Experimental Study on the Performance Decay of Thermal Insulation and Related Influence on Heating Energy Consumption in Buildings

Abstract

:1. Introduction and State of the Art

2. Materials, Methods and Experimental Investigation

- Adhesive;

- Insulation products;

- Mechanical-fixing devices;

- Rendering systems, typically consisting of a base coat, reinforcement (glass fiber), and a finishing coat/decorative coat;

- Secondary materials (any supplementary component/product used to form joints or to achieve continuity).

2.1. Insulating Materials Used in the Experimental Investigation

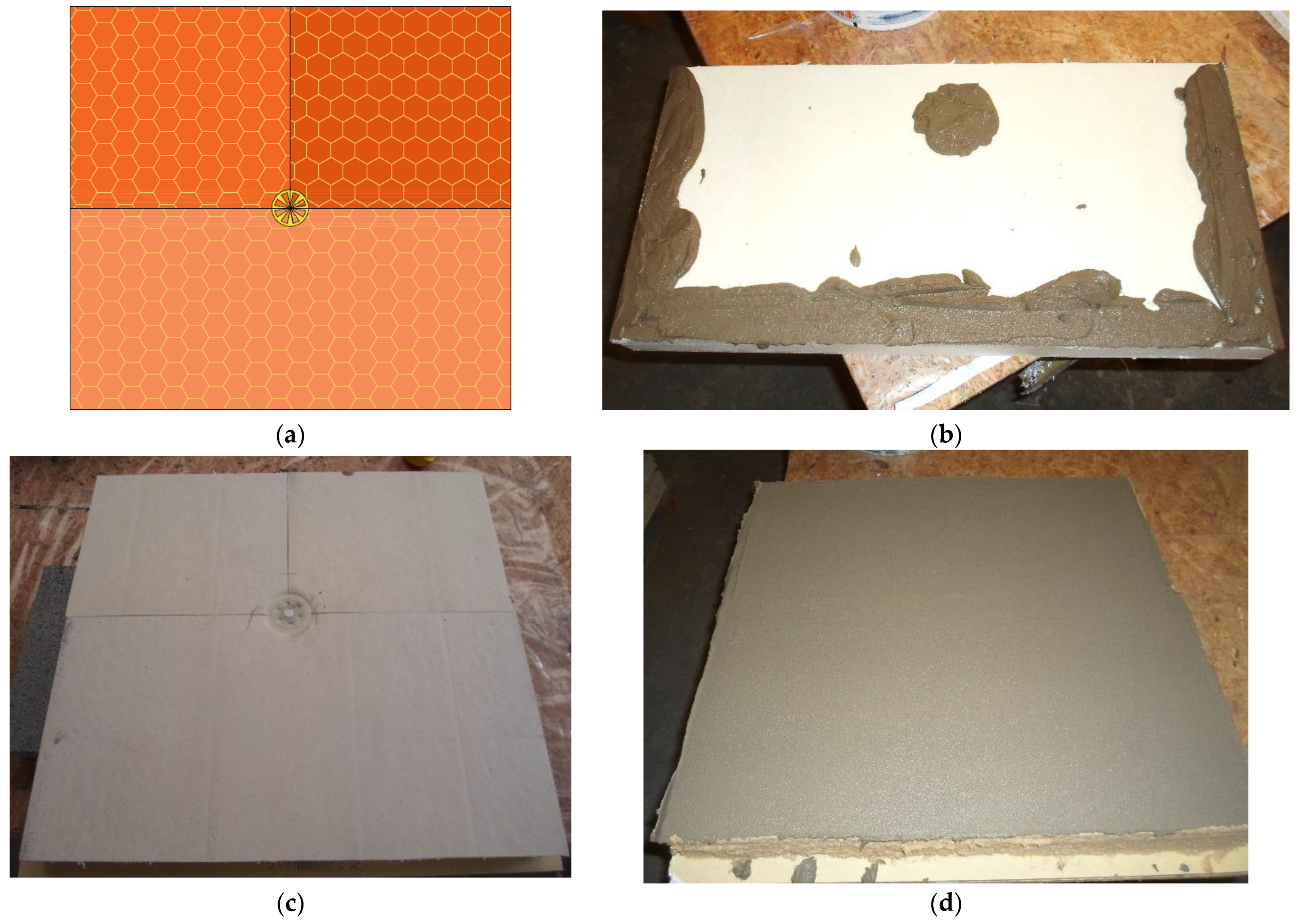

2.2. Specimens’ Characteristics

- Support of wooden OSB (Oriented Strand Board) (thickness = 2 mm) and outdoor plasterboard panel (thickness = 12.5 mm) instead of masonry wall, because not only the aim of the research was focused on the interaction between ETICS and environmental loads, and not on the back support, which has a negligible influence on durability of the system, but also as the insulation is supposed to be placed outside the support (external insulation).

- Skim-coating adhesive, a mineral adhesive/skim coat in powder form made of unsaponifiable resins, high-resistance Portland cement and selected sands with a maximum particle size of 0.6 mm.

- Thermal insulating material, with different widths as a consequence of the different conductivity, as specified in Table 1, in which the system name refers to the commercial name of the company that provided materials; the target value of thermal transmittance was chosen in compliance with Italian law requirements (D.M. 26 June 2015 [38]), considering the hypothesis of a busser double brick wall with internal cavity.

- Base coat with embedded reinforcing fiberglass mesh: the base coat material is the same skim-coating adhesive.

