1. Introduction

Aluminum alloy plate has the advantages of having a light weight, high strength, good ductility, low low-temperature brittle fracture sensitivity, corrosion resistance, and being easy to form [

1,

2]. These characteristics mean that it is widely used in the field of engineering structures, and can not only be used as a decoration material in concrete surfaces, doors, windows and curtain walls [

3] but also as a new material to support some models for construction projects [

4], reinforcement materials for concrete structures [

5,

6], and structural materials for offshore platforms [

7]. However, whether it is used as a structural material or a building decoration material, aluminum alloy panels often need to be effectively composited or bonded with cement-based materials such as mortar and concrete in some way in order to be applied in the field of engineering structures [

8].

Because the main element, Al, of aluminum alloy plate is active, it is easy for it to chemically react with the main components of cement-based materials such as hydroxides and silicates, and other strong alkaline substances, resulting in some quality problems such as honeycombs, pockmarks, pits and many bubbles on the surface of the mortar or concrete. In this regard, many scientific and technological workers and engineering technicians have also conducted many experimental studies from various aspects over these years. However, these studies mainly focused on the development of various formwork oils and mold-release agents on the surface of aluminum alloy to improve the surface quality of concrete, part of the research on the interface bonding performance of aluminum alloy plates and concrete using epoxy resin as an adhesive has not yet formed a systematic theory [

9,

10]. There are rare reports on the interface bonding performance of cement-based materials and aluminum alloy plates which have been directly bonded [

11].

As such, in this paper, experimental studies on the interface reaction, corrosion, carbonization, and deformation of the composites of aluminum alloy plates and cement-based materials were carried out in order to provide a reference for further research on the direct composite of aluminum alloy plate and concrete in the later period, and to provide a test basis for the improvement of the collaborative workability of aluminum alloy plate and cement-based materials.

2. Raw Materials and Test Methods

2.1. Raw Materials

The sleeve grouting material was made with a water-to-material ratio of 0.125 and a 28 d compressive strength of 80 MPa.

The raw materials for the concrete were BBMG cement PO 42.5, S95-grade slag powder, grade-II fly ash, fineness modulus 2.5 river sand, and 5 mm~31.5 mm continuous graded gravel. The concrete mixes are presented in

Table 1.

The alloy plates for testing were 1061 plate, the chemical composition of which was simple aluminum; 6061 plate, the chemical composition of which was aluminum-magnesium-silicon alloy; AZ31B plate, the chemical composition of which was magnesium-aluminum-zinc alloy; and 6061 plate with fluorocarbon paint sprayed on the surface, which was abbreviated as fluorocarbon aluminum alloy plate; the surfaces of the plates were all cleaned with acetone, and the surfaces had no visible defects such as cracks, pores, blisters, scratches, or dents, etc.

2.2. Test Method

The apparent state and performance of the grouting before and after solidification were investigated after grouting was added into the sleeve, which was made of different alloy plates with a surface thickness of about 3 mm.

The concrete was divided into benchmark concrete (poured with wooden formwork) and comparative concrete covered with fluorocarbon aluminum alloy plate (the fluorocarbon aluminum alloy plate was used directly as the formwork). The poured concrete entity was watered and cured on time, once a day, for 28 days. Among them, the corrosion test of the fluorocarbon aluminum alloy plate by concrete refers to “General principles of corrosion testing of metals and alloys” (GB/T 19291-2003) and “Outdoor exposure corrosion test of metals and alloys” (GB/T 19747-2005), including appearance changes and the weight loss rate to characterize the corrosion degree with different ages of concrete (28 d, 60 d, 90 d, 180 d, 360 d) on the fluorocarbon aluminum alloy plate.

The full-size test to study the effect of fluorocarbon aluminum alloy plate on concrete carbonization—which mainly simulates a concrete entity with a size of 0.40 m × 0.40 m × 0.80 m with the test environment—was selected as Beijing Outdoor, and the relevant parameters of the concrete and fluorocarbon aluminum alloy plate with two strength levels of C30 and C70 were measured for different ages (28 d, 90 d, 180 d, and 360 d). The depth of the concrete carbonization, the strength of the core samples, and the value of the cracks at the joint between the upper end of the fluorocarbon aluminum alloy plate and the concrete entity were measured.

