Environmental Assessment of a Diesel Engine Fueled with Various Biodiesel Blends: Polynomial Regression and Grey Wolf Optimization

Abstract

:1. Introduction

- Although there are many articles in the literature regarding engine performance and exhaust emission using different biodiesel fuel blends, there is still a gap in its acoustic emissions on the diesel engine. Commonly, the diesel engine is one of the major sources of noise in the automobile industry. Accordingly, significant consideration should be taken to minimize diesel engine noise levels.

- Biodiesel fuel has been extensively researched, as mentioned in the preceding literature. However, there is limited study in the literature on the use of the latest up-to-date optimization approaches in terms of GWO for environmental evaluation of corn, palm, and sunflower biodiesel blends. The GWO method has superior qualities over other swarm intelligence approaches, such as its high flexibility and speedy programmability [55]. Furthermore, GWO requires no search space derivation information and operates with fewer parameters [56]. Through the search phase, the algorithm benefits from a balance of exploration and exploitation, leading to high convergence [57].

- Moreover, there is no current literature on using polynomial regression with the GWO algorithm to reduce diesel engine exhaust emissions and improve engine performance. Considering the paucity of studies in the literature on the implementation of GWO in internal combustion engines, additional research is needed. The primary purpose of this research is to use the GWO to determine the optimal engine speed and fuel type in order to reduce exhaust and noise emissions, as well as to improve engine performance. The significant technical benefit of optimizing fuel type and engine speed is that it reduces the environmental effect of diesel engine exhaust and noise emissions while also improving engine performance. Furthermore, finding the relationship between independent factors, mathematically modeling the system, is an important benefit in cost and time savings by minimizing the number of experiments.

2. Experimental Setup, Equipment, and Procedure

2.1. Biodiesel Preparation

2.2. Exhaust Emission Measurement

2.3. Engine Noise Measurement

3. Mathematical Model

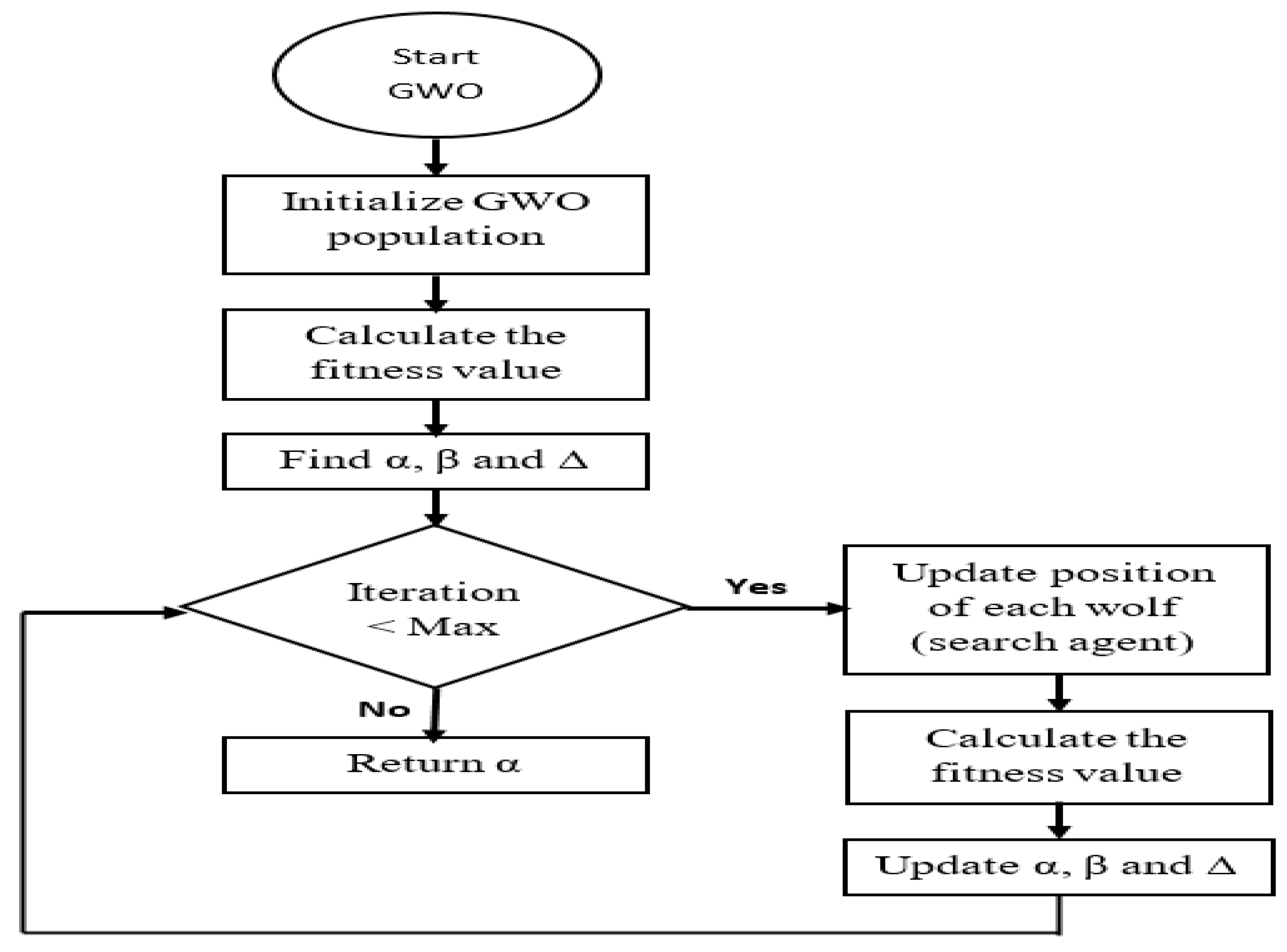

4. Parameter Optimization

- The first level reflects the command of the group. Alpha (α) is the name given to a wolf at this rank. The alpha is in charge of determining whether or not to hunt and giving commands to the other wolves in the pack. As a result, it might be deemed the best option.

- The chain’s nesting level is known as beta (β). At this stage, wolves assist alphas in making choices and monitoring the behavior of other groups. When alphas die or get elderly, betas can take their place.

- The bottom level has the lowest ranks, the delta (Δ) and omega (ω), who eat last after the upper-level wolves have finished.

