Toward Carbon-Neutral Concrete through Biochar–Cement–Calcium Carbonate Composites: A Critical Review

Abstract

:1. Introduction

2. Methods for Producing Carbon-Neutral Concrete

2.1. Greener Supply Chain and Production through Recycled Materials

2.2. Accelerated Carbonation Curing of Concrete

2.3. Cement Substitution with Lower-Carbon Materials

2.3.1. Biochar-Containing Concrete

2.3.2. Alternative Concretes

3. Performance Expectations for Carbon-Neutral Concrete

3.1. Carbon Storage Characteristics of Biochar and Calcium Carbonate

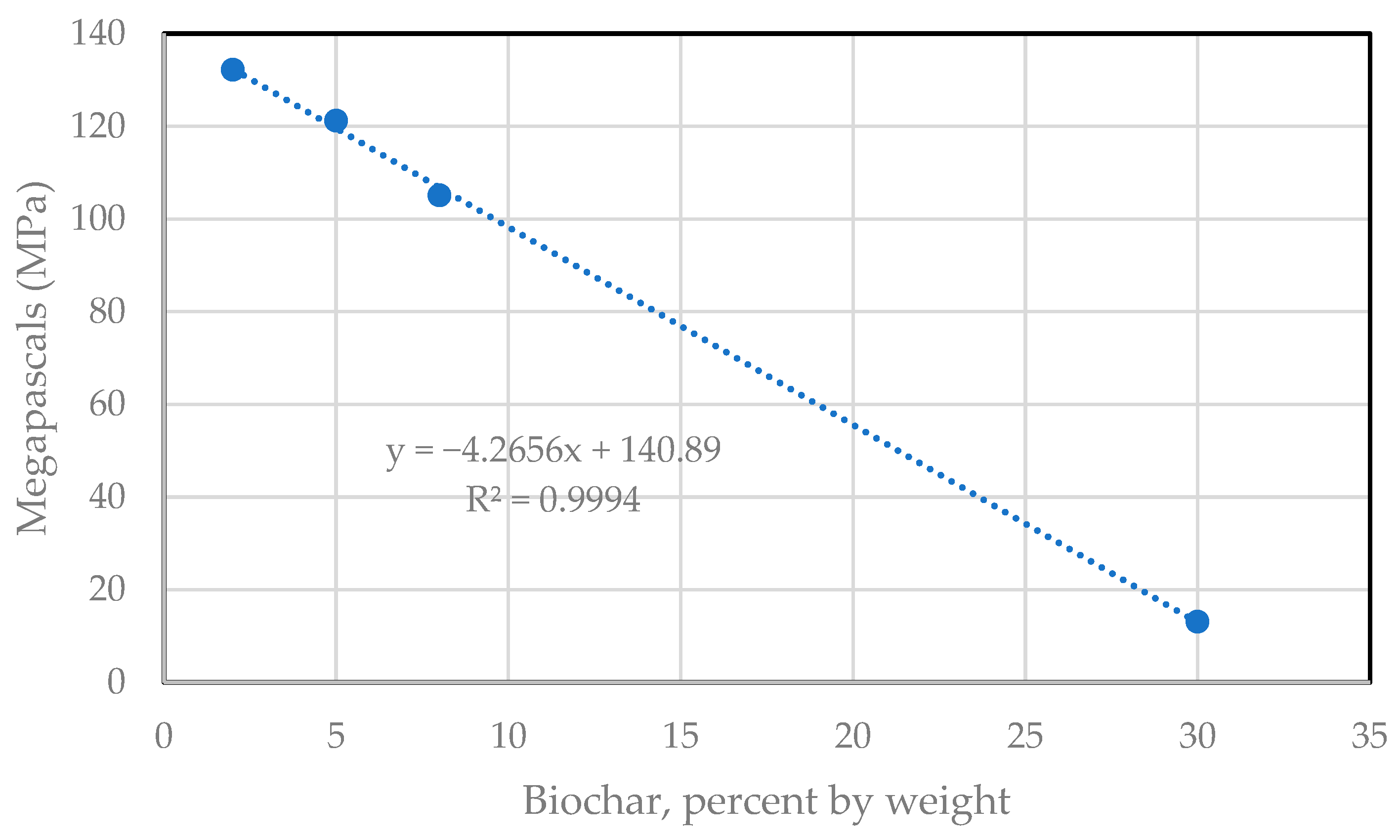

3.2. Compressive Strength Characteristics of Biochar and Calcium Carbonate

3.3. Additional Performance Characteristics of Biochar and Calcium Carbonate

| Reference | Compressive Strength | Splitting Tensile Strength | Flexural or Bending Strength | Fracture Energy |