3. Test Results and Analysis

3.1. Influence of the Alloy Plate on the Apparent State of the Sleeve Grouting Material

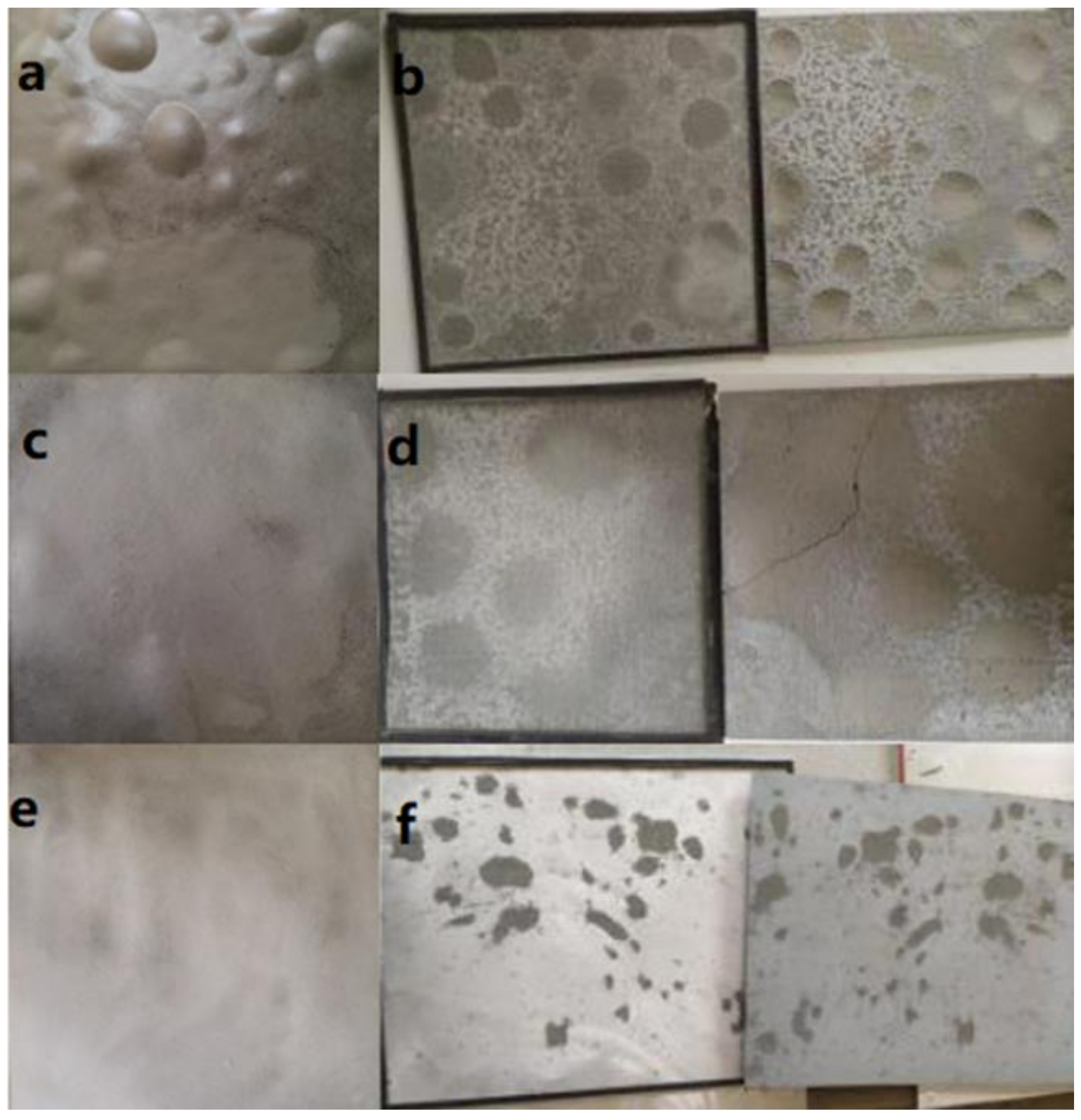

Because the aluminum content of the alloy plates is various, their chemical reaction is different when it comes into contact with the alkaline substance. We selected sleeve grouting materials with good fluidity, early strength and high strength, in order to compound them with different kinds of alloy plates and then study the influence of the apparent state of the alloy plate on the sleeve grouting material (

Figure 1).

The grouting slurry is a composite, strongly alkaline substance, and when it comes into contact with the aluminum alloy plate, a chemical reaction is inevitable. As shown in

Figure 1, the 1061 plate reacted violently with the slurry, and large and small pores were quickly visible on the surface of the slurry (

Figure 1a); the reaction between the 6061 plate and the slurry was less than that of the 1061 plate. About 5 minutes after the grout compounded, a small amount of pore bubbles floated to the surface of the slurry (

Figure 1c); whether it was the 1061 or 6061 plate, the grout could be peeled off directly after compounding for one day, as shown in

Figure 1b,d. There are a lot of tortuous gas marks (the path generated by the floating of CO

2, H

2 and other gases) and white floating ash (Al(OH)

3, CaCO

3, etc.) at the interface about 1 mm~2 mm between the grout and the alloy plate, and a large amount of grout adheres to the alloy plate. After the AZ31B plate with an aluminum content of only about 3 wt% was compounded with grout, as shown in

Figure 1e, there was no obvious reaction phenomenon during the solidification of the grout; the grout could be peeled off directly after compounding for one day, and a small amount of floating ash was attached to the surface of the alloy plate (

Figure 1f).

