1. Introduction

The COVID-19 pandemic caused a global health emergency that triggered an acute shortage of Personal Protective Equipment (PPE), putting essential healthcare workers at risk [

1,

2,

3,

4]. Starting March 2020, given the skyrocketing prices of PPE in the open market, healthcare institutions were confronted with the dire need to reshape their PPE procurement strategy. One avenue that financially constrained healthcare institutions pursued were platforms that offered access to donated PPE by individuals and organizations [

5]. We document a real-life case study of one of the most prominent donor platforms that emerged during this period: Get Us PPE. Our primary research questions include the following: What challenges does a global pandemic impose on healthcare supply chains? How can grassroots distribution channels complement traditional and mainstream operational efforts to address supply chain disruptions during an emergency? Our results highlight key lessons that could be applied for future efforts to counter operational issues during a pandemic. This is crucial for two reasons. First, the functioning of firms’ supply chains, especially in times of crises, is related to Environmental, Social, and Governance (ESG) risks and performance [

6,

7]. Next, improving network design to cut cost and reduce response time is considered critical for humanitarian logistics [

8,

9].

Global supply chains entail the complex management of a set of interconnected activities including planning, coordinating, and controlling movement of material from the suppliers to the customers [

10]. Traditionally, the objective of legacy approaches to supply chain and logistics management has been coordination and collaboration among the players to achieve system efficiency that is facilitated by fixed supply and predictable (albeit uncertain) demand. Unfortunately, singular events such as pandemics upend such legacy systems and severely disrupt conventional supply chain functioning, thereby causing a significant mismatch of materials and information. One such singular event was the COVID-19 pandemic that caused a global health emergency with significant negative impact on social and economic systems, forcing business leaders to rethink the role of business in society [

7].

A key challenge during COVID-19 was a global shortage of personal protective equipment (PPE), such as surgical masks, isolation gowns, and face shields [

10]. This paucity of PPE material increased the risk of infection to first responders and healthcare workers due to greater exposure to COVID-19 patients. In addition, PPE shortage also compromised the healthcare system by reducing workforce capacity and eroding patient confidence [

4]. Furthermore, there was an overreliance on foreign suppliers for essential medical supplies that led to the inability to ramp up production in the initial stages of the COVID-19 pandemic. To counter this deficiency, there was a multifaceted response from various quarters including private sector manufacturers as well as grassroots efforts from nontraditional suppliers [

10]. Unfortunately, procurement of this newly available, additional PPE material remained a persistent issue for healthcare facilities since they were not necessarily aware of the new suppliers or how best to procure from them [

10].

Consequently, these problems imposed severe pressures on an embattled and overwhelmed healthcare supply chain that exposed several gaps worthy of attention. First, it is important for researchers and practitioners to identify various ways of optimizing the healthcare supply chain since the cost of error might be a human’s life [

11], leading to potentially grim social consequences. Additionally, a breakdown of supply chain operations in this context might impede ESG performance [

4], leading to sustainability related issues. Again, more research is necessary on how to effect coordination and integration of organizational activities and optimize their skills and abilities for rapidly dispensing new technologies and medicines [

12]. Therefore, academicians rightfully admit that models that combine emergency relief and supply chain operations have been under-reported [

13] and therefore merit further examination.

To address these relevant gaps, we conducted an in-depth, exploratory case study to analyze the formation of Get Us PPE, a leading national grassroots organization providing essential protective gear such as PPE to healthcare providers on the frontlines of the COVID-19 pandemic. Although major healthcare facilities such as hospitals were the first to request PPE, the profile of requesters since mid-2020 predominantly consisted of small and under-resourced facilities like nursing homes, Title I schools, and clinics. In response, the organization was able to successfully deliver 17,540,571 units of PPE within a duration of a little more than a year by utilizing a fair distribution algorithm that balances logistical efficiency with health equity metrics such as proportion of Medicaid patients, community COVID vulnerability, facility type, and the type of population served. This ensured that the most vulnerable communities were served, requesters received the PPE types they requested in the right quantities, and most shipments did not travel more than 200 miles from donor locations, thus maintaining sustainability in transportation.

