A Numerical Methodology to Predict the Maximum Power Output of Tidal Stream Arrays

Abstract

:1. Introduction

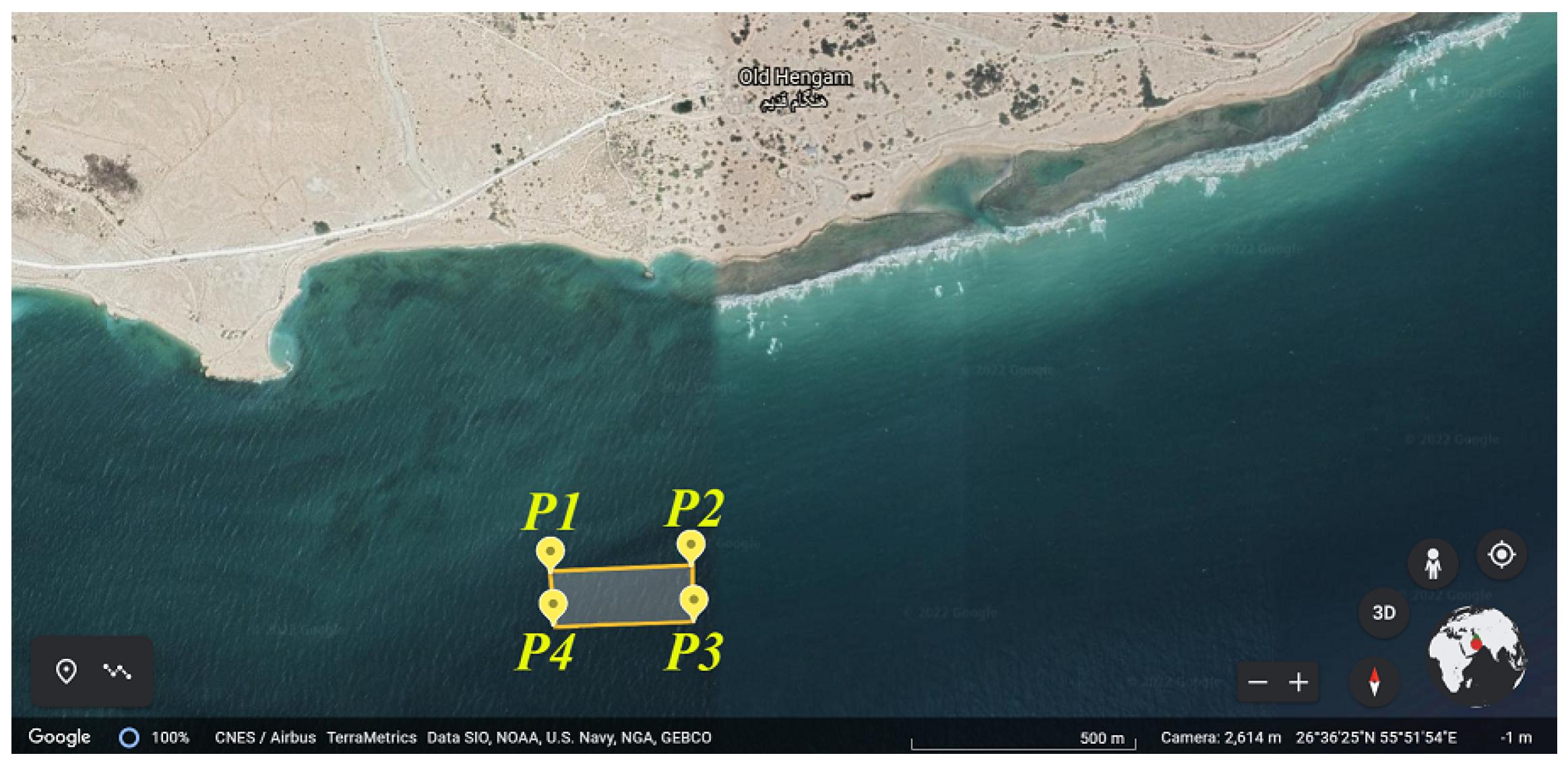

2. Tidal Site Selection

- Small pilot farms are preferred because of the availability of giant oil and gas resources in this part of Iran and the need for significant capital investment on the tidal energy projects.

- Existence of fragile marine life and habitat in this site leads to environmental issues for the development of large tidal farms in this site. Again small pilot farms are preferred.

- Minor variations of bathymetry in this site [1]. This will significantly decrease computational time and cost. Furthermore, it smoothens the pathway for idealizing the geometry and the flow field within site.