After we brushed the mold-release agent onto the alloy plate, the grout was compounded. No obvious reaction could be seen during the solidification of the grout. The grout could be peeled off directly after compounding for one day. A small amount of thin laitance adhered to the 1061 plate, and a very small amount of dot-shaped grouting material adhered to the 6061 plate; the AZ31B plate was relatively clean, and almost no grouting material adhered to it. From the test results, AZ31B plate was suitable for use as a building template, and the 1061 plate and 6061 plate have a certain adhesiveness with the grouting material after interface treatment, which could be used for the surface decoration of cement-based materials.

Because fluorocarbon coatings have excellent weather resistance, heat resistance, low-temperature resistance, and chemical resistance, aluminum alloy surface sprayed with fluorocarbon paint has been widely used in aluminum curtain walls, door and window components, and other fields in recent years [

12]. In this paper, fluorocarbon coatings were applied to the surface of 6061 plate in order to carry out the corrosion testing of concrete on fluorocarbon aluminum alloy plates, the influence of fluorocarbon aluminum alloy plates on the carbonization and curing performance of concrete, and the deformation between fluorocarbon aluminum alloy plates and concrete.

3.2. Corrosion of Fluorocarbon Aluminum Alloy Plate by Concrete

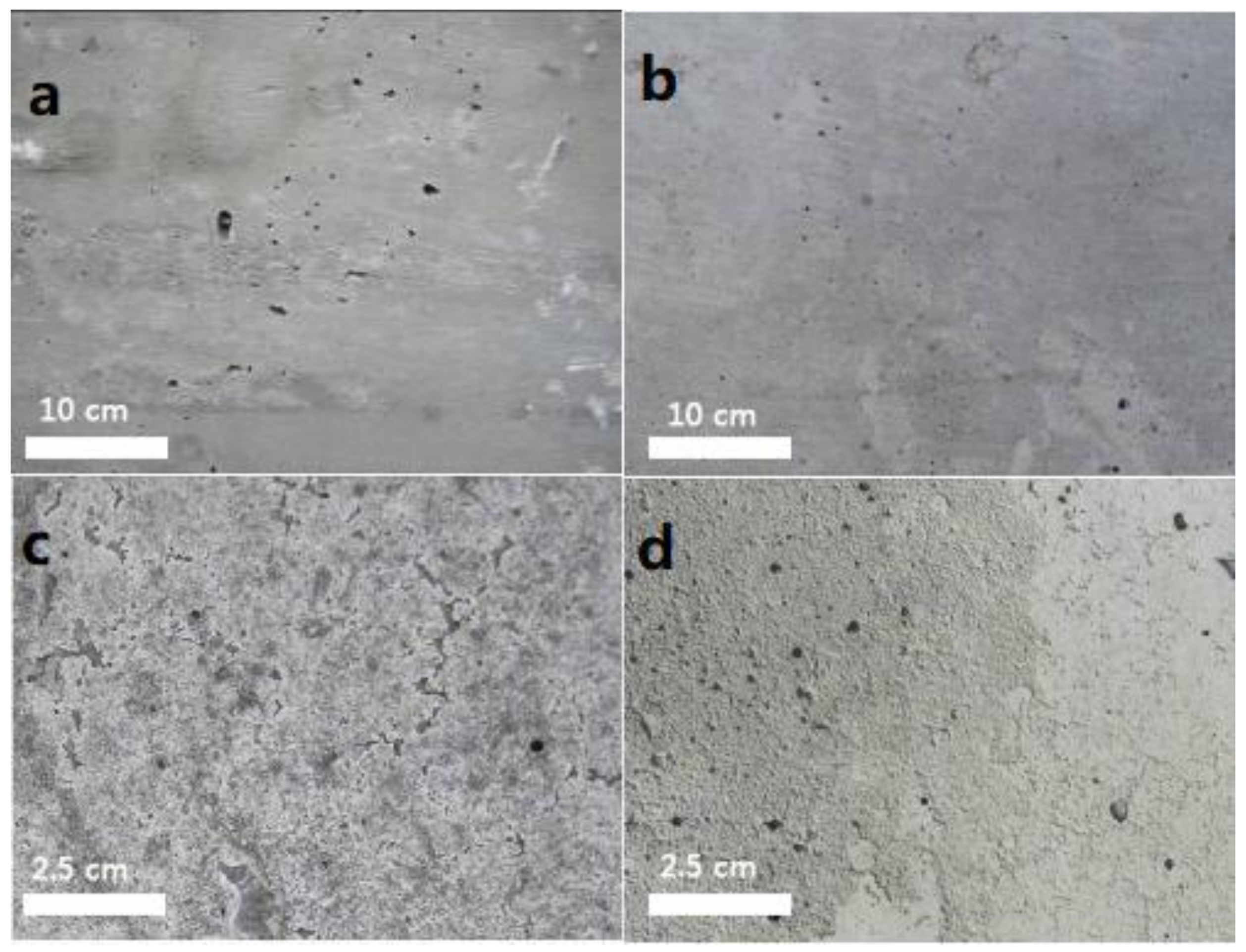

As shown in

Figure 2, after removing the mold, it was found that the surface of the benchmark concrete was relatively smooth, while the surface of the concrete covered with fluorocarbon aluminum alloy plate was not very smooth. It could be seen that there were complex physical and chemical reactions which worked together between the concrete surface and the fluorocarbon aluminum alloy plate. There was a certain bite force and friction force due to the combined reaction, such that the fluorocarbon aluminum alloy plate was not easily separated from the surface of the concrete. Because C70 concrete has a higher strength and a tighter bond with the fluorocarbon aluminum alloy plate, the surface of the C70 concrete covering the fluorocarbon aluminum alloy plate was relatively rougher.

