1. Introduction

Social sustainability could be achieved through the proper management of different systems, processes, organizations, and activities. Among the topics covered by the umbrella of social sustainability are health and social equity, human rights, social responsibility, product responsibility as well as decent working conditions. Some of these are closely interconnected with the topics of environmental sustainability. In recent years, more and more attention has been paid to indoor air quality because people spend about 80–90% of their time indoors [

1,

2]. Indoor air may be more polluted than outdoor air when anthropogenic sources such as copiers, laser printers, electrostatic precipitators, ozone generators, or other electrical devices producing ozone or aerosol particles are present indoors [

3,

4,

5,

6].

The main indoor pollutants resulting from the copying process are ozone, volatile organic compounds, nitrogen oxides, aerosol particles [

7,

8,

9]. Ozone is a very unstable, oxidizing gas with a half-life of less than 10 min in an office room [

10,

11,

12]. Usually, ozone concentrations in a premises without any ozone emission sources are approximately 250 times lower than its levels in ambient air due to ozone filtration through walls [

13]. However, ozone concentrations in a premises with operating copiers are in many cases significantly higher than outdoors.

Copying machines have become an unavoidable part of the everyday environment of millions of people worldwide, e.g., in offices, industries, shops, schools and laboratories [

14]. Technological processes such as copying are considered to be a critical source of chemical and physical contamination in work premises. During copying, approximately 20 ppb of ozone is produced per one copy [

15]. The highest levels of ozone during copying are emitted mostly when charging and releasing paper and when the copier drum and ultraviolet lamp are operating [

16,

17,

18]. Emissions from copying machines depends on a number of factors such as the technology standard used, machine type, duration and rate of operation, process conditions, etc. [

19]. Although copiers are becoming more and more modern and many of them have activated carbon filters, older and more polluting copiers may still be found in office premises. Additionally, studies carried out in different photocopying rooms have shown that not all newly manufactured photocopiers have filters and that even modern photocopying machines often do not assure safe levels of pollutants for human health.

Different countries have different requirements for the rooms where copiers are operated. For instance, in Russia, an area of at least 6 m

2 should be designated for each person working in the copying room, and people under the age of 18, pregnant women and persons suffering from certain diseases are not allowed to work on the copiers [

20]. In Lithuania, any restrictions on copying facilities have not been laid down yet. The Lithuanian hygiene standard HN 23:2011 states that a maximum permissible five-minute average ozone concentration in the air of a working place is 300 ppb, and the maximum permissible eight-hour concentration is 100 ppb [

21]. Other resources [

21,

22] state that the maximum permissible ozone concentration in the air at workplace is 50 ppb.

Aerosol particles enter a copying room from the outside, so the background of aerosol particles in the room (compared to ozone) is quite high. Moreover, aerosol particles appear in a copying room from mechanical processes [

23] and the most common size of these particles ranges from 0.1 to 2.5 μm [

24]. Large aerosol particles will stay in the atmosphere of a room for several minutes, while the tiniest particles will stay in the atmosphere of a room for significantly longer [

23]. Aerosols of anthropogenic origin account for 10–20% of the total quantity of aerosols [

25].

An atmosphere with an ozone concentration <20 ppb has disinfectant properties; therefore ozone is often used in medicine and ozone therapy for the treatment and prevention of various diseases. However, higher ozone concentrations may have severe effects on human throat, eyes and nostrils, and long-term exposure to ozone causes not only pulmonary function impairment but also stress and increased risk of cardiovascular diseases [

26,

27,

28,

29,

30].

Most of the inhaled aerosols remain on the hair inside the nose, the second part of them enters the airways and the third part enters the lungs and settles in the bronchi [

31,

32]. Very tiny aerosol particles are the most dangerous because they enter deep into the lungs [

33]. Aerosol particles may cause chronic diseases such as bronchitis, bronchial asthma, irreversible lung damage—pneumoconiosis for copying service workers [

5,

34,

35]. The effects of ozone and aerosol particles on the human nose, throat and eyes were found to be significantly stronger than those of each pollutant alone [

14,

36].

In addition, copying machines make noise. Active noise exceeding 80 dB during full-time operation impairs hearing function of a copying service worker which is restored during the rest period between working hours. However, the effects of noise on a human body are not limited to harmful effects on auditory organs because noise damages many human organs and systems: central nervous system, digestive and sensory organs, endocrine function, increased risk of arterial hypertension and myocardial infarction [

37,

38,

39].

The aim of the research was to investigate the dynamics of ozone and aerosol particle concentrations during technological processes (copying) and to assess the levels of physical and chemical pollution in the investigated office room.