5. Results and Discussion

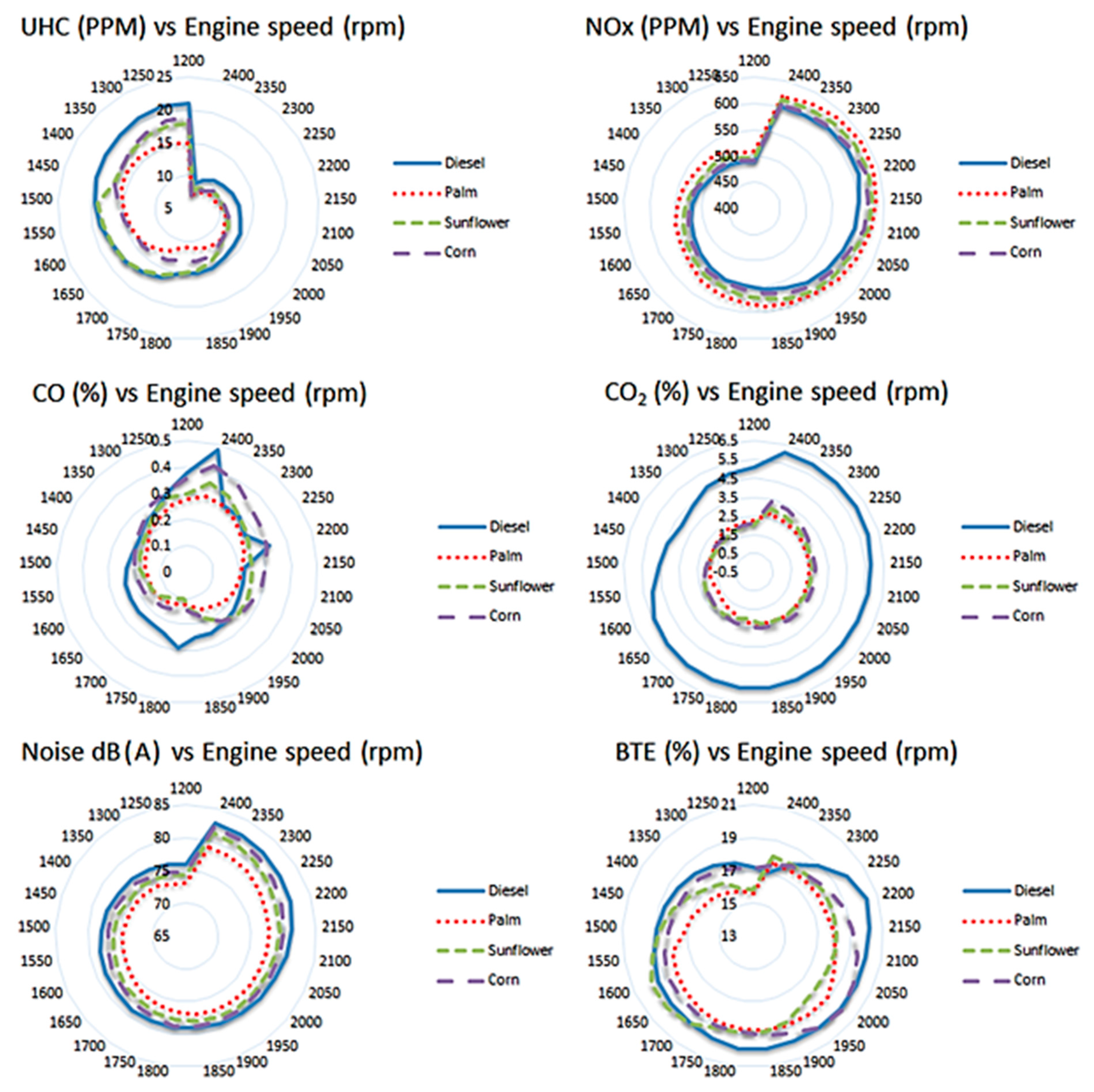

5.1. Exhaust Emission Analysis

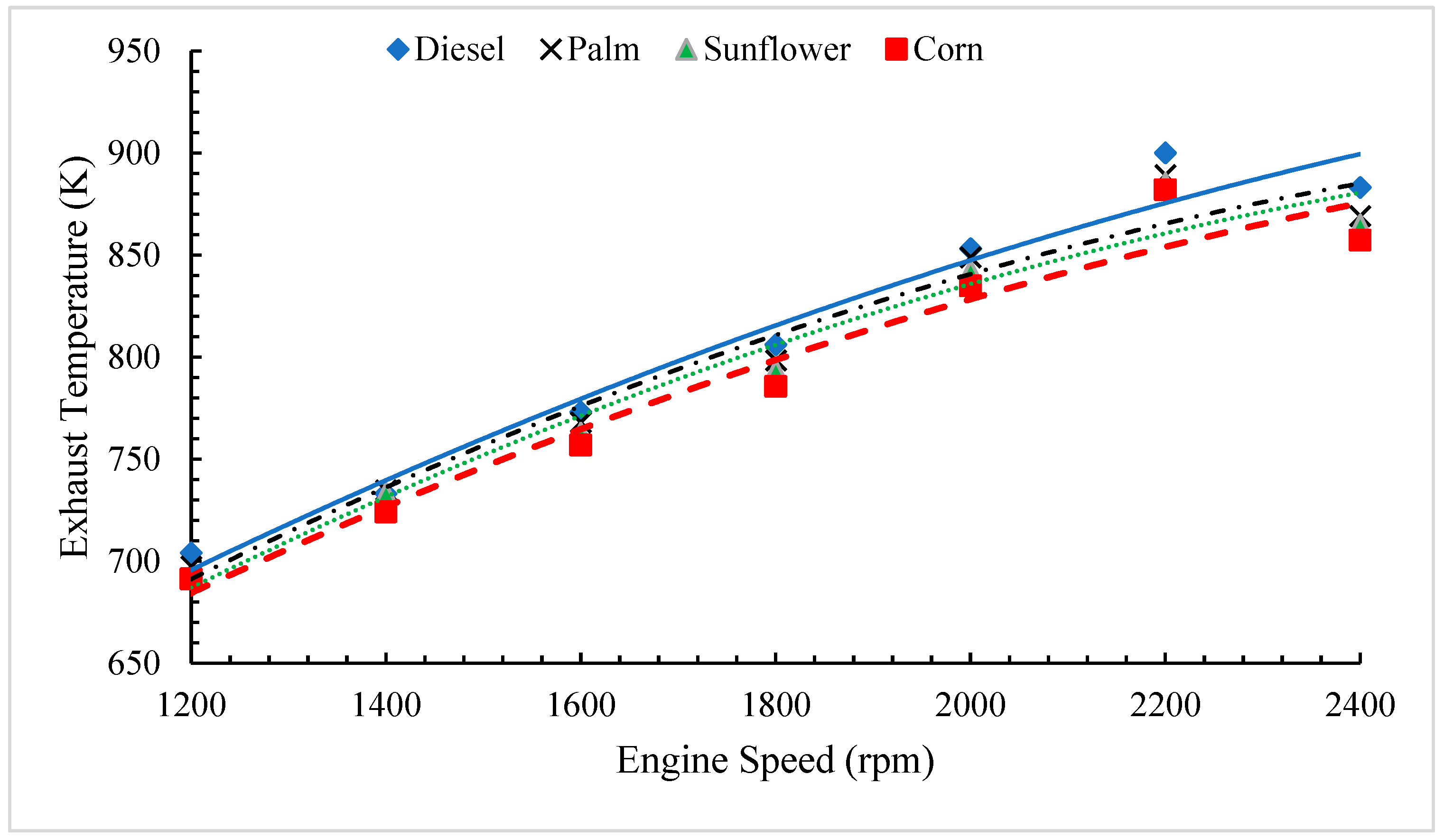

5.1.1. Exhaust Temperature

5.1.2. Unburned Hydrocarbon Emission (UHC)

5.1.3. Carbon Dioxide Emission (CO2)

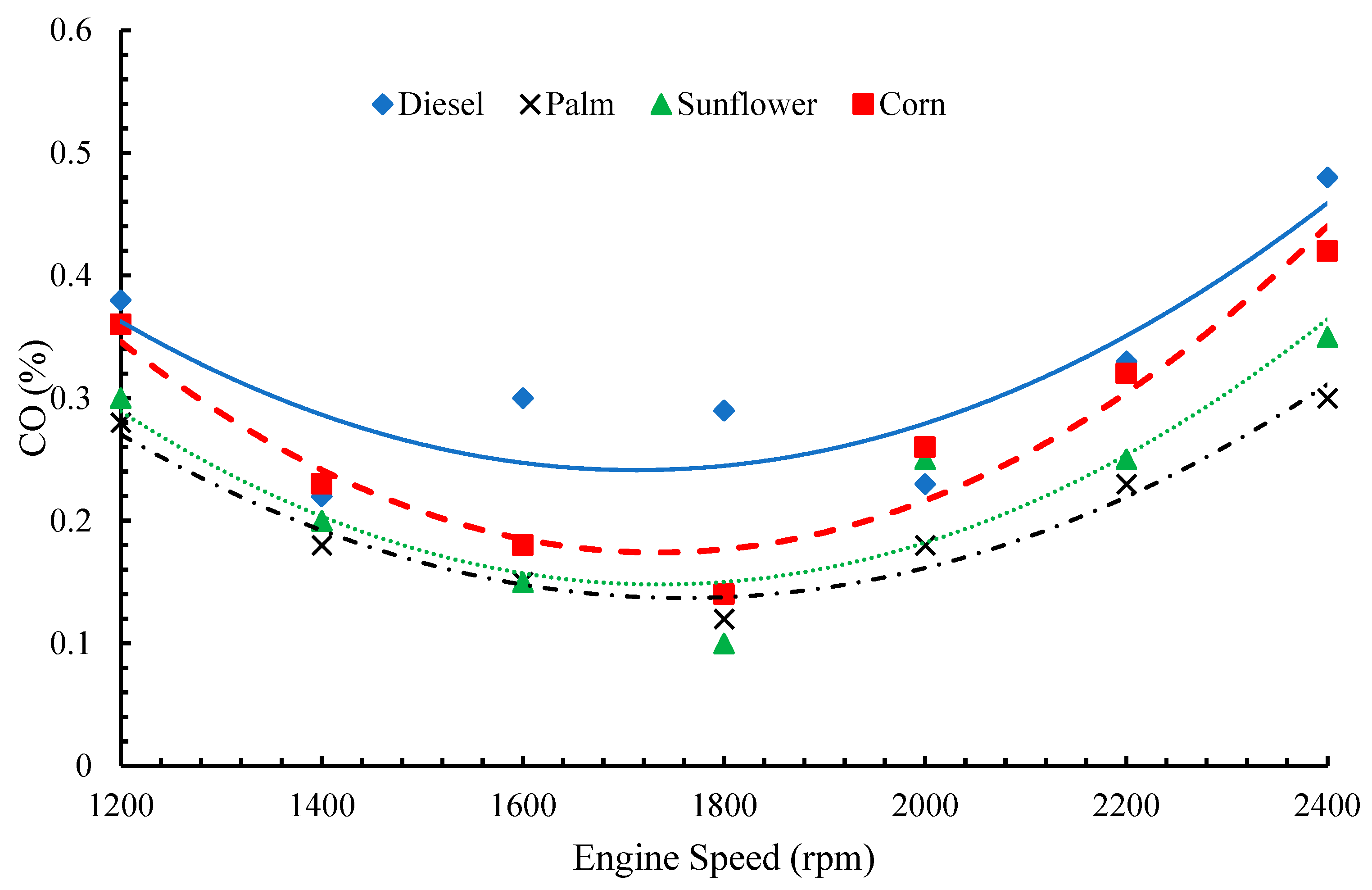

5.1.4. Carbon Monoxide Emission (CO)

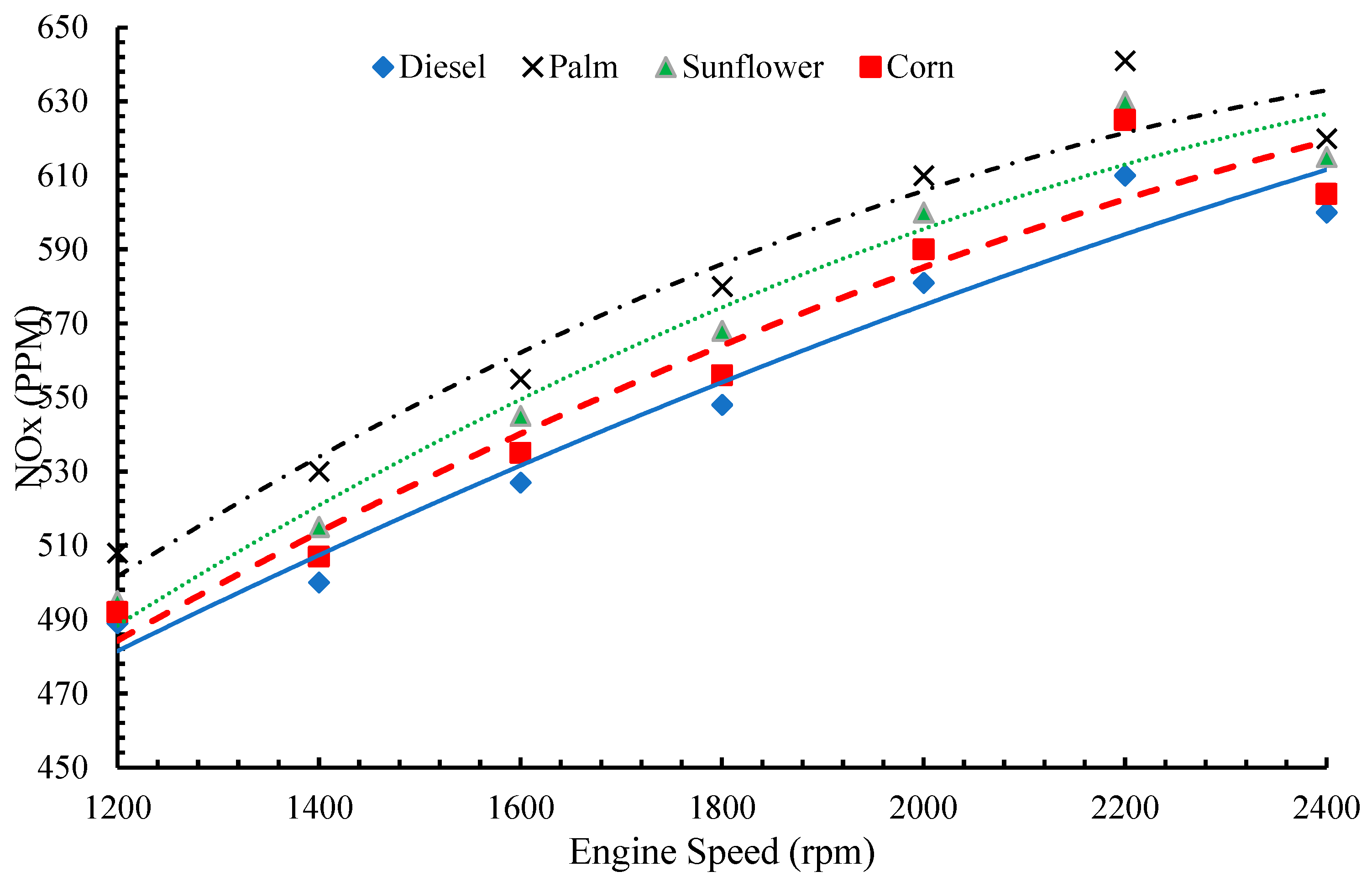

5.1.5. Nitrogen Oxides Emission (NOx)

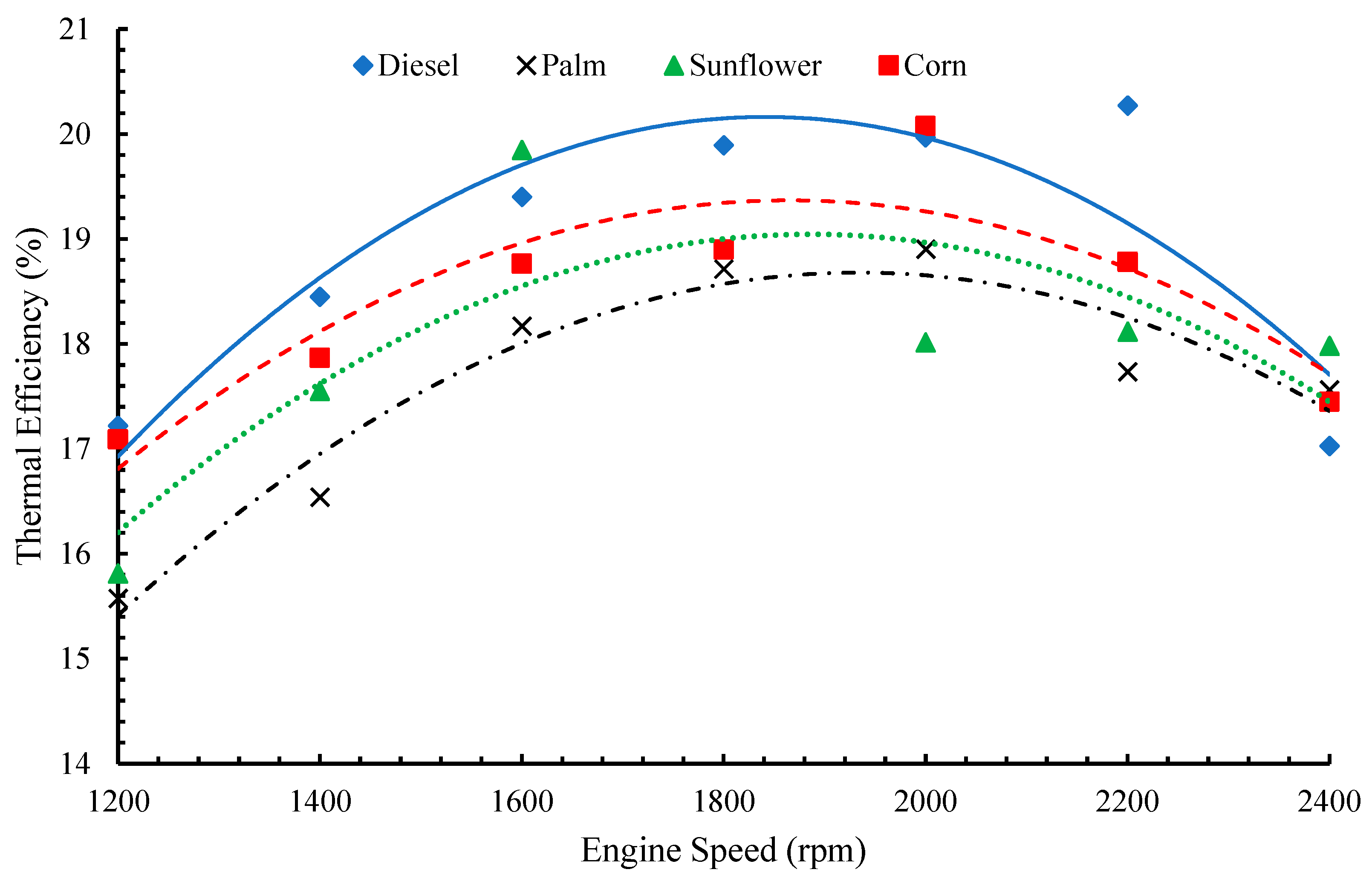

5.2. Engine Performance: Brake Thermal Efficiency

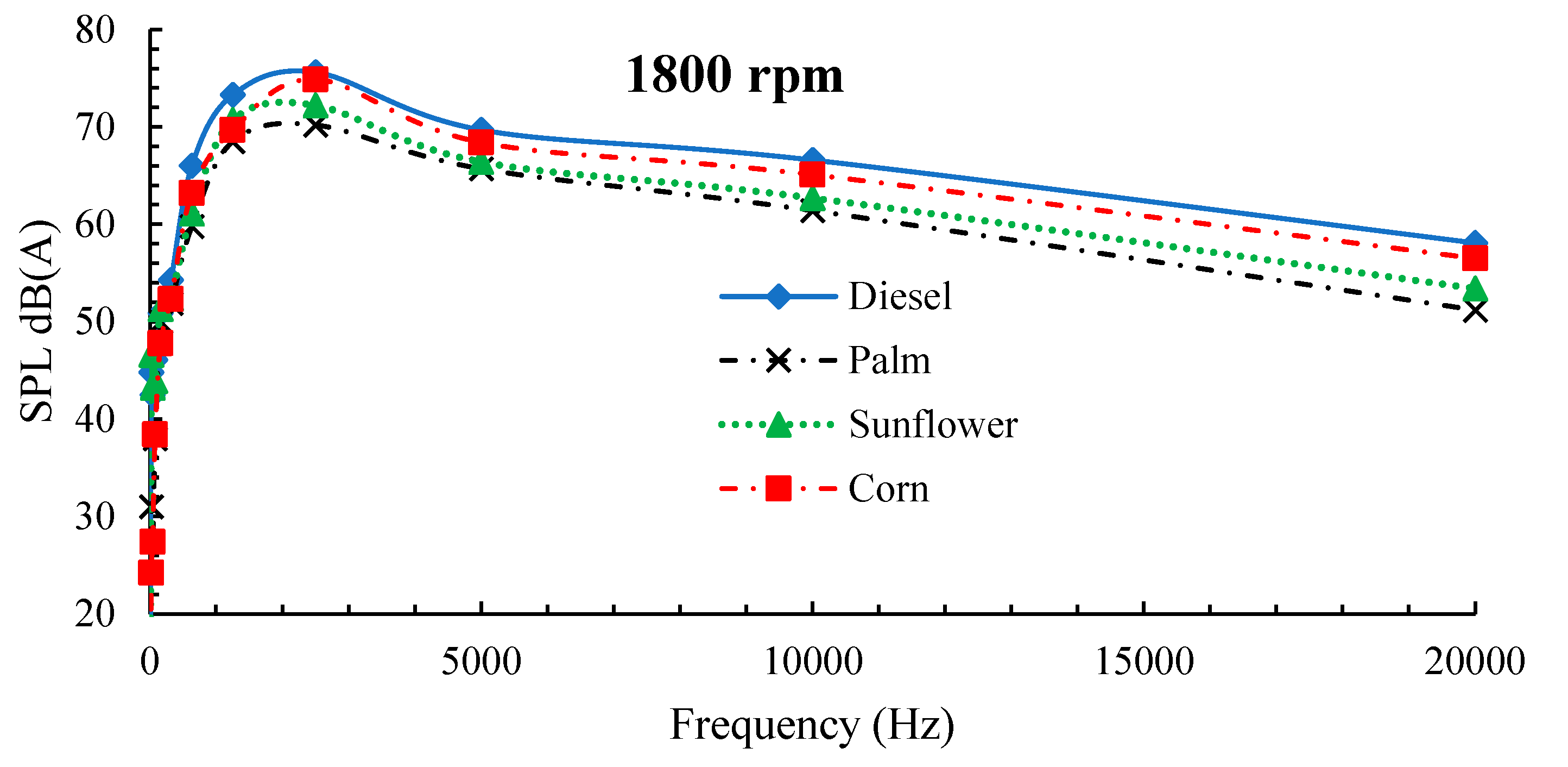

5.3. Noise Emission Analysis

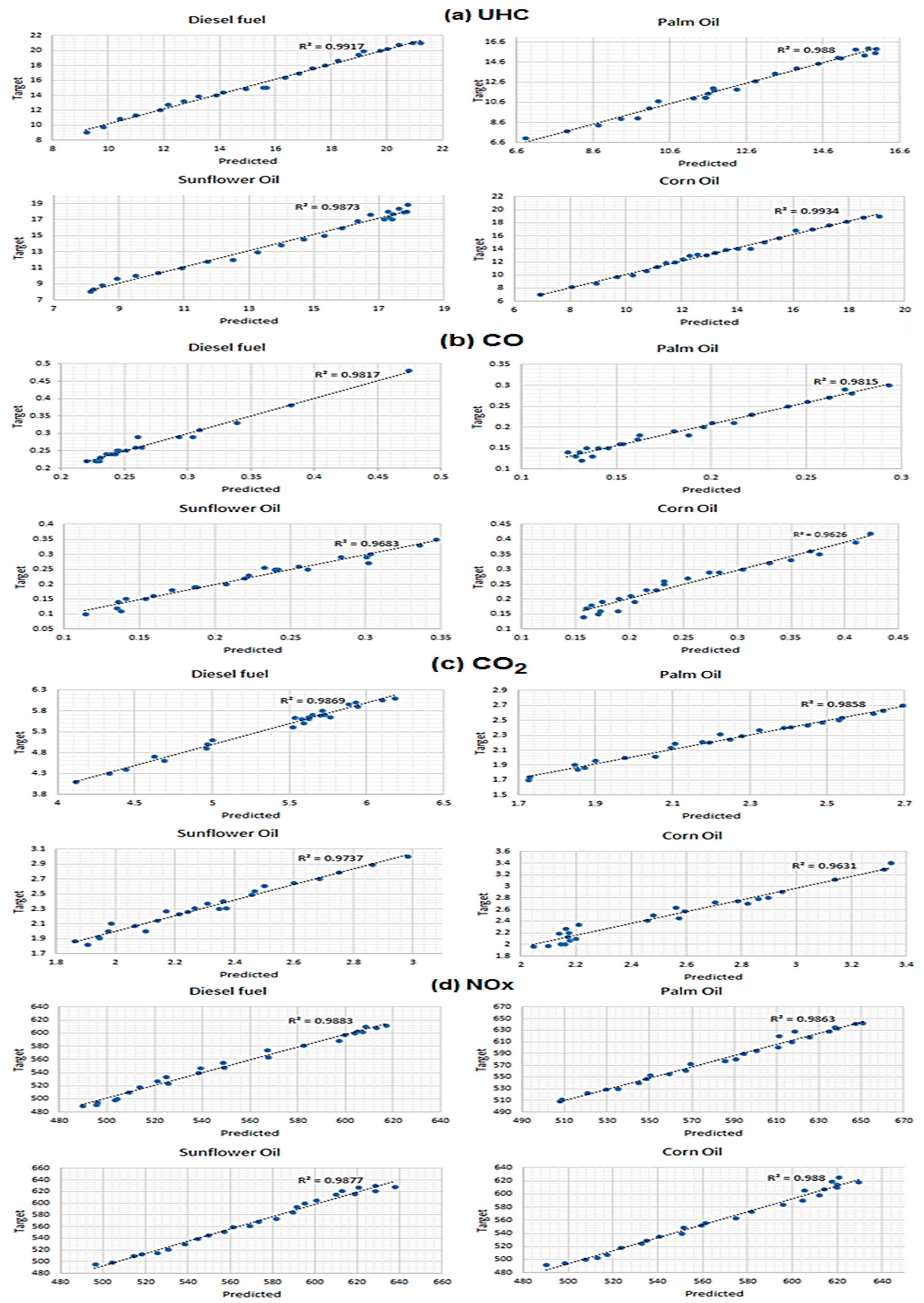

5.4. Polynomial Regression Model

5.5. Grey Wolf Optimization (GWO)

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| a | encircling coefficient | LS | least-squares |

| , | coefficient vectors | N | rotation engine speed |

| ABDC | after bottom dead center | n | polynomial degree |

| ANN | artificial neural network | NaOH | sodium hydroxide |

| ANOVA | analysis of variance | NOx | nitrogen oxides |

| ATDC | after top dead center | OPME | olive pomace oil methyl esters |

| BBD | Box–Behnken approach design | Prms | root mean square value of the pressure |

| BBDC | before bottom dead center | PM | particulate matter |

| BP | brake power | PME | palm oil methyl esters |

| BSFC | brake specific fuel consumption | PPC | partially premixed combustion |

| BT | brake torque | PR | polynomial regression |

| BTDC | before top dead center | PSO | particle swarm optimization |

| BTE | brake thermal efficiency | Pref | reference pressure value of 20 μPa |

| CA | crank angle | P(t) | pressure value at a specific time t |

| CH3NaO | sodium methoxide | P2(t) | time averaged pressure over T |

| CH3OH | methanol | r1, r2 | random vectors |

