3.1. Basalt Fiber and Nanomaterials

BF is known for improving flexural behavior of reinforced concrete, besides a considerable elastic behavior facing exposure to elevated temperatures. Despite their remarkable independent performance, some studies were conducted to show the combined effect of using BF and NS together on the mechanical and durability properties of mortar and concrete [

29,

44,

51,

52,

53,

54,

55,

56]. The addition of NS and BF together adversely affects workability; this observation is in agreement with previous studies [

29,

44], which shows that the slump of concrete reduces with an increasing of the BF and NS content. Nevertheless, this reduction can be offset with the use of supplementary cementitious materials (SCM) such as fly ash [

44]. For instance, by using each of the NS and BF independently, slump was reduced by 12% and 20%, respectively. While adding NS and BF together with the same dosage, the slump was reduced by only 22%. The available studies have not discussed this matter. However, this may be related to the fact that the NS particles may disperse the fibers (it may avoid agglomeration of fibers). In addition, the same facts can be seen for fresh density. A study [

44] showed that the fresh density of concrete reduces with the incorporation of BF, and there is not a significant change with the use of NS. Nevertheless, the results show that with the use of both NS and BF, the fresh density slightly increases.

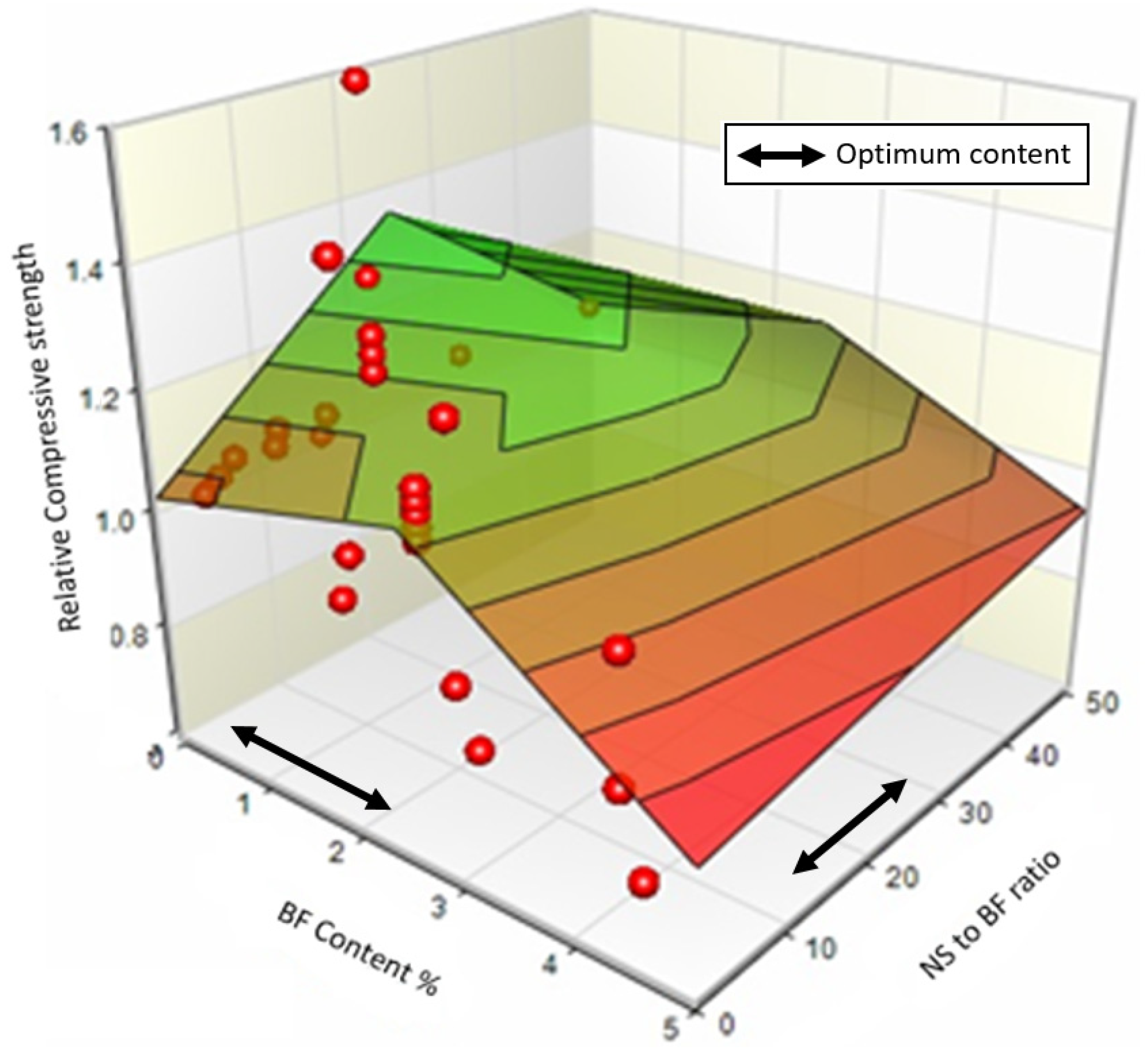

According to studies [

44,

51,

52,

53,

54,

55], as shown in

Figure 1, the optimum compressive strength of concrete can be obtained by using 0.037–2% of BF and with a ratio of NS to BF between 15 to 30. Moreover, using recycled aggregate and BF without NS reduces the compressive strength up to 30%, while the addition of NS by 6% enhances compressive strength up to 16%. The same trend was observed for axial compressive strength [

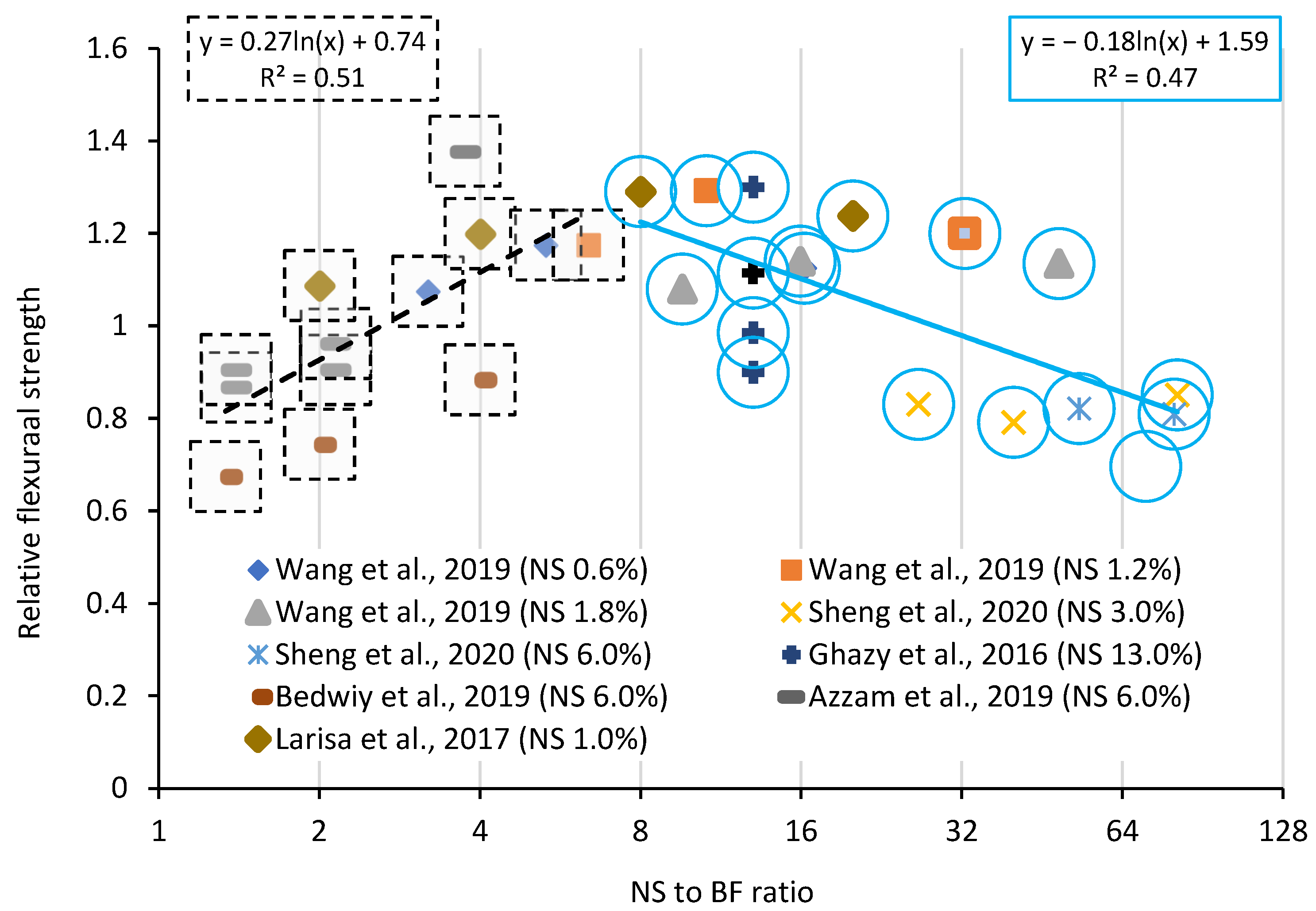

29]. In addition, flexural strength can be greatly affected by adding BF and NS to the cementitious mixes. For example, outputs of studies [

29,

51,

52,

54,

55,

56] show that the proportion of fiber and NS in the mixes is the most effective factor in improving flexural strength in which it can be improved up to 30% by using 0.1–1% of BF while the ratio of NS/BF is in between 6 to 10 (see

Figure 2). Nevertheless, increasing the content of NS by more than 3% adversely affects the flexural strength as shown in

Figure 2. Regarding the three-dimension figures, the NS/BF was considered in order to show the synergic effect of both materials (BF and NS) in the same mix. For example,

Figure 1 shows for constant basalt fiber content what will happen if we change the NS/BF ratio. Regarding the NS content, it can be found by multiplying the BF content by NS/BF content.

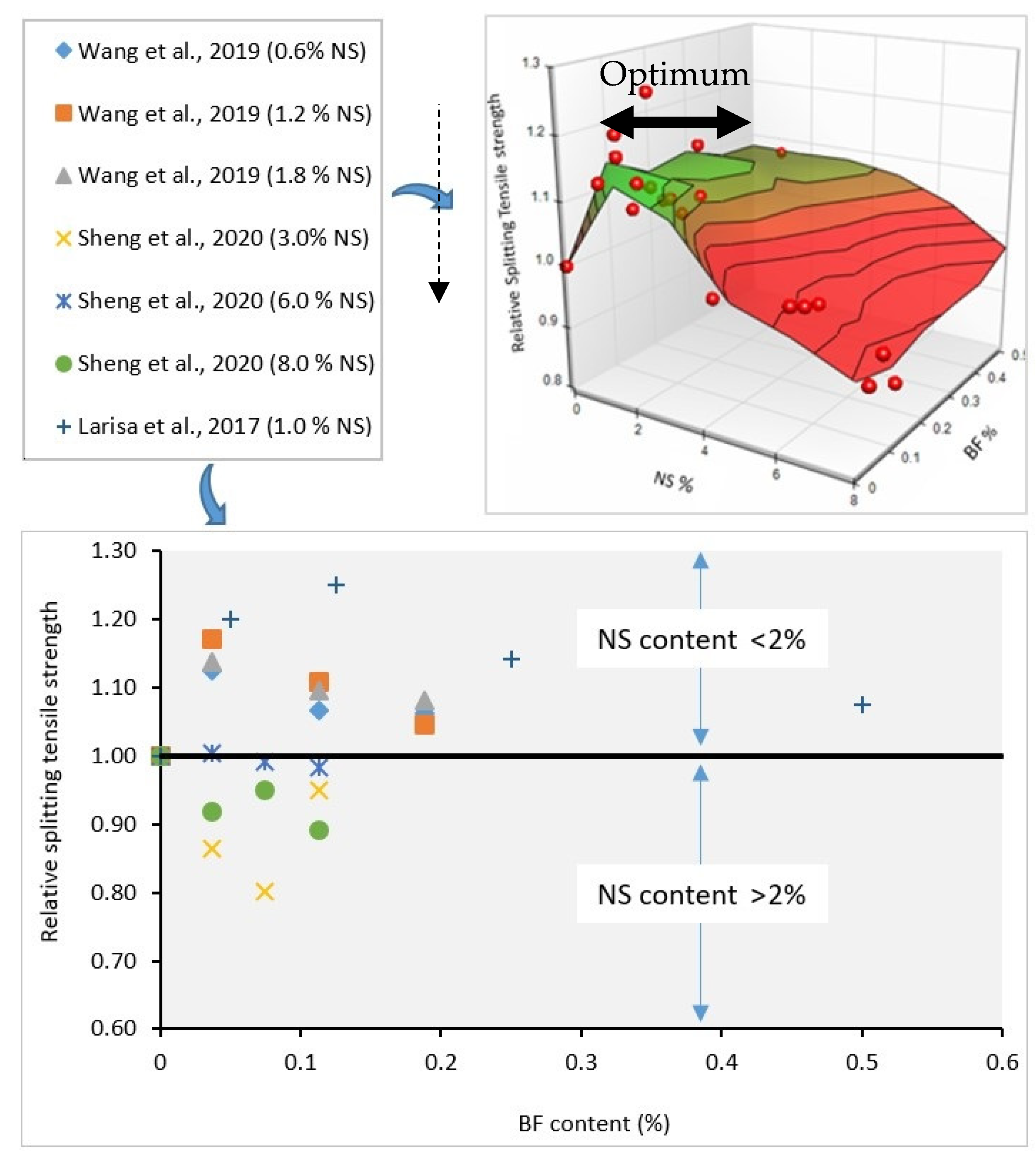

The simultaneous impact of NS and BF on splitting tensile was studied by [

29,

51,

57]. As shown in

Figure 3, the optimum value of splitting tensile strength can be obtained by using 0.6–1.8% of NS with 0.037 to 0.25% of BF. Using more than 2% of NS adversely affects the tensile strength of concrete/mortar (

Figure 3). This reduction in flexural and splitting tensile strength may be due to the reason that an excessive dosage of NS in the mix causes agglomeration of the nanoparticles on the fibers which led to pulling out of the fiber, due to a reduction in the bond between the matrix and the fiber.

In terms of durability, conducted studies are not sufficient to identify the influence of using BF and nanomaterials on cementitious composites. However, studies [

44,

56] stated that using BF and NS together improves corrosion resistance and electrical resistivity remarkably in comparison to the control mixes. Using carbon nanotube (CNT) with BF exceeds the frost resistance of the unmodified basalt fiber reinforced concrete by 1.5 times [

58]. The addition of NS to the BF reinforced matrix improves the drying shrinkage resistance, and the highest enhancement regarding shrinkage resistance was reported when both PPF and BF were used together with NS [

52]. Likewise, due to densifying the cementitious matrix, the addition of NS to BF reinforced mortar remarkably reduces the passing charge and improves the salt-frost scaling [

52]. A study [

52] concludes that the addition of NS for BF reinforced mortar reduces the intensity of the transition zone as the increase by adding fiber leads to a remarkable reduction in permeability. The performance of the heat-rain test is not satisfactory with the addition of nano clay (NC) to BF reinforced concrete [

59].

