Reducing Carbon Emissions for the Vehicle Routing Problem by Utilizing Multiple Depots

Abstract

:1. Introduction

2. Literature Review

3. Problem Description and Formulation

3.1. Mathematical Description of MDGVRPTW

3.2. Modeling Carbon Emissions

3.3. Set-Partitioning Model for the MDGVRPTW

4. Methodology

4.1. Column Generation Algorithm

| Algorithm 1: Column generation algorithm for MDGVRPTW |

| while (true) Solve the restricted MP (RMP) with added routes. Obtain the dual prices corresponding to constraint (7, 8). for (d in Vd) Solve the bidirectional label-setting algorithm under distinct depot d. if (No route with negative reduced cost exists) break else Add the route with minimal reduced cost to RMP. Output current solution in RMP as the final solution. return final solution. |

4.2. Bidirectional Label-Setting Algorithm

4.3. Branching Rule

5. Discussion

5.1. Experiment Environment

5.2. Factor Setup

5.3. Performance of the BAP Algorithm

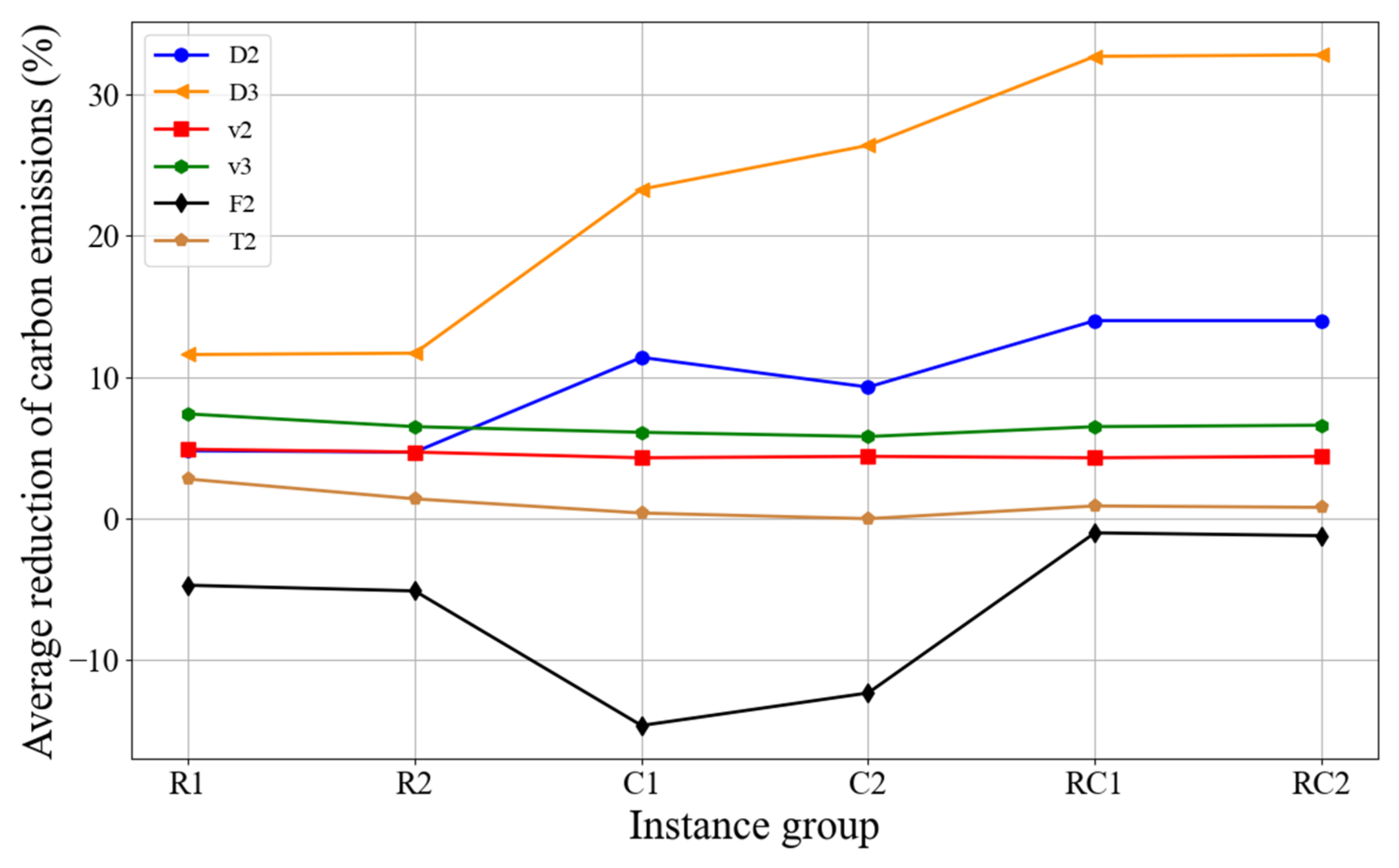

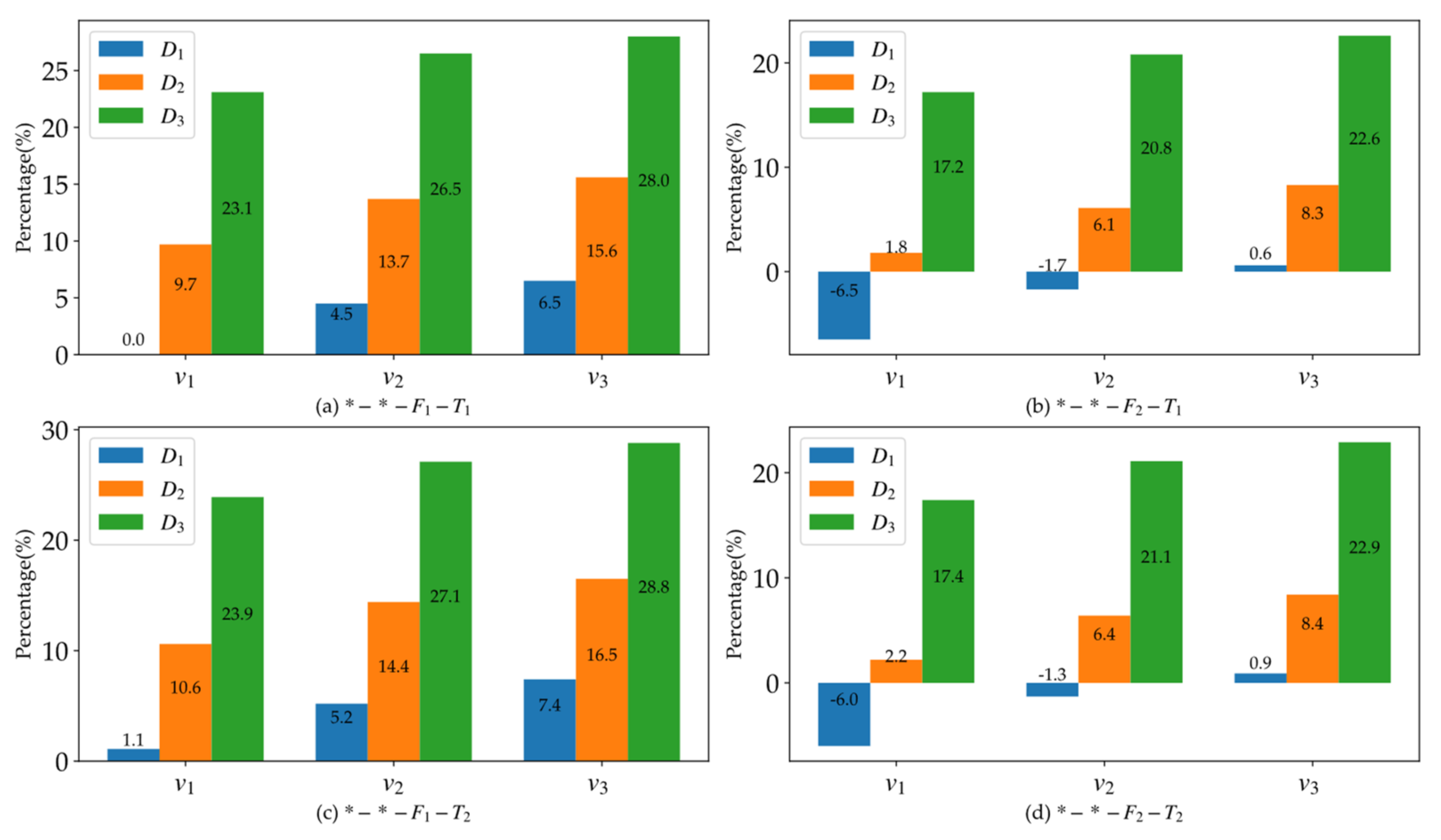

