Fault Detection of Wind Turbine Blades Using Multi-Channel CNN

Abstract

:1. Introduction

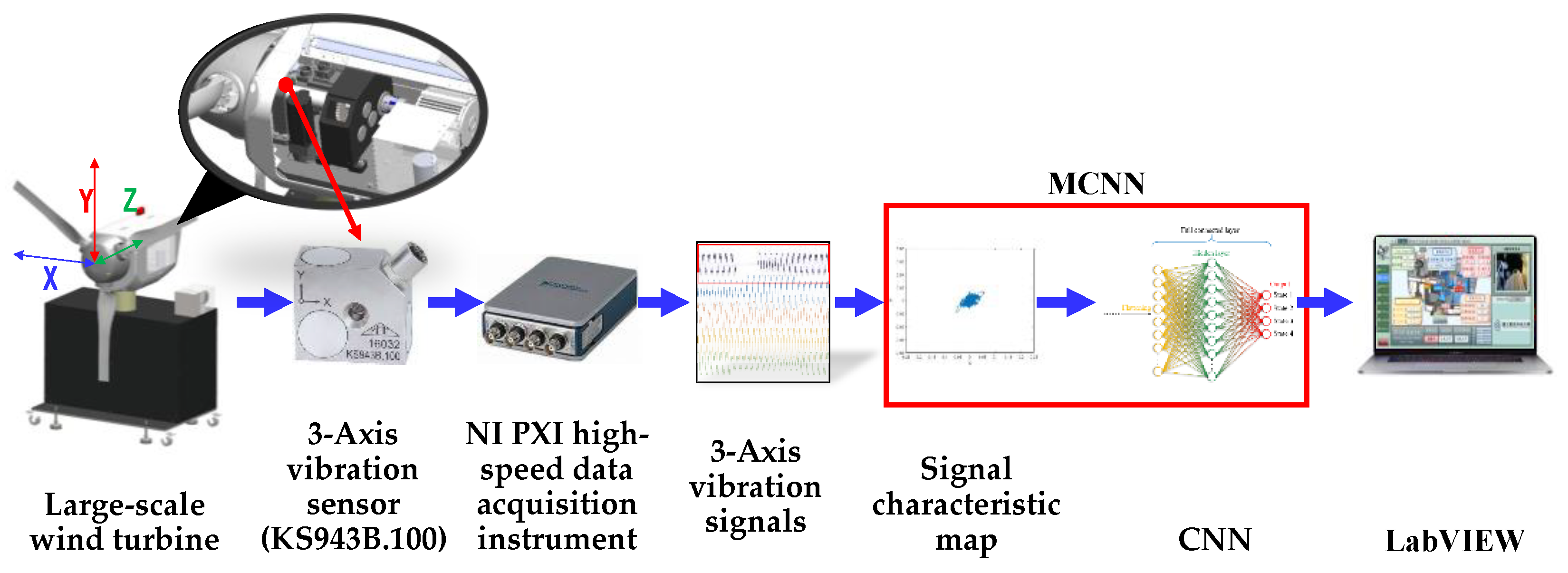

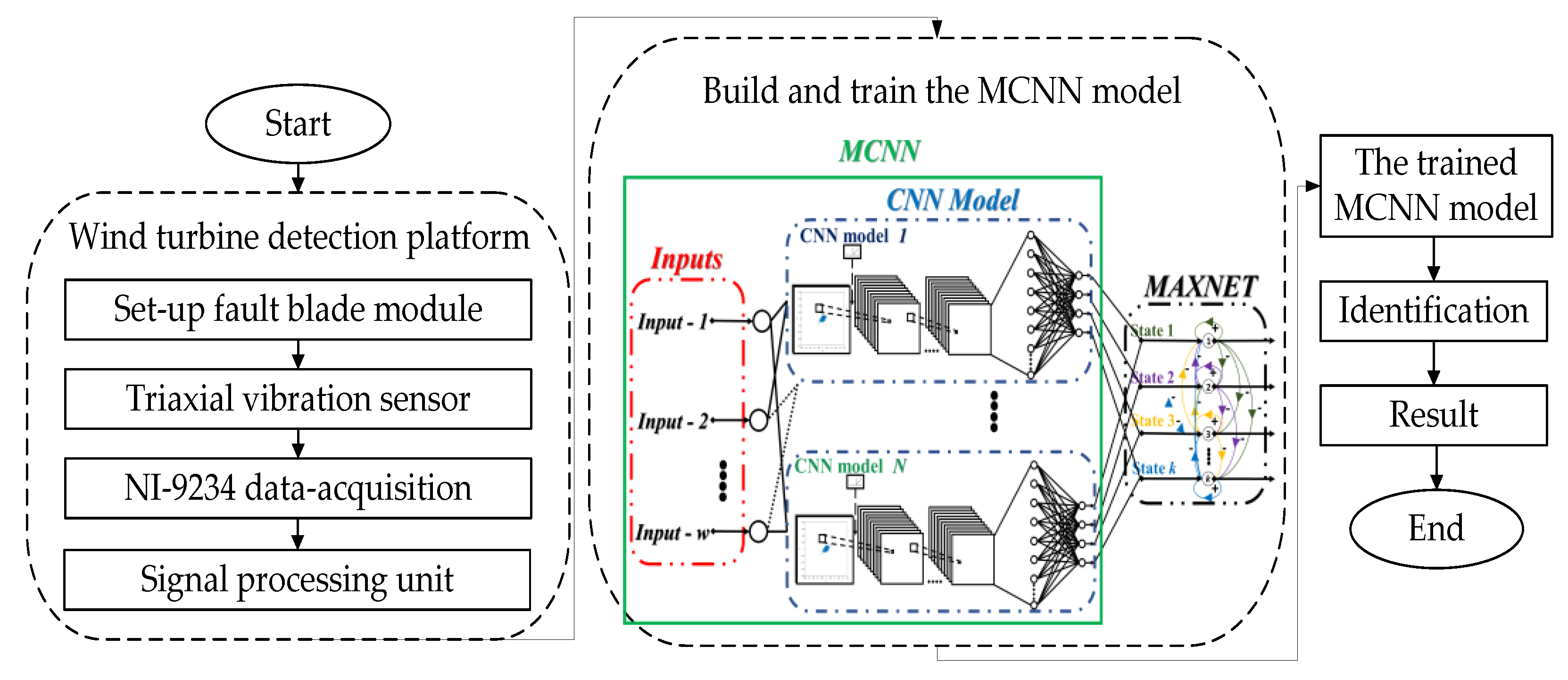

2. System Architecture

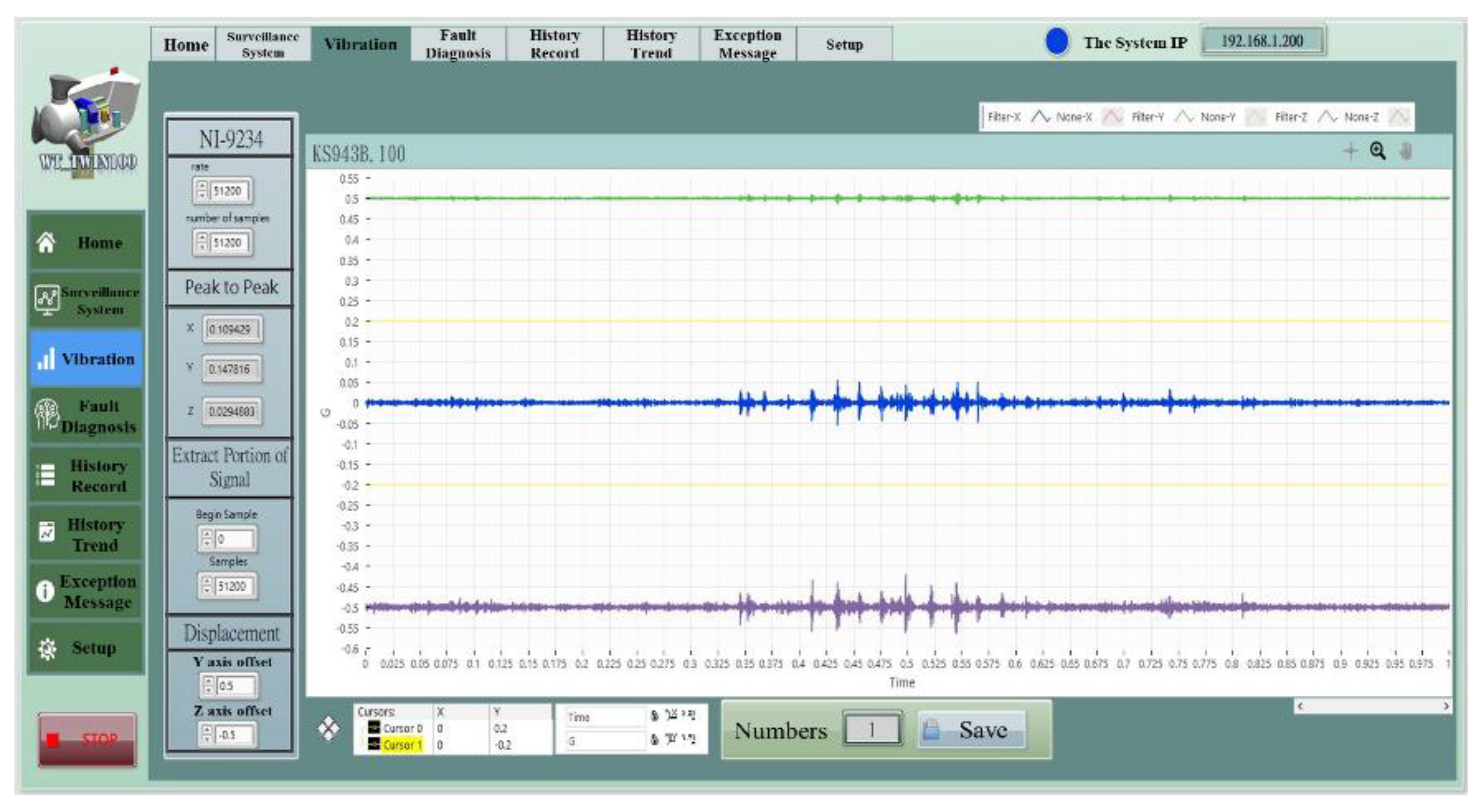

2.1. Capture of Wind Turbine Blade Fault Signals

2.2. Wind Turbine Blade Fault Modeling

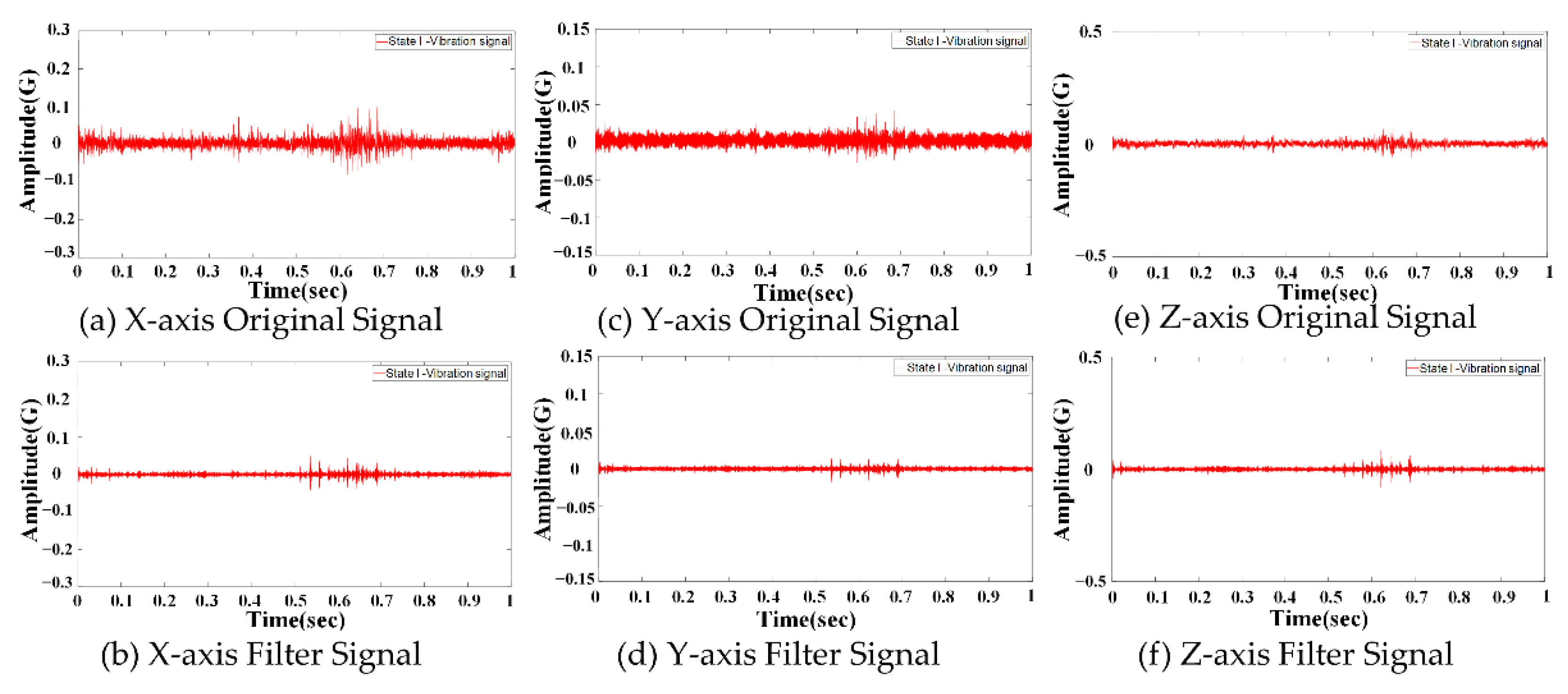

2.2.1. Normal Wind Turbine Blades (State 1)

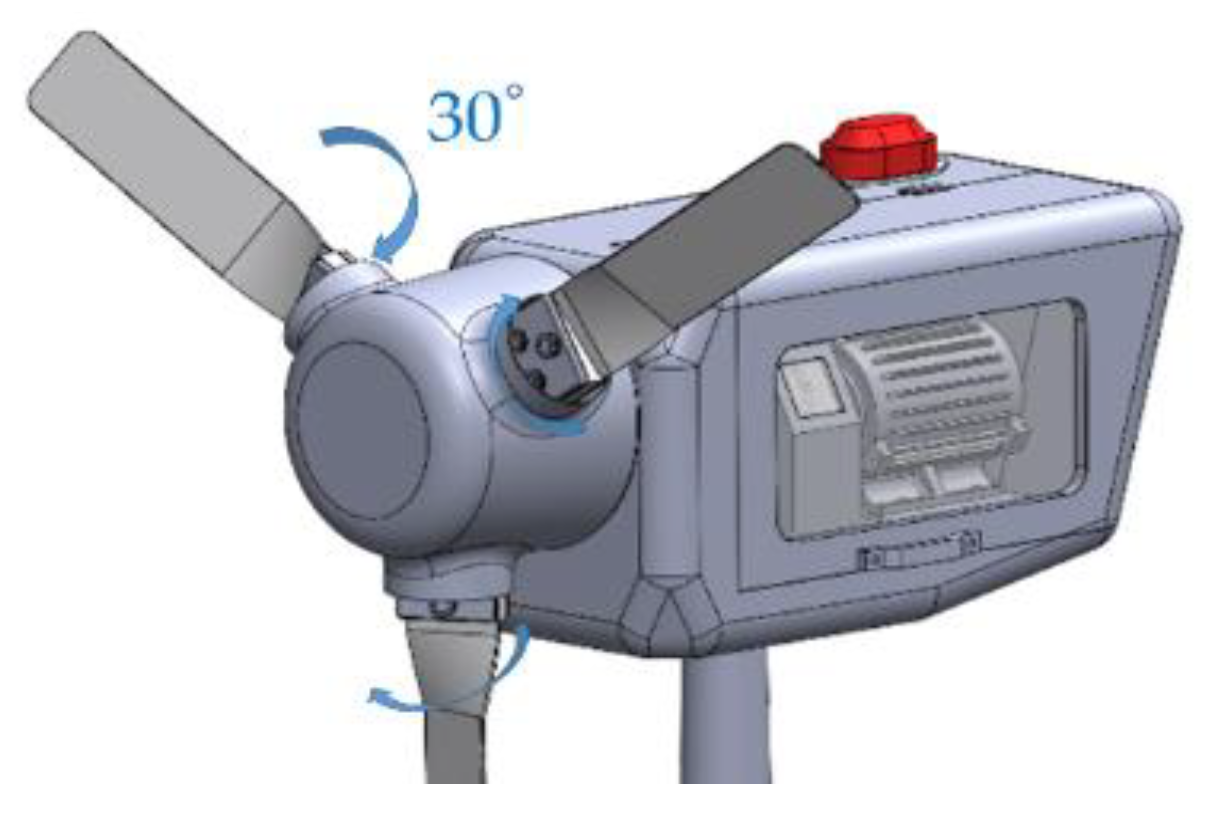

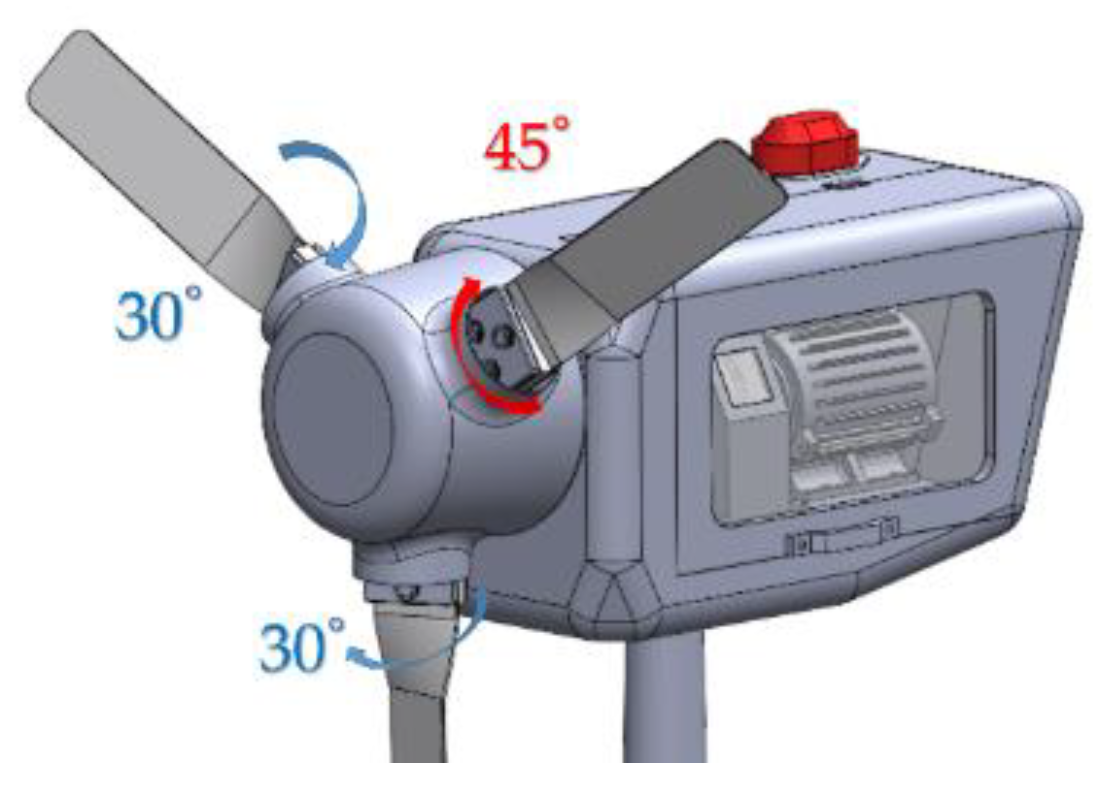

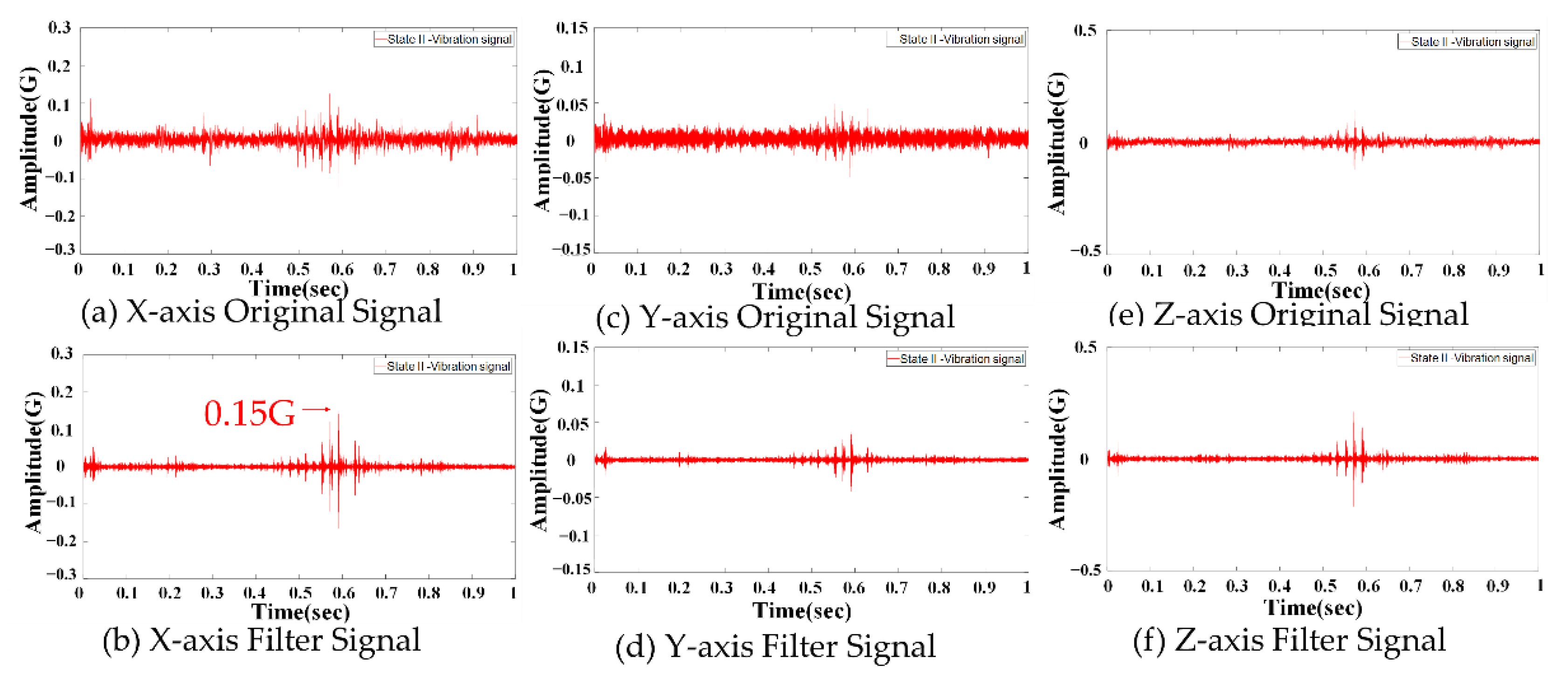

2.2.2. Blade Angle Anomaly (State 2)

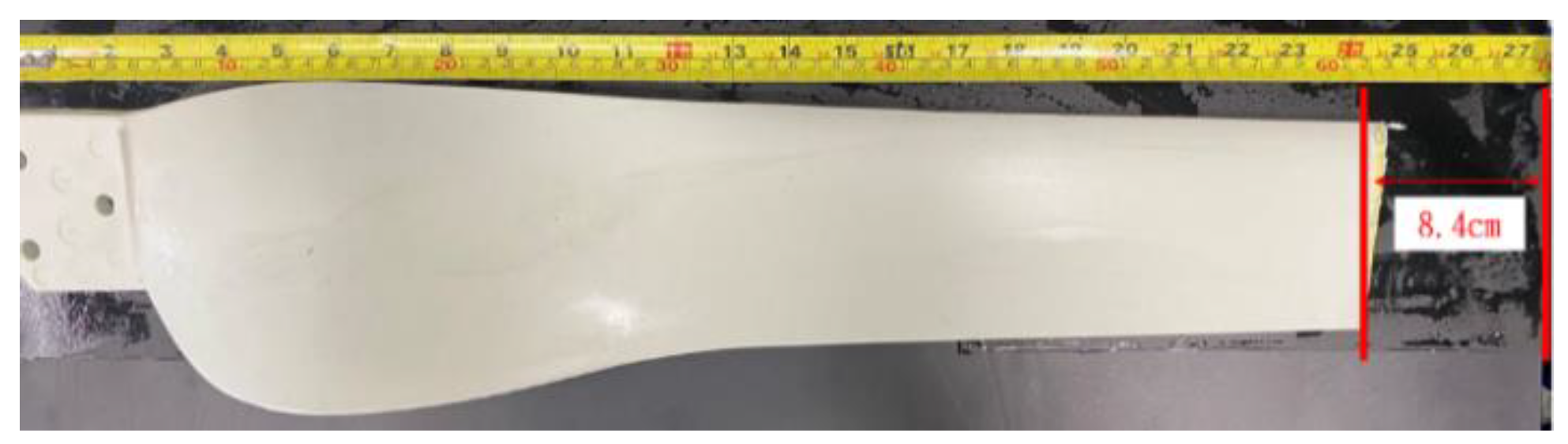

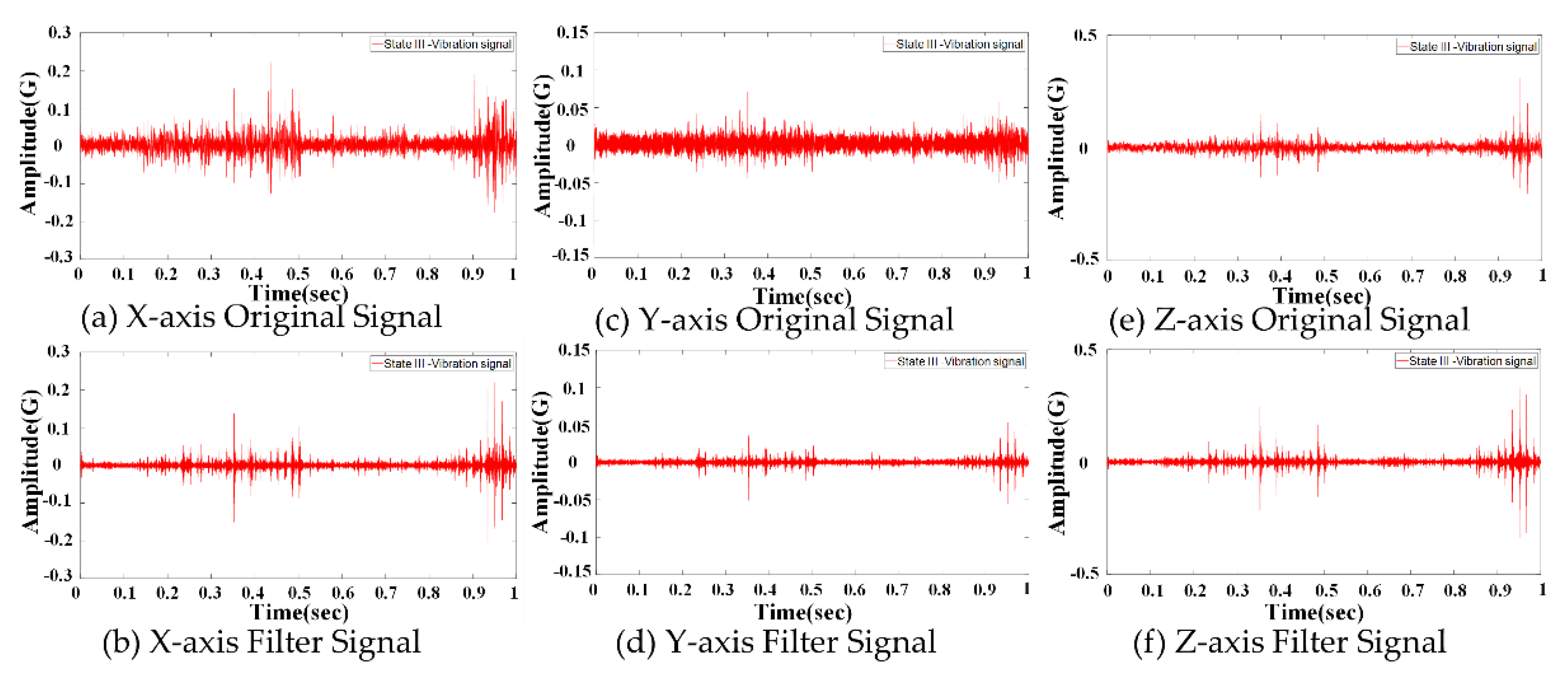

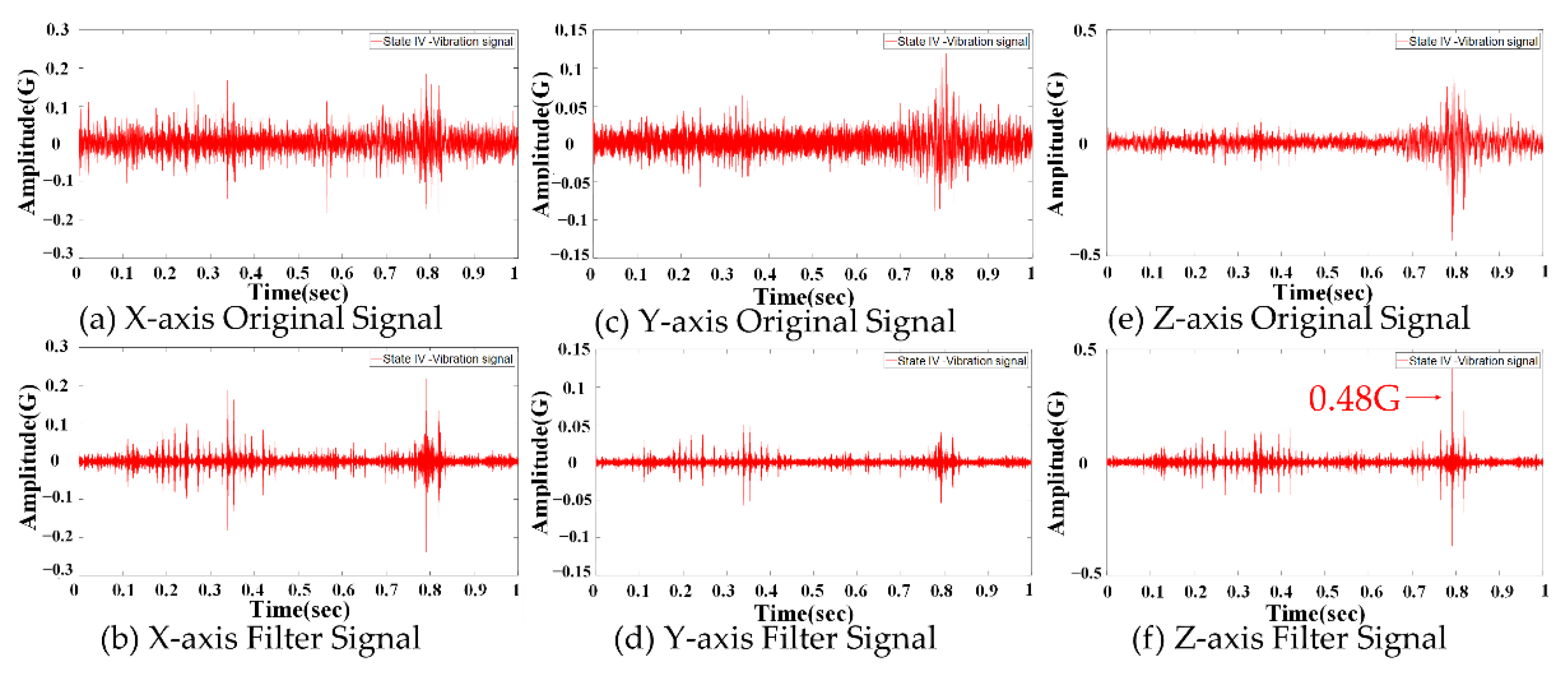

2.2.3. A Blade Suffering a Lightning Strike (State 3 and State 4)

3. Proposed Fault Diagnosis Algorithm

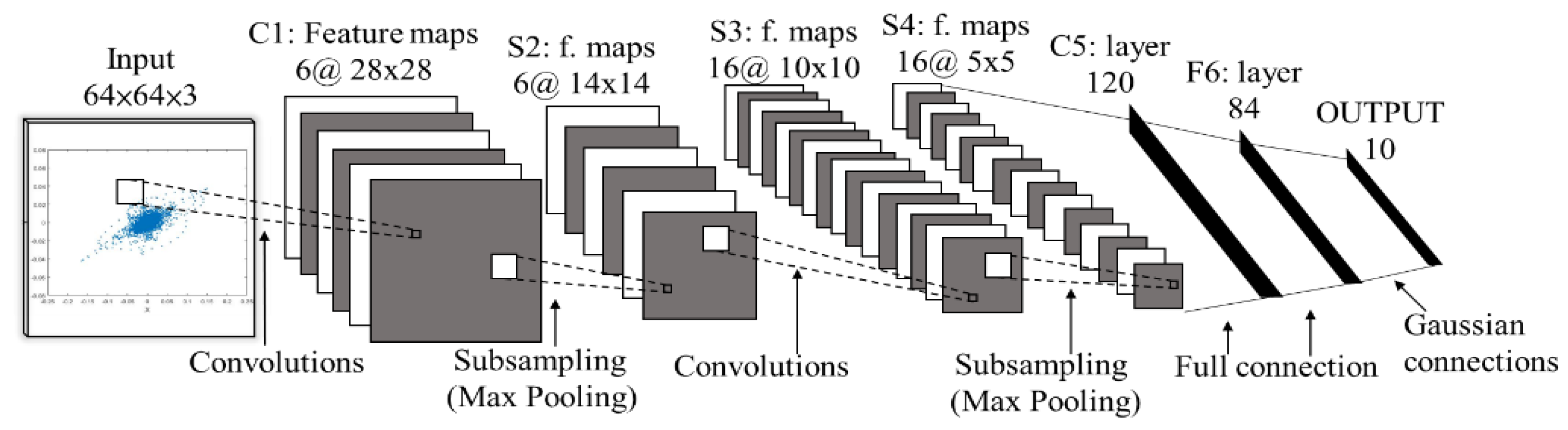

3.1. Convolutional Neural Network

3.1.1. Convolution Layer

3.1.2. Pooling Layer

3.1.3. Fully Connected Layer