|---|---|---|---|---|

| [63] | X | |||

| [64] | X | X | ||

| [65] | X | |||

| [9] | X | X | ||

| [20] | X | X | ||

| [66] | X | X | ||

| [67] | X | X | ||

| [68] | X | X | ||

| [39] | X | X | ||

| [13] |

3.4. Potential Benefits of Both Materials in a Carbon Storage System

4. Obstacles to Scaling the Use of Carbon-Neutral Concrete

4.1. Revising Architectural Codes and Standards

4.2. Uncertainties and Delays Create Resistance to Change

- (1)

- Legal issues in determining which stakeholder will have to carry the risk associated with CO2 storage. Such an uncertainty can greatly delay large-scale implementation of carbon-neutral concrete.

- (2)

- Lack of incentive for adoption. As long as specifications are based on material formulations or recipes (the most popular approach in standards worldwide) or on technical performance (strength and fluidity) and not on environmental performance, there will be no incentive for concrete producers to propose environmentally friendly mix designs.

- (3)

- Lack of incentive for optimization. Without a request from clients or national/regional policies to require materially efficient structural designs, design teams have no incentive to optimize their structure.

- (4)

- Lack of supply chain education and communication. Time constraints, fragmented supply chains, and lack of awareness were also cited as barriers for implementation.

4.3. Material Availability

4.4. Cost

5. Research Directions

5.1. Continued Exploration of Composite Material Properties

5.2. Important Material Properties and Interactions to Model

5.3. Examination of Long-Term Durability

5.4. Enhancing the Use of Life-Cycle Assessments (LCA) in Concrete Mix Optimization

5.5. Functionalizing Biochar with CO2 Adsorbent Capability to Enhance Carbon Negativity

5.6. Overcoming Economic and Social Obstacles to Scaling Carbon-Neutral Concrete

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- van Vuuren, D.P.; Stehfest, E.; Gernaat, D.E.H.J.; van den Berg, M.; Bijl, D.L.; de Boer, H.S.; Daioglou, V.; Doelman, J.C.; Edelenbosch, O.Y.; Harmsen, M.; et al. Alternative pathways to the 1.5 °C target reduce the need for negative emission technologies. Nat. Clim. Chang. 2018, 8, 391–397. [Google Scholar] [CrossRef]

- Alhashimi, H.A.; Aktas, C.B. Life cycle environmental and economic performance of biochar compared with activated carbon: A meta-analysis. Resour. Conserv. Recycl. 2017, 118, 13–26. [Google Scholar] [CrossRef] [Green Version]

- Panwar, N.; Pawar, A.; Salvi, B. Comprehensive review on production and utilization of biochar. SN Appl. Sci. 2019, 1, 168. [Google Scholar] [CrossRef] [Green Version]

- Schmidt, H.-P.; Kammann, C.; Hagemann, N.; Leifeld, J.; Bucheli, T.D.; Sánchez Monedero, M.A.; Cayuela, M.L. Biochar in agriculture—A systematic review of 26 global meta-analyses. GCB Bioenergy 2021, 13, 1708–1730. [Google Scholar] [CrossRef]

- Ye, L.; Camps-Arbestain, M.; Shen, Q.; Lehmann, J.; Singh, B.; Sabir, M.; Condron, L.M. Biochar effects on crop yields with and without fertilizer: A meta-analysis of field studies using separate controls. Soil Use Manag. 2020, 36, 2–18. [Google Scholar] [CrossRef]

- Cao, M.; Li, L.; Yin, H.; Ming, X. Microstructure and Strength of Calcium Carbonate (CaCO3) Whisker Reinforced Cement Paste After Exposed to High Temperatures. Fire Technol. 2019, 55, 1983–2003. [Google Scholar] [CrossRef]