2. Methodology

The experiment was carried out in a 16 m

2 working room where the copying machine “Toshiba” with a maximum capacity of 120 copies per minute was being operated. This copying room was adjacent to another room with an area of 19 m

2 and an exit to the outside (

Figure 1). The experiment was carried out during the winter season when the office room was naturally ventilated, i.e., the window was slightly open leaving a small gap. The room where the copying took place is at a distance from any streets and is therefore not affected by noise emitted by vehicles. The dynamics of ozone and 0.4 μm aerosol particle concentrations as well as microclimatic parameters (temperature, relative humidity, sound level) were investigated in the copying room. Copying in the room was performed from 8.00 a.m. to 7.00 p.m., while changes in the studied parameters in the work room were measured not only during the operation of the copier, but also during the rest of the day. The experiment was carried out in the office room during the technological process (copying) for one month. Data regarding the variation of the investigated pollutants for one working week when the copier was operated in an optimal operating mode are presented in this paper. The photocopying room is used by two employees working 8 h a day: one starts his work at 8 a.m. and ends at 4 p.m., and the other starts his work at 11 a.m. and ends at 7 p.m.

In order to assess the effects of ozone and aerosol particles on the health of copying service workers, the investigated pollutants were recorded at a height of 50 cm and at a distance of 40 cm from the copier where a worker is usually present. To determine the concentration of both ozone and aerosol particles, a Teflon tube through which room air was taken at the same point was used. For this purpose, an ozone analyzer O3 41 M, based on the principle of ultraviolet absorption, was used to determine ozone concentrations, and an aerosol particle counter, AZ-5, was used to determine aerosol particle concentrations. The sensitivity of the ozone analyzer used for the investigation is 0.5 ppb and its measurement range is 0–1000 ppb. The aerosol particle counter used for the experiment can record aerosol particles from 0.4 to 10 μm in size with an instrument tolerance not exceeding 20%. To determine the changes in aerosol particle size during copying, the size spectrum study of the aerosol particles (≤2.0 μm) was performed by recording particles of different sizes every 5 min.

The ozone concentration in the copying room was measured not only by a method of ultraviolet absorption but also by a method of passive sampling. A passive sampler is usually a small tube whose one end is filled with a sorbent which allows the collection of pollutants from the ambient air without an additional suction. Passive samplers allow us to quantify a sampled pollutant as an average concentration over the measurement period. The time during which a diffuse sampler accumulates a pollutant may vary from a few hours to a few weeks. In order to assess the effects of ozone on the health of a copying service worker, the passive samplers were attached to the same worker’s clothing at chest level during the entire working day. Ozone concentrations were measured by a method of passive sampling for four days. Each day a copying service worker started to wear a new passive sampler. The operating principle of a passive sampler is based on the chemical reactions taking place on an absorbent element (i.e., impregnated filter). Glass fiber filter impregnated with a solution of 1,2-di (4-pyridyl)-ethylene and acetic acid (DPE) is used in these samplers. The sorbent on a glass filter reacts with ozone which turns into pyridine-4-aldehyde (PDC). Passive samplers were opened at the very beginning of the working day and closed at the end of the working day. After exposure, the samples were stored in the refrigerator until their delivery to the laboratory for chemical analysis.

In order to investigate the distribution of ozone and aerosol particles in the office room at different copying machine operating speeds, the copying intensity was divided into five operating modes: 1—0 copies/min; 2—from 1 to 30 copies/min; 3—from 31 to 60 copies/min; 4—from 61 to 90 copies/min; 5—from 91 to 120 copies/min.

The DrDAQ data logger with built-in temperature, humidity and volume sensors was used for measuring microclimatic parameters. After connecting the temperature sensors to the DrDAQ data logger, the temperature in the copying room was measured at two heights, i.e., close to the ceiling and close to the floor, when determining the temperature difference in the investigated room. The temperature difference was calculated by finding the difference between the temperatures at two heights, i.e., the temperature measured at the floor was subtracted from the temperature measured at the ceiling. The relative humidity and noise level in the room were measured at the height of the copier. The studied microclimatic parameters were measured at a distance of 1 m from the copying machine. The DrDAQ data logger can measure temperature within a range of 10 to +105 °C, relative humidity within a range of 20 to 90%, and noise within a range of 55 to 100 dB. The concentrations of ozone and aerosol particles and microclimatic parameters in the copying room were measured uninterruptedly by recording five-minute average values on a computer.