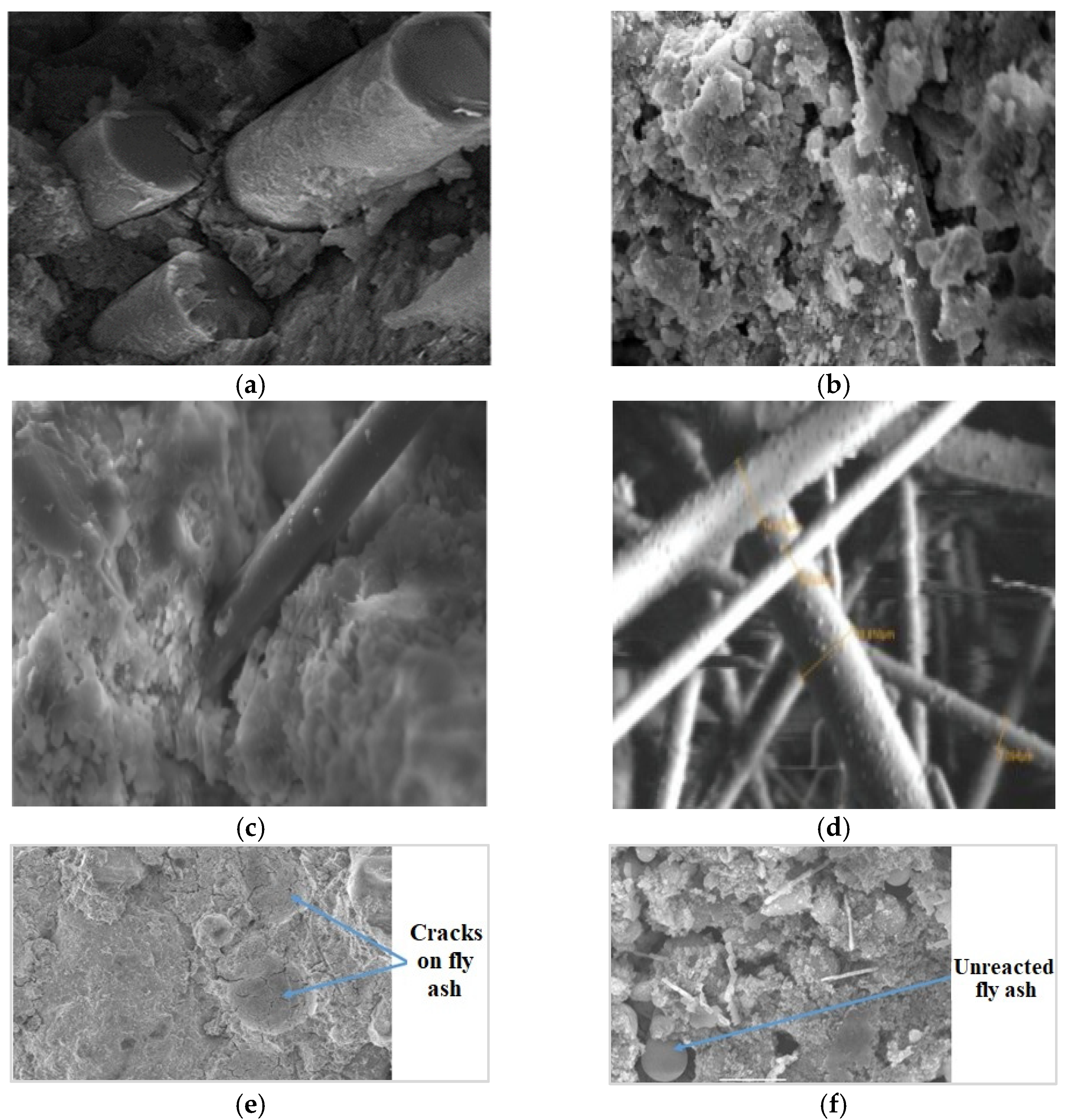

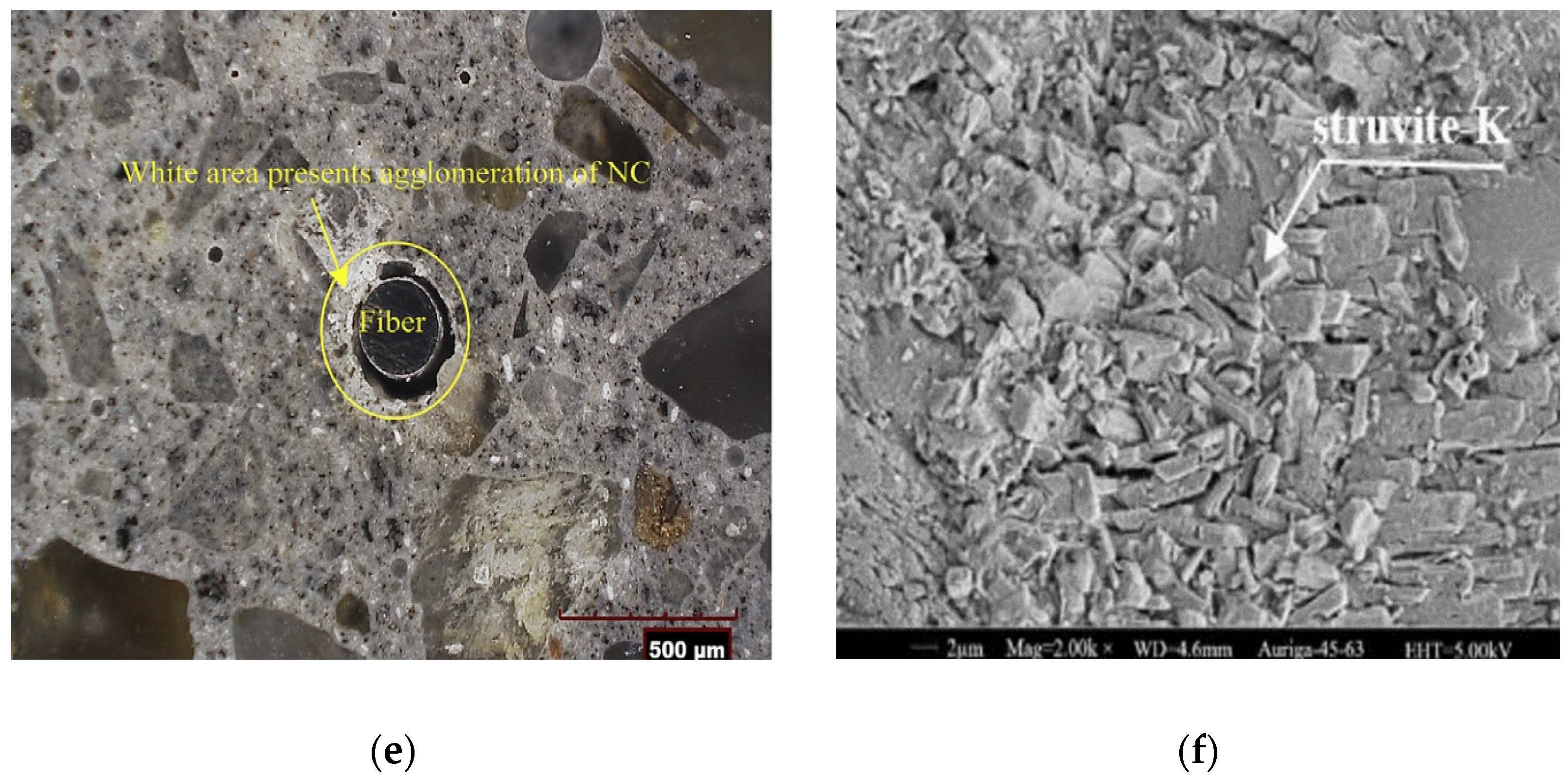

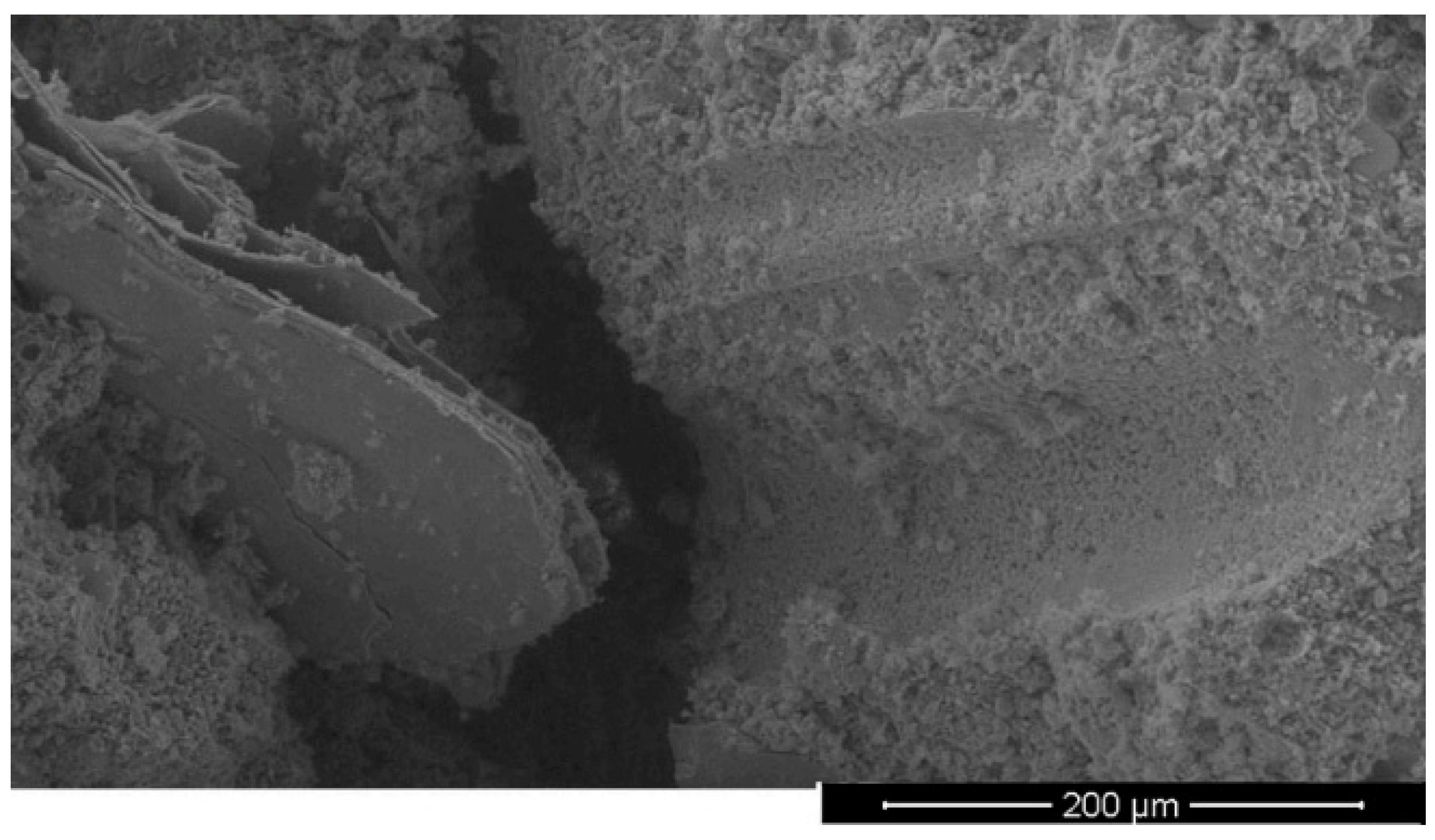

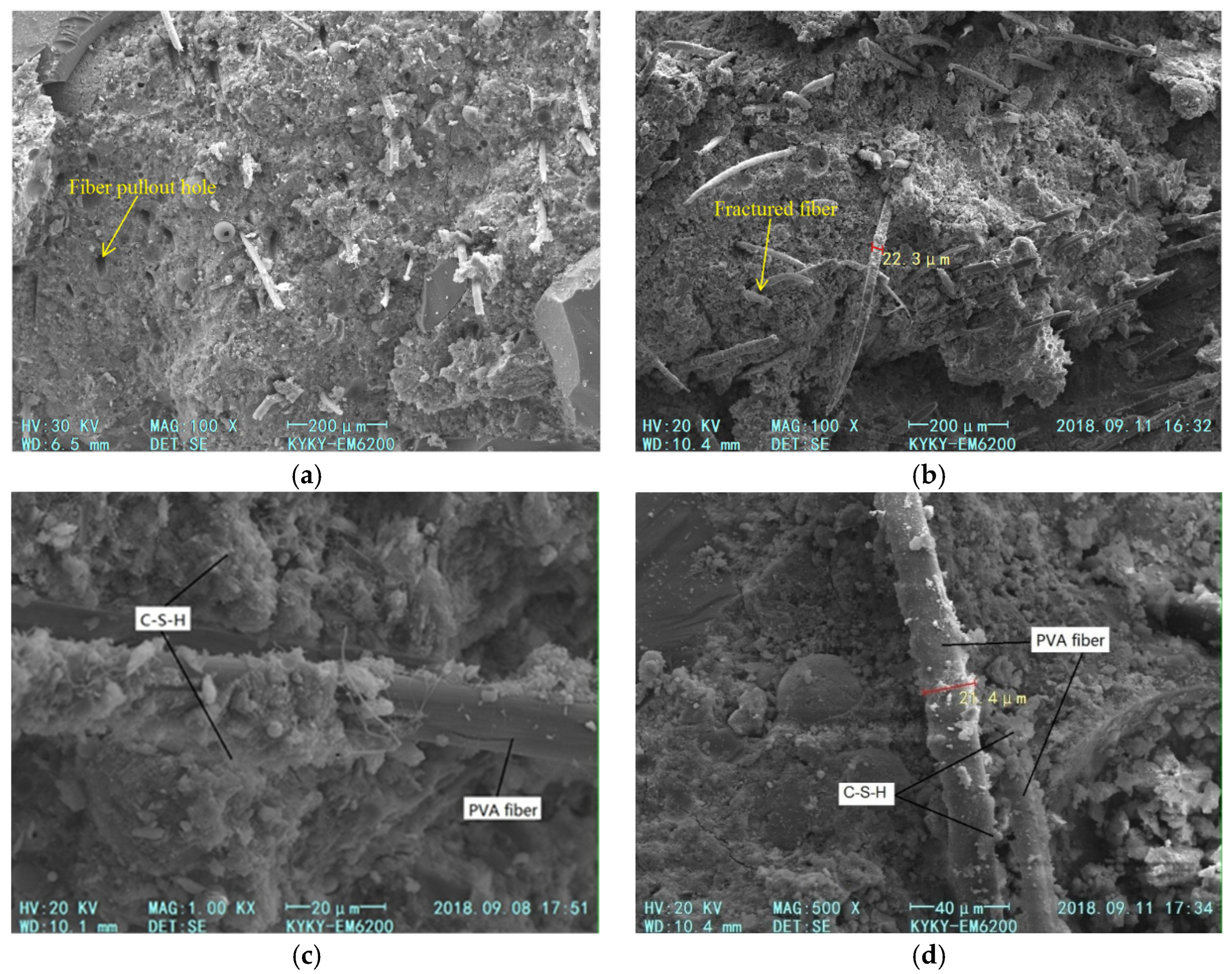

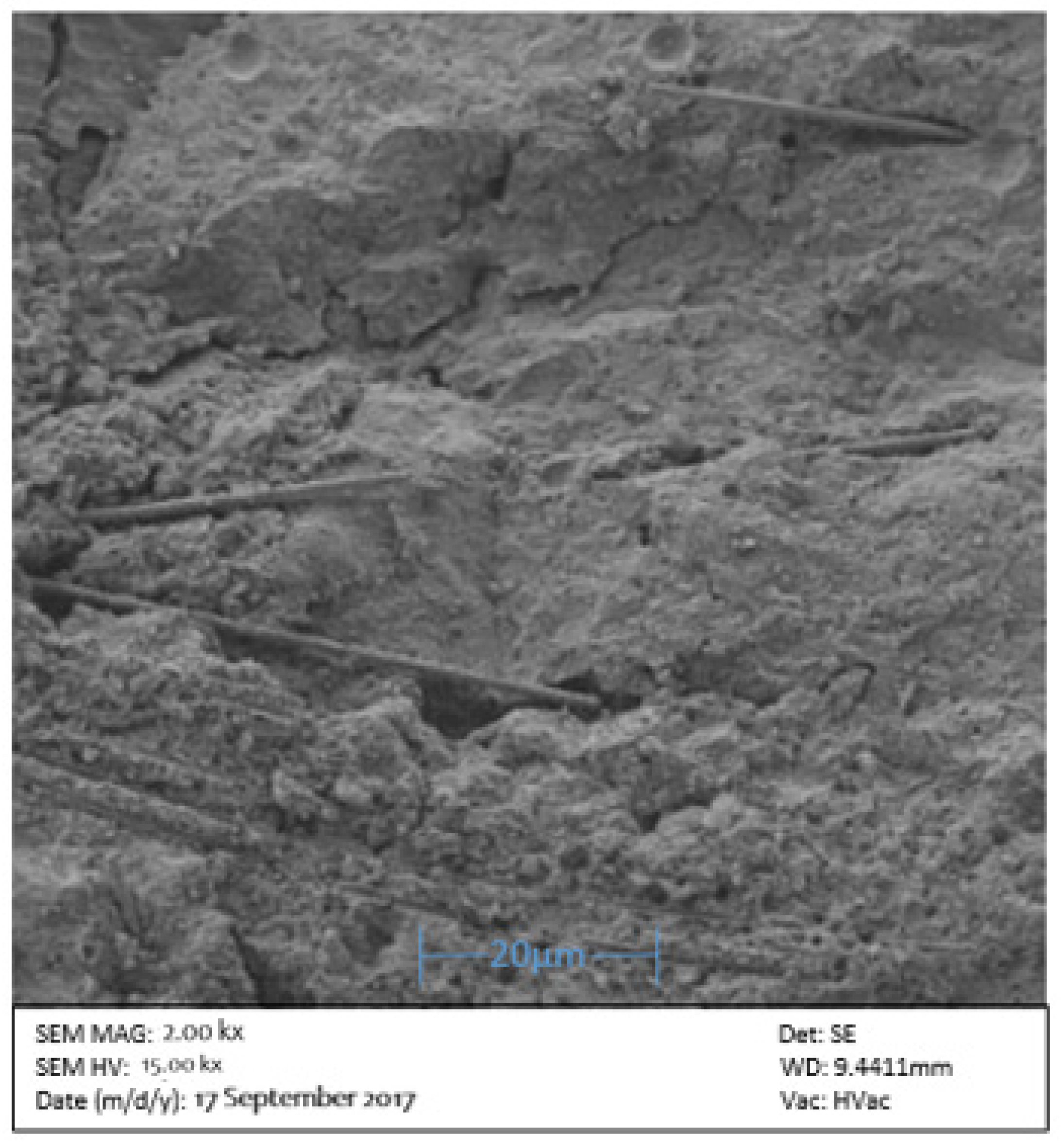

The microstructure of the mixes containing NS and BF was studied by [

29,

44,

53,

56,

60], as shown in

Figure 4. Based on the SEM figures, it can be shown that the bond between the cement matrix and the BF is the fundamental guarantee for the enhancement of the fibers, and when the interface layer between the cement matrix and BF is looser (see

Figure 4a,b), the fiber cannot effectively play the role of network support. Bonding improves with the addition of NS to the BF contained mix. When nanomaterials are combined with BF, more energy is required to debond the fiber, resulting in a considerable increase in toughness (

Figure 4c). A study [

56] used the boiling method to evaluate the corrosion resistance of NS modified BF reinforced concrete. It was observed that the surface of the fiber, boiled with the addition of NS, remains smooth and flat with minor inclusions of new growths relative to fibers without NS (see

Figure 4d).

In addition, the concentration of OH in the matrix reduces as a result of the reaction of NS particles with Ca(OH)

2 (CH) in the matrix prior to the BF to create C-S-H gel, which leads to improved binding of various ions, as supported by a study [

61] as well. Moreover, as stated by a study [

44], with the addition of fly ash with BF and NS, some of the fly ash particles remain unreacted (see

Figure 4f), and at the same time, micro cracks are appearing as shown in

Figure 4e.

The use of basalt fiber with other nanomaterials is very scarce. CNT, NC, nano metakaolin (NMK) and nano alumina were investigated with BF by studies [

58,

59,

62,

63]. It was observed that compressive strength reduced or slightly increased with the addition of these nanomaterials. Overall, the addition of CNT, NC, NMK and nano alumina to BF reinforced mixes improves the flexural strength remarkably. The highest flexural strength has been recorded with the addition of 0.1% CNT and 0.2% BF together relative to using any of them separately. In contrast to CNT and nA

l2O

3, the addition of BC with BF adversely affected splitting tensile strength.

3.2. Steel Fiber and Nanomaterials

SF is the most popular type of fiber used as concrete reinforcement. The incorporation of steel fibers (both long and short) improves the durability and mechanical properties of hardened concrete, namely the flexural strength, toughness, impact strength, resistance to fatigue, vulnerability to cracking and spalling. Most of the covered research used SF with NS [

30,

39,

52,

54,

64,

65,

66,

67,

68,

69], and was distantly followed by SF with each NC [

70], nCaCO

3 [

43,

49], NMK [

68], nFe [

36] and RNCB [

71]. Considering that fibers increase the concrete mixture viscosity by absorbing the cement paste, an increase in the volume of fibers may create some issues for the concrete workability, thus further adding a superplasticizer—SP—becomes necessary for increasing the slump. On the other hand, a high specific surface area of the ultra-fine nanomaterials with their rate of pozzolanic reaction plays an important role in the workability reduction in the fiber-reinforced cementitious composites. As illustrated in

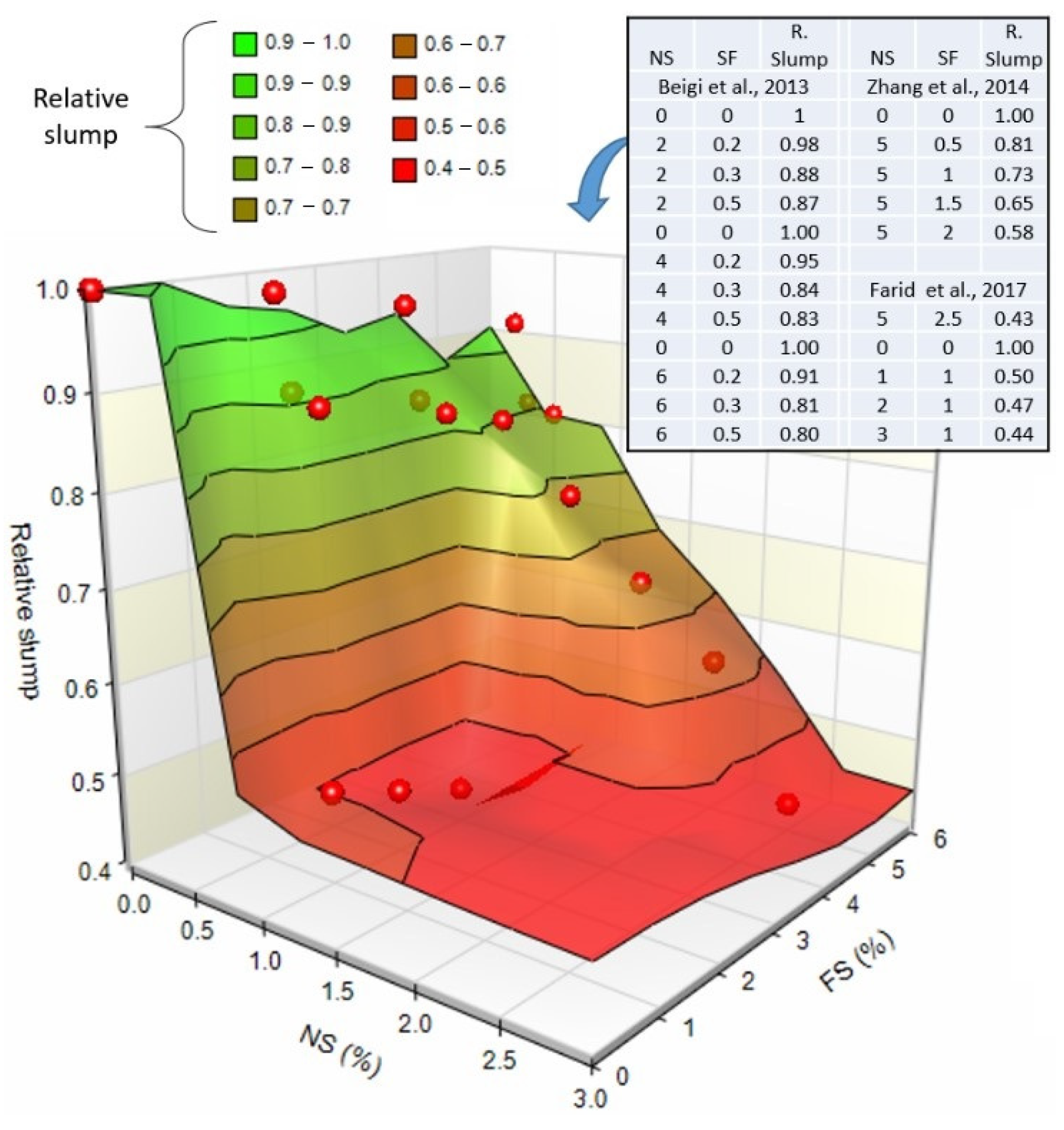

Figure 5, increasing the dosage of NS slightly affects workability if the SF content was not exceeding 0.5%. Nevertheless, for the same dosage of the SF addition of nFe and NC reduces the workability [

36,

70]. However, very limited data are available on the effect of the combined usage of fiber and nanomaterials on the air content of concrete/mortar. Due to the small particle size of nanomaterials, an air content decrease compared to ordinary mixes and the opposite can be seen with the addition of fiber. For example, with SF, the addition of NC can decrease the air content from 6.8% to 5.3% as stated by [

70]. Moreover, the NS particles can absorb part of the free water in the concrete and decrease the plastic shrinkage of concrete because of the large specific surface area of the nanoparticles. However, excessive amounts of nSiO

2 absorb a large amount of water. Therefore, the concrete shrinkage could be increased by an excessive amount of NS [

66,

72].

