Characteristics of Mining-Induced Slope Movement and Ground Behavior under Gully Landforms

Abstract

1. Introduction

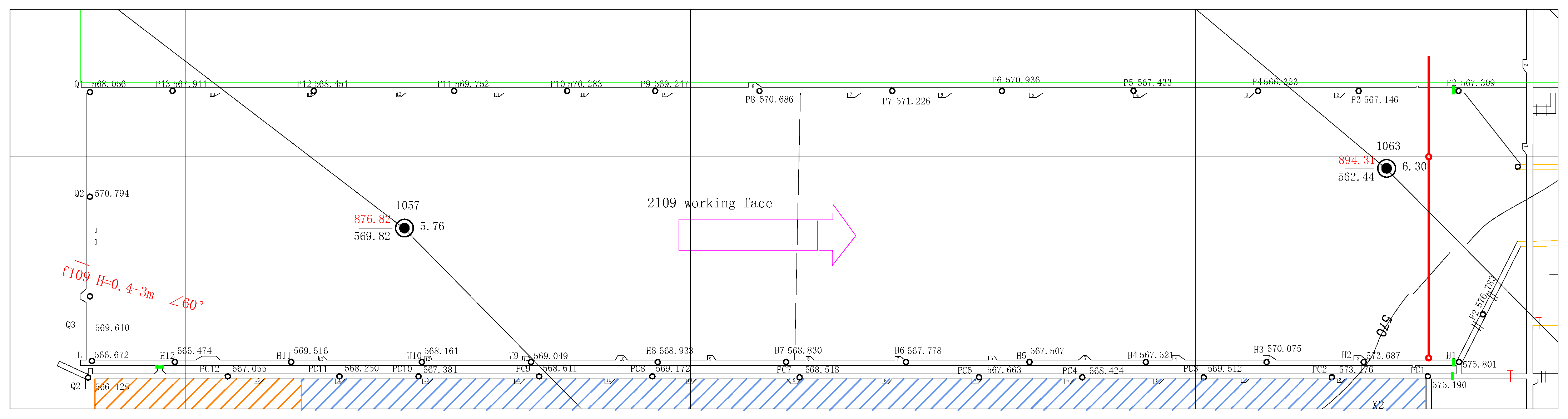

2. Background of Case Study

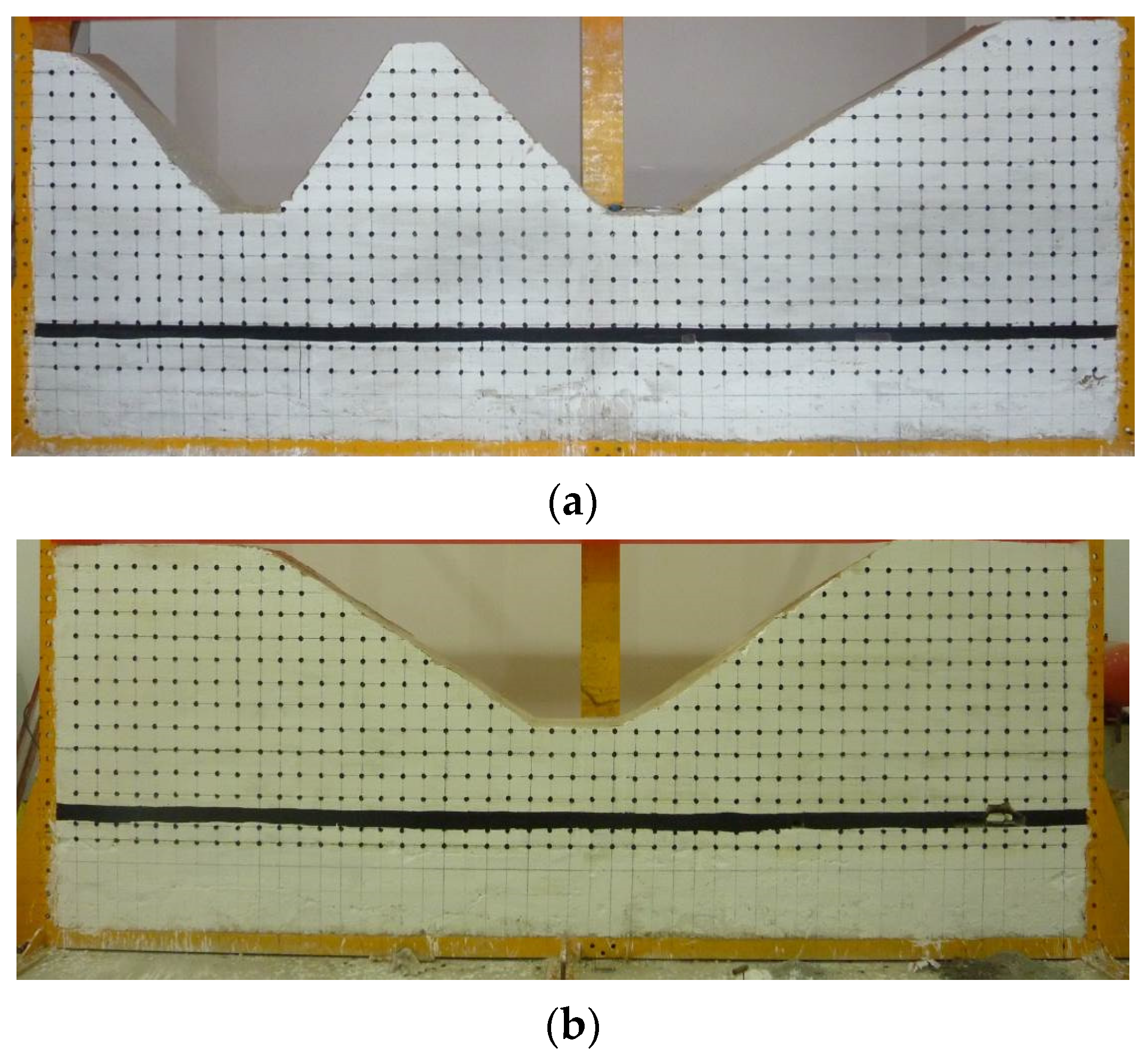

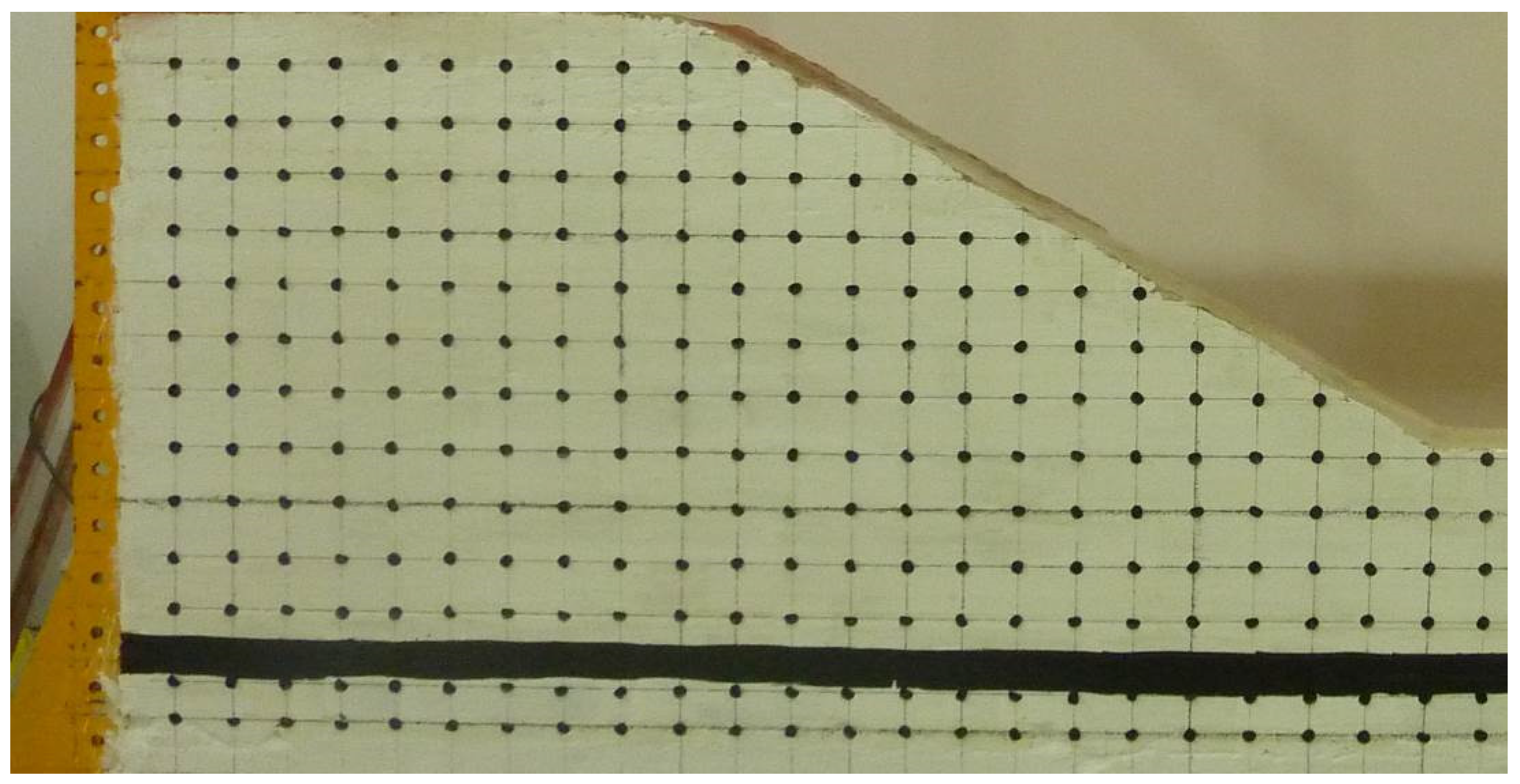

3. Model Design and Production of Similar Simulation

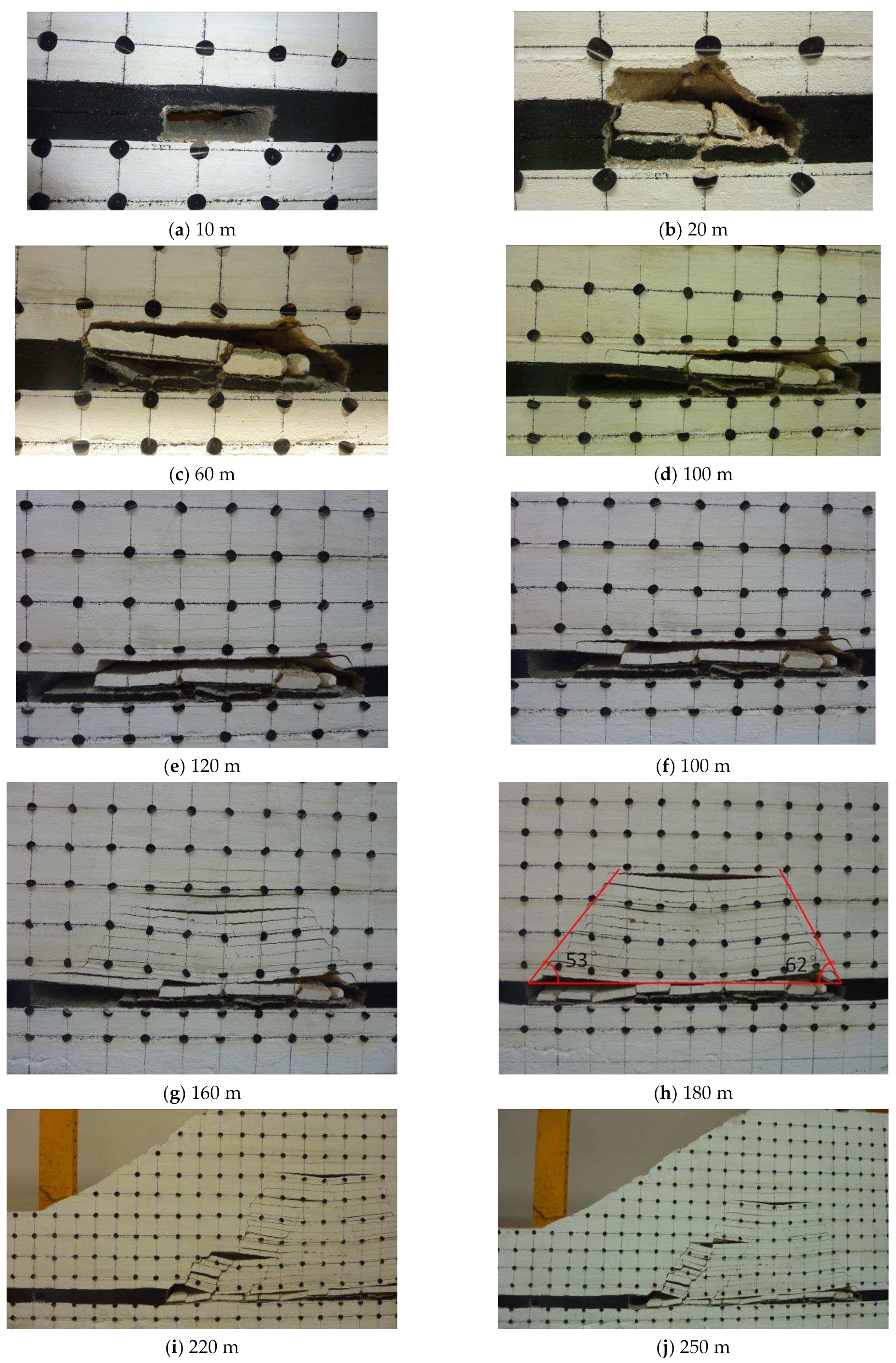

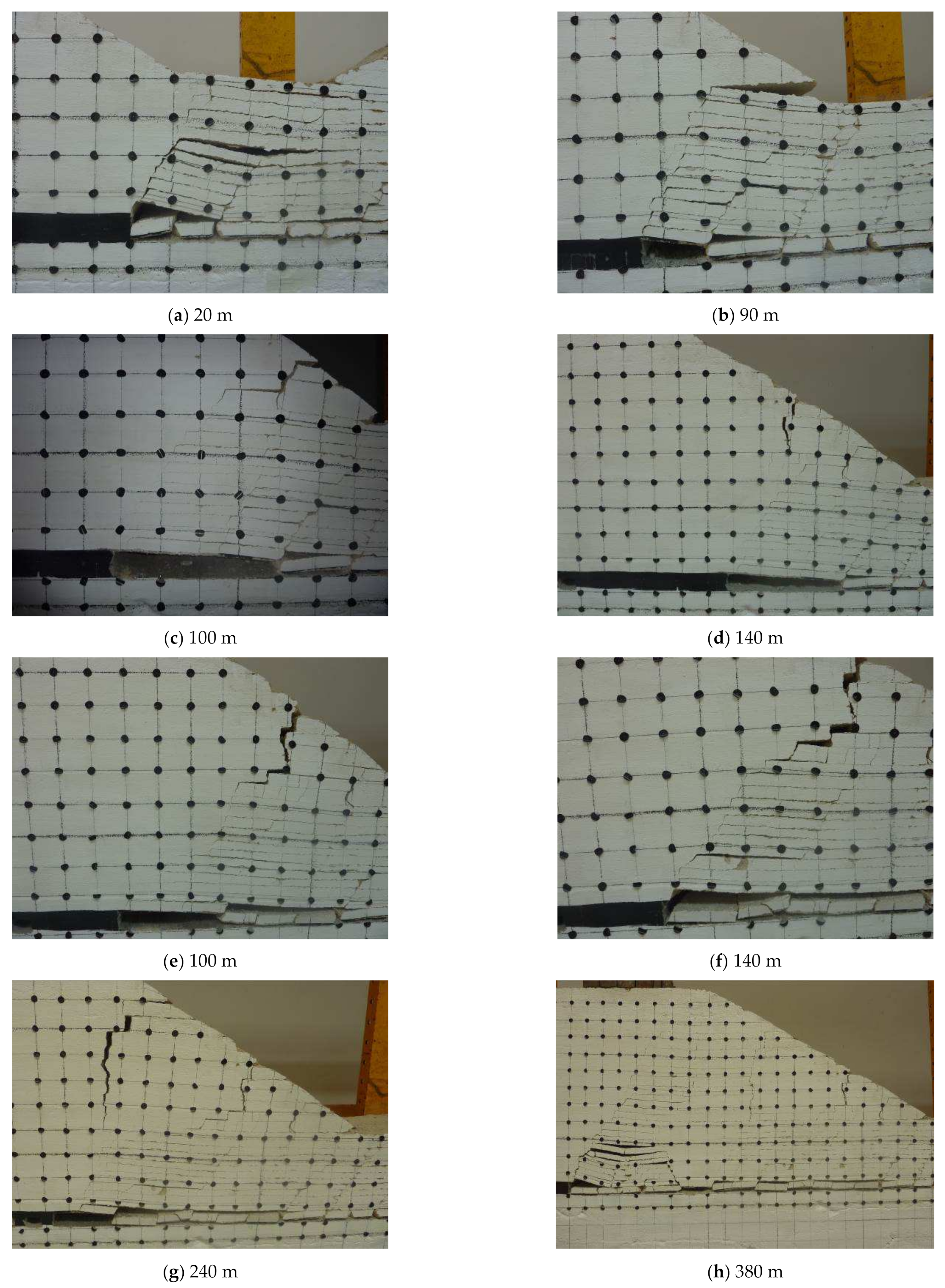