The results therefore demonstrate how Get Us PPE self-organized into a sustainable, innovative platform that served as a hub around which an ecosystem of different players such as donors, recipients, makers, financers, and other institutions and partners were systematically orchestrated in order to deliver the appropriate quantities of PPE products to the recipients most in need. In the process, we observe a robust supply chain network design that practitioners can implement in order to achieve operational efficiencies during a calamity. Get Us PPE’s approach integrates various factors such as donor and recipient preferences, distance, shipment complexity, etc. in determining the most effective and efficient way of moving PPE from donors to recipients. Consequently, there is improved matching of demand and supply of PPE material and a reduction in lead time and cost.

Our research thereby contributes to both theory and practice in several ways. First, we add to the contemporary literature that focuses on the development of automated tools for optimizing the allocation of scarce resources during COVID-19 [

10]. This paper thereby answers the call for more applied, contextual research in humanitarian operations [

14] and adds to the growing research on this topic [

6,

13]. It also demonstrates the importance of healthcare supply chain operations to ESG issues during a pandemic, which can be an accurate measure of firms’ sustainability and social impact [

7]. Finally, along the lines of recent academic work [

15], we also focus on organizational learning that can enable organizations to cope with and adapt to crises such as COVID-19.

The rest of the paper is organized as follows. In the literature review section, we briefly discuss healthcare supply chains, COVID-19 and its implications, and the supply-side and demand-side challenges COVID-19 imposes on a healthcare system. Then we discuss the formation of Get Us PPE and delve deep into the innovative supply chain architecture and logistics model afforded by its platform and the key performance outcomes that resulted from its execution. We thereby derive vital managerial and theoretical implications and identify limitations of our study as well as avenues for future research.

2. Literature Review

Healthcare supply chain management can be defined as the procurement and logistics of healthcare supplies and services [

16] that requires customer focus, systems approach, and strategic orientation [

17] with simultaneous consideration of clinical, operational, and financial implications. The healthcare supply chain has been typically considered unique and different from other industries due to high costs and regulations for healthcare providers, and heavy dependence on third party institutions in the distribution of products and services [

11]. Moreover, there is a complex network of stakeholders at various stages in the value chain [

11,

18], with different motivations and interests in operating healthcare supplies that makes integration essential for higher efficiencies and effectiveness.

However, implementing healthcare supply chain systems is complicated and arduous because of various factors such as information asymmetries, interactional complexity among stakeholders, ambiguous and disparate valuations of healthcare, lack of accurate costing information, perverse incentives resulting from payment structures, and siloed care delivery services [

16]. Furthermore, the proliferation of different technologies and online healthcare platforms that generate copious amounts of data induces challenges for stakeholders regarding how best to utilize methodologies, tools, and data [

16]. Finally, the lack of cohesiveness of healthcare systems has also been highlighted by extant research [

19]. Unfortunately, these idiosyncratic issues of healthcare supply chains get magnified in pandemic situations such as COVID-19 that we discuss next.

COVID-19 reared its ugly head in the United States in the early first quarter of 2020 with serious repercussions to the healthcare field. In particular, it ushered severe shortages in PPE, which failed to adequately protect essential health workers. This trend was especially dangerous since healthcare professionals needed PPE to safely provide care for patients with confirmed or suspected infection. A shortage of required equipment hindered them from performing their responsibilities adequately, while also exposing them to the virus. Additionally, several supply-side and demand-side disruptions magnified the issues for the healthcare industry.

Supply-Side and Demand-Side Disruptions

The PPE supply chain suffered from serious issues including insufficient domestic manufacturing, heavy dependence on imports, an inadequate federal stockpile, and fragmented distribution logistics. Prior to the pandemic, the majority of PPE used in the US was produced abroad; much of that production halted during the first wave of the pandemic [

4]. The U.S. Strategic National Stockpile (SNS) housed only 12 million N95s. Both the global supply chain and domestic capacity faced a profound market failure. While manufacturers from automakers to sports companies pivoted operations to produce some PPE items (e.g., face shields), a few items were difficult for repurposed facilities to produce. Production of N95 respirators, isolation gowns, nitrile gloves, and disinfectant wipes—all of which require specialized materials and stringent regulatory standards—were particularly challenging to ramp up.