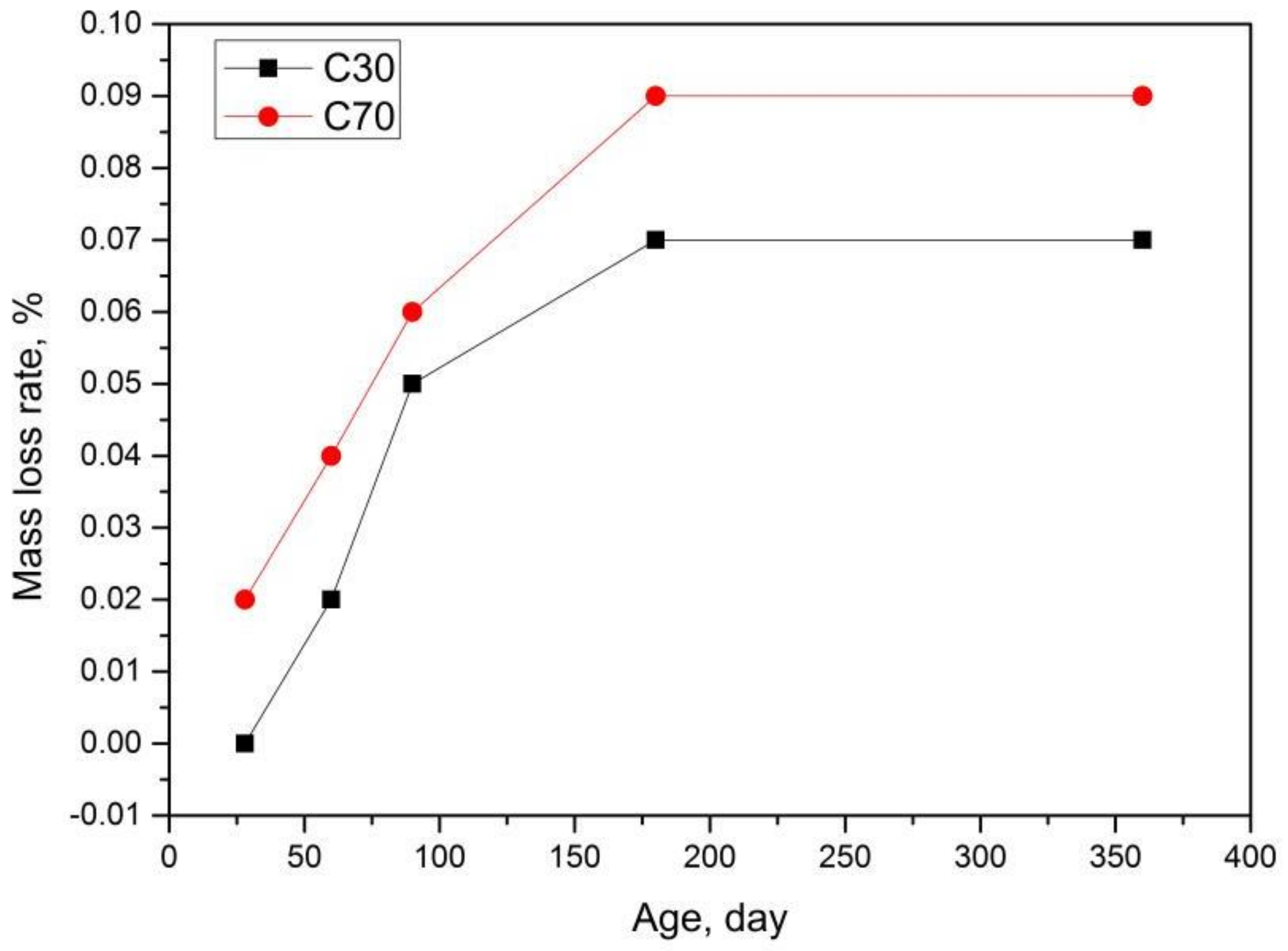

Because the alkaline environment of concrete will corrode the fluorocarbon aluminum alloy plate, the corrosion degree of the fluorocarbon aluminum alloy plate by concrete with different ages (28 d, 60 d, 90 d, 180 d, 360 d) was studied.

During the test period of one year, the appearance of the fluorocarbon aluminum alloy plate did not change significantly. It can be seen from

Figure 3 that the fluorocarbon aluminum alloy plate covering C30 concrete had no mass loss at 28 days of age, while the mass-loss rate of with C70 concrete was 0.02%. From 28 days of age to 180 days of age, the mass-loss rate gradually increased. The mass-loss rate of fluorocarbon aluminum alloy plate covered with C30 concrete from 180 d to 360 d age was 0.07%, while the mass-loss rate with C70 concrete was 0.09%. Overall, the corrosion of fluorocarbon paint aluminum alloy panels by concrete was not obvious. These reasons was that the inert layer produced by the fluorocarbon coating on the interface between the aluminum alloy plate and the concrete plays a role in isolating the chemical reaction between the active metal aluminum and the alkaline substance. However, because C70 concrete uses more cementitious materials, the content of alkaline substances in the hydration products was higher, and the corrosion to the fluorocarbon aluminum alloy plate was slightly heavier.

3.3. Influence on the Compressive Strength of Concrete by Fluorocarbon Aluminum Alloy Plate

The compressive strength of the benchmark concrete and the concrete core sample covered with aluminum alloy plate is shown in

Table 2.

Under the condition of the same age of the concrete core sample, the compressive strength of the concrete covered with the fluorocarbon aluminum alloy plate was greater than that of the benchmark concrete, which can be seen from

Table 2. The reason is that the concrete surface covered with aluminum alloy plates can effectively block the migration and diffusion of the internal moisture of the concrete to the external environment, forming an independent concrete hydration space that is not affected by the outside world, ensuring the water required for the cement hydration process, and improving the hydration degree and structural compactness of hardened concrete, thereby improving