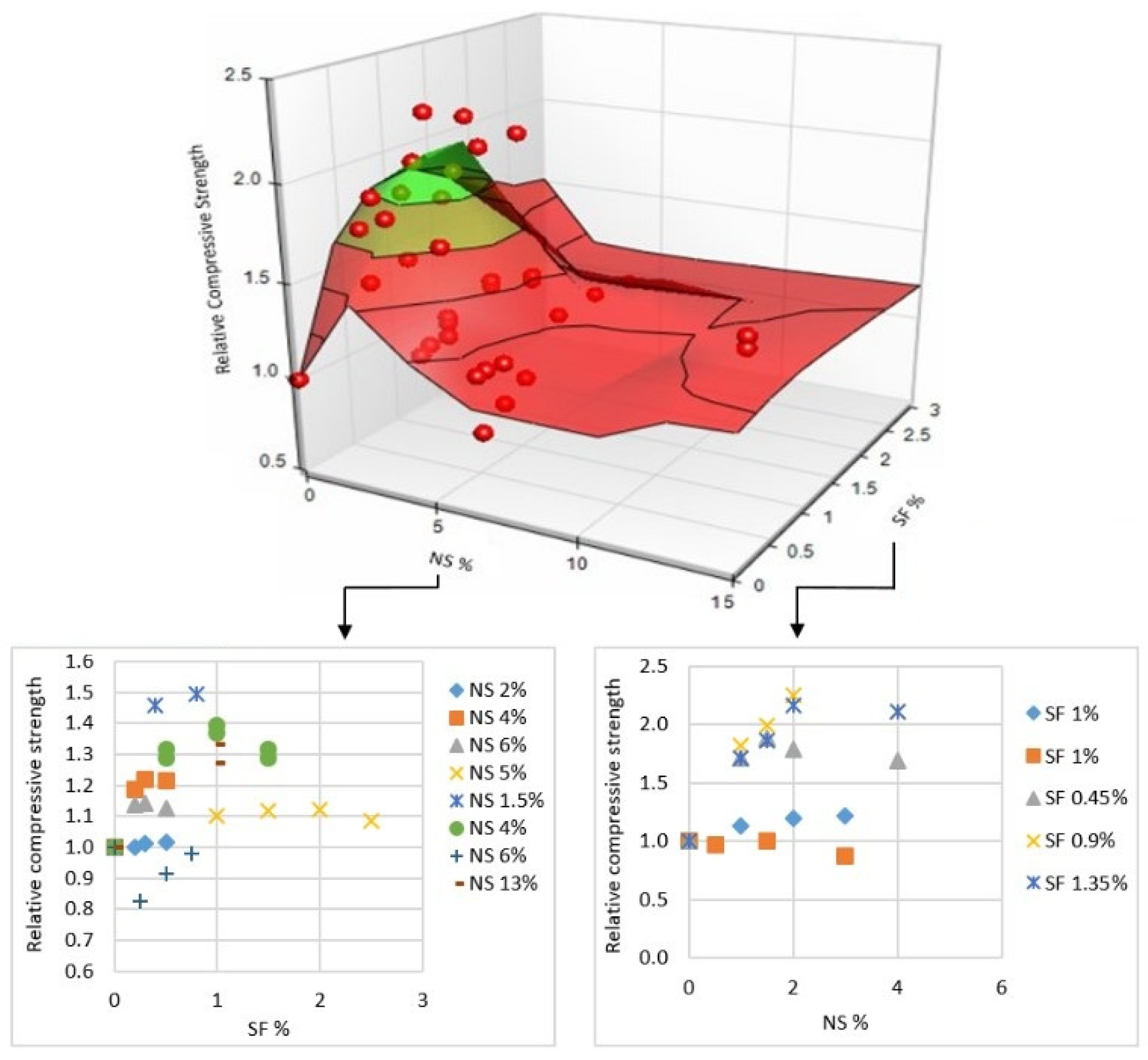

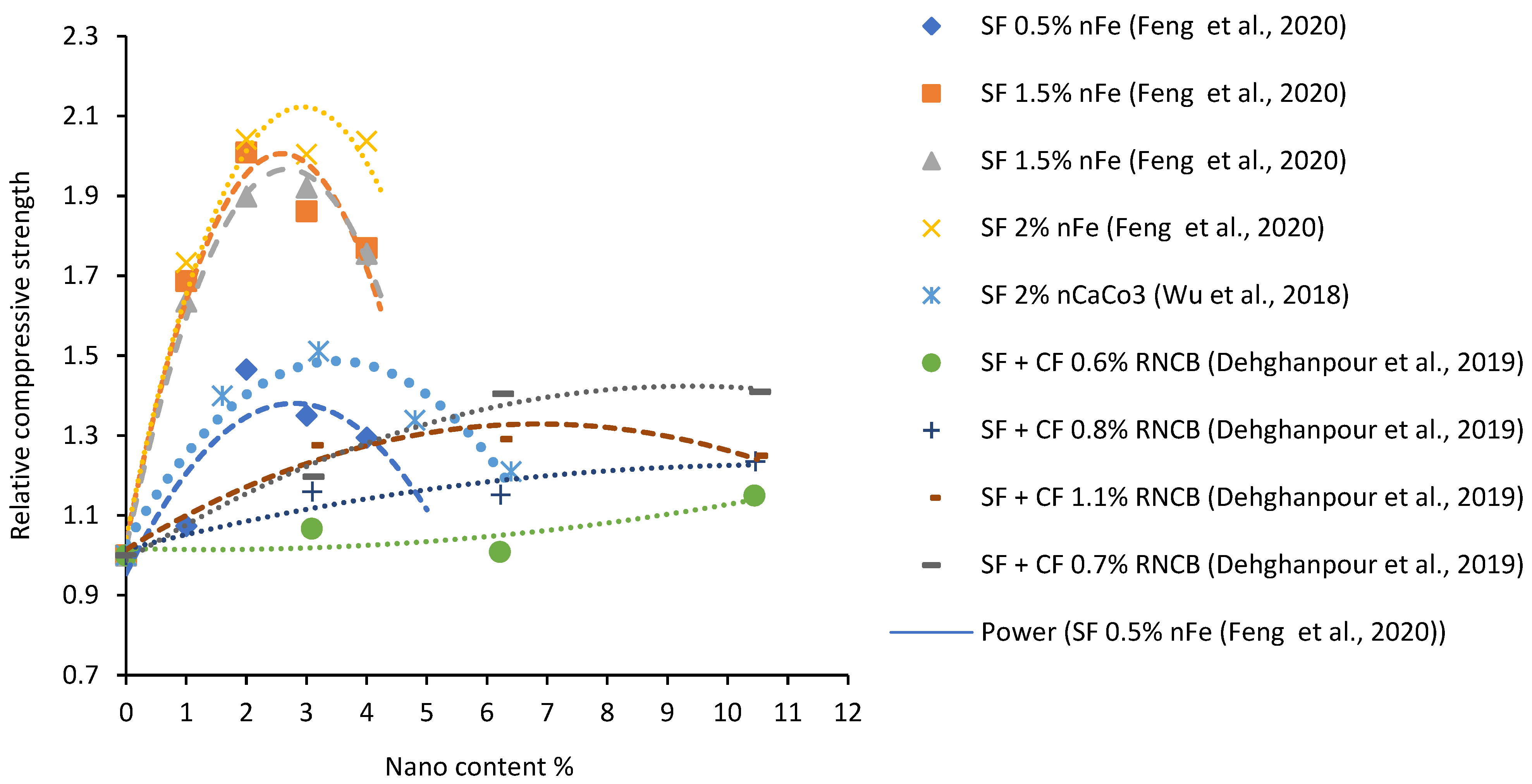

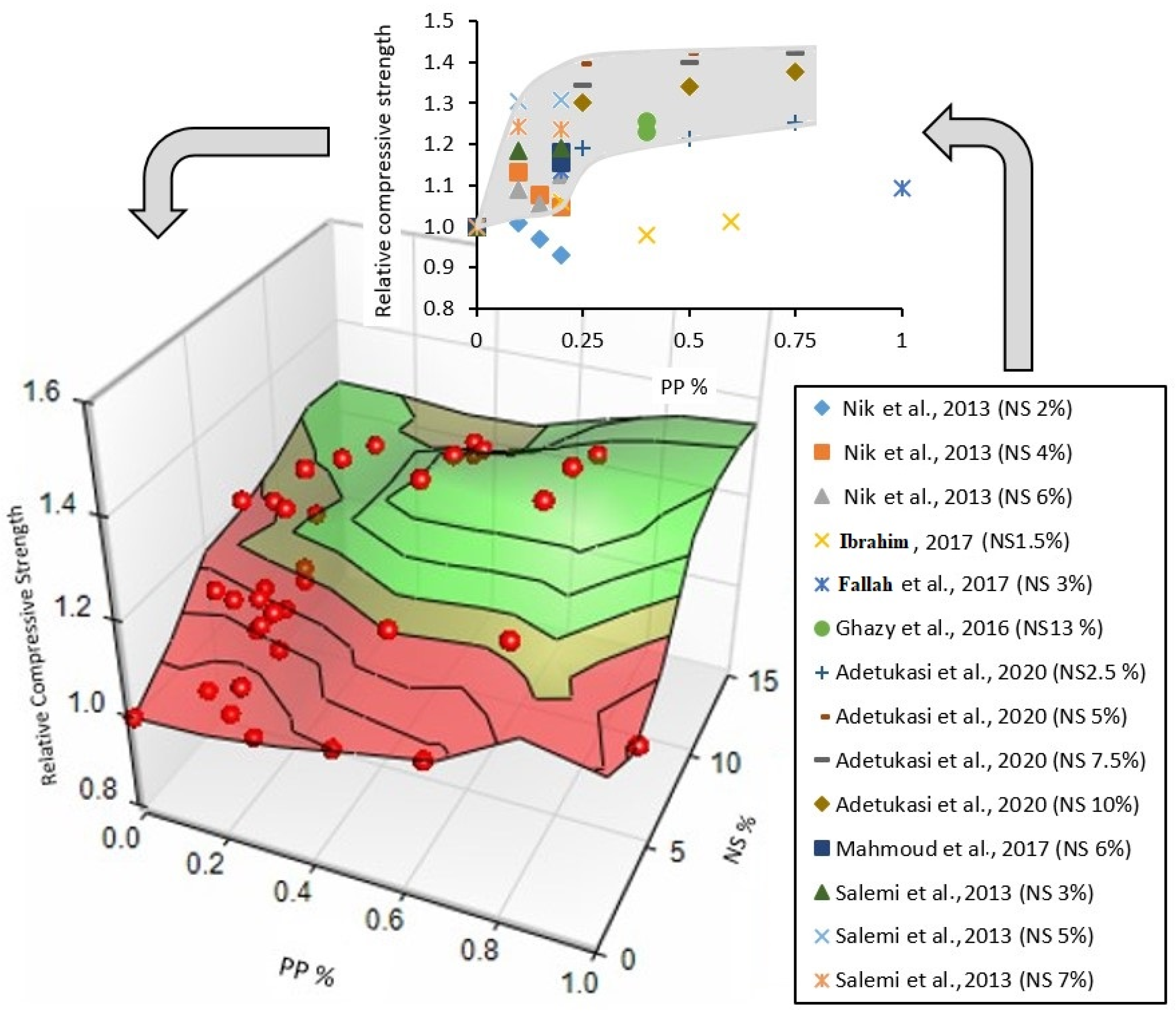

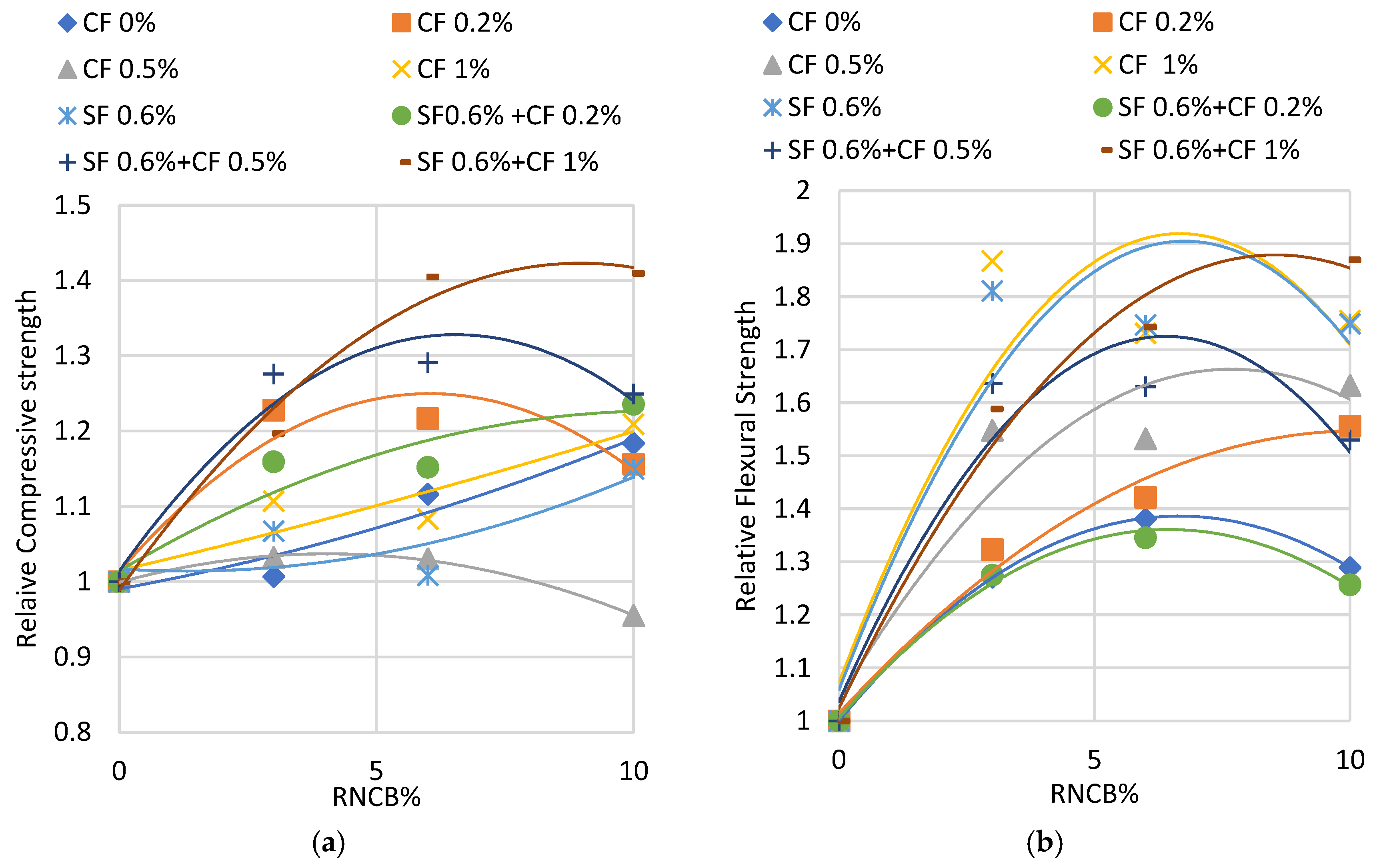

Using NS up to 4% with SF remarkably affects the compressive strength increment. As illustrated in

Figure 6, the optimum value of compressive strength can be obtained by the incorporation of 1–3% of NS with 0.5–1.5% of SF. Using SF more than 1.5% reduces its effectiveness, and the same fact can be seen with the use of NS more than 5% (compressive strength reduces up to 17%). This may belong to the formation of local weakness areas due to uneven dispersion of NS particles in the mixture [

67]. This shows that each of the nanomaterials positively affects compressive strength up to different dosages as shown in

Figure 7. For instance, using 2% of SF with each 2% nFe and 3% nCaCO

3 can be considered optimum content. Moreover, hybrid usage of SF and CF is more preferred with RNCB compared to the sole use of SF.

