RETRACTED: Systematic Multiscale Models to Predict the Compressive Strength of Cement Paste as a Function of Microsilica and Nanosilica Contents, Water/Cement Ratio, and Curing Ages

Abstract

1. Introduction

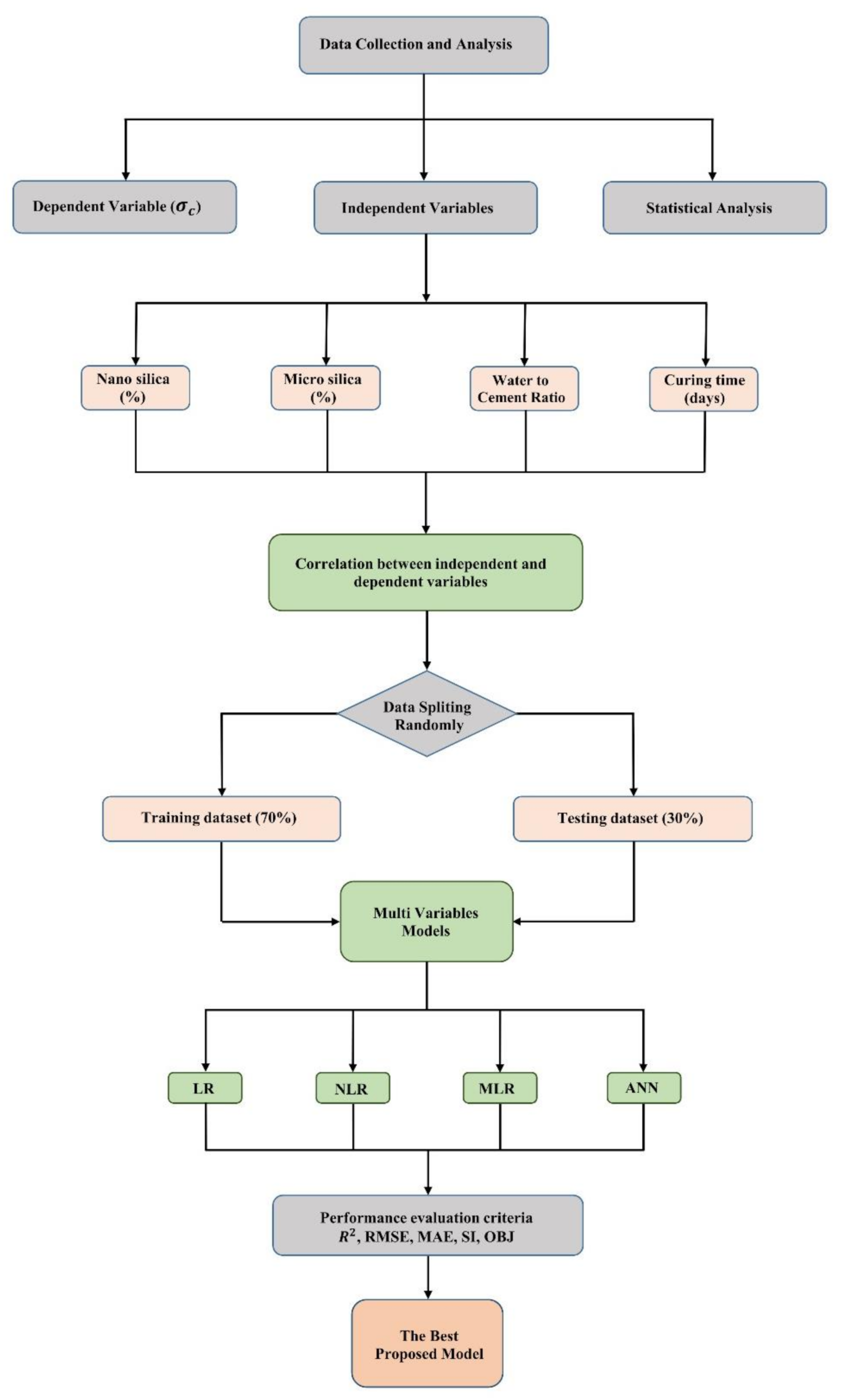

2. Materials and Methods

2.1. Methods

2.2. Statistical Evaluation

- (i)

- Water/cement ratio (w/c)

- (ii)

- Curing time

- (iii)

- NS content

- (iv)

- MS content

- (v)