3. Results

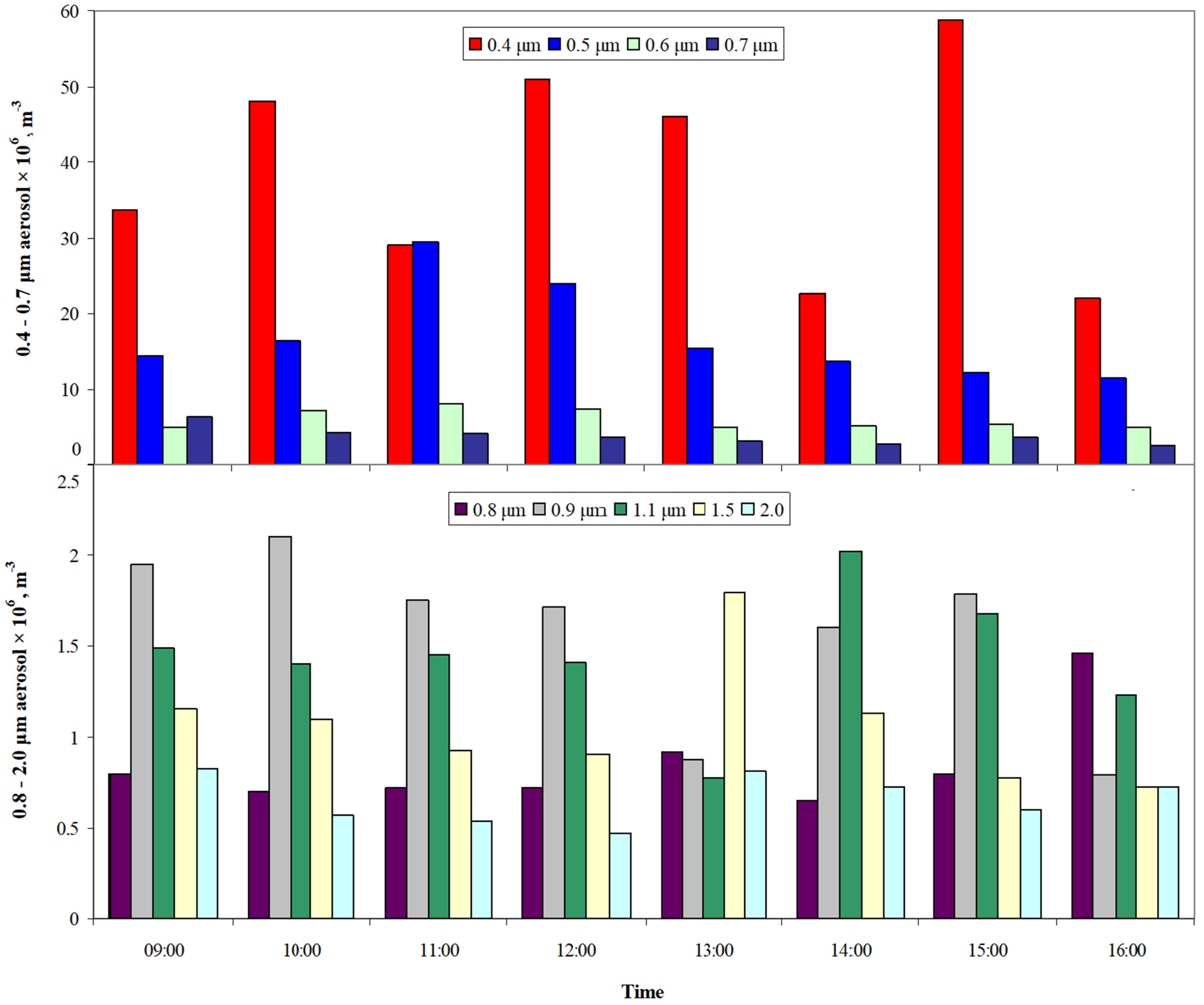

In order to find out the dominant aerosol particle size during the technological process (copying), the spectrum of aerosol particles (0.4–2.0 μm) was investigated with an aerosol particle counter AZ-5. The spectrum of the aerosol particles over one working day is shown in

Figure 2.

The obtained research data show that the most significant changes were observed in the concentrations of tiny aerosol particles in the room during the technological process (copying), while the changes in the concentrations of particles with an aerodynamic diameter of more than 0.7 μm in the copying room were insignificant. On the day of the spectrum study, the concentrations of aerosol particles of ≤0.5 μm in an aerodynamic diameter varied from 10 × 106 to 60 × 106 m−3, while the concentrations of aerosol particles of 0.6–0.7 μm diameter varied from 2 × 106 to 8 × 106 m−3. Meanwhile, the number concentration of aerosol particles of 0.8–2.0 μm in an aerodynamic diameter varied within the range from 0.5 × 106 to 2 × 106 m−3. The concentrations of aerosol particles tinier than 0.7 μm generated during this technological process are 15-times higher than those of larger particles. This shows the formation of fine aerosol particles (of <0.8 μm in an aerodynamic diameter) is mainly affected by an office copier. Moreover, the clearly expressed dynamics of aerosol particles of different sizes is observed during the working day, which is related to the intensity of the technological process. The formation of both fine and larger aerosol particles is also observed as the volume of copying work and the intensity of copying decrease (at 4.00 p.m.). Since the results of the spectral analysis showed that during the copying the concentrations and changes of fine aerosol particles are more significant, the study of the changes in the concentrations of 0.4 μm aerosol particles was chosen for a more detailed analysis.