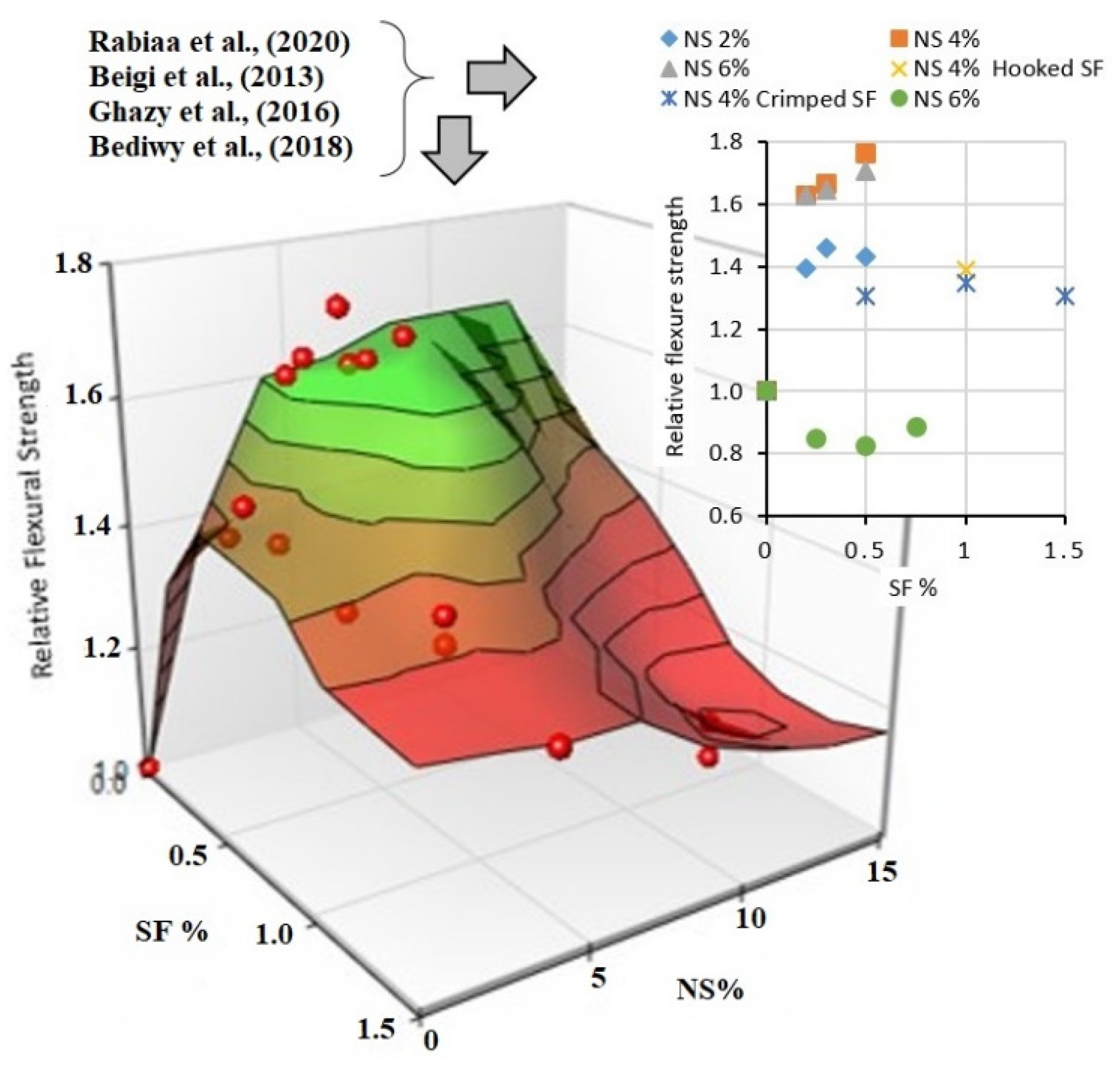

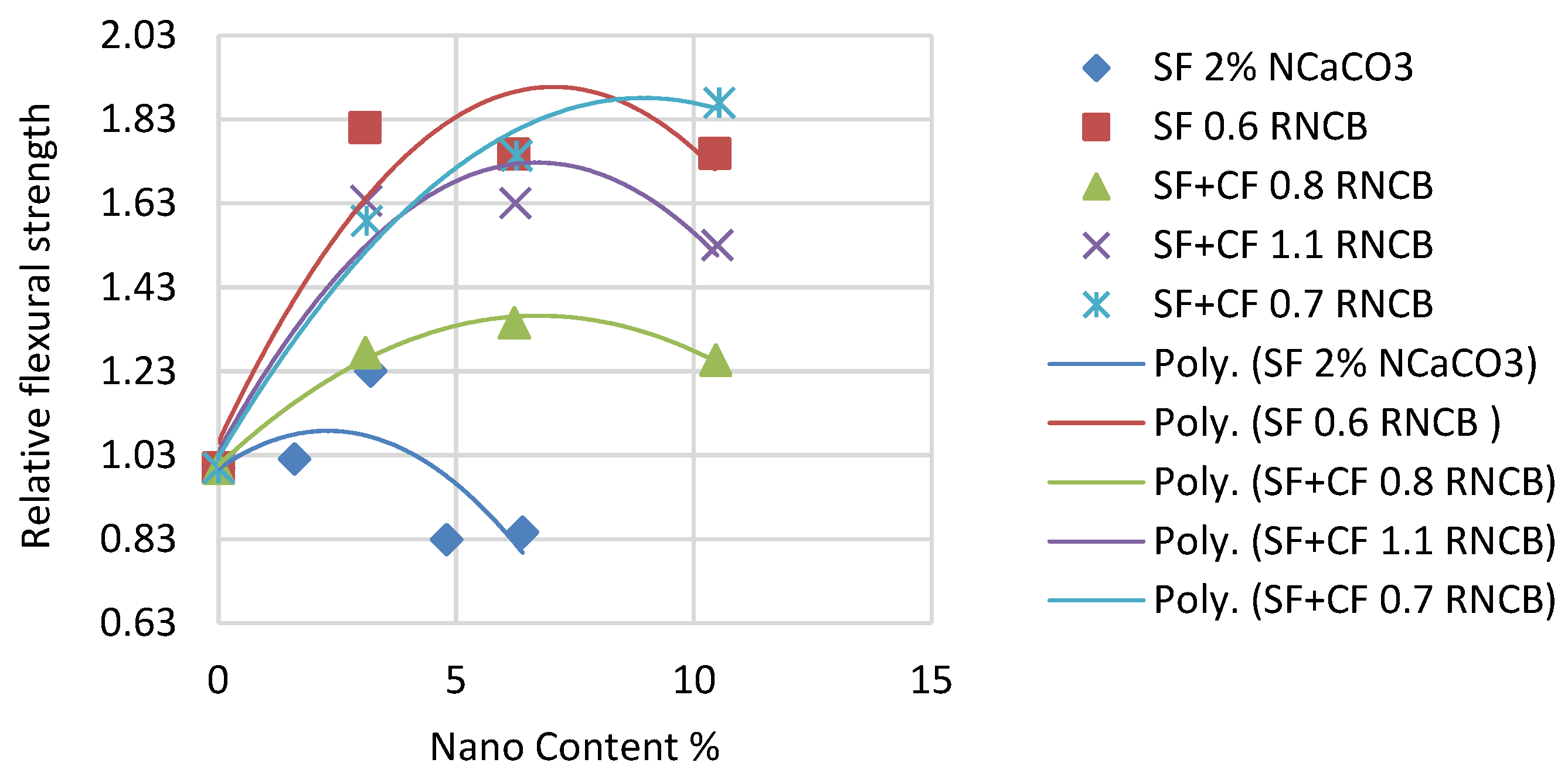

Flexural strength can be influenced by the addition of nanomaterials to SF reinforced cementitious composites. As shown in

Figure 8, the optimum value of flexural strength can be achieved by the incorporation of 2–5% of NS with 0.2–0.5% of SF. Same as compressive strength, increasing the dosage of SF and NS more than 0.5% and 5% respectively, will adversely affect the performance of cementitious composites. Moreover, adding the same incorporation ratio of NS for mixtures made with SF and basalt fiber, flexural strength adversely affected the SF contained mix [

54]. In contrast, with the use of pellets’ basalt fibers, flexural strength remarkably improved [

54]. Overall, the fibers and matrix have strong bonding that increases the force of fiber bridging which correspondingly improves the strength [

68,

72]. Flexural strength of 2% SF reinforced ultra high performance concrete—UHPC—can be slightly improved by using nCaCO

3 up to 3.2% [

30]. The improvement in flexural behavior was much greater while the RNCB was used with SF as shown in

Figure 9 [

49,

71]. The hybrid use of CF and SF was not as effective on flexural strength as compressive strength (see

Figure 9). Moreover, using hooked SF with 6% NMK was much more effective for flexural strength enhancement relative to crimpled SF due to higher bridging competency in the matrix [

68].

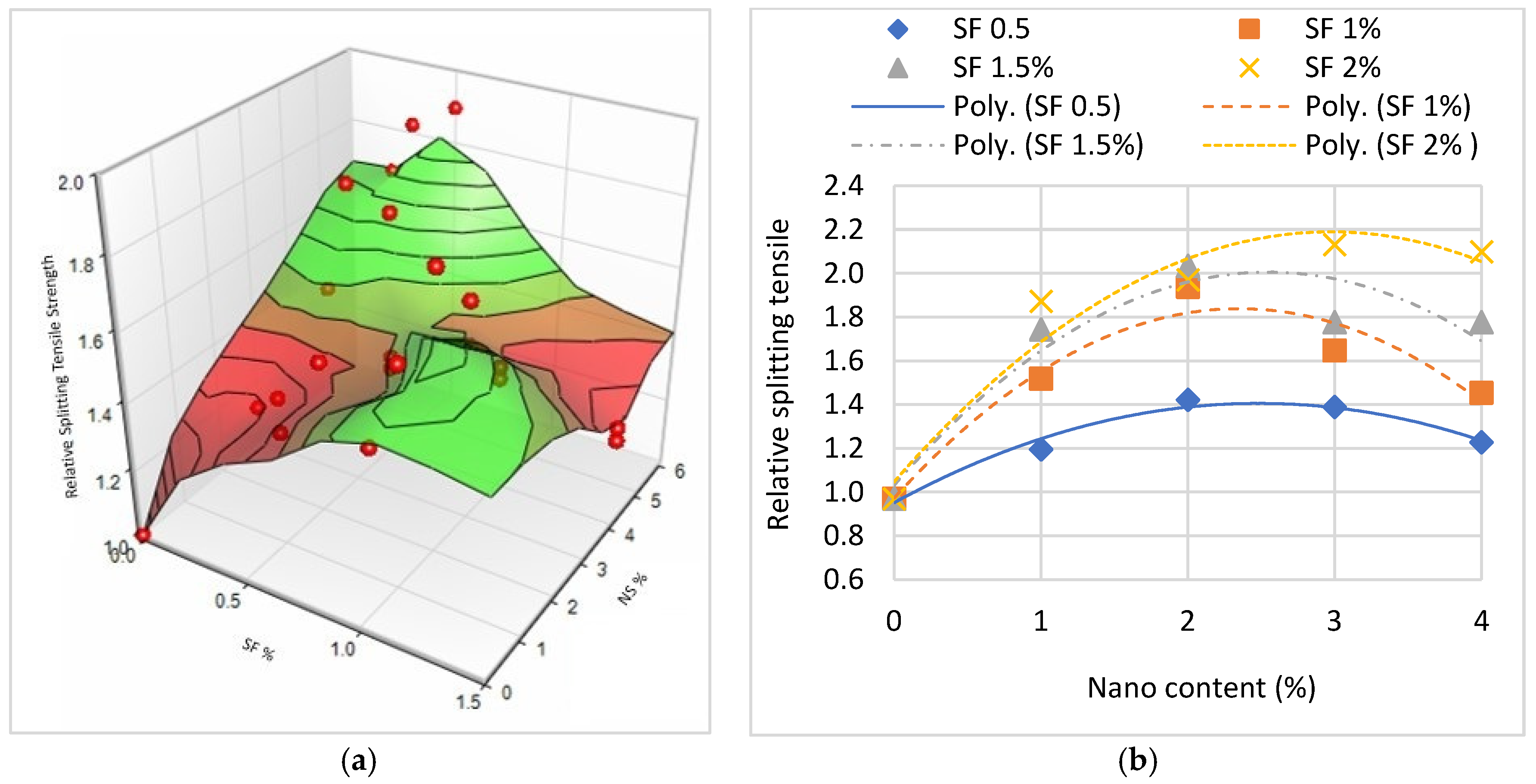

Furthermore, the simultaneous impact of SF and NS on splitting tensile strength was studied by [

30,

39,

68,

73]. As shown in

Figure 10a, the observed results conclude that increasing SF and NS inversely affects splitting tensile strength. In other words, the tensile strength of cementitious composites can be improved in two cases, either with low NS and high SF content or with high NS and low SF content. The highest value of tensile strength can be obtained using 6% of NS and 0.3% SF, but this content of NS as aforementioned adversely affects compressive and flexural strength. Owing to that, the optimum splitting tensile strength can be obtained with 2–3% NS and 1% of SF.

As shown in

Figure 10b, using 3% nFe with 2% SF recorded the optimum splitting tensile strength as stated by [

36]. Moreover, up to 1% hooked SF with 6% NMK obtained the highest splitting tensile strength. Nevertheless, SF of more than 1% is not much more effective with NMK due to the formation of the pores by fiber agglomeration. Moreover, using nFe more than 3% with SF will serve in the tensile strength increment. Furthermore, it can be concluded that nano-silica particles have a more momentous impact on the splitting tensile strength compared to the nano metakaolin particles due to the fact that nano-silica is more amorphous than nano metakaolin, and the silicon dioxide (SiO

2) percentage in NS is higher than that in metakaolin [

68].

Regarding durability performance of the cementitious mix, a limited number of research projects investigated the combined impact of nanomaterials and SF. Overall, the addition of nanomaterials, due to their filling and pozzolanic effects, in concrete leads to a denser structure with less porosity and water absorption [

30,

49,

52,

71]. For example, based on the water absorption test that indirectly evaluates the concrete porosity, the SF addition, beyond the optimum content (based on mechanical properties), increases the porosity and permeability due to facilitating bridging between pores [

30,

69,

73], and facilities the diffusion of CO

2 [

66]. Thus, it can be said that a small amount of SF resulted in no degradation in the permeation properties, whereas higher SF dosages would lead to a clear growth in the water absorption and sorptivity of the concrete [

41], and increase the resistance to CO

2 diffusion. Accordingly, the addition of nanomaterials, particularly NS, to SF reinforced concrete remarkably reduces the porosity, water absorption, cracking, freez-thaw and carbonation depth [

30,

49,

52,

66,

73]. Nevertheless, using NS more than 5% and SF more than 0.9% adversely influences the durability performance.

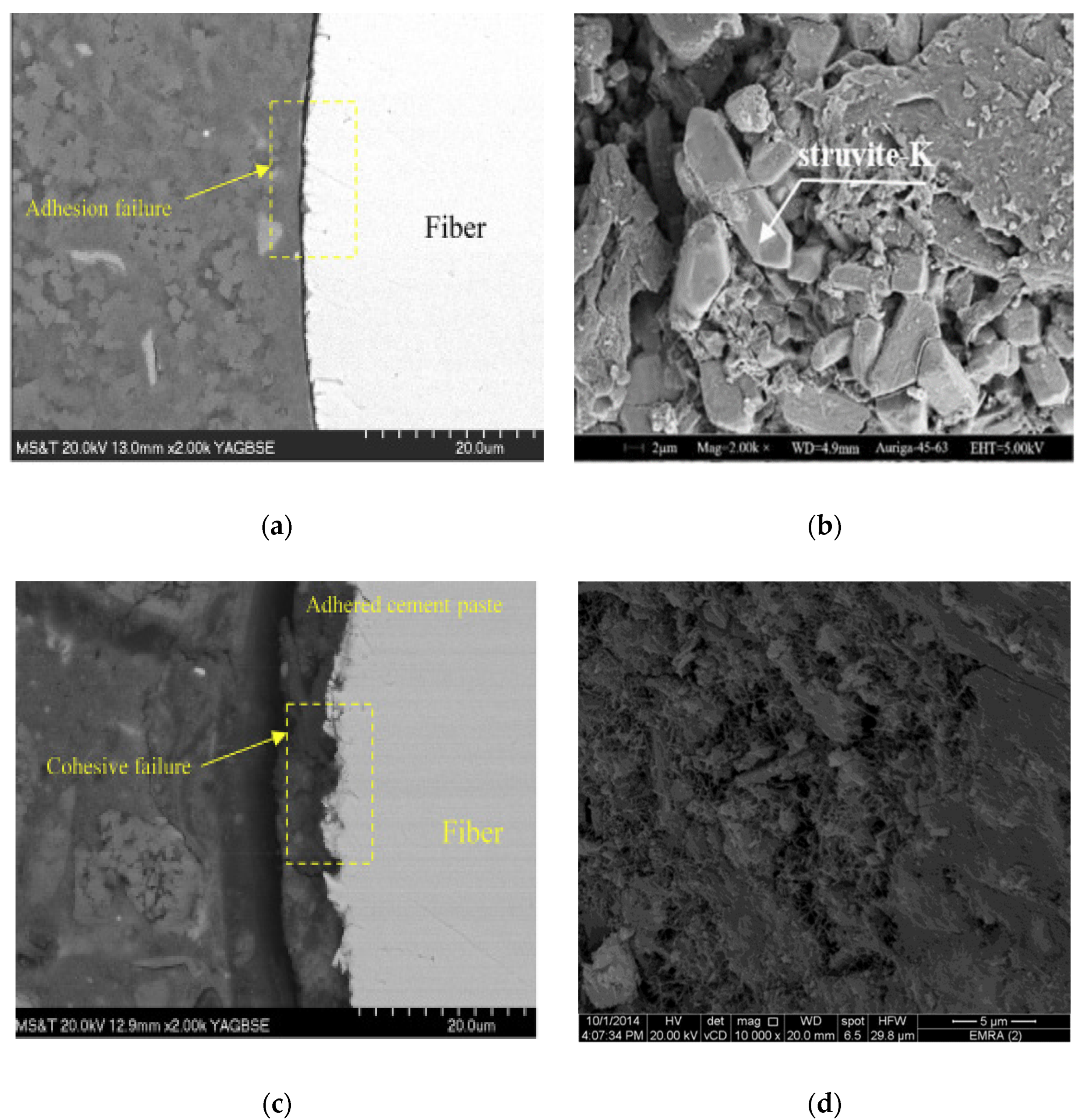

The microstructure of SF reinforced concrete/mortar containing nanomaterials specimens at 28 days was studied by studies [

36,

49,

69]. Without the addition of nanomaterial, in the mix of SF reinforced UHPC adhesive, failure was observed with obvious cracking space between the actual fiber and the matrix interface (see

Figure 11a). On the other hand, the addition of nFe up to 2%, due to uniform distribution and enhancing the compactness, decreases micro-cracks considerably for magnesium potassium phosphate cement mortar [

36] (see

Figure 11b). Backscattered electron microscopy (BSEM) examinations were performed for illustrating the microstructure of nCaCO

3 contained and SF reinforced UHPC by a study [

49], and the results show that when 3.2% of nCaCO

3 was used, the fiber-matrix interface was well bonded. However, some disconnected pores with sizes in the range from 2 to 20 mm were observed (see

Figure 11c). Moreover, the microstructure of the hardened cement paste containing NS appeared quite dense and compact with relatively fewer capillary pores as compared to the plain cement paste without NS; moreover, the bond filure mode changed to cohesive filure (see

Figure 11c) [

69]. Furthermore, an excessive amount of nanomaterials results in agglomeration of the nanoparticles ( see

Figure 11e as 6.4% n-CaCO

3 used), increasing the porosity ( see

Figure 11f as 5% nFe used) which is accompanied with lower bond strength.