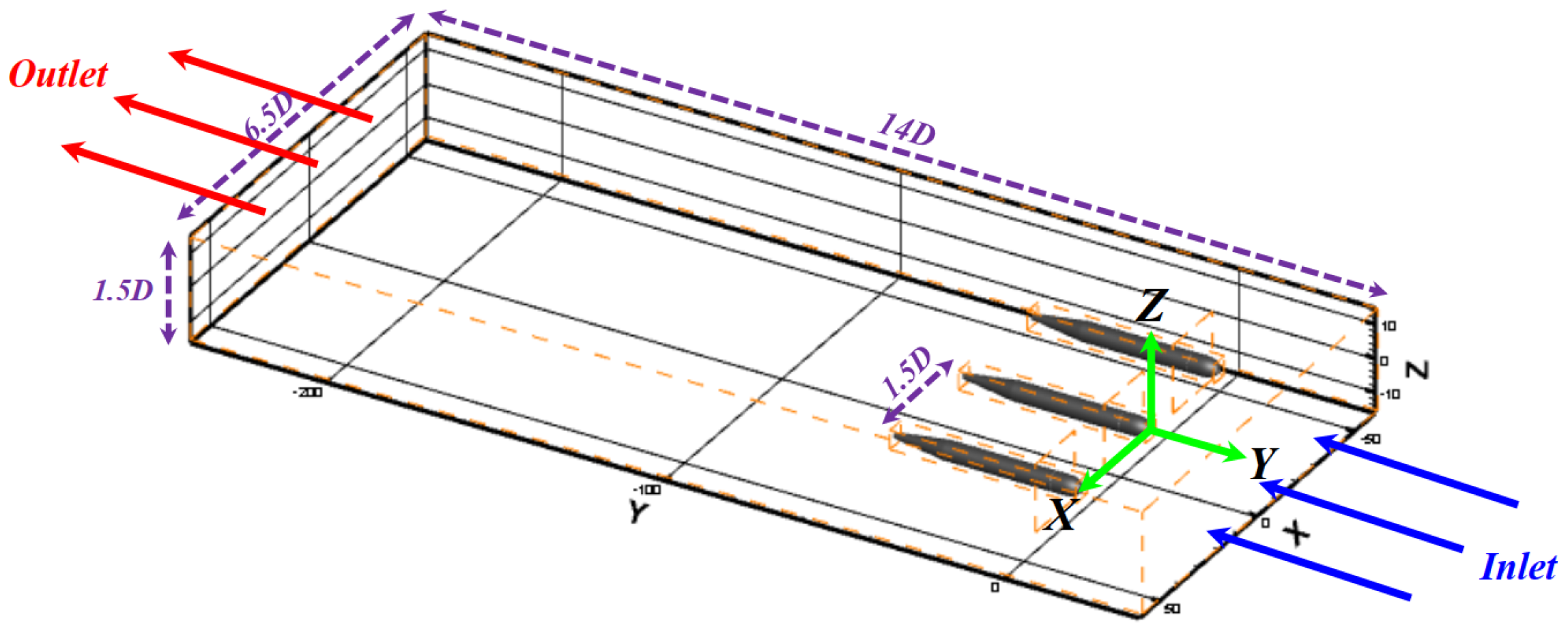

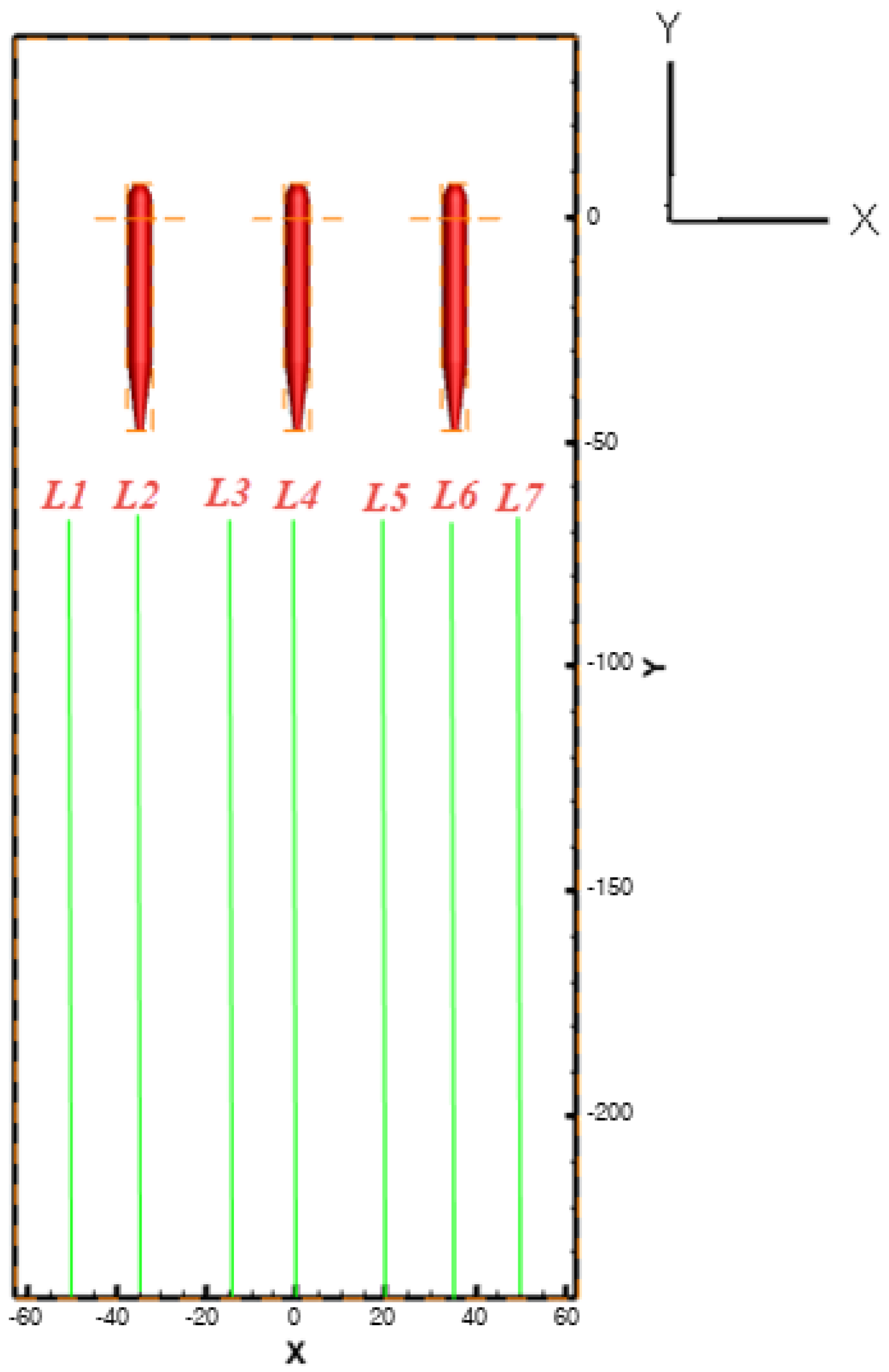

3. Numerical Model

3.1. Turbine Modeling: BEM