the compressive strength of the concrete core sample. Although the benchmark concrete was watered on time every day, there would still be water migration between the interior of the concrete and the surrounding environment; that is, the amount of water loss may sometimes be greater than that of water replenishment, resulting in a lower degree of cement hydration, which in turn leads to the relatively low compressive strength of the concrete core sample. It can be seen that, compared with the benchmark concrete, the concrete covered with the fluorocarbon aluminum alloy plate has a hydration space that is not affected by the outside world, its compressive strength is further improved, and it has obvious technical advantages in terms of maintenance.

3.4. Influence on the Carbonization Performance of Concrete by Fluorocarbon Aluminum Alloy Plate

Table 3 shows the carbonization depth of benchmark concrete and concrete covered with fluorocarbon aluminum alloy plates with different ages.

It can be seen from

Table 3 that, as the age increases, the carbonization depth of the C30 benchmark concrete column gradually increases, while that of the C70 benchmark concrete column gradually increases up to 0.5 mm; the phenomenon of the carbonization of concrete covered with fluorocarbon aluminum alloy plate is not seen. As such, the fluorocarbon aluminum alloy plate used for concrete surface decoration can improve the anti-carbonization performance of concrete.

For the benchmark concrete, continuous watering and curing for 28 days can ensure that the surface of the concrete is wet and the cement hydration is stable, such that no carbonization is seen at the age of 28 days. If watering and curing is stopped after 28 days of age, part of the moisture inside the concrete will migrate to the dry environment, the cement hydration process will also slow down, and the concrete will be carbonized. As the age increases, the carbon dioxide permeability coefficient gradually decreases as the depth increases. The fluorocarbon aluminum alloy plate covering the surface of the concrete occludes the surface of the concrete tightly, which can effectively block the evaporation and diffusion of water inside the concrete, as well as the infiltration of carbon dioxide from the outside, such that no carbonization is seen.