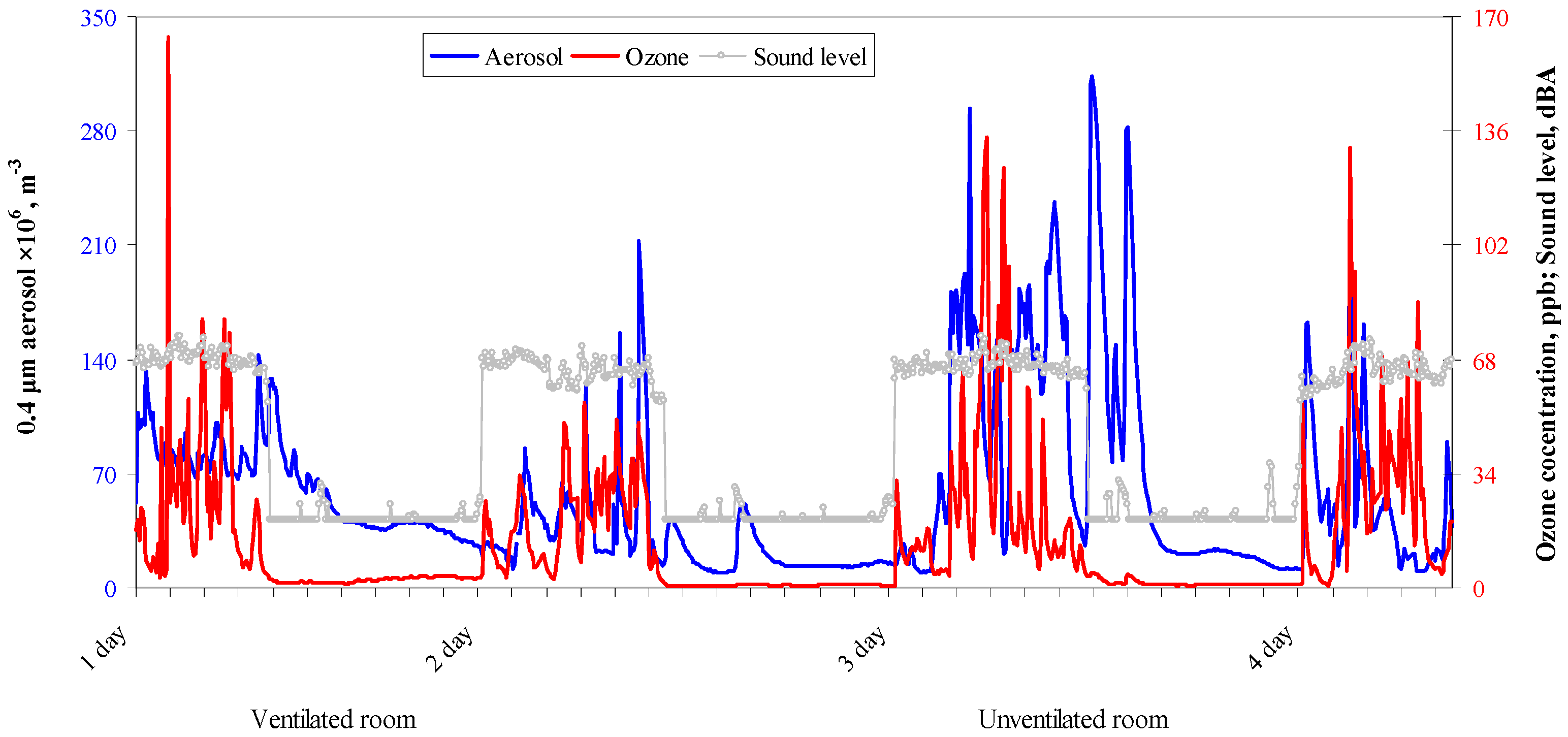

In the office room where the source of anthropogenic air pollution, i.e., a copier, was operated, the investigation of chemical and physical pollution was carried out for four days in a ventilated room and unventilated room. The variation of the concentration of ozone and 0.4 μm aerosol particles and the noise level in the copying room is shown in

Figure 3.