- Torres, A.; Simoni, M.U.; Keiding, J.K.; Müller, D.B.; zu Ermgassen, S.O.S.E.; Liu, J.; Jaeger, J.A.G.; Winter, M.; Lambin, E.F. Sustainability of the global sand system in the Anthropocene. One Earth 2021, 4, 639–650. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, Y.; Wang, L.; Ruan, S.; Chen, J.; Li, H.; Yang, J.; Mechtcherine, V.; Tsang, D.C.W. Biochar-augmented carbon-negative concrete. Chem. Eng. J. 2022, 431, 133946. [Google Scholar] [CrossRef]

- Sirico, A.; Bernardi, P.; Belletti, B.; Malcevschi, A.; Restuccia, L.; Ferro, G.A.; Suarez-Riera, D. Biochar-based cement pastes and mortars with enhanced mechanical properties. Frattura Ed Integrità Strutturale 2020, 14, 297–316. [Google Scholar] [CrossRef]

- Danish, A.; Ali Mosaberpanah, M.; Usama Salim, M.; Ahmad, N.; Ahmad, F.; Ahmad, A. Reusing biochar as a filler or cement replacement material in cementitious composites: A review. Constr. Build. Mater. 2021, 300, 124295. [Google Scholar] [CrossRef]

- Dixit, A.; Gupta, S.; Pang, S.D.; Kua, H.W. Waste Valorisation using biochar for cement replacement and internal curing in ultra-high performance concrete. J. Clean. Prod. 2019, 238, 117876. [Google Scholar] [CrossRef]

- Gupta, S.; Kashani, A.; Mahmood, A.H.; Han, T. Carbon sequestration in cementitious composites using biochar and fly ash–Effect on mechanical and durability properties. Constr. Build. Mater. 2021, 291, 123363. [Google Scholar] [CrossRef]

- Haque, M.I.; Khan, R.I.; Ashraf, W.; Pendse, H. Production of sustainable, low-permeable and self-sensing cementitious composites using biochar. Sustain. Mater. Technol. 2021, 28, e00279. [Google Scholar] [CrossRef]

- Khitab, A.; Ahmad, S.; Khan, R.A.; Arshad, M.T.; Anwar, W.; Tariq, J.; Khan, A.S.R.; Khan, R.B.N.; Jalil, A.; Tariq, Z. Production of Biochar and Its Potential Application in Cementitious Composites. Crystals 2021, 11, 527. [Google Scholar] [CrossRef]

- Maljaee, H.; Madadi, R.; Paiva, H.; Tarelho, L.; Ferreira, V.M. Incorporation of biochar in cementitious materials: A roadmap of biochar selection. Constr. Build. Mater. 2021, 283, 122757. [Google Scholar] [CrossRef]

- Mensah, R.A.; Shanmugam, V.; Narayanan, S.; Razavi, S.M.J.; Ulfberg, A.; Blanksvärd, T.; Sayahi, F.; Simonsson, P.; Reinke, B.; Försth, M.; et al. Biochar-Added Cementitious Materials—A Review on Mechanical, Thermal, and Environmental Properties. Sustainability 2021, 13, 9336. [Google Scholar] [CrossRef]

- Muthukrishnan, S.; Gupta, S.; Kua, H.W. Application of rice husk biochar and thermally treated low silica rice husk ash to improve physical properties of cement mortar. Theor. Appl. Fract. Mech. 2019, 104, 102376. [Google Scholar] [CrossRef]

- Restuccia, L.; Ferro, G.A. Influence of filler size on the mechanical properties of cement-based composites. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 797–805. [Google Scholar] [CrossRef]

- Sirico, A.; Bernardi, P.; Belletti, B.; Malcevschi, A.; Dalcanale, E.; Domenichelli, I.; Fornoni, P.; Moretti, E. Mechanical characterization of cement-based materials containing biochar from gasification. Constr. Build. Mater. 2020, 246, 118490. [Google Scholar] [CrossRef]

- Suarez-Riera, D.; Restuccia, L.; Ferro, G.A. The use of Biochar to reduce the carbon footprint of cement-based materials. Procedia Struct. Integr. 2020, 26, 199–210. [Google Scholar] [CrossRef]

- Tan, K.-H.; Wang, T.-Y.; Zhou, Z.-H.; Qin, Y.-H. Biochar as a Partial Cement Replacement Material for Developing Sustainable Concrete: An Overview. J. Mater. Civ. Eng. 2021, 33, 03121001. [Google Scholar] [CrossRef]