The rules in the carbonization depth of C70 concrete and C30 concrete are inconsistent, because C70 concrete uses more cementitious materials, and the content of alkaline substances in the hydration products is higher, which improves the ability of the concrete to resist carbonization, and if the hardened concrete has a higher strength and more compactness, then it can greatly reduce the diffusion rate of carbon dioxide in the concrete. Therefore, the higher the concrete’s strength is, the stronger its anti-carbonization performance.

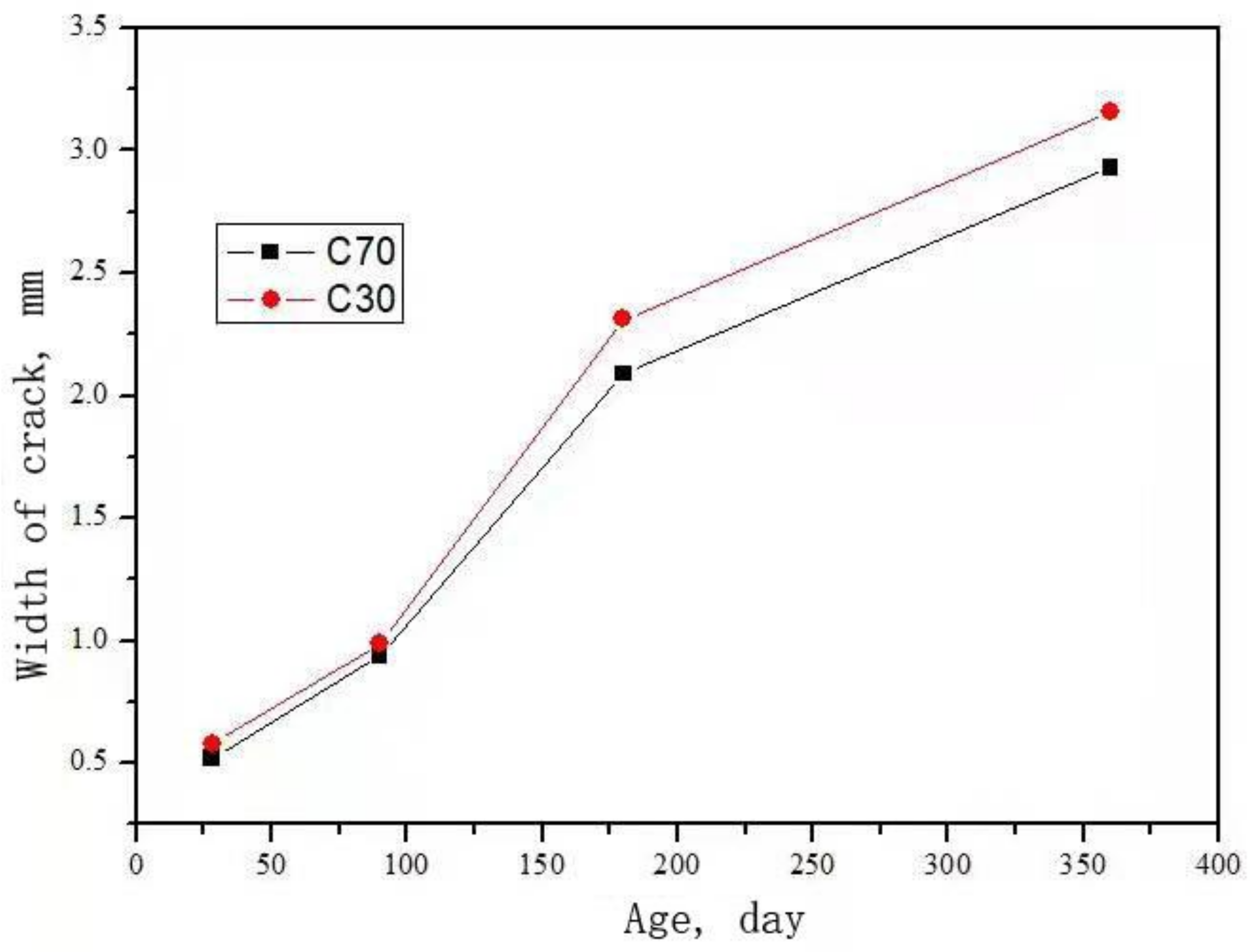

3.5. Deformation Analysis between Fluorocarbon Aluminum Alloy Plate and Concrete

Due to dry shrinkage and thermal expansion and contraction, the relative deformation between the fluorocarbon aluminum alloy plate and the concrete is inevitable. When the stress generated by the deformation is greater than the deformation bearing capacity of the joint between the two interfaces, a gap appears at the joint between the fluorocarbon aluminum alloy plate and the upper end of the concrete. The results of the deformation test at the joint between the upper end of the fluorocarbon aluminum alloy plate and the concrete at various ages are shown in

Figure 4 and

Table 4.