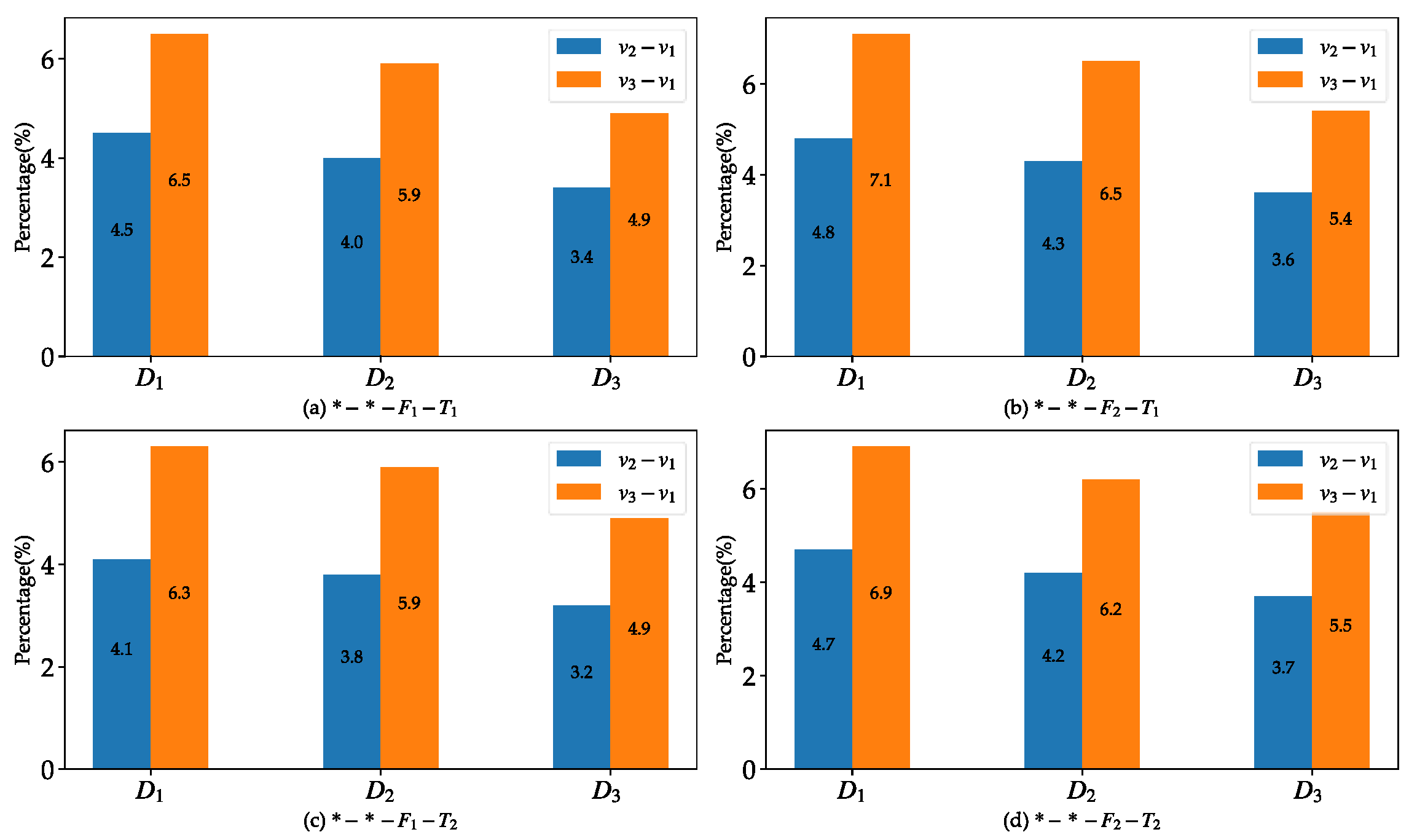

5.4. Sensitivity Analyses

6. Conclusions

- Without considering other costs, the multi-depot mode is the most useful and beneficial way to reduce carbon emissions, especially when the customer distribution is RC (semi-clustered). Based on our tests, carbon emissions can be effectively reduced by a maximum of 37.6%.

- The single-depot mode benefits more from improving the vehicle speed to reduce carbon emissions, and at most a 7.1% reduction can be achieved by changing the vehicle speed. On the other hand, improving the speed of vehicles is the most direct method of reducing carbon emissions without changing other factors.

- The growth in customer requirements could cause more greenhouse gases to be emitted into the environment. However, this type of growth in carbon emissions can be counteracted somewhat by multiple depots.

- The service time to customers has little effect on carbon emissions, especially when multiple depots are utilized.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Notation | Description | Typical Values |

