3D-Printed Blocks: Thermal Performance Analysis and Opportunities for Insulating Materials

Abstract

:1. Introduction

- to propose a new 3D-printed block to be used as thermal insulation of building walls, also considering criticalities and potentials related to its realization;

- to analyze the thermal performance of the prototype 3D-printed block via theoretical and experimental approaches (by means of InfraRed Thermography (IRT) technique and Heat Flow Meter (HFM) method in Hot Box apparatus);

- to evaluate the thermal performance of the 3D-printed block by filling its air cavities with waste materials, thus implementing the concept of circular economy.

2. Materials and Methods

- Fused Deposition Modelling (FDM) or Fused Filament Fabrication (FFF) is an additive manufacturing technology that involves the melting and extrusion of thermoplastic filaments. The filaments are then deposited “layer upon layer” by the extrusion nozzle in the printing area, thus creating anisotropic objects. The materials most used for FDM printing are Acrylonitrile Butadiene Styrene (ABS) and Polylactic Acid (PLA). Currently, FDM is the most popular printing process due to its fast prototyping and relatively low cost.

- Stereolithography (SLA or SL), the first 3DP process, is a technique based on a photochemical process, in which light is used to create polymers. It is still widely used as it allows to print isotropic objects, with high resolution and precision. Resin is generally used for SLA 3DP, such as standard, clear, and engineering (though, durable, heat resistant, flexible, and rigid) resin.

- Selective Laser Sintering (SLS) employs a high-power laser to melt small particles of powder material, resulting in robust, functional objects with complex geometries that are generally isotropic. The most used material for SLS is lightweight, strong and flexible nylon.

