Comprehensive Life Cycle Assessment Analysis of an Italian Composting Facility concerning Environmental Footprint Minimization and Renewable Energy Integration

Abstract

1. Introduction

2. Materials and Methods

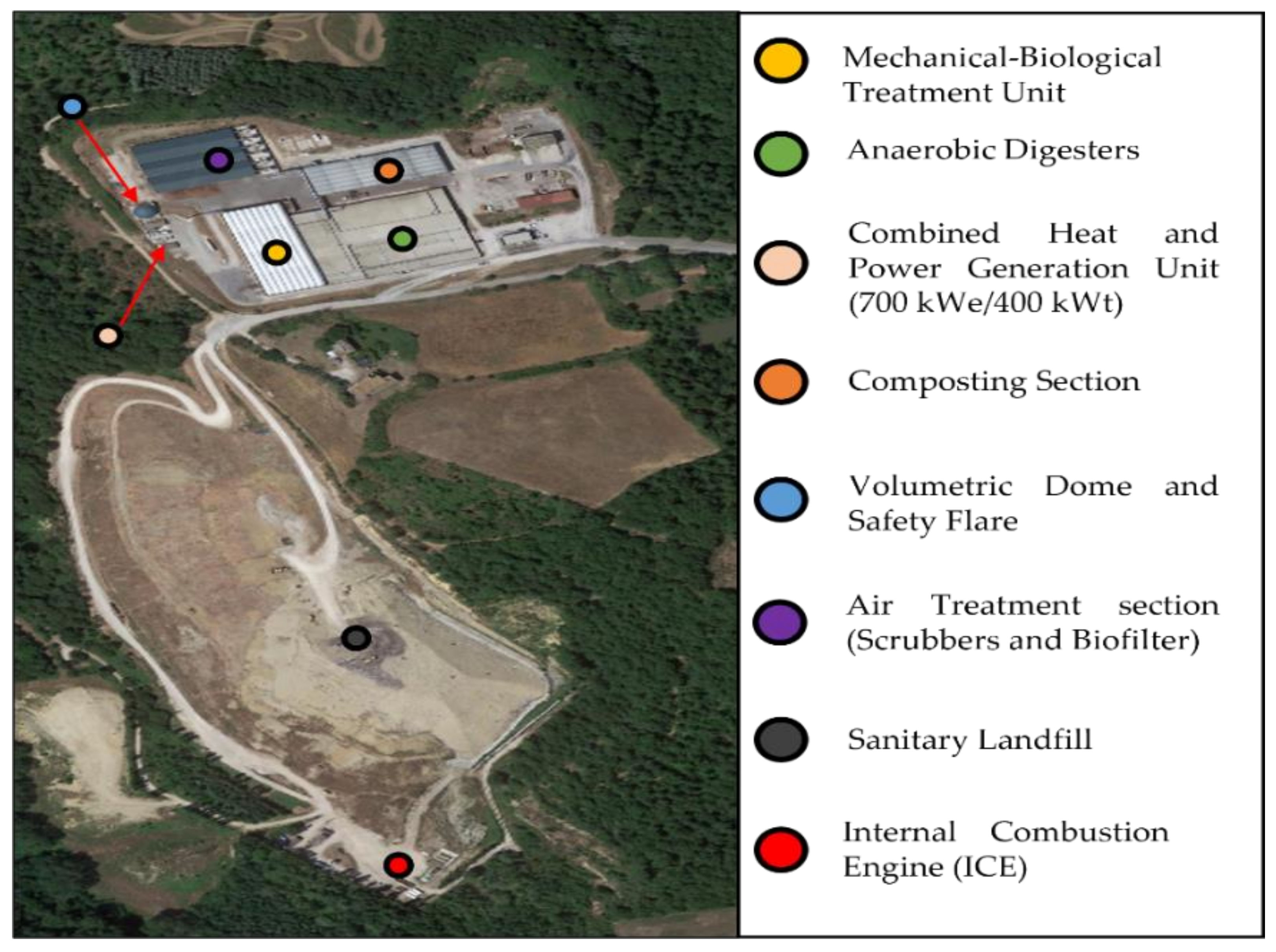

2.1. System Description

2.2. Goal and Scope

- The assessment of the environmental performances of the base case configuration and the sensitivity analyses of relevant operational parameters by means of the Monte–Carlo technique (MC);