Measurements of pollutant concentrations and noise levels showed that the concentrations of ozone and aerosol particles and the sound emitted by the copier in the office room were unevenly distributed due to different intensities of copier operation (copying works were performed from 8.00 a.m. and no activities were performed in the room after 7 p.m.). In addition, uneven variation of researched pollutants in the copying room may have been caused by different ventilation conditions. The room had not been ventilated for the previous two days, and a window had been opened in the room for the first two days. During the working hours, the concentration of ozone in the office room varied from 1 to 165 ppb, and the concentration of aerosol particle was (10–315) × 106 m−3. During the night, the ozone concentration in the office room fluctuated around 2 ppb, while the number of aerosol particles found during non-working hours was ~40 × 106 m−3.

During the period of investigation, the noise level in the copying room during the operation of the photocopier varied from 55 to 75 dBA. It should be noted that its level varied mostly together with the concentrations of ozone and aerosol particles, i.e., when the copying machine was operated. This shows that the main source of these pollutants in the office room was the copier. Meanwhile, the noise level in the copying room at night, when the copier was not operated, fluctuated around 20 dBA. The permissible eight-hour average noise level at the workplace is 85 dBA, so the permissible sound level in the researched office room was not exceeded even during the most intensive operation of the copier.

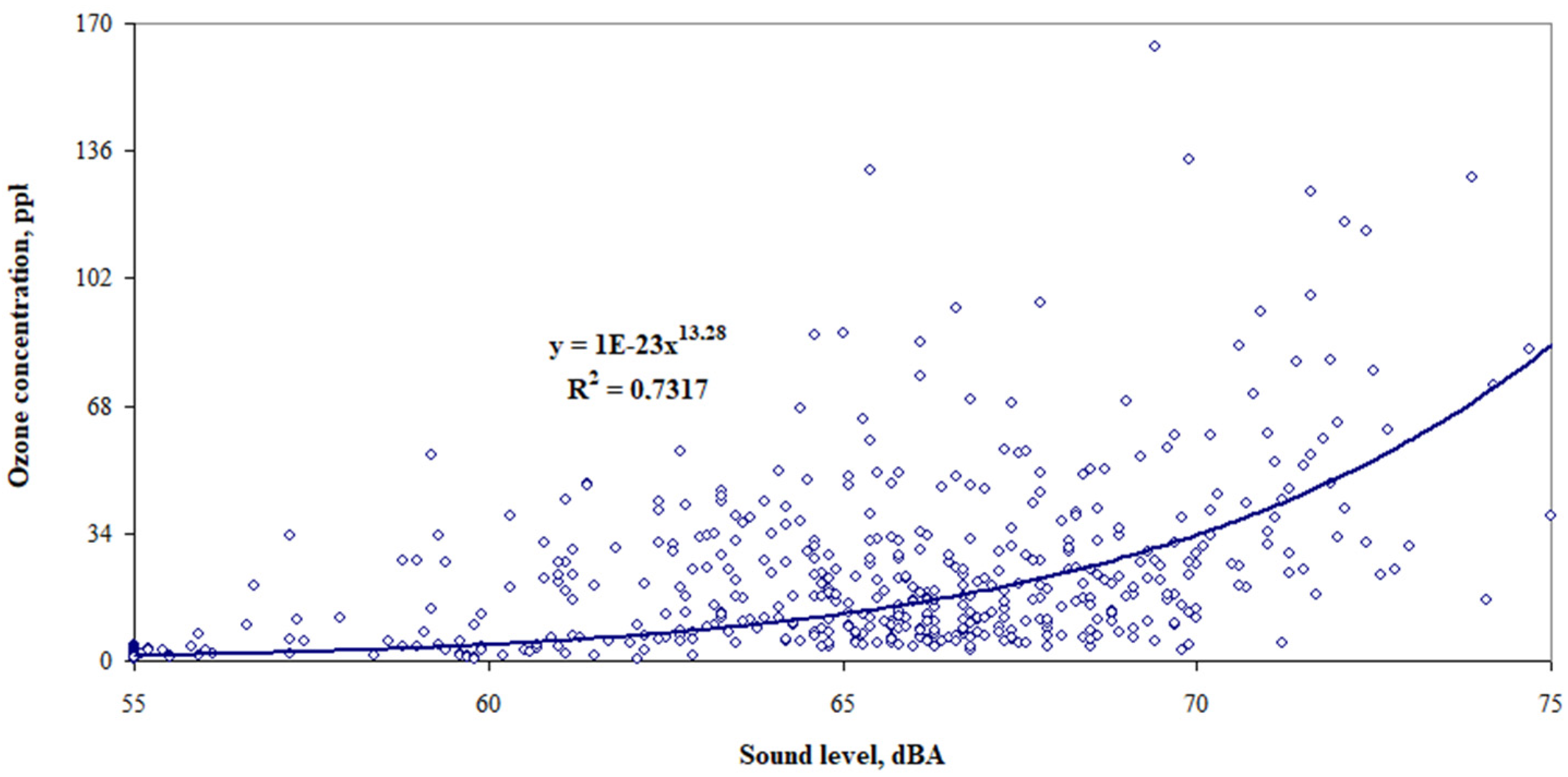

In order to assess whether the distribution of the investigated pollutants in the office room depends on the noise emitted by the copier, the relationship between ozone concentration and sound level has been investigated (

Figure 4).

