 92, 2061–2067. [Google Scholar] [CrossRef]

- Norazlina, H.; Fahmi, A.R.M.; Hafizuddin, W.M. CaCO3 from seashells as a reinforcing filler for natural rubber. J. Mech. Eng. Sci. 2015, 8, 1481–1488. [Google Scholar] [CrossRef]

- Chong, M.H.; Chun, B.C.; Chung, Y.-C.; Cho, B.G. Fire-retardant plastic material from oyster-shell powder and recycled polyethylene. J. Appl. Polym. Sci. 2006, 99, 583–1589. [Google Scholar] [CrossRef]

- Zhang, J.; Han, B.; Zhou, N.-L.; Fang, J.; Wu, J.; Ma, Z.-M.; Mo, H.; Shen, J. Preparation and characterization of nano/micro-calcium carbonate particles/polypropylene composites. J. Appl. Polym. Sci. 2011, 119, 3560–3565. [Google Scholar] [CrossRef]

- Martínez-García, C.; González-Fonteboa, B.; Martínez-Abella, F.; Carro-López, D. Performance of mussel shell as aggregate in plain concrete. Constr. Build. Mater. 2017, 139, 570–583. [Google Scholar] [CrossRef]

- Bamigboye, G.O.; Nworgu, A.T.; Odetoyan, A.O.; Kareem, M.; Enabulele, D.O.; Bassey, D.E. Sustainable use of seashells as binder in concrete production: Prospect and challenges. J. Build. Eng. 2021, 34, 101864. [Google Scholar] [CrossRef]

- Bamigboye, G.O.; Okara, O.; Bassey, D.E.; Jolayemi, K.J.; Ajimalofin, D. The Use of Senilia senilis seashells as a Substitute for Coarse Aggregate in Eco-friendly Concrete. J. Build. Eng. 2020, 32, 101811. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, D.; Liang, Y.; Qu, K.; Lu, K.; Chen, S.; Kong, M. Study on engineering properties of foam concrete containing waste seashell. Constr. Build. Mater. 2020, 260, 119896. [Google Scholar] [CrossRef]

- Soltanzadeh, F.; Emam-Jomeh, M.; Edalat-Behbahani, A.; Soltanzadeh, Z. Development and characterization of blended cements containing seashell powder. Constr. Build. Mater. 2018, 161, 292–304. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Hasaniyah, M.W.; Zeyad, A.M.; Awad, M.M.; Alaskar, A.; Mohamed, A.M.; Alyousef, R. Durability and mechanical properties of seashell partially-replaced cement. J. Build. Eng. 2020, 31, 101328. [Google Scholar] [CrossRef]

- Her, S.; Park, T.; Zalnezhad, E.; Bae, S. Synthesis and characterization of cement clinker using recycled pulverized oyster and scallop shell as limestone substitutes. J. Clean. Prod. 2021, 279, 123987. [Google Scholar] [CrossRef]

- Rodríguez-Galán, M.; Alonso-Fariñas, B.; Baena-Moreno, F.M.; Leiva, C.; Navarrete, B.; Vilches, L.F. Synthetic Slag Production Method Based on a Solid Waste Mix Vitrification for the Manufacturing of Slag-Cement. Materials 2019, 12, 208. [Google Scholar] [CrossRef] [Green Version]

- Chiou, I.J.; Chen, C.H.; Li, Y.H. Using oyster-shell foamed bricks to neutralize the acidity of recycled rainwater. Constr. Build. Mater. 2014, 64, 480–481. [Google Scholar] [CrossRef]

- Féjean, J.; Lanos, C.; Mélinge, Y.; Baux, C. Behaviour of fire-proofing materials containing gypsum, modifications induced by incorporation of inert filler. Chem. Eng. Res. Des. 2003, 81, 1230–1236. [Google Scholar] [CrossRef]

- Leiva, C.; García Arenas, C.; Vilches, L.F.; Vale, J.; Gimenez, A.; Ballesteros, J.C.; Fernández-Pereira, C. Use of FGD gypsum in fire resistant panels. Waste Manag. 2010, 30, 1123–1129. [Google Scholar] [CrossRef]

- Thomas, G. Thermal properties of gypsum plasterboard at high temperatures. Fire Mater. 2002, 26, 37–45. [Google Scholar] [CrossRef]

- Peceño, B.; Alonso-Fariñas, B.; Vilches, L.F.; Leiva, C. Study of seashell waste recycling in fireproofing material: Technical, environmental, and economic assessment. Sci. Total Environ. 2021, 790, 148102. [Google Scholar] [CrossRef] [PubMed]