- Wang, L.; Chen, L.; Tsang, D.C.W.; Guo, B.; Yang, J.; Shen, Z.; Hou, D.; Ok, Y.S.; Poon, C.S. Biochar as green additives in cement-based composites with carbon dioxide curing. J. Clean. Prod. 2020, 258, 120678. [Google Scholar] [CrossRef]

- Xu, Y.; Run-Sheng, L.; Yi, H.; Xiao-Yong, W. Behavior of Biochar-Modified Cementitious Composites Exposed to High Temperatures. Materials 2021, 14, 5414. [Google Scholar] [CrossRef]

- Yang, X.; Wang, X.-Y. Hydration-strength-durability-workability of biochar-cement binary blends. J. Build. Eng. 2021, 42, 103064. [Google Scholar] [CrossRef]

- Matschei, T.; Lothenbach, B.; Glasser, F.P. The role of calcium carbonate in cement hydration. Cem. Concr. Res. 2007, 37, 551–558. [Google Scholar] [CrossRef]

- Nicoara, A.I.; Stoica, A.E.; Vrabec, M.; Šmuc Rogan, N.; Sturm, S.; Ow-Yang, C.; Gulgun, M.A.; Bundur, Z.B.; Ciuca, I.; Vasile, B.S. End-of-life materials used as supplementary cementitious materials in the concrete industry. Materials 2020, 13, 1954. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lippiatt, N.; Ling, T.-C.; Pan, S.-Y. Towards carbon-neutral construction materials: Carbonation of cement-based materials and the future perspective. J. Build. Eng. 2020, 28, 101062. [Google Scholar] [CrossRef]

- D’Alessandro, A.; Fabiani, C.; Pisello, A.L.; Ubertini, F.; Materazzi, A.L.; Cotana, F. Innovative concretes for low-carbon constructions: A review. Int. J. Low-Carbon Technol. 2017, 12, 289–309. [Google Scholar] [CrossRef] [Green Version]

- Shi, C.; Tu, Z.; Guo, M.-Z.; Wang, D. Accelerated carbonation as a fast curing technology for concrete blocks. In Sustainable and Nonconventional Construction Materials using Inorganic Bonded Fiber Composites; Woodhead Publishing: Sawston, UK, 2017; pp. 313–341. [Google Scholar]

- Kaliyavaradhan, S.K.; Ling, T.-C. Potential of CO2 sequestration through construction and demolition (C&D) waste—An overview. J. CO2 Util. 2017, 20, 234–242. [Google Scholar]

- Pu, Y.; Li, L.; Wang, Q.; Shi, X.; Luan, C.; Zhang, G.; Fu, L.; Abomohra, A.E.-F. Accelerated carbonation technology for enhanced treatment of recycled concrete aggregates: A state-of-the-art review. Constr. Build. Mater. 2021, 282, 122671. [Google Scholar] [CrossRef]

- Gomes, R.I.; Farinha, C.B.; Veiga, R.; de Brito, J.; Faria, P.; Bastos, D. CO2 sequestration by construction and demolition waste aggregates and effect on mortars and concrete performance-An overview. Renew. Sustain. Energy Rev. 2021, 152, 111668. [Google Scholar] [CrossRef]

- Suescum-Morales, D.; Fernández-Rodríguez, J.M.; Jiménez, J.R. Use of carbonated water to improve the mechanical properties and reduce the carbon footprint of cement-based materials with recycled aggregates. J. CO2 Util. 2022, 57, 101886. [Google Scholar] [CrossRef]

- Al-Mansour, A.; Chow, C.L.; Feo, L.; Penna, R.; Lau, D. Green concrete: By-products utilization and advanced approaches. Sustainability 2019, 11, 5145. [Google Scholar] [CrossRef] [Green Version]

- Wang, F.; Harindintwali, J.D.; Yuan, Z.; Wang, M.; Wang, F.; Li, S.; Yin, Z.; Huang, L.; Fu, Y.; Li, L. Technologies and perspectives for achieving carbon neutrality. Innovation 2021, 2, 100180. [Google Scholar] [CrossRef] [PubMed]

- Legan, M.; Zupan, K.; Gotvajn, A.Ž. Biochar-Containing Building Materials and Carbon Footprint Reduction. 2021. Available online: http://sschi.chtf.stuba.sk/data/full_papers/316.pdf (accessed on 20 February 2022).