|---|---|---|

| Q | Capacity (Kg) | 1200 |

| w | Weight of empty vehicle (Kg) | 1890 |

| ρ | Air density (kg/m3) | 1.2041 |

| A | Frontal surface of the vehicle (m2) | 4 |

| g | Gravitational constant (m/s2) | 9.81 |

| ζ | Fuel-to-air mass | 1 |

| ϕ | Declination of the road | 0 |

| Cd | Coefficient of aerodynamic drag | 0.7 |

| Cr | Rolling resistance | 0.01 |

| v | Vehicle velocity (m/s) | 11.67 (42 km/h) |

| at | Acceleration (m/s2) | 0 |

| Κ | Heating value of typical diesel fuel (kJ/g) | 44 |

| Nf | Engine friction factor (kJ/rev/liter) | 0.2 |

| Ne | Engine speed (rev/s) | 40 |

| Nd | Engine displacement (liters) | 5 |

| ϵ | Vehicle drive train efficiency | 0.4 |

| Efficiency parameter for diesel engines | 0.9 | |

| γ | Index of fuel to carbon emission | 3.164 |

| Inst | #Root | #Opt | Gap (%) | Time | Inst | #Root | #Opt | Gap (%) | Time |

|---|---|---|---|---|---|---|---|---|---|

| r101 | 619.29 | 621.63 | 0 | 6.06 | c106 | 333.74 | 357.34 | 0 | 73.25 |

| r102 | 533.2 | 538.51 | 0 | 57.55 | c107 | 332.09 | 354.81 | 0 | 186.84 |

| r103 | 471.12 | 479.95 | 0 | 157.97 | c108 | 331.08 | 351.68 | 0 | 68.57 |

| r105 | 544.62 | 545.92 | 0 | 24.66 | c201 | 415.62 | 429.39 | 0 | 16.78 |

| r106 | 491.88 | 498.01 | 0 | 145.28 | c202 | 413.03 | 426.29 | 0 | 42.78 |

| r107 | 449.16 | 461.88 | 0 | 1098.33 | c203 | 407.62 | 418.69 | 0 | 217.94 |

| r108 | 421.76 | 432.3 | 0 | 2184.29 | c204 | 405.75 | 416.07 | 0 | 356.88 |

| r109 | 467.48 | 480.71 | 0 | 1057.52 | c205 | 412.02 | 417.33 | 0 | 4.09 |

| r110 | 438.94 | 455.9 | 0 | 2568.15 | c206 | 411.38 | 420.75 | 0 | 25.43 |

| r111 | 441.47 | 451.95 | 0 | 1214.95 | c207 | 409.74 | 416.6 | 0 | 63.51 |

| r112 | 420.34 | 431.22 | 0 | 1260.88 | c208 | 410.85 | 417.3 | 0 | 37.47 |

| r201 | 568.16 | 574.04 | 0 | 41.44 | rc101 | 575.03 | 641.85 | 0 | 2862.65 |

| r202 | 509.85 | 517.28 | 0 | 215.62 | rc102 | 557.88 | 632.61 | 6.5 | - |

| r203 | 457.64 | 465.23 | 0 | 56.63 | rc103 | 544.56 | 623.34 | 7.3 | - |

| r204 | 426.48 | 439.92 | 0 | 10050.5 | rc104 | 528.58 | 613.63 | 7.6 | - |

| r205 | 499.6 | 505.13 | 0 | 9.54 | rc105 | 560.5 | 634.26 | 6.3 | - |

| r206 | 465.84 | 472.64 | 0 | 70.96 | rc106 | 544.24 | 627.64 | 6.7 | - |

| r207 | 437.52 | 444.95 | 0 | 53.06 | rc107 | 529.94 | 614.67 | 6.7 | - |

| r208 | 421.13 | 431.82 | 0 | 594.92 | rc108 | 526.77 | 612.87 | 7.5 | - |

| r209 | 458.34 | 471.44 | 0 | 456.34 | rc201 | 601.16 | 657.51 | 0 | 10.42 |

| r210 | 473.27 | 485.67 | 0 | 630.78 | rc202 | 569.33 | 643.53 | 6.2 | - |

| r211 | 431.79 | 446.73 | 0 | 3311.23 | rc203 | 545.63 | 623.4 | 7.2 | - |

| c101 | 333.74 | 358.23 | 0 | 41.24 | rc204 | 528.58 | 618.69 | 8.3 | - |

| c102 | 331.14 | 350.98 | 0 | 608.34 | rc205 | 572.11 | 642.7 | 5.5 | - |

| c103 | 328.87 | 341.78 | 0 | 3455.21 | rc206 | 558.95 | 633.72 | 5.2 | - |

| c104 | 326.24 | 345.89 | 0.3 | - | rc207 | 539.37 | 625.4 | 6.9 | - |

| c105 | 333.3 | 355.19 | 0 | 54.46 | rc208 | 527 | 616.66 | 8 | - |

| Inst | #Root | #Opt | Gap (%) | Time | Inst | #Root | #Opt | Gap (%) | Time |

