Environmental/Economic Dispatch Using a New Hybridizing Algorithm Integrated with an Effective Constraint Handling Technique

Abstract

:1. Introduction

1.1. General

1.2. Related Works

- Strategies that seek to preserve solutions in the feasible region by eliminating infeasible solutions or retrieving them to feasible solutions;

- Strategies that are based on the penalty function. In these methods, violation of the constraint using a static or dynamic penalty function is added to the objective function of the problem;

- Strategies that make a clear distinction between feasible and infeasible solutions;

- Hybrid strategies.

- Every feasible solution takes precedence over the infeasible one;

- Between two feasible solutions, the solution with the objective function value is less preferred;

- Between two infeasible solutions, the solution with the least violation is preferable.

1.3. Contributions

- To introduce a new hybrid algorithm called AIWPSO-EMA and to solve CEED problems. The EMA algorithm performs well in solving large-scale optimization problems [49]. The AIWPSO algorithm that was recently introduced in [46] has the same advantages of the original PSO version (such as simple implementation) while not having the drawback of being trapped in local optima;

- Incorporate an effective constraint handling technique into the proposed hybrid algorithm to deal with system constraints in the CEED problems for the first time. This technique, despite its simple principles, performs well in handling constraints;

- To find optimum solutions to CEED problems and to demonstrate the superiority and robustness of the proposed method used comparing it with other methods and statistical analysis.

1.4. Organization of Article

2. Formulation of Problem

2.1. Fuel Cost

2.2. Emission

2.3. CEED Problem Formulation

2.4. Constraints

2.4.1. Power Generation Limits

2.4.2. Power Balance Equation

2.4.3. Ramp Rate Limit

2.4.4. Prohibited Operating Zones

3. The Proposed Method

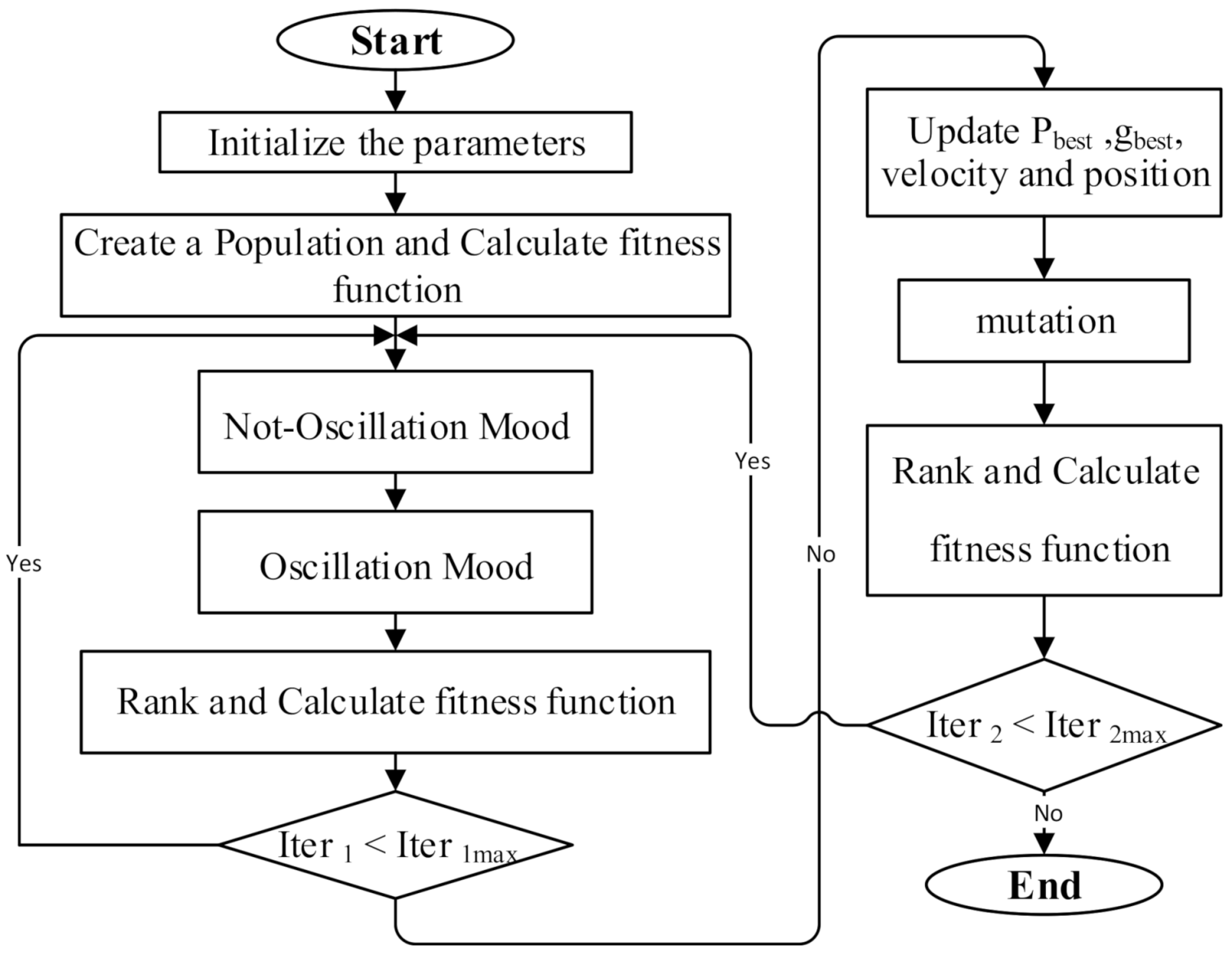

3.1. Hybridizing AIWPSO with EMA

3.2. Constraint Handling

4. Simulation Case Study Results

4.1. Benchmark Functions

4.2. Case Study 1

4.3. Case Study 2

4.4. Case Study 3

4.5. Case Study 4

4.6. Case Study 5

4.7. Discussion

4.7.1. Computation Time

4.7.2. Convergence Characteristics

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| FC | fuel cost of a thermal unit |