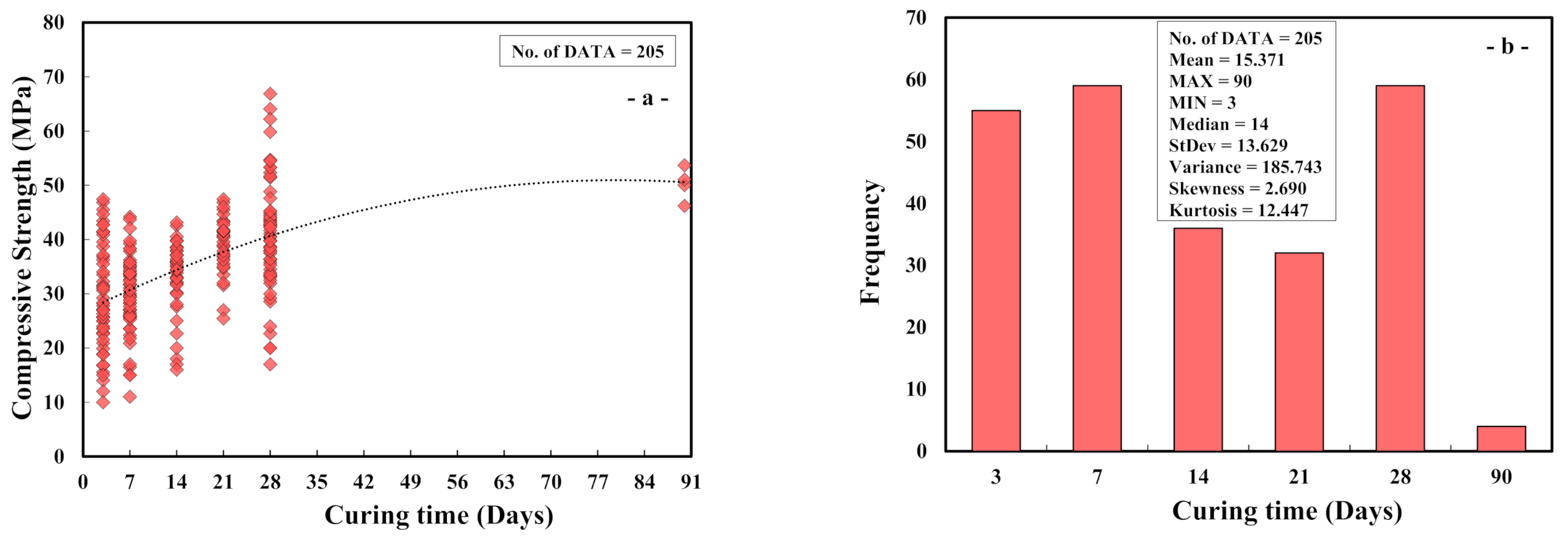

- Compressive strength

2.3. Modeling

2.3.1. Linear Regression Model (LR)

2.3.2. Nonlinear Regression Model (NLR)

2.3.3. Multi-Logistic Regression Model (MLR)

2.3.4. Artificial Neural Network Model (ANN)

2.3.5. Criteria for Evaluation of Models

2.3.6. Sensitivity of Parameters

3. Results

3.1. Predicted and Measured Compressive Strength Relationships

3.1.1. The LR Model

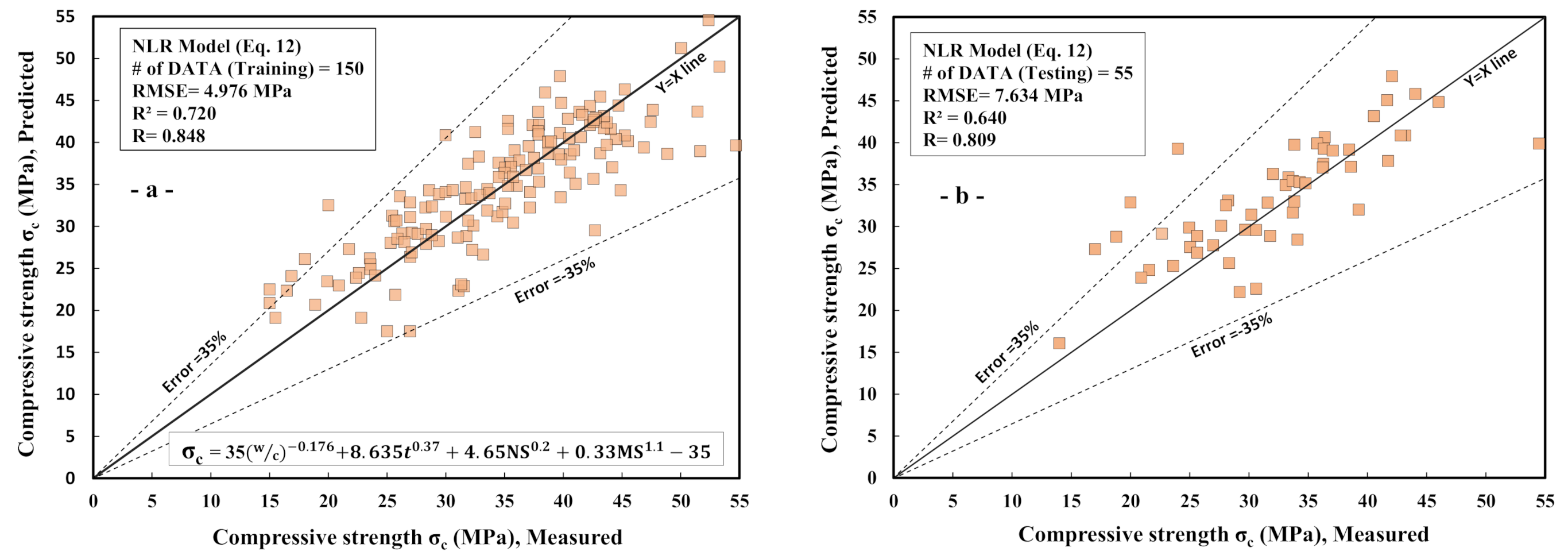

3.1.2. NLR Model

3.1.3. Multi-Logistic Regression Model (MLR)

3.1.4. Artificial Neural Network Model (ANN)

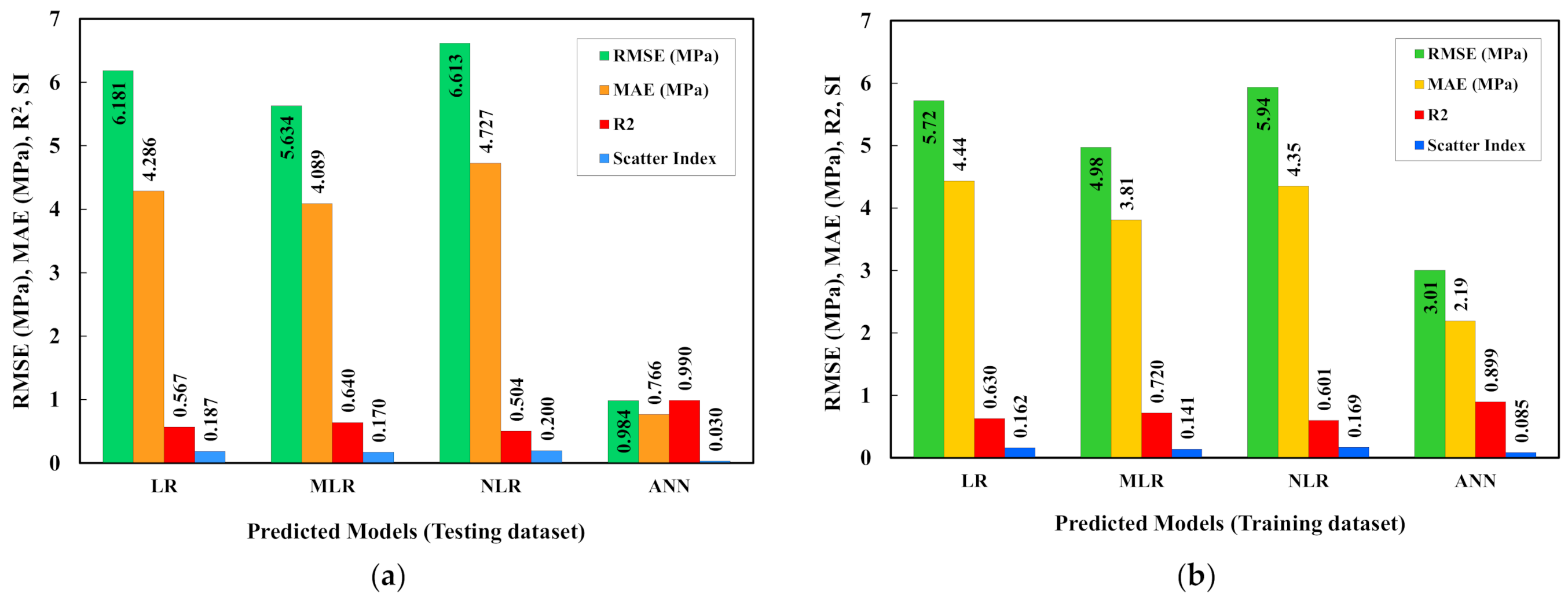

3.1.5. Comparison between Developed Models

3.1.6. Sensitivity of Parameters

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Seifan, M.; Mendoza, S.; Berenjian, A. Mechanical properties and durability performance of fly ash based mortar containing nano-and micro-silica additives. Constr. Build. Mater. 2020, 252, 119121. [Google Scholar] [CrossRef]