3.2. Model Setup and Boundary Conditions

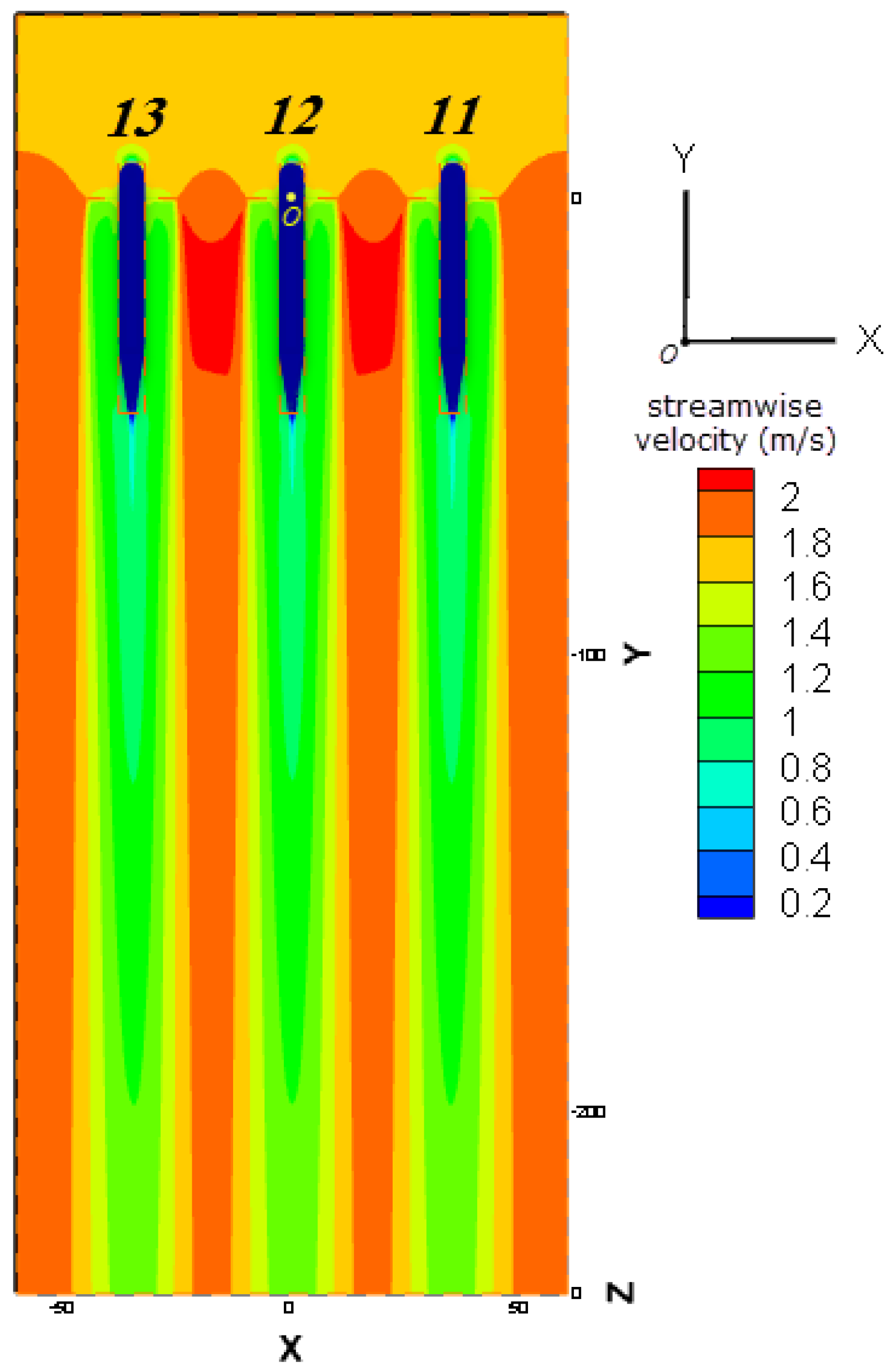

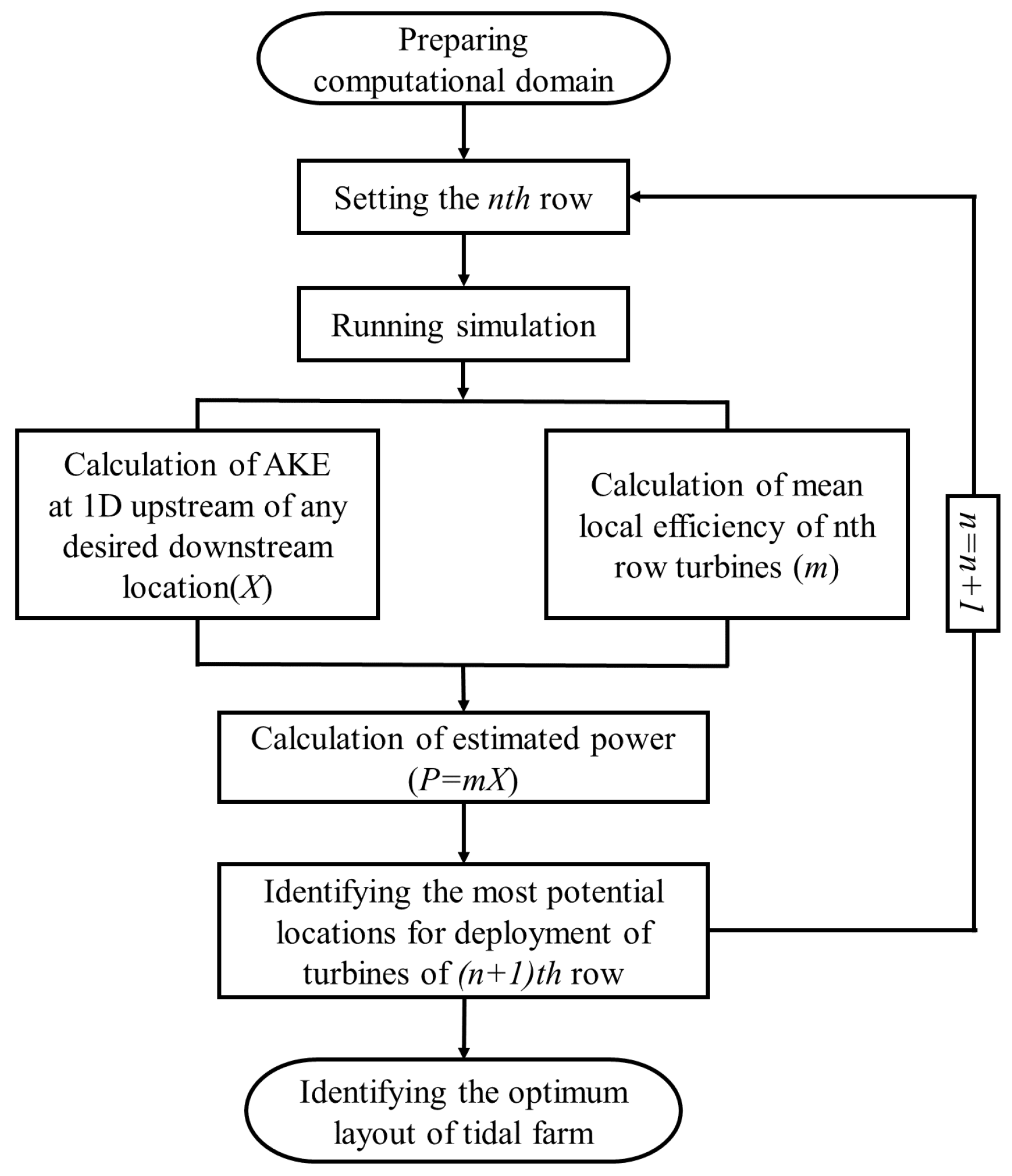