Demand-side factors that significantly contributed to the shortage included an increased average consumption rate or PPE burn rate, price gouging, and lack of distribution coordination at local and federal levels. Confirmed COVID-19 patients required more sets of PPE than suspected cases [

20]. The PPE burn rate was exacerbated by inadequate testing, which required hospitals to treat all symptomatic patients as positive for COVID-19 [

21].

The consequent supply–demand imbalance left the global PPE market vulnerable to price gouging. As prices for lifesaving equipment soared, health systems found their budgets strained by increasing costs, and small healthcare facilities found themselves unable to reliably source PPE. The absence of federal coordination also left urgent needs unmet. As the COVID-19 response became politically contentious, states were left to bid against each other, FEMA, and other countries for limited supplies [

6]. The governors of New York, Connecticut, New Jersey, Rhode Island, Pennsylvania, and Delaware formed a purchasing coalition to prevent price-gouging, but many states found themselves alone in navigating the volatile PPE market. This created a need for a nationally coordinated response to effectively address the PPE shortages caused by COVID-19.

These issues triggered a spurt in recent empirical research that focused on supply chain disruptions during emergencies and possible resolution mechanisms. For example, academicians have examined online platforms based on optimization models for producing supplier–requester pairs for face shields [

10]; documented problems faced and models developed during real-time response to COVID-19 [

22,

23]; discussed the design and analysis of a simulation model that was utilized in planning and implementing the world’s largest drive-through mass vaccination clinic in Louisville, Kentucky [

22]; presented a scalable forecasting framework with a Monte Carlo simulation to predict hospital bed occupancy [

24]; showcased a simulation approach to optimize plasma supply chain [

25]; and formulated a new MILP model to design a sustainable–resilience healthcare network that aimed at optimizing network total costs, environmental aspects, and social effects simultaneously [

26]. We add to this growing body of literature by taking a contextual look at the creation of a self-organizing platform ecosystem as a response to COVID-19.

Typically, catastrophes such as COVID-19 generate varied, unpredictable demand from customers and other stakeholders, as well as serious cost reduction pressures that are conducive conditions for platform formation [

27]. Recent times have seen the development of several technological applications by firms that serve as platforms to improve supply chains [

28,

29]. Examples include the Global Transaction Network Platform by GT Nexus and the eChoupal Platform etc. that were specifically deployed to enhance efficiencies in supply chain and logistics. The importance of platforms is underscored especially in the presence of a broad ecosystem, defined as “the alignment structure of a multilateral set of partners that need to interact in order for a focal value proposition to materialize” [

30]. The notion of a self-organizing innovative platform such as the Linux operating system is also relevant in this context [

31]. Against this backdrop, we discuss details about Get Us PPE and our case study methodology.

3. Methodology

3.1. Case Selection

Since platform formation has been typically driven by market and practice rather than theory, we adopted an exploratory, qualitative, case study approach in accordance with other recent studies [

32] and related theory-building principles [

33]. Such action research has been found to solve current practical problems while expanding scientific knowledge [

34]. Along these lines, we conducted an in-depth analysis of a single organization, Get Us PPE, that developed and offered a technology and data driven platform for the primary objective of achieving supply chain efficiency in the sourcing, transportation, and provision of PPE material within a healthcare ecosystem. Researchers posit that examination of a single case permits a greater in-depth understanding of the underlying phenomenon [

13,

35,

36]. Based on this investigation, we describe a robust supply chain architecture and logistics optimization model that facilitates a better match between demand and supply of PPE material.

3.2. Data Collection and Analysis

Based on our deep, collective involvement with leadership of the organization, we had firsthand access to all relevant documents and data about the development, functioning, and management of the organization. This also ensured high reliability and validity of the data for our analysis. The data collection for the case study included field notes of all co-authors and analysis of documents produced by Get Us PPE for the purposes of internal discussion and decision making [

36]. Specifically, the internal documents that were examined were minutes of all board meetings, slides of presentations at each board meeting, and other internal memos on technology and supply chain architecture. In addition, the description of the supply–demand matching algorithm and its implementation as well as corresponding code is publicly available [

37]. All collected data were summarized, collated, and analyzed to elicit several interesting findings while ensuring complete anonymity of names of individuals and institutions involved with specific actions.