| TC | total cost of a thermal unit |

| A,B,C | fuel cost coefficients of a thermal unit |

| φ | compromise coefficient between fuel cost and emission |

| D, θ | coefficients related to the valve-point effect |

| power demand | |

| P | output power of a thermal unit |

| power losses | |

| E | emission produced by a thermal unit |

| , | down and up ramp rate limits of the ath unit |

| α, β, γ, ζ, λ | emission factors related to a thermal unit |

| number of POZs of the ith unit | |

| exchange market information | |

| level of risk of member in groups 2 and 3 | |

| FF | fitness function |

| value changes of variable j of population i | |

| speed of member i at iteration it+1 | |

| position of member i at iteration it+1 | |

| fitness of gbest at the iteration it | |

| fitness of Pbest for the jth variable at the iteration it | |

| , | euclidean distance of the ith solution to positive and negative ideals |

| solution rank based on objective function value | |

| previous power output of the ath unit | |

| , | the highest and lowest level of risk in oscillation mood |

| , | lower and upper limits of POZ jth regarding ath generating unit |

| , | the highest and lowest level of risk in not-oscillation mood |

| ith member of the group X | |

| , | minimum and maximum limits of the variable j of member i |

| change value of the kth member in group 3 | |

| , | acceleration coefficients at the iteration it |

| increment value of some of the variables regarding member t | |

| Mu | mutation rate |

| sum of variables regarding member t | |

| solution rank based on the number of violated constraints | |

| yth variable regarding member t | |

| ordinary market risk in not-oscillation and oscillation moods, respectively, for kth iteration | |

| Μ | a constant parameter regarding each member which increases for less ranked members |

Appendix A

| Methods | P1 (p.u) | P2 (p.u) | P3 (p.u) | P4 (p.u) | P5 (p.u) | P6 (p.u) | |

|---|---|---|---|---|---|---|---|

| φ = 1 | WGSO [15] | 0.56521 | 0.40004 | 0.68748 | 0.95051 | 0.55006 | 0.2238 |

| GSO-T [12] | 0.51661 | 0.40127 | 0.6876 | 0.95063 | 0.55008 | 0.22721 | |

| KKO [56] | 0.1295 | 0.3224 | 0.5419 | 0.9690 | 0.5295 | 0.3654 | |

| ISA [12] | 0.0533 | 0.3956 | 0.6751 | 0.9354 | 0.5365 | 0.22967 | |

| KSO [57] | 0.1127 | 0.2917 | 0.5811 | 0.9953 | 0.5261 | 0.3524 | |

| Proposed Method | 0.05017 | 0.38415 | 0.6875 | 0.8 | 0.54999 | 0.39 | |

| φ = 0 | WGSO [15] | 0.41071 | 0.46396 | 0.54358 | 0.39035 | 0.54366 | 0.51461 |

| GSO-T [12] | 0.40982 | 0.46383 | 0.54414 | 0.38954 | 0.54461 | 0.5149 | |

| KKO [56] | 0.4128 | 0.4617 | 0.5455 | 0.3867 | 0.5457 | 0.5162 | |

| ISA [12] | 0.36474 | 0.38945 | 0.49354 | 0.53432 | 0.57284 | 0.48465 | |

| KSO [57] | 0.4111 | 0.4624 | 0.5436 | 0.3909 | 0.5479 | 0.5156 | |

| Proposed Method | 0.39467 | 0.4972 | 0.50726 | 0.45938 | 0.50793 | 0.49749 | |

| KSO | NSGA-II | MGAIPSO | GWO-AWDO | KKO | APSO | CIHSA | AWDO | Proposed Method | |