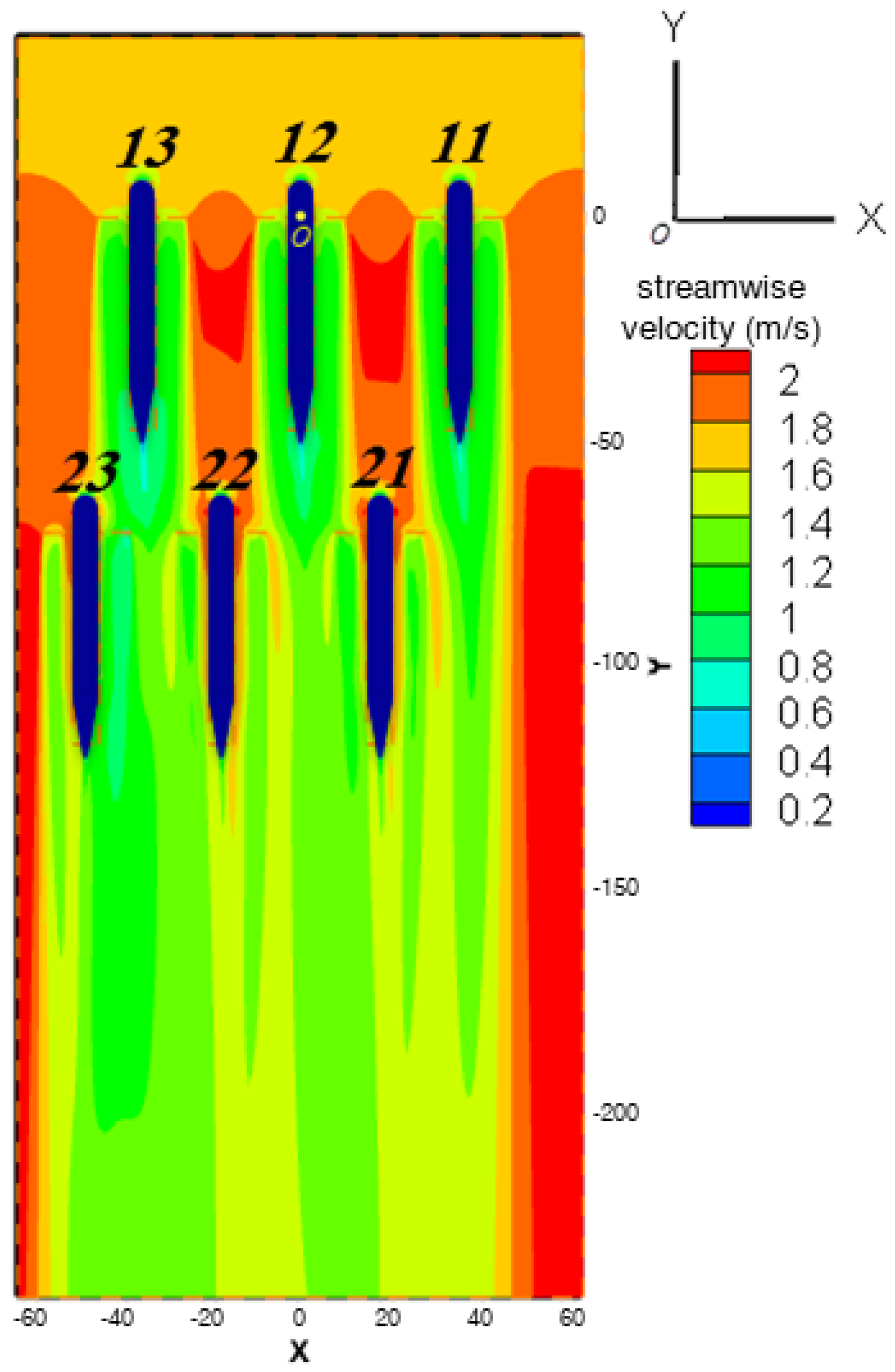

4. Numerical Results

- Basically, it is preferred that the turbines be located in a position with maximum kinetic energy flux and thus maximum energy.

- Turbulence effect should not be too destructive to cause damages on rotor blades and other devices.