4. Failure Characteristics of the Surrounding Rock of the Roadway under Different Positions

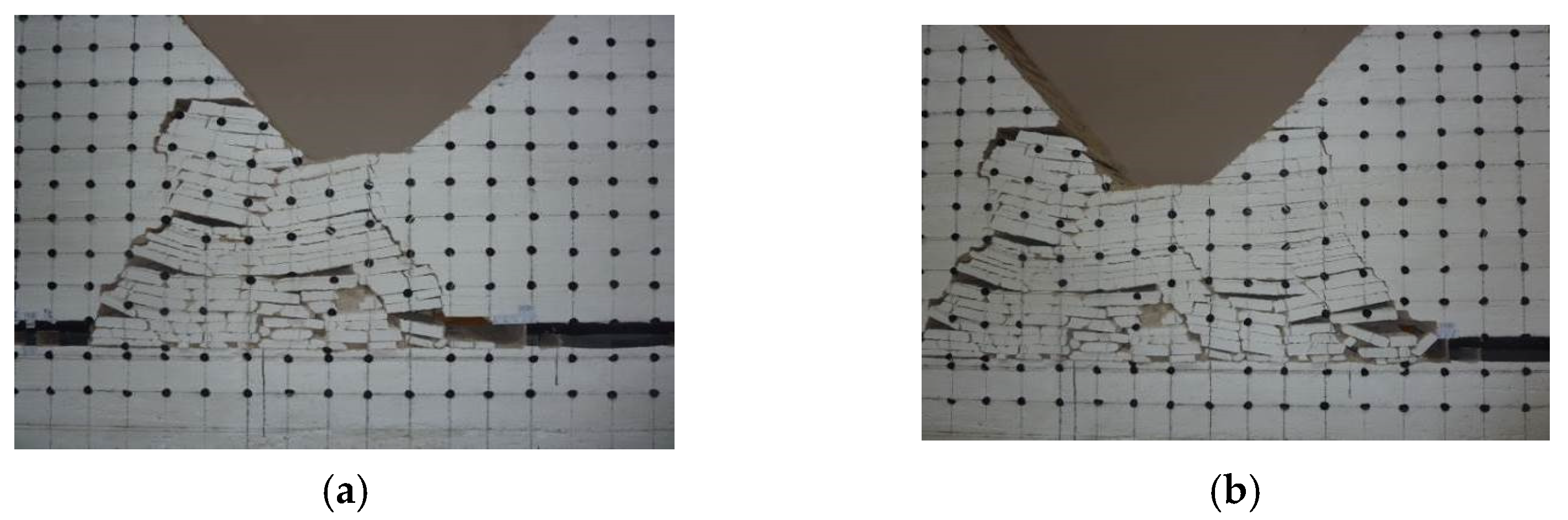

4.1. The Roadway Located below the Top of the Slope

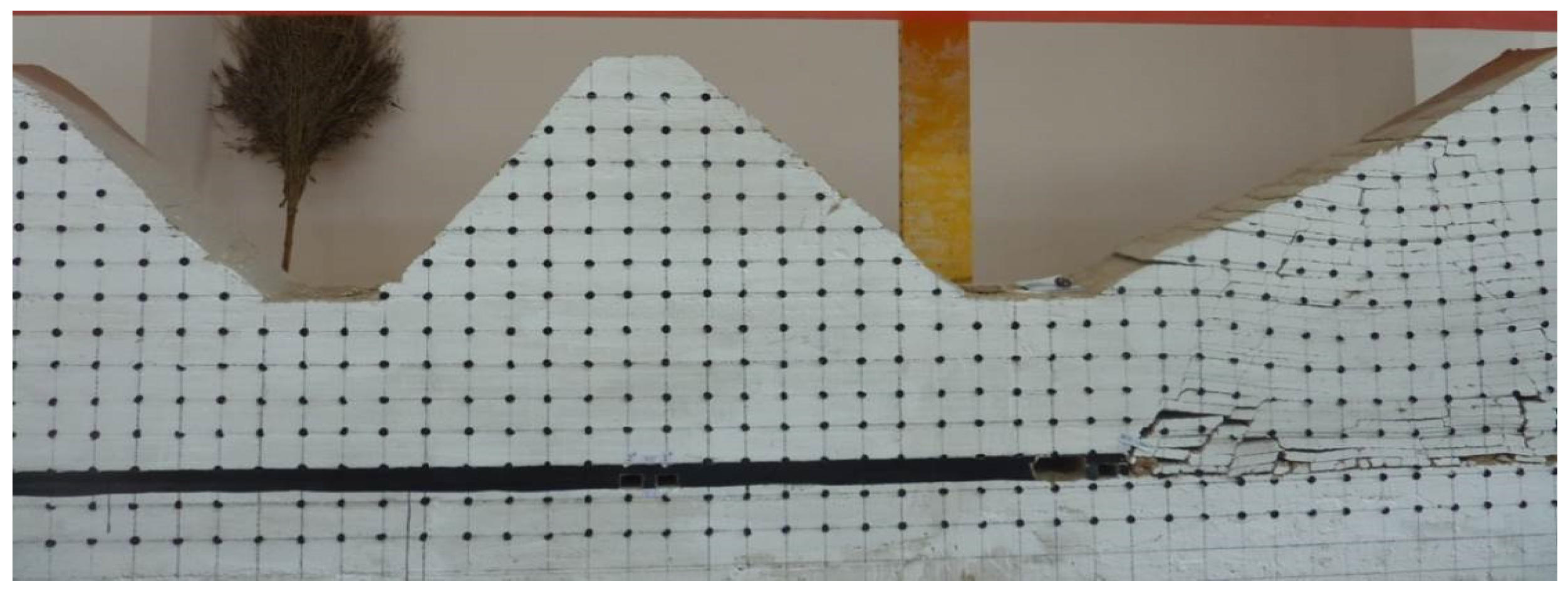

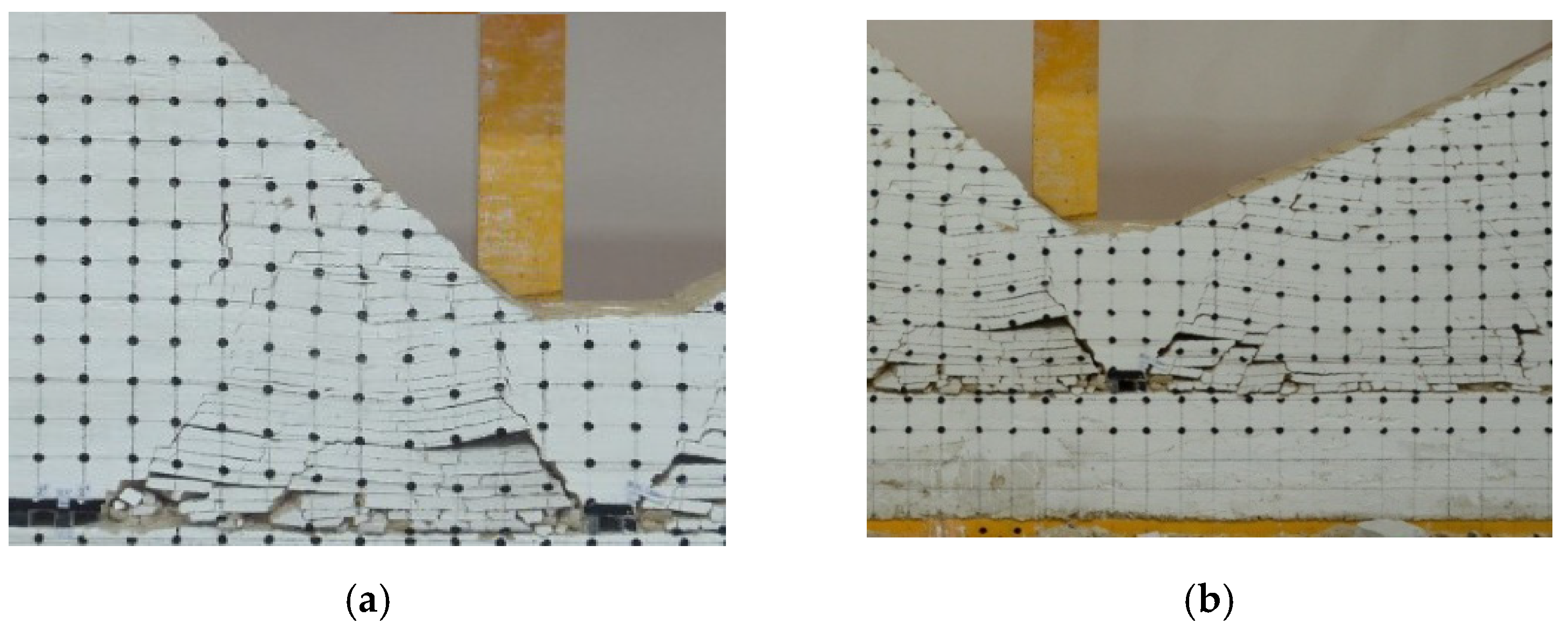

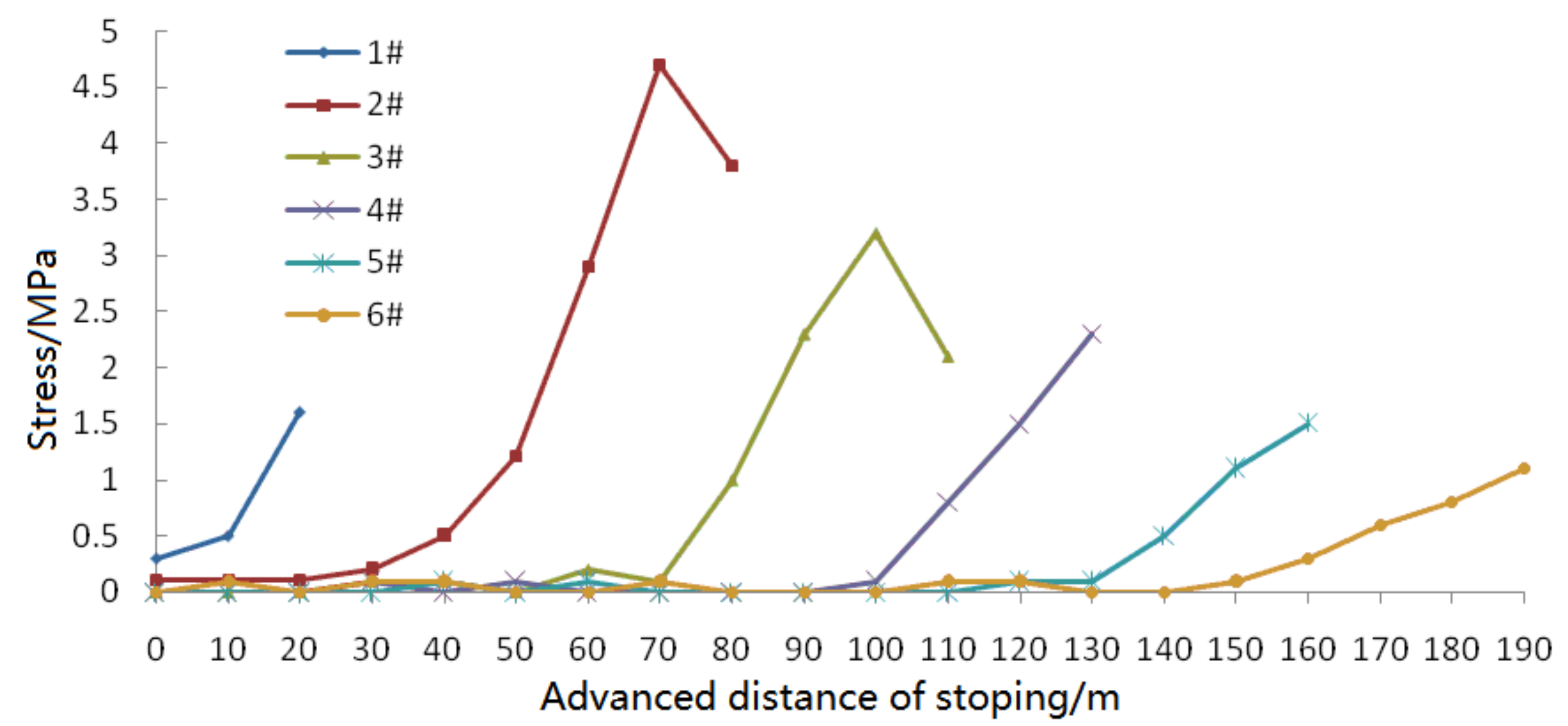

4.2. The Roadway Located below the Slope Surface

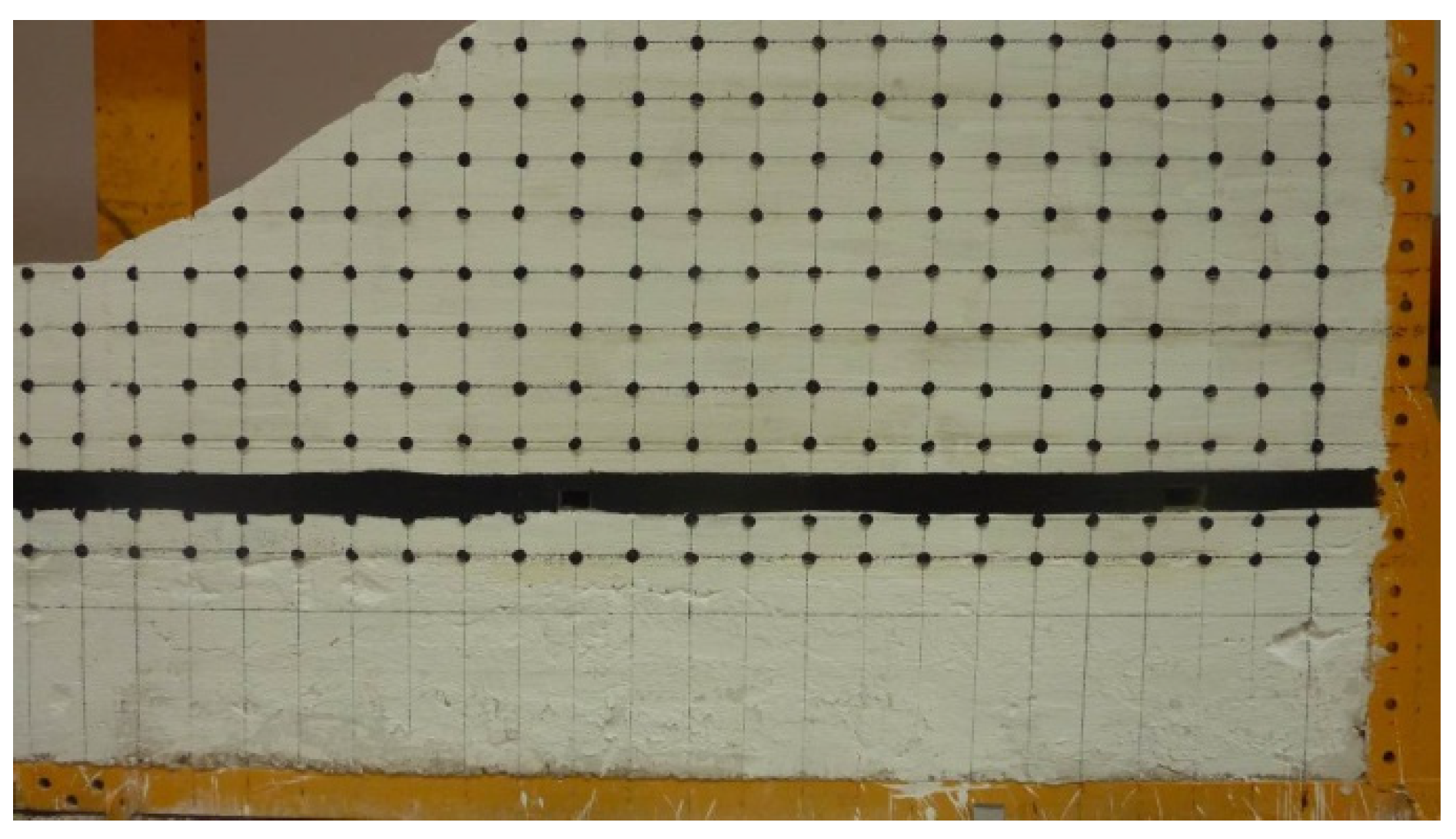