|---|---|---|---|---|---|---|---|---|---|

| r101 | 582.78 | 587.02 | 0 | 6.76 | c106 | 298.49 | 316.21 | 0 | 37.11 |

| r102 | 507.82 | 510.61 | 0 | 77.11 | c107 | 295.39 | 313.2 | 0 | 578.21 |

| r103 | 453.21 | 459.13 | 0 | 99.28 | c108 | 292.73 | 310.01 | 1 | - |

| r104 | 412.9 | 422.36 | 0 | 299.61 | c109 | 289.47 | 308.93 | 2 | - |

| r105 | 510.64 | 513.55 | 0 | 6.7 | c201 | 376.48 | 382.65 | 0 | 14.25 |

| r106 | 462.23 | 469.22 | 0 | 22.13 | c202 | 373.42 | 382.65 | 0 | 320.51 |

| r107 | 431.76 | 441.38 | 0 | 112.85 | c203 | 368.99 | 378.22 | 0 | 1397.41 |

| r108 | 402.78 | 414.55 | 0 | 1945.46 | c204 | 363.45 | 372.66 | 0.2 | - |

| r109 | 449.89 | 460.36 | 0 | 202.54 | c205 | 374.3 | 381.96 | 0 | 131.24 |

| r110 | 417.46 | 428.28 | 0 | 337.39 | c206 | 373.35 | 382.94 | 0 | 409.82 |

| r111 | 422.36 | 426.76 | 0 | 858.39 | c207 | 368.89 | 380.22 | 0.1 | - |

| r112 | 399.77 | 408.82 | 0 | 79.52 | c208 | 373.26 | 381.61 | 0 | 3761.58 |

| r201 | 543.26 | 545.41 | 0 | 6.12 | rc101 | 511.65 | 562.53 | 0 | 102.07 |

| r202 | 488.71 | 494.15 | 0 | 64.8 | rc102 | 492.6 | 547.69 | 4.8 | - |

| r203 | 443.09 | 450.11 | 0 | 187.42 | rc103 | 481.88 | 540.44 | 6.1 | - |

| r204 | 408.66 | 414.83 | 0 | 1453.08 | rc104 | 466.18 | 526.81 | 6.8 | - |

| r205 | 485.93 | 490.96 | 0 | 76.76 | rc105 | 496.12 | 547.88 | 4.6 | - |

| r206 | 444.42 | 449.89 | 0 | 142.9 | rc106 | 481.81 | 538.73 | 5.8 | - |

| r207 | 420.37 | 428.6 | 0 | 436.83 | rc107 | 466.88 | 528.23 | 6.7 | - |

| r208 | 400.37 | 409.86 | 0 | 519.95 | rc108 | 464.32 | 526.58 | 7.1 | - |

| r209 | 436.66 | 450.21 | 0 | 371 | rc201 | 531.27 | 565.91 | 0 | 7.17 |

| r210 | 451.41 | 462.61 | 0 | 460.02 | rc202 | 497.67 | 549.49 | 4.5 | - |

| r211 | 408.54 | 418.76 | 0 | 344.8 | rc203 | 482.54 | 540.44 | 6.1 | - |

| c101 | 298.87 | 315.83 | 0 | 31.64 | rc204 | 466.53 | 526.81 | 6.6 | - |

| c102 | 292.8 | 312.26 | 0 | 912.02 | rc205 | 504.53 | 550.79 | 3 | - |

| c103 | 286.97 | 306.53 | 0.7 | - | rc206 | 498.52 | 547.25 | 4.3 | - |

| c104 | 281.41 | 307.19 | 2.7 | - | rc207 | 477.73 | 533.32 | 5.8 | - |

| Inst | #Root | #Opt | Gap (%) | Time | Inst | #Root | #Opt | Gap (%) | Time |

|---|---|---|---|---|---|---|---|---|---|

| r101 | 539.02 | 541.61 | 0 | 7.61 | c106 | 260.21 | 275.17 | 0 | 50.06 |

| r102 | 473.02 | 468.02 | 0 | 12.53 | c107 | 255.02 | 264.13 | 0 | 1452.71 |

| r103 | 417.14 | 418.63 | 0 | 35.93 | c108 | 252.27 | 266.35 | 0.7 | - |

| r104 | 381.99 | 383.95 | 0 | 298.49 | c109 | 249.67 | 263.47 | 1.3 | - |

| r105 | 478.14 | 478.14 | 0 | 3.52 | c201 | 304.57 | 318.2 | 0 | 17.61 |

| r106 | 433.97 | 433.97 | 0 | 6.8 | c202 | 305.23 | 311.62 | 0 | 165.52 |

| r107 | 405.69 | 407.49 | 0 | 116.02 | c203 | 299.92 | 309.91 | 0 | 4126.34 |

| r108 | 377.21 | 376.99 | 0 | 748.11 | c204 | 295.9 | 299.98 | 0 | 1003.86 |

| r109 | 433.94 | 439.73 | 0 | 260.2 | c205 | 305.07 | 310.26 | 0 | 60.42 |

| r110 | 396.01 | 402.43 | 0 | 139.63 | c206 | 299.6 | 309.12 | 0 | 111.74 |

| r111 | 399.68 | 404.8 | 0 | 210.78 | c207 | 296.97 | 305.29 | 0 | 3025.16 |