| CI | compression ignition | R | correlation coefficient |

| CO | carbon monoxide | R2 | coefficient of determination |

| CO2 | carbon dioxide | RMS | root mean square |

| d | fuel type | RMSE | root mean square error |

| DC | direct current | rpm | revolution per minute |

| Df | degree of freedom | RSM | response surface methodology |

| D | wolf’s position | SL | sound level |

| E | exhaust emission | SPL | sound pressure level |

| EGR | exhaust gas recirculation | SSE | sum of square error |

| FFT | fast Fourier transform | SVM | support-vector machines |

| f | global best position | T | total interval of time |

| GA | genetic algorithm | t | current iteration |

| GWO | grey wolf optimization | TiO2 | titanium oxide |

| HC | hydrocarbon | Tmax | total number of iterations |

| I | intensity | UHC | unburned hydrocarbon |

| I0 | reference intensity equal 10−12 W/m2 @ frequency of 1000 Hz | x | independent variable |

| IDI | indirect injection | vector position of the grey wolf | |

| j | current grey wolves’ number | vector prey position | |

| k | iteration number | Y | dependent variable |

| LCA | life cycle assessment | α, β and Δ | three temporarily optimal solutions |

| LP | levels of the sound pressure in dB | regression coefficients |

References

- Borowski, G.; Alsaqoor, S.; Alahmer, A. Using Agglomeration Techniques for Coal and Ash Waste Management in the Circular Economy. Adv. Sci. Technol. Res. J. 2021, 15, 264–276. [Google Scholar] [CrossRef]

- Alahmer, A. Thermal Analysis of a Direct Evaporative Cooling System Enhancement with Desiccant Dehumidification for Vehicular Air Conditioning. Appl. Therm. Eng. 2016, 98, 1273–1285. [Google Scholar] [CrossRef]