2.1. Methodology Employed

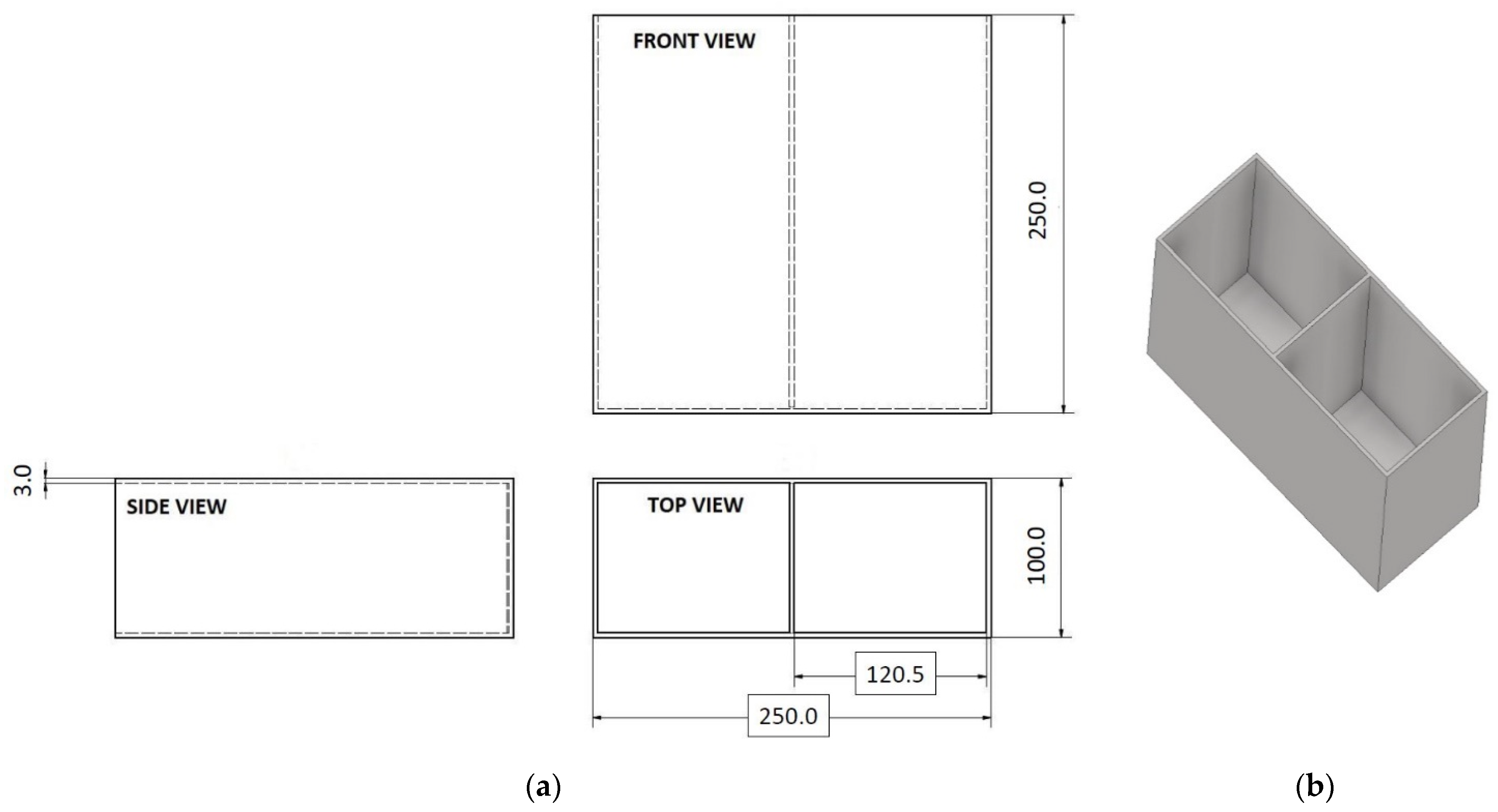

2.2. Design Phase

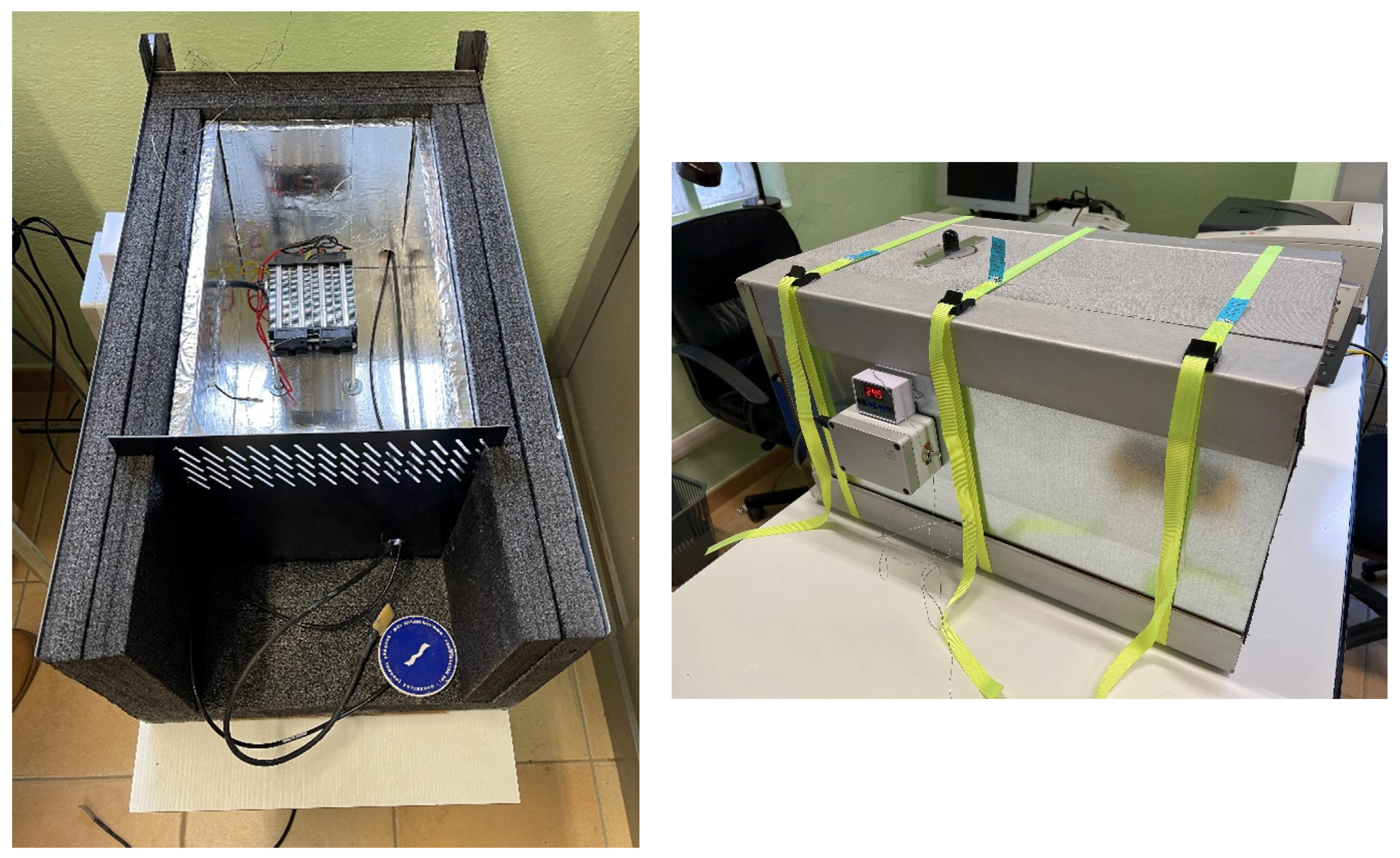

2.3. The Hot Box Apparatus

2.4. Performance Analysis

2.4.1. Theoretical Approach

2.4.2. Experimental Approach

2.5. Use of Recycling Materials

3. Results

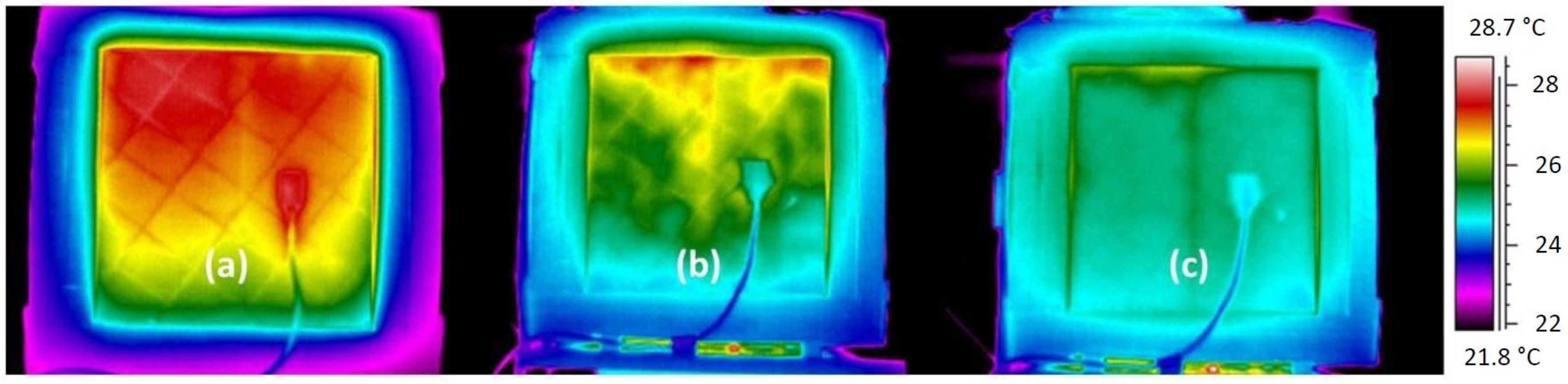

3.1. Infrared Thermography

3.2. Heat Flow Meter Method

4. Conclusions

- The 2D and 3D design phase of the block using different software (including AutoCAD Inventor® and Creality Slicer 4.2 software) allowed one to exploit the potential of the AM to create even complex geometries; however, the printing phase may require a non-negligible time that, therefore, must be evaluated in the design phase. In this work, the printing phase required about 14 h to realize the prototype block; therefore, an interesting future development of the work is represented by the research of solutions able to reduce the printing time, for example, modifying the diameter of the nozzle and evaluating different printing speeds; the use of AM allowed one to study solutions for reusing waste materials to be filled in the air cavities of the block, thus implementing the concept of circular economy;