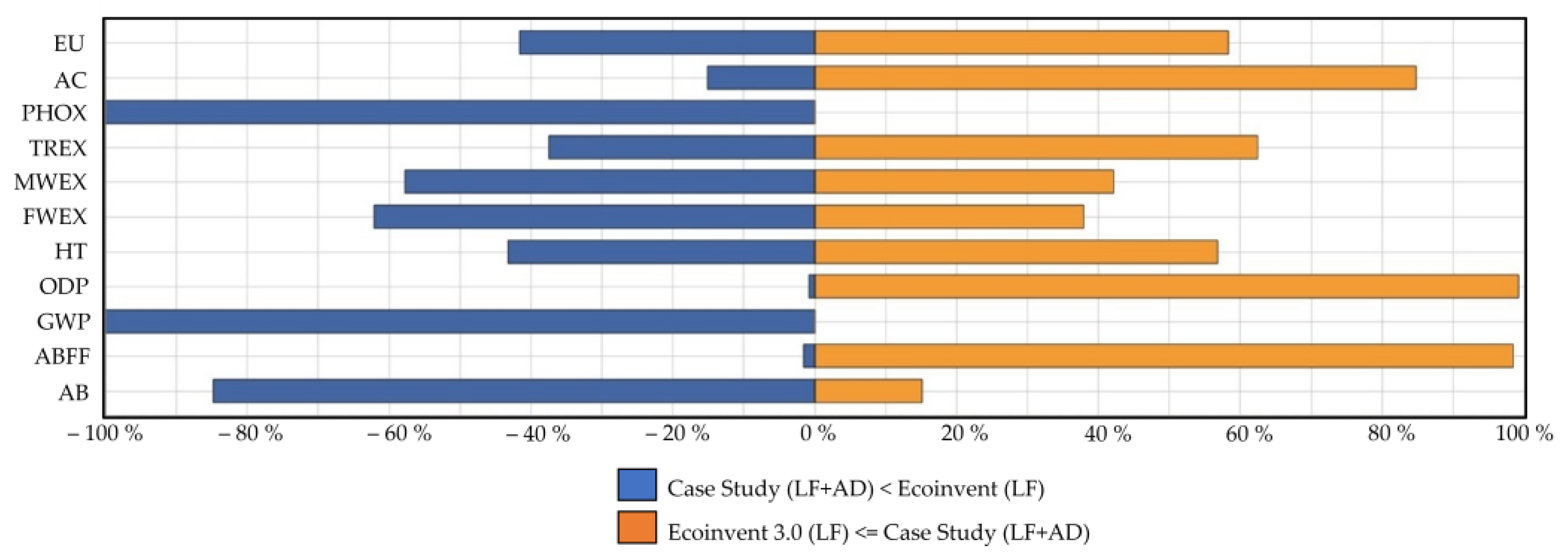

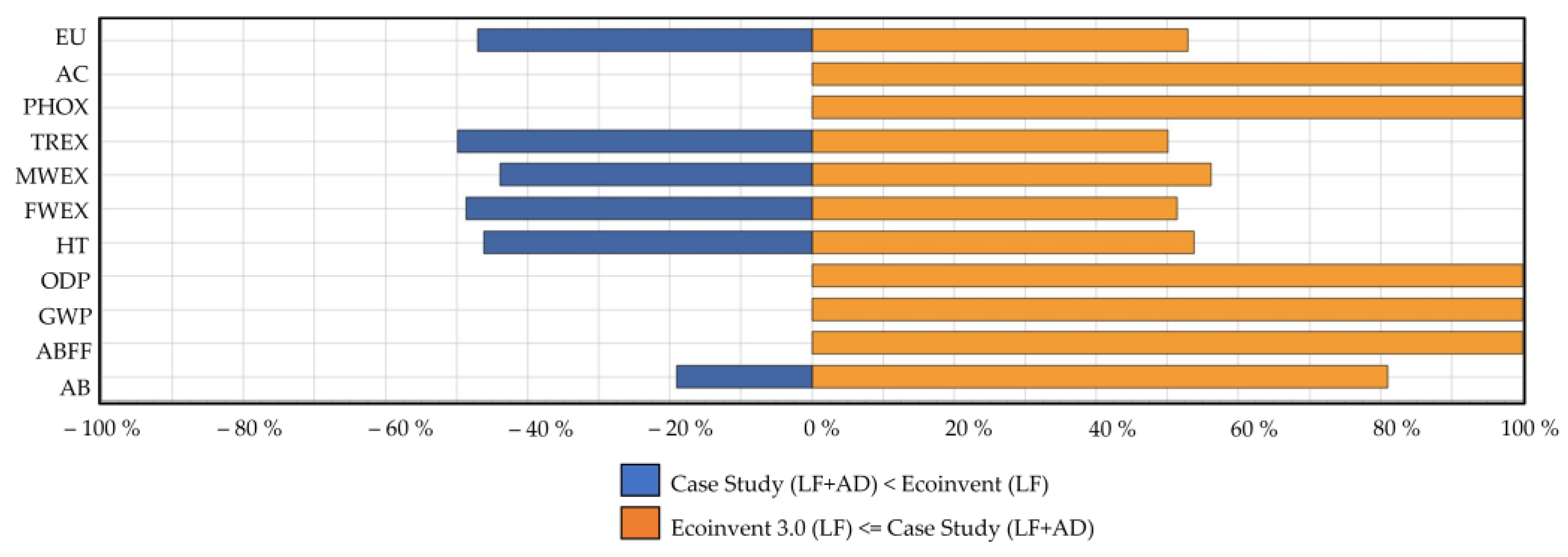

- The comparison between the impacts of the aforementioned system with those of a general sanitary landfill present in Ecoinvent database as benchmark;

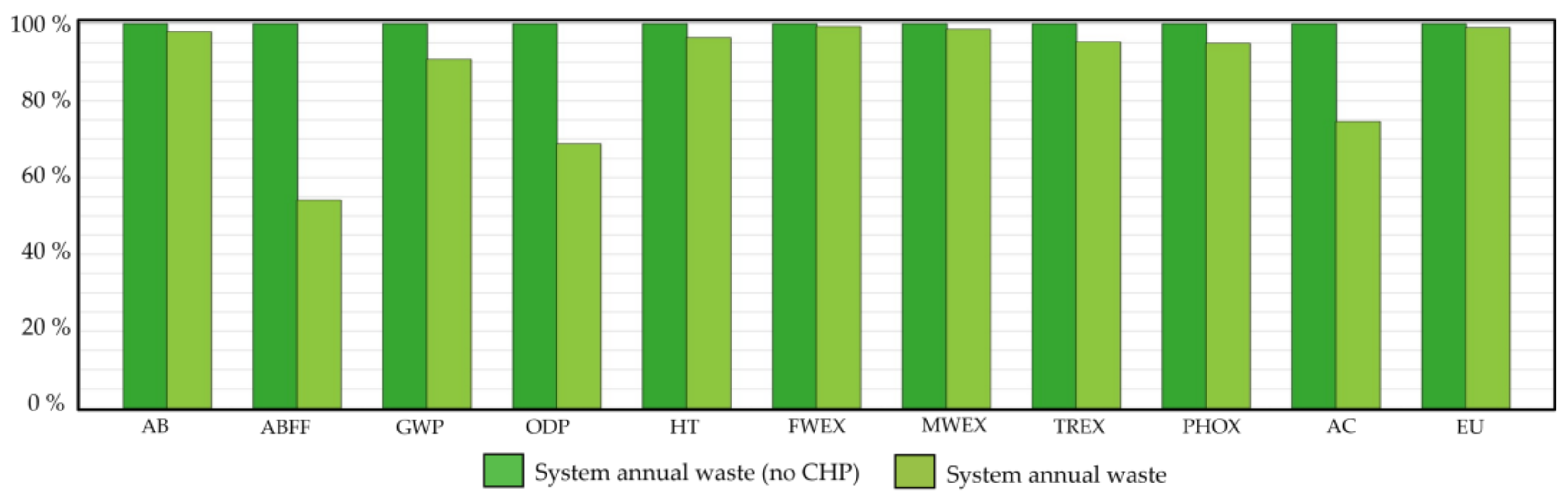

- A sensitivity analysis for the determination of the benefits introduced by the CHP unit coupled with the anaerobic digesters;