- A minimum distance between rotors should be adopted to let the biggest marine biota pass safely through rotors.

- Downstream turbines cannot be placed very close to the upstream turbines due to the negative effects of rotating blades. These effects can deteriorate tidal devices and eclipse the efficiency of the turbine.

5. Discussions and Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Local efficiency | |

| Global efficiency | |

| Uniform streamwise velocity at inlet | |

| Velocity at 1D upstream of turbine | |

| ADM | Actuator Disk Model |

| AKE | Available Kinetic Energy |

| AOA | Angle of Attack |

| BEM | Blade Element Momentum |

| CFD | Computational Fluid Dynamics |

| DOE | Department of Energy |

| HAHT | Horizontal Axis Hyrokinetic Turbines |

| HAWT | Horizontal Axis Wind Turbines |

| MHK | Marine Hydrokinetic |

| NAKE | Normalized Available Kinetic Energy |

| NREL | National Renewable Energy Laboratory |

| NTKE | Normalised Turbulence Kinetic Energy |

| RANS | Reynolds Averaged Navier-Stokes |

| SRF | Single Reference Frame |

| VBM | Virtual Blade Model |

References

- Radfar, S.; Panahi, R.; Javaherchi, T.; Filom, S.; Mazyaki, A.R. A comprehensive insight into tidal stream energy farms in Iran. Renew. Sustain. Energy Rev. 2017, 79, 323–338. [Google Scholar] [CrossRef]

- Thiébot, J.; Coles, D.; Bennis, A.C.; Guillou, N.; Neill, S.; Guillou, S.; Piggott, M. Numerical modelling of hydrodynamics and tidal energy extraction in the Alderney Race: A review. Philos. Trans. R. Soc. A 2020, 378, 20190498. [Google Scholar] [CrossRef] [PubMed]

- Harrison, M.; Batten, W.; Myers, L.; Bahaj, A. Comparison between CFD simulations and experiments for predicting the far wake of horizontal axis tidal turbines. IET Renew. Power Gener. 2010, 4, 613–627. [Google Scholar] [CrossRef] [Green Version]

- Malki, R.; Masters, I.; Williams, A.; Croft, T. The influence of tidal stream turbine spacing on performance. In Proceedings of the 9th European Wave and Tidal Energy Conference (EWTEC), Southampton, UK, 5–9 September 2011; pp. 10–14. [Google Scholar]

- Edmunds, M.; Malki, R.; Williams, A.; Masters, I.; Croft, T. Aspects of tidal stream turbine modelling in the natural environment using a coupled BEM–CFD model. Int. J. Mar. Energy 2014, 7, 20–42. [Google Scholar] [CrossRef] [Green Version]

- Tan, J.; Wang, S.; Yuan, P.; Wang, D.; Ji, H. The Energy Capture Efficiency Increased by Choosing the Optimal Layout of Turbines in Tidal Power Farm. In Energy Solutions to Combat Global Warming; Springer: Cham, Switzerland, 2017; pp. 207–226. [Google Scholar]

- Javaherchi, T.; Antheaume, S.; Aliseda, A. Hierarchical methodology for the numerical simulation of the flow field around and in the wake of horizontal axis wind turbines: Rotating reference frame, blade element method and actuator disk model. Wind Eng. 2014, 38, 181–201. [Google Scholar] [CrossRef]

- Lombardi, N.; Ordonez-Sanchez, S.; Zanforlin, S.; Johnstone, C. A hybrid BEM-CFD virtual blade model to predict interactions between tidal stream turbines under wave conditions. J. Mar. Sci. Eng. 2020, 8, 969. [Google Scholar] [CrossRef]

- Zori, L.A.; Rajagopalan, R.G. Navier—Stokes Calculations of Rotor—Airframe Interaction in Forward Flight. J. Am. Helicopter Soc. 1995, 40, 57–67. [Google Scholar] [CrossRef]

- Mozafari, A.J. Numerical Modeling of Tidal Turbines: Methodology Development and Potential Physical Environmental Effects; University of Washington: Washington, DC, USA, 2010. [Google Scholar]

- Ruith, M. Unstructured, multiplex rotor source model with thrust and moment trimming-Fluent’s VBM model. In Proceedings of the 23rd AIAA Applied Aerodynamics Conference, Toronto, ON, Canada, 6–9 June 2005; p. 5217. [Google Scholar]

- Javaherchi Mozafari, A.T. Numerical Investigation of Marine Hydrokinetic Turbines: Methodology Development for Single Turbine and Small Array Simulation, and Application to Flume and Full-Scale Reference Models. Ph.D. Thesis, University of Washington, Washington, DC, USA, 2014. [Google Scholar]