- The IR thermography has shown that the 3D-printed block with the air cavities is subject to a considerable thermal stratification that tends to decrease when the cavities are filled with polystyrene and wool;

- The HFM method allowed one to have a quantitative knowledge of the thermal behavior of the 3D-printed block in the three configurations analyzed (with and without cavity filling materials);

- Filling the air cavities with wool determined the best thermal behavior with a thermal conductance value of 0.78 W/m2·K ± 3.05%, with respect to polystyrene with which a conductance equal to 1.57 W/m2·K ± 3.02% was obtained. Clearly, the results obtained are still far from the thermal performance of high-insulating materials, already used in the construction sector. However, this work represents a first step toward the use of additive manufacturing in the field of building insulating materials, and given the potential of AM, significant improvements can be expected.

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- International Energy Agency (IEA). Data and Statistics. Available online: https://www.iea.org/data-and-statistics/data-browser?country=WORLD&fuel=Energy%20consumption&indicator=TFCShareBySector (accessed on 6 December 2021).

- International Energy Agency (IEA). CO2 Emissions from Fuel Combustion; Beyond 2020 Online Database; International Energy Agency: Paris, France, 2012. [Google Scholar]

- International Energy Agency (IEA). World Energy Outlook; International Energy Agency: Paris, France, 2021. [Google Scholar]

- de Rubeis, T.; Falasca, S.; Curci, G.; Paoletti, D.; Ambrosini, D. Sensitivity of heating performance of an energy self-sufficient building to climate zone, climate change and HVAC system solutions. Sustain. Cities Soc. 2020, 61, 102300. [Google Scholar] [CrossRef]

- Pajonk, A.; Prieto, A.; Blum, U.; Knaack, U. Multi-material additive manufacturing in architecture and construction: A review. J. Build. Eng. 2022, 45, 103603. [Google Scholar] [CrossRef]

- Wangler, T.; Roussel, N.; Bos, F.P.; Salet, T.A.M.; Flatt, R.J. Digital concrete: A review. Cem. Concr. Res. 2019, 123, 105780. [Google Scholar] [CrossRef]

- Pessoa, S.; Guimarães, A.S.; Lucas, S.S.; Simões, N. 3D printing in the construction industry—A systematic review of the thermal performance in buildings. Renew. Sust. Energ. Rev. 2021, 141, 110794. [Google Scholar] [CrossRef]

- He, Y.; Zhang, Y.; Zhang, C.; Zhou, H. Energy-saving potential of 3D printed concrete building with integrated living wall. Energ. Build. 2020, 222, 110110. [Google Scholar] [CrossRef]

- Grabowska, B.; Kasperski, J. The Thermal Conductivity of 3D Printed Plastic Insulation Materials—The Effect of Optimizing the Regular Structure of Closures. Materials 2020, 13, 4400. [Google Scholar] [CrossRef] [PubMed]

- Mihalache, A.; Hrituc, A.; Boca, M.; Oroian, B.; Candrea, I.; Botezatu, C.; Slatineanu, L. Thermal Insulation Capacity of a 3D Printed Material. Macromol. Symp. 2021, 396, 2000286. [Google Scholar] [CrossRef]

- Sarakinioti, M.V.; Turrin, M.; Konstantinou, T.; Tenpierik, M.; Knaack, U. Developing an integrated 3D-printed façade with complex geometries for active temperature control. Mater. Today Commun. 2018, 15, 275–279. [Google Scholar] [CrossRef] [Green Version]