- Al-Dabbas, M.; Alahmer, A.; Mamkagh, A.; Gomaa, M.R. Productivity Enhancement of the Solar Still by Using Water Cooled Finned Condensing Pipe. Desalination Water Treat. 2021, 213, 35–43. [Google Scholar] [CrossRef]

- Zacharczuk, W.; Andruszkiewicz, A.; Tatarek, A.; Alahmer, A.; Alsaqoor, S. Effect of Ca-Based Additives on the Capture of SO2 during Combustion of Pulverized Lignite. Energy 2021, 231, 120988. [Google Scholar] [CrossRef]

- Aladayleh, W.; Alahmer, A. Recovery of Exhaust Waste Heat for ICE Using the Beta Type Stirling Engine. J. Energy 2015, 2015, 495418. [Google Scholar] [CrossRef] [Green Version]

- Alahmer, A. Performance and Emission Assessments for Different Acetone Gasoline Blends Powered Spark Ignition Engine. Int. J. Veh. Struct. Syst. 2018, 10, 127–132. [Google Scholar] [CrossRef]

- Ianniello, R.; Belgiorno, G.; Di Luca, G.; Beatrice, C.; Di Blasio, G. Ethanol in Dual-Fuel and Blend Fueling Modes for Advanced Combustion in Compression Ignition Engines. In Alcohol as an Alternative Fuel for Internal Combustion Engines; Springer: Berlin/Heidelberg, Germany, 2021; pp. 5–27. [Google Scholar]

- Shamun, S.; Belgiorno, G.; Di Blasio, G. Engine Parameters Assessment for Alcohols Fuels Application in Compression Ignition Engines. In Alternative Fuels and Their Utilization Strategies in Internal Combustion Engines; Springer: Berlin/Heidelberg, Germany, 2020; pp. 125–139. [Google Scholar]

- Belgiorno, G.; Boscolo, A.; Dileo, G.; Numidi, F.; Pesce, F.C.; Vassallo, A.; Ianniello, R.; Beatrice, C.; Di Blasio, G. Experimental Study of Additive-Manufacturing-Enabled Innovative Diesel Combustion Bowl Features for Achieving Ultra-Low Emissions and High Efficiency. SAE Int. J. Adv. Curr. Pract. Mobil. 2020, 3, 672–684. [Google Scholar] [CrossRef]