According to

Figure 4 and

Table 4, the deformation values of the joint between the fluorocarbon aluminum alloy plate and the C30 and C70 concrete at the ages of 28 days to 90 days increased by 70.7% and 70.9%, respectively, and the growth rates of the two were similar. From 90 to 180 days of age, the deformation values of the joint between the fluorocarbon aluminum alloy plate and the C30 and C70 concrete top end increased by 133.3% and 122.3%, respectively. The deformation values of the joint between the alloy plate and the upper end of the C70 concrete increased greatly; the deformation value of the joint between the fluorocarbon aluminum alloy plate and the upper end of the C30 and C70 concrete from 180 days to 360 days increased by 32.5% and 40.2%, respectively.

The deformation value of the joint between the fluorocarbon aluminum alloy plate and the upper end of the C70 concrete was slightly smaller than that of the same age of the C30 concrete. This is due to the higher strength of the concrete, and the bond being tighter. The reasons for the increase in the deformation value of the joint between the fluorocarbon aluminum alloy plate and the upper end of the concrete is the difference in the mix ratio and age of the concrete, and the change in temperature [

13,

14].

According to the linear expansion coefficient adopted in Table 5.2.11 of the “Technical Specification for Daylighting Roof and Metal Roofing” (JGJ 255-2012), the linear expansion coefficient of fluorocarbon aluminum alloy plate is about twice that of concrete, as shown in

Table 5; when the environmental temperature changes greatly, there is a large relative deformation difference between the two. The concrete pouring time for the test was in early May, and the maximum outdoor temperature was about 25 °C after 90 days, in early August, and the maximum outdoor temperature was about 35 °C; the age of 180 days was in early November, and the maximum outdoor temperature was about 15 °C.

From May to August, the deformation value between the fluorocarbon aluminum alloy plate and the concrete column gradually increased due to the gradual increase in the temperature. When the temperature reached its highest in August and September, the deformation value increased significantly; after November, the temperature began to drop, and the corresponding increase in the deformation of the fluorocarbon aluminum alloy plate and concrete column decreased, but the cumulative deformation value continued to increase.

Therefore, under the conditions of large changes in temperature and no external constraints, the deformations of the concrete and aluminum alloy plates will be significantly different due to their different thermal expansion coefficients. The specific manifestation is that the cumulative deformation of the joints continues to increase, and the bonding force between the aluminum alloy plate decoration material and the concrete is reduced, resulting in a gap, or even the plate falling off. As such, when aluminum alloy plates are used to decorate concrete in areas with higher temperatures, specific technical measures should be used to fix the aluminum alloy plate by means of adhesion and anchoring.

4. Engineering Demonstration

Because 1061 plate has good corrosion resistance and thermal conductivity, can withstand bending, has a surface similar to the back of ceramic veneer aluminum honeycomb composite plate, can be coated with water-based acrylic polymer emulsion tile glue, can be compounded directly, and can be used with bonded mortar for floor construction, some demonstrations have been successfully carried out in the renovation project, such as a hospital in Zhangjiakou and a laboratory in a Beijing enterprise.

Due to 6061 plate having the advantages of corrosion resistance, high toughness, a lack of deformation after processing, easy color film, and good oxidation resistance, etc., fluorocarbon paint can be sprayed onto the surface of 6061 plate or used as ceramic veneer for an aluminum honeycomb composite surface, and can also be directly compounded with mortar or concrete for wall decoration.

There is a scientific research demonstration project in Yangquan City with the fluorocarbon aluminum alloy plate bolted to the base wall, used as a decorative panel, with cement-based thermal insulation mortar poured between the decorative panel and the base wall to form a thermal insulation decorative point hanging system, overcoming some of the poor adaptability problems of external walls which use the existing technology to glue anchor insulation and a decoration-integrated plate system; the effect of this kind of practical engineering application is very good.

5. Conclusions

(1) Different aluminum contents in alloy plates have different effects on the apparent state of cement-based materials.

(2) Concrete has a bite effect on the fluorocarbon paint-coated aluminum alloy plate, but the corrosion of the fluorocarbon aluminum alloy plate is not obvious.

(3) Compared with the benchmark concrete, the concrete covered with aluminum alloy panels has a hydration space that is not affected by the outside world, its compressive strength and carbonization resistance were further improved, and it has obvious technical advantages in terms of curing.

(4) When aluminum alloy plates are used for surface decoration in areas with higher temperatures, specific technical measures should be taken to control the temperature deformation value between the concrete and the aluminum alloy plates.