- Senff, L.; Hotza, D.; Labrincha, J. Effect of diatomite addition on fresh and hardened properties of mortars investigated through mixture experiments. Adv. Appl. Ceram. 2011, 110, 142–150. [Google Scholar] [CrossRef]

- Ahmed, H.U.; Mohammed, A.A.; Rafiq, S.; Mohammed, A.S.; Mosavi, A.; Sor, N.H.; Qaidi, S. Compressive Strength of Sustainable Geopolymer Concrete Composites: A State-of-the-Art Review. Sustainability 2021, 13, 13502. [Google Scholar] [CrossRef]

- Ghosh, A.; Ghosh, A.; Neogi, S. Reuse of fly ash and bottom ash in mortars with improved thermal conductivity performance for buildings. Heliyon 2018, 4, e00934. [Google Scholar] [CrossRef] [PubMed]

- Darban, S.; Tehrani, H.G.; Karballaeezadeh, N.; Mosavi, A. Application of analytical hierarchy process for Structural Health Monitoring and Prioritizing of Concrete Bridges in Iran. Appl. Sci. 2021, 11, 8086. [Google Scholar] [CrossRef]

- Shaikh, F.; Supit, S.; Sarker, P. A study on the effect of nano silica on compressive strength of high volume fly ash mortars and concretes. Mater. Des. 2014, 60, 433–442. [Google Scholar] [CrossRef]

- Kumar, R.; Mohd Yaseen, A.Y.B.; Shafiq, N.; Jalal, A. Influence of metakaolin, fly ash and nano silica on mechanical and durability properties of concrete. Key Eng. Mater. 2021, 11, 8–14. [Google Scholar] [CrossRef]

- Mohsen, M.O.; Al Ansari, M.S.; Taha, R.; Al Nuaimi, N.; Taqa, A.A. Carbon nanotube effect on the ductility, flexural strength, and permeability of concrete. J. Nanomater. 2019, 2019, 1452. [Google Scholar] [CrossRef]

- Morsy, M.; Al-Salloum, Y.; Almusallam, T.; Abbas, H. Effect of nano-metakaolin addition on the hydration characteristics of fly ash blended cement mortar. J. Therm. Anal. Calorim. 2014, 116, 845–852. [Google Scholar] [CrossRef]

- Ali Khan, M.; Zafar, A.; Akbar, A.; Javed, M.F.; Mosavi, A. Application of Gene Expression Programming (GEP) for the prediction of compressive strength of geopolymer concrete. Materials 2021, 14, 1106. [Google Scholar] [CrossRef]

- Kumar, R.; Shafiq, N.; Kumar, A.; Jhatial, A.A. Investigating embodied carbon, mechanical properties, and durability of high-performance concrete using ternary and quaternary blends of metakaolin, nano-silica, and fly ash. Environ. Sci. Pollut. Res. 2021, 28, 49074–49088. [Google Scholar] [CrossRef] [PubMed]

- Shahbazpanahi, S.; Tajara, M.K.; Faraj, R.H.; Mosavi, A. Studying the C–H Crystals and Mechanical Properties of Sustainable Concrete Containing Recycled Coarse Aggregate with Used Nano-Silica. Crystals 2021, 11, 122. [Google Scholar] [CrossRef]

- Karunarathne, V.K.; Paul, S.C.; Šavija, B. Development of nano-SiO2 and bentonite-based mortars for corrosion protection of reinforcing steel. Materials 2019, 12, 2622. [Google Scholar] [CrossRef] [PubMed]

- Pourjavadi, A.; Fakoorpoor, S.M.; Khaloo, A.; Hosseini, P. Improving the performance of cement-based composites containing superabsorbent polymers by utilization of nano-SiO2 particles. Mater. Des. 2012, 42, 94–101. [Google Scholar] [CrossRef]

- Kim, K.-M.; Heo, Y.-S.; Kang, S.-P.; Lee, J. Effect of sodium silicate-and ethyl silicate-based nano-silica on pore structure of cement composites. Cem. Concr. Compos. 2014, 49, 84–91. [Google Scholar] [CrossRef]

- Abbasi, S.; Jannaty, M.H.; Faraj, R.H.; Shahbazpanahi, S.; Mosavi, A. The effect of incorporating silica stone waste on the mechanical properties of sustainable concretes. Materials 2020, 13, 3832. [Google Scholar] [CrossRef] [PubMed]

- Vickers, N.J. Animal communication: When i’m calling you, will you answer too? Curr. Biol. 2017, 27, R713–R715. [Google Scholar] [CrossRef] [PubMed]

- Shah, M.; Amin, M.; Khan, K.; Niazi, M.; Aslam, F.; Alyousef, R.; Javed, M.; Mosavi, A. Performance Evaluation of Soft Computing for Modeling the Strength Properties of Waste Substitute Green Concrete. Sustainability 2021, 13, 2867. [Google Scholar] [CrossRef]

- Maravelaki-Kalaitzaki, P.; Agioutantis, Z.; Lionakis, E.; Stavroulaki, M.; Perdikatsis, V. Physico-chemical and mechanical characterization of hydraulic mortars containing nano-titania for restoration applications. Cem. Concr. Compos. 2013, 36, 33–41. [Google Scholar] [CrossRef]

- Mohseni, E.; Miyandehi, B.M.; Yang, J.; Yazdi, M.A. Single and combined effects of nano-SiO2, nano-Al2O3 and nano-TiO2 on the mechanical, rheological and durability properties of self-compacting mortar containing fly ash. Constr. Build. Mater. 2015, 84, 331–340. [Google Scholar] [CrossRef]

- Ahmad, J.; Tufail, R.F.; Aslam, F.; Mosavi, A.; Alyousef, R.; Faisal Javed, M.; Zaid, O.; Khan Niazi, M.S. A step towards sustainable self-compacting concrete by using partial substitution of wheat straw ash and bentonite clay instead of cement. Sustainability 2021, 13, 824. [Google Scholar] [CrossRef]

- Madandoust, R.; Mohseni, E.; Mousavi, S.Y.; Namnevis, M. An experimental investigation on the durability of self-compacting mortar containing nano-SiO2, nano-Fe2O3 and nano-CuO. Constr. Build. Mater. 2015, 86, 44–50. [Google Scholar] [CrossRef]

- Horszczaruk, E.; Aleksandrzak, M.; Cendrowski, K.; Jędrzejewski, R.; Baranowska, J.; Mijowska, E. Mechanical properties cement based composites modified with nano-Fe3O4/SiO2. Constr. Build. Mater. 2020, 251, 118945. [Google Scholar] [CrossRef]

- Qing, Y.; Zenan, Z.; Deyu, K.; Rongshen, C. Influence of nano-SiO2 addition on properties of hardened cement paste as compared with silica fume. Constr. Build. Mater. 2007, 21, 539–545. [Google Scholar] [CrossRef]