3.3. Case Description: Formation, Growth, and Structure of Get Us PPE

Get Us PPE was formed in the early stages of the pandemic as a grassroots coalition of medical professionals, scientists, programmers, and citizens tackling the persistent PPE shortage. On 16 March 2020, #GetMePPE started as a hashtag on Twitter to raise awareness for hospital equipment shortages and the Defense Production Act (DPA). Over the next three days, a team of frontline emergency room physicians and health experts drafted a petition pleading for PPE for healthcare workers. On 20 March 2020,

GetUsPPE.org (accessed on 8 January 2022) was launched as a distribution channel to match PPE supplies to requests. Its initial model was direct: register the need for PPE nationwide and enable anyone with PPE to donate to facilities closest to them. The two grassroots initiatives merged into a single team and began outreach to groups across the country.

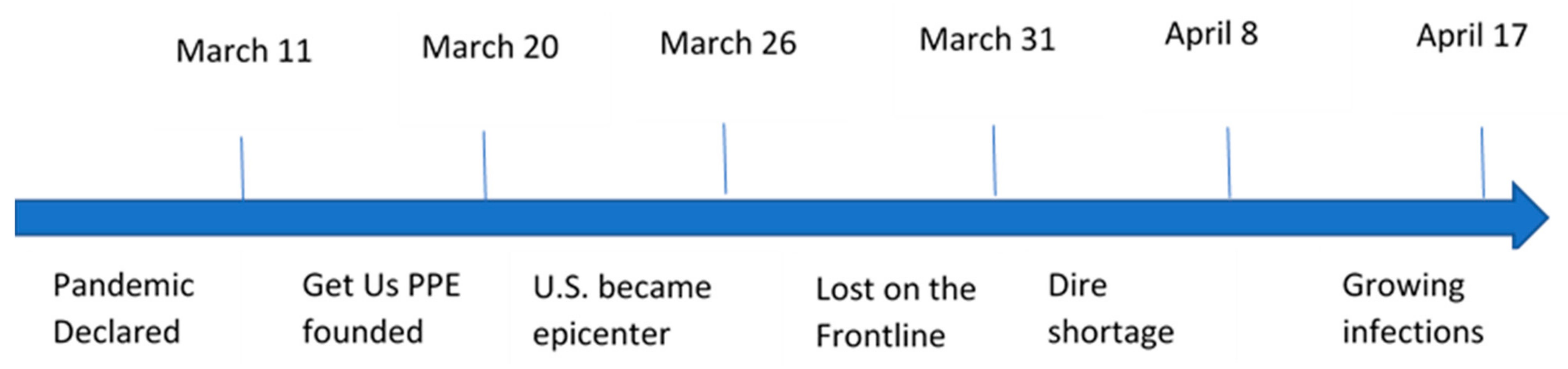

Figure 1 tracks the timeline of its formation.

Get Us PPE.org quickly built partnerships with dozens of smaller community efforts. By 22 March 2020, Get Us PPE mobilized over 200 volunteers. The physician founders then developed a formal board and organized operations into four teams and multiple sub-teams: administrative, communications and development, operations, and technology. In order to execute its value proposition of fulfilling PPE requirements, Get Us PPE interacted with a broad ecosystem including PPE donors, recipients, affiliates, partners, and makers.