- Gupta, S.; Kua, H.W.; Koh, H.J. Application of biochar from food and wood waste as green admixture for cement mortar. Sci. Total Environ. 2018, 619, 419–435. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W.; Cynthia, S.Y.T. Use of biochar-coated polypropylene fibers for carbon sequestration and physical improvement of mortar. Cem. Concr. Compos. 2017, 83, 171–187. [Google Scholar] [CrossRef]

- Legan, M.; Gotvajn, A.Ž.; Zupan, K. Potential of biochar use in building materials. J. Environ. Manag. 2022, 309, 114704. [Google Scholar] [CrossRef]

- Pradhan, S.; Poh, A.C.B.; Qian, S. Impact of service life and system boundaries on life cycle assessment of sustainable concrete mixes. J. Clean. Prod. 2022, 342, 130847. [Google Scholar] [CrossRef]

- Piccolo, F.; Andreola, F.; Barbieri, L.; Lancellotti, I. Synthesis and Characterization of Biochar-Based Geopolymer Materials. Appl. Sci. 2021, 11, 10945. [Google Scholar] [CrossRef]

- Jami, T.; Karade, S.; Singh, L. A review of the properties of hemp concrete for green building applications. J. Clean. Prod. 2019, 239, 117852. [Google Scholar] [CrossRef]

- Wang, L.; Chen, L.; Poon, C.; Wang, C.-H.; Ok, Y.S.; Mechtcherine, V.; Tsang, D.C. Roles of biochar and CO2 curing in sustainable magnesia cement-based composites. ACS Sustain. Chem. Eng. 2021, 9, 8603–8610. [Google Scholar] [CrossRef]

- Akinyemi, B.A.; Adesina, A. Recent advancements in the use of biochar for cementitious applications: A review. J. Build. Eng. 2020, 32, 101705. [Google Scholar] [CrossRef]

- Roberts, K.G.; Gloy, B.A.; Joseph, S.; Scott, N.R.; Lehmann, J. Life Cycle Assessment of Biochar Systems: Estimating the Energetic, Economic, and Climate Change Potential. Environ. Sci. Technol. 2010, 44, 827–833. [Google Scholar] [CrossRef] [PubMed]

- Kua, H.W.; Ng, M.S.; Ong, K. Innovative uses of biochar as carbon sequestering building materials in wall plaster and pellets. Acad. J. Civ. Eng. 2017, 35, 575–580. [Google Scholar]

- Pan, Y.; Birdsey, R.A.; Fang, J.; Houghton, R.; Kauppi, P.E.; Kurz, W.A.; Phillips, O.L.; Shvidenko, A.; Lewis, S.L.; Canadell, J.G.; et al. A Large and Persistent Carbon Sink in the World’s Forests. Science 2011, 333, 988–993. [Google Scholar] [CrossRef] [Green Version]

- Leng, L.; Xu, X.; Wei, L.; Fan, L.; Huang, H.; Li, J.; Lu, Q.; Li, J.; Zhou, W. Biochar stability assessment by incubation and modelling: Methods, drawbacks and recommendations. Sci. Total Environ. 2019, 664, 11–23. [Google Scholar] [CrossRef]

- Chang, R.; Kim, S.; Lee, S.; Choi, S.; Kim, M.; Park, Y. Calcium Carbonate Precipitation for CO2 Storage and Utilization: A Review of the Carbonate Crystallization and Polymorphism. Front. Energy Res. 2017, 5, 17. [Google Scholar] [CrossRef] [Green Version]

- Gupta, S.; Kua, H.W.; Pang, S.D. Biochar-mortar composite: Manufacturing, evaluation of physical properties and economic viability. Constr. Build. Mater. 2018, 167, 874–889. [Google Scholar] [CrossRef]

- Gupta, S.; Krishnan, P.; Kashani, A.; Kua, H.W. Application of biochar from coconut and wood waste to reduce shrinkage and improve physical properties of silica fume-cement mortar. Constr. Build. Mater. 2020, 262, 120688. [Google Scholar] [CrossRef]

- Han, T. Application of peanut biochar as admixture in cement mortar. Proc. IOP Conf. Ser. Earth Environ. Sci. 2020, 531, 012061. [Google Scholar] [CrossRef]