3.1.4. Activation Layer

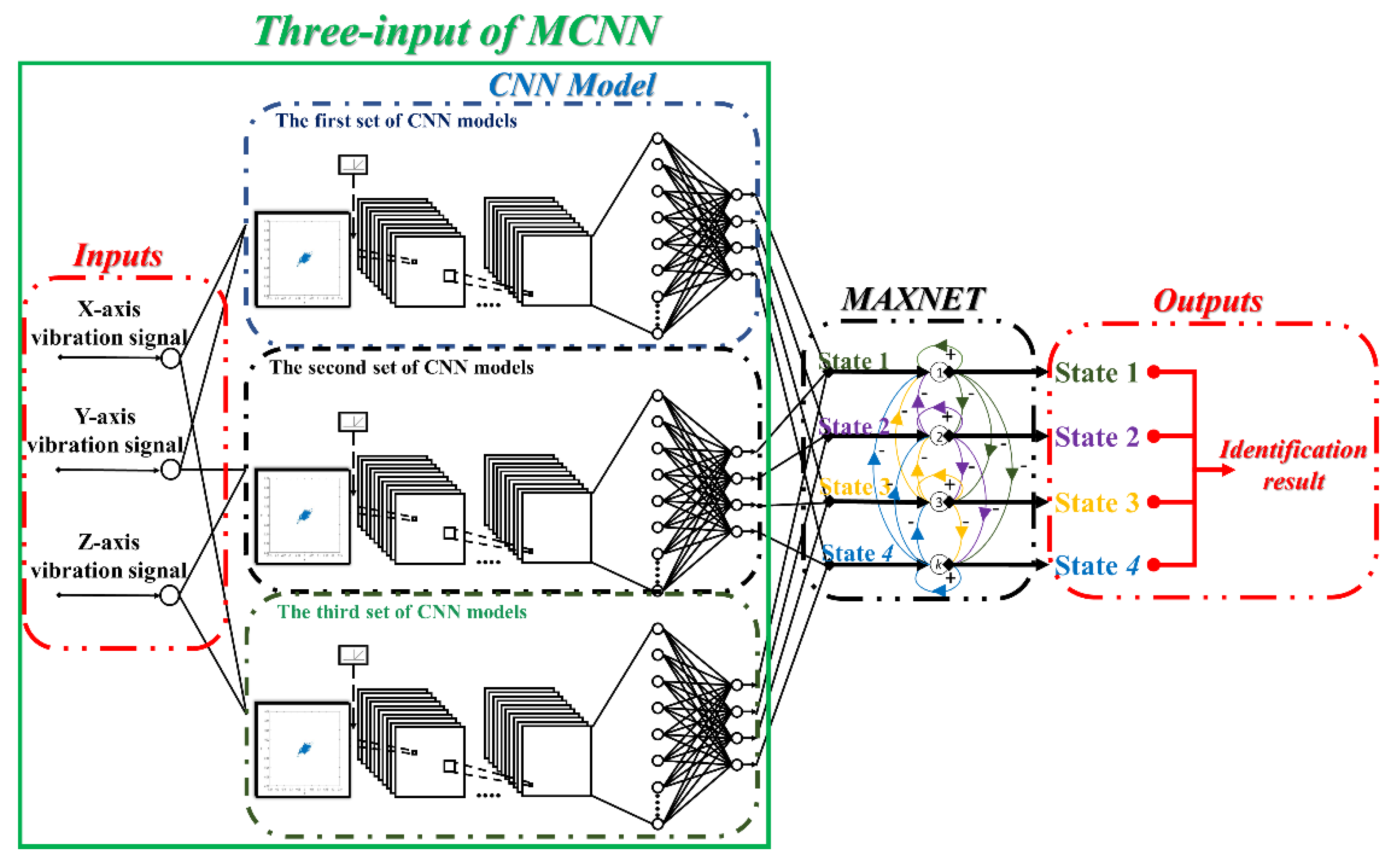

3.2. Multi-Channel Convolutional Neural Network

3.2.1. MCNN Architecture

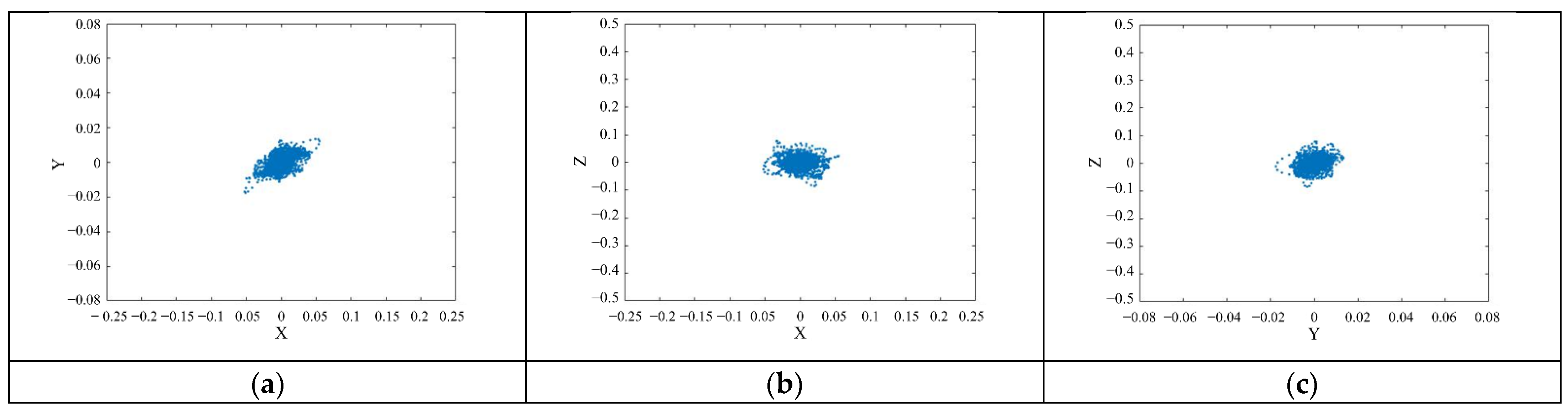

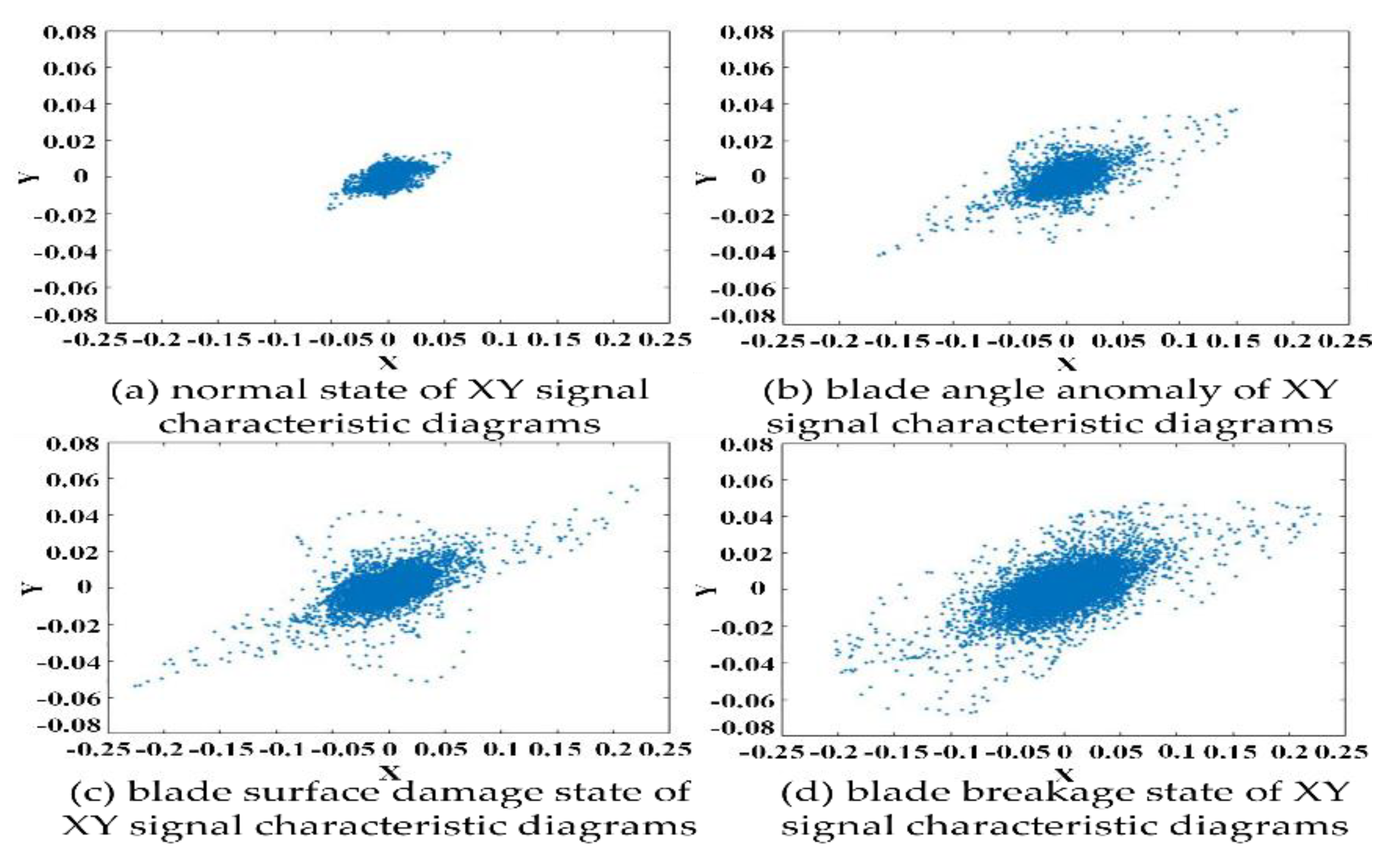

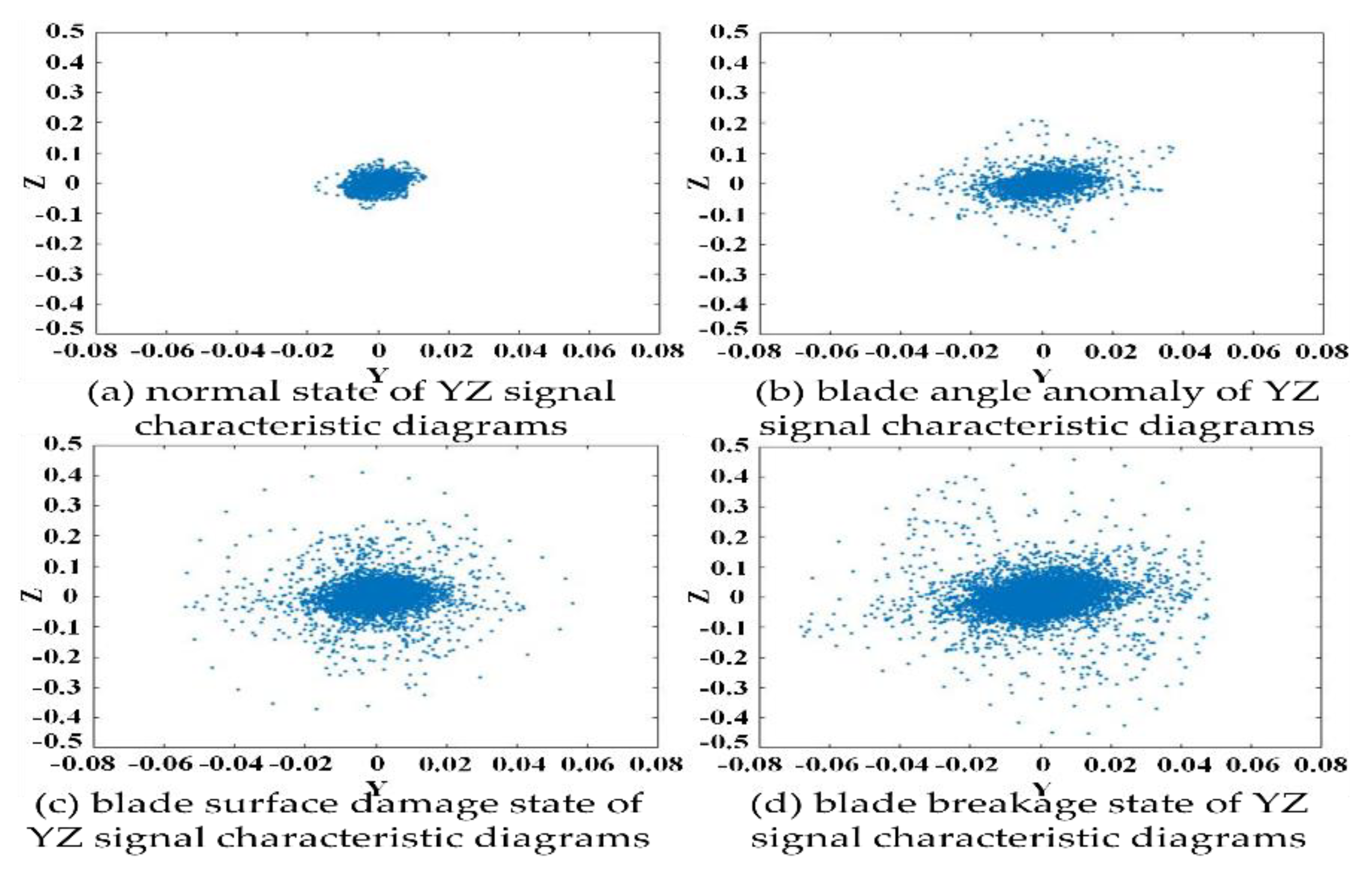

3.2.2. Signal Characteristic Diagrams of MCNN

3.2.3. MCNN Diagnosis Result Classifier

4. Results

4.1. Wind Turbine Blade and Blade Angle Signal Measurement

4.1.1. Model of the Turbine Blades in the Normal State

4.1.2. Model of the Wind Turbine Blades in the Blade Angle Anomaly State

4.1.3. Model of the Wind Turbine Blades in the Blade Surface Damage State

4.1.4. Model of the Large Wind Turbine Blades in the Blade Breakage State

4.2. MCNN Identification System

4.2.1. Signal Characteristic Diagrams of MCNN

4.2.2. MCNN Identification Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pu, Z.; Li, C.; Zhang, S.; Bai, Y. Fault Diagnosis for Wind Turbine Gearboxes by Using Deep Enhanced Fusion Network. IEEE Trans. Instrum. Meas. 2021, 70, 1–11. [Google Scholar] [CrossRef]