3.4. The Get Us PPE Ecosystem

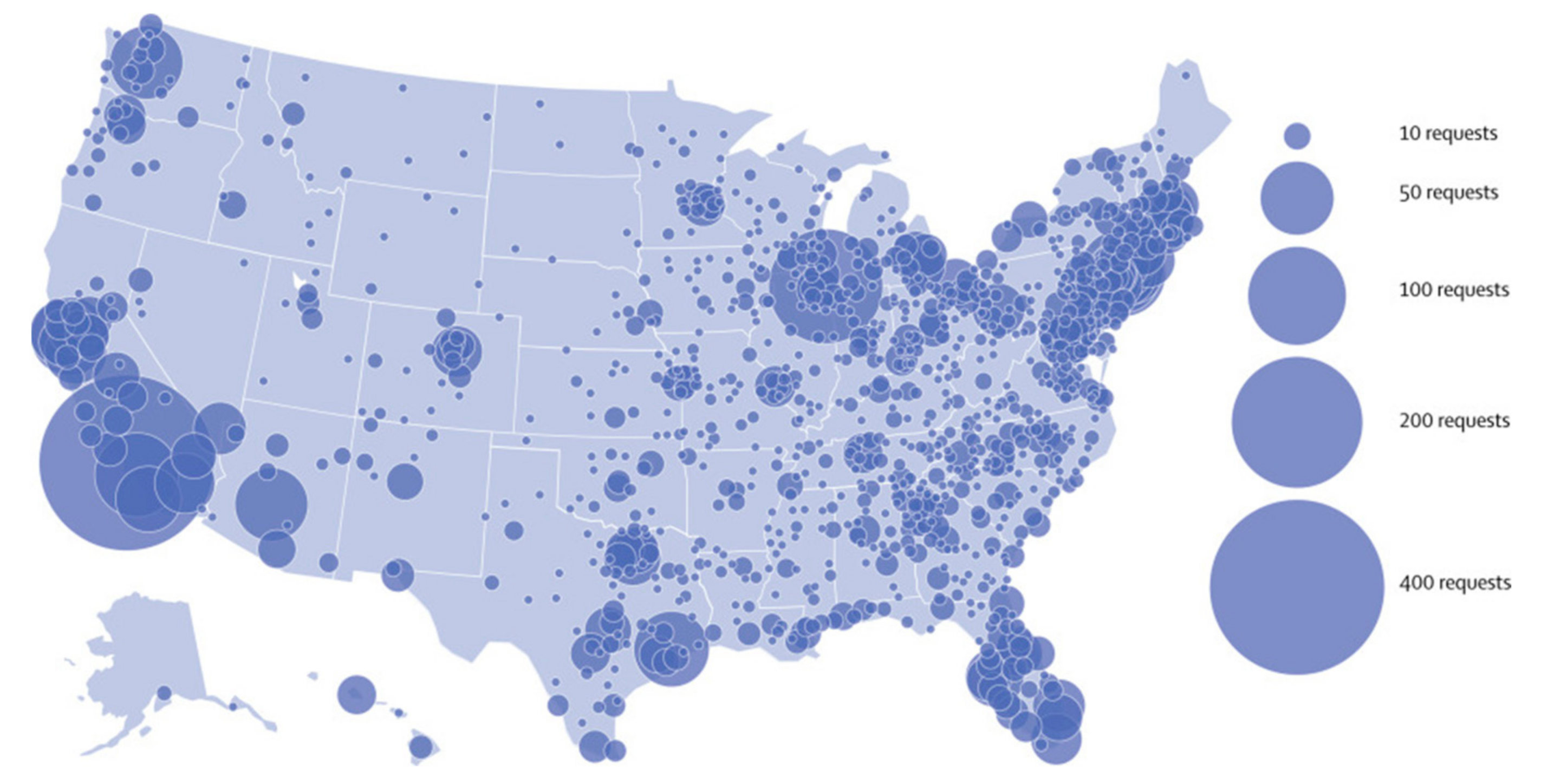

Get Us PPE.org started with a simple online intake form where individuals and organizations could report their location and needs for PPE. As of 2 May 2020, 6169 verified requests for PPE had been received from health institutions and individuals all over the country, which is depicted by

Figure 2. Requests came from not only hospitals (27%), but also outpatient clinics (15%), skilled nursing facilities (9%), assisted living and rehabilitation facilities (5%), home health agencies (5%), and emergency medical services (3%). All these entities represented potential recipients in the PPE ecosystem for Get Us PPE.

Each circle represents a county in which a health-care organization submitted a request for PPE, sized by the number of organizations in the county submitting a request.

These requests captured a quantitative, real-time snapshot of widespread shortages.

Table 1 outlines the various categories of PPE that were sought by recipients.

To match PPE supply with demand, the Match Team utilized algorithmic matching, partnerships, and targeted outreach to identify the most appropriate donors for each recipient. When the initial manual match process became too time-consuming, an open-source algorithm was developed to maximize matching efficiency and highest need.

Table 2 and

Table 3 visually depict the matching that was implemented in the process.