- Finishing coat: coating based on acrylic resins in dispersion within additives that facilitate the application and formation of a film as well as marble granules and quartz sand with controlled absorption; max. particle size of 1.2 mm.

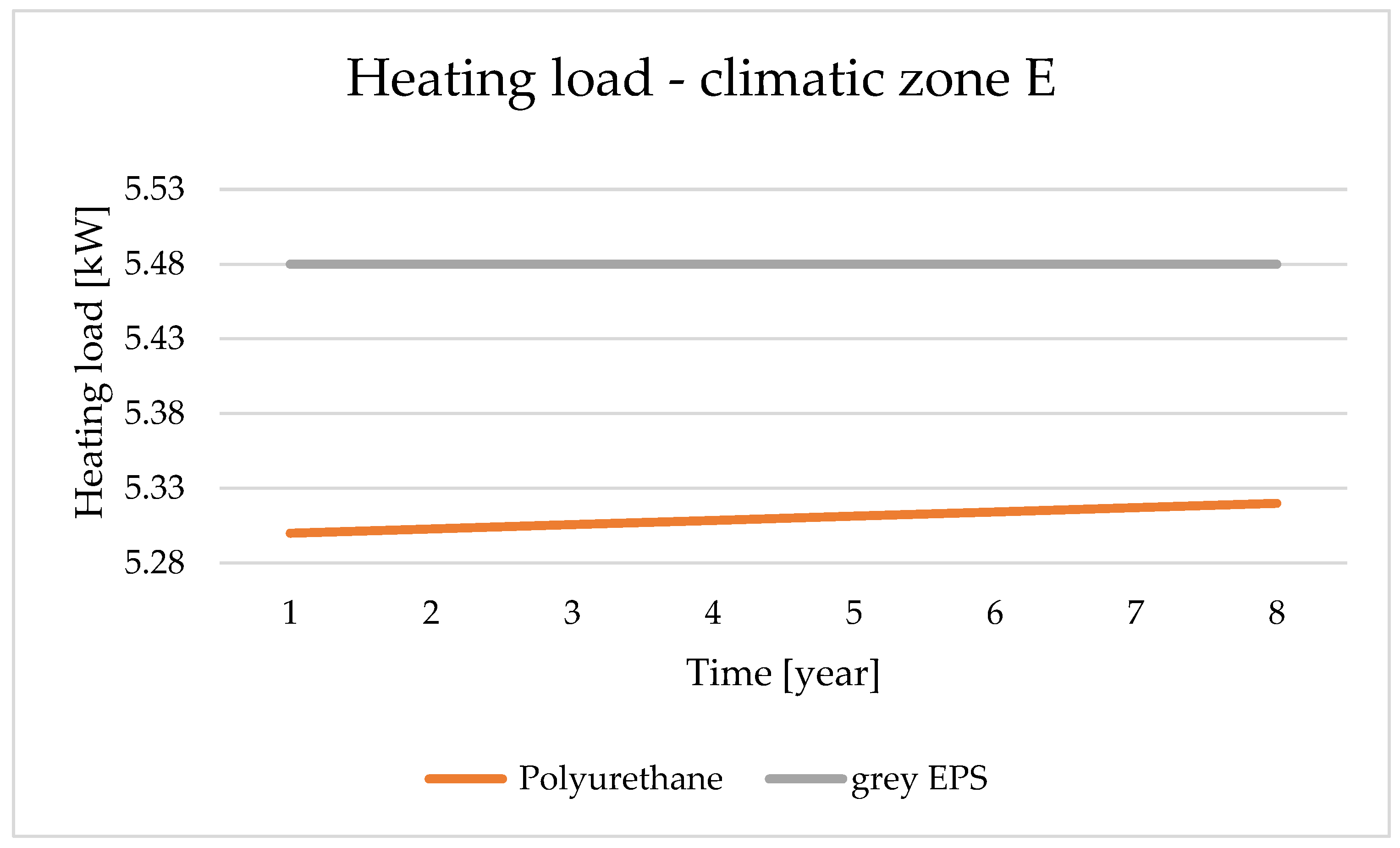

2.3. Experimental Approach by Means of Accelerated Ageing

- Summer and winter thermal shocks;

- Freeze–thaw cycles;

- Driving rain;

- Cyclic variations in temperature and relative humidity.

2.4. Designed Accelerated Ageing Cycles

- A total of 80 heat–rain cycles: each cycle took 6 h and consisted firstly in heating up to 80 °C (rising for 1 h) and maintaining the temperature at (80 + 5) °C for 2 h (total of 3 h), then spraying for 1 h with 1.5 ± 0.5 l/m2 min amount of water and water temperature at 15 ± 5 °C, and thirdly leaving for 2 h for drainage at 20 ± 5 °C;

- A total of 7 heat–Cold cycles: each cycle lasted 24 h, comprising an initial exposure of 8 h to −10 ± 2 °C (fall for 2 h), then 9 h to 70 ± 2 °C (rise for 1 h) and maximum 30% RH and finally an exposure of 7 h to −10 ± 2 °C (fall for 2 h);

- A total of 15 freeze and thaw cycles: each cycle lasts 24 h, comprising an initial exposure for 8 h to water at 23 ± 4 °C by immersion of the specimens, with the skin submerged in a water bath, according to the method described in EAD 040083 (Section 2.2.7) [26], then, freezing to −20 ± 5 °C for 14 h, and a final insertion in the stove at +50 °C for 2 h.