| r112 | 374.49 | 378.51 | 0 | 186.33 | c208 | 299.63 | 305.61 | 0 | 1042.35 |

| r201 | 498.87 | 498.87 | 0 | 2.64 | rc101 | 407.78 | 444.92 | 0 | 84.55 |

| r202 | 460.05 | 461.44 | 0 | 24 | rc102 | 392.11 | 433.18 | 5.6 | - |

| r203 | 408.57 | 408.79 | 0 | 21.93 | rc103 | 382.91 | 420.91 | 5.2 | - |

| r204 | 379.49 | 384.96 | 0 | 347.49 | rc104 | 369.11 | 410.31 | 7.6 | - |

| r205 | 464.48 | 466.34 | 0 | 20.89 | rc105 | 396.54 | 432.27 | 3.7 | - |

| r206 | 420.75 | 423.88 | 0 | 56.49 | rc106 | 378.07 | 415.46 | 5.2 | - |

| r207 | 394.9 | 396.77 | 0 | 66.31 | rc107 | 371.11 | 408.31 | 6.2 | - |

| r208 | 375.03 | 380.19 | 0 | 636.76 | rc108 | 367.37 | 405.56 | 7.3 | - |

| r209 | 419.14 | 422.96 | 0 | 11.88 | rc201 | 418.12 | 449.29 | 0 | 30.22 |

| r210 | 419.51 | 425.24 | 0 | 225.15 | rc202 | 397.94 | 434.96 | 4 | - |

| r211 | 384.17 | 389.77 | 0 | 84.78 | rc203 | 389.65 | 419.17 | 4.7 | - |

| c101 | 260.59 | 276.72 | 0 | 28.18 | rc204 | 369.11 | 407.9 | 7.1 | - |

| c102 | 254.32 | 271.95 | 1.8 | - | rc205 | 407.97 | 438.02 | 0 | 630.3 |

| c103 | 245.91 | 263.21 | 1.8 | - | rc206 | 397.08 | 427.58 | 2.1 | - |

| c104 | 240.05 | 267.48 | 5.8 | - | rc207 | 379.87 | 416.19 | 5.6 | - |

| Condition | D1 | Avg. R (%) | D2 | Avg. R (%) | D3 | Avg. R (%) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R1 | R2 | C1 | C2 | RC1 | RC2 | R1 | R2 | C1 | C2 | RC1 | RC2 | R1 | R2 | C1 | C2 | RC1 | RC2 | ||||

| v1–F1–T1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 4.8 | 4.7 | 11.4 | 9.3 | 14 | 14 | 9.7 | 11.6 | 11.7 | 23.3 | 26.4 | 32.7 | 32.8 | 23.1 |

| v2–F1–T1 | 4.9 | 4.7 | 4.3 | 4.4 | 4.3 | 4.4 | 4.5 | 9.6 | 9 | 15.3 | 13.2 | 17.5 | 17.8 | 13.7 | 15.9 | 15.7 | 26.3 | 29.8 | 35.5 | 35.7 | 26.5 |

| v3–F1–T1 | 7.4 | 6.5 | 6.1 | 5.8 | 6.5 | 6.6 | 6.5 | 11.6 | 11 | 16.6 | 14.9 | 19.6 | 19.7 | 15.6 | 18.1 | 17.3 | 27.6 | 31.2 | 36.9 | 36.9 | 28 |

| v1–F2–T1 | −4.7 | −5.1 | −14.6 | −12.3 | −1 | −1.2 | −6.5 | 0.9 | 0.3 | 1.2 | 0 | 4.1 | 4.5 | 1.8 | 8.4 | 8.2 | 17.2 | 21.2 | 23.8 | 24.3 | 17.2 |

| v2–F2–T1 | 0.4 | −0.3 | −9.5 | −7.2 | 3.3 | 3.1 | −1.7 | 5.3 | 5 | 5.6 | 4.4 | 7.9 | 8.3 | 6.1 | 12.5 | 12.5 | 20.8 | 23.8 | 27.5 | 27.5 | 20.8 |

| v3–F2–T1 | 2.7 | 1.9 | −6.8 | −5.1 | 5.4 | 5.2 | 0.6 | 7.7 | 7.2 | 7.7 | 6.5 | 10.5 | 10.1 | 8.3 | 14.8 | 14.5 | 22.6 | 25.5 | 28.8 | 29.1 | 22.6 |

| v1–F1–T2 | 2.8 | 1.4 | 0.4 | 0 | 0.9 | 0.8 | 1.1 | 7.4 | 6.7 | 11.3 | 9.4 | 14.3 | 14.4 | 10.6 | 13.9 | 12.9 | 23.3 | 26.9 | 33.5 | 33.1 | 23.9 |

| v2–F1–T2 | 6.9 | 5.9 | 4.4 | 4.2 | 5 | 5 | 5.2 | 11.3 | 10.7 | 14.9 | 13.4 | 18 | 18.1 | 14.4 | 17.5 | 16.8 | 26.5 | 30.1 | 35.9 | 35.8 | 27.1 |

| v3–F1–T2 | 9.1 | 8.2 | 6.5 | 6.3 | 7 | 7.1 | 7.4 | 13.5 | 13.3 | 16.9 | 15.2 | 19.9 | 19.9 | 16.5 | 19.4 | 18.7 | 28.1 | 31.7 | 37.6 | 37.4 | 28.8 |

| v1–F2–T2 | −3.4 | −4.2 | −14.5 | −12.2 | −0.7 | −0.9 | −6 | 1.7 | 1.5 | 1.5 | 0.4 | 4.2 | 3.7 | 2.2 | 9.7 | 9.3 | 17.4 | 20.6 | 23.8 | 23.8 | 17.4 |

| v2–F2–T2 | 1.5 | 0.3 | −9.6 | −7.3 | 3.7 | 3.5 | −1.3 | 6.3 | 5.8 | 5.7 | 4.7 | 7.8 | 8.1 | 6.4 | 13.7 | 13.2 | 21 | 24.6 | 27.2 | 26.8 | 21.1 |