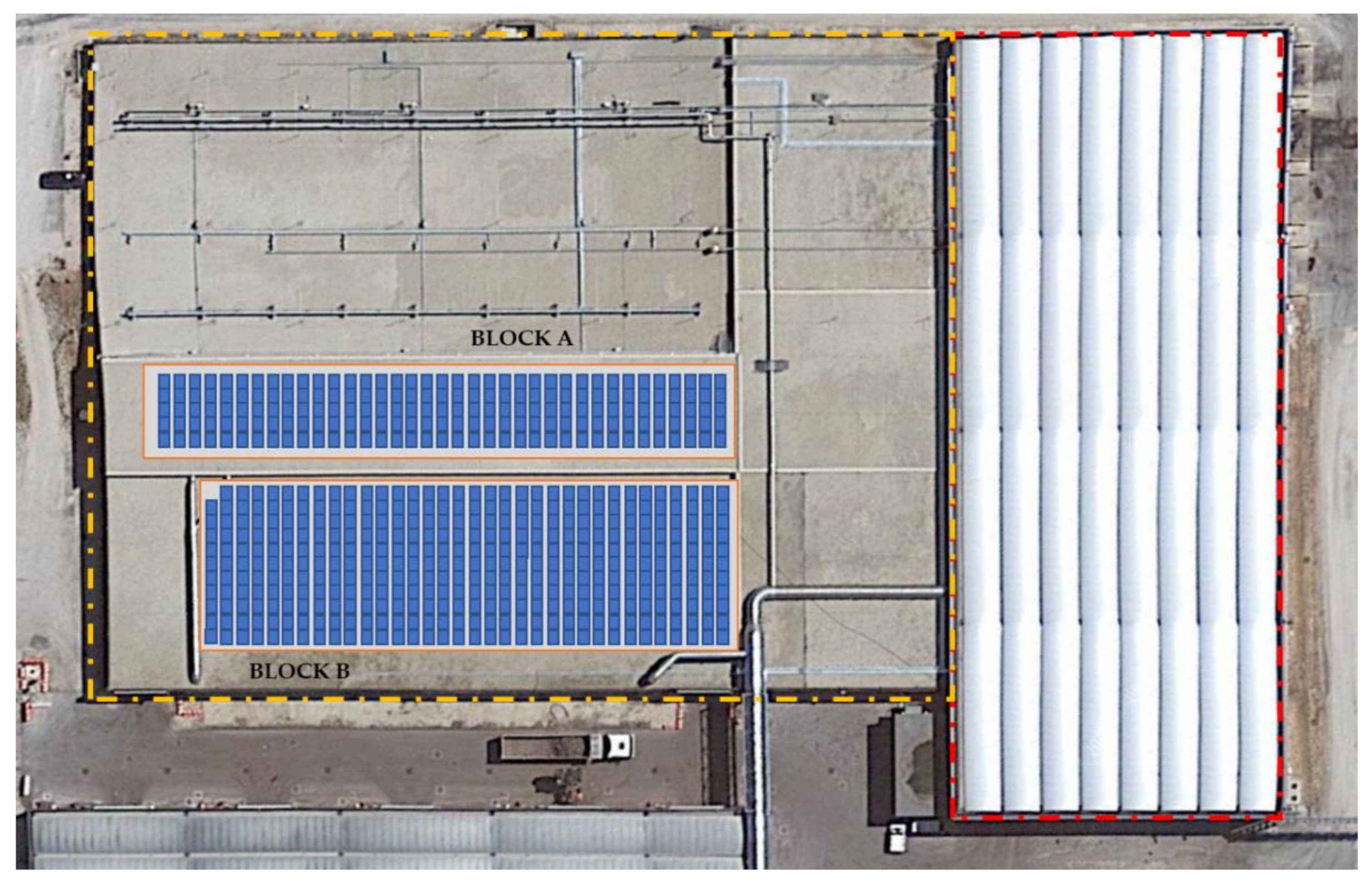

- The installation of a PV plant on the roof of the anaerobic digesters section. A Monte Carlo analysis is also performed in this case to estimate the influence of the data deviation;

- The environmental impact generated by the gasification of the residual solid waste and its comparison with secondary data related to incineration and landfill treatment processes as reported in Ecoinvent database.