- Di Blasio, G.; Beatrice, C.; Ianniello, R.; Pesce, F.C.; Vassallo, A.; Belgiorno, G.; Avolio, G. Balancing Hydraulic Flow and Fuel Injection Parameters for Low-Emission and High-Efficiency Automotive Diesel Engines. SAE Int. J. Adv. Curr. Pract. Mobil. 2019, 2, 638–652. [Google Scholar]

- Dimitrakopoulos, N.; Belgiorno, G.; Tunér, M.; Tunestål, P.; Di Blasio, G. Effect of EGR Routing on Efficiency and Emissions of a PPC Engine. Appl. Therm. Eng. 2019, 152, 742–750. [Google Scholar] [CrossRef]

- Khalid, A.; Tajuddin, A.S.A.; Jaat, N.; Manshoor, B.; Zaman, I.; Hadi, S.A.A.; Nursal, R.S. Performance and Emissions of Diesel Engine Fuelled with Preheated Biodiesel Fuel Derived from Crude Palm, Jatropha, and Waste Cooking Oils. Int. J. Automot. Mech. Eng. 2017, 14, 4273–4284. [Google Scholar] [CrossRef]

- Abed, K.A.; Gad, M.S.; El Morsi, A.K.; Sayed, M.M.; Elyazeed, S.A. Effect of Biodiesel Fuels on Diesel Engine Emissions. Egypt. J. Pet. 2019, 28, 183–188. [Google Scholar] [CrossRef]

- Kalligeros, S.; Zannikos, F.; Stournas, S.; Lois, E.; Anastopoulos, G.; Teas, C.; Sakellaropoulos, F. An Investigation of Using Biodiesel/Marine Diesel Blends on the Performance of a Stationary Diesel Engine. Biomass Bioenergy 2003, 24, 141–149. [Google Scholar] [CrossRef]

- Masum, B.M.; Masjuki, H.H.; Kalam, M.A.; Fattah, I.M.R.; Palash, S.M.; Abedin, M.J. Effect of Ethanol–Gasoline Blend on NOx Emission in SI Engine. Renew. Sustain. Energy Rev. 2013, 24, 209–222. [Google Scholar] [CrossRef]

- Sanjid, A.; Masjuki, H.H.; Kalam, M.A.; Rahman, S.M.A.; Abedin, M.J.; Palash, S.M. Production of Palm and Jatropha Based Biodiesel and Investigation of Palm-Jatropha Combined Blend Properties, Performance, Exhaust Emission and Noise in an Unmodified Diesel Engine. J. Clean. Prod. 2014, 65, 295–303. [Google Scholar] [CrossRef]

- Sanjid, A.; Masjuki, H.H.; Kalam, M.A.; Abedin, M.J.; Rahman, S.M.A. Experimental Investigation of Mustard Biodiesel Blend Properties, Performance, Exhaust Emission and Noise in an Unmodified Diesel Engine. APCBEE Procedia 2014, 10, 149–153. [Google Scholar] [CrossRef] [Green Version]

- Ndayishimiye, P.; Tazerout, M. Use of Palm Oil-Based Biofuel in the Internal Combustion Engines: Performance and Emissions Characteristics. Energy 2011, 36, 1790–1796. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Dimaratos, A.M.; Giakoumis, E.G.; Rakopoulos, D.C. Study of Turbocharged Diesel Engine Operation, Pollutant Emissions and Combustion Noise Radiation during Starting with Bio-Diesel or n-Butanol Diesel Fuel Blends. Appl. Energy 2011, 88, 3905–3916. [Google Scholar] [CrossRef]

- Uludamar, E.; Yıldızhan, Ş.; Aydın, K.; Özcanlı, M. Vibration, Noise and Exhaust Emissions Analyses of an Unmodified Compression Ignition Engine Fuelled with Low Sulphur Diesel and Biodiesel Blends with Hydrogen Addition. Int. J. Hydrog. Energy 2016, 41, 11481–11490. [Google Scholar] [CrossRef]

- Patel, C.; Agarwal, A.K.; Tiwari, N.; Lee, S.; Lee, C.S.; Park, S. Combustion, Noise, Vibrations and Spray Characterization for Karanja Biodiesel Fuelled Engine. Appl. Therm. Eng. 2016, 106, 506–517. [Google Scholar] [CrossRef]

- Yuvarajan, D.; Babu, M.D.; BeemKumar, N.; Kishore, P.A. Experimental Investigation on the Influence of Titanium Dioxide Nanofluid on Emission Pattern of Biodiesel in a Diesel Engine. Atmos. Pollut. Res. 2018, 9, 47–52. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Rakopoulos, D.C.; Rakopoulos, C.D. Combustion Noise Radiation during Dynamic Diesel Engine Operation Including Effects of Various Biofuel Blends: A Review. Renew. Sustain. Energy Rev. 2016, 54, 1099–1113. [Google Scholar] [CrossRef]

- Wang, S.; Chalu, C.; Duclaux, N.; Paquien, M. Noise Optimization of Diesel Engines with New Combustion Systems. SAE Int. J. Passeng. Cars Mech. Syst. 2009, 2, 1387–1395. [Google Scholar] [CrossRef]

- Patel, C.; Lee, S.; Tiwari, N.; Agarwal, A.K.; Lee, C.S.; Park, S. Spray Characterization, Combustion, Noise and Vibrations Investigations of Jatropha Biodiesel Fuelled Genset Engine. Fuel 2016, 185, 410–420. [Google Scholar] [CrossRef]

- Adaileh, W.; Alahmer, A. Reduction of the Spark Ignition Engine Emissions Using Limestone Filter. Can. J. Pure Appl. Sci. 2014, 8, 2761–2767. [Google Scholar]

- Alsaqoor, S.; Alahmer, A.; Aljabarin, N.; Gougazeh, M.; Czajczynska, D.; Krzyzynska, R. Effects of Utilization of Solid and Semi-Solid Organic Waste Using Pyrolysis Techniques. In Proceedings of the 2017 8th International Renewable Energy Congress (IREC), Amman, Jordan, 21–23 March 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Redel-Macías, M.D.; Pinzi, S.; Ruz, M.F.; Cubero-Atienza, A.J.; Dorado, M.P. Biodiesel from Saturated and Monounsaturated Fatty Acid Methyl Esters and Their Influence over Noise and Air Pollution. Fuel 2012, 97, 751–756. [Google Scholar] [CrossRef]

- Aydın, F. The Impacts of Diesel and Canola Biodiesel Fuels on Noise Emission on Diesel Engines. Int. J. Automot. Eng. Technol. 2019, 8, 134–139. [Google Scholar] [CrossRef]

- Torregrosa, A.J.; Broatch, A.; Plá, B.; Mónico, L.F. Impact of Fischer–Tropsch and Biodiesel Fuels on Trade-Offs between Pollutant Emissions and Combustion Noise in Diesel Engines. Biomass Bioenergy 2013, 52, 22–33. [Google Scholar] [CrossRef] [Green Version]

- Bunce, M.; Snyder, D.; Adi, G.; Hall, C.; Koehler, J.; Davila, B.; Kumar, S.; Garimella, P.; Stanton, D.; Shaver, G. Optimization of Soy-Biodiesel Combustion in a Modern Diesel Engine. Fuel 2011, 90, 2560–2570. [Google Scholar] [CrossRef]

- How, H.G.; Masjuki, H.H.; Kalam, M.A.; Teoh, Y.H. An Investigation of the Engine Performance, Emissions and Combustion Characteristics of Coconut Biodiesel in a High-Pressure Common-Rail Diesel Engine. Energy 2014, 69, 749–759. [Google Scholar] [CrossRef]

- Torregrosa, A.J.; Broatch, A.; García, A.; Mónico, L.F. Sensitivity of Combustion Noise and NOx and Soot Emissions to Pilot Injection in PCCI Diesel Engines. Appl. Energy 2013, 104, 149–157. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, S.; Hassan, M.H.; Kalam, M.A.; Rahman, S.M.A.; Abedin, M.J.; Shahir, A. An Experimental Investigation of Biodiesel Production, Characterization, Engine Performance, Emission and Noise of Brassica Juncea Methyl Ester and Its Blends. J. Clean. Prod. 2014, 79, 74–81. [Google Scholar] [CrossRef]

- Nguyen, T.A.; Mikami, M. Effect of Hydrogen Addition to Intake Air on Combustion Noise from a Diesel Engine. Int. J. Hydrog. Energy 2013, 38, 4153–4162. [Google Scholar] [CrossRef]

- Jafarmadar, S.; Khalilaria, S.; Saraee, H.S. Prediction of the Performance and Exhaust Emissions of a Compression Ignition Engine Using a Wavelet Neural Network with a Stochastic Gradient Algorithm. Energy 2018, 142, 1128–1138. [Google Scholar]

- Alahmer, A.; Ajib, S. Solar Cooling Technologies: State of Art and Perspectives. Energy Convers. Manag. 2020, 214, 112896. [Google Scholar] [CrossRef]

- Ajib, S.; Alahmer, A. Solar Cooling Technologies. In Energy Conversion-Current Technologies and Future Trends; IntechOpen: London, UK, 2018. [Google Scholar]

- Kumar, S.; Jain, S.; Kumar, H. Process Parameter Assessment of Biodiesel Production from a Jatropha–Algae Oil Blend by Response Surface Methodology and Artificial Neural Network. Energy Sources Part A Recovery Util. Environ. Eff. 2017, 39, 2119–2125. [Google Scholar] [CrossRef]

- Adam, I.K.; Aziz, A.R.A.; Yusup, S.; Heikal, M.; Hagos, F.Y. Optimization of Performance and Emissions of a Diesel Engine Fuelled with Rubber Seed-Palm Biodiesel Blends Using Response Surface Method. Asian J. Appl. Sci. 2016, 4, 401–421. [Google Scholar]