- Wang, L.; Zheng, D.; Zhang, S.; Cui, H.; Li, D. Effect of nano-SiO2 on the hydration and microstructure of Portland cement. Nanomaterials 2016, 6, 241. [Google Scholar] [CrossRef]

- Li, L.; Huang, Z.; Zhu, J.; Kwan, A.; Chen, H. Synergistic effects of micro-silica and nano-silica on strength and microstructure of mortar. Constr. Build. Mater. 2017, 140, 229–238. [Google Scholar] [CrossRef]

- Sajedi, F.; Razak, H.A. Comparison of different methods for activation of ordinary Portland cement-slag mortars. Constr. Build. Mater. 2011, 25, 30–38. [Google Scholar] [CrossRef]

- Mala, A.A.; Sherwani, A.F.H.; Younis, K.H.; Faraj, R.H.; Mosavi, A. Mechanical and fracture parameters of ultra-high performance fiber reinforcement concrete cured via steam and water: Optimization of binder content. Materials 2021, 14, 2016. [Google Scholar] [CrossRef]

- Piro, N.S.; Salih, A.; Hamad, S.M.; Kurda, R. Comprehensive multiscale techniques to estimate the compressive strength of concrete incorporated with carbon nanotubes at various curing times and mix proportions. J. Mater. Res. Technol. 2021, 15, 6506–6527. [Google Scholar] [CrossRef]

- Ashrafian, A.; Taheri Amiri, M.J.; Masoumi, P.; Asadi-shiadeh, M.; Yaghoubi-chenari, M.; Mosavi, A.; Nabipour, N. Classification-based regression models for prediction of the mechanical properties of roller-compacted concrete pavement. Appl. Sci. 2020, 10, 3707. [Google Scholar] [CrossRef]

- Ghafor, K.; Qadir, S.; Mahmood, W.; Mohammed, A. Statistical variations and new correlation models to predict the mechanical behaviour of the cement mortar modified with silica fume. Geomech. Geoengin. 2020, 14, 1–13. [Google Scholar] [CrossRef]

- Navabi, D.; Javidruzi, M.; Hafezi, M.R.; Mosavi, A. The high-performance light transmitting concrete and experimental analysis of using polymethylmethacrylate optical fibers in it. J. Build. Eng. 2021, 38, 102076. [Google Scholar] [CrossRef]

- Kooshkaki, A.; Eskandari-Naddaf, H. Effect of porosity on predicting compressive and flexural strength of cement mortar containing micro and nano-silica by multi-objective ANN modeling. Constr. Build. Mater. 2019, 212, 176–191. [Google Scholar] [CrossRef]

- Setiati, N.R. Effects of additional nanosilica of compressive strength on mortar. Mater. Sci. Eng. 2021, 11, 012065. [Google Scholar]

- Bekem Kara, İ.; Durmuş, Ö.F. Effect of nano silica on cement mortars containing micro silica. Chall. J. Concr. Res. Lett. 2019, 10, 42–49. [Google Scholar] [CrossRef]

- Habeeb, G.M.; Ghali, Z.A.S. Effect of Accelerated Curing on Compressive Strength of High Strength Concrete with Nano-Silica. Available online: https://www.researchgate.net/profile/Ghalib-Habeeb/publication/309734552_EFFECT_OF_ACCELERATED_CURING_ON_COMPRESSIVE_STRENGTH_OF_HIGH_STRENGTH_CONCRETE_WITH_NANO-_SILICA/links/5820a47808ae12715afbc867/EFFECT-OF-ACCELERATED-CURING-ON-COMPRESSIVE-STRENGTH-OF-HIGH-STRENGTH-CONCRETE-WITH-NANO-SILICA.pdf (accessed on 30 September 2021).

- Garg, R.; Garg, R.; Bansal, M.; Aggarwal, Y. Experimental study on strength and microstructure of mortar in presence of micro and nano-silica. Mater. Today Proc. 2021, 43, 769–777. [Google Scholar] [CrossRef]

- Golafshani, E.M.; Behnood, A.; Arashpour, M. Predicting the compressive strength of normal and High-Performance Concretes using ANN and ANFIS hybridized with Grey Wolf Optimizer. Constr. Build. Mater. 2020, 232, 117266. [Google Scholar] [CrossRef]

- FM Zain, M.; Abd, S. Multiple regression model for compressive strength prediction of high performance concrete. J. Appl. Sci. 2009, 9, 155–160. [Google Scholar] [CrossRef]

- Mohammed, A.; Mahmood, W.; Ghafor, K. TGA, rheological properties with maximum shear stress and compressive strength of cement-based grout modified with polycarboxylate polymers. Constr. Build. Mater. 2020, 235, 117534. [Google Scholar] [CrossRef]

- Sarwar, W.; Ghafor, K.; Mohammed, A. Modeling the rheological properties with shear stress limit and compressive strength of ordinary Portland cement modified with polymers. J. Build. Pathol. Rehabil. 2019, 4, 25. [Google Scholar] [CrossRef]

- Vipulanandan, C.; Mohammed, A.; Ganpatye, A. Smart cement performance enhancement with NanoAl2O3 for real time monitoring applications using Vipulanandan models. Offshore Technol. 2021, 12, 123. [Google Scholar]

- Li, M.-F.; Tang, X.-P.; Wu, W.; Liu, H.-B. General models for estimating daily global solar radiation for different solar radiation zones in mainland China. Energy Convers. Manag. 2013, 70, 139–148. [Google Scholar] [CrossRef]

- Mohammed, A.; Rafiq, S.; Mahmood, W.; Noaman, R.; Ghafor, K.; Qadir, W.; Kadhum, Q. Characterization and modeling the flow behavior and compression strength of the cement paste modified with silica nano-size at different temperature conditions. Constr. Build. Mater. 2020, 257, 119590. [Google Scholar] [CrossRef]

- Burhan, L.; Ghafor, K.; Mohammed, A. Enhancing the fresh and hardened properties of the early age concrete modified with powder polymers and characterized using different models. Adv. Civ. Eng. Mater. 2020, 9, 227–249. [Google Scholar] [CrossRef]

- Almohammad-albakkar, M.; Behfarnia, K. Effects of the combined usage of micro and nano-silica on the drying shrinkage and compressive strength of the self-compacting concrete. J. Sustain. Cem.-Based Mater. 2020, 41, 1–19. [Google Scholar] [CrossRef]

- Afzali-Naniz, O.; Mazloom, M. Fracture behavior of self-compacting semi-lightweight concrete containing nano-silica. Adv. Struct. Eng. 2019, 22, 2264–2277. [Google Scholar] [CrossRef]

- Mohammed, A.; Rafiq, S.; Sihag, P.; Kurda, R.; Mahmood, W. Soft computing techniques: Systematic multiscale models to predict the compressive strength of HVFA concrete based on mix proportions and curing times. J. Build. Eng. 2020, 2020, 101851. [Google Scholar] [CrossRef]