- He, Q.; Zhao, J.; Jiang, G.; Xie, P. An Unsupervised Multiview Sparse Filtering Approach for Current-Based Wind Turbine Gearbox Fault Diagnosis. IEEE Trans. Instrum. Meas. 2020, 69, 5569–5578. [Google Scholar] [CrossRef]

- Wang, J.; Qiao, W.; Qu, L. Wind Turbine Bearing Fault Diagnosis Based on Sparse Representation of Condition Monitoring Signals. IEEE Trans. Ind. Appl. 2019, 55, 1844–1852. [Google Scholar] [CrossRef]

- Huang, N.; Chen, Q.; Cai, G.; Xu, D.; Zhang, L.; Zhao, W. Fault Diagnosis of Bearing in Wind Turbine Gearbox Under Actual Operating Conditions Driven by Limited Data With Noise Labels. IEEE Trans. Instrum. Meas. 2021, 70, 1–10. [Google Scholar] [CrossRef]

- Liu, Z.; Tang, X.; Wang, X.; Mugica, J.E.; Zhang, L. Wind Turbine Blade Bearing Fault Diagnosis Under Fluctuating Speed Operations via Bayesian Augmented Lagrangian Analysis. IEEE Trans. Ind. Inform. 2021, 17, 4613–4623. [Google Scholar] [CrossRef]