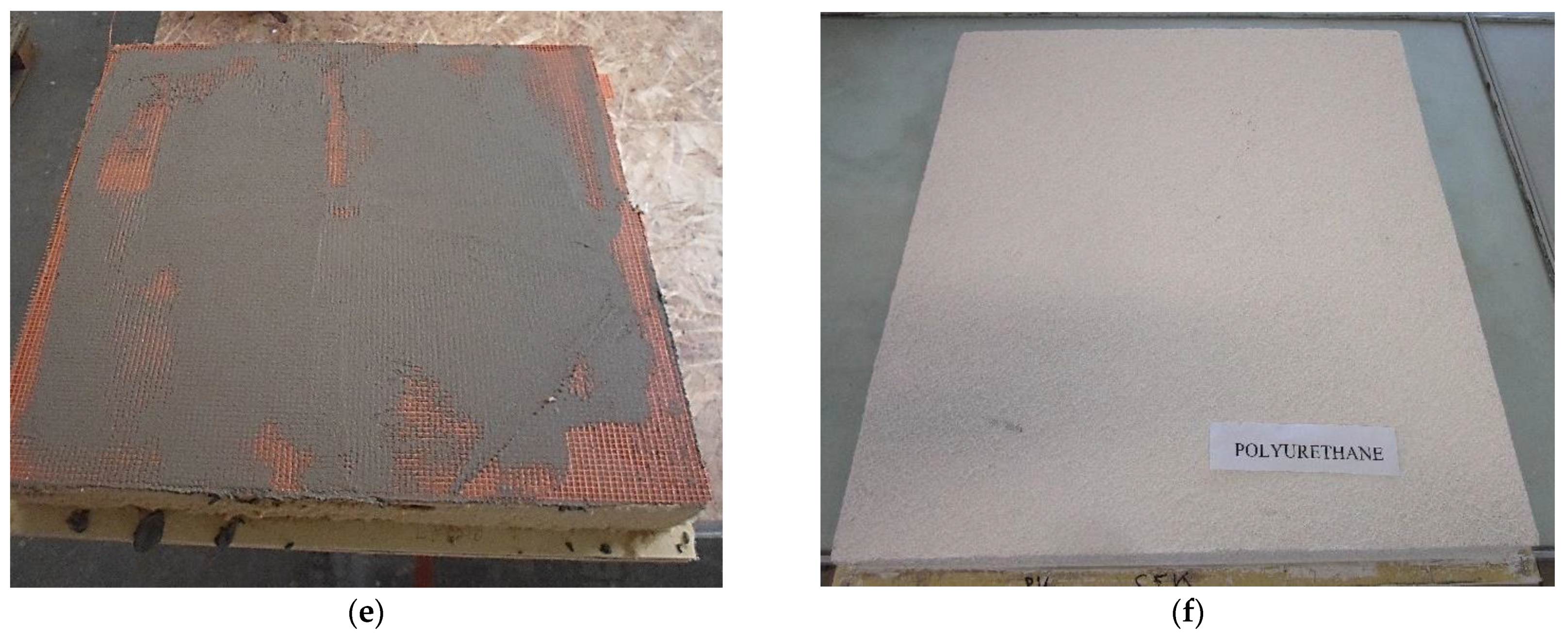

2.5. Performance Decay Assessment

- Realization of ETICS samples by varying the insulating material between grey EPS and PU without varying the other layers;

- Measurement of decay before the test; collection of data related to sampled ETICS thermal resistance at time T0;

- Execution of accelerated ageing test on the samples in climatic chambers;

- Measurement of the state of decay after accelerated ageing cycles; collection of data related to sampled ETICS thermal resistance at time T1;

- Realization of the performance–time curve for each of the solutions represented by the two samples.

- The declared conductivity and related calculated thermal transmittance and thermal resistance of whole ETICS;

- The experimentally measured thermal transmittance and thermal resistance of the studied ETICS before accelerated ageing cycles, at time T0;

- The experimentally measured thermal transmittance and thermal resistance of the studied ETICS after accelerated ageing cycles, at time T1.

3. Application of Experimental Results to a Case Study

Results for the Case Study and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Global Status Report for Buildings and Construction. Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector. Available online: https://www.unenvironment.org/resources/publication/2019-global-status-report-buildings-and-construction-sector (accessed on 3 January 2021).

- World Green Building Council. New Report: The Building and Construction Sector Can Reach Net Zero Carbon Emissions by 2050. World GBC 2019. Available online: https://www.worldgbc.org/news-media/WorldGBC-embodied-carbon-report-published (accessed on 28 December 2020).

- European Commission. Energy Performance of Buildings Directive. 2020. Available online: https://ec.europa.eu/energy/topics/energy-efficiency/energy-efficient-buildings/energy-performance-buildings-directive_en#:~:text=Buildings%20are%20responsible%20for%20approximately,building%20stock%20is%20energy%20inefficient (accessed on 28 December 2020).