|---|---|---|---|---|---|---|---|---|---|

| P1 | 112.80 | 113.868 | 111.056 | 113.542 | 114.00 | 114 | 114 | 113.703 | 113.999 |

| P2 | 112.68 | 113.638 | 110.770 | 114.023 | 113.045 | 114 | 114 | 114 | 114 |

| P3 | 119.67 | 120 | 97.397 | 119.808 | 119.744 | 120 | 120 | 119.936 | 119.999 |

| P4 | 179.66 | 180.788 | 129.866 | 181.147 | 181.102 | 178.711 | 169.368 | 180.531 | 171.912 |

| P5 | 96.68 | 97 | 87.799 | 97.940 | 96.5081 | 97 | 97 | 97 | 97 |

| P6 | 139.72 | 140 | 105.411 | 139.204 | 139.796 | 129.8 | 124.257 | 138.312 | 124.221 |

| P7 | 298.30 | 300 | 259.584 | 300.439 | 299.686 | 300 | 299.711 | 300 | 299.506 |

| P8 | 284.60 | 299.008 | 209.799 | 299.347 | 298.619 | 299.700 | 297.914 | 300 | 300 |

| P9 | 284.60 | 288.889 | 284.500 | 296.159 | 289.447 | 298.8 | 297.260 | 297.139 | 300 |

| P10 | 130.00 | 131.613 | 130.001 | 130.244 | 131.386 | 130 | 130 | 130.919 | 136.077 |

| P11 | 311.49 | 246.512 | 318.367 | 245.322 | 247.114 | 308.2 | 307.573 | 245.219 | 292.776 |

| P12 | 315.59 | 318.874 | 318.416 | 318.268 | 318.381 | 307.6 | 307.001 | 318.063 | 292.294 |

| P13 | 394.28 | 395.722 | 394.277 | 393.914 | 395.689 | 433.981 | 433.807 | 394.237 | 423.689 |

| P14 | 394.28 | 394.136 | 394.278 | 396.696 | 393.82 | 407.5 | 408.955 | 396.475 | 405.035 |

| P15 | 394.28 | 305.578 | 394.276 | 307.591 | 305.891 | 410 | 411.450 | 306.860 | 406.808 |

| P16 | 394.28 | 394.696 | 394.279 | 393.400 | 394.283 | 410 | 411.450 | 393.945 | 406.808 |

| P17 | 488.33 | 489.423 | 399.519 | 489.380 | 489.706 | 453.314 | 452.156 | 489.859 | 440.447 |

| P18 | 497.57 | 488.270 | 399.519 | 487.768 | 487.897 | 453.400 | 452.179 | 488.569 | 440.451 |

| P19 | 487.59 | 500.8 | 508.151 | 497.993 | 500.104 | 437.300 | 437.466 | 497.988 | 444.520 |

| P20 | 421.52 | 455.200 | 50.863 | 455.443 | 455.719 | 437.311 | 437.466 | 454.853 | 444.520 |

| P21 | 433.54 | 434.663 | 515.033 | 432.103 | 434.334 | 437.403 | 437.467 | 432.555 | 446.889 |

| P22 | 433.54 | 434.15 | 517.355 | 434.788 | 434.86 | 437.381 | 437.467 | 434.265 | 446.890 |

| P23 | 433.62 | 445.838 | 516.261 | 444.529 | 446.6 | 437.873 | 437.976 | 444.707 | 447.2 |

| P24 | 433.57 | 450.750 | 433.521 | 452.917 | 451 | 437.934 | 437.976 | 452.868 | 447.2 |

| P25 | 433.52 | 491.274 | 510.139 | 493.187 | 491.259 | 437.6 | 437.759 | 492.267 | 447.25 |

| P26 | 433.52 | 436.341 | 512.540 | 434.464 | 435.771 | 437.600 | 437.759 | 434.136 | 447.25 |

| P27 | 10.00 | 11.245 | 10.000 | 11.641 | 11.079 | 19.143 | 19.531 | 10.753 | 23.7527 |

| P28 | 10.00 | 10 | 10.001 | 10.248 | 10.3466 | 19.148 | 19.531 | 11.108 | 23.753 |

| P29 | 10.00 | 12.071 | 10.003 | 11.935 | 12.2337 | 19.140 | 19.531 | 11.191 | 23.7527 |

| P30 | 97.00 | 97 | 87.786 | 96.064 | 96.6001 | 97 | 97 | 97 | 97 |

| P31 | 187.91 | 189.482 | 159.747 | 188.447 | 189.436 | 176.100 | 175.807 | 189.252 | 175.035 |

| P32 | 186.12 | 174.797 | 159.734 | 174.844 | 175.188 | 176.1 | 175.807 | 174.634 | 175.035 |

| P33 | 188.51 | 189.284 | 159.738 | 188.497 | 189.992 | 176.1 | 175.807 | 188.809 | 175.035 |

| P34 | 199.72 | 200 | 199.992 | 199.587 | 199.679 | 200 | 200 | 200 | 200 |

| P35 | 200.00 | 199.913 | 199.998 | 199.195 | 199.89 | 200 | 200 | 198.656 | 200 |

| P36 | 200.00 | 199.503 | 164.801 | 200.008 | 199.905 | 200 | 200 | 200.456 | 200 |

| P37 | 110.00 | 108.306 | 89.112 | 109.591 | 108.554 | 104.5 | 104.255 | 109.428 | 101.789 |

| P38 | 110.00 | 110 | 89.116 | 109.871 | 109.71 | 104.5 | 104.255 | 110 | 101.790 |

| P39 | 110.00 | 109.789 | 89.112 | 108.041 | 108.639 | 104.5 | 104.255 | 108.507 | 101.790 |

| P40 | 421.52 | 421.560 | 58.868 | 422.395 | 421.912 | 437.356 | 437.466 | 421.782 | 444.521 |

Appendix B

| Unit | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 150 | 455 | 150 | 1.89 | 0.0050 | 300 | 0.035 | 23.333 | −1.500 | 0.016 |