- Shi, Z.F.; Liu, J.; Li, H.W.; Zhang, Q.; Xiao, G.J. Dynamic simulation of a planet roller bearing considering the cage bridge crack. Eng. Fail. Anal. 2022, 131, 105849. [Google Scholar] [CrossRef]

- Liu, J.; Xu, Z.D. A simulation investigation of lubricating characteristics for a cylindrical roller bearing of a high-power gearbox. Tribol. Int. 2022, 167, 107373. [Google Scholar] [CrossRef]

- Ibrahim, R.K.; Watson, S.J.; Djurović, S.; Crabtree, C.J. An Effective Approach for Rotor Electrical Asymmetry Detection in Wind Turbine DFIGs. IEEE Trans. Ind. Electron. 2018, 65, 8872–8881. [Google Scholar] [CrossRef] [Green Version]

- Artigao, E.; Honrubia-Escribano, A.; Gómez-Lázaro, E. In-Service Wind Turbine DFIG Diagnosis Using Current Signature Analysis. IEEE Trans. Ind. Electron. 2020, 67, 2262–2271. [Google Scholar] [CrossRef]

- Oh, K.-Y.; Park, J.-Y.; Lee, J.-S.; Epureanu, B.I.; Lee, J.-K. A Novel Method and Its Field Tests for Monitoring and Diagnosing Blade Health for Wind Turbines. IEEE Trans. Instrum. Meas. 2015, 64, 1726–1733. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, X.; Zhang, L. Fault Diagnosis of Industrial Wind Turbine Blade Bearing Using Acoustic Emission Analysis. IEEE Trans. Instrum. Meas. 2020, 69, 6630–6639. [Google Scholar] [CrossRef]

- Malik, H.; Mishra, S. Artificial neural network and empirical mode decomposition based imbalance fault diagnosis of wind turbine using TurbSim, FAST and Simulink. IET Renew. Power Gener. 2017, 11, 889–902. [Google Scholar] [CrossRef]

- Yang, J.; Zhao, L.; Lang, Z.-Q.; Zhang, Y. Wind Turbine Blade Condition Monitoring and Damage Detection by Image-Based Method and Frequency-Based Analysis. In Proceedings of the 2018 10th International Conference on Modelling, Identification and Control (ICMIC), Guiyang, China, 2–4 July 2018; pp. 1–6. [Google Scholar]