- Maier, M.; Salazar, B.; Unluer, C.; Taylor, H.K.; Ostertag, C.P. Thermal and mechanical performance of a novel 3D printed macro-encapsulation method for phase change materials. J. Build. Eng. 2021, 43, 103124. [Google Scholar] [CrossRef]

- Hager, I.; Golonka, A.; Putanowicz, R. 3D printing of buildings and building components as the future of sustainable construction? Procedia Eng. 2016, 151, 292–299. [Google Scholar] [CrossRef] [Green Version]

- News Europena Parliamnet. Available online: https://www.europarl.europa.eu/news/en/headlines/economy/20151201STO05603/circular-economy-definition-importance-and-benefits (accessed on 15 December 2021).

- de Rubeis, T.; Muttillo, M.; Nardi, I.; Pantoli, L.; Stornelli, V.; Ambrosini, D. Integrated Measuring and Control System for Thermal Analysis of Buildings Components in Hot Box Experiments. Energies 2019, 12, 2053. [Google Scholar] [CrossRef] [Green Version]

- de Rubeis, T.; Nardi, I.; Muttillo, M. Development of a low-cost temperature data monitoring. An upgrade for hot box apparatus. J. Phys. Conf. Ser. 2017, 923, 012039. [Google Scholar] [CrossRef]

- EN ISO 6946:2017; Building Components and Building Elements—Thermal Resistance and Thermal Transmittance—Calculation Methods. European Committee for Standardization: Brussels, Belgium, 2017.

- EN ISO 9869-1:2014; Thermal Insulation—Building Elements—In-Situ Measurement of Thermal Resistance and Thermal Transmittance, Part 1: Heat Flow Meter Method. European Committee for Standardization: Brussels, Belgium, 2014.

- Holman, J.P. Experimental Methods for Engineers, 8th ed.; McGraw-Hill Series in Mechanical Engineering: New York, NY, USA, 2012; ISBN 13: 9780073529301. [Google Scholar]

| Sensor | Type | Measuring Range | Resolution |

|---|---|---|---|

| Heat flow meter | Hukseflux HFP01 | From −2000 to 2000 W/m2 | 60 × 10−6 V/(W/m2) |

| Surface temperature | LSI Lastem EST124-Pt100 | From −50 to 70 °C | 0.01 °C |

| Datalogger | LSI Lastem M-Log ELO008 | From −300 to +1200 mV | 40 μV |

| IR camera | FLIR ThermaCAM® S65 | 320 × 240 pixels | 0.01 °C |

| Case | Mean Heat Flux [W/m2] | Conductance [W/m2·K] | Transmittance 1 [W/m2·K] |

|---|---|---|---|

| 3D block with air cavities | 44.91 ± 3.00% | 3.50 ± 3.15% | 2.19 ± 3.15% |

| 3D block with polystyrene | 29.20 ± 3.00% | 1.57 ± 3.02% | 1.24 ± 3.02% |

| 3D block with wool | 17.11 ± 3.00% | 0.78 ± 3.05% | 0.69 ± 3.05% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Rubeis, T. 3D-Printed Blocks: Thermal Performance Analysis and Opportunities for Insulating Materials. Sustainability 2022, 14, 1077. https://doi.org/10.3390/su14031077

de Rubeis T. 3D-Printed Blocks: Thermal Performance Analysis and Opportunities for Insulating Materials. Sustainability. 2022; 14(3):1077. https://doi.org/10.3390/su14031077

Chicago/Turabian Stylede Rubeis, Tullio. 2022. "3D-Printed Blocks: Thermal Performance Analysis and Opportunities for Insulating Materials" Sustainability 14, no. 3: 1077. https://doi.org/10.3390/su14031077

APA Stylede Rubeis, T. (2022). 3D-Printed Blocks: Thermal Performance Analysis and Opportunities for Insulating Materials. Sustainability, 14(3), 1077. https://doi.org/10.3390/su14031077