- Xu, H.; Yin, B.; Liu, S.; Jia, H. Performance Optimization of Diesel Engine Fueled with Diesel-Jatropha Curcas Biodiesel Blend Using Response Surface Methodology. J. Mech. Sci. Technol. 2017, 31, 4051–4059. [Google Scholar] [CrossRef]

- Bhowmik, S.; Paul, A.; Panua, R.; Ghosh, S.K.; Debroy, D. Performance-Exhaust Emission Prediction of Diesosenol Fueled Diesel Engine: An ANN Coupled MORSM Based Optimization. Energy 2018, 153, 212–222. [Google Scholar] [CrossRef]

- Yilmaz, N.; Ileri, E.; Atmanlı, A.; Deniz Karaoglan, A.; Okkan, U.; Sureyya Kocak, M. Predicting the Engine Performance and Exhaust Emissions of a Diesel Engine Fueled with Hazelnut Oil Methyl Ester: The Performance Comparison of Response Surface Methodology and LSSVM. J. Energy Resour. Technol. 2016, 138, 052206. [Google Scholar] [CrossRef]

- Dey, S.; Reang, N.M.; Majumder, A.; Deb, M.; Das, P.K. A Hybrid ANN-Fuzzy Approach for Optimization of Engine Operating Parameters of a CI Engine Fueled with Diesel-Palm Biodiesel-Ethanol Blend. Energy 2020, 202, 117813. [Google Scholar] [CrossRef]

- Tosun, E.; Aydin, K.; Bilgili, M. Comparison of Linear Regression and Artificial Neural Network Model of a Diesel Engine Fueled with Biodiesel-Alcohol Mixtures. Alex. Eng. J. 2016, 55, 3081–3089. [Google Scholar] [CrossRef] [Green Version]

- Uslu, S. Optimization of Diesel Engine Operating Parameters Fueled with Palm Oil-Diesel Blend: Comparative Evaluation between Response Surface Methodology (RSM) and Artificial Neural Network (ANN). Fuel 2020, 276, 117990. [Google Scholar] [CrossRef]

- Yıldırım, S.; Tosun, E.; Çalık, A.; Uluocak, İ.; Avşar, E. Artificial Intelligence Techniques for the Vibration, Noise, and Emission Characteristics of a Hydrogen-Enriched Diesel Engine. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 41, 2194–2206. [Google Scholar] [CrossRef]

- Najafi, B.; Faizollahzadeh Ardabili, S.; Mosavi, A.; Shamshirband, S.; Rabczuk, T. An Intelligent Artificial Neural Network-Response Surface Methodology Method for Accessing the Optimum Biodiesel and Diesel Fuel Blending Conditions in a Diesel Engine from the Viewpoint of Exergy and Energy Analysis. Energies 2018, 11, 860. [Google Scholar] [CrossRef] [Green Version]

- Saqib, M.; Mumtaz, M.W.; Mahmood, A.; Abdullah, M.I. Optimized Biodiesel Production and Environmental Assessment of Produced Biodiesel. Biotechnol. Bioprocess Eng. 2012, 17, 617–623. [Google Scholar] [CrossRef]

- Samuel, O.D.; Okwu, M.O.; Oyejide, O.J.; Taghinezhad, E.; Afzal, A.; Kaveh, M. Optimizing Biodiesel Production from Abundant Waste Oils through Empirical Method and Grey Wolf Optimizer. Fuel 2020, 281, 118701. [Google Scholar] [CrossRef]

- Gujarathi, P.K.; Shah, V.A.; Lokhande, M.M. Grey Wolf Algorithm for Multidimensional Engine Optimization of Converted Plug-in Hybrid Electric Vehicle. Transp. Res. Part D Transp. Environ. 2018, 63, 632–648. [Google Scholar] [CrossRef]

- Ileri, E.; Karaoglan, A.D.; Akpinar, S. Optimizing Cetane Improver Concentration in Biodiesel-Diesel Blend via Grey Wolf Optimizer Algorithm. Fuel 2020, 273, 117784. [Google Scholar] [CrossRef]

- Luo, K. Enhanced Grey Wolf Optimizer with a Model for Dynamically Estimating the Location of the Prey. Appl. Soft Comput. 2019, 77, 225–235. [Google Scholar] [CrossRef]

- Vijay, R.K.; Nanda, S.J. A Quantum Grey Wolf Optimizer Based Declustering Model for Analysis of Earthquake Catalogs in an Ergodic Framework. J. Comput. Sci. 2019, 36, 101019. [Google Scholar] [CrossRef]

- Faris, H.; Aljarah, I.; Al-Betar, M.A.; Mirjalili, S. Grey Wolf Optimizer: A Review of Recent Variants and Applications. Neural Comput. Appl. 2018, 30, 413–435. [Google Scholar] [CrossRef]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey Wolf Optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef] [Green Version]

- Mohanty, S.; Subudhi, B.; Ray, P.K. A New MPPT Design Using Grey Wolf Optimization Technique for Photovoltaic System under Partial Shading Conditions. IEEE Trans. Sustain. Energy 2015, 7, 181–188. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Sarakatsanis, C.K. A Comparative Assessment of Biodiesel Cetane Number Predictive Correlations Based on Fatty Acid Composition. Energies 2019, 12, 422. [Google Scholar] [CrossRef] [Green Version]

- Zahan, K.A.; Kano, M. Biodiesel Production from Palm Oil, Its by-Products, and Mill Effluent: A Review. Energies 2018, 11, 2132. [Google Scholar] [CrossRef] [Green Version]

- Ito, T.; Sakurai, Y.; Kakuta, Y.; Sugano, M.; Hirano, K. Biodiesel Production from Waste Animal Fats Using Pyrolysis Method. Fuel Process. Technol. 2012, 94, 47–52. [Google Scholar] [CrossRef]

- Alptekin, E.; Canakci, M.; Sanli, H. Biodiesel Production from Vegetable Oil and Waste Animal Fats in a Pilot Plant. Waste Manag. 2014, 34, 2146–2154. [Google Scholar] [CrossRef]

- Bies, D.A.; Hansen, C.; Howard, C. Engineering Noise Control; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Mirjalili, S.; Saremi, S.; Mirjalili, S.M.; Coelho, L.d.S. Multi-Objective Grey Wolf Optimizer: A Novel Algorithm for Multi-Criterion Optimization. Expert Syst. Appl. 2016, 47, 106–119. [Google Scholar] [CrossRef]

- Naserbegi, A.; Aghaie, M.; Zolfaghari, A. Implementation of Grey Wolf Optimization (GWO) Algorithm to Multi-Objective Loading Pattern Optimization of a PWR Reactor. Ann. Nucl. Energy 2020, 148, 107703. [Google Scholar] [CrossRef]

- Liu, H.-P.; Strank, S.; Werst, M.; Hebner, R.; Osara, J. Combustion Emissions Modeling and Testing of Neat Biodiesel Fuels. Energy Sustain. 2010, 43949, 131–140. [Google Scholar]

- Masharuddin, S.M.S.; Karim, Z.A.A.; Said, M.A.M.; Amran, N.H.; Ismael, M.A. The Evolution of a Single Droplet Water-in-Palm Oil Derived Biodiesel Emulsion Leading to Micro-Explosion. Alex. Eng. J. 2022, 61, 541–547. [Google Scholar] [CrossRef]

- Yilmaz, N.; Atmanli, A.; Vigil, F.M. Quaternary Blends of Diesel, Biodiesel, Higher Alcohols and Vegetable Oil in a Compression Ignition Engine. Fuel 2018, 212, 462–469. [Google Scholar] [CrossRef]

- Deepanraj, B.; Dhanesh, C.; Senthil, R.; Kannan, M.; Santhoshkumar, A.; Lawrence, P. Use of Palm Oil Biodiesel Blends as a Fuel for Compression Ignition Engine. Am. J. Appl. Sci. 2011, 8, 1154–1158. [Google Scholar] [CrossRef]

- Murillo, S.; Miguez, J.L.; Porteiro, J.; Granada, E.; Moran, J.C. Performance and Exhaust Emissions in the Use of Biodiesel in Outboard Diesel Engines. Fuel 2007, 86, 1765–1771. [Google Scholar] [CrossRef]

- Lapuerta, M.; Armas, O.; Rodriguez-Fernandez, J. Effect of Biodiesel Fuels on Diesel Engine Emissions. Prog. Energy Combust. Sci. 2008, 34, 198–223. [Google Scholar] [CrossRef]

- Song, J.T.; Zhang, C.H. An Experimental Study on the Performance and Exhaust Emissions of a Diesel Engine Fuelled with Soybean Oil Methyl Ester. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2008, 222, 2487–2496. [Google Scholar] [CrossRef]

- Sureshkumar, K.; Velraj, R.; Ganesan, R. Performance and Exhaust Emission Characteristics of a CI Engine Fueled with Pongamia Pinnata Methyl Ester (PPME) and Its Blends with Diesel. Renew. Energy 2008, 33, 2294–2302. [Google Scholar] [CrossRef]

- Ashok, B.; Nanthagopal, K.; Subbarao, R.; Johny, A.; Mohan, A.; Tamilarasu, A. Experimental Studies on the Effect of Metal Oxide and Antioxidant Additives with Calophyllum Inophyllum Methyl Ester in Compression Ignition Engine. J. Clean. Prod. 2017, 166, 474–484. [Google Scholar] [CrossRef]

- Muralidharan, K.; Vasudevan, D. Performance, Emission and Combustion Characteristics of a Variable Compression Ratio Engine Using Methyl Esters of Waste Cooking Oil and Diesel Blends. Appl. Energy 2011, 88, 3959–3968. [Google Scholar] [CrossRef]