Get Us PPE partners also assisted in delivering local and large-scale corporate PPE donations to recipient organizations. One noteworthy example was a joint effort with Boston Scientific and Amazon, through which Get Us PPE delivered one million face shields to hospitals and health centers in more than 40 US states and territories. Local affiliates were an important player in the supply ecosystem critical to successful PPE distribution. Hence, the national organization worked closely with regional groups by sharing data, building marketing collaborations, and providing grant support. Regional affiliates assisted distribution efforts on the ground and helped keep the national database of PPE needs up to date. Affiliates across the country helped distribute a donation of over one million face shields from Boston Scientific.

Finally, small-scale manufacturers and makers were instrumental in bolstering the global supply of PPE. The Get Us PPE Makers Team worked with a network of individual and national maker groups producing PPE for healthcare workers by providing a directory of makerspaces, vetted designs, discounted raw materials, and grants to support registered makers. The presence of these diverse categories of players within a vibrant ecosystem during a pandemic necessitates judicious utilization of data and technology for improving PPE supply chain. Next, we discuss the details of the platform that Get Us PPE created for articulating its value proposition.

3.5. The Get Us PPE Data-Tech Platform

One of Get Us PPE’s primary efforts was focused on developing and strengthening its data and technology-based platform. Its members quickly realized that in order to direct resources appropriately, real-time information on PPE shortages must be captured with maximum granularity and be kept as updated as possible. Further, transparency about the scope, location, and characteristics of need would allow more equitable distribution of PPE as collective needs changed over time. To enable this to happen, various teams within Get Us PPE worked collaboratively.

The Frontend/UX Team made the Get Us PPE website easier to navigate, and managed the online intake form where individuals and organizations requesting PPE reported characteristics such as their name, organization type, address, recipient role in supply chain, and needs for PPE. Get Us PPE.org also collected information from people or organizations wanting to donate PPE. County-level data from public datasets (including region, rural-urban status, median income, and COVID-19 deaths) were subsequently compiled to inform equitable allocation.

The Data Science team also worked to improve data integrity, forecasting, analytics, and ground truth around PPE needs nationwide. This data-tech driven platform filled in informational and logistical gaps that caused mismatches in supply and demand. Further, the team developed a robust supply chain architecture and a unique optimization algorithm that quickly turned into a cloud-based service and provided an output regarding how and where to move the PPE effectively and efficiently.

5. Discussion and Implications

The advent of COVID-19 imposed grim challenges on supply chain logistics, especially for the healthcare sector. To counter the dangerous repercussions of this pandemic, Get Us PPE was created to facilitate an optimal match between demand and supply of PPE material that was crucial for health care professionals to perform their critical duties. This case study tracked the formation and functioning of Get Us PPE that underscored how to successfully optimize dynamic supply chains in turbulent situations. Our paper thereby uncovers several best practices and key success factors that serve as prescriptive guidance for both academics and practitioners.

First, the performance of Get Us PPE highlights that well planned and executed grassroots endeavors can successfully augment more mainstream and traditional campaigns during challenging situations. Get Us PPE was able to deliver more than 17.5 million sets of PPE to diverse consumer segments within a time period of a little more than a year through the admirable efforts of its volunteers. Therefore, from a policy perspective, governmental organizations should encourage the complementary efforts of such volunteer run grassroots organizations and unblock the obstacles in their path, which can catalyze an effective and efficient response to crisis. This has the potential to positively impact the functioning of society as a whole.

Second, our study showcases the formation of the Get Us PPE platform that integrated modern technology tools with contemporary data science techniques so that real-time information on PPE shortages could be captured with maximum granularity and be updated regularly. This real-time automated matching system thereby enabled transparency about the scope, location, and characteristics of need, which would permit more equitable distribution of PPE and cater to changing needs of diverse stakeholders over time. Although the technology sector has brought forth several self-organizing technology platforms such as Linux, Mozilla, Wikipedia, etc., to the best of our knowledge, this is the first of such self-organizing platforms [

31] of its kind in the field of humanitarian logistics. This is because it encompasses organized innovative work that was self-selected by the various teams within Get Us PPE, who led elements of development without much ex-ante guidance and control. The data aspect within the platform also emphasizes the importance of improving data integrity, forecasting and analytics that can fill in informational and logistical gaps, and improving mismatches in supply and demand during an emergency.