A statistically significant strong correlation was found between the ozone concentration and the sound level in the copying room during the operation of the photocopier, the correlation coefficient in this case was 0.86. Meanwhile, the influence of the noise emitted by the copier on the dispersion of aerosol particles in the office room was less significant. The correlation between these variables was moderate, i.e., the correlation coefficient between the concentration of 0.4 μm aerosol particles and the sound level in the copying room during the operation of the photocopier was 0.42.

In the copying room, the higher temperature (26.1 °C) was found near the ceiling, while the average temperature close to the ground was lower, i.e., 24.8 °C. The estimated temperature difference varied from −1.0 to 3.6 °C and shows how intensively the air mixing takes place in the copying room. The relatively insignificant temperature differences show that the heat released during the copying process in the office room does not cause intensive movement of vertical air flows in the room which results in concentration of tested pollutants in the copying area, often leading to an excess of the permissible values of pollutant in the working rooms. During the first two days of the experiment when the copying room was ventilated, the relative humidity recorded in the copying room was 12% higher than that during the last two days of the experiment. The relative humidity in the copying room varied from 19.9 to 26.8%.

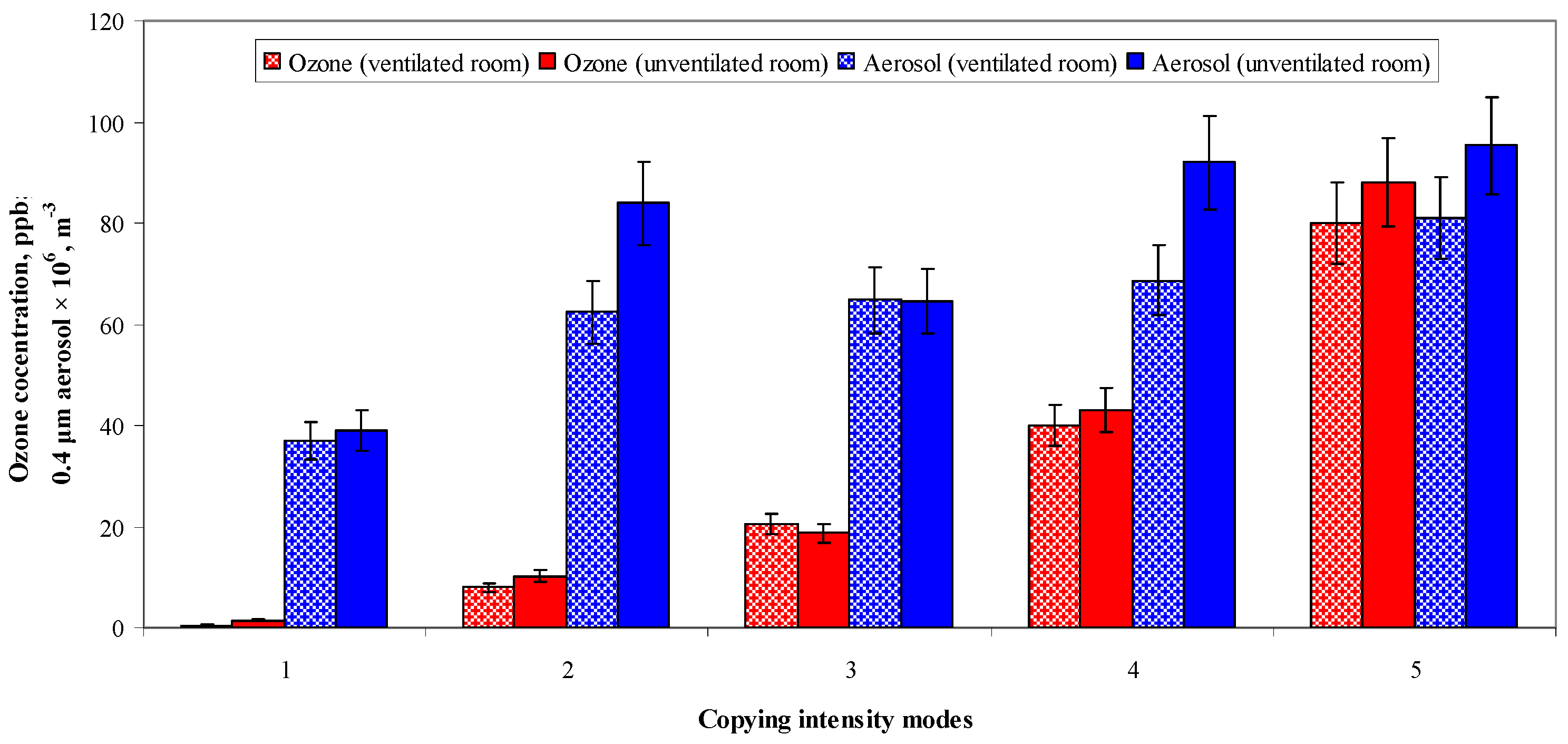

The variation of ozone and aerosol particles in the ventilated and unventilated copying room caused by different copying modes is shown in

Figure 5.