2.3. System Boundaries

2.4. Inventory Analysis

2.4.1. Residual Solid Waste Characterization

2.4.2. Energy Production and Biogas Profile

2.4.3. Electricity and Fuel Consumption

2.4.4. Gaseous Emissions

2.4.5. Liquid Emissions

2.4.6. Soil Emissions

2.5. Impact Categories and Life Cycle Impact Assessment

3. Results and Discussions

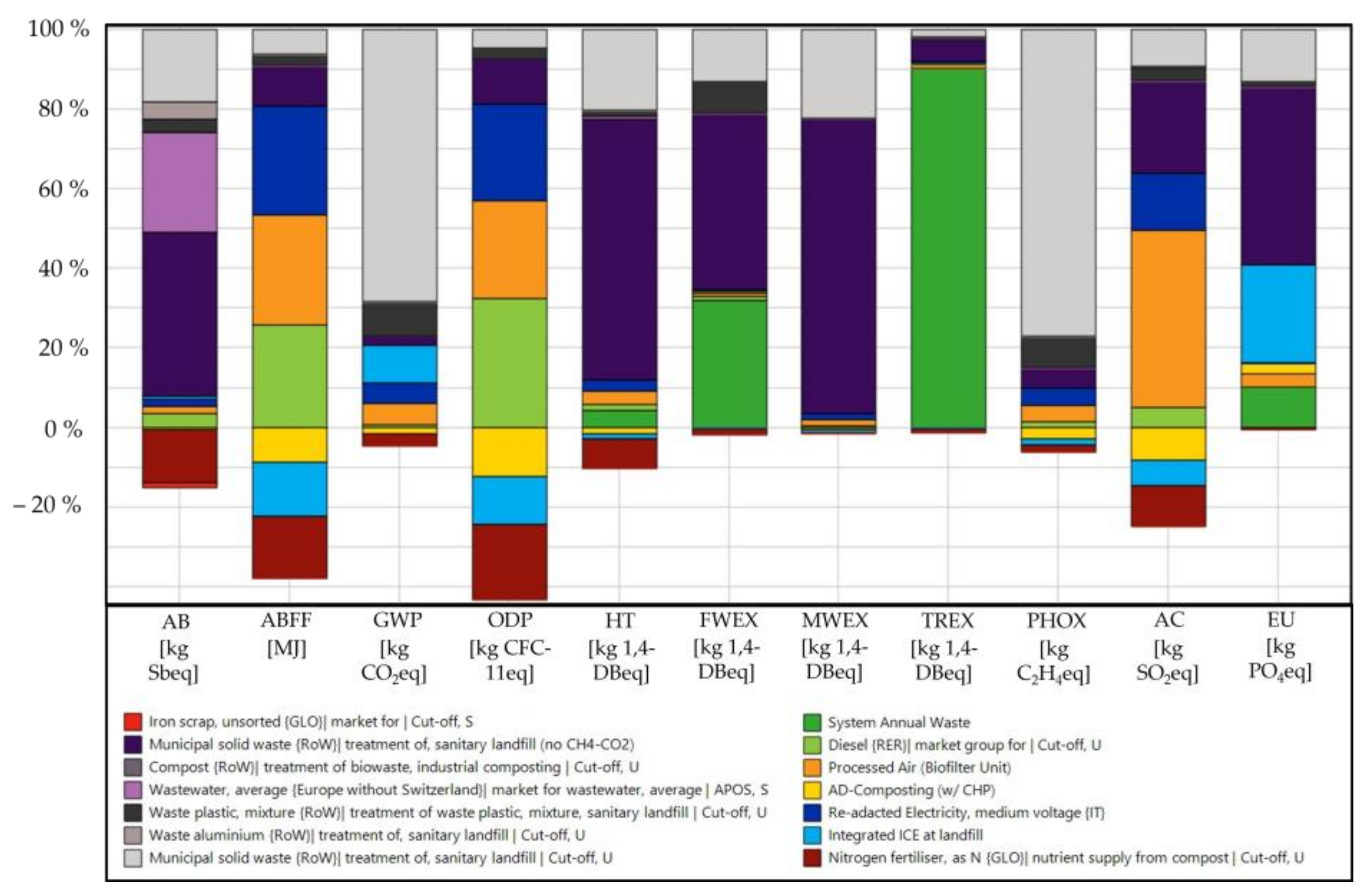

3.1. Base Case Scenario

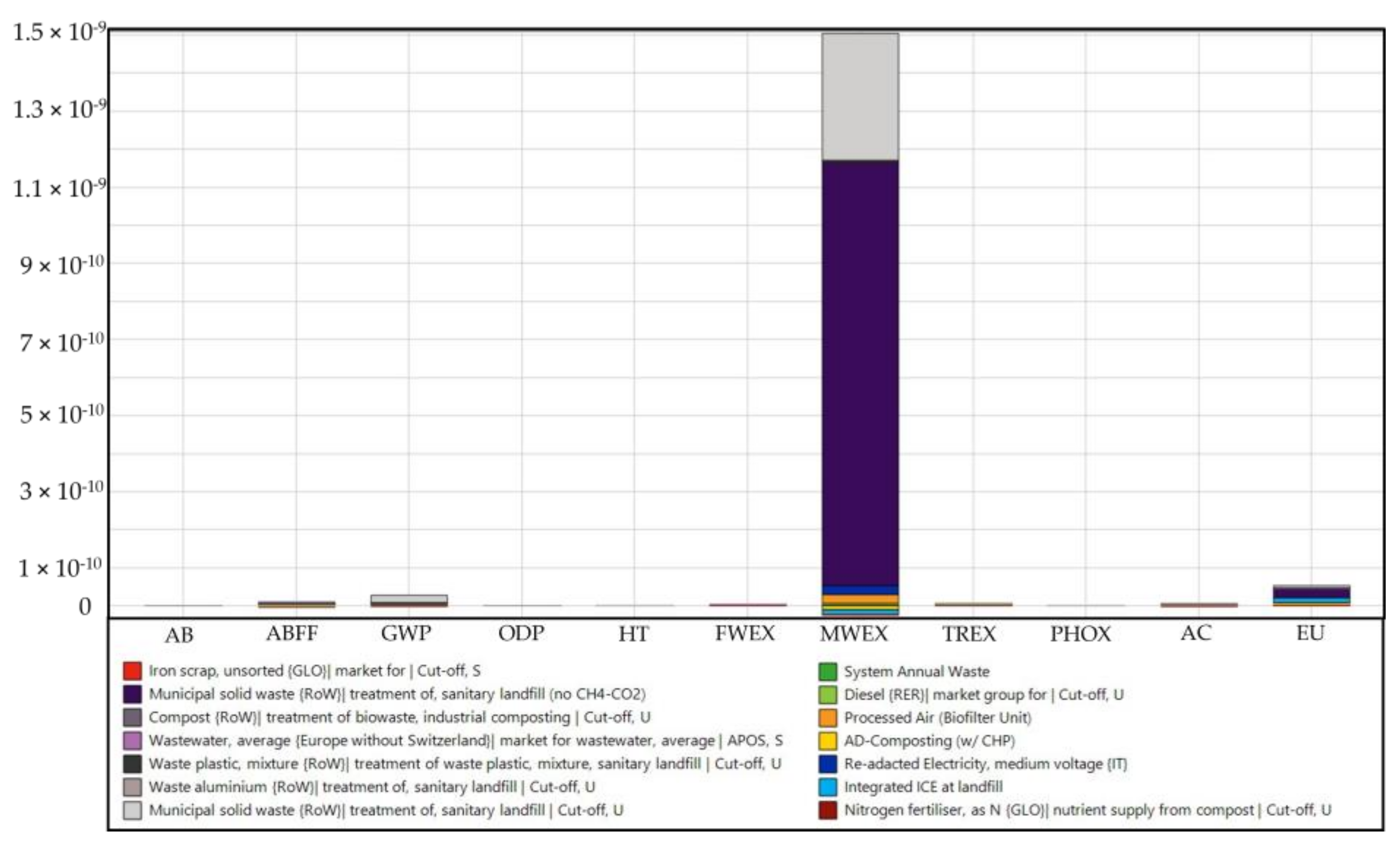

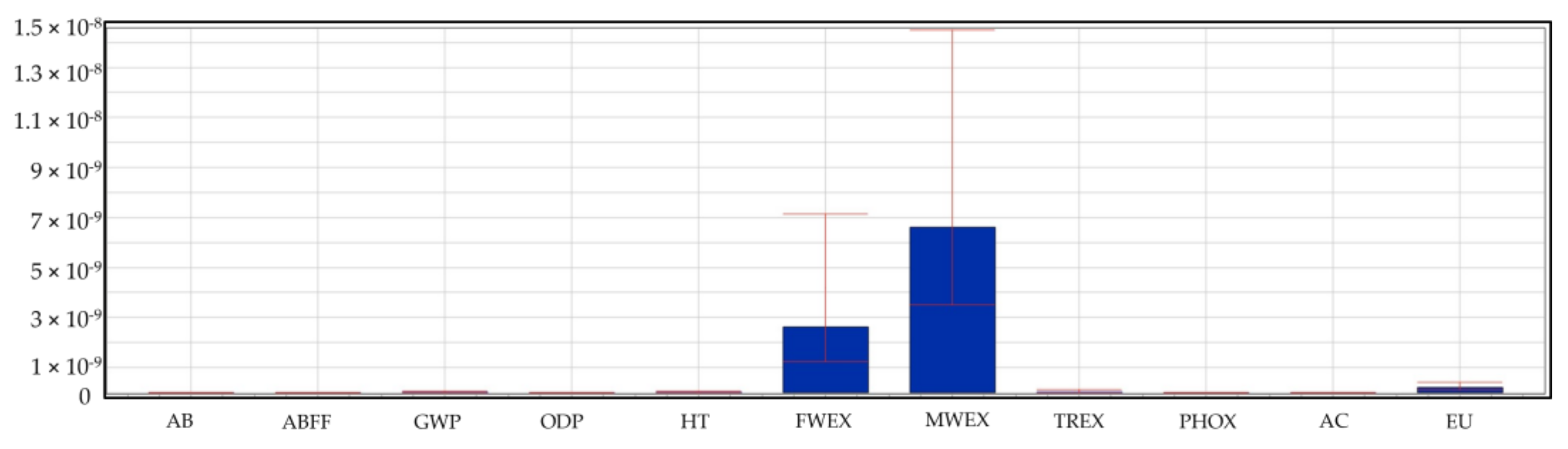

3.1.1. Monte–Carlo Analysis

3.1.2. System Comparison with Ecoinvent Database

3.1.3. Sensitivity Analysis

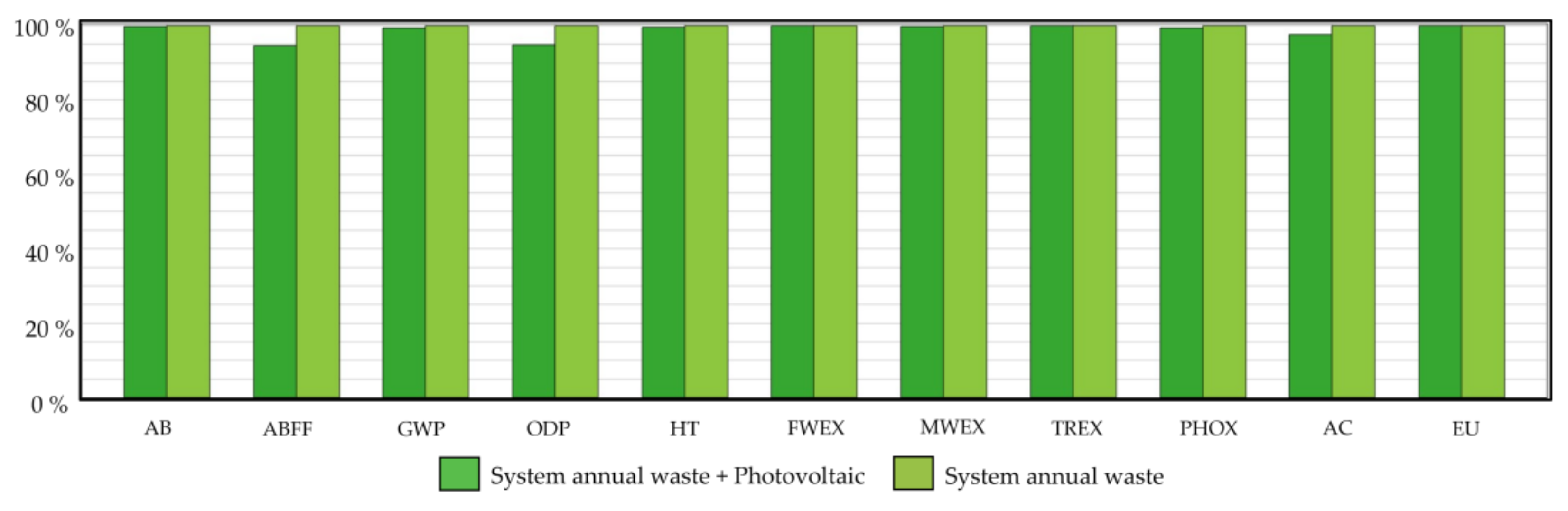

3.2. Photovoltaic Implementation

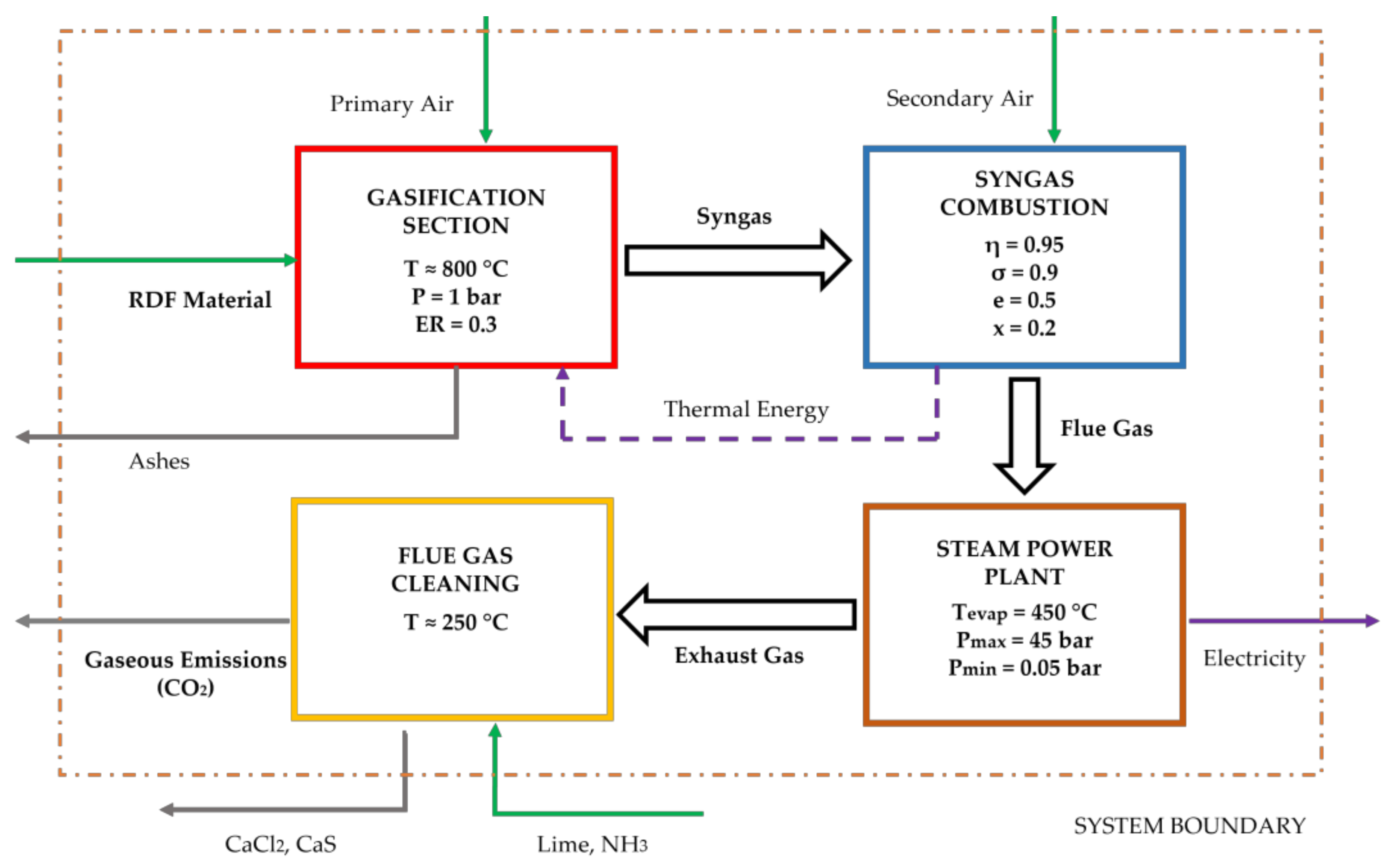

3.3. Gasification Process Implementation

4. Conclusions

- The use of biogas from anaerobic digestion and sanitary landfill in power units can reduce the contribution of composting facilities in many impact categories. In particular, for the case study under investigation, the CHP and the ICE units contribute to a reduction of the ODP by up to −42%, of the ABFF by about −38%, of the AC by −25% and of the AB by −15%;

- Despite the fact that the quality of the organic fraction of MSW may be subjected to strong deviations (reflecting in a wide range of the impact categories such as TREX LB and UB +246%), its valorisation through anaerobic digestion brings clear benefits from an environmental point of view;

- The integration of a PV plant in the site under investigation marginally contributes to the reduction of the environmental impact (6% for ABFF and 5% for ODP), due to the limited space available on the roofs;

- The RDF gasification and the use of the produced syngas in a conventional steam power plant has a significant influence on many impact categories. In particular, for the case study under investigation, characterized by 20 ktons/year of RMSW, corresponding syngas production can add 2 MW of power capacity with consistent variations of PHOX (−41%), MWEX-HT (−11%) and AB-FWEX (−10%).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| AB | Abiotic Depletion, kg Sbeq |