3.3. Polypropylene Fiber and Nanomaterials

Polypropylene as synthetic fibers attracted researchers due to their lower cost and weight, resistance against corrosion and acids, excellent toughness and enhanced shrinkage cracking resistance [

74,

75]. Besides their usage independently, nanomaterials and polypropylene PPF are used together in the cementitious mixes. Most of the conducted research used PPF with NS [

35,

39,

40,

42,

45,

46,

52,

53,

64,

73], and was distantly followed by PPF with nTiO

2 [

40] and nAl

2O

3 [

35]. Workability was found to be reduced as both nAl

2O

3 and NS content increased in the PPF reinforced mixes [

35,

45,

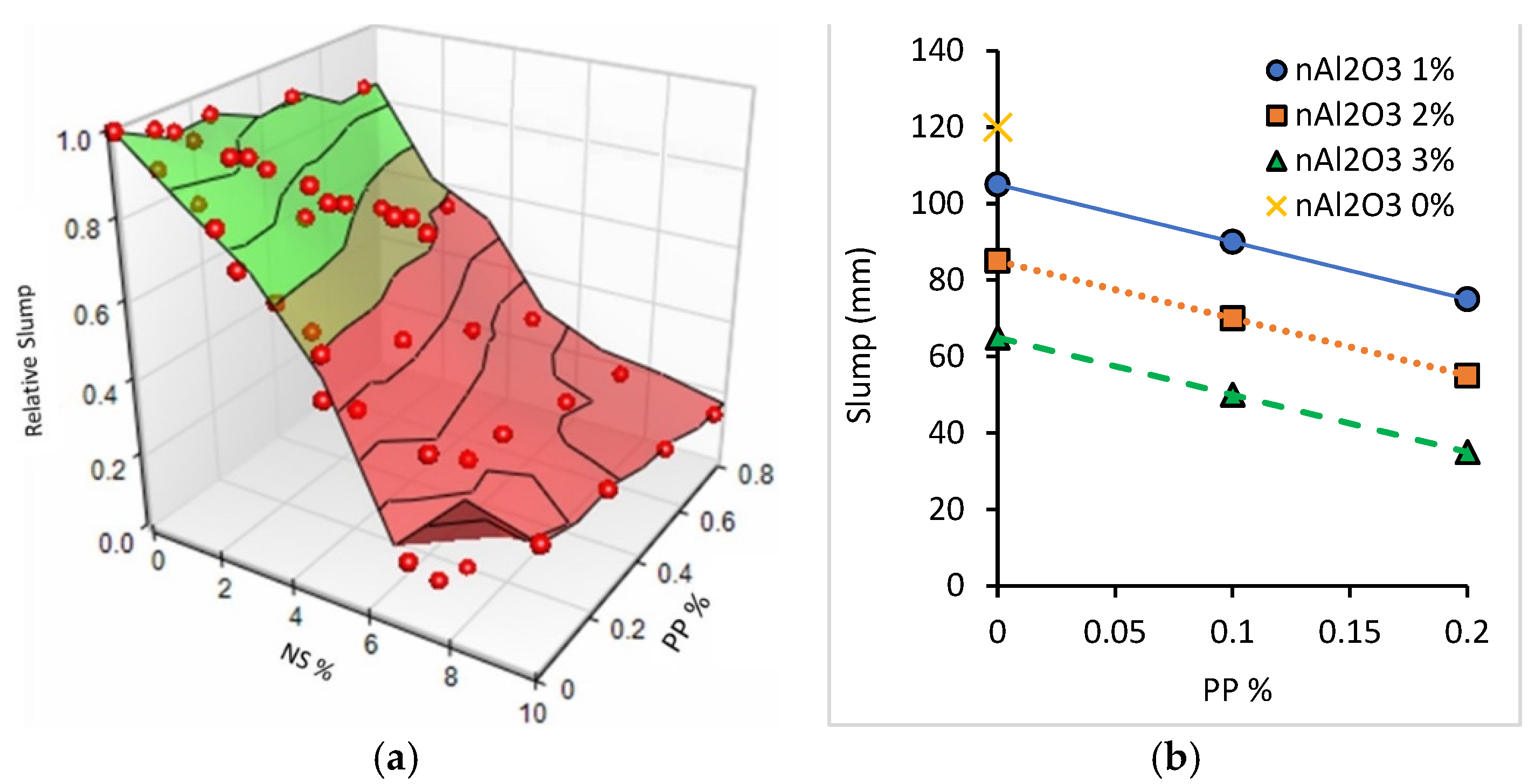

73]. As illustrated in

Figure 12a, introducing NS was much more effective in the slump reduction relative to the PPF fiber addition in which the reduction is gradual while the content of PPF increases. On the contrary, the fall in slump values is steeper as the NS content increases. The obvious reduction in the slump value with the introduction of NS may be attributed to the high pozzolan activity which leads to the formation of gels that have water retention capacities and a high surface area (see

Table 3) that increases the water absorption of the mix in the fresh state [

35]. Moreover, it can be noted with the addition of the same content of PPF, incorporating nAl

2O

3 causes more of a reduction in the slump value compared to a NS addition with the same dosage (see

Figure 12b). Same as the other fibers, workability reduction is directly proportional to the addition of PPF as well as the mixing procedure that may let microbubbles enter the zone between fibers and cement paste which slightly increases the water absorption in the hardened state of the mix [

35]. It can be concluded that reduction in workability is not too much while up to 0.25% PPF was used with 2% and 1% of NS and nAl

2O

3. Moreover, using PPF with Ns and nAl

2O

3 improves the stability better than SF and GF [

73].

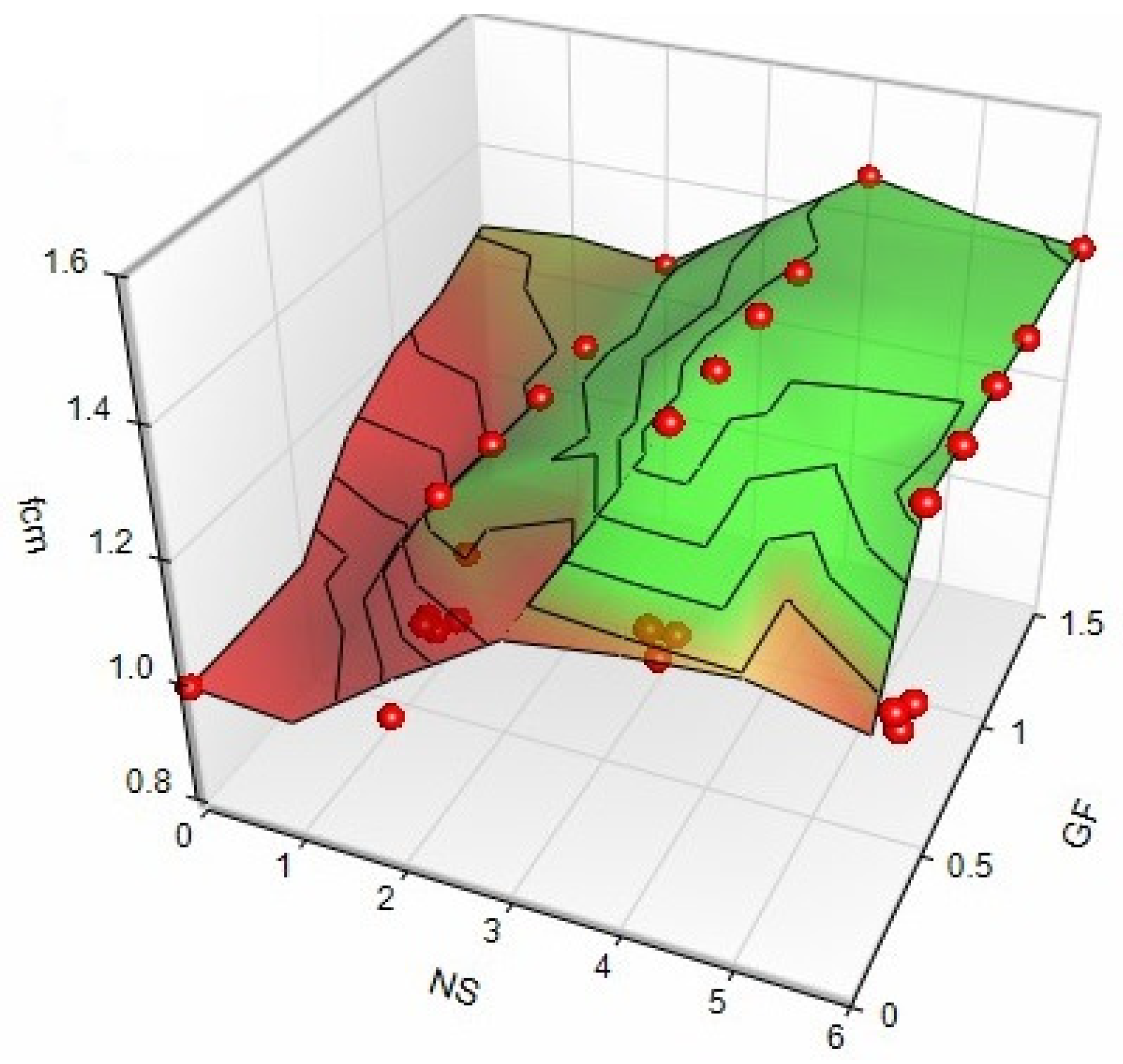

As illustrated in

Figure 13, the addition of PPF alone will not make any positive effect on compressive strength. Meanwhile, with an increment of the NS dosage, the influence appears in a positive manner. In fact, 5% of NS can be considered as optimum content if it has been used with 0.6–0.8% of PPF. Observably, the pozzolan and filling effect of nSiO

2 can be noted in reinforcing the fiber zone and cement matrix, in which the PPF does not have a significant effect on compressive strength. In addition, NS led to a reduction in the wall effect between PPF and its surrounding matrix. Consequently, a harder bond formed between PPF and the matrix that improved compressive strength [

46].

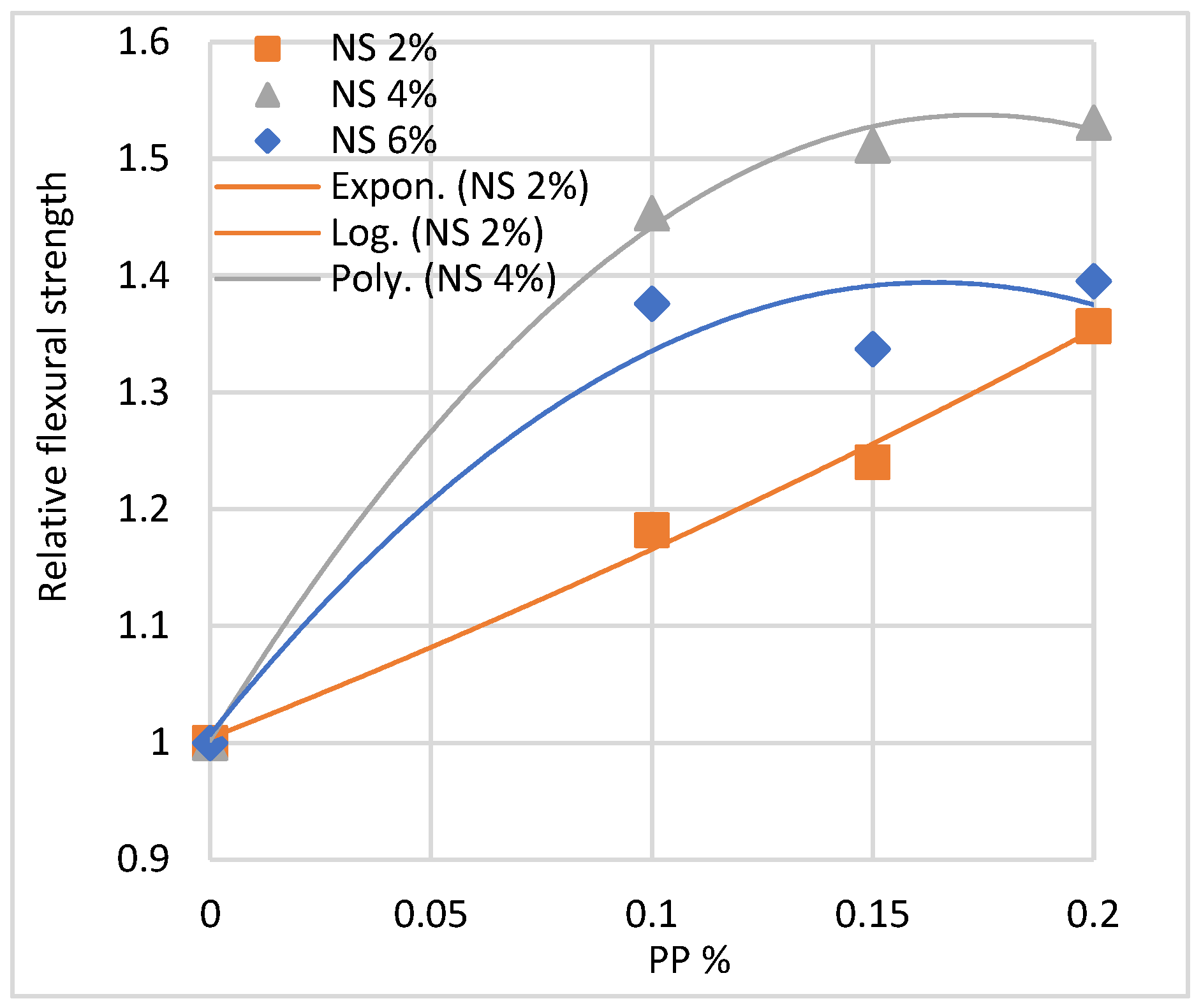

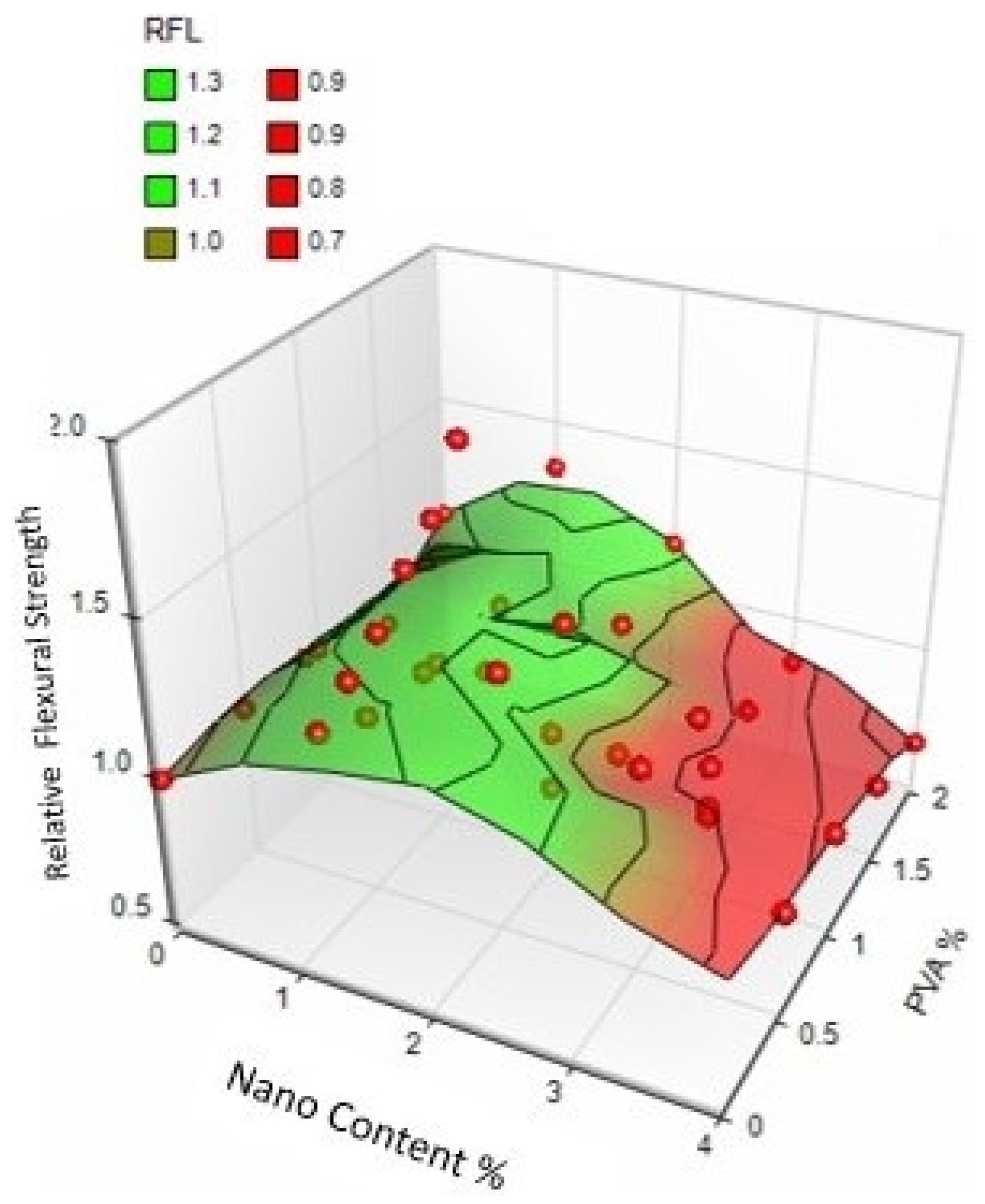

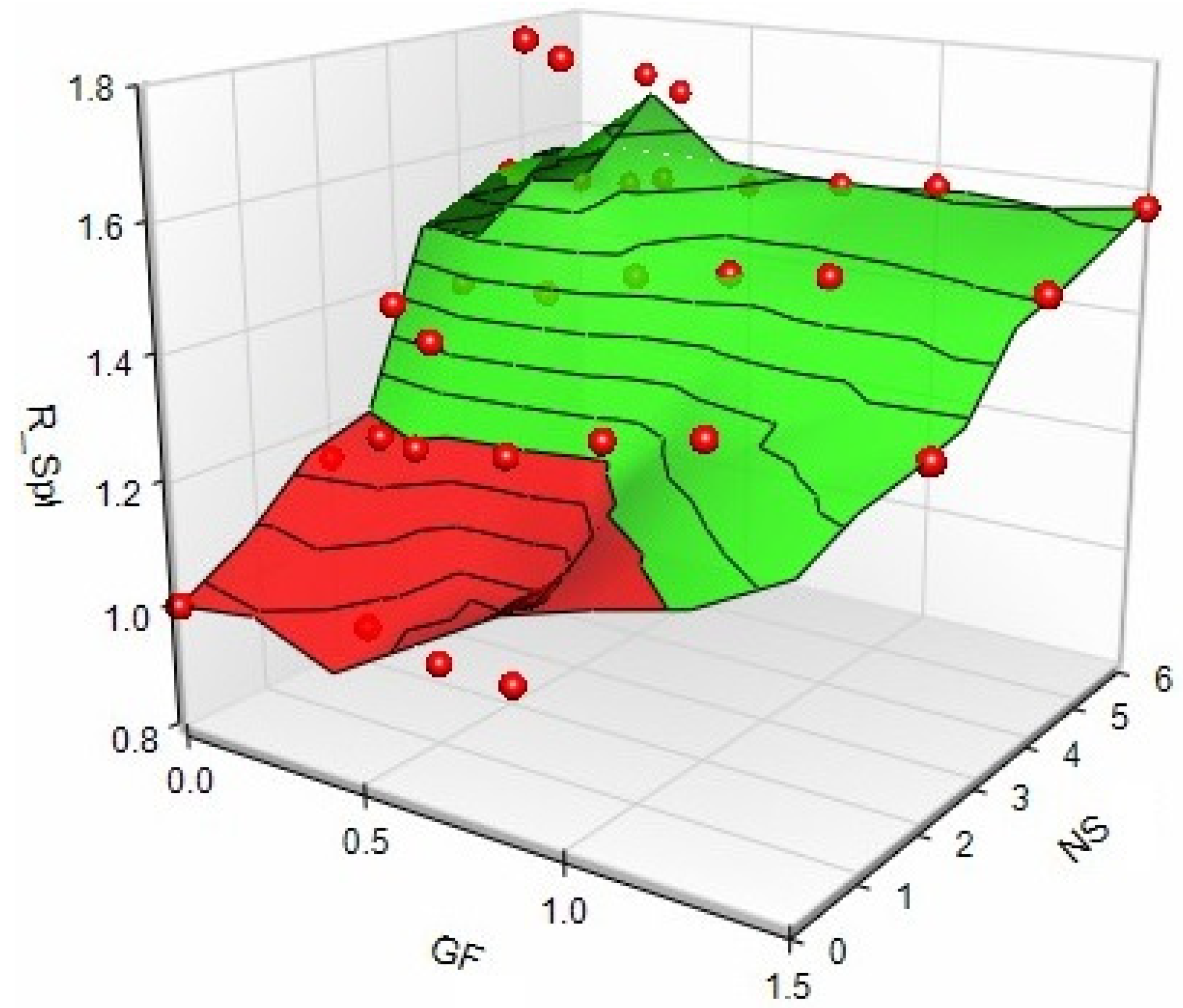

The impact of utilizing NS [

46,

52,

73] and nTiO

2 [

40] on the flexural strength of PPF reinforced cementitious mixes was studied. A study [