- Luján, S.V.; Arrebola, C.V.; Rodríguez Sánchez, A.; Aguilera Benito, P.; Cortina, M.G. Experimental comparative study of the thermal performance of the façade of a building refurbished using ETICS, and quantification of improvements. Sustain. Cities Soc. 2019, 51, 101713. [Google Scholar] [CrossRef]

- Alba-Rodríguez, A.M.D.; Martínez-Rocamora, A.; González-Vallejo, P.; Ferreira-Sánchez, A.; Marrero, M. Building rehabilitation versus demolition and new construction: Economic and environmental assessment. Environ. Impact Assess. Rev. 2017, 66, 115–126. [Google Scholar] [CrossRef]

- Saretta, E.; Caputo, P.; Frontini, F. A review study about energy renovation of building facades with BIPV in urban environment. Sustain. Cities Soc. 2019, 44, 343–355. [Google Scholar] [CrossRef]

- Ameur, M.; Kharbouch, Y.; Mimet, A. Optimization of passive design features for a naturally ventilated residential building according to the bioclimatic architecture concept and considering the northern Morocco climate. Build. Simul. 2020, 13, 677–689. [Google Scholar] [CrossRef]

- Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the Energy Performance of Buildings (Recast). 2010. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2010:153:0013:0035:EN:PDF (accessed on 1 January 2022).

- Pajek, L.; Košir, M. Strategy for achieving long-term energy efficiency of European single-family buildings through passive climate adaptation. Appl. Energy 2021, 297, 117116. [Google Scholar] [CrossRef]

- D’Agostino, D.; de’ Rossi, F.; Marigliano, M.; Marino, C.; Minichiello, F. Evaluation of the optimal thermal insulation thickness for an office building in different climates by means of the basic and modified “cost-optimal” methodology. J. Build. Eng. 2019, 24, 100743. [Google Scholar] [CrossRef]

- Kumar, D.; Zou, P.X.W.; Memon, R.A.; Alam, M.D.M.; Sanjayan, J.G.; Kumar, S. Life-cycle cost analysis of building wall and insulation materials. J. Build. Phys. 2020, 43, 428–455. [Google Scholar] [CrossRef]

- Neya, I.; Yamegueu, D.; Coulibaly, Y.; Messan, A.; Sountong-Noma Ouedraogo, A.L. Impact of insulation and wall thickness in compressed earth buildings in hot and dry tropical regions. J. Build. Eng. 2021, 33, 101612. [Google Scholar] [CrossRef]

- Geng, Y.; Han, X.; Zhang, H.; Shi, L. Optimization and cost analysis of thickness of vacuum insulation panel for structural insulating panel buildings in cold climates. J. Build. Eng. 2021, 33, 101853. [Google Scholar] [CrossRef]

- Huang, H.; Zhou, Y.; Huang, R.; Wu, H.; Sun, Y.; Huang, G.; Xu, T. Optimum insulation thicknesses and energy conservation of building thermal insulation materials in Chinese zone of humid subtropical climate. Sustain. Cities Soc. 2020, 52, 101840. [Google Scholar] [CrossRef]

- Jie, P.; Zhang, F.; Fang, Z.; Wang, H.; Zhao, Y. Optimizing the insulation thickness of walls and roofs of existing buildings based on primary energy consumption, global cost and pollutant emissions. Energy 2018, 159, 1132–1147. [Google Scholar] [CrossRef]

- Paraschiv, L.S.; Acomi, N.; Serban, A.; Paraschiv, S. A web application for analysis of heat transfer through building walls and calculation of optimal insulation thickness. Energy Rep. 2020, 6, 343–353. [Google Scholar] [CrossRef]

- Hens, H.; Carmeliet, J. Performance Prediction for Masonry Walls with EIFS Using Calculation Procedures and Laboratory Testing. J. Therm. Environ. Bldg. Sci. 2002, 25, 2. [Google Scholar] [CrossRef]

- European Regulation n° 305/2011: Construction Product Regulation; European parliament: Bruxelles, Belgium, 2011.

- UNI/TR 11715 Code; Thermal Insulation Products for Buildings–Design and In-Situ Installation of External Thermal Insulation Composite Systems with Renders (ETICS). Italian National Unification Body (acronym UNI): Milan, Italy, 2018.

- EAD 040083; External Thermal Insulation Composite Systems (ETICS) with Renderings. European Organisation for Technical Approvals: Brussels, Belgium, 2019.

- Amaro, B.; de Brito, J.; Flores-Colen, I. Statistical survey of the pathology, diagnosis and rehabilitation of ETICS in walls. J. Civ. Eng. Manag. 2012, 20, 511–526. [Google Scholar] [CrossRef] [Green Version]

- Samuelson, I.; Jansson, A. Putsade Regelväggar. [ETICS on Framework Walls], SP Rapport 2009:16; SP Technical Research Institute of Sweden: Borås, Sweden, 2009. [Google Scholar]

- Lisø, K.R. Building Envelope Performance in Harsh Climates: Methods for Geographically Dependent Design. Ph.D. Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2006. [Google Scholar]

- Stazi, F.; Di Perna, C.; Munafò, P. Durability of 20-year-old external insulation and assessment of various types of retrofitting to meet new energy regulations. Energy Build. 2009, 41, 721–731. [Google Scholar] [CrossRef]

- Jelle, B.P. The Role of Accelerated Climate Ageing of Building Materials, Components and Structures in the Laboratory. In Proceedings of the 7th Nordic conference on Construction Economics and Organisation, Trondheim, Norway, 12–14 June 2013. [Google Scholar]

- Jelle, B.P. Accelerated climate ageing of building Materials, Components and Structures in the Laboratory. Mater. Sci. 2011, 47, 6475–6496. [Google Scholar] [CrossRef] [Green Version]