- Sufian, S.F. Numerical Modelling of Impacts from Horizontal Axis Tidal Turbines; The University of Liverpool: Liverpool, UK, 2016. [Google Scholar]

- Li, X.; Li, M.; McLelland, S.J.; Jordan, L.B.; Simmons, S.M.; Amoudry, L.O.; Ramirez-Mendoza, R.; Thorne, P.D. Modelling tidal stream turbines in a three-dimensional wave-current fully coupled oceanographic model. Renew. Energy 2017, 114, 297–307. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Li, M.; Jordan, L.B.; McLelland, S.; Parsons, D.R.; Amoudry, L.O.; Song, Q.; Comerford, L. Modelling impacts of tidal stream turbines on surface waves. Renew. Energy 2019, 130, 725–734. [Google Scholar] [CrossRef]

- Attene, F.; Balduzzi, F.; Bianchini, A.; Campobasso, M.S. Using Experimentally Validated Navier-Stokes CFD to Minimize Tidal Stream Turbine Power Losses Due to Wake/Turbine Interactions. Sustainability 2020, 12, 8768. [Google Scholar] [CrossRef]

- Bianchini, A.; Balduzzi, F.; Gentiluomo, D.; Ferrara, G.; Ferrari, L. Potential of the Virtual Blade Model in the analysis of wind turbine wakes using wind tunnel blind tests. Energy Procedia 2017, 126, 573–580. [Google Scholar] [CrossRef]

- Naderi, S.; Parvanehmasiha, S.; Torabi, F. Modeling of horizontal axis wind turbine wakes in Horns Rev offshore wind farm using an improved actuator disc model coupled with computational fluid dynamic. Energy Convers. Manag. 2018, 171, 953–968. [Google Scholar] [CrossRef]

- Lawson, M.J.; Li, Y.; Sale, D.C. Development and verification of a computational fluid dynamics model of a horizontal-axis tidal current turbine. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Rotterdam, The Netherlands, 19–24 June 2011; Volume 44373, pp. 711–720. [Google Scholar]

- CTCN. Tidal Energy; Energy Research Centre of the Netherlands (ECN). 2016. Available online: https://www.ctc-n.org/technologies/tidal-energy (accessed on 10 December 2021).

- Filom, S.; Radfar, S.; Panahi, R.; Amini, E.; Neshat, M. Exploring Wind Energy Potential as a Driver of Sustainable Development in the Southern Coasts of Iran: The Importance of Wind Speed Statistical Distribution Model. Sustainability 2021, 13, 7702. [Google Scholar] [CrossRef]

- Masters, I.; Williams, A.; Croft, T.N.; Togneri, M.; Edmunds, M.; Zangiabadi, E.; Fairley, I.; Karunarathna, H. A comparison of numerical modelling techniques for tidal stream turbine analysis. Energies 2015, 8, 7833–7853. [Google Scholar] [CrossRef] [Green Version]

- Li, X. Three-Dimensional Modelling of Tidal Stream Energy Extraction for Impact Assessment; The University of Liverpool: Liverpool, UK, 2016. [Google Scholar]

- Makridis, A.; Chick, J. Validation of a CFD model of wind turbine wakes with terrain effects. J. Wind. Eng. Ind. Aerodyn. 2013, 123, 12–29. [Google Scholar] [CrossRef]

- Javaherchi, T.; Stelzenmuller, N.; Aliseda, A. Experimental and numerical analysis of the performance and wake of a scale–model horizontal axis marine hydrokinetic turbine. J. Renew. Sustain. Energy 2017, 9, 044504. [Google Scholar] [CrossRef]

- Sæterstad, M.L. Dimensioning Loads for a Tidal Turbine. Master’s Thesis, Department of Energy and Process Engineering, NTNU, Trondheim, Norway, 2011. [Google Scholar]

- DNVGL-ST-0164: Tidal Turbines. Standard, DNV.GL. 2015. Available online: https://www.dnv.com/energy/standards-guidelines/dnv-st-0164-tidal-turbines.html (accessed on 13 November 2021).

- Hansen, K.S. Benchmarking of Lillgrund offshore wind farm scale wake models. In Proceedings of the EERA DeepWind 2014 Deep Sea Offshore Wind R & D Conference, Trondheim, Norway, 22–24 January 2014. [Google Scholar]