| 2 | 150 | 455 | 115 | 2.00 | 0.0055 | 200 | 0.042 | 21.022 | −1.820 | 0.031 |

| 3 | 20 | 130 | 40 | 3.50 | 0.0060 | 200 | 0.042 | 22.050 | −1.249 | 0.013 |

| 4 | 20 | 130 | 122 | 3.15 | 0.0050 | 150 | 0.063 | 22.983 | −1.355 | 0.012 |

| 5 | 150 | 470 | 125 | 3.05 | 0.0050 | 150 | 0.063 | 21.313 | −1.900 | 0.020 |

| 6 | 135 | 460 | 120 | 2.75 | 0.0070 | 150 | 0.063 | 21.900 | 0.805 | 0.007 |

| 7 | 135 | 465 | 70 | 3.45 | 0.0070 | 150 | 0.063 | 23.001 | −1.400 | 0.015 |

| 8 | 60 | 300 | 70 | 3.45 | 0.0070 | 150 | 0.063 | 24.003 | −1.800 | 0.018 |

| 9 | 25 | 160 | 130 | 2.45 | 0.0050 | 150 | 0.063 | 25.121 | −2.000 | 0.019 |

| 10 | 25 | 10 | 130 | 2.45 | 0.0050 | 100 | 0.084 | 22.990 | −1.360 | 0.012 |

| 11 | 20 | 80 | 135 | 2.35 | 0.0055 | 100 | 0.084 | 27.010 | −2.100 | 0.033 |

| 12 | 20 | 80 | 200 | 1.60 | 0.0045 | 100 | 0.084 | 25.101 | −1.800 | 0.018 |

| 13 | 25 | 85 | 70 | 3.45 | 0.0070 | 100 | 0.084 | 24.313 | −1.8110 | 0.018 |

| 14 | 15 | 55 | 45 | 3.89 | 0.0060 | 100 | 0.084 | 27.119 | −1.921 | 0.030 |

| Unit | POZs |

|---|---|

| 2 | [185 225] [305 335] [420 450] |

| 5 | [180 200] [305 335] [390 420] |

| 6 | [230 255] [36 395] [430 455] |

| 12 | [30 40] [55 65] |

| Unit | |||

|---|---|---|---|

| 1 | 400 | 120 | 80 |

| 2 | 300 | 120 | 80 |

| 3 | 105 | 130 | 130 |

| 4 | 100 | 130 | 130 |

| 5 | 90 | 120 | 80 |

| 6 | 400 | 120 | 80 |

| 7 | 350 | 120 | 80 |

| 8 | 95 | 100 | 65 |

| 9 | 105 | 100 | 60 |

| 10 | 110 | 100 | 60 |

| 11 | 60 | 80 | 80 |

| 12 | 40 | 80 | 80 |

| 13 | 30 | 80 | 80 |

| 14 | 20 | 55 | 55 |

| B = 10−6 × | [14 | 12 | 7 | −1 | −3 | −1 | −1 | −1 | −3 | 5 | −3 | −2 | 4 | 3 |

| 12 | 15 | 13 | 0 | −5 | −2 | 0 | 1 | −2 | −4 | −4 | 0 | 4 | 10 | |

| 7 | 13 | 76 | −1 | −13 | −9 | −1 | 0 | −8 | −12 | −17 | 0 | −26 | 111 | |

| −1 | 0 | −1 | 34 | −7 | −4 | 11 | 50 | 29 | 32 | −11 | 0 | 1 | 1 | |

| −3 | −5 | −13 | −7 | 90 | 14 | −3 | −12 | −10 | −13 | 7 | −2 | −2 | −24 | |

| −1 | −2 | −9 | −4 | 14 | 16 | 0 | −6 | −5 | −8 | 11 | −1 | −2 | −17 | |

| −1 | 0 | −1 | 11 | −3 | 0 | 15 | 17 | 15 | 9 | −5 | 7 | 0 | −2 | |

| −1 | 1 | 0 | 50 | −12 | −6 | 17 | 168 | 82 | 79 | −23 | −36 | 1 | 5 | |

| −3 | −2 | −8 | 29 | −10 | −5 | 15 | 82 | 129 | 116 | −21 | −25 | 7 | −12 | |

| −5 | −4 | −12 | 32 | −13 | −8 | 9 | 79 | 116 | 200 | −27 | −34 | 9 | −11 | |

| −3 | −4 | −17 | −11 | 7 | 11 | −5 | −23 | −21 | −27 | 140 | 1 | 4 | −38 | |

| −2 | 0 | 0 | 0 | −2 | −1 | 7 | −36 | −25 | −34 | 1 | 54 | −1 | −4 | |

| 4 | 4 | −26 | 1 | −2 | −2 | 0 | 1 | 7 | 9 | 4 | −1 | 103 | −101 | |

| 3 | 10 | 111 | 1 | −24 | −17 | −2 | 5 | −12 | −11 | −38 | −4 | −101 | 578 ] |

References

- Bora, T.C.; Mariani, V.C.; dos Santos Coelho, L. Multi-objective optimization of the environmental-economic dispatch with reinforcement learning based on non-dominated sorting genetic algorithm. Appl. Therm. Eng. 2019, 146, 688–700. [Google Scholar] [CrossRef]

- Rex, C.E.; Beno, M.M.; Annrose, J. A solution for combined economic and emission dispatch problem using hybrid optimization techniques. J. Electr. Eng. Technol. 2019, 1–10. [Google Scholar] [CrossRef]

- Murugan, R.; Mohan, M.R.; Rajan, C.C.; Sundari, P.D.; Arunachalam, S. Hybridizing bat algorithm with artificial bee colony for combined heat and power economic dispatch. Appl. Soft Comput. 2018, 72, 189–217. [Google Scholar] [CrossRef]

- Sun, J.; Li, Y. Social cognitive optimization with tent map for combined heat and power economic dispatch. Int. Trans. Electr. Energy Syst. 2019, 29, e2660. [Google Scholar] [CrossRef] [Green Version]

- Hajiamosha, P.; Rastgou, A.; Abdi, H.; Bahramara, S. A Piecewise Linearization Approach to Non-Convex and Non-Smooth Combined Heat and Power Economic Dispatch. J. Oper. Autom. Power Eng. 2022, 10, 40–53. [Google Scholar]

- Hosseini-Hemati, S.; Beigvand, S.D.; Abdi, H.; Rastgou, A. Society-based Grey Wolf Optimizer for large scale Combined Heat and Power Economic Dispatch problem considering power losses. Appl. Soft Comput. 2021, 117, 108351. [Google Scholar] [CrossRef]

- Yang, Q.; Liu, P.; Zhang, J.; Dong, N. Combined heat and power economic dispatch using an adaptive cuckoo search with differential evolution mutation. Appl. Energy 2022, 307, 118057. [Google Scholar] [CrossRef]

- Shalini, S.P.; Lakshmi, K. Solution to Economic Emission Dispatch problem using Lagrangian relaxation method. In Proceedings of the 2014 International Conference on Green Computing Communication and Electrical Engineering (ICGCCEE), Coimbatore, India, 6 March 2014; pp. 1–6. [Google Scholar]

- Zhan, J.P.; Wu, Q.H.; Guo, C.X.; Zhou, X.X. Fast γ-iteration method for economic dispatch with prohibited operating zones. IEEE Trans. Power Syst. 2013, 29, 990–991. [Google Scholar] [CrossRef]

- Chen, S.D.; Chen, J.F. A direct Newton–Raphson economic emission dispatch. Int. J. Electr. Power Energy Syst. 2003, 25, 411–417. [Google Scholar] [CrossRef]

- Bishe, H.M.; Kian, A.R.; Esfahani, M.S. A Primal-dual Interior point method for solving environmental/economic power dispatch problem. Int. Rev. Electr. Eng. 2011, 6, 1463–1473. [Google Scholar]

- Karthik, N.; Parvathy, A.K.; Arul, R. Multi-objective economic emission dispatch using interior search algorithm. Int. Trans. Electr. Energy Syst. 2019, 29, e2683. [Google Scholar] [CrossRef] [Green Version]

- Xiong, G.; Shuai, M.; Hu, X. Combined heat and power economic emission dispatch using improved bare-bone multi-objective particle swarm optimization. Energy 2022, 244, 123108. [Google Scholar] [CrossRef]

- Nourianfar, H.; Abdi, H. Solving power systems optimization problems in the presence of renewable energy sources using modified exchange market algorithm. Sustain. Energy Grids Netw. 2021, 26, 100449. [Google Scholar] [CrossRef]

- Jayakumar, D.N.; Venkatesh, P. Glowworm swarm optimization algorithm with topsis for solving multiple objective environmental economic dispatch problem. Appl. Soft Comput. 2014, 23, 375–386. [Google Scholar] [CrossRef]

- Sakthivel, V.P.; Suman, M.; Sathya, P.D. Combined economic and emission power dispatch problems through multi-objective squirrel search algorithm. Appl. Soft Comput. 2021, 100, 106950. [Google Scholar] [CrossRef]

- Yu, X.; Yu, X.; Lu, Y.; Sheng, J. Economic and emission dispatch using ensemble multi-objective differential evolution algorithm. Sustainability 2018, 10, 418. [Google Scholar] [CrossRef] [Green Version]

- Shaw, B.; Mukherjee, V.; Ghoshal, S.P. A novel opposition-based gravitational search algorithm for combined economic and emission dispatch problems of power systems. Int. J. Electr. Power Energy Syst. 2012, 35, 21–33. [Google Scholar] [CrossRef]

- Mahmoud, K.; Abdel-Nasser, M.; Mustafa, E.; M Ali, Z. Improved salp–swarm optimizer and accurate forecasting model for dynamic economic dispatch in sustainable power systems. Sustainability 2020, 12, 576. [Google Scholar] [CrossRef] [Green Version]