During operation of the copier in mode No. 1, copying works are not performed, therefore the background of the investigated pollutants was registered in the office room during the study period. Meanwhile, the periods between the copying stages have been assigned to mode No. 2, when the copier operates at minimum capacity, i.e., at the slowest pace.

During the investigation period, the photocopier was operated quite intensively and the period during which the copying did not take place accounted for less than 10% of the working time of the copying room. Operation of the photocopier in mode No. 2 (1 to 30 copies/min) accounted for 40% of the working time of the copying room on average, while its operation in mode No. 5 (91 to 120 copies/min) accounted for 8% of the working time of the copying room on the average.

The obtained results show that the concentration of ozone and aerosol particles in the copying room also increases with the increasing intensity of the copying process. Variations in the concentration of ozone and aerosol particles while changing the copying intensity may be described by a gradual function. The maximum average ozone concentration of 88 ppb (unventilated) and 80 ppb (ventilated room) and the concentration of 0.4 μm aerosol particles of 81 × 106 m−3 (unventilated) and 95 × 106 m−3 (ventilated room) were recorded during operation of the copier in mode No. 5 (91–120 copies/min). The dependence of pollutants on the copying mode shows that, during the automatic copying (mode No. 5: 91 to 120 copies/min), the average concentration of ozone is >40-times and that of aerosol particles is >2-times higher than those when the copier is not operated (mode No. 1: 0 copies/min). The concentration of ozone and aerosol particles in the unventilated copying room was found to be about 1.2-times higher than that in the ventilated room.

In order to investigate not only the distribution of ozone concentration in the copying room, but also to assess the level of ozone concentration at the inhalation site of the copying service worker, the ozone concentration in the office room was measured by using the passive ozone sampling method.

During the research period, the average eight-hour ozone concentration at the inhalation site of the copying service worker measured with passive samplers varied from 80 to 146 ppb (

Figure 6). Lower ozone concentration values were measured with passive samplers on those working days when the copying room was ventilated (1 day and 2 day). The obtained research data show that the permissible eight-hour ozone concentration of 100 ppb at the workspace set by the Lithuanian hygiene standard HN 23:2011 had been exceeded for three days out of four. This shows that the investigated working room where the copying works were performed is not safe for the health of the worker due to the exceeded permissible ozone concentration level. Although ozone concentrations were measured by using different measurement methods at different measuring points, and the ozone concentrations determined by using the passive sampling method were four-times higher than the ozone concentrations determined by using the ultraviolet absorption method, the highest and lowest ozone concentrations measured by both methods were found on the same days of the experiment and the estimated ozone level reflects the distribution of ozone concentration not only in the inhalation area of the copying services worker, but also at a short distance (40 cm) from the copier.

4. Discussion

Achievement of SDG’s is on the agenda of policy makers from different regions around the world. However, industry representatives are exactly those who are obliged to take different measures and manage their resources appropriately to assure economic, societal, and environmental sustainability and turn policy plans into reality. Industrial development associated with the emergence of new technologies and business models (i.e., ideas and practices discussed in the articles and books related to green logistics or green supply chain management, sustainable manufacturing or operations management) can be seen as an unavoidable prerequisite for creating a favorable environment for sustainable development.

Due to the revolution in the photocopying industry, the availability of documents and perceptible image has increased quickly at extremely inexpensive and affordable cost. Although technical progress in the copying industry contributes to the creation of material well-being in offices, the extremely complex and environmentally unfriendly processes involved in copying pose a number of dangers to humans. Unfortunately, irresponsible, uncontrolled and extensive use has caused irreversible negative effects on not only the ecosystem, by continuous release of O

3, particulate matter and other pollutants, but also the health of workers occupationally exposed to those pollutants. Moreover, copying machines also produce noise pollution. Since copying service workers spend an average of eight hours at work, this means that 30% of their time they are exposed to health hazardous conditions. Pollution in copying premises can cause headache, nausea, eye and respiratory irritation and other disorders to a copying service worker [

40,

41,

42,

43,

44]. The harmful effects of ozone on humans may be negligible, and the first symptoms of the disorder may disappear quite quickly even as the harmful effects of ozone remain [

45]. Moreover, the combined effects of two pollutants (ozone and aerosol particles) on the human eyes, nasopharynx and throat are significantly stronger than those of each pollutant alone [

14]. The reasonable use of copiers and the reduction of the negative consequences of copying on the environment and the persons involved in copying are a matter of perspective for every company providing copying services. Poor air pollution control and forecasting measures during copying often do not show the true level of threat posed by copying machines.