- Asadi Zeidabadi, Z.; Bakhtiari, S.; Abbaslou, H.; Ghanizadeh, A.R. Synthesis, characterization and evaluation of biochar from agricultural waste biomass for use in building materials. Constr. Build. Mater. 2018, 181, 301–308. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W. Effect of water entrainment by pre-soaked biochar particles on strength and permeability of cement mortar. Constr. Build. Mater. 2018, 159, 107–125. [Google Scholar] [CrossRef]

- Praneeth, S.; Saavedra, L.; Zeng, M.; Dubey, B.K.; Sarmah, A.K. Biochar admixtured lightweight, porous and tougher cement mortars: Mechanical, durability and micro computed tomography analysis. Sci. Total Environ. 2021, 750, 142327. [Google Scholar] [CrossRef] [PubMed]

- Saulat, H.; Cao, M.; Khan, M.M.; Khan, M.; Khan, M.M.; Rehman, A. Preparation and applications of calcium carbonate whisker with a special focus on construction materials. Constr. Build. Mater. 2020, 236, 117613. [Google Scholar] [CrossRef]

- Li, L.I.; Li, Z.; Cao, M.; Tang, Y.I.; Zhang, Z.H.E. Nanoindentation and porosity fractal dimension of calcium carbonate whisker reinforced cement paste after elevated temperatures (up to 900 °C). Fractals 2021, 29, 2140001. [Google Scholar] [CrossRef]

- Renders, G.A.P.; Mulder, L.; Langenbach, G.E.J.; van Ruijven, L.J.; van Eijden, T.M.G.J. Biomechanical effect of mineral heterogeneity in trabecular bone. J. Biomech. 2008, 41, 2793–2798. [Google Scholar] [CrossRef]

- Keaveny, T.M.; Hayes, W.C. A 20-Year Perspective on the Mechanical Properties of Trabecular Bone. J. Biomech. Eng. 1993, 115, 534–542. [Google Scholar] [CrossRef]

- Cao, M.; Xu, L.; Zhang, C. Rheology, fiber distribution and mechanical properties of calcium carbonate (CaCO3) whisker reinforced cement mortar. Composites. Part A Appl. Sci. Manuf. 2016, 90, 662–669. [Google Scholar] [CrossRef]

- Cao, M.; Ming, X.; He, K.; Li, L.; Shen, S. Effect of Macro-, Micro- and Nano-Calcium Carbonate on Properties of Cementitious Composites-A Review. Materials 2019, 12, 781. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.; Che, Y.; Shi, M. Influences of calcium carbonate nanoparticles on the workability and strength of 3D printing cementitious materials containing limestone powder. J. Build. Eng. 2021, 44, 102976. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W.; Pang, S. Biochar-concrete composite: Manufacturing, characterization and performance evaluation at elevated temperature. Acad. J. Civ. Eng. 2019, 37, 507–513. [Google Scholar]

- Kovács, P.; Pokorný, J.; Šál, J.; Ševčík, R. The influence of biochar addition on the strength and microstructural characteristics of cement pastes. Proc. IOP Conf. Ser. Mater. Sci. Eng. 2020, 960, 042097. [Google Scholar] [CrossRef]

- Mrad, R.; Chehab, G. Mechanical and Microstructure Properties of Biochar-Based Mortar: An Internal Curing Agent for PCC. Sustainability 2019, 11, 2491. [Google Scholar] [CrossRef] [Green Version]

- Qin, Y.; Pang, X.; Tan, K.; Bao, T. Evaluation of pervious concrete performance with pulverized biochar as cement replacement. Cem. Concr. Compos. 2021, 119, 104022. [Google Scholar] [CrossRef]

- Tan, K.; Qin, Y.; Wang, J. Evaluation of the properties and carbon sequestration potential of biochar-modified pervious concrete. Constr. Build. Mater. 2022, 314, 125648. [Google Scholar] [CrossRef]

- Falliano, D.; De Domenico, D.; Quattrocchi, S.; Cosenza, P.; Ricciardi, G.; Restuccia, L.; Ferro, G.A. Mechanical properties and carbon footprint of 3D-printable cement mortars with biochar additions. In Proceedings of the MATEC Web of Conferences; IOP Publishing: Bristol, UK, 2020; p. 01017. [Google Scholar]