- Bochen, J. Durability assessment of durability materials exposed to atmosphere agents by testing in simulated environment. ACEE 2013, 6, 17–25. [Google Scholar]

- Bochen, J.; Gil, S. Study on the microstructure of thin-layer facade plasters of thermal insulating system during artificial weathering. Constr. Build. Mater. 2009, 23, 2559–2566. [Google Scholar] [CrossRef]

- Bochen, J. Properties of pore structure of thin-layer external plasters under ageing in simulated environment. Constr. Build. Mater. 2009, 23, 2958–2963. [Google Scholar] [CrossRef]

- Brandt, E. Building Materials and Components in Vertical Position: Exposure to Accelerated Climatic Strains; Nordest Espoo: Alborg, Finland, 2000. [Google Scholar]

- Daniotti, B.; Iacono, P. Evaluating the Service Life of External Walls: A Comparison between Long-Term and Short-Term Exposure. In Proceedings of the 10th International Conference on Durability of Building Materials and Components, Lyon, France, 17–20 April 2005. [Google Scholar]

- Daniotti, B.; Spagnolo, S.L.; Paolini, R. Climatic Data Analysis to Define Accelerated Ageing for Reference Service Life Evaluation. In Proceedings of the 11th International Conference on Durability of Building Materials and Components, Istanbul, Turkey, 11–14 May 2008. [Google Scholar]

- Daniotti, B.; Lupica Spagnolo, S.; Paolini, R. Procedures for Reference Service Life Assessment of Building Components: Advances in research. In Proceedings of the International Conference on Construction & Building Research, Madrid, Spain, 14–26 June 2009. [Google Scholar]

- ISO 15686-2Code; Building and Constructed Assets–Service Life Planning: Service Life Prediction Procedures. International Organization for Standardization (acronym ISO): Genève, Switzerland, 2001.

- ETAG004; Guidelines for European Technical Approval of External Thermal Insulation Composite Systems (ETICS) with Rendering. European Organisation for Technical Approvals: Brussels, Belgium, 2014.

- Daniotti, B.; Paolini, R.; Re Cecconi, F. Effects of Ageing and Moisture on Thermal Performance of ETICS Cladding. In Durability of Building Materials and Components, 3nd ed.; Building Pathology and Rehabilitation, de Freitas, V.P., Delgado, J.M.P.Q., Eds.; Springer: Berlin/Heidelberg, Germany, 2009; Volume 3, pp. 121–171. [Google Scholar]

- Parracha, J.L.; Borsoi, G.; Flores-Colen, I.; Veiga, R.; Nunes, L. Impact of natural and artificial aging on the properties of multilayer external wall thermal insulation systems. Constr. Build. Mater. 2022, 317, 125834. [Google Scholar] [CrossRef]

- Decreto interministeriale 26 giugno 2015—Applicazione Delle Metodologie di Calcolo Delle Prestazioni Energetiche e Definizione Delle Prescrizioni e dei Requisiti Minimi Degli Edifici. (In Italian). Available online: https://www.mise.gov.it/index.php/it/normativa/decreti-interministeriali/2032966-decreto-interministeriale-26-giugno-2015-applicazione-delle-metodologie-di-calcolo-delle-prestazioni-energetiche-e-definizione-delle-prescrizioni-e-dei-requisiti-minimi-degli-edifici (accessed on 2 January 2022).

- Landolfi, R.; Nicolella, M. Durability Assessment of ETICS: Comparative Evaluation of Different Insulating Materials. Sustainability 2022, 14, 980. [Google Scholar] [CrossRef]

- UNI EN 12667; Prestazione Termica dei Materiali e dei Prodotti per L’edilizia. Determinazione Della Resistenza Termica Con il Metodo della Piastra Calda con Anello di Guardia e con il Metodo del Termoflussimetro. Italian National Unification Body (acronym UNI): Milan, Italy, 2002.

- Glicksman, L.R.; Stewart, J. The Measurement of the Morphology of Closed Cell Foams Which Control the Overall Thermal Conductivity. In Proceedings of the Third Conference Insulation Materials: Testing and Applications, Quebec, QC, Canada, 15–17 May 1997. [Google Scholar]

- EN 13165; Thermal Insulation Products for Buildings, Factory Made Rigid Polyurethane Foam (PU) Products. Specification European Committee for Standardization (CEN): Bruxelles, Belgium, 2012.

- Albrecht, W. Change over Time in the thermal conductivity of ten-year-old PUR rigid foam boards with diffusion-open facings. Cell. Polym. 2004, 23, 161–172. [Google Scholar] [CrossRef]

- Stefani, A. Stabilità Nel Tempo Delle Prestazioni Isolanti; Poliuretano Luglio 2003; Associazione Nazionale Poliuretano Espanso rigido (ANPE): Vicenza, Italy, 2003; pp. 8–10. [Google Scholar]

- EN 13172; Thermal Insulation Products. Evaluation of Conformity. European Committee for Standardization (CEN): Bruxelles, Belgium, 2012.

- Decreto del Presidente della Repubblica 26 Agosto 1993, n. 412 Regolamento Recante Norme per la Progettazione, L’installazione, L’esercizio e la Manutenzione Degli Impianti Termici Degli Edifici ai Fini del Contenimento dei Consumi di Energia, in Attuazione Dell’art. 4, Comma 4, Della Legge 9 Gennaio 1991, n. 10. Available online: https://www.bosettiegatti.eu/info/norme/statali/1993_0412.htm (accessed on 2 January 2022). (In Italian).