4.3. The Roadway Located below the Bottom of Slope

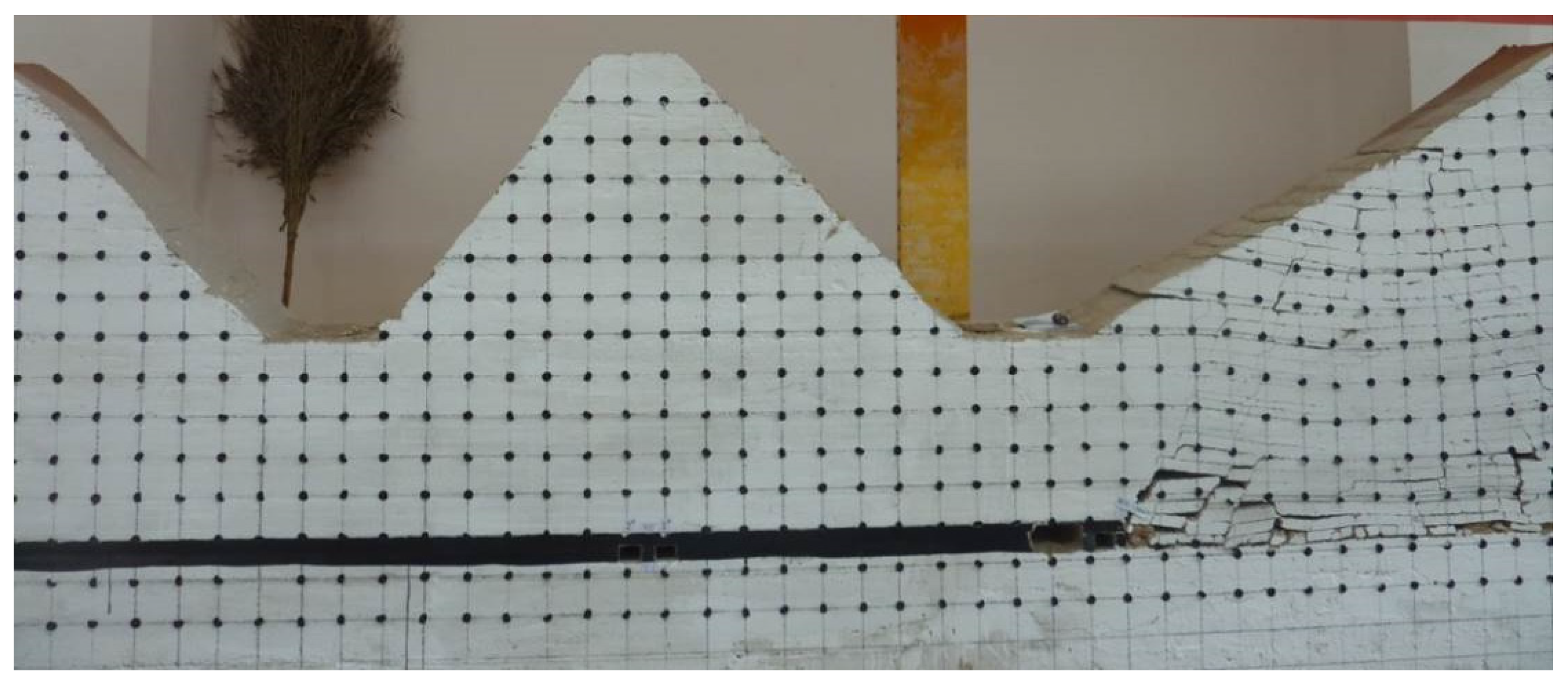

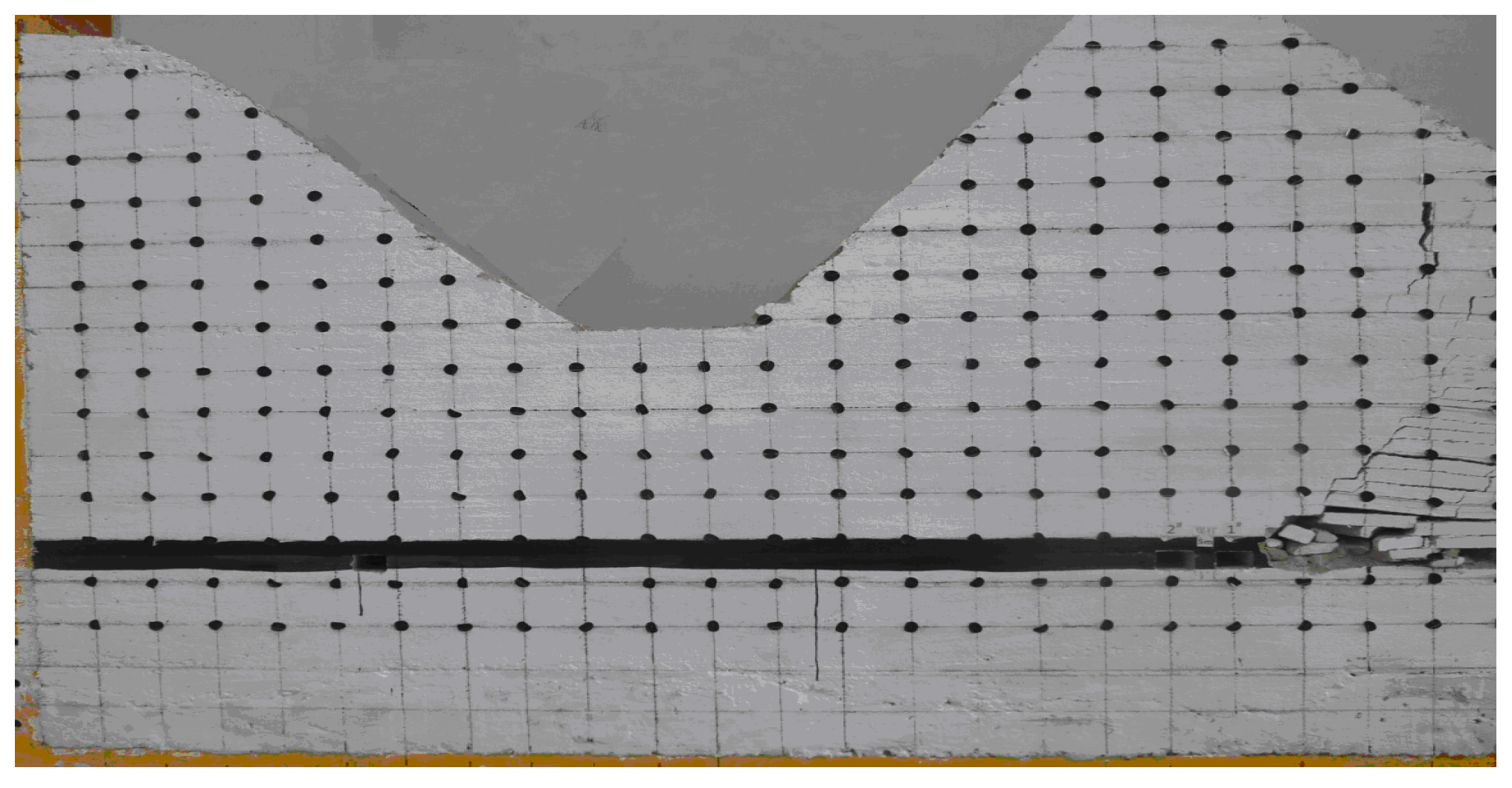

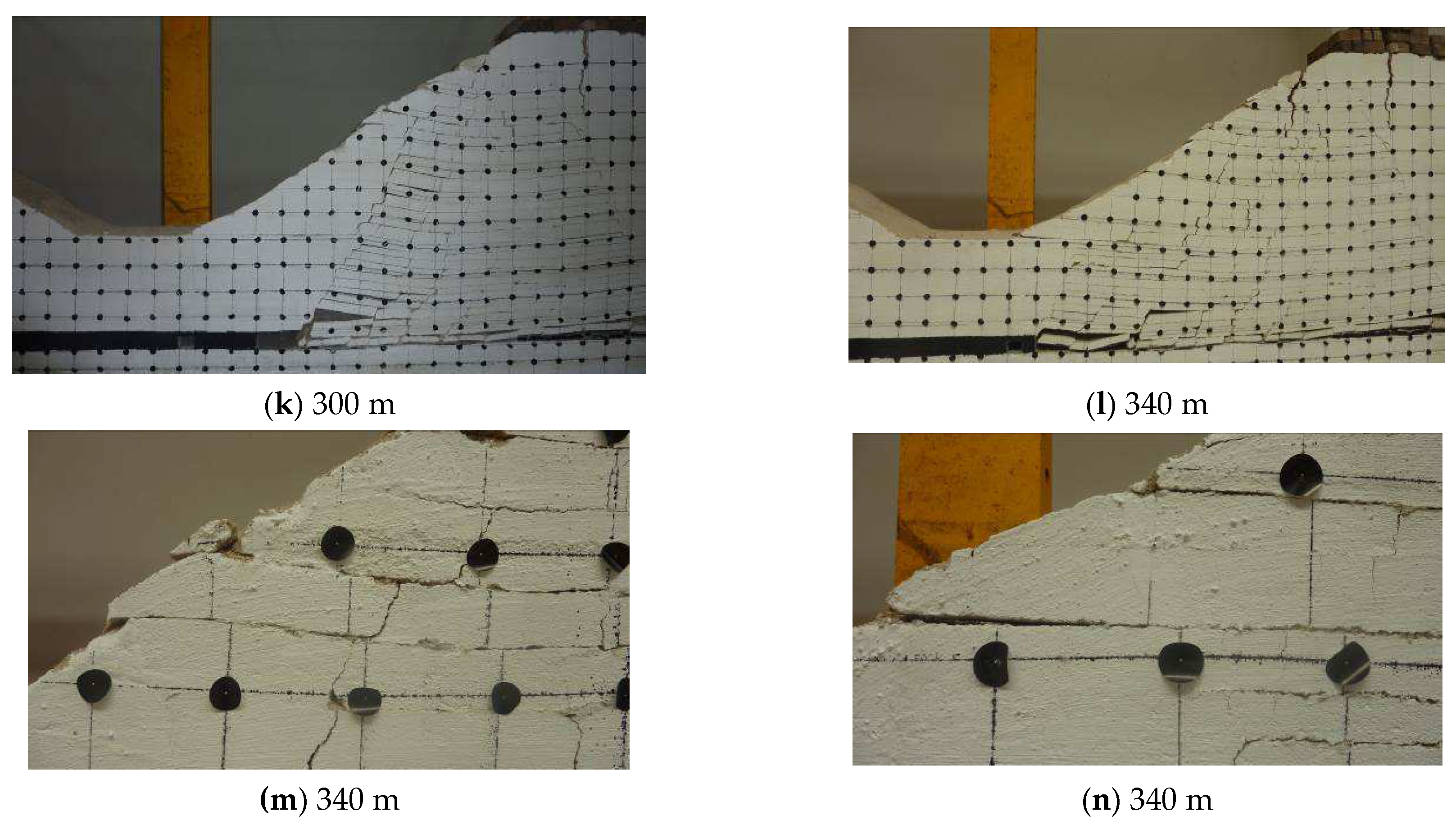

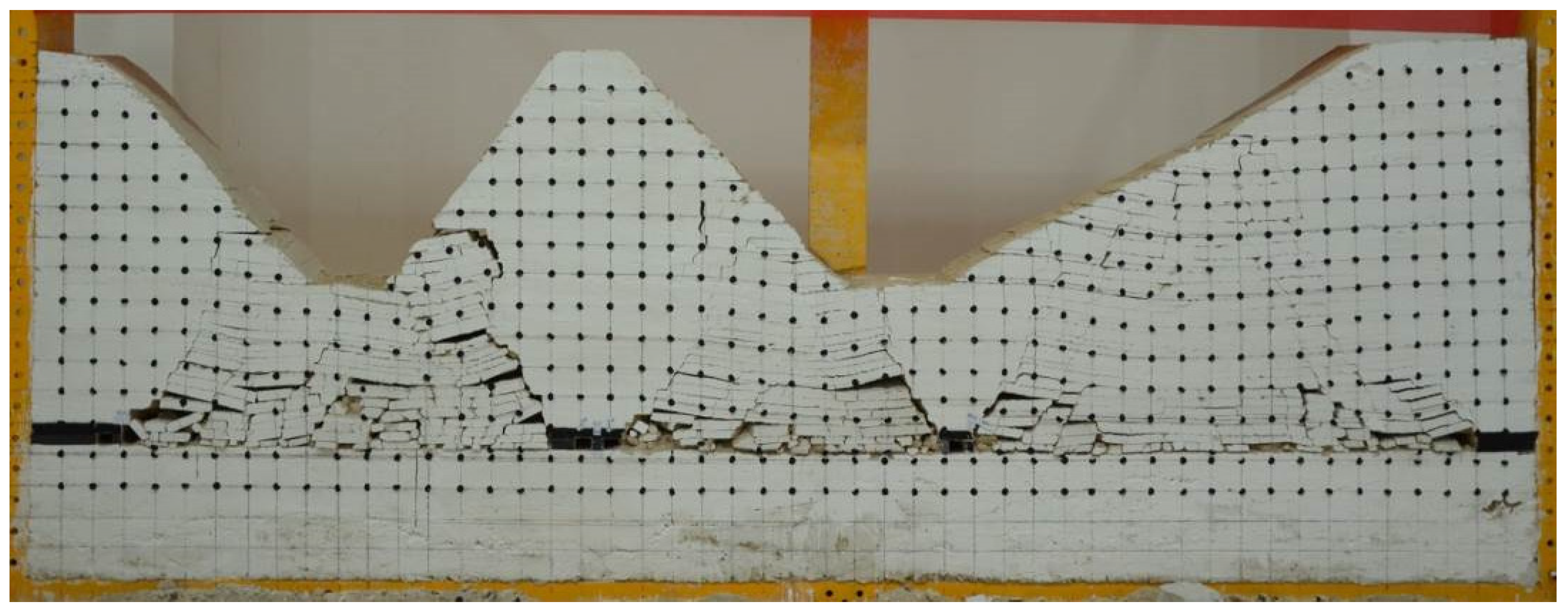

5. Laws of Ground Behavior in Different Directions of Working

- (1)

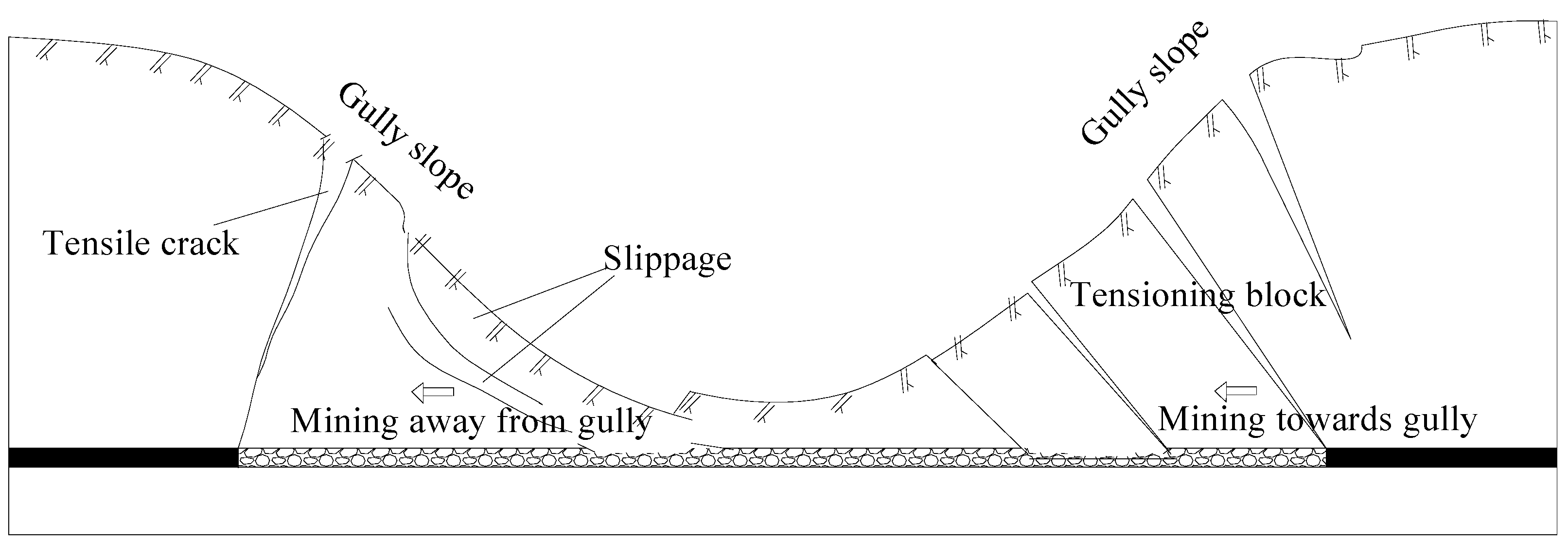

- Mining towards the gully.

- The right side of the slope was goaf; therefore, the restriction degree of the slope body decreased, especially in the right horizontal direction, which led to a tendency of the overlying strata sliding to the bottom right of the gully, in addition to downward displacement in the process of stoping. Therefore, when the pulling force towards the right reached a certain degree, a relatively obvious tensile crack was generated at the top of the slope, and the crack developed downward along with working face mining, and finally, the surface tension cracks connected with longitudinal fissures formed by overburden collapse, causing overlying strata with weakened constraints to slip towards the bottom of the gully.

- Due to the influence of actual mining, the shear strength of the weak surface of overburden gradually became smaller. The slope of the gully was near the goaf; therefore, resistance to additional horizontal stress overburden depended only on the friction between the layers. When the additional horizontal stress was greater than the shear resistance between strata, the strata of the slope body would slip horizontally towards the bottom of the gully to release the additional horizontal stress caused by actual mining.