- Yee, K.F.; Tan, K.T.; Abdullah, A.Z.; Lee, K.T. Life Cycle Assessment of Palm Biodiesel: Revealing Facts and Benefits for Sustainability. Appl. Energy 2009, 86, S189–S196. [Google Scholar] [CrossRef]

- Sharon, H.; Jai Shiva Ram, P.; Jenis Fernando, K.; Murali, S.; Muthusamy, R. Fueling a Stationary Direct Injection Diesel Engine with Diesel-Used Palm Oil-Butanol Blends—An Experimental Study. Energy Convers. Manag. 2013, 73, 95–105. [Google Scholar] [CrossRef]

- Agarwal, A.K. Biofuels (Alcohols and Biodiesel) Applications as Fuels for Internal Combustion Engines. Prog. Energy Combust. Sci. 2007, 33, 233–271. [Google Scholar] [CrossRef]

- Nalgundwar, A.; Paul, B.; Sharma, S.K. Comparison of Performance and Emissions Characteristics of DI CI Engine Fueled with Dual Biodiesel Blends of Palm and Jatropha. Fuel 2016, 173, 172–179. [Google Scholar] [CrossRef]

- Rakopoulos, D.C.; Rakopoulos, C.D.; Giakoumis, E.G.; Dimaratos, A.M.; Founti, M.A. Comparative Environmental Behavior of Bus Engine Operating on Blends of Diesel Fuel with Four Straight Vegetable Oils of Greek Origin: Sunflower, Cottonseed, Corn and Olive. Fuel 2011, 90, 3439–3446. [Google Scholar] [CrossRef]

- Ozsezn, A.N.; Canakci, M. Determination of Performance and Combustion Characteristics of a Diesel Engine Fueled with Canola and Waste Palm Oil Methyl Esters. Energy Convers. Manag. 2011, 52, 108–116. [Google Scholar] [CrossRef]

- Alahmer, A. Reduction a Particulate Matter of Diesel Emission by the Use of Several Oxygenated Diesel Blend Fuels. Int. J. Therm. Environ. Eng. 2014, 7, 45–50. [Google Scholar]

- Alahmer, A.; Yamin, J.; Sakhrieh, A.; Hamdan, M.A. Engine Performance Using Emulsified Diesel Fuel. Energy Convers. Manag. 2010, 51, 1708–1713. [Google Scholar] [CrossRef]

- Alahmer, A. Influence of Using Emulsified Diesel Fuel on the Performance and Pollutants Emitted from Diesel Engine. Energy Convers. Manag. 2013, 73, 361–369. [Google Scholar] [CrossRef]

- Da Silva Trindade, W.R.; dos Santos, R.G. Review on the Characteristics of Butanol, Its Production and Use as Fuel in Internal Combustion Engines. Renew. Sustain. Energy Rev. 2017, 69, 642–651. [Google Scholar] [CrossRef]

- Abedin, M.J.; Masjuki, H.H.; Kalam, M.A.; Varman, M.; Arbab, M.I.; Fattah, I.M.; Masum, B.M. Experimental Investigation of a Multicylinder Unmodified Diesel Engine Performance, Emission, and Heat Loss Characteristics Using Different Biodiesel Blends: Rollout of B10 in Malaysia. Sci. World J. 2014, 2014, 349858. [Google Scholar] [CrossRef] [Green Version]

- Kalam, M.A.; Masjuki, H.H.; Jayed, M.H.; Liaquat, A.M. Emission and Performance Characteristics of an Indirect Ignition Diesel Engine Fuelled with Waste Cooking Oil. Energy 2011, 36, 397–402. [Google Scholar] [CrossRef]

- Senatore, A.; Cardone, M.; Buono, D.; Rocco, V. Combustion Study of a Common Rail Diesel Engine Optimized to Be Fueled with Biodiesel. Energy Fuels 2008, 22, 1405–1410. [Google Scholar] [CrossRef]

- Alahmer, A.; Rezk, H.; Aladayleh, W.; Mostafa, A.O.; Abu-Zaid, M.; Alahmer, H.; Gomaa, M.R.; Alhussan, A.A.; Ghoniem, R.M. Modeling and Optimization of a Compression Ignition Engine Fueled with Biodiesel Blends for Performance Improvement. Mathematics 2022. accepted. [Google Scholar]

- Maillard, J.; Jagla, J. Effect of Load on Engine Noise for the Auralization of Road Traffic. In Proceedings of the Euronoise 2015, Maastricht, The Netherlands, 31 May–3 June 2015. [Google Scholar]

- Rahman, S.M.A.; Masjuki, H.H.; Kalam, M.A.; Abedin, M.J.; Sanjid, A.; Sajjad, H. Production of Palm and Calophyllum Inophyllum Based Biodiesel and Investigation of Blend Performance and Exhaust Emission in an Unmodified Diesel Engine at High Idling Conditions. Energy Convers. Manag. 2013, 76, 362–367. [Google Scholar] [CrossRef]

- Sharon, H.; Karuppasamy, K.; Kumar, D.R.S.; Sundaresan, A. A Test on DI Diesel Engine Fueled with Methyl Esters of Used Palm Oil. Renew. Energy 2012, 47, 160–166. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Antonopoulos, K.A.; Rakopoulos, D.C.; Hountalas, D.T.; Giakoumis, E.G. Comparative Performance and Emissions Study of a Direct Injection Diesel Engine Using Blends of Diesel Fuel with Vegetable Oils or Bio-Diesels of Various Origins. Energy Convers. Manag. 2006, 47, 3272–3287. [Google Scholar] [CrossRef]

- Siavash, N.K.; Najafi, G.; Hassan-Beygi, S.R.; Ahmadian, H.; Ghobadian, B.; Yusaf, T.; Mazlan, M. Time–Frequency Analysis of Diesel Engine Noise Using Biodiesel Fuel Blends. Sustainability 2021, 13, 3489. [Google Scholar] [CrossRef]

- Alahmer, A.; Aladayleh, W. Effect Two Grades of Octane Numbers on the Performance, Exhaust and Acoustic Emissions of Spark Ignition Engine. Fuel 2016, 180, 80–89. [Google Scholar] [CrossRef]

- Chiatti, G.; Chiavola, O.; Palmieri, F. Vibration and Acoustic Characteristics of a City-Car Engine Fueled with Biodiesel Blends. Appl. Energy 2017, 185, 664–670. [Google Scholar] [CrossRef]

- Sarıdemir, S.; Ağbulut, Ü. Combustion, Performance, Vibration and Noise Characteristics of Cottonseed Methyl Ester–Diesel Blends Fuelled Engine. Biofuels 2019, 1–10. [Google Scholar] [CrossRef]

- Redel-Macías, M.D.; Pinzi, S.; Leiva, D.; Cubero-Atienza, A.J.; Dorado, M.P. Air and Noise Pollution of a Diesel Engine Fueled with Olive Pomace Oil Methyl Ester and Petrodiesel Blends. Fuel 2012, 95, 615–621. [Google Scholar] [CrossRef]

- Shrivastava, N. Experimental Investigation of Performance, Emission, and Noise Parameters of Water-Emulsified Karanja Biodiesel: A Prospective Indian Fuel. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 1009–1017. [Google Scholar] [CrossRef]

- Patel, C.; Sharma, N.; Tiwari, N.; Agarwal, A.K. Effects of Spray Droplet Size and Velocity Distributions on Emissions from a Single Cylinder Biofuel Engine; SAE Technical Paper: 2016-01-0994; SAE International: Warrendale, PA, USA, 2016; Available online: https://www.sae.org/publications/technical-papers/content/2016-01-0994/ (accessed on 22 December 2021).

- Fattah, I.M.R.; Masjuki, H.H.; Liaquat, A.M.; Ramli, R.; Kalam, M.A.; Riazuddin, V.N. Impact of Various Biodiesel Fuels Obtained from Edible and Non-Edible Oils on Engine Exhaust Gas and Noise Emissions. Renew. Sustain. Energy Rev. 2013, 18, 552–567. [Google Scholar] [CrossRef]

- Alahmer, A.I.; Adaileh, W.M.; Al Zubi, M.A. Monitoring of a Spark Ignition Engine Malfunctions Using Acoustic Signal Technique. Int. J. Veh. Noise Vib. 2014, 10, 201–213. [Google Scholar] [CrossRef]