- Hassan, M.H.; Houssein, E.H.; Mahdy, M.A.; Kamel, S. An improved manta ray foraging optimizer for cost-effective emission dispatch problems. Eng. Appl. Artif. Intell. 2021, 100, 104155. [Google Scholar] [CrossRef]

- Shaheen, A.M.; El-Sehiemy, R.A.; Elattar, E.E.; Abd-Elrazek, A.S. A modified crow search optimizer for solving non-linear OPF problem with emissions. IEEE Access 2021, 9, 43107–43120. [Google Scholar] [CrossRef]

- Elattar, E.E. Environmental economic dispatch with heat optimization in the presence of renewable energy based on modified shuffle frog leaping algorithm. Energy 2019, 171, 256–269. [Google Scholar] [CrossRef]

- Duan, Y.; He, X. A non-convex dispatch problem with generator constraints using neural network and particle swarm optimization. Iran. J. Sci. Technol. Trans. Electr. Eng. 2020, 44, 185–196. [Google Scholar] [CrossRef]

- Nazari-Heris, F.; Mohammadi-Ivatloo, B.; Nazarpour, D. Economic dispatch of renewable energy and CHP-based multi-zone microgrids under limitations of electrical network. Iran. J. Sci. Technol. Trans. Electr. Eng. 2020, 44, 155–168. [Google Scholar] [CrossRef]

- Alshammari, M.E.; Ramli, M.A.; Mehedi, I.M. An elitist multi-objective particle swarm optimization algorithm for sustainable dynamic economic emission dispatch integrating wind farms. Sustainability 2020, 12, 7253. [Google Scholar] [CrossRef]

- Sundaram, A. Multiobjective multi-verse optimization algorithm to solve combined economic, heat and power emission dispatch problems. Appl. Soft Comput. 2020, 91, 106195. [Google Scholar] [CrossRef]

- Kansal, V.; Dhillon, J.S. Emended salp swarm algorithm for multiobjective electric power dispatch problem. Appl. Soft Comput. 2020, 90, 106172. [Google Scholar] [CrossRef]

- Liang, H.; Liu, Y.; Li, F.; Shen, Y. A multiobjective hybrid bat algorithm for combined economic/emission dispatch. Int. J. Electr. Power Energy Syst. 2018, 101, 103–115. [Google Scholar] [CrossRef]

- Singh, N.J.; Dhillon, J.S.; Kothari, D.P. Multiobjective thermal power load dispatch using adaptive predator–prey optimization. Appl. Soft Comput. 2018, 66, 370–383. [Google Scholar] [CrossRef]

- Alawode, K.O.; Adegboyega, G.A.; Abimbola Muhideen, J. NSGA-II/EDA Hybrid Evolutionary Algorithm for Solving Multi-objective Economic/Emission Dispatch Problem. Electr. Power Compon. Syst. 2018, 46, 1160–1172. [Google Scholar] [CrossRef]

- Visutarrom, T.; Chiang, T.C. Environmental/Economic Dispatch using Multiobjective Adaptive Differential Evolution with Hybrid Mutation. In Proceedings of the 2019 International Conference on Technologies and Applications of Artificial Intelligence (TAAI), Kaohsiung, Taiwan, 21 November 2019; pp. 1–6. [Google Scholar]

- Rezaie, H.; Kazemi-Rahbar, M.H.; Vahidi, B.; Rastegar, H. Solution of combined economic and emission dispatch problem using a novel chaotic improved harmony search algorithm. J. Comput. Des. Eng. 2019, 6, 447–467. [Google Scholar] [CrossRef]

- Yadav, N.K. Hybridization of particle swarm optimization with differential evolution for solving combined economic emission dispatch model for smart grid. J. Eng. Res. 2019, 7, 244–257. [Google Scholar]

- Sundaram, A. Combined heat and power economic emission dispatch using hybrid NSGA II-MOPSO algorithm incorporating an effective constraint handling mechanism. IEEE Access 2020, 8, 13748–13768. [Google Scholar] [CrossRef]

- Bhargava, G.; Yadav, N.K. Solving combined economic emission dispatch model via hybrid differential evaluation and crow search algorithm. Evol. Intell. 2020, 13, 1–9. [Google Scholar] [CrossRef]

- Gu, H.; Zhu, H.; Chen, P.; Si, F. Improved Hybrid Biogeography-Based Algorithm for Combined Heat and Power Economic Dispatch with Feasible Operating Region and Energy Saving Potential. Electr. Power Compon. Syst. 2019, 47, 1677–1690. [Google Scholar] [CrossRef]

- Krishnamurthy, S.; Tzoneva, R.; Apostolov, A. Method for a parallel solution of a combined economic emission dispatch problem. Electr. Power Compon. Syst. 2017, 45, 393–409. [Google Scholar] [CrossRef]

- Man-Im, A.; Ongsakul, W.; Singh, J.G.; Boonchuay, C. Multi-objective economic dispatch considering wind power penetration using stochastic weight trade-off chaotic NSPSO. Electr. Power Compon. Syst. 2017, 45, 1525–1542. [Google Scholar] [CrossRef]

- Mahdi, F.P.; Vasant, P.; Kallimani, V.; Watada, J.; Fai, P.Y.; Abdullah-Al-Wadud, M. A holistic review on optimization strategies for combined economic emission dispatch problem. Renew. Sustain. Energy Rev. 2018, 81, 3006–3020. [Google Scholar] [CrossRef]

- Elattar, E.E.; Shaheen, A.M.; Elsayed, A.M.; El-Sehiemy, R.A. Optimal power flow with emerged technologies of voltage source converter stations in meshed power systems. IEEE Access 2020, 8, 166963–166979. [Google Scholar] [CrossRef]

- Shaheen, A.M.; Elsayed, A.M.; El-Sehiemy, R.A. Optimal economic–environmental operation for AC-MTDC grids by improved crow search algorithm. IEEE Syst. J. 2021, 1–8. [Google Scholar] [CrossRef]

- Al Harthi, M.; Ghoneim, S.; Elsayed, A.; El-Sehiemy, R.; Shaheen, A.; Ginidi, A. A Multi-Objective Marine Predator Optimizer for Optimal Techno-Economic Operation of AC/DC Grids. Stud. Inform. Control 2021, 30, 89–99. [Google Scholar] [CrossRef]