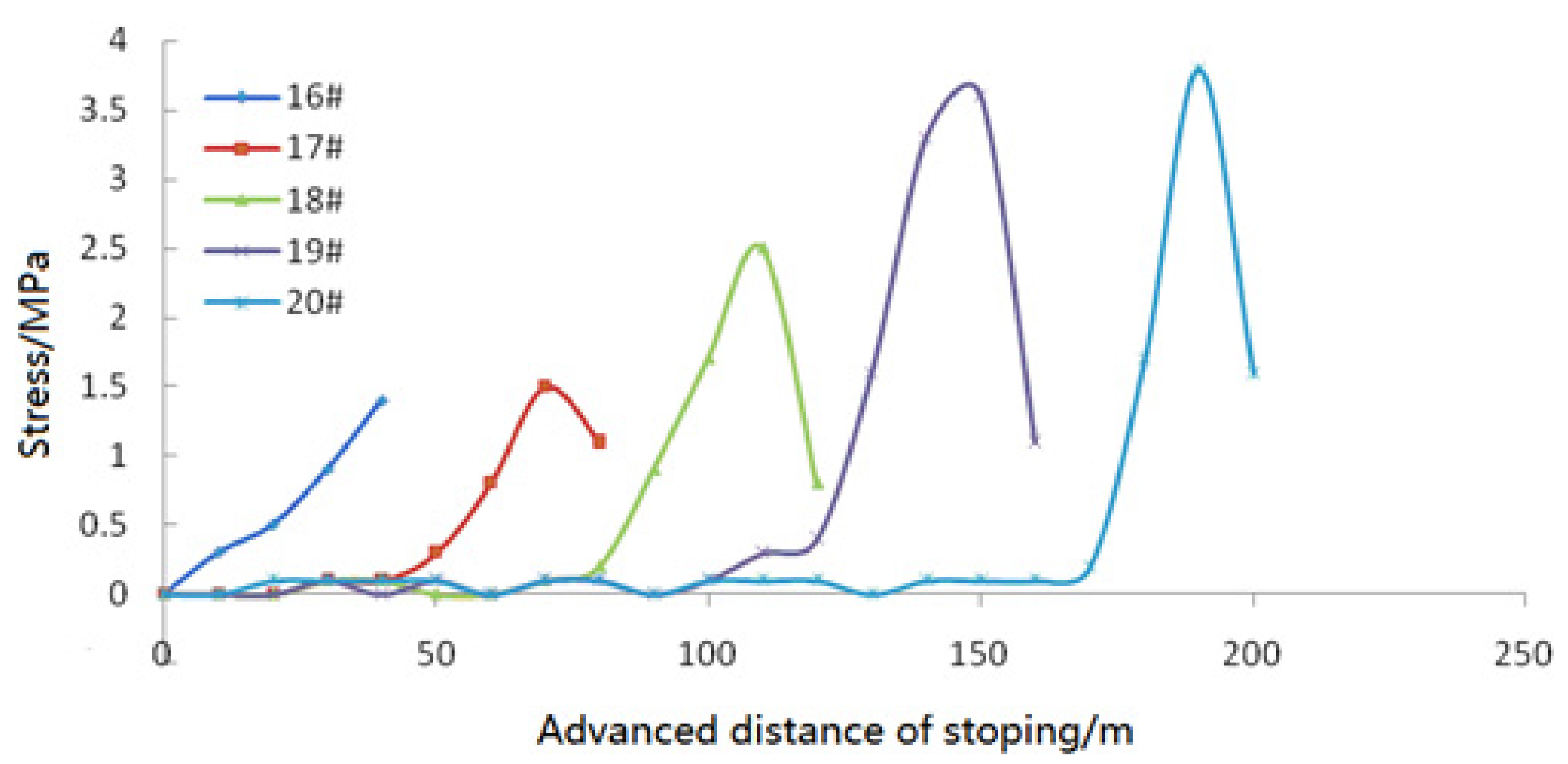

- Laws of advanced abutment pressure and displacement of slope

- (2)

- Mining away from the gully.

6. Comprehensive Analysis of Test Results

- When the roadway was located below the top of the slope, the two sides of the roadway were vulnerable to compression damage during excavation; after mining, the deformation of rock surrounding the roadway was aggravated by mining stress, and the abutment pressure of the coal body on the two sides of the roadway increased;

- When the roadway was located below the bottom of the gully, the stability of rock surrounding the roadway was good during the excavation; after mining, the roadway was less affected by mining and could remain stable;

- When the roadway was located below the slope surface, the failure of surrounding rock exhibited significant asymmetry under the influence of mining stress.

- When mining towards the gully, the ground behavior of the working face was different from that of the conventional surface mining section. The concrete manifestation showed that the ground behavior was gentle, the interval distance periodical weight was longer, and the advance abutment pressure was small, i.e., the concentration factor of the advance abutment pressure was small.

- When mining away from the gully, the ground behavior laws were very different from those of mining towards the gully; the ground behavior appeared intense. With the increase in overburden thickness, the interval distance periodical weight became shorter and shorter, and the roof behavior appeared intense. Dynamic pressure was easily induced, with a high concentration factor of advance abutment pressure.

7. Conclusions

- When a roadway is located below the top of the slope, the deformation of rock surrounding the roadway is aggravated by mining stress; when a roadway is located below the bottom of a gully, it is less affected by mining and could remain stable. Therefore, the actual mining roadway should be situated in the area below the bottom of the gully as much as possible.

- The ground behavior laws of the working face in the gully geomorphology area are related to the position of the working face and the direction of working. When mining towards a gully, the ground behavior is gentle, the interval distance periodical weight is longer, and the surface slips towards the gully; when mining away from a gully, the ground behavior appears intense, and the pressure is sudden and short with an increase in overburden thickness and decrease in interval distance periodical weight.

- When the working face passes through a gully, dumping of the hydraulic support should be prevented in sections with mining towards the gully; in sections of mining away from a gully, the supports should be strengthened to prevent the support and other equipment from being crushed.

- In actual mining, mining towards the gully should be adopted as much as possible in the stoping of the working face. In this way, the ground behavior is gentle, the interval distance periodical weight is longer, and the advance abutment pressure is small.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, D.S.; Fan, G.W.; Wang, X.F. Characteristics and stability of slope movement response to underground mining of shallow coal seams away from gullies. Int. J. Min. Sci. Technol. 2012, 22, 47–50. [Google Scholar] [CrossRef]

- Zhang, Z.Q.; Xu, J.L.; Zhu, W.B.; Zhenjun, S. Simulation research on the influence of eroded primary key strata on dynamic strata pressure of shallow coal seams in gully terrain. Int. J. Min. Sci. Technol. 2012, 22, 51–55. [Google Scholar] [CrossRef]

- Si, G.; Jamnikar, S.; Lazar, J.; Shi, J.Q.; Durucan, S.; Korre, A.; Zavšek, S. Monitoring and modelling of gas dynamics in multi-level longwall top coal caving of ultra-thick coal seams, part I: Borehole measurements and a conceptual model for gas emission zones. Int. J. Coal Geol. 2015, 144, 98–110. [Google Scholar] [CrossRef]

- Xie, Y.S.; Zhao, Y.S. Numerical simulation of the top coal caving process using the discrete element method. Int. J. Rock Mech. Min. Sci. 2009, 46, 983–991. [Google Scholar] [CrossRef]

- Vakili, A.; Hebblewhite, B.K. A new cavability assessment criterion for Longwall Top Coal Caving. Int. J. Rock Mech. Min. Sci. 2010, 47, 1317–1329. [Google Scholar] [CrossRef]

- Wang, J.C.; Yang, S.L.; Li, Y.; Wei, L.K.; Liu, H.H. Caving mechanisms of loose top-coal in longwall top-coal caving mining method. Int. J. Rock Mech. Min. Sci. 2014, 71, 160–170. [Google Scholar] [CrossRef]

- Wang, J.C.; Zhang, J.W.; Li, Z.L. A new research system for caving mechanism analysis and its application to sublevel top-coal caving mining. Int. J. Rock Mech. Min. Sci. 2016, 88, 273–285. [Google Scholar] [CrossRef]

- Xie, G.X.; Chang, J.C.; Yang, K. Investigation on displacement field characteristics of tunnels surrounding rock and coal seam at FMTC face. J. Coal Sci. Eng. 2006, 12, 1–5. [Google Scholar]

- Xie, G.X.; Chang, J.C.; Yang, K. Investigations into stress shell characteristics of surrounding rock in fully mechanized top-coal caving face. Int. J. Rock Mech. Min. Sci. 2009, 46, 172–181. [Google Scholar] [CrossRef]