The levels of chemical pollution in copying rooms can be reduced by taking some precautionary measures such as having adequate ventilation for the flow of fresh air, proper maintenance of machine, using a good quality of toners in photocopy machines, closing the lid during the photocopy operation, etc. The formation of pollutants during copying has been studied by many scientists. Although there is quite a range of studies of indoor air quality in copying rooms, the model of the copier, the size of the room where the copying works are performed and the microclimatic conditions are very often not specified, therefore it is very often impossible to compare the obtained research data with those of other researchers. This research is a complex study on chemical and physical pollution in an office room with an operating copier which covers not only data on the dynamics of ozone, aerosol particles and noise, but also the assessment of the influence of copying intensity and ventilation conditions on variations of the investigated pollutants. In this study, the determination of ozone concentrations by using different methods allowed the authors not only to determine the ozone concentration in the inhalation area of the copying services worker and near the copier, but also to assess the risk of the levels of pollutants to the health of the worker, while the data on ozone concentrations obtained at different points in the copying room are valuable in modelling and predicting the distribution of this pollutant in the copying room.

Destillats et al. [

4] have found out that tiny aerosol particles are dominant during the photocopying: the concentration of the aerosol particles whose aerodynamic diameter >0.1 μm measured during the operation of the photocopier was (6–3800) × 10

6 m

−3. Having carried out the spectrum study of aerosol particles (of 0.4–2.0 μm), we found out that during the copying, the highest emissions and more significant changes in dynamics were those of the aerosol particles of 0.4 μm. During the experiment the concentration of aerosol particles of this aerodynamic diameter, measured when the photocopier was in operation, was (10–315) × 10

6 m

−3. The data on the concentrations of aerosol particles received in the investigated room were close to the research data obtained by Destillats. Weschler [

41] discovered that ozone emissions from five different photocopiers ranged from 8 to 66 ppb of ozone per one copy before maintenance compared with 0.5 to 2 ppb of ozone per one copy after maintenance. During this research, we found that ozone emissions varied from 1 pbb per one copy (while a copier is operated in the slowest mode) to 60 ppb per one copy (during the automatic copying). However, the concentrations of aerosol particles and ozone may differ due to the characteristics of the room, the photocopier which is used or ventilation conditions.

It is known that the surface of the floor has a significant effect on the formation of studied pollutants which has not been extensively researched, therefore research on the effect of floor surfaces on the dispersion of the studied pollutants in copying rooms is a future research perspective of the authors. The authors have already conducted research on the influence of floor surfaces on ozone formation in an experimental climatic chamber [

46] and are planning to conduct research in office rooms during the technological processes.

5. Conclusions

Copiers operating in office premises may be classified as local sources of air pollution by ozone and aerosol particles indoors whose dynamics are mainly determined by copying intensity.

During operation of the copier in the automatic mode (91–120 copies/min), the ozone concentration was 820% and the aerosol particle concentration was 29% higher than those found during its operation at the slowest pace (1–30 copies/min).

The ozone concentration in the ventilated copying room was found to be 8% and the concentration of 0.4 μm aerosol particles—16% lower than that in the unventilated room.

The aerosol particle spectrum study shows that the formation of coarse particles is lower than that of fine particles during copying. It was found that the concentration of 0.8–2.0 μm particles was 93% lower than that of 0.4–0.7 μm particles.

The noise emitted by the copier in the office room varied most frequently together with the concentrations of ozone and aerosol particles, and the influence of noise on the changes in the ozone concentration in the copying room is more significant than the concentration of aerosol particles. The correlation coefficient between ozone concentration and sound level was 0.86 while that between aerosol particle concentration and sound level was 0.42.

The average noise level in the copying room (60 dBA) is almost 30% lower than the permissible eight-hour noise level at the workplace (85 dBA), therefore it does not represent a hazard to the health of the copying service worker.

The ozone concentration at the inhalation site of the worker in the copying room exceeded the permissible ozone concentration value set by the Lithuanian hygiene standard HN 23:2011, i.e., 100 ppb, for 75% of the working time. On two days of the study, the average eight-hour ozone concentration was 46%, and, on one day of the study, 14% higher than the permissible ozone concentration in the atmosphere of the working environment, and only on one day out of four did the ozone concentration in the office room not exceed the permissible concentration of this pollutant.