- Thomas, M. Supplementary Cementing Materials in Concrete; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Moayedi, H.; Mosavi, A. A water cycle-based error minimization technique in predicting the bearing capacity of shallow foundation. Eng. Comput. 2021, 14, 1–14. [Google Scholar] [CrossRef]

- Perez, H.; Tah, J.H.; Mosavi, A. Deep learning for detecting building defects using convolutional neural networks. Sensors 2019, 19, 3556. [Google Scholar] [CrossRef] [PubMed]

- Alaloul, W.S.; Altaf, M.; Musarat, M.A.; Faisal Javed, M.; Mosavi, A. Systematic Review of Life Cycle Assessment and Life Cycle Cost Analysis for Pavement and a Case Study. Sustainability 2021, 13, 4377. [Google Scholar] [CrossRef]

- Mosavi, A.; Rabczuk, T. Learning and intelligent optimization for material design innovation. Learn. Intell. Optim. 2017, 14, 358–363. [Google Scholar]

- Gomez, C.; Oller, J.; Paradells, J. Sensors-12-11734-Naam van de docent. Sensors 2012, 12, 11734–11753. [Google Scholar] [CrossRef]

- Awan, H.H.; Javed, M.F.; Yousaf, A.; Aslam, F.; Alabduljabbar, H.; Mosavi, A. Experimental Evaluation of Untreated and Pretreated Crumb Rubber Used in Concrete. Crystals 2021, 11, 558. [Google Scholar] [CrossRef]

- Band, S.S.; Mosavi, A.; Reuter, U. Smart Structural Health Monitoring of Flexible Pavements Using Machine Learning Methods. Coatings 2020, 10, 1100. [Google Scholar]

- Mohammadzadeh, S.D.; Kazemi, S.-F.; Mosavi, A.; Nasseralshariati, E.; Tah, J.H. Prediction of compression index of fine-grained soils using a gene expression programming model. Infrastructures 2019, 4, 26. [Google Scholar] [CrossRef]

- Haji-Savameri, M.; Norouzi-Apourvari, S.; Irannejad, A.; Hemmati-Sarapardeh, A.; Schaffie, M.; Mosavi, A. Experimental study and modelling of asphaltene deposition on metal surfaces with superhydrophobic and low sliding angle inner coatings. Sci. Rep. 2021, 11, 16812. [Google Scholar] [CrossRef]

- Shojaei, S.; Shojaei, S.; Band, S.S.; Farizhandi, A.A.K.; Ghoroqi, M.; Mosavi, A. Application of Taguchi method and response surface methodology into the removal of malachite green and auramine-O by NaX nanozeolites. Sci. Rep. 2021, 11, 16054. [Google Scholar] [CrossRef]

- Riahi-Madvar, H.; Dehghani, M.; Seifi, A.; Salwana, E.; Shamshirband, S.; Mosavi, A.; Chau, K.-w. Comparative analysis of soft computing techniques RBF, MLP, and ANFIS with MLR and MNLR for predicting grade-control scour hole geometry. Eng. Appl. Comput. Fluid Mech. 2019, 13, 529–550. [Google Scholar] [CrossRef]

- Mahmoudi, M.R.; Baleanu, D.; Qasem, S.N.; Mosavi, A.; Band, S.S. Testing the equality of several independent stationary and non-stationary time series models with fractional Brownian motion errors. Alex. Eng. J. 2021, 60, 1767–1775. [Google Scholar] [CrossRef]

- Chen, H.; Heidari, A.A.; Chen, H.; Wang, M.; Pan, Z.; Gandomi, A.H. Multi-population differential evolution-assisted Harris hawks optimization: Framework and case studies. Future Gener. Comput. Syst. 2020, 111, 175–198. [Google Scholar] [CrossRef]

- Hu, J.; Chen, H.; Heidari, A.A.; Wang, M.; Zhang, X.; Chen, Y.; Pan, Z. Orthogonal learning covariance matrix for defects of grey wolf optimizer: Insights, balance, diversity, and feature selection. Knowl.-Based Syst. 2021, 213, 106684. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, R.; Heidari, A.A.; Wang, X.; Chen, Y.; Wang, M.; Chen, H. Towards augmented kernel extreme learning models for bankruptcy prediction: Algorithmic behavior and comprehensive analysis. Neurocomputing 2021, 430, 185–212. [Google Scholar] [CrossRef]

- Zhao, D.; Liu, L.; Yu, F.; Heidari, A.A.; Wang, M.; Liang, G.; Muhammad, K.; Chen, H. Chaotic random spare ant colony optimization for multi-threshold image segmentation of 2D Kapur entropy. Knowl.-Based Syst. 2021, 216, 106510. [Google Scholar] [CrossRef]

- Shan, W.; Qiao, Z.; Heidari, A.A.; Chen, H.; Turabieh, H.; Teng, Y. Double adaptive weights for stabilization of moth flame optimizer: Balance analysis, engineering cases, and medical diagnosis. Knowl.-Based Syst. 2021, 214, 106728. [Google Scholar] [CrossRef]

- Tu, J.; Chen, H.; Liu, J.; Heidari, A.A.; Zhang, X.; Wang, M.; Ruby, R.; Pham, Q.-V. Evolutionary biogeography-based whale optimization methods with communication structure: Towards measuring the balance. Knowl.-Based Syst. 2021, 212, 106642. [Google Scholar] [CrossRef]

| No. | Ref. | w/c Ratio per Mass | Curing Time (Days) | Additives (%) | Compressive Strength (MPa) | |