- Elsayed, A.M.; Shaheen, A.M.; Alharthi, M.M.; Ghoneim, S.S.; El-Sehiemy, R.A. Adequate operation of hybrid AC/MT-HVDC power systems using an improved multi-objective marine predators optimizer. IEEE Access 2021, 9, 51065–51087. [Google Scholar] [CrossRef]

- Zou, D.; Li, S.; Kong, X.; Ouyang, H.; Li, Z. Solving the combined heat and power economic dispatch problems by an improved genetic algorithm and a new constraint handling strategy. Appl. Energy 2019, 237, 646–670. [Google Scholar] [CrossRef]

- Hsieh, M.N.; Chiang, T.C.; Fu, L.C. A hybrid constraint handling mechanism with differential evolution for constrained multiobjective optimization. In Proceedings of the 2011 IEEE Congress of Evolutionary Computation (CEC), New Orleans, LA, USA, 5 June 2011; pp. 1785–1792. [Google Scholar]

- Li, M.; Chen, H.; Wang, X.; Zhong, N.; Lu, S. An improved particle swarm optimization algorithm with adaptive inertia weights. Int. J. Inf. Technol. Decis. Mak. 2019, 18, 833–866. [Google Scholar] [CrossRef]

- Ghorbani, N. Combined heat and power economic dispatch using exchange market algorithm. Int. J. Electr. Power Energy Syst. 2016, 82, 58–66. [Google Scholar] [CrossRef]

- de Paula Garcia, R.; de Lima, B.S.; de Castro Lemonge, A.C.; Jacob, B.P. A rank-based constraint handling technique for engineering design optimization problems solved by genetic algorithms. Comput. Struct. 2017, 187, 77–87. [Google Scholar] [CrossRef]

- Nazari-Heris, M.; Mohammadi-Ivatloo, B.; Gharehpetian, G.B. A comprehensive review of heuristic optimization algorithms for optimal combined heat and power dispatch from economic and environmental perspectives. Renew. Sustain. Energy Rev. 2018, 81, 2128–2143. [Google Scholar] [CrossRef]

- Gherbi, Y.A.; Bouzeboudja, H.; Gherbi, F.Z. The combined economic environmental dispatch using new hybrid metaheuristic. Energy 2016, 115, 468–477. [Google Scholar] [CrossRef]

- Nourianfar, H.; Abdi, H. Solving the multi-objective economic emission dispatch problems using Fast Non-Dominated Sorting TVAC-PSO combined with EMA. Appl. Soft Comput. 2019, 85, 105770. [Google Scholar] [CrossRef]

- Goudarzi, A.; Li, Y.; Xiang, J. A hybrid non-linear time-varying double-weighted particle swarm optimization for solving non-convex combined environmental economic dispatch problem. Appl. Soft Comput. 2020, 86, 105894. [Google Scholar] [CrossRef]

- Basu, M. Economic environmental dispatch using multi-objective differential evolution. Appl. Soft Comput. 2011, 11, 2845–2853. [Google Scholar] [CrossRef]

- Maity, D.; Banerjee, S.; Chanda, C.K. Bare bones teaching learning-based optimization technique for economic emission load dispatch problem considering transmission losses. Iran. J. Sci. Technol. Trans. Electr. Eng. 2019, 43, 77–90. [Google Scholar] [CrossRef]

- Hemamalini, S.P.; Simon, S.P. Emission constrained economic dispatch with valve-point effect using particle swarm optimization. In Proceedings of the Tencon 2008–2008 IEEE Region 10 Conference, Hyderabad, India, 19 November 2008; pp. 1–6. [Google Scholar]

- Srivastava, A.; Das, D.K. A new Kho-Kho optimization Algorithm: An application to solve combined emission economic dispatch and combined heat and power economic dispatch problem. Eng. Appl. Artif. Intell. 2020, 94, 103763. [Google Scholar] [CrossRef]

- Dong, R.; Wang, S. New optimization algorithm inspired by kernel tricks for the economic emission dispatch problem with valve point. IEEE Access 2020, 8, 16584–16594. [Google Scholar] [CrossRef]

- Banerjee, S.; Sarkar, D. Emission Constrained Optimal Allocation of Generation using AWDO Technique. Int. J. Smart Grid Sustain. Energy Technol. 2018, 2, 88–96. [Google Scholar] [CrossRef] [Green Version]

- Güvenc, U.; Sönmez, Y.; Duman, S.; Yörükeren, N. Combined economic and emission dispatch solution using gravitational search algorithm. Sci. Iran. 2012, 19, 1754–1762. [Google Scholar] [CrossRef] [Green Version]

- Sinha, N.; Chakrabarti, R.; Chattopadhyay, P.K. Evolutionary programming techniques for economic load dispatch. IEEE Trans. Evol. Comput. 2003, 7, 83–94. [Google Scholar] [CrossRef]

- Mandal, K.K.; Mandal, S.; Bhattacharya, B.; Chakraborty, N. Non-convex emission constrained economic dispatch using a new self-adaptive particle swarm optimization technique. Appl. Soft Comput. 2015, 28, 188–195. [Google Scholar] [CrossRef]

- Rezaie, H.; Abedi, M.; Rastegar, S.; Rastegar, H. Economic emission dispatch using an advanced particle swarm optimization technique. World J. Eng. 2019, 16, 23–32. [Google Scholar] [CrossRef]

| Parameter | Case Study Number | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Population | 50 | 50 | 100 | 100 | 200 |

| C1i, C2i | 0.5 | 0.5 | 0.5 | 0.46 | 0.52 |

| C1f, C2f | 2.5 | 2.5 | 2.5 | 1.96 | 2.5 |

| g1 [max, min] | [0.02, 0.002] | [0.05, 0.04] | [0.02, 0.002] | [0.02, 0.002] | [0.02, 0.002] |

| g2 [max, min] | [0.01, 0.001] | [0.04, 0.03] | [0.01, 0.001] | [0.01, 0.001] | [0.01, 0.001] |