Third, the Get Us PPE case study explains the creation and utilization of a highly successful ecosystem that could be an ideal template to execute in an emergency. As mentioned earlier, the Get Us PPE ecosystem comprised of recipients and donors of PPE material that were well complemented by the stellar efforts of partners, affiliates, and makers. A key takeaway is the importance of ecosystem partners to work synergistically towards a well-conceived goal since there are substantial interdependencies among these stakeholders that could potentially jeopardize execution. In the process, we also add to the pervasive ecosystem literature that spans across a variety of domains including business models, platforms, coopetition, multi-sided markets, networks, technology systems, supply chains, and value networks [

24].

Fourth, we summarized a robust supply chain architecture and logistics optimization model that could be implemented by practitioners during a crisis. The optimization model considered several important factors such as donor and recipient characteristics, distance, and shipment complexity to optimize the PPE supply–demand match. The model was developed based on empirical analysis and it considered data-driven insights in order to reduce costs and time in optimizing PPE delivery and distribution. The results suggest that use of the model increases the number of hospitals that can be supplied with PPE by reducing mismatches of PPE in local geographies. Moreover, Get Us PPE was able to achieve this objective while minimizing the miles travelled and hence logistics costs. Get Us PPE also found that collecting appropriate geospatial data were critical to achieve efficient supply chains and logistics in a pandemic.

Fifth, this paper underscores the significance of organizational learning that provides useful knowledge and coping mechanisms for adapting to COVID-19 and the consequent global economic crises affecting industries, economies, and societies. Specifically, the notion of collective crisis learning involves the knowledge of coordinating responses that may include resource mobilization, addressing challenges, and structuring the necessary administrative units [

10,

41]. Along these lines, our paper provides an excellent opportunity to academicians as well as practitioners to review the efforts of a grassroots campaign post crises, analyze structures and processes, and interpret execution. The best practices revealed by our study can guide the actions of organizations and other community members to cope with the next crisis.

Finally, it is important to highlight the influence of a well-functioning health care supply chain and operations system on environmental, social, and governance issues (ESG). This aspect has captured the attention of businesses, governments, and academics who have acknowledged the importance of ESG in managing supply chains. This is even more relevant in the healthcare sector, where supply chain management has the ability to significantly account for health, safety, sustainability, and the environment, especially in times of crises. The disruptions in US medical supply chains during COVID-19 and the collective inability to ramp up production of essential medical supplies initially during the pandemic demonstrate the impact on sustainability. In addition, the key learnings from our study are generalizable to other humanitarian areas involving donations, such as the delivery of food, clothing, and other essentials to recipients affected by not just pandemics but other emergent natural disasters such as forest fires or tornadoes. Even during COVID-19, problems emerged beyond healthcare supplies, such as lines at food banks reaching record highs. Therefore, we suggest that decision-makers need to maintain an appropriate balance of economic, environmental, and social aspects during the development and implementation of their supply chain network to improve sustainability and resilience to pandemics.

While we believe our results are generalizable beyond PPE, they are not without limitations. Since the COVID-19 crisis unfolded rapidly, the Get Us PPE organization did not have the time or the resources to test alternative strategies in PPE allocation or collect detailed survey data on stakeholder incentives. Therefore, unlike longer term organizations or businesses that have the benefit of evaluating counterfactual scenarios and making final decisions based on such A/B testing, all strategic pathways listed in this case report are based on intuitive understanding of the different tradeoffs with no comparative benchmark. However, our insights may be used as a benchmark against other case studies on humanitarian endeavors in the future.

This research could be developed further in two major directions. First, the algorithms used at Get Us PPE could be generalized to account for further shipment complexity, broader equity metrics, and different methodologies to address equity such as priority systems vs. reservations. Second, the development of self-organizing platforms and their impact on a wide variety of socio-economic problems is a topic that deserves further scrutiny. For example, it is worth examining whether there are more systematic ways of outreach that would enable people with the right skill sets to contribute to such effort. Finally, Get Us PPE’s matching model was deterministic and optimized myopically using existing data on requests and donors. In an evolving pandemic, an active surveillance system that forecasts the future and accounts for it in the optimization is crucial to managing the resulting supply chain crisis. We hope future research will address these questions in further detail.