- Prada, M.; Prada, I.A.; Cristea, M.; Popescu, D.E.; Bungău, C.; Aleya, L.; Bungău, C.C. New solutions to reduce greenhouse gas emissions through energy efficiency of buildings of special importance—Hospitals. Sci. Total Environ. 2020, 718, 137446. [Google Scholar] [CrossRef] [PubMed]

- Bungău, C.C.; Prada, I.F.; Prada, M.; Bungău, C. Design and Operation of Constructions: A Healthy Living Environment-Parametric Studies and New Solutions. Sustainability 2019, 11, 6824. [Google Scholar] [CrossRef] [Green Version]

| Insulating Panel 1 | Whole ETICS | ||||

|---|---|---|---|---|---|

| Insulating Materials | Commercial ETICS Name | s (mm) | λD (W/mK) | Thermal Transmittance (W/m2K) | Thermal Resistance (m2K/W) |

| Polyurethane | Termok8 Slim | 50 | 0.028 | 0.51 | 1.97 |

| Grey EPS | Termok8 Modulare Biostone | 60 | 0.031 | 0.47 | 2.12 |

| Cycle Typology | Cycle Number | Phase/Insertion in: | Phase Dt (h) | Cycle Dt (h) | T (°C) | RH (%) |

|---|---|---|---|---|---|---|

| Heat–Rain | 80 | Heater | 3 | 6 | 80 | 50 |

| Spryer | 1 | 15 ± 5 | 100 | |||

| Drainage | 2 | 15 ± 5 | 100–50 | |||

| Heat–Cold | 7 | Climatic chamber | 8 | 24 | 70 | 30 |

| Climatic chamber | 16 | −10 | 0 | |||

| Freeze and thaw | 15 | Water bath | 8 | 24 | 15 ± 5 | 100 |

| Freezer | 14 | −20 | 0 | |||

| Stove | 2 | 50 | 50 |

| Symbol | Thermal Characteristics | Whole ETICS within following Insulating Materials | Measurement Unit | |

|---|---|---|---|---|

| Polyurethane | EPS | |||

| λD | Declared thermal conductivity | 0.028 | 0.031 | W/mK |

| UC | Calculated thermal transmittance | 0.51 | 0.47 | W/m2K |

| RC | Calculated thermal resistance | 1.97 | 2.12 | m2K/W |

| λ0 | Measured thermal conductivity before ageing | 0.025 | 0.034 | W/mK |

| U0 | Measured thermal transmittance before ageing | 0.44 | 0.49 | W/m2K |

| R0 | Measured thermal resistance before ageing | 2.28 | 2.02 | m2K/W |

| λ1 | Measured thermal conductivity after ageing | 0.026 | 0.034 | W/mK |

| U1 | Measured thermal transmittance after ageing | 0.46 | 0.50 | W/m2K |

| R1 | Measured thermal resistance after ageing | 2.18 | 2.02 | m2K/W |

| Polyurethane | |||

|---|---|---|---|

| PALERMO | Declared | Measured t = 0 | Measured t = 1 |

| Thickness [m] | 0.04 | ||

| Density [kg/m3] | 35 | ||

| Specific Heat [J/kgK] | 1464 | ||

| Conductivity [W/mK] | 0.028 | 0.025 | 0.026 |

| Thermal transmittance of 35 cm vertical wall [W/m2K] | 0.383 | 0.359 | 0.367 |

| Thermal transmittance of 60 cm vertical wall [W/m2K] | 0.301 | 0.286 | 0.291 |

| Heating thermal load [kW] | 2.89 | 2.85 | 2.86 |

| Grey EPS | |||

|---|---|---|---|

| PALERMO | Declared | Measured t = 0 | Measured t = 1 |

| Thickness [m] | 0.04 | ||

| Density [kg/m3] | 10.35 | ||

| Specific Heat [J/kgK] | 1340 | ||

| Conductivity [W/mK] | 0.031 | 0.034 | 0.0341 |

| Thermal transmittance of a 35 cm vertical wall [W/m2K] | 0.404 | 0.424 | 0.424 |

| Thermal transmittance of a 60 cm vertical wall [W/m2K] | 0.314 | 0.325 | 0.326 |