| ABFF | Abiotic Depletion Fossil Fuel, MJ |

| AC | Acidification, kg SO2eq |

| AD | Anaerobic digestion |

| CHP | Heat and Power cogeneration |

| CML-IA | Institute of Environmental Sciences (CML) Baseline Method |

| COD | Chemical Oxygen Demand, mg/L |

| e | Air excess |

| E | Energy production, kWh |

| EU | Eutrophication, kg PO4eq |

| FWEX | Fresh Water Ecotoxicity, kg 1,4-DBeq |

| GHG | Greenhouse gas (emissions) |

| GWP | Global Warming Potential, kg CO2eq |

| HT | Human Toxicity, kg 1,4-DBeq |

| ICE | Internal Combustion Energy |

| LB | Lower Bound |

| LCA | Life Cycle Assessment |

| LCI | Life Cycle Inventory |

| LCIA | Life Cycle Impact Assessment |

| LF | Landfill |

| LPG | Liquid Petrol Gas |

| LQC | Low quality compost |

| LQC | High Quality Compost |

| M | Mass, kg |

| MBT | Mechanical biological treatment unit |

| MC | Monte–Carlo |

| MSW | Municipal Solid Waste |

| MWEX | Marine Water Ecotoxicity, kg 1,4-DBeq |

| N | Number of samples (Monte–Carlo) |

| ODP | Ozone Layer Depletion, kg CFC-11eq |

| OFMSW | Organic Fraction of Municipal solid waste |

| P | Pressure, bar |

| PHOX | Photochemical Oxidation, kg C2H4eq |

| RMSW | Residual Municipal solid waste |

| T | Temperature, °C |

| TOC | Total Organic Carbon, g/kg |

| TOE | Ton of Oil Equivalent |

| TON | Total Organic Nitrogen |

| TREX | Terrestrial Ecotoxicity, kg 1,4-DBeq |

| UB | Upper Bound |

| V | Volume, Nm3 |

| VOS | Volatile organic Substances, g/kg |

| WtE | Waste to Energy |

| x | Flue gas recirculation |

| Greek Letters | |

| α | Average biogas yield, kWh/m3 |

| ρ | Density, kg/m3 |

| η | Combustion efficiency |

| δ | Standard deviation |

| δM | Standard error of the mean (Monte–Carlo) |

| σ | Heat exchanger efficiency |

References

- Puertas, R.; Marti, L. Renewable Energy Production Capacity and Consumption in Europe. Sci. Total Environ. 2022, 853, 158592. [Google Scholar] [CrossRef] [PubMed]

- Municipal Waste Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Municipal_waste_statistics (accessed on 14 July 2022).

- Rapporto Rifiuti Urbani-Edizione. 2021. Available online: https://www.isprambiente.gov.it/it/pubblicazioni/rapporti/rapporto-rifiuti-urbani-edizione-2021 (accessed on 23 July 2022).

- Demirbas, A. Biogas Production from the Organic Fraction of Municipal Solid Waste. Energy Sources Part A Recovery Util. Environ. Eff. 2006, 28, 1127–1134. [Google Scholar] [CrossRef]

- Vasco-Correa, J.; Khanal, S.; Manandhar, A.; Shah, A. Anaerobic Digestion for Bioenergy Production: Global Status, Environmental and Techno-Economic Implications, and Government Policies. Bioresour. Technol. 2018, 247, 1015–1026. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Kuroki, A.; Tong, Y.W. A Mini-Review on In Situ Biogas Upgrading Technologies via Enhanced Hydrogenotrophic Methanogenesis to Improve the Quality of Biogas From Anaerobic Digesters. Front. Energy Res. 2020, 8, 69. [Google Scholar] [CrossRef]

- Kim, M.; Ahn, Y.-H.; Speece, R.E. Comparative Process Stability and Efficiency of Anaerobic Digestion; Mesophilic vs. Thermophilic. Water Res. 2002, 36, 4369–4385. [Google Scholar] [CrossRef]

- Pubblicazioni Statistiche-Terna Spa. Available online: https://www.terna.it/it/sistema-elettrico/statistiche/pubblicazioni-statistiche (accessed on 14 July 2022).

- Al-Rumaihi, A.; McKay, G.; Mackey, H.R.; Al-Ansari, T. Environmental Impact Assessment of Food Waste Management Using Two Composting Techniques. Sustainability 2020, 12, 1595. [Google Scholar] [CrossRef]

- Khandelwal, H.; Dhar, H.; Thalla, A.K.; Kumar, S. Application of Life Cycle Assessment in Municipal Solid Waste Management: A Worldwide Critical Review. J. Clean. Prod. 2019, 209, 630–654. [Google Scholar] [CrossRef]

- Morselli, L.; De Robertis, C.; Luzi, J.; Passarini, F.; Vassura, I. Environmental Impacts of Waste Incineration in a Regional System (Emilia Romagna, Italy) Evaluated from a Life Cycle Perspective. J. Hazard. Mater. 2008, 159, 505–511. [Google Scholar] [CrossRef]

- European Commission; Joint Research Centre; Institute for Environment and Sustainability. International Reference Life Cycle Data System (ILCD) Handbook: General Guide for Life Cycle Assessment: Detailed Guidance; Publications Office: Luxembourg, 2010. [Google Scholar]

- Fruergaard, T.; Astrup, T. Optimal Utilization of Waste-to-Energy in an LCA Perspective. Waste Manag. 2011, 31, 572–582. [Google Scholar] [CrossRef]

- Grosso, M.; Nava, C.; Testori, R.; Rigamonti, L.; Viganò, F. The Implementation of Anaerobic Digestion of Food Waste in a Highly Populated Urban Area: An LCA Evaluation. Waste Manag. Res. 2012, 30, 78–87. [Google Scholar] [CrossRef]

- Güereca, L.P.; Gassó, S.; Baldasano, J.M.; Jiménez-Guerrero, P. Life Cycle Assessment of Two Biowaste Management Systems for Barcelona, Spain. Resour. Conserv. Recycl. 2006, 49, 32–48. [Google Scholar] [CrossRef]

- Cusenza, M.A.; Cellura, M.; Guarino, F.; Longo, S. Life Cycle Environmental Assessment of Energy Valorization of the Residual Agro-Food Industry. Energies 2021, 14, 5491. [Google Scholar] [CrossRef]

- Buttol, P.; Masoni, P.; Bonoli, A.; Goldoni, S.; Belladonna, V.; Cavazzuti, C. LCA of Integrated MSW Management Systems: Case Study of the Bologna District. Waste Manag. 2007, 27, 1059–1070. [Google Scholar] [CrossRef]

- Dong, J.; Chi, Y.; Zou, D.; Fu, C.; Huang, Q.; Ni, M. Energy–Environment–Economy Assessment of Waste Management Systems from a Life Cycle Perspective: Model Development and Case Study. Appl. Energy 2014, 114, 400–408. [Google Scholar] [CrossRef]

- Ekvall, T.; Finnveden, G. The Application of Life Cycle Assessment to Integrated Solid Waste Management: Part 2—Perspectives on energy and material recovery from paper. Process Saf. Environ. Prot. 2000, 78, 288–294. [Google Scholar] [CrossRef]

- Fantin, V.; Giuliano, A.; Manfredi, M.; Ottaviano, G.; Stefanova, M.; Masoni, P. Environmental Assessment of Electricity Generation from an Italian Anaerobic Digestion Plant. Biomass Bioenergy 2015, 83, 422–435. [Google Scholar] [CrossRef]

- International Organization for Standardization. Environmental Management: Life Cycle Assessment; Principles and Framework; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Starr, K.; Gabarrell, X.; Villalba, G.; Talens, L.; Lombardi, L. Life Cycle Assessment of Biogas Upgrading Technologies. Waste Manag. 2012, 32, 991–999. [Google Scholar] [CrossRef]

- Blengini, G.A. Using LCA to Evaluate Impacts and Resources Conservation Potential of Composting: A Case Study of the Asti District in Italy. Resour. Conserv. Recycl. 2008, 52, 1373–1381. [Google Scholar] [CrossRef]

- Cadena, E.; Colón, J.; Artola, A.; Sánchez, A.; Font, X. Environmental Impact of Two Aerobic Composting Technologies Using Life Cycle Assessment. Int. J. Life Cycle Assess. 2009, 14, 401–410. [Google Scholar] [CrossRef]