- Hou, E.J.; Huang, C.S.; Lee, Y.C.; Chu, H.T. Upcycled aquaculture waste as textile ingredient for promoting circular economy. Sustain. Mater. Technol. 2022, 31, e00336. [Google Scholar] [CrossRef]

- Zhan, J.; Lu, J.; Wang, D. Review of shell waste reutilization to promote sustainable shellfish aquaculture. Rev. Aquac. 2021, 14, 477–488. [Google Scholar] [CrossRef]

- Wang, W.; Wei, W.; Gao, S.; Chen, G.; Yuan, J.; Li, Y. Agricultural and Aquaculture Wastes as Concrete Components: A Review. Front. Mater. 2021, 8, 762568. [Google Scholar] [CrossRef]

- Morris, J.P.; Backeljau, T.; Chapelle, G. Shells from aquaculture: A valuable biomaterial, not a nuisance waste product. Rev. Aquac. 2019, 11, 42–57. [Google Scholar] [CrossRef] [Green Version]

- Coelho, A.; de Brito, J. Economic viability analysis of a construction and demolition waste recycling plant in Portugal—Part I: Location, materials, technology, and economic analysis. J. Clean. Prod. 2013, 39, 338–352. [Google Scholar] [CrossRef]

- Yang, D.; Fan, L.; Shi, F.; Liu, Q.; Wang, Y. Comparative study of cement manufacturing with different strength grades using the coupled LCA and partial LCC methods—A case study in China. Resour. Conserv. Recycl. 2017, 119, 60–68. [Google Scholar] [CrossRef]

- Zhang, R.; Ma, X.; Shen, X.; Zhai, Y.; Zhang, T.; Ji, C.; Hong, J. PET bottles recycling in China: An LCA coupled with LCC case study of blanket production made of waste PET bottles. J. Environ. Manag. 2020, 260, 110062. [Google Scholar] [CrossRef]

- Iraldo, F.; Facheris, C.; Nucci, B. Is product durability better for environment and for economic efficiency? A comparative assessment applying LCA and LCC to two energy-intensive products. J. Clean. Prod. 2017, 140, 1353–1364. [Google Scholar] [CrossRef]

- Ruiz, G.; Chávez, F.; Santamaría, S.; Araujo, W.; Timaná, J.; Schmitt, R. Laboratory evaluation of seashell used as fine aggregate in hot mix asphalt. Int. J. Pavement Eng. 2020, 21, 620–628. [Google Scholar] [CrossRef]

- Di Maria, A.; Eyckmans, J.; Van Acker, K. Downcycling versus recycling of construction and demolition waste: Combining LCA and LCC to support sustainable policy making. Waste Manag. 2018, 75, 3–21. [Google Scholar] [CrossRef] [PubMed]

- Rizos, V.; Behrens, A.; van der Gaast, W.; Hofman, E.; Ioannou, A.; Kafyeke, T.; Flamos, A.; Rinaldi, R.; Papadelis, S.; Hirschnitz-Garbers, M.; et al. Implementation of circular economy business models by small and medium-sized enterprises (SMEs): Barriers and enablers. Sustainability 2016, 8, 1212. [Google Scholar] [CrossRef] [Green Version]

- Soltanzadeh, F.; Behbahani, A.E.; Pereira, E.N.B.; Teixeira, C.A. A life-cycle approach to integrate environmental and mechanical properties of blended cements containing seashell powder. Sustainability 2021, 13, 13120. [Google Scholar] [CrossRef]

- Uribe, E.; Sfeir, R.; Bakit, J. Informe Final FIPA 2017-12. Análisis del Desarrollo Histórico y Colapso del Cultivo del Ostión del Norte Como Herramienta Para el Re-Impulso de la Actividad en la III y IV Regiones. Coquimbo. 2018. Available online: https://www.researchgate.net/profile/Jose-Bakit/research (accessed on 28 April 2022).

- SERNAGEOMIN. Servicio Nacional de Geología y Minería. In Anuario de la Minería de Chile. 2020. Available online: https://www.sernageomin.cl/anuario-de-la-mineria-de-chile (accessed on 28 April 2022).

- EN 13279-1; Yesos de Construcción y Conglomerantes a Base de Yeso Para la Construcción—Parte 1: Definiciones y Especificaciones. European Committee for Standardization: Brussels, Belgium, 2009.

- ASTM D3682; Standard Test Method for Major and Minor Elements in Combustion Residues from Coal Utilization Processes. ASTM International: West Conshohocken, PA, USA, 2013. [CrossRef]

- ASTM D 854; Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer. ASTM International: West Conshohocken, PA, USA, 2014. [CrossRef]

- EN 13279-2; Gypsum Binders and Gypsum Plasters—Part 2: Test Methods. European Committee for Standardization: Brussels, Belgium, 2014.