| v3–F2–T2 | 3.5 | 2.6 | −7.1 | −5 | 5.8 | 5.7 | 0.9 | 8.4 | 7.9 | 7.7 | 6.7 | 9.8 | 9.9 | 8.4 | 15.7 | 15 | 22.7 | 26 | 29.2 | 28.7 | 22.9 |

| Condition | D1 | Avg. R (%) | D2 | Avg. R (%) | D3 | Avg. R (%) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R1 | R2 | C1 | C2 | RC1 | RC2 | R1 | R2 | C1 | C2 | RC1 | RC2 | R1 | R2 | C1 | C2 | RC1 | RC2 | ||||

| v1–F1 | 2.8 | 1.4 | 0.4 | 0 | 0.9 | 0.8 | 1.1 | 2.6 | 2 | −0.1 | 0.1 | 0.3 | 0.4 | 0.9 | 2.3 | 1.2 | 0 | 0.5 | 0.8 | 0.3 | 0.8 |

| v2–F1 | 2 | 1.2 | 0.1 | −0.2 | 0.7 | 0.6 | 0.7 | 1.7 | 1.7 | −0.4 | 0.2 | 0.5 | 0.3 | 0.7 | 1.6 | 1.1 | 0.2 | 0.3 | 0.4 | 0.1 | 0.6 |

| v3–F1 | 1.7 | 1.7 | 0.4 | 0.5 | 0.5 | 0.5 | 0.9 | 1.9 | 2.3 | 0.3 | 0.3 | 0.3 | 0.2 | 0.9 | 1.3 | 1.4 | 0.5 | 0.5 | 0.7 | 0.5 | 0.8 |

| v1–F2 | 1.3 | 0.9 | 0.1 | 0.1 | 0.3 | 0.3 | 0.5 | 0.8 | 1.2 | 0.3 | 0.4 | 0.1 | −0.8 | 0.4 | 1.3 | 1.1 | 0.2 | −0.6 | 0 | −0.5 | 0.2 |

| v2–F2 | 1.1 | 0.6 | −0.1 | −0.1 | 0.4 | 0.4 | 0.4 | 1 | 0.8 | 0.1 | 0.3 | −0.1 | −0.2 | 0.3 | 1.2 | 0.7 | 0.2 | 0.8 | −0.3 | −0.7 | 0.3 |

| v3–F2 | 0.8 | 0.7 | −0.3 | 0.1 | 0.4 | 0.5 | 0.3 | 0.7 | 0.7 | 0 | 0.2 | −0.7 | −0.2 | 0.1 | 0.9 | 0.5 | 0.1 | 0.5 | 0.4 | −0.4 | 0.3 |

References

- International Energy Agency. Tracking Report 2020; International Energy Agency: Paris, France, 2020. [Google Scholar]

- Braekers, K.; Ramaekers, K.; Van Nieuwenhuyse, I. The Vehicle Routing Problem: State of the Art Classification and Review. Comput. Ind. Eng. 2016, 99, 300–313. [Google Scholar] [CrossRef]

- Lin, C.; Choy, K.L.; Ho, G.T.; Chung, S.H.; Lam, H. Survey of Green Vehicle Routing Problem: Past and Future Trends. Expert Syst. Appl. 2014, 41, 1118–1138. [Google Scholar] [CrossRef]

- Demir, E.; Bektaş, T.; Laporte, G. A Review of Recent Research on Green Road Freight Transportation. Eur. J. Oper. Res. 2014, 237, 775–793. [Google Scholar] [CrossRef] [Green Version]

- Flood, M.M. The Traveling-Salesman Problem. Oper. Res. 1956, 4, 61–75. [Google Scholar] [CrossRef]

- Hernández-Pérez, H.; Salazar-González, J.-J. A Branch-and-Cut Algorithm for a Traveling Salesman Problem with Pickup and Delivery. Discrete Appl. Math. 2004, 145, 126–139. [Google Scholar] [CrossRef] [Green Version]

- Johnson, D.S.; McGeoch, L.A. 8. the Traveling Salesman Problem: A Case Study. In Local Search in Combinatorial Optimization; Princeton University Press: Princeton, NJ, USA, 2018; pp. 215–310. [Google Scholar]

- Baniasadi, P.; Foumani, M.; Smith-Miles, K.; Ejov, V. A Transformation Technique for the Clustered Generalized Traveling Salesman Problem with Applications to Logistics. Eur. J. Oper. Res. 2020, 285, 444–457. [Google Scholar] [CrossRef]

- Montoya-Torres, J.R.; Franco, J.L.; Isaza, S.N.; Jiménez, H.F.; Herazo-Padilla, N. A Literature Review on the Vehicle Routing Problem with Multiple Depots. Comput. Ind. Eng. 2015, 79, 115–129. [Google Scholar] [CrossRef]

- Sharma, N.; Monika, M. A Literature Survey on Multi-Depot Vehicle Routing Problem. Int. J. Res. Dev. 2015, 3, 1752–1757. [Google Scholar]

- Tillman, F.A. The Multiple Terminal Delivery Problem with Probabilistic Demands. Transp. Sci. 1969, 3, 192–204. [Google Scholar] [CrossRef]

- Zhou, Z.; Ha, M.; Hu, H.; Ma, H. Half Open Multi-Depot Heterogeneous Vehicle Routing Problem for Hazardous Materials Transportation. Sustainability 2021, 13, 1262. [Google Scholar] [CrossRef]

- Bettinelli, A.; Ceselli, A.; Righini, G. A Branch-and-Cut-and-Price Algorithm for the Multi-Depot Heterogeneous Vehicle Routing Problem with Time Windows. Transp. Res. Part C Emerg. Technol. 2011, 19, 723–740. [Google Scholar] [CrossRef]