- Sauve, G.; Van Acker, K. The Environmental Impacts of Municipal Solid Waste Landfills in Europe: A Life Cycle Assessment of Proper Reference Cases to Support Decision Making. J. Environ. Manag. 2020, 261, 110216. [Google Scholar] [CrossRef]

- Lee, U.; Han, J.; Wang, M. Evaluation of Landfill Gas Emissions from Municipal Solid Waste Landfills for the Life-Cycle Analysis of Waste-to-Energy Pathways. J. Clean. Prod. 2017, 166, 335–342. [Google Scholar] [CrossRef]

- Damgaard, A.; Manfredi, S.; Merrild, H.; Stensøe, S.; Christensen, T.H. LCA and Economic Evaluation of Landfill Leachate and Gas Technologies. Waste Manag. 2011, 31, 1532–1541. [Google Scholar] [CrossRef] [PubMed]

- Lo, S.; Ma, H.; Lo, S. Quantifying and Reducing Uncertainty in Life Cycle Assessment Using the Bayesian Monte Carlo Method. Sci. Total Environ. 2005, 340, 23–33. [Google Scholar] [CrossRef] [PubMed]

- Doka, G.; Hischier, R. Waste Treatment and Assessment of Long-Term Emissions (8pp). Int. J. Life Cycle Assess. 2005, 10, 77–84. [Google Scholar] [CrossRef]

- Ekvall, T.; Assefa, G.; Björklund, A.; Eriksson, O.; Finnveden, G. What Life-Cycle Assessment Does and Does Not Do in Assessments of Waste Management. Waste Manag. 2007, 27, 989–996. [Google Scholar] [CrossRef] [PubMed]

- Clift, R.; Doig, A.; Finnveden, G. The Application of Life Cycle Assessment to Integrated Solid Waste Management: Part 1—Methodology. Process. Saf. Environ. Prot. 2000, 78, 279–287. [Google Scholar] [CrossRef]

- Havukainen, J.; Zhan, M.; Dong, J.; Liikanen, M.; Deviatkin, I.; Li, X.; Horttanainen, M. Environmental Impact Assessment of Municipal Solid Waste Management Incorporating Mechanical Treatment of Waste and Incineration in Hangzhou, China. J. Clean. Prod. 2017, 141, 453–461. [Google Scholar] [CrossRef]

- Kim, M.-H.; Kim, J.-W. Comparison through a LCA Evaluation Analysis of Food Waste Disposal Options from the Perspective of Global Warming and Resource Recovery. Sci. Total Environ. 2010, 408, 3998–4006. [Google Scholar] [CrossRef]

- Násner, A.M.L.; Lora, E.E.S.; Palacio, J.C.E.; Rocha, M.H.; Restrepo, J.C.; Venturini, O.J.; Ratner, A. Refuse Derived Fuel (RDF) Production and Gasification in a Pilot Plant Integrated with an Otto Cycle ICE through Aspen PlusTM Modelling: Thermodynamic and Economic Viability. Waste Manag. 2017, 69, 187–201. [Google Scholar] [CrossRef]

- Chiemchaisri, C.; Charnnok, B.; Visvanathan, C. Recovery of Plastic Wastes from Dumpsite as Refuse-Derived Fuel and Its Utilization in Small Gasification System. Bioresour. Technol. 2010, 101, 1522–1527. [Google Scholar] [CrossRef]

- Rigamonti, L.; Grosso, M.; Giugliano, M. Life Cycle Assessment of Sub-Units Composing a MSW Management System. J. Clean. Prod. 2010, 18, 1652–1662. [Google Scholar] [CrossRef]

- Istrate, I.-R.; Iribarren, D.; Gálvez-Martos, J.-L.; Dufour, J. Review of Life-Cycle Environmental Consequences of Waste-to-Energy Solutions on the Municipal Solid Waste Management System. Resour. Conserv. Recycl. 2020, 157, 104778. [Google Scholar] [CrossRef]

- Menikpura, S.N.M.; Sang-Arun, J.; Bengtsson, M. Integrated Solid Waste Management: An Approach for Enhancing Climate Co-Benefits through Resource Recovery. J. Clean. Prod. 2013, 58, 34–42. [Google Scholar] [CrossRef]

- Gentil, E.C.; Damgaard, A.; Hauschild, M.; Finnveden, G.; Eriksson, O.; Thorneloe, S.; Kaplan, P.O.; Barlaz, M.; Muller, O.; Matsui, Y.; et al. Models for Waste Life Cycle Assessment: Review of Technical Assumptions. Waste Manag. 2010, 30, 2636–2648. [Google Scholar] [CrossRef] [PubMed]

- Ecoinvent Database. Ecoinvent. Available online: https://ecoinvent.org/the-ecoinvent-database/ (accessed on 27 September 2022).

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The Ecoinvent Database Version 3 (Part I): Overview and Methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- CML-IA Characterisation Factors. Available online: https://www.universiteitleiden.nl/en/research/research-output/science/cml-ia-characterisation-factors (accessed on 14 July 2022).

- Rigamonti, L.; Falbo, A.; Grosso, M. Improving Integrated Waste Management at the Regional Level: The Case of Lombardia. Waste Manag. Res. 2013, 31, 946–953. [Google Scholar] [CrossRef] [PubMed]

- Giugliano, M.; Cernuschi, S.; Grosso, M.; Rigamonti, L. Material and Energy Recovery in Integrated Waste Management Systems. An Evaluation Based on Life Cycle Assessment. Waste Manag. 2011, 31, 2092–2101. [Google Scholar] [CrossRef]

- Rabl, A.; Benoist, A.; Dron, D.; Peuportier, B.; Spadaro, J.V.; Zoughaib, A. How to Account for CO2 Emissions from Biomass in an LCA. Int. J. Life Cycle Assess. 2007, 12, 281. [Google Scholar] [CrossRef]

- Dastjerdi, B.; Strezov, V.; Rajaeifar, M.A.; Kumar, R.; Behnia, M. A Systematic Review on Life Cycle Assessment of Different Waste to Energy Valorization Technologies. J. Clean. Prod. 2021, 290, 125747. [Google Scholar] [CrossRef]

- You, S.; Ok, Y.S.; Chen, S.S.; Tsang, D.C.W.; Kwon, E.E.; Lee, J.; Wang, C.-H. A Critical Review on Sustainable Biochar System through Gasification: Energy and Environmental Applications. Bioresour. Technol. 2017, 246, 242–253. [Google Scholar] [CrossRef]

- Ayodele, T.R.; Ogunjuyigbe, A.S.O.; Alao, M.A. Life Cycle Assessment of Waste-to-Energy (WtE) Technologies for Electricity Generation Using Municipal Solid Waste in Nigeria. Appl. Energy 2017, 201, 200–218. [Google Scholar] [CrossRef]

- Modulo Fotovoltaico HF330KA Monocristallino 330 W 24 V. Available online: http://www.solarenergypoint.it/shop/sun-earth-hf330ka-modulo-fotovoltaico-monocristallino-330w (accessed on 16 September 2022).

- Life Cycle Assessment of Solar Energy Systems for the Provision of Heating, Cooling and Electricity in Buildings: A Comparative Analysis|Elsevier Enhanced Reader. Energy Convers. Manag. 2022, 257, p. 115402.

- Integrating Climate Change and Energy Mix Scenarios in LCA of Buildings and Districts|Elsevier Enhanced Reader. Appl. Energy. 2016, 184, pp. 619–629.