| Heating thermal load [kW] | 2.92 | 2.95 | 2.95 |

| Polyurethane | |||

|---|---|---|---|

| NAPLES | Declared | Measured t = 0 | Measured t = 1 |

| Thickness [m] | 0.06 | ||

| Specific Heat [J/kgK] | 1464 | ||

| Density [kg/m3] | 35 | ||

| Conductivity [W/mK] | 0.028 | 0.025 | 0.026 |

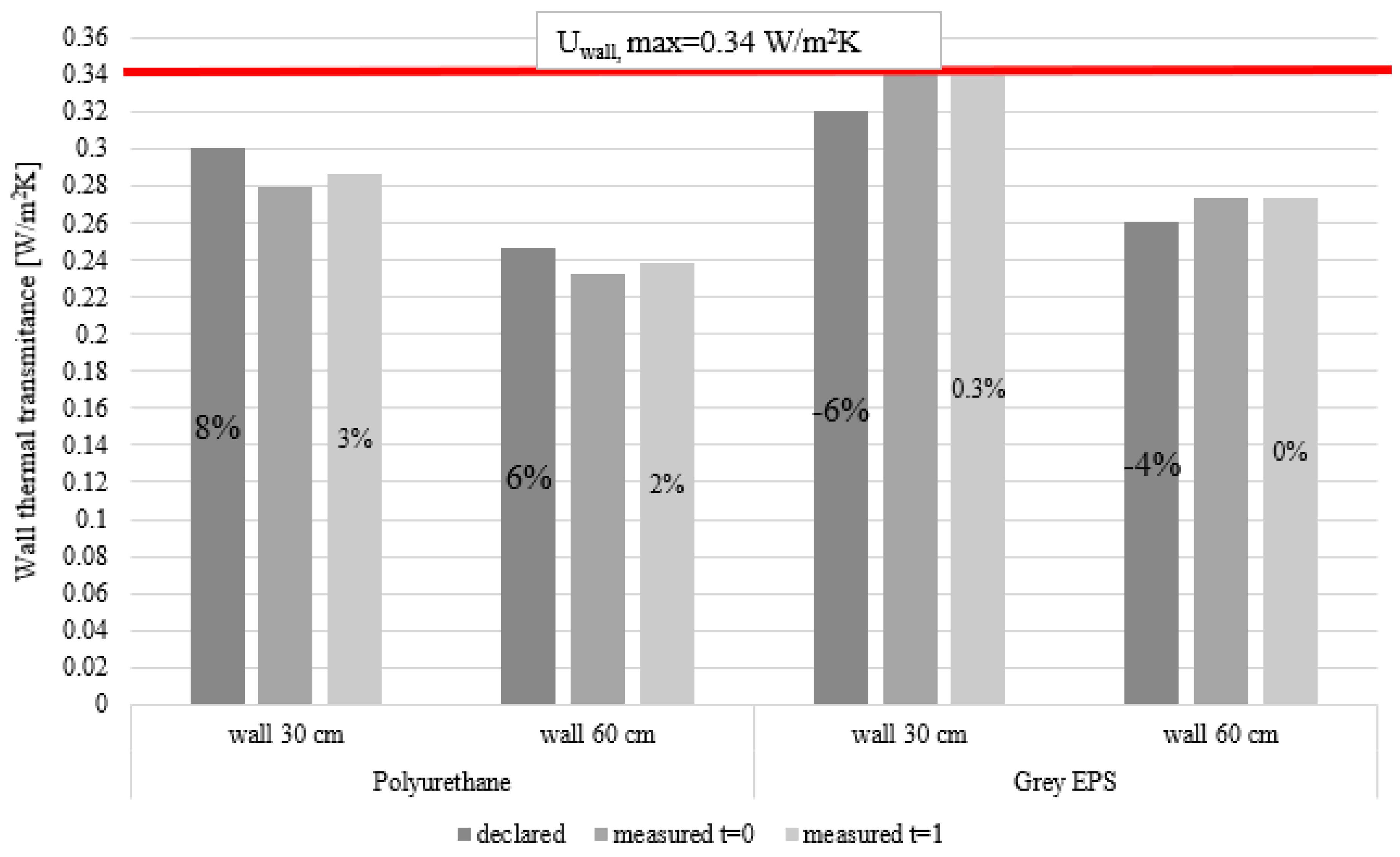

| Thermal transmittance of a 35 cm vertical wall [W/m2K] | 0.301 | 0.279 | 0.286 |

| Thermal transmittance of a 60 cm vertical wall [W/m2K] | 0.247 | 0.233 | 0.238 |

| Heating thermal load [kW] | 3.9 | 3.8 | 3.83 |

| Grey EPS | |||

|---|---|---|---|

| NAPLES | Declared | Measured t = 0 | Measured t = 1 |

| Thickness [m] | 0.06 | ||

| Specific Heat [J/kgK] | 1340 | ||

| Density [kg/m3] | 10.35 | ||

| Conductivity [W/mK] | 0.031 | 0.034 | 0.0341 |

| Thermal transmittance of a 35 cm vertical wall [W/m2K] | 0.32 | 0.34 | 0.341 |

| Thermal transmittance of a 60 cm vertical wall [W/m2K] | 0.261 | 0.273 | 0.273 |