- ASTM E 605; Standard Test Methods for Thickness and Density of Sprayed Fire-Resistive Material (SFRM) Applied to Structural Members. ASTM International: West Conshohocken, PA, USA, 2015. [CrossRef]

- Cerulli, T.; Pistolesi, C.; Maltese, C.; Salvioni, D. Durability of traditional plasters with respect to blast furnace slag-based plaster. Cem. Concr. Compos. 2003, 33, 1375–1383. [Google Scholar] [CrossRef]

- ASTM C 1012-13; Standard Test Method for Length Change of Hydraulic-Cement Mortars Exposed to Sulphate Solution. ASTM International: West Conshohocken, PA, USA, 2013.

- EN 12390-9; Testing Hardened Concrete—Part 9: Freeze–Thaw Resistance. Scaling Brussels. European Committee for Standardization: Brussels, Belgium, 2008.

- Servicio de Impuestos Internos. Dólar Observado. Available online: https://www.sii.cl/valores_y_fechas/dolar/dolar2020.htm (accessed on 28 April 2022).

- Guerrero-Rios, R.J.; Hernández, N.T.; Espinoza-Rodríguez, N.; Barrios-Garrido, H.; Montiel, M.; Morales, F. Condition index and size of the estuarine clam at Curarire, Zulia State, Venezuela. Zootec. Trop. 2015, 33, 327–336. [Google Scholar]

- EN 12859; Gypsum Blocks—Definitions, Requirements and Test Methods. European Committee for Standardization: Brussels, Belgium, 2012.

- Vafaei, M.; Allahverdi, A.; Dong, P.; Bassim, N. Acid attack on geopolymer cement mortar based on waste-glass powder and calcium aluminate cement at mild concentration. Constr. Build. Mater. 2018, 193, 363–372. [Google Scholar] [CrossRef]

- Collepardi, M.; Borsoi, A.; Collepardi, S.; Ogoumah Olagot, J.J.; Troli, R. Effects of shrinkage reducing admixture in shrinkage compensating concrete under non-wet curing conditions. Cem. Concr. Compos. 2005, 27, 704–708. [Google Scholar] [CrossRef]

- Zhang, Y.; Hua, Y.; Zhu, X. Investigation of the durability of eco-friendly concrete material incorporating artificial lightweight fine aggregate and pozzolanic minerals under dual sulfate attack. J. Clean. Prod. 2022, 331, 130022. [Google Scholar] [CrossRef]

- Prieler, R.; Langbauer, R.; Gerhardter, H.; Kitzmüller, P.; Thumser, S.; Schwabegger, G.; Hochenauer, C. Modelling approach to predict the fire-related heat transfer in porous gypsum based on multi-phase simulations including water vapour transport, phase change and radiative heat transfer. Appl. Therm. Eng. 2022, 206, 118013. [Google Scholar] [CrossRef]

- Colak, A. The long-term durability performance of gypsum-Portland cement-natural pozzolan blends. Cem. Concr. Res. 2002, 32, 109–115. [Google Scholar] [CrossRef]

- Haas, W.; Krausmann, F.; Wiedenhofer, D.; Heinz, M. How circular is the global economy? An assessment of material flows, waste production, and recycling in the European union and the world in 2005. J. Ind. Ecol. 2015, 19, 765–777. [Google Scholar] [CrossRef]

- Luhar, S.; Cheng, T.W.; Luhar, I. Incorporation of natural waste from agricultural and aquacultural farming as supplementary materials with green concrete: A review. Compos. Part B Eng. 2019, 175, 107076. [Google Scholar] [CrossRef]

- Barros, C.; Bello, P.; Valiño, S.; Bao, M.; Arias, J. Odours Prevention and Control in the Shell Waste Valorisation. In Proceedings of the International Symposium on EcoTopia Science, Nagoya, Japan, 7 February 2007. [Google Scholar]

- von Brand, E.; Abarca, A.; Merino, G.E.; Stotz, W. Scallop fishery and aquaculture in Chile: A history of developments and declines. Dev. Aquac. Fish. Sci. 2016, 40, 1047–1072. [Google Scholar] [CrossRef]

- Kluger, L.C.; Taylor, M.H.; Wolff, M.; Stotz, W.; Mendo, J. From an open-access fishery to a regulated aquaculture business: The case of the most important Latin American bay scallop (Argopecten purpuratus). Rev. Aquac. 2019, 11, 187–203. [Google Scholar] [CrossRef] [Green Version]