Author Contributions

Conceptualization, L.P., D.Y., J.Z., Y.X., M.A. and Y.L.; methodology, L.P., D.Y., J.Z., Y.X., M.A. and Y.L.; software, L.P., D.Y., J.Z., Y.X., M.A. and Y.L.; validation, L.P., D.Y., J.Z., Y.X., M.A. and Y.L.; formal analysis, L.P., D.Y., J.Z., Y.X., M.A. and Y.L.; investigation, L.P., D.Y., J.Z., Y.X., M.A. and Y.L.; resources, L.P., D.Y., J.Z., Y.X., M.A. and Y.L.; data curation, L.P., D.Y., J.Z., Y.X., M.A. and Y.L.; writing—original draft preparation, L.P., D.Y. and Y.L.; writing—review and editing, J.Z., Y.X. and M.A.; visualization, L.P., D.Y., J.Z., Y.X., M.A. and Y.L.; supervision, L.P., D.Y., J.Z., Y.X., M.A. and Y.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by fund project of China Academy of Building Sciences Co., Ltd., grant NO.20190106330730003, the National key R&D plan, grant NO.2016YFC0700905, and Henan Zhumadian Industrial Innovation and Development Research Project, grant NO.18012025.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data generated or analyzed during this study are included in this article.

Acknowledgments

The authors wish to thank the scientific research fund project of China Academy of Building Sciences Co., Ltd., for supporting the research in this paper through grant NO.20190106330730003, the National key R&D plan for supporting the research in the paper through grant NO.2016YFC0700905, and Henan Zhumadian Industrial Innovation and Development Research Project for supporting the research in the paper through grant NO. 18012025.

Conflicts of Interest

The authors declare that they have no conflict of interest.

References

- Kaddour, S.; Aour, B.; Bennouna, M.S.; Talha, A.; Bouiadjra, B.B. Effect of corrosion on the quality of repair of the aluminum alloy A5083 H11 by bonded composites. Frat. Integrita Strutt. 2020, 53, 51–65. [Google Scholar] [CrossRef]

- Jiang, D.; Huang, H.; Liu, G.; Zhang, M. Study on bond slip performance of aluminum alloy- concrete interface based on double shear test. Eng. Mech. 2020, S1, 287–295. [Google Scholar]

- Zhang, R.; Qiu, R.; Xu, C. Analysis of advantages and disadvantages of aluminum alloy formwork. China Constr. Met. Struct. 2013, 14, 46–47. [Google Scholar]

- Wang, S. Application of aluminum alloy formwork construction technology in super high-rise complexes. Constr. Technol. 2015, 2, 88–92. [Google Scholar]

- Chang, H.; Zhou, W. Test on the bonding performance of the interface between the aluminum alloy plate and concrete with inorganic adhesive. J. Harbin Inst. Technol. 2019, 6, 58–63. [Google Scholar]

- Yang, L.; Deng, Z.; Yang, H. Bonding properties of aluminum alloy plate and concrete. Chin. J. Civ. Environ. Eng. 2019, 3, 111–119. [Google Scholar]

- Zhang, J.; Liu, F.; Liu, K. The seismic analysis of novel aluminum offshore platform. Struct. Eng. 2018, 34, 37–41. [Google Scholar]

- Liu, C.; Fang, D.; Zhao, L. Reflection on earthquake damage of buildings in 2015 Nepal earthquake and seismic measures for post-earthquake reconstruction. Structures 2021, 30, 647–658. [Google Scholar] [CrossRef]

- Tailhan, J.L.; Rossi, P.; Boulay, C. Tensile and bending behaviour of a strain hardening cement-based composite: Experimental and numerical analysis. Cem. Concr. Compos. 2012, 34, 166–171. [Google Scholar] [CrossRef]

- Boshoff, W.P.; van Zijl, G.P.A.G. A computational model for strain-hardening fibre-reinforced cement-based composites. J. South Afr. Inst. Civ. Eng. 2007, 49, 24–31. [Google Scholar]

- Han, T.S.; Feenstra, P.H.; Billington, S.L. Simulation of highly ductile fiber-reinforced cement-based composite components under cyclic loading. Struct. J. 2003, 100, 749–757. [Google Scholar]

- Gong, Y.; Tao, Y. Technical progress and application prospects of fluorocarbon powder coatings for architectural aluminum profiles. Coat. Ind. 2017, 47, 63–68. [Google Scholar]

- Davis Raymond, E. A summary of the results of investigations having to do with volumetric changes in cements, mortars and concretes due to causes other than stress. ACI J. 1930, 26, 407. [Google Scholar]

- Yao, W.; Zheng, X. Influence of the mix ratio parameters on the thermal expansion coefficient of concrete. J. Tongji Univ. 2007, 35, 77–81. [Google Scholar]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).