73] reports that using NS up to 4% with PPF up to 0.15% enhances the flexural strength of normal strength self-compacting concrete (SCC) in which the scored relative flexural strength reached up to 1.53 (

Figure 14). Moreover, a study [

46] used 1% of NS with up to 1% PPF; the relative flexural strength of the SCC was enhanced up to 2.37. It can be concluded that with a low dosage of NS, up to 1%, increasing the content PPF can improve the flexural strength, but for a higher dosage of NS content (>1%), the increase in PPF will not be effective. Any further increase in the content of NS and nTiO

2 caused an adverse impact on the flexural strength which can be ascribed to the formation of micro-cracks which influence the flexural strength [

40,

46,

52,

73]. Moreover, using other higher elastic modulus fibers with PPF simultaneously will not be effective in enhancing the flexural strength as stated by a study [

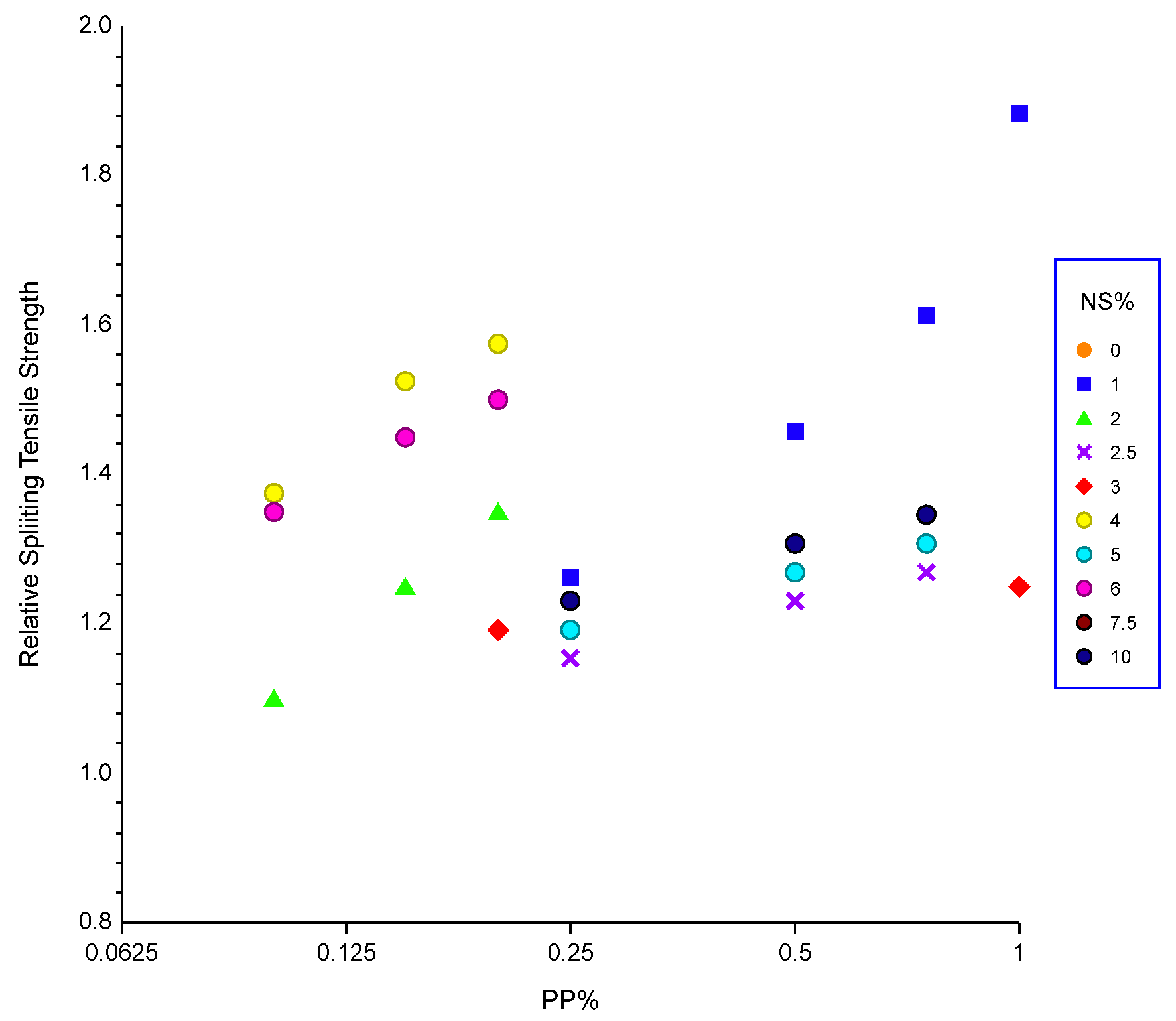

52]. According to the findings of studies [

42,

45,

46,

73], the addition of NS improves the tensile strength of the cementitious mixes. As illustrated in

Figure 15, while PPF was used, the low dosage of nano particles is more effective in tensile strength improvement. While a low dosage of NS as 1% used showed that the tensile strength improves dramatically with an increasing dosage of PPF. Nevertheless, with a high content of nano as 3, 5, 6 or 7%, varying the content of PPF slightly improves the tensile strength. According to a study [

46], this can be attributed to an increase in nanoparticles provides a harder bond between PPF and the matrix, but because of the smooth surface of PPF, a hard bond between PPF and its surrounding matrix does not change its failure mode to rupture; i.e., PPF still de-bonded from the surrounding matrix. Moreover, the ductility and crack-arresting effect of PPF serves in tensile strength improvement [

45].

On one hand, the addition of nano-particles to the cementitious mixes improves density and reduces the porosity and water absorption [

45,

73,

76]. Moreover, the type and fineness of the particles play a significant role in their performance. On the other hand, the PPF addition increases the interface in concrete and results in the increase in the void content in concrete [

40,

77] that leads to a reduction in density and increasing porosity. Thus, if a proper incorporation ratio of the PPF is not used, it may adversely affect the durability. A study [

40] stated that in concrete containing both PPF and NS, the chloride penetration was reduced that can be attributed to the low density and the increased void content of this concrete. This reduction can be compensated if another fiber, with low dosage, such as MP [

42] or BF [

52], was used with NS contained PPF reinforced mixes. A study [

42] stated that the optimum percentage of each of the two types of fibers together with that of nano-silica has lower water absorption in comparison with the plain concrete, the one containing the optimum percentage of nano-silica, and the one containing only the optimum percentage of either of the two fibers. Moreover, due to the small specific gravity of PPF, shrinkage reduced significantly in the Nano and fiber reinforced mortars with hybrid fibers 0.6% BF and 0.4% PPF [

52]. Moreover, chloride ion penetration remarkably reduced in the case of using PPF with NS for SCC [

73] or PPF and BF with NS for mortar mixes [

52]. The microstructure of the nanomaterials and PPF reinforced cementitious mixes has not been studied sufficiently. The presence of active nano-silica produces calcium silicate hydrate that improves the microstructure of fiber-reinforced concrete against chloride ion penetration and reduces the associated corrosion in concrete [

73]. At the same time, the smooth surface of PPF prevents formation of a hard bond between PPF and their surrounding matrix. Utilizing nano-silica resulted in the improvement in bond properties at the interface between the fiber and the matrix according to a study [

46]. Moreover, as shown in

Figure 16, studies [

42,

45] show that a density increase is associated with an increasing content of NS but a decrease with an increasing content of PPF.

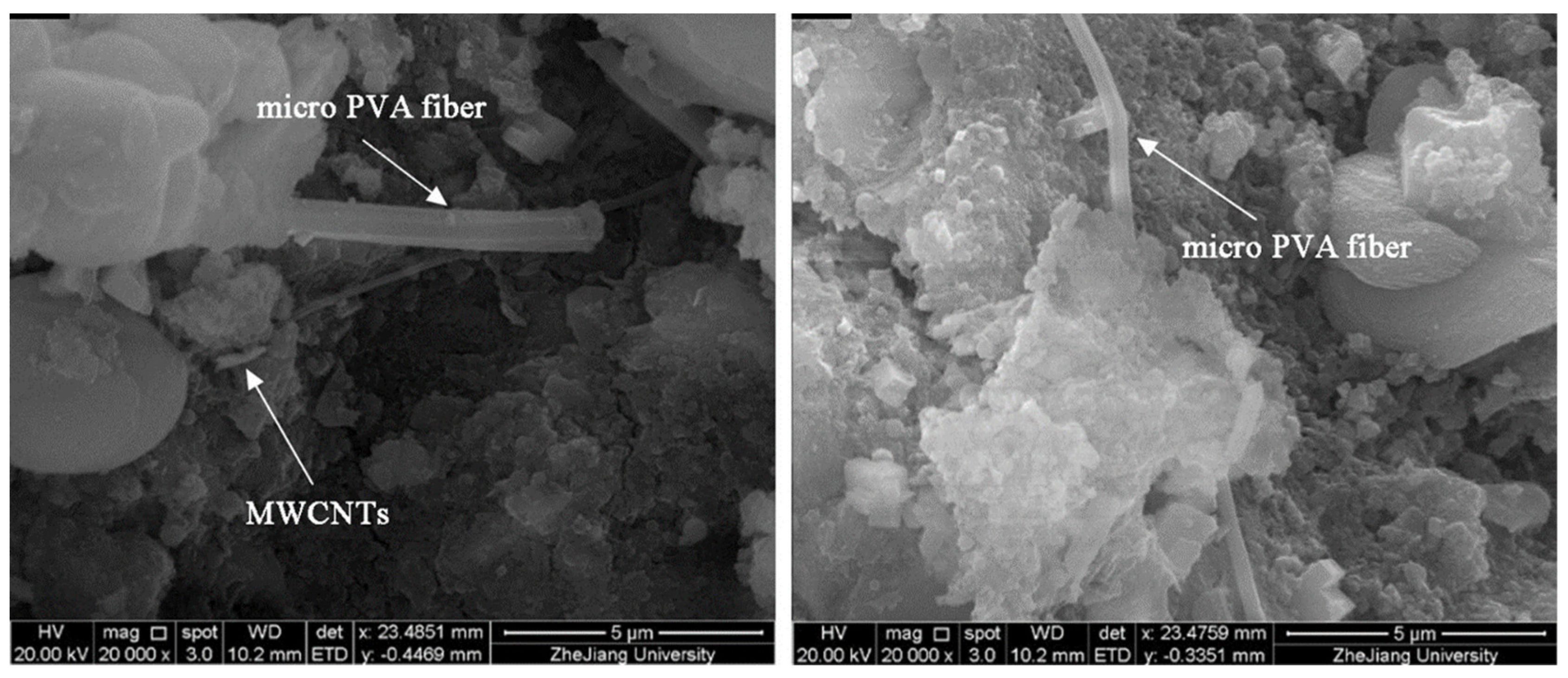

Considering the microstructural analysis of the compositions, which is shown in

Figure 17, the PPF was dominantly de-bonded from its surrounding matrix, and some PPF was even ruptured. It can be inferred that the improvement in the interface between PPF and the matrix did not change the failure mode of PPF [

46].

3.4. PVA Fiber and Nanomaterials

Six conducted studies that used PVA fibers and nanomaterials together are considered in this study. Nanomaterials and PVA fibers greatly affect the workability of cementitious composites. The free water of the mix is absorbed by PVA fiber due to its good hydrophilic properties [

32,

33]. Moreover, using finer sand size adversely affects workability and mechanical performance due to its higher tendency for absorbing water which results in insufficient water for hydration [

33]. The effect of NS on workability reduction is more than nCaCO

3 [

78], and is less than NC [

41] for the cementitious composites. Nevertheless, for 3D printing PVA mortar, the addition of multi-walled carbon nanotubes (MWCNT)s has no detectable effect on the buildability, such as stacking stability, shape ability, and integrity [

48]. As shown in

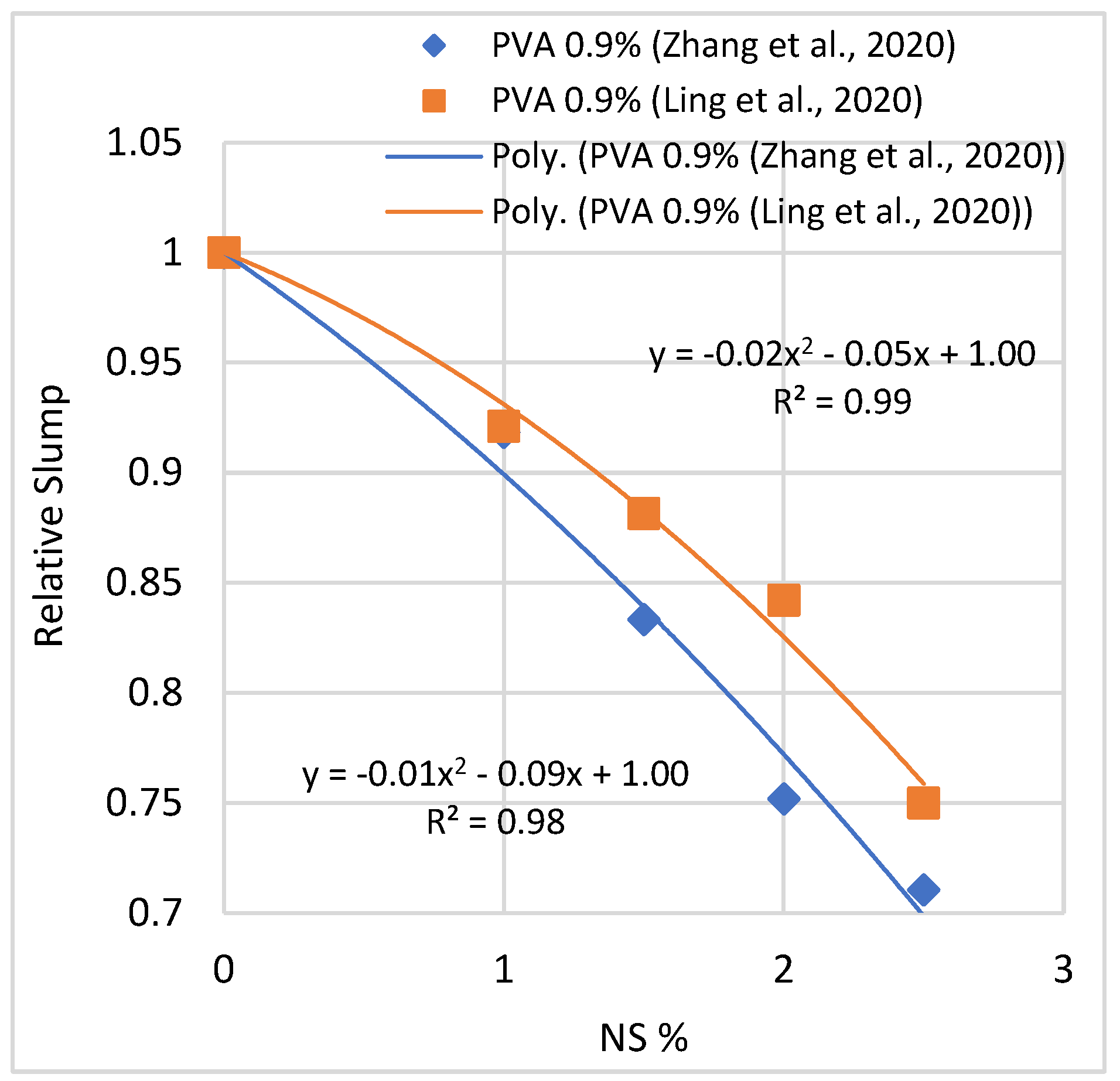

Figure 18, according to studies [

41,

78], increasing the dosage of NS adversely affects the workability with the presence of PVA in the mortar mixes.

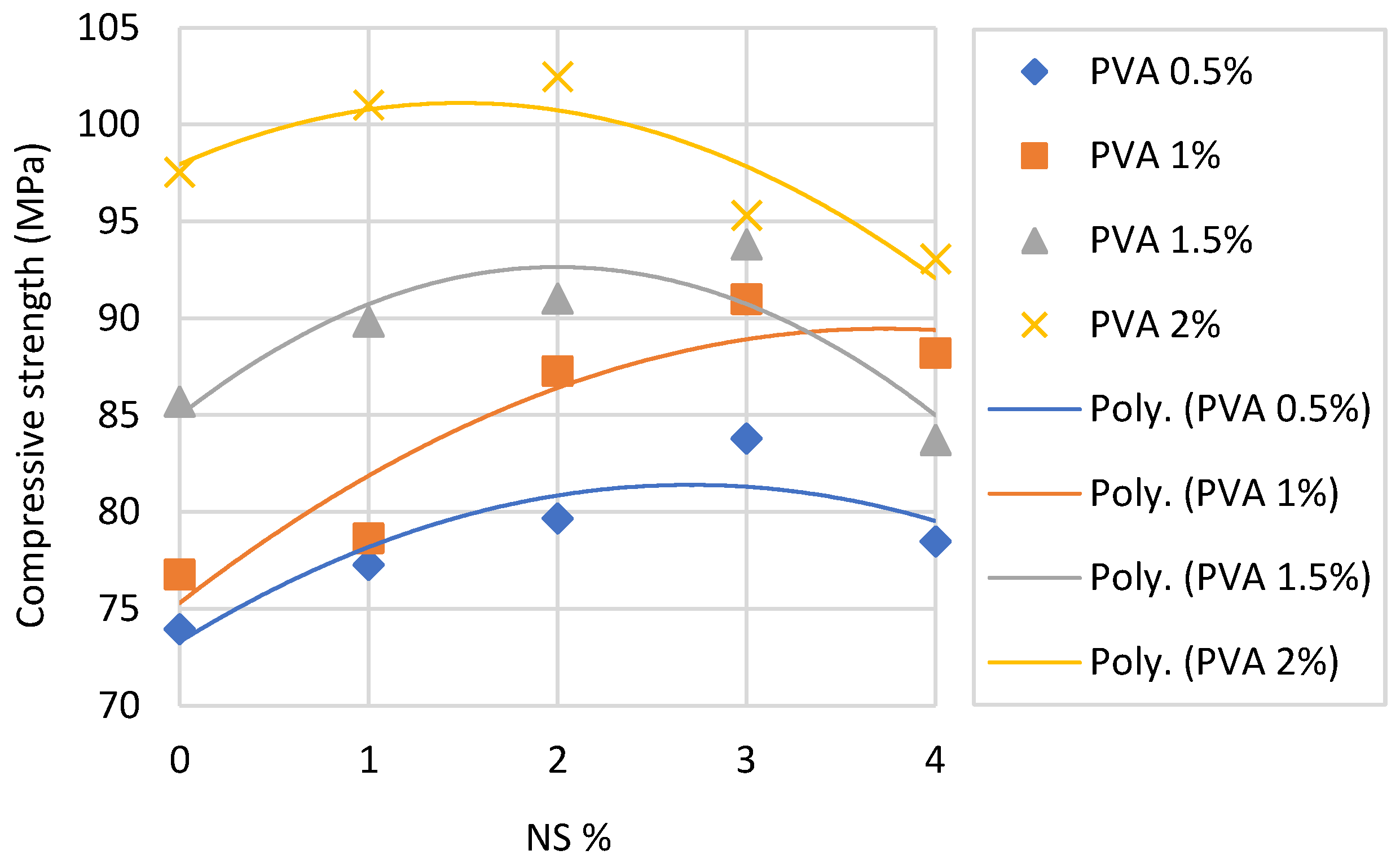

As illustrated in

Figure 19, the addition of PVA without nanoparticles positively affects compressive strength of engineered cementitious composites (ECC) [

47]. The highest compressive strength was obtained with the use of 2% of PVA and 2% of NS in the same mix. The incorporation beyond 2% of NS and 1.5% of PVA in the reinforced ECC and mortar may not improve compressive strength anymore [

41,

47]. This can be attributed to the agglomeration of the high dosage of nanoparticles in the mix which led to weakening the bond between the aggregates or fibers with the matrix.