|---|---|---|---|---|---|---|

| Nanosilica (30–100 nm) (NS) | Microsilica (0.2 μm) (MS) | |||||

| 1 | [33] | 0.4 | 3 | 0 | 0 | 15.51 |

| 2 | 0.4 | 3 | 1.4 | 0 | 16.85 | |

| 3 | 0.4 | 3 | 4.2 | 0 | 23.60 | |

| 4 | 0.4 | 3 | 2.8 | 0 | 21.57 | |

| 5 | 0.4 | 3 | 0 | 4 | 18.88 | |

| 6 | 0.4 | 3 | 2.8 | 4 | 26.97 | |

| 7 | 0.4 | 3 | 4.2 | 4 | 25.62 | |

| 8 | 0.4 | 3 | 1.4 | 4 | 28.31 | |

| 9 | 0.4 | 3 | 4.2 | 9 | 26.29 | |

| 10 | 0.4 | 3 | 0 | 9 | 20.90 | |

| 11 | 0.4 | 3 | 1.4 | 9 | 28.31 | |

| 12 | 0.4 | 3 | 2.8 | 9 | 31.01 | |

| 13 | 0.4 | 3 | 4.2 | 13 | 26.97 | |

| 14 | 0.4 | 3 | 2.8 | 13 | 25.62 | |

| 15 | 0.4 | 3 | 0 | 13 | 23.60 | |

| 16 | 0.4 | 3 | 1.4 | 13 | 24.94 | |

| 17 | 0.4 | 7 | 0 | 0 | 20.90 | |

| 18 | 0.4 | 7 | 1.4 | 0 | 25.62 | |

| 19 | 0.4 | 7 | 4.2 | 0 | 32.36 | |

| 20 | 0.4 | 7 | 2.8 | 0 | 29.66 | |

| 21 | 0.4 | 7 | 1.4 | 4 | 35.73 | |

| 22 | 0.4 | 7 | 0 | 4 | 23.60 | |

| 23 | 0.4 | 7 | 2.8 | 4 | 34.38 | |

| 24 | 0.4 | 7 | 4.2 | 4 | 33.71 | |

| 25 | 0.4 | 7 | 2.8 | 9 | 39.78 | |

| 26 | 0.4 | 7 | 1.4 | 9 | 35.06 | |

| 27 | 0.4 | 7 | 4.2 | 9 | 33.71 | |

| 28 | 0.4 | 7 | 0 | 9 | 26.97 | |

| 29 | 0.4 | 7 | 0 | 13 | 28.31 | |

| 30 | 0.4 | 7 | 1.4 | 13 | 31.69 | |

| 31 | 0.4 | 7 | 4.2 | 13 | 35.73 | |

| 32 | 0.4 | 7 | 2.8 | 13 | 33.71 | |

| 33 | 0.4 | 14 | 0 | 0 | 22.65 | |

| 34 | 0.4 | 14 | 1.4 | 0 | 29.97 | |

| 35 | 0.4 | 14 | 4.2 | 0 | 37.94 | |

| 36 | 0.4 | 14 | 2.8 | 0 | 35.29 | |

| 37 | 0.4 | 14 | 1.4 | 4 | 42.56 | |

| 38 | 0.4 | 14 | 2.8 | 4 | 40.55 | |

| 39 | 0.4 | 14 | 4.2 | 4 | 37.87 | |

| 40 | 0.4 | 14 | 0 | 4 | 31.91 | |

| 41 | 0.4 | 14 | 2.8 | 9 | 43.14 | |

| 42 | 0.4 | 14 | 1.4 | 9 | 39.82 | |

| 43 | 0.4 | 14 | 4.2 | 9 | 38.46 | |

| 44 | 0.4 | 14 | 0 | 9 | 33.83 | |

| 45 | 0.4 | 14 | 4.2 | 13 | 39.72 | |

| 46 | 0.4 | 14 | 2.8 | 13 | 36.40 | |

| 47 | 0.4 | 14 | 0 | 13 | 33.10 | |

| 48 | 0.4 | 14 | 1.4 | 13 | 35.75 | |

| 49 | 0.4 | 21 | 0 | 0 | 26.95 | |

| 50 | 0.4 | 21 | 1.4 | 0 | 36.27 | |

| 51 | 0.4 | 21 | 4.2 | 0 | 40.90 | |

| 52 | 0.4 | 21 | 2.8 | 0 | 39.58 | |

| 53 | 0.4 | 21 | 1.4 | 4 | 46.86 | |

| 54 | 0.4 | 21 | 2.8 | 4 | 45.51 | |

| 55 | 0.4 | 21 | 0 | 4 | 33.54 | |

| 56 | 0.4 | 21 | 4.2 | 4 | 41.50 | |

| 57 | 0.4 | 21 | 2.8 | 9 | 47.43 | |

| 58 | 0.4 | 21 | 1.4 | 9 | 43.45 | |

| 59 | 0.4 | 21 | 0 | 9 | 36.80 | |

| 60 | 0.4 | 21 | 4.2 | 9 | 42.75 | |

| 61 | 0.4 | 21 | 2.8 | 13 | 44.70 | |

| 62 | 0.4 | 21 | 1.4 | 13 | 41.37 | |

| 63 | 0.4 | 21 | 0 | 13 | 38.72 | |

| 64 | 0.4 | 21 | 4.2 | 13 | 46.00 | |

| 65 | 0.4 | 28 | 1.4 | 0 | 29.97 | |

| 66 | 0.4 | 28 | 4.2 | 0 | 37.94 | |

| 67 | 0.4 | 28 | 2.8 | 0 | 35.29 | |

| 68 | 0.4 | 28 | 0 | 4 | 31.91 | |

| 69 | 0.4 | 28 | 4.2 | 4 | 37.87 | |

| 70 | 0.4 | 28 | 1.4 | 4 | 42.56 | |

| 71 | 0.4 | 28 | 2.8 | 4 | 40.55 | |

| 72 | 0.4 | 28 | 4.2 | 9 | 38.46 | |

| 73 | 0.4 | 28 | 1.4 | 9 | 39.82 | |

| 74 | 0.4 | 28 | 2.8 | 9 | 43.14 | |

| 75 | 0.4 | 28 | 0 | 9 | 33.83 | |

| 76 | 0.4 | 28 | 4.2 | 13 | 39.72 | |

| 77 | 0.5 | 3 | 0 | 0 | 26.95 | |

| 78 | 0.5 | 3 | 4.2 | 13 | 42.71 | |

| 79 | 0.5 | 7 | 0 | 0 | 16.47 | |

| 80 | 0.5 | 7 | 1.4 | 0 | 21.76 | |

| 81 | 0.5 | 7 | 4.2 | 0 | 25.88 | |

| 82 | 0.5 | 7 | 2.8 | 0 | 25.29 | |

| 83 | 0.5 | 7 | 1.4 | 4 | 31.76 | |

| 84 | 0.5 | 7 | 0 | 4 | 22.35 | |

| 85 | 0.5 | 7 | 4.2 | 4 | 27.65 | |

| 86 | 0.5 | 7 | 2.8 | 4 | 30.59 | |

| 87 | 0.5 | 7 | 4.2 | 9 | 28.82 | |

| 88 | 0.5 | 7 | 0 | 9 | 23.53 | |

| 89 | 0.5 | 7 | 2.8 | 9 | 33.53 | |

| 90 | 0.5 | 7 | 1.4 | 9 | 30.00 | |

| 91 | 0.5 | 7 | 4.2 | 13 | 30.59 | |

| 92 | 0.5 | 7 | 2.8 | 13 | 29.41 | |

| 93 | 0.5 | 7 | 0 | 13 | 26.47 | |

| 94 | 0.5 | 7 | 1.4 | 13 | 28.24 | |

| 95 | 0.5 | 14 | 0 | 0 | 25.03 | |

| 96 | 0.5 | 14 | 1.4 | 0 | 28.06 | |

| 97 | 0.5 | 14 | 4.2 | 0 | 32.89 | |

| 98 | 0.5 | 14 | 2.8 | 0 | 31.66 | |