- Dal, H.; Emiroğlu, A.O.; Bilge, H.; Şen, M. Experimental Investigation of the Effects of Chicken and Turkey Biodiesel Blends on Diesel Engine Noise Emissions. Int. J. Environ. Sci. Technol. 2019, 16, 5147–5154. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Rakopoulos, C.D.; Dimaratos, A.M.; Rakopoulos, D.C. Combustion Noise Radiation during the Acceleration of a Turbocharged Diesel Engine Operating with Biodiesel or N-Butanol Diesel Fuel Blends. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2012, 226, 971–986. [Google Scholar] [CrossRef]

| Parameter | Specification |

|---|---|

| Type | Lister LV1 |

| Nominal speed range | 1000–3000 rpm |

| Maximum power | 9 HP (6.7 kW) @ 3000 rpm |

| Number of cylinders | Single |

| Injection | Direct |

| Engine operation | Four-stroke |

| Bore * Stroke | 85.73 × 82.55 mm |

| Compression ratio | 17:1 |

| Injector opening pressure | 180 bar |

| Intake valve opening/closing | 15° CA BTDC/41° CA ABDC |

| Exhaust valve opening/closing | 41° CA BBDC/15° CA ATDC |

| Air intake process | Naturally aspirated |

| Type of cooling | Air-cooled |

| Dynamometer | A swinging field direct current (DC) dynamometer |

| Properties | Diesel | Corn Biodiesel | Palm Biodiesel | Sunflower Biodiesel | Test Method | Equipment |

|---|---|---|---|---|---|---|

| Cetane Number [58] | 47 | 53 | 61 | 52 | ASTM D613 | - |

| Heating Value (MJ/kg) | 43.5 | 39.5 | 40.1 | 39.8 | ASTM D240 | Automatic adiabatic bomb calorimeter |

| Specific gravity at 15 °C (kg/m3) | 0.83 | 0.86 | 0.85 | 0.85 | IP 190/93 | Capillary stoppered pycnometer |

| Viscosity at 40 °C (cSt) | 3.85 | 4.77 | 5.28 | 4.96 | ASTM D445 | EMILA rotary viscometer apparatus |

| Sources | % (wt) Palmitic (C16:0) | % (wt) Stearic (C18:0) | % (wt) Oleic (C18:1) | % (wt) Linoleic (C18:2) | % (wt) Linolenic (C18:3) |

|---|---|---|---|---|---|

| Palm oil | 45 | 4 | 39 | 11 | - * |

| Sunflower | 3–10 | 1–10 | 14–35 | 55–75 | <0.3 |

| Corn | 8–10 | 1–4 | 30–50 | 34.56 | 0.5–1.5 |

| Emission | Test Method | Accuracy | Resolution | Maximum Limit |

|---|---|---|---|---|

| CO2 | Nondispersive infrared | ±5% of reading ±0.5% volume | 0.01% | 16% |

| CO | Nondispersive infrared | ±5% of reading ±0.5% volume | 0.01% | 10% |

| UHC | Nondispersive infrared | ±5% of reading | 1 ppm | 5000 |

| NOx | Fuel cell | 0–4000 ppm ±4%; 4000–5000 ppm ±5% | 1 ppm | 5000 |

| Experiment | Fuel Type | SSE | RMSE | R2 |

|---|---|---|---|---|

| UHC | Diesel | 8.45 × 10−4 | 8.40 × 10−3 | 9.92 × 10−1 |

| Palm Biodiesel | 2.38 × 10−3 | 1.22 × 10−2 | 9.88 × 10−1 | |

| Sunflower Biodiesel | 2.57 × 10−3 | 1.29 × 10−2 | 9.87 × 10−1 | |

| Corn Biodiesel | 4.21 × 10−4 | 6.10 × 10−3 | 9.93 × 10−1 | |

| CO2 | Diesel | 4.55 × 10−3 | 4.77 × 10−2 | 9.87 × 10−1 |

| Palm Biodiesel | 6.82 × 10−3 | 1.85 × 10−2 | 9.86 × 10−1 | |

| Sunflower Biodiesel | 1.25 × 10−3 | 2.50 × 10−2 | 9.74 × 10−1 | |

| Corn Biodiesel | 5.47 × 10−3 | 1.35 × 10−2 | 9.63 × 10−1 | |

| CO | Diesel | 5.28 × 10−4 | 2.24 × 10−2 | 9.82 × 10−1 |

| Palm Biodiesel | 4.97 × 10−4 | 1.58 × 10−2 | 9.82 × 10−1 | |

| Sunflower Biodiesel | 1.89 × 10−3 | 3.08 × 10−2 | 9.68 × 10−1 | |

| Corn Biodiesel | 2.24 × 10−3 | 2.73 × 10−2 | 9.63 × 10−1 | |

| NOx | Diesel | 4.55 × 10−3 | 1.18 × 10−2 | 9.88 × 10−1 |

| Palm Biodiesel | 6.82 × 10−3 | 1.39 × 10−2 | 9.86 × 10−1 | |

| Sunflower Biodiesel | 1.25 × 10−3 | 1.25 × 10−2 | 9.88 × 10−1 | |

| Corn Biodiesel | 5.47 × 10−3 | 1.21 × 10−2 | 9.88 × 10−1 | |

| BTE | Diesel | 1.31 × 10−3 | 2.67 × 10−2 | 9.74 × 10−1 |

| Palm Biodiesel | 2.36 × 10−3 | 3.31 × 10−2 | 9.68 × 10−1 | |

| Sunflower Biodiesel | 1.37 × 10−3 | 2.34 × 10−2 | 9.77 × 10−1 | |

| Corn Biodiesel | 3.64 × 10−3 | 2.54 × 10−2 | 9.75 × 10−1 | |

| Noise | Diesel | 6.29 × 10−4 | 6.50 × 10−3 | 9.90 × 10−1 |

| Palm Biodiesel | 4.39 × 10−4 | 5.80 × 10−3 | 9.93 × 10−1 | |

| Sunflower Biodiesel | 3.80 × 10−5 | 3.70 × 10−3 | 9.95 × 10−1 | |

| Corn Biodiesel | 7.17 × 10−4 | 9.60 × 10−3 | 9.88 × 10−1 |

| Response | Df | f-Value | p-Value |

|---|---|---|---|

| UHC | 2 | 21.79 | <0.0001 |

| CO2 | 3 | 21.50 | <0.008 |

| CO | 3 | 34.56 | <0.001 |

| NOx | 2 | 597.56 | <0.0001 |

| BTE | 2 | 34.86 | <0.0006 |

| Noise | 2 | 80.79 | <0.0001 |

| Experiment | Fuel Type | Engine Speed | Optimum Value |

|---|---|---|---|

| UHC (PPM) | Diesel | 2400 | 9 |

| Palm Biodiesel | 2400 | 7 | |

| Sunflower Biodiesel | 2400 | 8 | |

| Corn Biodiesel | 2400 | 7 | |

| CO2 (%) | Diesel | 1367 | 3.92 |

| Palm Biodiesel | 1576 | 1.64 | |

| Sunflower Biodiesel | 1373 | 1.82 | |

| Corn Biodiesel | 1342 | 1.95 | |

| CO (%) | Diesel | 1407 | 0.22 |

| Palm Biodiesel | 1765 | 0.12 | |

| Sunflower Biodiesel | 1787 | 0.11 | |

| Corn Biodiesel | 1762 | 0.14 | |

| NOx (PPM) | Diesel | 1200 | 489 |

| Palm Biodiesel | 1200 | 508 | |

| Sunflower Biodiesel | 1200 | 495 | |

| Corn Biodiesel | 1200 | 492 | |

| BTE(%) | Diesel | 2183 | 20.31 |

| Palm Biodiesel | 1937 | 19.10 | |

| Sunflower Biodiesel | 1631 | 19.89 | |

| Corn Biodiesel | 1988 | 20.02 | |

| Noise leveldB(A) | Diesel | 1200 | 75.9 |

| Palm Biodiesel | 1200 | 73 | |

| Sunflower Biodiesel | 1200 | 74.4 | |

| Corn Biodiesel | 1200 | 74.8 |

| Response | Weight | Target |

|---|---|---|

| UHC | 0.1 | Minimize |

| CO2 | 0.1 | Minimize |

| CO | 0.2 | Minimize |

| NOx | 0.2 | Minimize |

| BTE | 0.3 | Maximize |

| Noise | 0.1 | Minimize |

| Experimental | Fuel Type | Engine Speed (rpm) | CO (%) | CO2 (%) | NOx (ppm) | UHC (ppm) | BTE (%) | Noise dB(A) |

|---|---|---|---|---|---|---|---|---|

| Optimum Values | Diesel | 1862 | 0.26 | 5.69 | 555.14 | 15.02 | 1.98 | 79.14 |

| Palm | 1743 | 0.13 | 2.01 | 577.00 | 11.48 | 1.87 | 76.24 | |

| Sunflower | 1612 | 0.15 | 2.32 | 546.00 | 17.84 | 1.99 | 76.51 | |

| Corn | 1867 | 0.16 | 2.50 | 563.00 | 13.09 | 1.94 | 78.86 |

| Fuel Type | Engine Speed | CO | CO2 | NOx | UHC | BTE | Noise |

|---|---|---|---|---|---|---|---|

| Palm Biodiesel | ▼ −6.39% | ▼ −49.46% | ▼ −64.70% | ▲ 3.94% | ▼ −23.61% | ▼ −5.56% | ▼ −48.63% |

| Sunflower Biodiesel | ▼ −13.43% | ▼ −41.29% | ▼ −59.25% | ▼ −1.65% | ▲ 18.76% | ▲ 0.35% | ▼ −45.34% |

| Corn Biodiesel | ▲ 0.27% | ▼ −37.79% | ▼ −56.09% | ▲ 1.42% | ▼ −12.90% | ▼ −2.08% | ▼ −6.16% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alahmer, A.; Alahmer, H.; Handam, A.; Rezk, H. Environmental Assessment of a Diesel Engine Fueled with Various Biodiesel Blends: Polynomial Regression and Grey Wolf Optimization. Sustainability 2022, 14, 1367. https://doi.org/10.3390/su14031367

Alahmer A, Alahmer H, Handam A, Rezk H. Environmental Assessment of a Diesel Engine Fueled with Various Biodiesel Blends: Polynomial Regression and Grey Wolf Optimization. Sustainability. 2022; 14(3):1367. https://doi.org/10.3390/su14031367

Chicago/Turabian StyleAlahmer, Ali, Hussein Alahmer, Ahmed Handam, and Hegazy Rezk. 2022. "Environmental Assessment of a Diesel Engine Fueled with Various Biodiesel Blends: Polynomial Regression and Grey Wolf Optimization" Sustainability 14, no. 3: 1367. https://doi.org/10.3390/su14031367

APA StyleAlahmer, A., Alahmer, H., Handam, A., & Rezk, H. (2022). Environmental Assessment of a Diesel Engine Fueled with Various Biodiesel Blends: Polynomial Regression and Grey Wolf Optimization. Sustainability, 14(3), 1367. https://doi.org/10.3390/su14031367