- Bakit, J.; Uribe, E.; Sfeir, R.; Carmona, R. Relación de la Producción en Chile del Ostión del Norte Argopecten purpuratus con Aspectos Ambientales, Comerciales y de Desarrollo Científico. In Proceedings of the VIII Congreso Nacional de Acuicultura, Arica, Chile, 11 September 2007. [Google Scholar]

- Barros, M.C.; Bello, P.M.; Bao, M.; Torrado, J.J. From waste to commodity: Transforming shells into high purity calcium carbonate. J. Clean. Prod. 2009, 17, 400–407. [Google Scholar] [CrossRef]

| S (%) (1) | G (%) (2) | |

|---|---|---|

| SiO2 | N.D. (3) | 0.88 |

| Al2O3 | N.D. (3) | 0.18 |

| Fe2O3 | N.D. (3) | N.D. (3) |

| MnO | N.D. (3) | 0.02 |

| MgO | N.D. (3) | N.D. (3) |

| CaO | 54.76 | 40.56 |

| Na2O | 0.57 | 0.07 |

| K2O | N.D. (3) | N.D. (3) |

| TiO2 | N.D. (3) | N.D. (3) |

| P2O5 | 0.13 | N.D. |

| SO3 | 0.32 | 45.56 |

| PC | 44.42 | 12.52 |

| Median size (μm) | 180 | 25 |

| Specific gravity (g/cm3) | 2.76 | 2.77 |

| Density (kg/m3) | Compressive Strength (MPa) | |

|---|---|---|

| 0% S | 1528.16 ± 2.10 | 13.51 ± 1.37 |

| 40% S | 1474.00 ± 12.54 | 13.10 ± 1.53 |

| 50% S | 1468.15 ± 16.01 | 10.88 ± 0.54 |

| Pre-Treatment | Cost (US$) | ||

|---|---|---|---|

| 0% S | 40% S | 50% S | |

| Wash water | 0 | 2.12 | 2.70 |

| Propane consumption | 0 | 25.23 | 32.07 |

| Grinding energy | 0 | 0.60 | 0.76 |

| Pre-treatment cost | 0 | 27.95 | 35.53 |

| Construction Material | Manufacturing Cost (US$) | ||

|---|---|---|---|

| 0% S | 40% S | 50% S | |

| Gypsum | 206.77 | 132.43 | 112.27 |

| Pre-treated scallop shell | 0.0 | 27.95 | 35.53 |

| Water | 0.39 | 0.41 | 0.41 |

| Energy | 0.12 | 0.12 | 0.12 |

| Total production costs | 207.28 | 160.92 | 148.35 |

| Scallop Landings (t) | Scallop Shells (t) | |||

|---|---|---|---|---|

| Region | SSF | Aquaculture | Generation | Availability |

| Antofagasta | - | 28 | 16.8 | 8.4 |

| Atacama | - | 595 | 357 | 178.5 |

| Coquimbo | - | 10.690 | 6.414 | 3.207 |

| Total | - | 11,313 | 6787.8 | 3393.9 |

| Description | Units | Value |

|---|---|---|

| Cost associated with waste transport | US$ | 101.01 |

| Cost of landfill disposal | US$/kg | 0.02 |

| Total cost | US$ | 303.03 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peceño, B.; Bakit, J.; Cortes, N.; Alonso-Fariñas, B.; Bonilla, E.; Leiva, C. Assessing Durability Properties and Economic Potential of Shellfish Aquaculture Waste in the Construction Industry: A Circular Economy Perspective. Sustainability 2022, 14, 8383. https://doi.org/10.3390/su14148383

Peceño B, Bakit J, Cortes N, Alonso-Fariñas B, Bonilla E, Leiva C. Assessing Durability Properties and Economic Potential of Shellfish Aquaculture Waste in the Construction Industry: A Circular Economy Perspective. Sustainability. 2022; 14(14):8383. https://doi.org/10.3390/su14148383

Chicago/Turabian StylePeceño, Begoña, José Bakit, Niris Cortes, Bernabé Alonso-Fariñas, Enzo Bonilla, and Carlos Leiva. 2022. "Assessing Durability Properties and Economic Potential of Shellfish Aquaculture Waste in the Construction Industry: A Circular Economy Perspective" Sustainability 14, no. 14: 8383. https://doi.org/10.3390/su14148383

APA StylePeceño, B., Bakit, J., Cortes, N., Alonso-Fariñas, B., Bonilla, E., & Leiva, C. (2022). Assessing Durability Properties and Economic Potential of Shellfish Aquaculture Waste in the Construction Industry: A Circular Economy Perspective. Sustainability, 14(14), 8383. https://doi.org/10.3390/su14148383