| Max-iteration of EMA loop | 50 | 50 | 50 | 50 | 50 |

| Max-iteration | 10 | 10 | 10 | 10 | 10 |

| mu | 0.5 | 0.5 | 0.5 | 0.4 | 0.4 |

| PPF | 62.036 | 65.216 | 43.559 | 1.8343 | 1.2189 1 |

| Function Name | CPSO [46] | APSO [46] | AIWPSO [46] | Proposed Method | |

|---|---|---|---|---|---|

| Sphere | Mean | 4.24 × 10−4 | 4.73 × 10−4 | 7.14 × 10−15 | 3.22 × 10−55 |

| Min | 2.12 × 10−4 | 2.55 × 10−4 | 2.59 × 10−15 | 1.41 × 10−55 | |

| Rosenbrock | Mean | 2.94 × 101 | 2.82 × 101 | 2.18 × 101 | 2.24 × 10−8 |

| Min | 2.26 × 101 | 2.22 × 101 | 1.99 × 101 | 1.89 × 10−8 | |

| Ackley | Mean | 5.60 × 101 | 2.51 × 101 | 1.72 × 10−4 | 8.08 × 10−19 |

| Min | 1.70 × 101 | 1.12 × 101 | 8.70 × 10−10 | 3.77 × 10−20 | |

| Rastrigin | Mean | 2.34 × 102 | 1.25 × 101 | 2.40 × 10−14 | 1.90 × 10−38 |

| Min | 1.24 × 102 | 1.03 × 100 | 1.24 × 10−14 | 1.54 × 10−40 | |

| schwefel P2.22 | Mean | 4.11 × 10−1 | 3.15 × 10−1 | 4.20 × 10−2 | 6.20 × 10−15 |

| Min | 2.05 × 10−1 | 1.15 × 10−1 | 1.09 × 10−2 | 1.15 × 10−15 | |

| Rotated hyper ellipsoid | Mean | 1.34 × 101 | 1.32 × 101 | 2.62 × 10−14 | 2.44 × 10−23 |

| Min | 6.10 × 10−2 | 4.52 × 10−2 | 1.01 × 10−14 | 2.32 × 10−25 | |

| Output | P1 (MW) | P2 (MW) | P3 (MW) | P4 (MW) | P5 (MW) | P6 (MW) | Cost ($/h) | Emission (lb/h) | Total Power (MW) | Power Losses (MW) |

|---|---|---|---|---|---|---|---|---|---|---|

| QTLBO [54] | 107.310 | 121.497 | 206.501 | 206.583 | 304.984 | 304.604 | 64912 | 1281 | 1251.478 | 51.478 |

| BBTLBO 1 [54] | 56.826 | 74.003 | 197.791 | 224.262 | 321.621 | 325.000 | 60863 | 1294.7 | 1199.502 | 50.109 |

| MODE [54] | 108.628 | 115.946 | 206.797 | 210.000 | 301.888 | 308.413 | 64843 | 1286 | 1251.672 | NA 2 |

| Proposed Method | 107.150 | 119.848 | 206.172 | 206.227 | 307.080 | 304.435 | 64841 | 1281 | 1250.912 | 50.912 |

| Methods | Cost ($/h) | Emission (ton/h) | Losses (p.u) | Cost ($/h) | Emission (ton/h) | Losses (p.u) | ||

|---|---|---|---|---|---|---|---|---|

| WGSO [15] | φ = 1 | 613.469 | 0.22331 | NA | φ = 0 | 679.318 | 0.19418 | NA |

| GSO-T [12] | 613.463 | 0.22343 | NA | 679.221 | 0.19418 | NA | ||

| KKO [56] | 605.68 | 0.21789 | 0.023 | 646.457 | 0.19418 | 0.034 | ||

| ISA [12] | 613.274 | 0.22265 | NA | 659.365 | 0.19356 | NA | ||

| KSO [57] | 605.896 | 0.2211 | 0.025 | 646.600 | 0.1942 | 0.035 | ||

| Proposed Method | 612.913 | 0.200 57 | 0.028 | 677.432 | 0.18607 | 0.030 |

| Method | Cost ($/h) | Std. | ||

|---|---|---|---|---|

| Min | Max | Mean | ||

| WGSO [15] | 613.4694 | 614.5266 | 613.6621 | 0.0031082 |

| GSO-T [12] | 613.4626 | 613.9756 | 613.6830 | 0.0016427 |

| ISA [12] | 613.274 | 613.952 | 613.398 | 0.001035 |

| Proposed method | 612.913 | 613.325 | 613.024 | 0.000937 |

| Output | KKO | GSA | KSO | ISA | GWO-AWDO | CIHSA | Proposed Method | |

|---|---|---|---|---|---|---|---|---|

| Emission | Cost | |||||||

| P1 | 54.992 | 54.999 | 55.000 | 53.143 | 54.944 | 55.00 | 55.00 | 55.00 |

| P2 | 78.891 | 79.958 | 80.000 | 78.965 | 79.730 | 80.00 | 80.00 | 80.00 |

| P3 | 78.794 | 79.434 | 81.134 | 78.103 | 80.133 | 81.081 | 81.134 | 89.016 |

| P4 | 88.747 | 85.000 | 81.3637 | 97.117 | 86.226 | 80.93 | 81.363 | 85.755 |

| P5 | 159.814 | 142.106 | 160.000 | 152.74 | 143.590 | 160.0 | 160.0 | 102.92 |

| P6 | 160.555 | 166.567 | 240.000 | 163.02 | 165.942 | 240.0 | 240.0 | 112.63 |

| P7 | 262.174 | 292.874 | 294.485 | 257.94 | 292.770 | 290.8 | 294.48 | 300.0 |

| P8 | 308.857 | 313.238 | 297.270 | 302.14 | 312.457 | 296.689 | 297.27 | 326.78 |

| P9 | 430.307 | 441.177 | 396.765 | 432.76 | 440.304 | 398.842 | 396.76 | 464.44 |

| P10 | 461.039 | 428.630 | 395.576 | 465.86 | 427.815 | 398.331 | 395.57 | 470.0 |

| Cost ×105 ($/h) | 1.13481 * | 1.1349 | 1.16412 | 1.1217 * | 1.1330 * | 1.1639 | 1.16411 | 1.1180 |

| Emission (ton/h) | 3982.85 * | 4111.4 | 3932.24 | 3995.6 * | 4108.80 | 3932.44 | 3932.20 | 4384.3 |