- Contardo, C.; Martinelli, R. A New Exact Algorithm for the Multi-Depot Vehicle Routing Problem under Capacity and Route Length Constraints. Discrete Optim. 2014, 12, 129–146. [Google Scholar] [CrossRef] [Green Version]

- Muter, I.; Cordeau, J.-F.; Laporte, G. A Branch-and-Price Algorithm for the Multidepot Vehicle Routing Problem with Interdepot Routes. Transp. Sci. 2014, 48, 425–441. [Google Scholar] [CrossRef]

- Işık, C.; Ahmad, M.; Ongan, S.; Ozdemir, D.; Irfan, M.; Alvarado, R. Convergence Analysis of the Ecological Footprint: Theory and Empirical Evidence from the USMCA Countries. Environ. Sci. Pollut. Res. 2021, 3, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Isik, C.; Ongan, S.; Ozdemir, D.; Ahmad, M.; Irfan, M.; Alvarado, R.; Ongan, A. The Increases and Decreases of the Environment Kuznets Curve (EKC) for 8 OECD Countries. Environ. Sci. Pollut. Res. 2021, 28, 28535–28543. [Google Scholar] [CrossRef] [PubMed]

- Işık, C.; Ongan, S.; Bulut, U.; Karakaya, S.; Irfan, M.; Alvarado, R.; Ahmad, M.; Rehman, A. Reinvestigating the Environmental Kuznets Curve (EKC) Hypothesis by a Composite Model Constructed on the Armey Curve Hypothesis with Government Spending for the US States. Environ. Sci. Pollut. Res. 2021, 1–12. [Google Scholar] [CrossRef]

- Bektaş, T.; Demir, E.; Laporte, G. Green Vehicle Routing. In Green Transportation Logistics; Springer: Berlin/Heidelberg, Germany, 2016; pp. 243–265. [Google Scholar]

- Moghdani, R.; Salimifard, K.; Demir, E.; Benyettou, A. The Green Vehicle Routing Problem: A Systematic Literature Review. J. Clean. Prod. 2021, 279, 123691. [Google Scholar] [CrossRef]

- Asghari, M.; Al-e, S.M.J.M. Green Vehicle Routing Problem: A State-of-the-Art Review. Int. J. Prod. Econ. 2021, 231, 107899. [Google Scholar] [CrossRef]

- Ghorbani, E.; Alinaghian, M.; Gharehpetian, G.; Mohammadi, S.; Perboli, G. A Survey on Environmentally Friendly Vehicle Routing Problem and a Proposal of Its Classification. Sustainability 2020, 12, 9079. [Google Scholar] [CrossRef]

- Demir, E.; Bektaş, T.; Laporte, G. A Comparative Analysis of Several Vehicle Emission Models for Road Freight Transportation. Transp. Res. Part Transp. Environ. 2011, 16, 347–357. [Google Scholar] [CrossRef]

- Bektaş, T.; Laporte, G. The Pollution-Routing Problem. Transp. Res. Part B Methodol. 2011, 45, 1232–1250. [Google Scholar] [CrossRef]

- Franceschetti, A.; Honhon, D.; Van Woensel, T.; Bektaş, T.; Laporte, G. The Time-Dependent Pollution-Routing Problem. Transp. Res. Part B Methodol. 2013, 56, 265–293. [Google Scholar] [CrossRef] [Green Version]

- Koç, Ç.; Bektaş, T.; Jabali, O.; Laporte, G. The Fleet Size and Mix Pollution-Routing Problem. Transp. Res. Part B Methodol. 2014, 70, 239–254. [Google Scholar] [CrossRef]

- Dabia, S.; Demir, E.; Woensel, T.V. An Exact Approach for a Variant of the Pollution-Routing Problem. Transp. Sci. 2017, 51, 607–628. [Google Scholar] [CrossRef]

- Rauniyar, A.; Nath, R.; Muhuri, P.K. Multi-Factorial Evolutionary Algorithm Based Novel Solution Approach for Multi-Objective Pollution-Routing Problem. Comput. Ind. Eng. 2019, 130, 757–771. [Google Scholar] [CrossRef]

- Wang, J.; Yu, Y.; Tang, J. Compensation and Profit Distribution for Cooperative Green Pickup and Delivery Problem. Transp. Res. Part B Methodol. 2018, 113, 54–69. [Google Scholar] [CrossRef]

- Peng, B.; Zhang, Y.; Gajpal, Y.; Chen, X. A Memetic Algorithm for the Green Vehicle Routing Problem. Sustainability 2019, 11, 6055. [Google Scholar] [CrossRef] [Green Version]

- Yu, Y.; Wang, S.; Wang, J.; Huang, M. A Branch-and-Price Algorithm for the Heterogeneous Fleet Green Vehicle Routing Problem with Time Windows. Transp. Res. Part B Methodol. 2019, 122, 511–527. [Google Scholar] [CrossRef]

- Figliozzi, M.A. Carbon Emissions Reductions in Last Mile and Grocery Deliveries Utilizing Air and Ground Autonomous Vehicles. Transp. Res. Part Transp. Environ. 2020, 85, 102443. [Google Scholar] [CrossRef]

- Pribyl, O.; Blokpoel, R.; Matowicki, M. Addressing EU Climate Targets: Reducing CO2 Emissions Using Cooperative and Automated Vehicles. Transp. Res. Part Transp. Environ. 2020, 86, 102437. [Google Scholar] [CrossRef]

- Saleh, M.; Hatzopoulou, M. Greenhouse Gas Emissions Attributed to Empty Kilometers in Automated Vehicles. Transp. Res. Part Transp. Environ. 2020, 88, 102567. [Google Scholar] [CrossRef]

- Zeng, W.; Miwa, T.; Morikawa, T. Eco-Routing Problem Considering Fuel Consumption and Probabilistic Travel Time Budget. Transp. Res. Part Transp. Environ. 2020, 78, 102219. [Google Scholar] [CrossRef]