| 99 | 0.5 | 14 | 1.4 | 4 | 37.17 | |

| 100 | 0.5 | 14 | 2.8 | 4 | 36.04 | |

| 101 | 0.5 | 14 | 0 | 4 | 27.61 | |

| 102 | 0.5 | 14 | 4.2 | 4 | 34.28 | |

| 103 | 0.5 | 14 | 4.2 | 9 | 34.49 | |

| 104 | 0.5 | 14 | 1.4 | 9 | 34.99 | |

| 105 | 0.5 | 14 | 2.8 | 9 | 38.60 | |

| 106 | 0.5 | 14 | 0 | 9 | 30.20 | |

| 107 | 0.5 | 14 | 1.4 | 13 | 32.81 | |

| 108 | 0.5 | 14 | 4.2 | 13 | 37.06 | |

| 109 | 0.5 | 14 | 2.8 | 13 | 35.84 | |

| 110 | 0.5 | 14 | 0 | 13 | 32.18 | |

| 111 | 0.5 | 21 | 0 | 0 | 25.44 | |

| 112 | 0.5 | 21 | 1.4 | 0 | 32.03 | |

| 113 | 0.5 | 21 | 4.2 | 0 | 36.27 | |

| 114 | 0.5 | 21 | 2.8 | 0 | 35.04 | |

| 115 | 0.5 | 21 | 2.8 | 4 | 40.60 | |

| 116 | 0.5 | 21 | 1.4 | 4 | 41.74 | |

| 117 | 0.5 | 21 | 4.2 | 4 | 37.06 | |

| 118 | 0.5 | 21 | 0 | 4 | 31.58 | |

| 119 | 0.5 | 21 | 4.2 | 9 | 37.85 | |

| 120 | 0.5 | 21 | 1.4 | 9 | 38.97 | |

| 121 | 0.5 | 21 | 2.8 | 9 | 43.19 | |

| 122 | 0.5 | 21 | 0 | 9 | 34.77 | |

| 123 | 0.5 | 21 | 1.4 | 13 | 37.39 | |

| 124 | 0.5 | 21 | 0 | 13 | 35.55 | |

| 125 | 0.5 | 21 | 4.2 | 13 | 41.62 | |

| 126 | 0.5 | 21 | 2.8 | 13 | 40.41 | |

| 127 | 0.5 | 28 | 0 | 0 | 28.57 | |

| 128 | 0.5 | 28 | 1.4 | 0 | 36.31 | |

| 129 | 0.5 | 28 | 4.2 | 0 | 40.48 | |

| 130 | 0.5 | 28 | 2.8 | 0 | 38.69 | |

| 131 | 0.5 | 28 | 1.4 | 4 | 45.24 | |

| 132 | 0.5 | 28 | 2.8 | 4 | 44.05 | |

| 133 | 0.5 | 28 | 4.2 | 4 | 42.26 | |

| 134 | 0.5 | 28 | 0 | 4 | 33.33 | |

| 135 | 0.5 | 28 | 2.8 | 9 | 47.62 | |

| 136 | 0.5 | 28 | 1.4 | 9 | 43.45 | |

| 137 | 0.5 | 28 | 4.2 | 9 | 42.26 | |

| 138 | 0.5 | 28 | 0 | 9 | 37.50 | |

| 139 | 0.5 | 28 | 0 | 13 | 38.69 | |

| 140 | 0.5 | 28 | 4.2 | 13 | 45.24 | |

| 141 | 0.5 | 28 | 1.4 | 13 | 41.67 | |

| 142 | 0.5 | 28 | 2.8 | 13 | 44.05 | |

| 143 | [34] | 0.84 | 3 | 5 | 5 | 15.00 |

| 144 | 0.84 | 3 | 0 | 5 | 14.00 | |

| 145 | 0.84 | 7 | 0 | 5 | 15.00 | |

| 146 | 0.84 | 7 | 5 | 5 | 17.00 | |

| 147 | 0.84 | 14 | 5 | 5 | 20.00 | |

| 148 | 0.84 | 14 | 0 | 5 | 18.00 | |

| 149 | 0.84 | 28 | 5 | 5 | 24.00 | |

| 150 | 0.84 | 28 | 0 | 5 | 20.00 | |

| 151 | [35] | 0.6 | 7 | 2 | 5 | 34.09 |

| 152 | 0.6 | 7 | 3 | 5 | 31.79 | |

| 153 | 0.6 | 28 | 1 | 5 | 43.69 | |

| 154 | 0.6 | 28 | 2 | 5 | 44.47 | |

| 155 | 0.6 | 28 | 0 | 5 | 41.04 | |

| 156 | 0.6 | 28 | 3 | 5 | 42.81 | |

| 157 | 0.6 | 90 | 0 | 5 | 50.03 | |

| 158 | 0.6 | 90 | 2 | 5 | 53.68 | |

| 159 | 0.6 | 90 | 1 | 5 | 51.04 | |

| 160 | [36] | 0.4 | 3 | 0 | 0 | 22.80 |

| 161 | 0.4 | 3 | 2 | 0 | 22.60 | |

| 162 | 0.4 | 3 | 1.5 | 0 | 24.00 | |

| 163 | 0.4 | 3 | 0 | 10 | 19.90 | |

| 164 | 0.4 | 3 | 2 | 10 | 18.80 | |

| 165 | 0.4 | 7 | 2 | 0 | 27.10 | |

| 166 | 0.4 | 7 | 1.5 | 0 | 28.80 | |

| 167 | 0.4 | 7 | 0 | 15 | 25.80 | |

| 168 | 0.4 | 7 | 2 | 10 | 26.10 | |

| 169 | 0.4 | 7 | 0 | 10 | 29.40 | |

| 170 | 0.4 | 28 | 0 | 0 | 34.50 | |

| 171 | 0.4 | 28 | 2 | 0 | 32.50 | |

| 172 | 0.4 | 28 | 1.5 | 0 | 37.90 | |

| 173 | 0.4 | 28 | 0 | 15 | 42.60 | |

| 174 | [37] | 0.5 | 3 | 1 | 0 | 29.21 |

| 175 | 0.5 | 3 | 2.5 | 0 | 31.31 | |

| 176 | 0.5 | 3 | 2 | 0 | 31.55 | |

| 177 | 0.5 | 3 | 1.5 | 0 | 30.61 | |

| 178 | 0.5 | 3 | 0 | 0 | 25.00 | |

| 179 | 0.5 | 3 | 0 | 30 | 28.27 | |

| 180 | 0.5 | 3 | 2 | 30 | 35.52 | |

| 181 | 0.5 | 3 | 0 | 20 | 27.10 | |

| 182 | 0.5 | 3 | 2 | 20 | 37.16 | |

| 183 | 0.5 | 3 | 2 | 10 | 32.25 | |

| 184 | 0.5 | 3 | 0 | 10 | 25.70 | |

| 185 | 0.5 | 7 | 0 | 0 | 31.08 | |

| 186 | 0.5 | 7 | 0 | 40 | 35.29 | |

| 187 | 0.5 | 7 | 2 | 40 | 42.07 | |

| 188 | 0.5 | 7 | 2 | 30 | 43.71 | |

| 189 | 0.5 | 7 | 0 | 30 | 36.22 | |

| 190 | 0.5 | 7 | 2 | 20 | 44.18 | |

| 191 | 0.5 | 7 | 0 | 20 | 34.82 | |

| 192 | 0.5 | 7 | 0 | 10 | 33.18 | |

| 193 | 0.5 | 7 | 2 | 10 | 39.26 | |

| 194 | 0.5 | 28 | 1 | 0 | 51.66 | |

| 195 | 0.5 | 28 | 0 | 0 | 44.88 | |

| 196 | 0.5 | 28 | 2.5 | 0 | 54.47 | |

| 197 | 0.5 | 28 | 2 | 0 | 54.70 | |