- Wu, J.; Li, Z.; Huang, D.; Liu, X.; Tang, C.; Parikh, S.J.; Xu, J. A novel calcium-based magnetic biochar is effective in stabilization of arsenic and cadmium co-contamination in aerobic soils. J. Hazard. Mater. 2020, 387, 122010. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Wu, C.; Hou, W.; Zhao, Q.; Liang, X.; Lin, S.; Li, H.; Xie, Y. Biological calcium carbonate with a unique organic–inorganic composite structure to enhance biochar stability. Environ. Sci. Processes Impacts 2021, 23, 1747–1758. [Google Scholar] [CrossRef]

- Sahibulla, S.M.M.; Jaisingh, S.J. Pozzolanic biosilica, biochar, and egg shell in setting time, WVTR, and compression strength of biocement mortar: A Taguchi GRA validation. Biomass Convers. Biorefinery 2021. [Google Scholar] [CrossRef]

- Kelemen, P.; Benson, S.M.; Pilorgé, H.; Psarras, P.; Wilcox, J. An overview of the status and challenges of CO2 storage in minerals and geological formations. Front. Clim. 2019, 1, 9. [Google Scholar] [CrossRef]

- Tanzer, S.; Blok, K.; Ramirez, A. Decarbonising Industry via BECCS: Promising Sectors, Challenges, and Techno-economic Limits of Negative Emissions. Curr. Sustain. Renew. Energy Rep. 2021, 8, 253–262. [Google Scholar] [CrossRef]

- Adesina, A. Recent advances in the concrete industry to reduce its carbon dioxide emissions. Environ. Chall. 2020, 1, 100004. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Barreneche, C.; Miró, L.; Morera, J.M.; Bartolí, E.; Fernández, A.I. Low carbon and low embodied energy materials in buildings: A review. Renew. Sustain. Energy Rev. 2013, 23, 536–542. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L. Investigating the embodied energy and carbon of buildings: A systematic literature review and meta-analysis of life cycle assessments. Renew. Sustain. Energy Rev. 2021, 143, 110935. [Google Scholar] [CrossRef]

- Habert, G.; Miller, S.A.; John, V.M.; Provis, J.L.; Favier, A.; Horvath, A.; Scrivener, K.L. Environmental impacts and decarbonization strategies in the cement and concrete industries. Nat. Rev. Earth Environ. 2020, 1, 559–573. [Google Scholar] [CrossRef]

- Arif, M.; Jan, T.; Riaz, M.; Fahad, S.; Adnan, M.; Ali, K.; Mian, I.A.; Khan, B.; Rasul, F. Biochar; a remedy for climate change. In Environment, Climate, Plant and Vegetation Growth; Springer: Cham, Switzerland, 2020; pp. 151–171. [Google Scholar] [CrossRef]

- Makul, N. Modern sustainable cement and concrete composites: Review of current status, challenges and guidelines. Sustain. Mater. Technol. 2020, 25, e00155. [Google Scholar] [CrossRef]

- Terlouw, T.; Bauer, C.; Rosa, L.; Mazzotti, M. Life cycle assessment of carbon dioxide removal technologies: A critical review. Energy Environ. Sci. 2021, 14, 1701–1721. [Google Scholar] [CrossRef]

- Yang, Q.; Mašek, O.; Zhao, L.; Nan, H.; Yu, S.; Yin, J.; Li, Z.; Cao, X. Country-level potential of carbon sequestration and environmental benefits by utilizing crop residues for biochar implementation. Appl. Energy 2021, 282, 116275. [Google Scholar] [CrossRef]

- Restuccia, L.; Ferro, G.A.; Suarez-Riera, D.; Sirico, A.; Bernardi, P.; Belletti, B.; Malcevschi, A. Mechanical characterization of different biochar-based cement composites. Procedia Struct. Integr. 2020, 25, 226–233. [Google Scholar] [CrossRef]

- Kua, H.W.; Gupta, S.; Tan, C. Biochar as a bond enhancement in fiber-reinforced mortar. Acad. J. Civ. Eng. 2017, 35, 569–574. [Google Scholar]

- Liu, R.; Xiao, H.; Guan, S.; Zhang, J.; Yao, D. Technology and method for applying biochar in building materials to evidently improve the carbon capture ability. J. Clean. Prod. 2020, 273, 123154. [Google Scholar] [CrossRef]