| Corner ID | Latitude (deg) | Longitude (deg) |

|---|---|---|

| P1 | 26.6072 | 55.8700 |

| P2 | 26.6072 | 55.8728 |

| P3 | 26.6060 | 55.8728 |

| P4 | 26.6060 | 55.8700 |

| Turbine ID | AKE at 1D Upstream (kW) | Power (kW) | (%) | (%) |

|---|---|---|---|---|

| 11 | 782.08 | 326.78 | 41.82 | 41.09 |

| 12 | 782.49 | 332.99 | 42.56 | 41.87 |

| 13 | 782.10 | 327.07 | 41.78 | 41.13 |

| Distance from the First Row | NAKE | NTKE |

|---|---|---|

| 2D | 1.31 | 0.115 |

| 2.5D | 1.28 | 0.110 |

| 3D | 1.26 | 0.106 |

| 3.5D | 1.25 | 0.103 |

| 4D | 1.24 | 0.100 |

| 4.5D | 1.23 | 0.098 |

| 5D | 1.21 | 0.096 |

| Turbine ID | AKE at 1D Upstream (kW) | Extracted Power (kW) | (%) | (%) | Estimated Power Based on Equation (6) (kW) | Difference between Columns 3 and 6 (%) |

|---|---|---|---|---|---|---|

| 11 | 782.08 | 326.78 | 41.82 | 41.09 | 328.89 | −0.64 |

| 12 | 782.49 | 332.99 | 42.56 | 41.87 | 329.06 | −1.18 |

| 13 | 782.10 | 327.07 | 41.78 | 41.13 | 329.89 | −0.56 |

| 21 | 1008.03 | 417.46 | 52.49 | 41.41 | 423.91 | −1.54 |

| 22 | 1008.20 | 435.19 | 54.72 | 43.16 | 423.98 | 2.58 |

| 23 | 771.262 | 318.61 | 40.06 | 41.31 | 324.34 | −1.80 |

| Case | Downstream Distance | Rotor X-Location (*R) | Rotor Y-Location (*R) | Rotor Z-Location (*R) | Extracted Power (kW) | Estimated Power (Equation (6)) (kW) | Difference between Columns 6 and 7 (%) |

|---|---|---|---|---|---|---|---|

| 0 | −10 | 0 | 143.29 | 149.46 | −4.13 | ||

| Coaxial | 5D | −3.5 | −10 | 0 | 142.28 | 144.95 | −1.84 |

| −3.5 | −10 | 0 | 142.09 | 145.54 | −2.37 | ||

| 1 | −10 | 0 | 312.78 | 318.30 | −1.74 | ||

| Staggered | 5D | −2.5 | −10 | 0 | 310.50 | 319.50 | −2.82 |

| 4.5 | −10 | 0 | 295.72 | 303.91 | −2.70 | ||

| 0 | −15 | 0 | 165.32 | 172.77 | −4.31 | ||

| Coaxial | 7.5D | −3.5 | −15 | 0 | 166.01 | 169.72 | −2.18 |

| −3.5 | −15 | 0 | 166.36 | 169.65 | −1.95 | ||

| Staggered | 7.5D | −1 | −15 | 0 | 319.24 | 313.75 | −1.75 |

| −4.5 | −15 | 0 | 322.48 | 304.88 | 5.77 | ||

| 2.5 | −15 | 0 | 315.12 | 313.70 | 0.45 | ||

| 1 | −15 | 0 | 319.58 | 313.96 | 1.79 | ||

| −2.5 | −15 | 0 | 315.43 | 313.92 | 0.48 | ||

| 4.5 | −15 | 0 | 322.92 | 304.72 | 5.77 | ||

| 0 | −20 | 0 | 185.95 | 149.46 | −2.66 | ||

| Coaxial | 10D | −3.5 | −20 | 0 | 194.11 | 194.67 | −0.29 |

| −3.5 | −20 | 0 | 194.36 | 193.99 | 0.19 | ||

| 1 | −20 | 0 | 325.99 | 311.54 | 4.64 | ||

| Staggered | 10D | −2.5 | −20 | 0 | 321.84 | 310.70 | 3.58 |

| 4.5 | −20 | 0 | 326.33 | 312.76 | 4.34 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Radfar, S.; Panahi, R.; Majidi Nezhad, M.; Neshat, M. A Numerical Methodology to Predict the Maximum Power Output of Tidal Stream Arrays. Sustainability 2022, 14, 1664. https://doi.org/10.3390/su14031664

Radfar S, Panahi R, Majidi Nezhad M, Neshat M. A Numerical Methodology to Predict the Maximum Power Output of Tidal Stream Arrays. Sustainability. 2022; 14(3):1664. https://doi.org/10.3390/su14031664

Chicago/Turabian StyleRadfar, Soheil, Roozbeh Panahi, Meysam Majidi Nezhad, and Mehdi Neshat. 2022. "A Numerical Methodology to Predict the Maximum Power Output of Tidal Stream Arrays" Sustainability 14, no. 3: 1664. https://doi.org/10.3390/su14031664

APA StyleRadfar, S., Panahi, R., Majidi Nezhad, M., & Neshat, M. (2022). A Numerical Methodology to Predict the Maximum Power Output of Tidal Stream Arrays. Sustainability, 14(3), 1664. https://doi.org/10.3390/su14031664