| 198 | 0.5 | 28 | 2 | 40 | 62.19 | |

| 199 | 0.5 | 28 | 0 | 40 | 52.36 | |

| 200 | 0.5 | 28 | 2 | 30 | 64.06 | |

| 201 | 0.5 | 28 | 0 | 30 | 53.30 | |

| 202 | 0.5 | 28 | 0 | 20 | 51.43 | |

| 203 | 0.5 | 28 | 2 | 20 | 66.87 | |

| 204 | 0.5 | 28 | 2 | 10 | 59.85 | |

| 205 | 0.5 | 28 | 0 | 10 | 48.85 | |

| No. of Data = 205 | Ranged between 0.4 and 0.84 | Varied between 3 and 90 Days | Ranged between 0 and 15% | Ranged between 0 and 40% | Varied between 14 and 67 MPa | |

| LM No: | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model Parameters | a | 1.71 | −6.42 | 0.08 | 6.84 | 0.28 | 4.02 | 5.35 | −16.8 | 5.89 | −2.73 | 10.73 | 4.25 | 5.83 | 2.08 |

| b | 6.88 | 7.41 | 2.46 | 3.47 | 12.64 | −1.56 | −6.63 | −2.13 | 2.27 | 7.26 | −1.29 | −0.26 | −2.86 | 1.70 | |

| c | −10.2 | 0.98 | −4.43 | 6.14 | −4.81 | 5.09 | −3.40 | −1.08 | 14.48 | −0.58 | −1.64 | 0.97 | 7.04 | 3.92 | |

| d | 4.83 | −0.67 | −0.83 | −2.05 | −2.78 | 6.71 | 4.56 | 8.22 | −4.98 | 3.00 | 1.33 | 0.03 | 6.22 | −2.30 | |

| e | −3.28 | 0.07 | −5.60 | 5.85 | −3.14 | 0.87 | −6.99 | −10.6 | −7.96 | 2.13 | 6.91 | −2.37 | 1.56 | −2.58 | |

| Nodes | 0.80 | 1.58 | −3.90 | 0.75 | 1.99 | 2.08 | −1.79 | 0.73 | 3.28 | −0.73 | 1.46 | 0.86 | −1.64 | −5.93 | |

| Threshold | −1.75 | ||||||||||||||

| # of Layers | # of Neuron | # of Neurons for Each Layer * | R ** | MAE (MPa) | RMSE (MPa) |

|---|---|---|---|---|---|

| 1 | 2 | 2 | 0.862 | 4.019 | 5.048 |

| 1 | 3 | 3 | 0.883 | 3.729 | 4.675 |

| 1 | 4 | 4 | 0.897 | 3.467 | 4.416 |

| 1 | 5 | 5 | 0.921 | 3.1 | 3.908 |

| 1 | 6 | 6 | 0.928 | 2.715 | 3.552 |

| 1 | 7 | 7 | 0.929 | 2.623 | 3.515 |

| 1 | 8 | 8 | 0.94 | 2.452 | 3.29 |

| 1 | 9 | 9 | 0.937 | 2.54 | 3.299 |

| 1 | 10 | 10 | 0.943 | 2.395 | 3.149 |

| 1 | 12 | 12 | 0.945 | 2.392 | 3.14 |

| 1 | 14 | 14 | 0.948 | 2.19 | 3.005 |

| 1 | 15 | 15 | 0.944 | 2.443 | 3.122 |

| 2 | 4 | 2 + 2 | 0.857 | 3.862 | 4.869 |

| 2 | 6 | 2 + 4 | 0.857 | 3.851 | 4.863 |

| 2 | 8 | 4 + 4 | 0.901 | 3.286 | 4.202 |

| 2 | 12 | 4 + 8 | 0.942 | 2.383 | 3.158 |

| 2 | 14 | 6 + 8 | 0.95 | 2.143 | 2.936 |

| 2 | 15 | 6 + 9 | 0.931 | 2.557 | 3.422 |

| 2 | 16 | 6 + 10 | 0.939 | 2.436 | 3.269 |

| 2 | 16 | 2 + 14 | 0.889 | 3.46 | 4.317 |

| 2 | 15 | 5 + 10 | 0.932 | 2.612 | 3.408 |

| 2 | 12 | 8 + 4 | 0.956 | 2.048 | 2.771 |

| 2 | 16 | 8 + 8 | 0.962 | 1.815 | 2.552 |

| 2 | 18 | 9 + 9 | 0.964 | 1.863 | 2.58 |

| 2 | 18 | 12 + 6 | 0.961 | 1.878 | 2.627 |

| 2 | 21 | 14 + 7 | 0.977 | 1.392 | 2.1 |

| 3 | 12 | 2 + 4 + 6 | 0.857 | 3.857 | 4.865 |

| 3 | 18 | 3 + 6 + 9 | 0.92 | 2.883 | 3.702 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahimzadeh, C.Y.; Salih, A.; Barzinjy, A.A. RETRACTED: Systematic Multiscale Models to Predict the Compressive Strength of Cement Paste as a Function of Microsilica and Nanosilica Contents, Water/Cement Ratio, and Curing Ages. Sustainability 2022, 14, 1723. https://doi.org/10.3390/su14031723

Rahimzadeh CY, Salih A, Barzinjy AA. RETRACTED: Systematic Multiscale Models to Predict the Compressive Strength of Cement Paste as a Function of Microsilica and Nanosilica Contents, Water/Cement Ratio, and Curing Ages. Sustainability. 2022; 14(3):1723. https://doi.org/10.3390/su14031723

Chicago/Turabian StyleRahimzadeh, Chiya Y., Ahmed Salih, and Azeez A. Barzinjy. 2022. "RETRACTED: Systematic Multiscale Models to Predict the Compressive Strength of Cement Paste as a Function of Microsilica and Nanosilica Contents, Water/Cement Ratio, and Curing Ages" Sustainability 14, no. 3: 1723. https://doi.org/10.3390/su14031723

APA StyleRahimzadeh, C. Y., Salih, A., & Barzinjy, A. A. (2022). RETRACTED: Systematic Multiscale Models to Predict the Compressive Strength of Cement Paste as a Function of Microsilica and Nanosilica Contents, Water/Cement Ratio, and Curing Ages. Sustainability, 14(3), 1723. https://doi.org/10.3390/su14031723