- Boumaaza, M.; Belaadi, A.; Bourchak, M.; Jawaid, M.; Hamid, S. Comparative study of flexural properties prediction of Washingtonia filifera rachis biochar bio-mortar by ANN and RSM models. Constr. Build. Mater. 2022, 318, 125985. [Google Scholar] [CrossRef]

- Dissanayake, P.D.; You, S.; Igalavithana, A.D.; Xia, Y.; Bhatnagar, A.; Gupta, S.; Kua, H.W.; Kim, S.; Kwon, J.-H.; Tsang, D.C. Biochar-based adsorbents for carbon dioxide capture: A critical review. Renew. Sustain. Energy Rev. 2020, 119, 109582. [Google Scholar] [CrossRef]

- Ye, H.; Radlińska, A.; Neves, J. Drying and carbonation shrinkage of cement paste containing alkalis. Mater. Struct. 2017, 50, 1–13. [Google Scholar] [CrossRef]

- Tahanpour Javadabadi, M.; Hajmohammadian Baghban, M. Sustainable Concrete: A Review. Int. J. Struct. Civ. Eng. Res. 2019, 8, 126–132. [Google Scholar] [CrossRef]

- Gupta, S.; Kashani, A. Utilization of biochar from unwashed peanut shell in cementitious building materials–Effect on early age properties and environmental benefits. Fuel Processing Technol. 2021, 218, 106841. [Google Scholar] [CrossRef]

- Zhao, M.Y.; Enders, A.; Lehmann, J. Short- and long-term flammability of biochars. Biomass Bioenergy 2014, 69, 183–191. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W. Factors determining the potential of biochar as a carbon capturing and sequestering construction material: Critical review. J. Mater. Civ. Eng. 2017, 29, 04017086. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W. Biochar as a carbon sequestering construction material in cementitious mortar. Acad. J. Civ. Eng. 2017, 35, 563–568. [Google Scholar]

- Rostami, R.; Klemm, A.J.; Almeida, F.C.R. Reduction of shrinkage by Superabsorbent polymers (SAP) in fibre reinforced mortars. Constr. Build. Mater. 2021, 288, 123109. [Google Scholar] [CrossRef]

- de Souza, F.B.; Yao, X.; Gao, W.; Duan, W. Graphene opens pathways to a carbon-neutral cement industry. Sci. Bull. 2022, 67, 5–8. [Google Scholar] [CrossRef]

- Santos, T.; Almeida, J.; Silvestre, J.D.; Faria, P. Life cycle assessment of mortars: A review on technical potential and drawbacks. Constr. Build. Mater. 2021, 288, 123069. [Google Scholar] [CrossRef]

- Kim, T.; Lee, S.; Chae, C.U.; Jang, H.; Lee, K. Development of the CO2 emission evaluation tool for the life cycle assessment of concrete. Sustainability 2017, 9, 2116. [Google Scholar] [CrossRef] [Green Version]

- Feiz, R.; Ammenberg, J.; Baas, L.; Eklund, M.; Helgstrand, A.; Marshall, R. Improving the CO2 performance of cement, part I: Utilizing life-cycle assessment and key performance indicators to assess development within the cement industry. J. Clean. Prod. 2015, 98, 272–281. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Winters, D.; Boakye, K.; Simske, S. Toward Carbon-Neutral Concrete through Biochar–Cement–Calcium Carbonate Composites: A Critical Review. Sustainability 2022, 14, 4633. https://doi.org/10.3390/su14084633

Winters D, Boakye K, Simske S. Toward Carbon-Neutral Concrete through Biochar–Cement–Calcium Carbonate Composites: A Critical Review. Sustainability. 2022; 14(8):4633. https://doi.org/10.3390/su14084633

Chicago/Turabian StyleWinters, Dahl, Kwaku Boakye, and Steven Simske. 2022. "Toward Carbon-Neutral Concrete through Biochar–Cement–Calcium Carbonate Composites: A Critical Review" Sustainability 14, no. 8: 4633. https://doi.org/10.3390/su14084633

APA StyleWinters, D., Boakye, K., & Simske, S. (2022). Toward Carbon-Neutral Concrete through Biochar–Cement–Calcium Carbonate Composites: A Critical Review. Sustainability, 14(8), 4633. https://doi.org/10.3390/su14084633