The flexural strength of PVA reinforced NS and nCaCO

3 contained cementesious composites was investigated by studies [

33,

41,

47]. As shown in

Figure 20, the optimum flexural strength can be obtained by the use of 1–2% of NS with 1–1.5% of PVA. Moreover, it can be noted that the enhancement effect of the PVA becomes weaker on flexural strength when the dosage of NS exceeds 2%. This may be attributed to formation bundant ettringite which could lose strength caused by the internal stress [

79]. Similar to compressive strength, the mixture of NC had lower flexural strength than that of NS [

41]. Furthermore, in the mix of ECC, the presence of NS increases the density of the ITZ between PVA and the matrix that leads to a reduction in stress at the crack tips to less than the bridging stress across the crack. Consequently, more energy is required to de-bond the fiber, which subsequently leads to an increase in the flexural capacity of the ECC [

47]. In addition, a study [

48] states that using MWCNT in the 3D printing PVA can achieve the mechanical properties and 3D printing requirements if in the range of 0.01–0.05% was used. Inappropriately, tensile performance of PVA reinforced cementitious mixes containing nanomaterials was not studied by any of the conducted studies.

In studies [

47,

78], the durability performance of PVA reinforced nano contained cementitious mixes was considered. It can be concluded that the addition of NS and nCaCO

3 to the PVA reinforced mix resulted in difficult CO

2 diffusion which enhances carbonation resistance. More reduction in carbonation depth was scored while PVA fiber and nanomaterials were used relative to using nano or the fiber solely in the mix. For instance, without using PVA fiber with the addition of 2% of NS and nCaCO

3, the reduction was determined as 20% and 11.7%, while with the fiber, the reduction increases to 23.4% and 12.8%, respectively. In addition, using any amounts of NS or nCaCO

3 less than 2% with PVA fiber remarkably improves durability of the cementitious composites in terms of permeability resistance, cracking resistance as well as freezing-thawing resistance. However, the improvement of nSiO

2 on durability is much better than that of nCaCO

3. A study [

47] states that the combined effect of PVA fiber and NS quantity on resisting shrinkage is greater compared to the effect of PVA fiber alone. This could be interpreted as a result of an improved matrix–fiber interaction, which improves the area of contact by densifying the ITZ in these regions [

41,

47].

The addition of NS rather than decreasing porosity and densifying the mix (see

Figure 21) also increased the bonding strength between the fiber and composite matrix [

41,

47,

78]. Consequently, most PVA fibers were fractured instead of pull-out occurring during tension by adding NS [

41]. According to a study [

78], as illustrated in

Figure 21, the generated C-H-S gel in the NS contained mix is higher relative to the nCaCO

3 contained PVA reinforced mix. The C-S-H gel has an obvious influence on bond performance and ITZ enhancement in the mix. Therefore, as aforementioned, NS is more fulfilled with PVA reinforced cementitious composites relative to nCaCO

3 in terms of serving the durability.

In the printing mortar, some microscopic fibers are released from the PVA fiber during the mixing process as shown in

Figure 22 [

48]. Therefore, the dispersed fiber with the carbon nanotube in the mix enhances the hardened property resulting in a higher bridging effect on the micro-cracks.

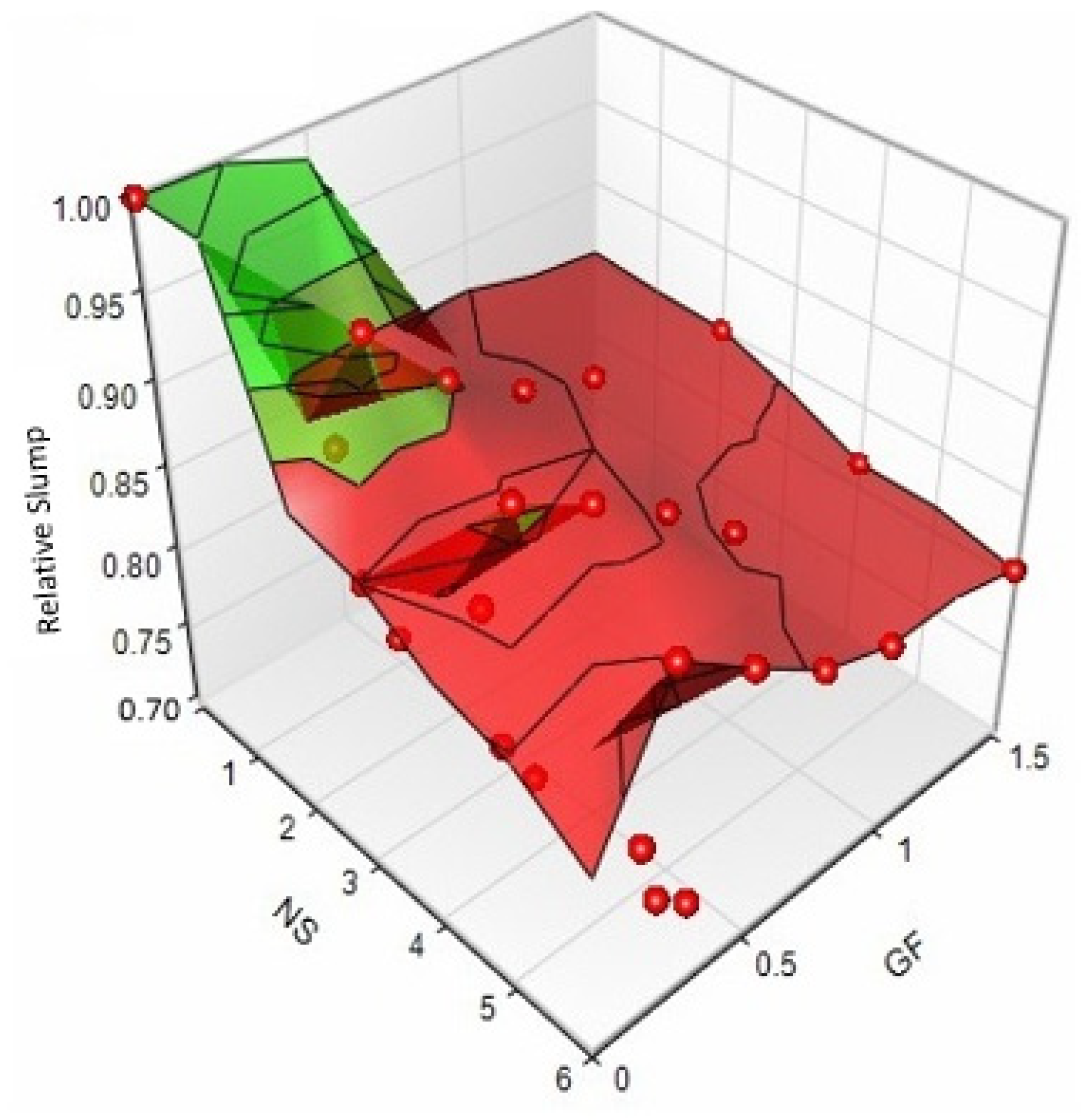

3.5. Glass Fiber and Nanomaterials

The simultaneous impact of using nanomaterials and GF on mechanical property and durability performance of cementitious composites was not studied by studies [

31,

39,

43,

64,

73,

80]. Evidently, the addition of nanomaterials and/or fibers adversely affects the workability and would lead to an excessively high SP dosage. Relative slump reduction is illustrated in

Figure 23; increasing the dosage of each of NS and GF adversely influences the workability [

31,

39,

73]. Moreover, for printing 3D mortar, the addition of NC and GF significantly enhanced the shape retention ability. However, using NC with GF and carbon fiber showed better shape retention relative to using SF. At the same time, it should be noted that high workability is not desired for extrusion and 3D printing because a high workability could lead to an excessive drop in height and the belly cross-section after the subsequent layer is deposited [

43]. The adverse effect of simultaneous usage of nanoparticles and GF on workability can be ascribed to increasing the locking probability and water absorption. On the other side, its property leads to improvement in the internal strength and enhances the compressive strength according to studies [

31,

39,

64] as shown in

Figure 24. Moreover, improving the friction and internal collisions between aggregates and fibers can be the reason for the strength increment [

81].

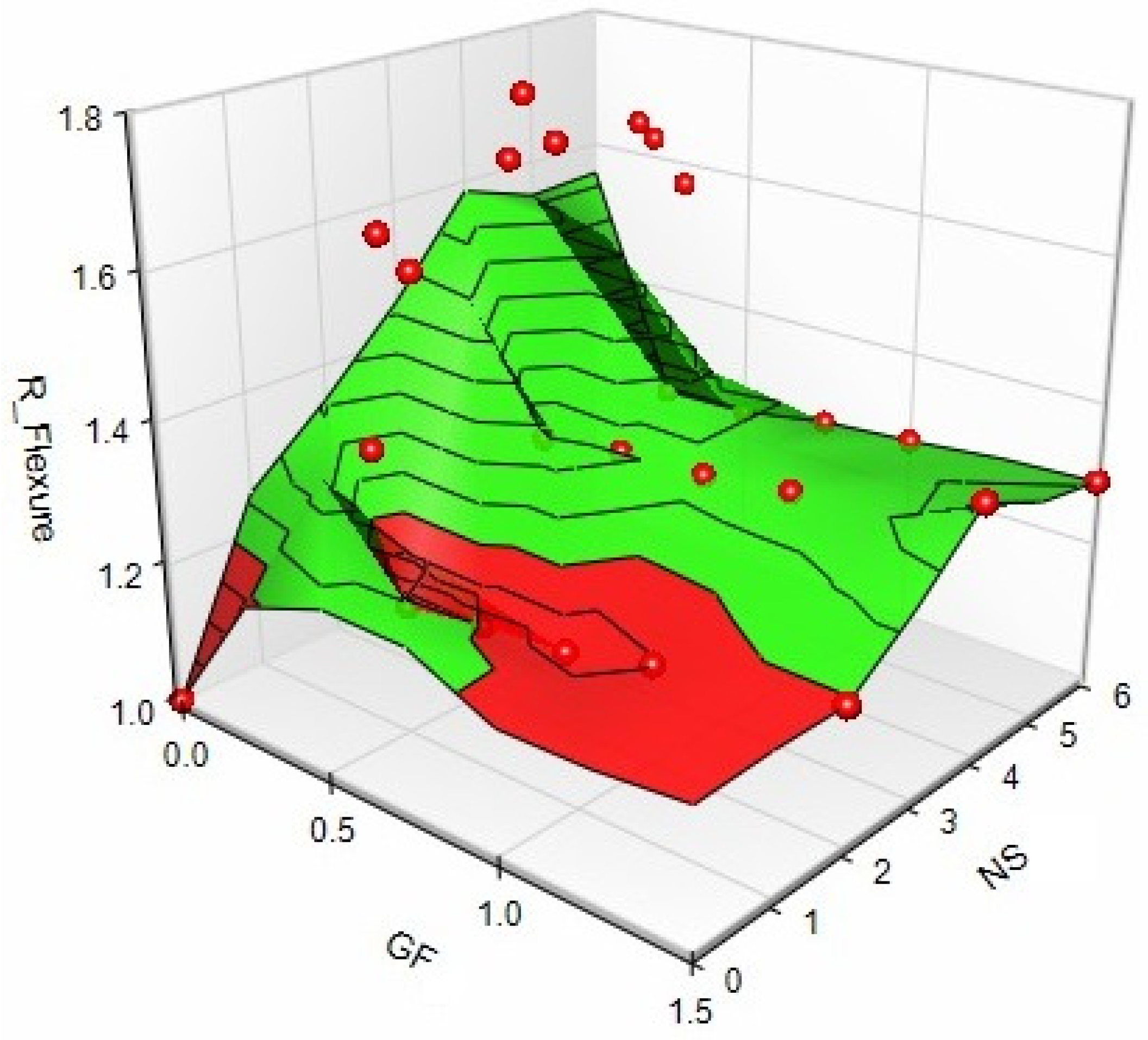

Figure 24 illustrates that optimum compressive strength can be obtained with usage 0.75–1.5% of GF with NS greater than 3%. However, the addition NS beyond 3% may not adversely affect the GF reinforced cementitious mixes as has been noted with other fibers, but as shown in

Figure 23, the workability reduction is large. The relative flexural strength is shown in

Figure 25. The combined use of GF and NS in all mixed designs of normal and lightweight SCC concrete increased the 28-day flexural strength remarkably [

31,

73]. This significant enhancement can be ascribed as that of the NS particles, with their pozzolanic and filler effect, improving the properties of the cement paste contact area with fibers and aggregates and increasing the adhesion of the contact areas [

80]. Meanwhile, the tensile strength improvement of nano contained GF reinforced concrete can be noted evidently as shown in

Figure 26. From the results, it can be noticed that, with an increasing GF dosage, the tensile strength slightly increases [

31,

73] or decreases [

39], while, with addition of NS to the GF reinforced mixture, the splitting tensile strength improves greatly. This increment may belong to the stress transformation from the matrix to the fibers [

31], or the presence of a larger contact area between fibers and the matrix which results in higher friction [

73]. The positive effect of NS on increasing tensile strength was also mentioned in previous studies [

82]. Thus, as illustrated in

Figure 26, the optimum tensile strength can be obtained by using GF more than 0.25% up to 1% with NS between 2 to 3%. Furthermore, in the light weight concrete, the influence of the NS addition to the GF reinforced concrete is higher in comparison to normal weight concrete. This can be attributed to improved hardness of the lightweight aggregate through reducing the cavities and improving the contact surface between the matrix and the aggregate, in which the cracking is usually started and passed through the lightweight aggregates [

31].

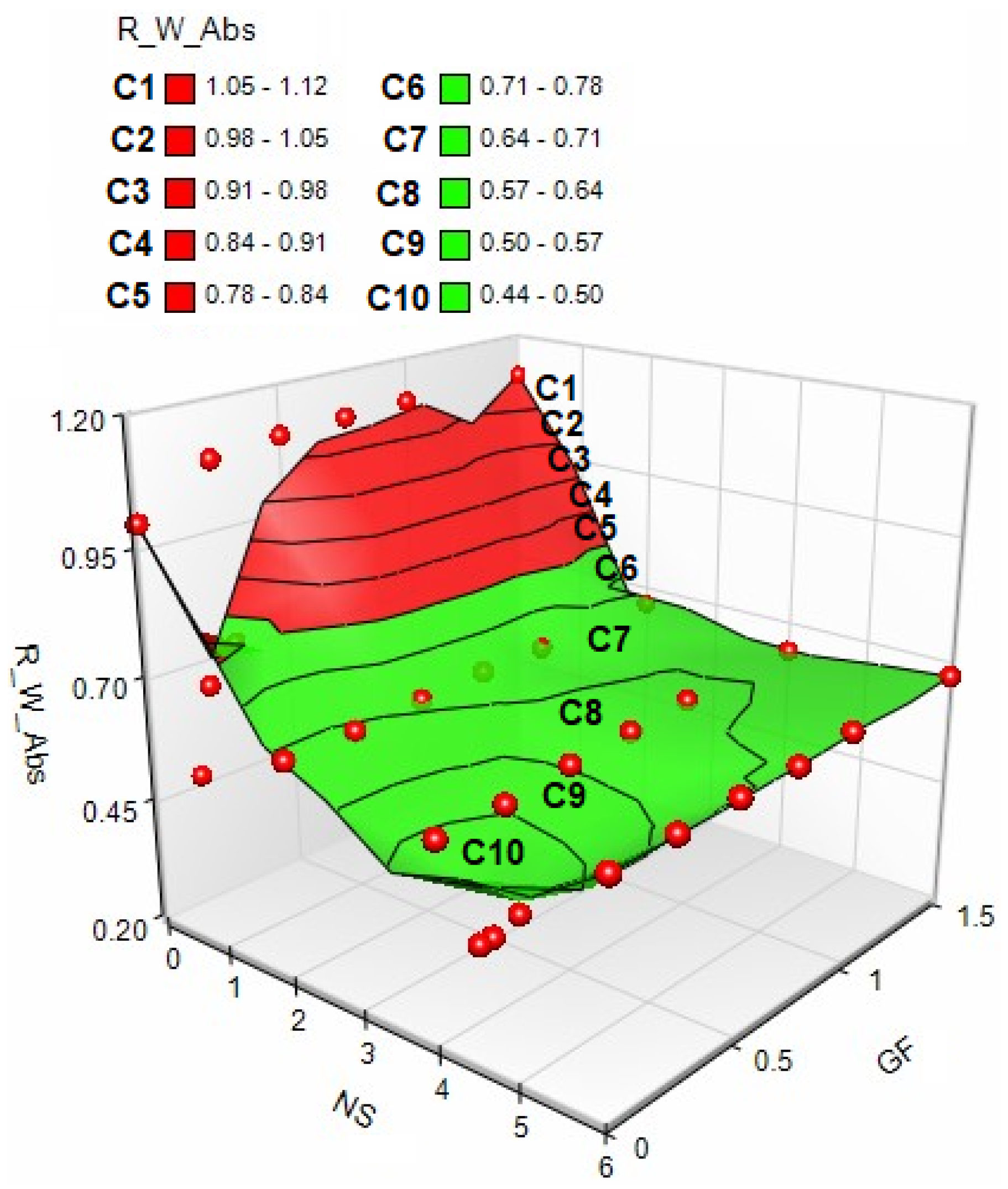

Most corrosive substances, which are adversely affecting the long-term performance, are penetrating the concrete through water [

31]. As aforementioned, the use of NS in all mixed designs reduced the water absorption percentage of cementitious composites due to the NS tendency for filling the fine holes in the silicate gel structure of the mix. According to the obtained outcomes of studies [

31,

73], the addition of GF without NS adversely affects the water absorption of the concrete specimens, whereas, with introducing NS to the mix, the water absorption greatly decreases as shown in

Figure 27. Besides, it can be noted that the varying influence of NS on water absorption reduction is not significant with increasing the dosage more than 2%, even while the content reaching to 6% water absorption increment commenced. Therefore, the optimum percentage of NS as 2% can be considered with GF reinforced concrete mixes.