| Heating thermal load [kW] | 3.9 | 4.0 | 4.12 |

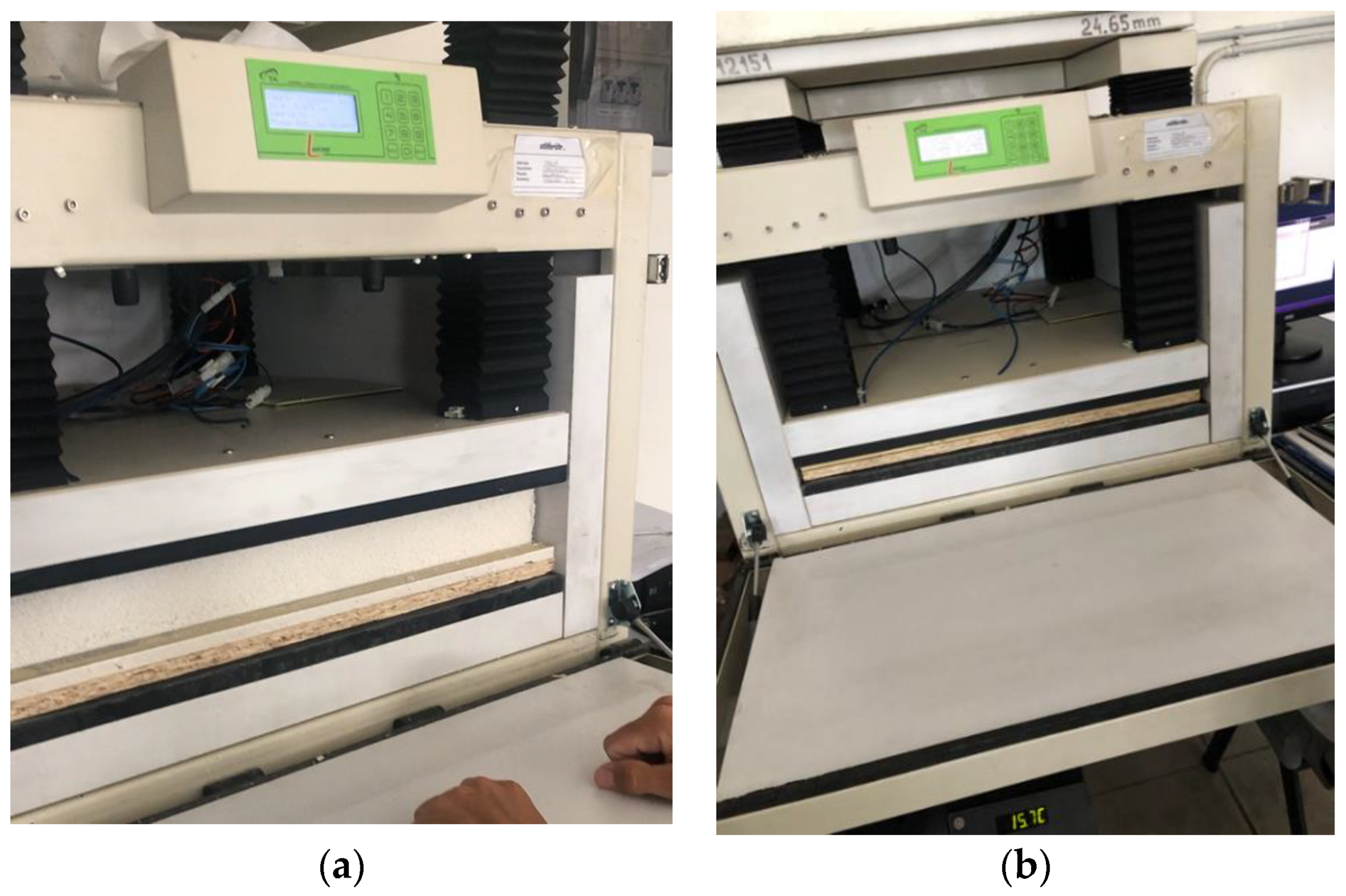

| Polyurethane | |||

|---|---|---|---|

| TURIN | Declared | Measured t = 0 | Measured t = 1 |

| Thickness [m] | 0.1 | ||

| Specific Heat [J/kgK] | 1464 | ||

| Density [kg/m3] | 35 | ||

| Conductivity [W/mK] | 0.028 | 0.025 | 0.026 |

| Thermal transmittance of a 35 cm vertical wall [W/m2K] | 0.210 | 0.193 | 0.199 |

| Thermal transmittance of a 60 cm vertical wall [W/m2K] | 0.189 | 0.170 | 0.174 |

| Heating thermal load [kW] | 5.36 | 5.30 | 5.32 |

| Grey EPS | |||

|---|---|---|---|

| TURIN | Declared | Measured t = 0 | Measured t = 1 |

| Thickness [m] | 0.1 | ||

| Specific Heat [J/kgK] | 1340 | ||

| Density [kg/m3] | 10.35 | ||

| Conductivity [W/mK] | 0.031 | 0.0340 | 0.0341 |

| Thermal transmittance of a 35 cm vertical wall [W/m2K] | 0.227 | 0.242 | 0.243 |

| Thermal transmittance of a 60 cm vertical wall [W/m2K] | 0.195 | 0.207 | 0.207 |

| Heating thermal load [kW] | 5.77 | 5.48 | 5.48 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

D’Agostino, D.; Landolfi, R.; Nicolella, M.; Minichiello, F. Experimental Study on the Performance Decay of Thermal Insulation and Related Influence on Heating Energy Consumption in Buildings. Sustainability 2022, 14, 2947. https://doi.org/10.3390/su14052947

D’Agostino D, Landolfi R, Nicolella M, Minichiello F. Experimental Study on the Performance Decay of Thermal Insulation and Related Influence on Heating Energy Consumption in Buildings. Sustainability. 2022; 14(5):2947. https://doi.org/10.3390/su14052947

Chicago/Turabian StyleD’Agostino, Diana, Roberto Landolfi, Maurizio Nicolella, and Francesco Minichiello. 2022. "Experimental Study on the Performance Decay of Thermal Insulation and Related Influence on Heating Energy Consumption in Buildings" Sustainability 14, no. 5: 2947. https://doi.org/10.3390/su14052947

APA StyleD’Agostino, D., Landolfi, R., Nicolella, M., & Minichiello, F. (2022). Experimental Study on the Performance Decay of Thermal Insulation and Related Influence on Heating Energy Consumption in Buildings. Sustainability, 14(5), 2947. https://doi.org/10.3390/su14052947