- Sahoo, S.; Kushwah, K.; Sunaniya, A.K. Health Monitoring of Wind Turbine Blades through Vibration Signal Using Advanced Signal Processing Techniques. In Proceedings of the 2020 Advanced Communication Technologies and Signal Processing (ACTS), Silchar, India, 4–6 December 2020; pp. 1–6. [Google Scholar]

- Liu, X.; Zhang, X.; Wang, L. Fault Diagnosis Method of Wind Turbine Gearbox Based on Deep Belief Network and Vibration Signal. In Proceedings of the 2018 IEEE 57th Annual Conference of the Society of Instrument and Control Engineers of Japan (SICE), Nara, Japan, 11–14 September 2018; pp. 1699–1704. [Google Scholar]

- Yu, X.; Tang, B.; Zhang, K. Fault Diagnosis of Wind Turbine Gearbox Using a Novel Method of Fast Deep Graph Convolutional Networks. IEEE Trans. Instrum. Meas. 2021, 70, 1–14. [Google Scholar] [CrossRef]

- Firuzi, K.; Vakilian, M.; Phung, B.T.; Blackburn, T.R. Partial Discharges Pattern Recognition of Transformer Defect Model by LBP & HOG Features. IEEE Trans. Power Deliv. 2019, 34, 542–550. [Google Scholar]

- Hu, J.; Kuang, Y.; Liao, B.; Cao, L.; Dong, S.; Li, P. A Multichannel 2D Convolutional Neural Network Model for Task-Evoked fMRI Data Classification. Comput. Intell. Neurosci 2019, 2019, 5065214. [Google Scholar] [CrossRef] [PubMed]

- Schwenk, H.; Bengio, Y. Training methods for adaptive boosting of neural networks for character recognition. In Advances in Neural Information Processing Systems 10: Proceedings of the 1997 Conference; The MIT Press: Cambridge, MA, USA, 1998; pp. 647–653. [Google Scholar]

- Saghafinia, A.; Kahourzade, S.; Mahmoudi, A.; Hew, W.P.; Uddin, M.N. On line trained fuzzy logic and adaptive continuous wavelet transform based high precision fault detection of IM with broken rotor bars. In Proceedings of the 2012 IEEE Industry Applications Society Annual Meeting, Las Vegas, NV, USA, 7–11 October 2012; pp. 1–8. [Google Scholar]