| CPU (s) | NA | NA | NA | 2.04 | NA | NA | 2.31 | 2.27 |

| Losses (MW) | 84.17 | 83.98 | 81.59 | NA | 83.91 | 81.67 | 81.6 | 86.5 |

| Output | 1750 MW | 2150 MW | 2650 MW | ||||||

|---|---|---|---|---|---|---|---|---|---|

| ECD | ELD | CEED | ECD | ELD | CEED | ECD | ELD | CEED | |

| P1 | 280.000 | 329.5235 | 280.024 | 284.523 | 419.280 | 329.519 | 388.041 | 419.281 | 419.279 |

| P2 | 180.000 | 225.000 | 180.016 | 180.021 | 299.611 | 185.000 | 225.000 | 374.402 | 225.000 |

| P3 | 79.892 | 20.000 | 94.799 | 129.992 | 94.800 | 105.721 | 129.991 | 111.719 | 129.989 |

| P4 | 90.965 | 69.802 | 69.8665 | 119.730 | 119.733 | 119.733 | 129.990 | 119.732 | 129.972 |

| P5 | 150.000 | 150.000 | 150.011 | 150.034 | 150.012 | 150.026 | 170.000 | 169.800 | 169.984 |

| P6 | 280.000 | 280.000 | 284.599 | 334.470 | 284.600 | 284.600 | 460.000 | 420.000 | 455.000 |

| P7 | 230.000 | 233.857 | 234.733 | 234.730 | 234.730 | 234.733 | 410.491 | 334.468 | 384.332 |

| P8 | 73.005 | 60.000 | 60.022 | 159.730 | 60.007 | 159.733 | 159.987 | 159.731 | 159.733 |

| P9 | 74.425 | 74.8621 | 74.8665 | 159.998 | 124.731 | 159.992 | 159.993 | 124.729 | 162.000 |

| P10 | 91.175 | 137.183 | 99.800 | 159.999 | 137.201 | 159.991 | 159.991 | 159.995 | 159.992 |

| P11 | 44.366 | 56.784 | 57.400 | 79.991 | 57.400 | 79.991 | 79.987 | 79.991 | 79.993 |

| P12 | 73.005 | 54.000 | 64.383 | 55.000 | 79.285 | 79.993 | 79.992 | 79.991 | 79.994 |

| P13 | 73.282 | 62.362 | 62.400 | 84.992 | 62.400 | 84.992 | 84.988 | 84.989 | 84.993 |

| P14 | 45.820 | 15.000 | 52.400 | 54.889 | 52.400 | 52.400 | 54.989 | 52.400 | 54.968 |

| Cost ($/h) | 9514.64 | 8325.21 | 8750.39 | 11,279.83 | 10,149.54 | 10,746.22 | 15,040.11 | 13,961.90 | 14,514.16 |

| Emission (lb/h) | 2984.36 | 3940.82 | 3047.57 | 4046.56 | 6159.26 | 4180.65 | 7865.89 | 9528.07 | 7918.40 |

| Losses (MW) | 15.93 | 18.37 | 15.32 | 38.09 | 26.19 | 36.42 | 43.44 | 41.22 | 45.22 |

| Method | APSO [62] | SOHPSO-TVAC [61] | Proposed Method | ||

|---|---|---|---|---|---|

| Load (MW) | 1750 | ECD (Emission) (lb/h) | 2984.431 | 3182.50 | 2984.36 |

| ELD (Cost) ($/h) | 8322.003 | 8621.52 | 8325.21 | ||

| CEED (Total Cost) ($/h) | 12,491.322 | 12,745.692 | 12,465.08 | ||

| 2150 | ECD (Emission) (lb/h) | 4075.5318 | 4603.90 | 4046.56 | |

| ELD (Cost) ($/h) | 10,222.371 | 10,778.00 | 10,149.54 | ||

| CEED (Total Cost) ($/h) | 17,159.145 | 18,876.501 | 17,142.20 | ||

| 2650 | ECD (Emission) (lb/h) | 7877.248 | 8269.90 | 7865.89 | |

| ELD (Cost) ($/h) | 14,080.275 | 14,209.00 | 13,961.90 | ||

| CEED (Total Cost) ($/h) | 26,963.048 | 30,382.425 | 26,957.93 | ||

| Case Study Number | CPU Speed (GHz) | ART | RRT | |

|---|---|---|---|---|

| 1 | TLBO | 2 | 2.18 | 2.90 |

| QTLBO | 2 | 1.91 | 2.54 | |

| BBTLBO 1 | NA | NA | NC 1 | |

| MODE | 3 | 3.09 | 6.18 | |

| Proposed method | 1.5 | 2.01 | 2.01 | |

| 2 | ISA | NA | 2 | NC |

| KSO | 2.4 | NA | NC | |

| Proposed method | 1.5 | 2.02 | 2.02 | |

| 3 | GWO-AWDO | 2.2 | NA | NC |

| ISA | NA | 2.04 | NC | |

| CIHSA | 3.5 | NA | NC | |

| PDE | 3 | 4.23 | 8.46 | |

| SPEA-2 | 3 | 7.53 | 15.06 | |

| KSO | 2.4 | NA | NC | |

| Proposed method | 1.5 | 2.31 | 2.31 | |

| 4 | MGAIPSO | 2.5 | NA | NC |

| GWO/AWDO | 2.2 | NA | NC | |

| APSO | NA | NA | NC | |

| ISA | NA | 2.72 | NC | |

| CIHSA | 3.5 | NA | NC | |

| Proposed method | 1.5 | 2.95 | 2.95 | |

| 5 | APSO | NA | NA | NC |

| Proposed method | 1.5 | 2.19 | 2.19 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nourianfar, H.; Abdi, H. Environmental/Economic Dispatch Using a New Hybridizing Algorithm Integrated with an Effective Constraint Handling Technique. Sustainability 2022, 14, 3173. https://doi.org/10.3390/su14063173

Nourianfar H, Abdi H. Environmental/Economic Dispatch Using a New Hybridizing Algorithm Integrated with an Effective Constraint Handling Technique. Sustainability. 2022; 14(6):3173. https://doi.org/10.3390/su14063173

Chicago/Turabian StyleNourianfar, Hossein, and Hamdi Abdi. 2022. "Environmental/Economic Dispatch Using a New Hybridizing Algorithm Integrated with an Effective Constraint Handling Technique" Sustainability 14, no. 6: 3173. https://doi.org/10.3390/su14063173

APA StyleNourianfar, H., & Abdi, H. (2022). Environmental/Economic Dispatch Using a New Hybridizing Algorithm Integrated with an Effective Constraint Handling Technique. Sustainability, 14(6), 3173. https://doi.org/10.3390/su14063173