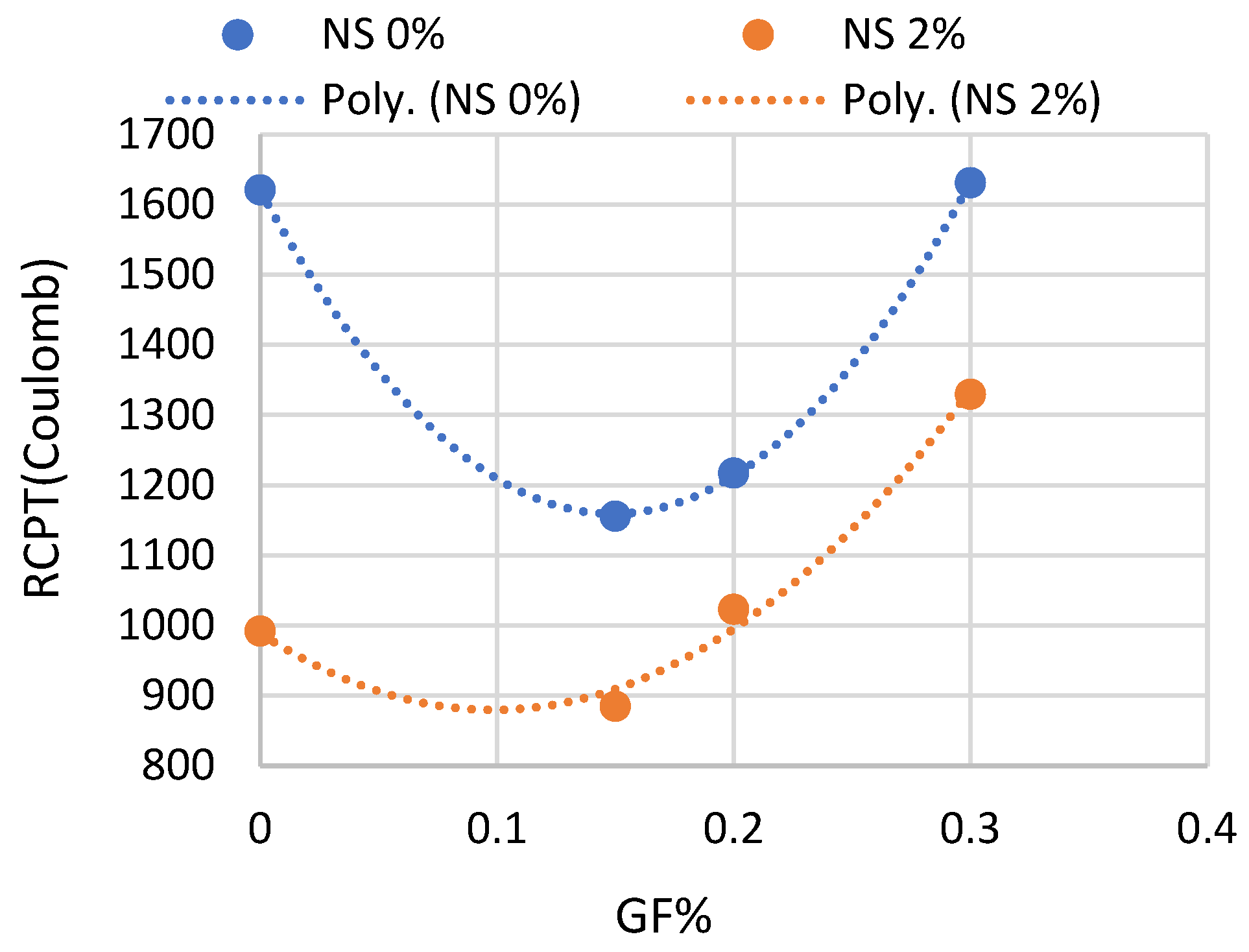

In addition, the associated corrosion in the cementitious composites is directly proportional to the reduction in chloride ion penetration. A study [

73] states that chloride ion penetration of GF reinforced normal strength SCC concrete can be reduced up to 20% by utilizing NS up to 4% (see

Figure 28). This can be attributed to the improvement in the microstructure of the concrete as shown in

Figure 29 which results from calcium silicate hydrate production [

31].

The electrical resistivity is an auxiliary tool to investigate the corrosion probability of buried rears in concrete. A study [

31] states that the presence of GF has a little contrary effect on the electrical resistivity of the test specimens while using NS up to 6% with GF and improves the electrical resistivity progressively (

Figure 30). This can be attributed to the pozzolanic behavior of NS that by increment of the hydration process fills the spaces in the mix of the concrete.

3.6. Other Fibers and Nanomaterials

Despite the aforementioned fibers, other types of fibers are used by the conducted research of this review as shown in

Table 1. Regarding the influence on the workability, the addition of nanoparticles due to high surface area and addition of fibers due to absorbing more cement paste to wrap around leads to an increase in the viscosity and a decrease in the slump of a concrete mixture [

83]. Therefore, with increasing the dosage of the fibers and nanoparticles simultaneously, the workability reduces significantly. This statement is verified by increasing the content of coir fiber and NS [

37], carbon fiber CF and graphene nanoplatelet filler GNP [

34], CF and recycled nano carbon black (RNCB) [

71], CF and nano calcium carbonate [

43], linen fiber and nano metakaolin [

84], macropolymeric fibers MPF and NS [

42], coconut fibers and NS [

85], forta-ferro fiber and NS [

30], carbon nano fiber CNF and carbon nano tube CNT [

86]. The workability of concrete is reduced with addition of CF up to 50% [

71]. Due to the adverse effect of using recycled carbon fiber or RNCB on the workability, for compensating the required workability, the amount of the utilized SP must be doubled or more [

34,

71]. However, according to a study [

87], for the workability and consistency of the concrete containing fibers, the slump test is not a suitable indicator as the mixture may exhibit low slumps while having sufficient workability and consistency. Therefore, a study [

43] recommends demand of SP as a better parameter that reflects the fibers and nanomaterials on workability.

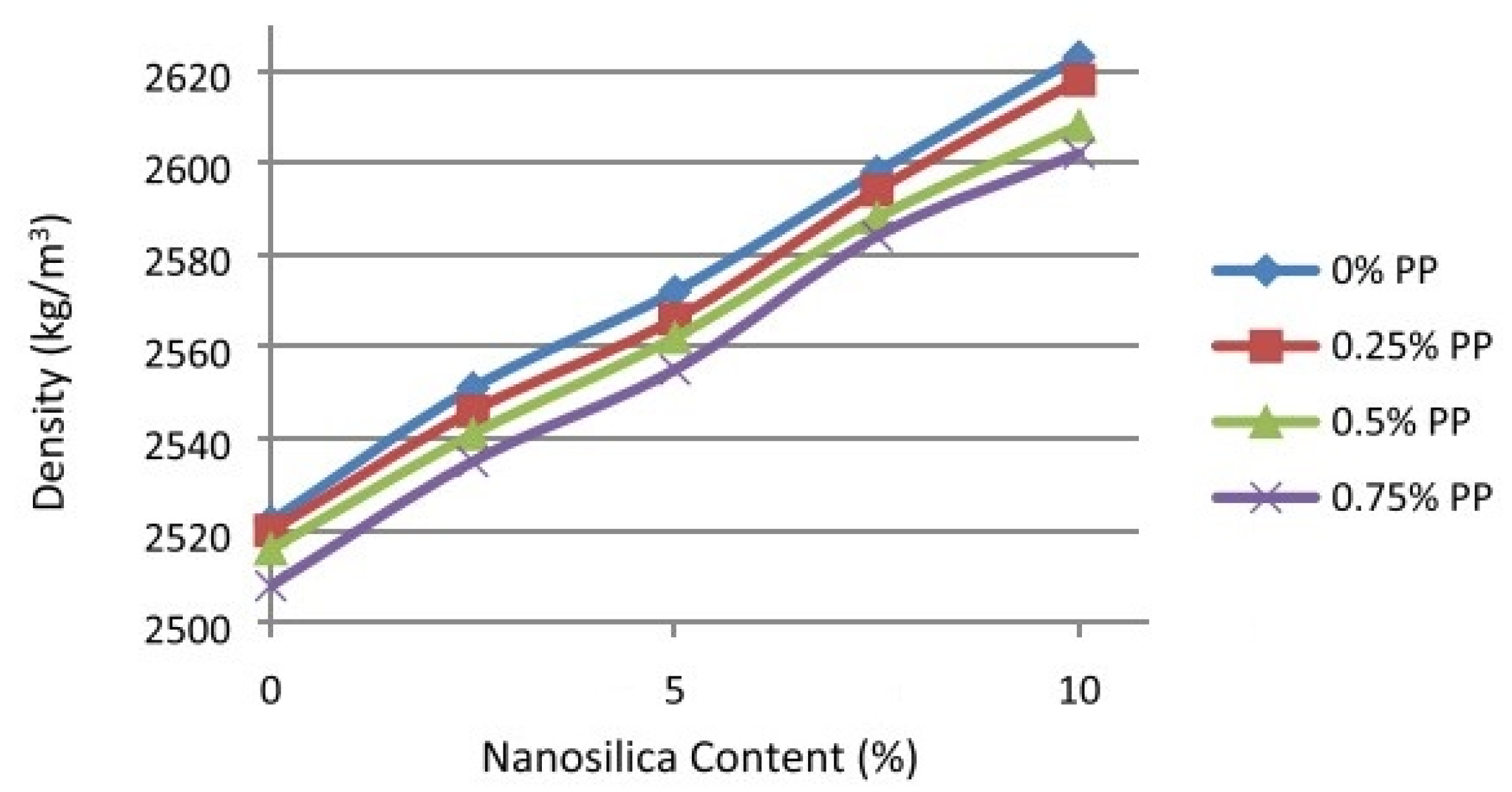

Regarding the effect of the combined usage of fibers and nanoparticles on the density of the produced mixes, the following conclusions can be drawn. The specific gravity of the used fiber and nanomaterials plays an important role in the reduction or increment of the density in the produced mix. A study [

30] states that the addition of steel and forta-ferro fibers improves density. While according to studies [

37,

88], Coir, polypropylene and macro-polymeric (MP) hemp fabric (HF) fibers are reducing the density. Moreover, using NS with the fibers cannot compensate the reduction in density with Coir, PP and MP fibers, due to the lightweight nature of the nanoparticles relative to the replaced cement particles [

37,

42], while NS with steel and forta-ferro fibers reduces the density increment [

30], and nano clay up to 1% increases density with HF fiber [

88,

89].

Regarding the compressive strength, a study [

34] states that using each carbon fiber or GNP solely does not affect the compressive strength of mortar remarkably. On the contrary, when both GNP and fibers are used, the worsening of mechanical strength increases and becomes 12% lower for virgin carbon fiber VCF and 19% lower for recycled carbon fiber RCF additions. The addition of nCaCO

3 to CF reinforced extrudable high strength concrete was studied by a study [

43]. It is being concluded that with up to 4% nCaCO

3 with a constant 0.5% of CF, the compressive improves by 12%, while using CF without nCaCO

3 slightly increased the compressive strength. In terms of compressive strength improvement, according to a study [

71], using carbon fiber is better with recycled nano carbon black RNCB rather than SF. Moreover, a hybrid of 0.6% SF and 0.5% CF with RNCB scored the best performance of compressive and flexural strength as illustrated in

Figure 31a,b. Moreover, the use of WWE fiber with RNCB slightly improves the compressive and flexural strength, but hybrid usage of WWE and CF with RNCB improves the flexural strength, and the compressive strength reduces to lower than the control specimen. Thus, as shown in

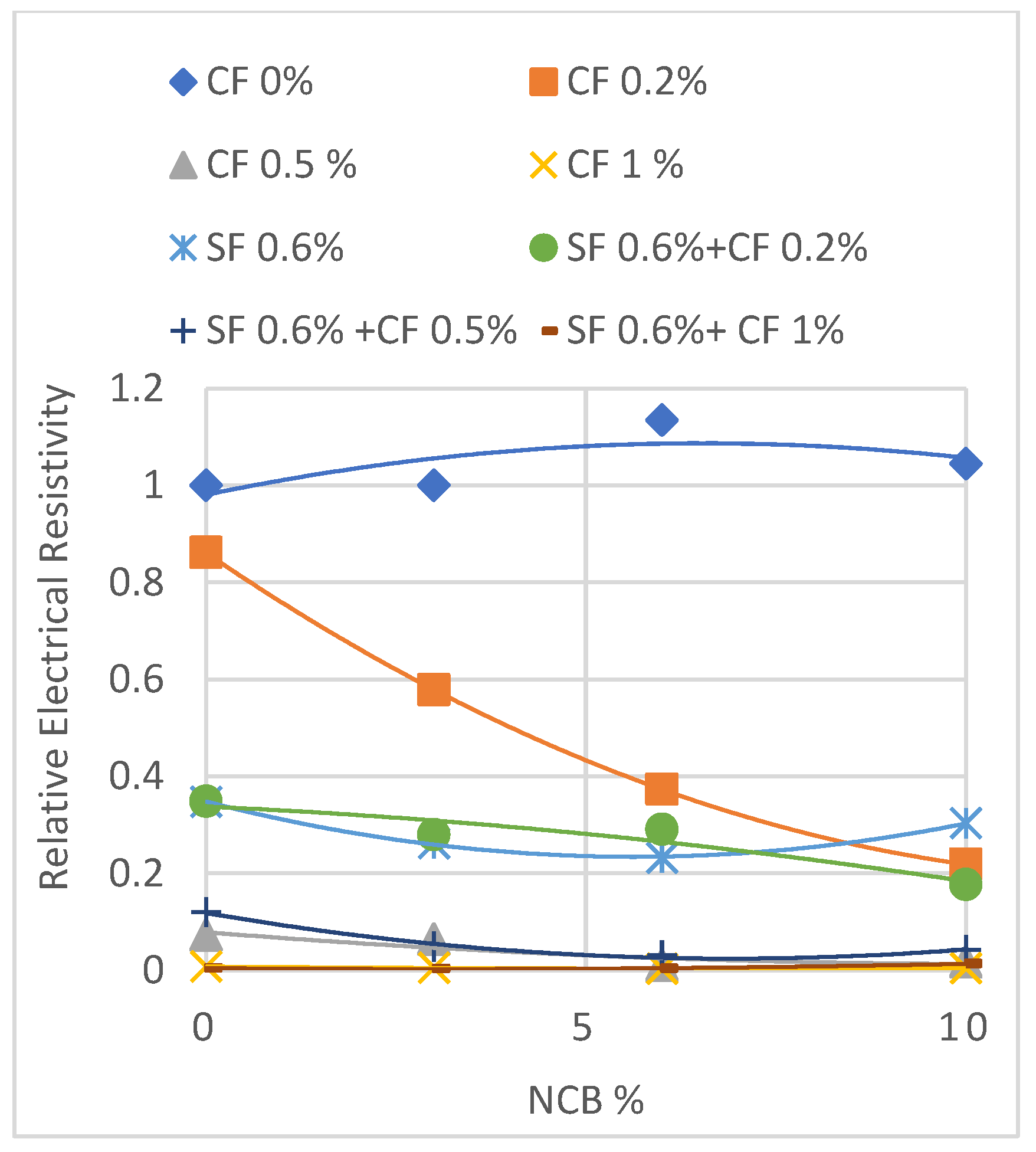

Figure 31, the optimum flexural and compressive strength can be obtained using 0.6% SF and 0.5 with 10% RNCB. Moreover, using CF of more than 0.5%, the electrical resistivity significantly decreased with and without SF (

Figure 32). The addition of GNP to mortars containing carbon or SF decreases the flexural strength and electrical resistivity [

34].

Other types of fibers such as forta-ferro [

30], nano cellulose [

90], coir [

37], coconut [

85] and flax [

91] fibers are used with NS in the composite mixes (

Table 4). Increasing the content of NS with the constant content of 0.5% of forta-ferro reduces workability and increases splitting tensile strength. Up to 2% of NS, the compressive strength improved. Moreover, the porosity and water absorption increase due to fiber addition; these increments can be compensated by increasing content of NS to the mix [

30]. The performance of nano cellulose fiber with NS was experimented by a study [

90]. The results show that with increasing the amount of NS with a low content of nano cellulose fiber (0.35%) obtained the maximum compressive strength. Moreover, (0.75%) nano celluloFse with up to 1.5% of NS works effectively in terms of tensile strength enhancement. It can be ascribed to the combination of NS with the fiber that affected the hydration reaction due to the existence of single dispersed nano cellulose fibers, in which it works as extra nucleation spots for the hydrates and enhance the activity of the NS. A study [

37] shows that the use of coir fiber with NS causes an acceptable reduction in slump flow relative to the other fibers. Additionally, besides the increment of the dosage of NS up to 3.7%, the fiber usage up to 0.2% enhances compressive strength to the maximum, while the water to binder ratio to its minimum (0.42) and fly ash to its maximum (64 kg/m

3) were used. As shown in

Table 4, the increase in the dosage of coir fiber adversely affects the abrasion resistance of the concrete; however, a decrease in the water binder ratio and increase in NS content reduce the loss in weight of the concrete. This can be attributed to the outcome that the coir fibers are not able to fill the voids completely. From the observations in a study [

85], it can be concluded that as the percentage of NS in the concrete increases, with the same 1% content of coconut fiber, the loss in the workability also increases as compared to the conventional concrete sample. On the other hand, with 0.5% of NS, the compressive strength reaches to its maximum effect, and any further usage of nano will reduce that effect. Moreover, a study [

91] reports that usage of Flax fiber with NS significantly improves flexural strength of geopolymer composites and reduces the degradation of the flax fiber. With 10 layers of flax fiber, 1% of NS scored the optimum results in terms of flexural strength and density of the geoplymer composite mixes. This may be due to densifying of the mix while NS has a low specific weight relative to fly ash and enhancing the adhesion of the fiber with the sounded matrix.

Despite the aforementioned types of nanomaterials and fibers,

Table 5 depicts the simultaneous usage of other types of nanomaterials and Fibers. A study [

84] found that when perlite was added to nano metakaolin contained and linen fiber reinforced cementitious composites, the flexural strength, density and thermal conductivity reduce remarkably. Thus, the use of a natural fiber such as linen, which has a porous core, with perlites in the production of lightweight material is beneficial in terms of heat transfer and energy consumption. Another study [

71] found that usage of recycled carbon nano black with waste wire erosion as fiber remarkably improves compressive and flexural strength as well as electrical conductivity. However, the use of carbon fiber with WWE may triple the cost of the mixes. On the other hand, the compressive strength reduces, but the electrical conductivity and impact energy improve tremendously, which may serve in the smart concrete production [

71]. Calcined nano clay with hemp fibers were used together in cement composites by [

88,

89,

92]. A study [

88] concludes that increasing the dosage of NC reduces dry density, and more than 1% of NC increases the porosity of the mix. With 2.5% of HF, using 1% of NC can be considered as an optimum ratio in terms of enhancing the flexural strength and reducing the porosity due to achieving a better fiber/matrix interface. The same phenomena were supported by the experimental outcomes of a study [

89], in which by increasing the content of HF from 2.5 to 6.9%, the flexural strength scored an obvious improvement (

Table 6). When NC was introduced to HF [

92] and flax fiber [

93], the natural fibers experienced less degradation; accordingly, the durability of the natural fiber reinforced mixes improved. Furthermore, the sequence of implemented studies by [

88,

89,

92,

94] recommends the use of 6.9% of NaOH treated HF with 1% of NC, and any further usage in the NC tends to reduce its positive effect on physical, mechanical, durability and thermal properties.