- Arena, U. Fluidized Bed Gasification. In Fluidized Bed Technologies for Near-Zero Emission Combustion and Gasification; Elsevier: Amsterdam, The Netherlands, 2013; pp. 765–812. ISBN 978-0-85709-541-1. [Google Scholar]

- Parrillo, F.; Ardolino, F.; Calì, G.; Marotto, D.; Pettinau, A.; Arena, U. Fluidized Bed Gasification of Eucalyptus Chips: Axial Profiles of Syngas Composition in a Pilot Scale Reactor. Energy 2021, 219, 119604. [Google Scholar] [CrossRef]

- Inceneritore F3 Rifiuti Urbani e Speciali Di Ravenna-HERAmbiente. Available online: https://ha.gruppohera.it/impianti/rifiuti_industriali/impianto_incenerimento_ravenna (accessed on 19 September 2022).

| Parameter | CHP | ||

|---|---|---|---|

| 100% Load | 75% Load | 50% Load | |

| Electrical Power [kW] | 700 | 525 | 350 |

| Thermal Power [kW] | 379 | 309 | 242 |

| Fuel Consumption [kW] | 1664 | 1290 | 920 |

| El. Efficiency | 42.1 | 40.7 | 38 |

| Th. Efficiency | 41.5 | 43.7 | 46.8 |

| Total Efficiency | 83.6 | 84.4 | 84.8 |

| Activity | Amount [mg/Nm3] | ||

|---|---|---|---|

| Nominal Power [kW] | Annual Consumption [kWh] | % of the Total | |

| Anaerobic Digesters | 50 | 247,847 | 5.5 |

| Volumetric Dome | 82 | 467,359 | 10.4 |

| Biofilter | 585 | 2,160,231 | 48.1 |

| Aerobic stabilization | 114 | 441,343 | 9.8 |

| Biotunnel | 105 | 483,267 | 10.8 |

| Landfill | 75 | 197,892 | 4.4 |

| Waste pre-treatment | 203 | 496,507 | 11 |

| Element | Amount [mg/Nm3] | ||

|---|---|---|---|

| Biofilter | CHP | ICE | |

| Particulates | - | 1.24 | 3 |

| TOC | 64.5 | 116 | 93 |

| CO | - | 89 | 373 |

| NOX | - | 147 | 272 |

| SO2 | - | - | 1 |

| HCL | - | - | 3 |

| H2S | 0.035 | - | - |

| NH3 | 4.64 | - | - |

| VOS | 4.71 | - | - |

| Element | Amount [mg/L] | |

|---|---|---|

| Leachates | Wastewater | |

| COD | 16,110 | 13,678 |

| N (as Ammonia) | 3528 | 20,791 |

| Chlorine | 2809 | 21,109 |

| Metals | 37 | 559 |

| Phenols | 4 | 35 |

| Toluene | 0.01 | - |

| Element | High-Quality Compost (HQC) | |

|---|---|---|

| Amount | U.M. | |

| Metals (1) | 224.46 | mg/kg |

| Potassium | 1.53 | % d.b. |

| Sodium | 1.26 | |

| Calcium | 3.92 | |

| Magnesium | 0.77 | |

| TOC | 45.48 | |

| TON | 95.83 | |

| C/N ratio | 19.41 | |

| Impact Factor | Monte Carlo Analysis—Variation in Percentage Terms | |

|---|---|---|

| Best Case | Worst Case | |

| Abiotic depletion | −33% | 64% |

| Abiotic depletion (fossil fuels) | −25% | 24% |

| Acidification | −23% | 44% |

| Eutrophication | −44% | 97% |

| Fresh water aquatic ecotox. | −58% | 140% |

| Global warming (GWP100a) | −41% | 71% |

| Human toxicity | −54% | 108% |

| Marine aquatic ecotoxicity | −52% | 100% |

| Ozone layer depletion (ODP) | −43% | 76% |

| Photochemical oxidation | −47% | 81% |

| Terrestrial ecotoxicity | −66% | 246% |

| Residual MSW Property | Value (Best Estimate) | U.M. |

|---|---|---|

| Dry residual at 105 °C | 25 | % |

| Ash content (600 °C) | 1.2 | |

| Hydrogen (d.b.) | 8.43 | |

| Total Organic Carbon (TOC) | 418 | g/kg |

| Density | 0.61 | g/cm3 |

| LHV | 21800 | KJ/kg |

| Impact Factor Characterization | CASE | ||||

|---|---|---|---|---|---|

| Base Case | RDF Gasification | Incineration | Sanitary Landfill | ||

| AB | [kg Sbeq] | 9.36864 × 10−6 | 8.37439 × 10−6 | 6.40124 × 10−5 | 1.26672 × 10−5 |

| ABFF | [MJ] | 230.9462169 | 226.421873 | 218.839066 | 143.3276608 |

| GWP | [kg CO2eq] | 137.3503973 | 203.8017347 | 512.6599606 | 623.1065875 |

| ODP | [kg CFC-11eq] | 2.18394 × 10−6 | 2.16154 × 10−6 | 2.85011 × 10−6 | 1.09273 × 10−6 |

| HT | [kg 1,4-DBeq] | 13.94518915 | 12.4240435 | 83.38466568 | 19.89651147 |

| FWEX | [kg 1,4-DBeq] | 2.76645732 | 2.480519326 | 28.29727625 | 2.329612823 |

| MWEX | [kg 1,4-DBeq] | 172603.0985 | 153130.3439 | 266897.9012 | 245536.5574 |

| TREX | [kg 1,4-DBeq] | 0.365422428 | 0.362140746 | 0.549152347 | 0.042360738 |

| PHOX | [kg C2H4eq] | 0.025667117 | 0.015170677 | 0.00487331 | 0.133445373 |

| AC | [kg SO2eq] | 0.138055157 | 0.129016136 | 0.196995917 | 0.108478345 |

| EU | [kg PO4eq] | 0.696789395 | 0.647438367 | 0.069082204 | 0.582796912 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Biancini, G.; Marchetti, B.; Cioccolanti, L.; Moglie, M. Comprehensive Life Cycle Assessment Analysis of an Italian Composting Facility concerning Environmental Footprint Minimization and Renewable Energy Integration. Sustainability 2022, 14, 14961. https://doi.org/10.3390/su142214961

Biancini G, Marchetti B, Cioccolanti L, Moglie M. Comprehensive Life Cycle Assessment Analysis of an Italian Composting Facility concerning Environmental Footprint Minimization and Renewable Energy Integration. Sustainability. 2022; 14(22):14961. https://doi.org/10.3390/su142214961

Chicago/Turabian StyleBiancini, Giovanni, Barbara Marchetti, Luca Cioccolanti, and Matteo Moglie. 2022. "Comprehensive Life Cycle Assessment Analysis of an Italian Composting Facility concerning Environmental Footprint Minimization and Renewable Energy Integration" Sustainability 14, no. 22: 14961. https://doi.org/10.3390/su142214961

APA StyleBiancini, G., Marchetti, B., Cioccolanti, L., & Moglie, M. (2022). Comprehensive Life Cycle Assessment Analysis of an Italian Composting Facility concerning Environmental Footprint Minimization and Renewable Energy Integration. Sustainability, 14(22), 14961. https://doi.org/10.3390/su142214961