- Saucedo-Dorantes, J.J.; Arellano-Espitia, F.; Delgado-Prieto, M.; Osornio-Rios, R.A. Diagnosis Methodology Based on Deep Feature Learning for Fault Identification in Metallic, Hybrid and Ceramic Bearings. Sensors 2021, 21, 5832. [Google Scholar] [CrossRef]

- Jiang, G.; He, H.; Xie, P.; Tang, Y. Stacked Multilevel-Denoising Autoencoders: A New Representation Learning Approach for Wind Turbine Gearbox Fault Diagnosis. IEEE Trans. Instrum. Meas. 2017, 66, 2391–2402. [Google Scholar] [CrossRef]

- Dao, C.; Kazemtabrizi, B.; Crabtree, C. Wind turbine reliability data review and impacts on levelised cost of energy. Wind Energy 2019, 22, 1848–1871. [Google Scholar] [CrossRef] [Green Version]

- Pao, L.Y.; Johnson, K.E. Control of Wind Turbines. IEEE Control Syst. Mag. 2011, 31, 44–62. [Google Scholar]

- Qiao, W.; Lu, D. A Survey on Wind Turbine Condition Monitoring and Fault Diagnosis—Part I: Components and Subsystems. IEEE Trans. Ind. Electron. 2015, 62, 6536–6545. [Google Scholar] [CrossRef]

- Chou, J.-S.; Chiu, C.-K.; Huang, I.-K.; Chi, K.-N. Failure Analysis of Wind Turbine Blade under Critical Wind Loads. Eng. Fail. Anal. 2013, 27, 99–118. [Google Scholar] [CrossRef]

- Wilson, N.; Myers, J.; Cummins, K.L.; Hutchinson, M.; Nag, A. Lightning Attachment to Wind Turbines in Central Kansas: Video Observations Correlation with The NLDN and In-situ Peak Current Measurements. In Proceedings of the European Wind Energy Association Annual Event, Vienna, Austria, 4–7 February 2013; pp. 1–8. [Google Scholar]

- Cummins, K.L.; Qucik, M.G.; Rison, W.; Krehbiel, P.; Thomas, R.; Mcharg, G.; Engle, J.; Myers, J.; Nag, A.; Cramer, J.; et al. Overview of the Kansas Windfarm2013 Field Program. In Proceedings of the 23rd International Lightning Detection Conference, Tucson, AZ, USA, 18–19 March 2014. [Google Scholar]

- IEC 61400-24 Ed.1.0. Wind Turbines–Part 24: Lightning Protection. 2010. IEC: Geneva, Switzerland, 2010.

- Garolera, A.C.; Madsen, S.F.; Nissim, M.; Myers, J.D.; Holboell, J. Lightning Damage to Wind Turbine Blades From Wind Farms in the U.S. IEEE Trans. Power Delivery 2016, 31, 1043–1049. [Google Scholar] [CrossRef]

- Ranjan, R.; Bansal, A.; Zheng, J.; Xu, H.; Gleason, J.; Lu, B.; Nanduri, A.; Chen, J.C.; Castillo, C.D.; Chellappa, R. A Fast and Accurate System for Face Detection, Identification, and Verification. IEEE Trans. Biom. Behav. Identity Sci. 2019, 1, 82–96. [Google Scholar] [CrossRef] [Green Version]

- Pereira, S.; Pinto, A.; Alves, V.; Silva, C.A. Brain Tumor Segmentation Using Convolutional Neural Networks in MRI Images. IEEE Trans. Med. Imaging 2016, 35, 1240–1251. [Google Scholar] [CrossRef]

- Liu, R.; Meng, G.; Yang, B.; Sun, C.; Chen, X. Dislocated Time Series Convolutional Neural Architecture: An Intelligent Fault Diagnosis Approach for Electric Machine. IEEE Trans. Ind. Inform. 2017, 13, 1310–1320. [Google Scholar] [CrossRef]

- Lecun, Y.; Bottou, L.; Bengio, Y.; Haffner, P. Gradient-Based Learning Applied to Document Recognition. Proc. IEEE 1998, 86, 2278–2324. [Google Scholar] [CrossRef] [Green Version]

- Wong, S.Y.; Yap, K.S.; Lim, C.P.; Lee, E.W.M. Hybrid Data Regression Model Based on the Generalized Adaptive Resonance Theory Neural Network. IEEE Access 2019, 7, 116438–116452. [Google Scholar] [CrossRef]

- Lippmann, R. An introduction to computing with neural nets. IEEE ASSP Mag. 1987, 4, 4–22. [Google Scholar] [CrossRef]

| Channel | Layers of CNN | Convolutional Kernel Size | Activation | Pooling |

|---|---|---|---|---|

| 1st CNN channel XY axis | 11 | 3 × 3 | ReLu | Max pooling |

| 2nd CNN channel YZ axis | 11 | 7 × 7 | ReLu | Max pooling |

| 3rd CNN channel XZ axis | 11 | 7 × 7 | ReLu | Max pooling |

| Fault Type | Description |

| State 1 | Normal wind turbine blades (The angle of each blade is 30°) |

| State 2 | Blade angle anomaly (One of the blades has an angle of 45°) |

| State 3 | A blade suffering a lightning strike (Surface damages at an 8.4 cm position) |

| State 4 | Broken blade (The 8.4 cm front part of a blade was cut off) |

| Vibration Signal Information | Description |

| Wind turbine operation speed | 12 RPM |

| Vibration signal acquisition time | 50 millisecond |

| Sampling frequency | 51.2 kS/s |

| Methods | Vibration Signals (axis) | Training Time (second) | Accuracy (%) | Average Accuracy (%) | Recognition Time (second) | Average Recognition Time (second) |

|---|---|---|---|---|---|---|

| MCNN | X, Y, Z | 100 | 87.8 | 87.8 | 2.02 | 2.02 |

| CNN | X, Y | 100 | 86 | 84 | 1.56 | 1.73 |

| CNN | X, Z | 100 | 82 | 1.69 | ||

| CNN | Y, Z | 100 | 84 | 1.95 | ||

| HOG+BPNN | X, Y | 10,000 | 77.5 | 64.92 | 1.02 | 1.01 |

| HOG+BPNN | X, Z | 10,000 | 52 | 1 | ||

| HOG+BPNN | Y, Z | 10,000 | 65.25 | 1 | ||

| HOG+SVM | X, Y | X | 78.75 | 77.83 | 3.36 | 3.21 |

| HOG+SVM | X, Z | X | 77.25 | 2.94 | ||

| HOG+SVM | Y, Z | X | 78 | 3.32 | ||

| HOG+KNN | X, Y | X | 77.5 | 77.5 | 2.95 | 2.98 |

| HOG+KNN | X, Z | X | 78 | 2.92 | ||

| HOG+KNN | Y, Z | X | 77 | 3.08 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, M.-H.; Lu, S.-D.; Hsieh, C.-C.; Hung, C.-C. Fault Detection of Wind Turbine Blades Using Multi-Channel CNN. Sustainability 2022, 14, 1781. https://doi.org/10.3390/su14031781

Wang M-H, Lu S-D, Hsieh C-C, Hung C-C. Fault Detection of Wind Turbine Blades Using Multi-Channel CNN. Sustainability. 2022; 14(3):1781. https://doi.org/10.3390/su14031781

Chicago/Turabian StyleWang, Meng-Hui, Shiue-Der Lu, Cheng-Che Hsieh, and Chun-Chun Hung. 2022. "Fault Detection of Wind Turbine Blades Using Multi-Channel CNN" Sustainability 14, no. 3: 1781. https://doi.org/10.3390/su14031781

APA StyleWang, M.-H., Lu, S.-D., Hsieh, C.-C., & Hung, C.-C. (2022). Fault Detection of Wind Turbine Blades Using Multi-Channel CNN. Sustainability, 14(3), 1781. https://doi.org/10.3390/su14031781