- Wang, Z.; Wen, P. Optimization of a Low-Carbon Two-Echelon Heterogeneous-Fleet Vehicle Routing for Cold Chain Logistics under Mixed Time Window. Sustainability 2020, 12, 1967. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Wang, F.; He, Y. Electric Vehicle Routing Problem with Battery Swapping Considering Energy Consumption and Carbon Emissions. Sustainability 2020, 12, 10537. [Google Scholar] [CrossRef]

- Li, J.; Wang, R.; Li, T.; Lu, Z.; Pardalos, P.M. Benefit Analysis of Shared Depot Resources for Multi-Depot Vehicle Routing Problem with Fuel Consumption. Transp. Res. Part Transp. Environ. 2018, 59, 417–432. [Google Scholar] [CrossRef]

- Li, Y.; Soleimani, H.; Zohal, M. An Improved Ant Colony Optimization Algorithm for the Multi-Depot Green Vehicle Routing Problem with Multiple Objectives. J. Clean. Prod. 2019, 227, 1161–1172. [Google Scholar] [CrossRef]

- Wang, Y.; Assogba, K.; Fan, J.; Xu, M.; Liu, Y.; Wang, H. Multi-Depot Green Vehicle Routing Problem with Shared Transportation Resource: Integration of Time-Dependent Speed and Piecewise Penalty Cost. J. Clean. Prod. 2019, 232, 12–29. [Google Scholar] [CrossRef]

- Zhang, W.; Gajpal, Y.; Appadoo, S.; Wei, Q. Multi-Depot Green Vehicle Routing Problem to Minimize Carbon Emissions. Sustainability 2020, 12, 3500. [Google Scholar] [CrossRef] [Green Version]

- Peng, B.; Wu, L.; Yi, Y.; Chen, X. Solving the Multi-Depot Green Vehicle Routing Problem by a Hybrid Evolutionary Algorithm. Sustainability 2020, 12, 2127. [Google Scholar] [CrossRef] [Green Version]

- Costa, L.; Contardo, C.; Desaulniers, G. Exact Branch-Price-and-Cut Algorithms for Vehicle Routing. Transp. Sci. 2019, 53, 946–985. [Google Scholar] [CrossRef]

| No. | Instance Class | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|---|

| Coordinate | R | [35,35] | [0,0] | [67,77] | [0,77] | [67,0] |

| C | [40,50] | [22,25] | [75,58] | [13,63] | [65,20] | |

| RC | [40,50] | [0,0] | [75,58] | [14,73] | [70,20] |

| Factor | Class of Instances | Number of Depots | Speed | Demands | Service Time |

|---|---|---|---|---|---|

| Condition | R1 | D1 | v1 | F1 | T1 |

| R2 | D2 | v2 | F2 | T2 | |

| C1 | D3 | v3 | |||

| C2 | |||||

| RC1 | |||||

| RC2 |

| Class | No. of Inst | D1 | D2 | D3 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| No. of Solved | Time (s) | Gap (%) | No. of Solved | Time (s) | Gap (%) | No. of Solved | Time (s) | Gap (%) | ||

| R1 | 12 | 12 | 1343.3 | 0 | 12 | 337.31 | 0 | 12 | 168.83 | 0 |

| R2 | 11 | 11 | 1408.28 | 0 | 11 | 369.43 | 0 | 11 | 136.21 | 0 |

| C1 | 9 | 8 | 914.04 | 0.03 | 5 | 319.95 | 0.71 | 4 | 586.65 | 1.27 |

| C2 | 8 | 8 | 95.61 | 0 | 6 | 1005.8 | 0.04 | 8 | 1194.13 | 0 |

| RC1 | 8 | 1 | 2862.65 | 6.08 | 1 | 102.07 | 5.24 | 1 | 84.55 | 5.1 |

| RC2 | 8 | 1 | 10.42 | 5.91 | 1 | 7.17 | 4.68 | 2 | 330.26 | 3.89 |

| Average | 1105.72 | 2 | 356.96 | 1.78 | 416.77 | 1.71 | ||||

| Condition\Group | R1 | R2 | C1 | C2 | RC1 | RC2 | Avg. R (%) |

|---|---|---|---|---|---|---|---|

| D2 | 4.8 | 4.7 | 11.4 | 9.3 | 14 | 14 | 9.7 |

| D3 | 11.6 | 11.7 | 23.3 | 26.4 | 32.7 | 32.8 | 23.1 |

| v2 | 4.9 | 4.7 | 4.3 | 4.4 | 4.3 | 4.4 | 4.5 |

| v3 | 7.4 | 6.5 | 6.1 | 5.8 | 6.5 | 6.6 | 6.5 |

| F2 | −4.7 | −5.1 | −14.6 | −12.3 | −1 | −1.2 | −6.5 |

| T2 | 2.8 | 1.4 | 0.4 | 0 | 0.9 | 0.8 | 1.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Han, C.; Yu, Y.; Huang, M.; Sun, W.; Kaku, I. Reducing Carbon Emissions for the Vehicle Routing Problem by Utilizing Multiple Depots. Sustainability 2022, 14, 1264. https://doi.org/10.3390/su14031264

Wang S, Han C, Yu Y, Huang M, Sun W, Kaku I. Reducing Carbon Emissions for the Vehicle Routing Problem by Utilizing Multiple Depots. Sustainability. 2022; 14(3):1264. https://doi.org/10.3390/su14031264

Chicago/Turabian StyleWang, Sihan, Cheng Han, Yang Yu, Min Huang, Wei Sun, and Ikou Kaku. 2022. "Reducing Carbon Emissions for the Vehicle Routing Problem by Utilizing Multiple Depots" Sustainability 14, no. 3: 1264. https://doi.org/10.3390/su14031264

APA StyleWang, S., Han, C., Yu, Y., Huang, M., Sun, W., & Kaku, I. (2022). Reducing Carbon Emissions for the Vehicle Routing Problem by Utilizing Multiple Depots. Sustainability, 14(3), 1264. https://doi.org/10.3390/su14031264