- Li, L.; Liu, Z.G.; Chen, P.P.; Liu, G. Study on fully-mechanized top coal caving mining under water body with shallow overburden and thin bedrock. Adv. Mater. Res. 2013, 734–737, 644–649. [Google Scholar] [CrossRef]

- Zhu, Y.J.; Peng, G. Similar material simulation research on movement law of roof over-lying strata in stope of fully mechanized caving face with large mining height. J. Coal Sci. Eng. 2010, 16, 6–10. [Google Scholar] [CrossRef]

- Liu, J.; Chen, S.L.; Wang, H.J.; Li, Y.C.; Geng, X.W. The migration law of overlay rock and coal in deeply inclined coal seam with fully mechanized top coal caving. J. Environ. Biol. 2015, 36, 821–827. [Google Scholar]

- Alehossein, H.; Poulsen, B.A. Stress analysis of longwall top coal caving. Int. J. Rock Mech. Min. Sci. 2010, 47, 30–41. [Google Scholar] [CrossRef]

- Shen, J.; Meng, D.; Wei, L. Study on the structural system of roof in fully mechanized top coal caving. Appl. Mech. Mater. 2011, 90–93, 2041–2044. [Google Scholar] [CrossRef]

- He, F.L.; Wang, X.M.; Zhang, D.Q.; He, S.S. Study on parameters of support for control of roof fall and rib spalling in large fully mechanized top coal caving end face. Adv. Mater. Res. 2013, 616–618, 421–425. [Google Scholar] [CrossRef]

- Du, F.; Bai, H.B. Mechanical model for immediate roof structure of thin bedrock in fully-mechanized sublevel caving face. Electron. J. Geotech. Eng. 2012, 17, 3075–3088. [Google Scholar]

- Yin, G.; Li, X.; Guo, W. Photo-eiastic experimental and field measurement study of ground pressure of surrounding rock of large dip angle working coal face. Chin. J. Rock Mech. Eng. 2010, 29, 3336–3343. [Google Scholar]

- Zhang, J.; Xu, G.; Ma, M.; Wang, H.; Qi, F. Strata behavior law at fully mechanized caving face in thick coal seam with large dip angle Safety in Coal Mines. Saf. Coal Mines 2014, 45, 181–183. [Google Scholar]

- Wu, X.Z.; Jiang, Y.J.; Guan, Z.C.; Wang, G. Estimating the support effect of the energy-absorbing rock bolt based on the mechanical work transfer ability. Int. J. Rock Mech. Min. Sci. 2018, 103, 168–178. [Google Scholar] [CrossRef]

- Gu, S.; Chen, P.; Wang, J.; Wang, H. Field measurement study of mine strata pressure behavior law of coal mining face under goaf. Coal Mine Eng. 2013, 9, 64–67. [Google Scholar]

- Lin, S.Z. A modelling research into slope deformation activities associated with underground mining. J. Xi’an Coll. Geol. 1989, 11, 70–79+112. [Google Scholar]

- Singh, V.K. Slope stability study for optimum design of an opencast project. J. Sci. Ind. Res. 2006, 65, 47–56. [Google Scholar]

- Sun, L.; Zhang, Y.; Wang, Y.; Liu, Q. Study on the Reoxidation Characteristics of Soaked and Air-Dried Coal. J. Energy Resour. Technol. 2019, 141, 022203. [Google Scholar] [CrossRef]

- Erginal, A.E.; Türkeş, M.; Ertek, T.A. Geomorphological investigation of the excavation-induced Dundar landslide, Bursa, Turkey. Geogr. Ann. Ser. A Phys. Geogr. 2008, 90, 109–123. [Google Scholar] [CrossRef]

- Kang, J.R. Analysis of effect of fissures caused by underground mining on ground movement and deformation. Chin. J. Rock Mech. Eng. 2008, 27, 59–64. [Google Scholar]

- Singh, R.; Mandal, P.K.; Singh, A.K.; Kumar, R.; Maiti, J.; Ghosh, A.K. Upshot of strata movement during underground mining of a thick coal seam below hilly terrain. Int. J. Rock Mech. Min. Sci. 2008, 45, 29–46. [Google Scholar] [CrossRef]

- Fan, K.G.; Liu, G.L.; Xiao, T.Q. Study on overlying strata movement and structure features aroused by mountainous shallow buried coal seam mining. In Proceedings of the 2nd International Conference on Mine Hazards Prevention and Control, Qingdao, China, 15–17 October 2010; Volume 12, pp. 76–82. [Google Scholar]

- Yuan, T. Research on Mining Subsidence Laws in Shaanxi Loess Gully Region. Master’s Thesis, Xi’an University of Science and Technology, Xi’an, China, 2011. [Google Scholar]

- Ji, H.; Yu, X.Y. Analysis and study on formation mechanism of subsidence disaster in gully region of shallow depth seam. Coal Eng. 2012, 6, 69–71. [Google Scholar]

- Li, W.X.; Mei, S.H.; Zai, S.H.; Zhao, S.; Liang, X. Fuzzy models for analysis of rock mass displacements due to underground mining in mountainous areas. Int. J. Rock Mech. Min. Sci. 2006, 43, 503–511. [Google Scholar] [CrossRef]

- He, M.C.; Feng, J.L.; Sun, X.M. Stability evaluation and optimal excavated design of rock slope at Antaibao open pit coal mine, China. Int. J. Rock Mech. Min. Sci. 2008, 45, 289–302. [Google Scholar] [CrossRef]

- Yu, L.; Ignatov, Y.; Ivannikov, A.; Khotchenkov, E.; Krasnoshtanov, D. Common features in the manifestation of natural and induced geodynamic events in the eastern regions of Russia and China. IOP Conf. Ser. Earth Environ. Sci. 2019, 324, 012004. [Google Scholar] [CrossRef]

- Rybak, J.; Khayrutdinov, M.M.; Kuziev, D.A.; Kongar-Syuryun, C.B.; Babyr, N.V. Prediction of the geomechanical state of the rock mass when mining salt deposits with stowing. J. Min. Inst. 2022, 253, 61–70. [Google Scholar] [CrossRef]

- Khayrutdinov, A.M.; Kongar-Syuryun, C.B.; Kowalik, T.; Tyulyaeva, Y.S. Stress-strain behavior control in rock mass using different-stregth backfill. Min. Inf. Anal. Bull. 2020, 2020, 42–55. [Google Scholar] [CrossRef]

- Rybak, J.; Gorbatyuk, S.M.; Kongar-Syuryun, C.B.; Khairutdinov, A.M.; Tyulyaeva, Y.S.; Makarov, P.S. Utilization of Mineral Waste: A Method for Expanding the Mineral Resource Base of a Mining and Smelting Company. Metallurgist 2021, 64, 851–861. [Google Scholar] [CrossRef]

| Thickness/m | Rock Layer | Layer Thickness (m) | Sand | Carbonate (kg) | Gypsum (kg) |

|---|---|---|---|---|---|

| 7 | Medium sandstone | 2.00 | 12.80 | 0.96 | 2.24 |

| 1.50 | 9.60 | 0.72 | 1.68 | ||

| 5 | Mudstone | 2.50 | 16.66 | 1.66 | 1.66 |

| 12 | Sandy mudstone | 2.50 | 17.14 | 0.86 | 2.00 |

| 2.00 | 13.71 | 0.68 | 1.60 | ||

| 2.00 | 13.71 | 0.68 | 1.60 | ||

| 2.00 | 13.71 | 0.68 | 1.60 | ||

| 7 | Mudstone | 2.00 | 13.33 | 1.33 | 1.33 |

| 6 | Fine sandstone | 2.00 | 12.00 | 2.00 | 2.00 |

| 2.00 | 12.00 | 2.00 | 2.00 | ||

| 2.00 | 12.00 | 2.00 | 2.00 | ||

| 4 | Mudstone | 2.00 | 13.33 | 1.33 | 1.33 |

| 6.3 | Coal | 2.00 | 13.71 | 0.68 | 1.60 |

| 1.50 | 10.28 | 0.52 | 1.20 | ||

| 4 | Medium sandstone | 2.00 | 12.80 | 0.96 | 2.24 |

| 15 | Mudstone | 2.50 | 16.66 | 1.66 | 1.66 |

| 2.50 | 16.66 | 1.66 | 1.66 | ||

| 2.50 | 16.66 | 1.66 | 1.66 | ||

| 18 | Sandy mudstone | 3.00 | 20.57 | 1.28 | 2.40 |

| 2.00 | 13.71 | 0.68 | 1.60 | ||

| 2.00 | 13.71 | 0.68 | 1.60 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, S.; Kang, Y. Characteristics of Mining-Induced Slope Movement and Ground Behavior under Gully Landforms. Sustainability 2022, 14, 13941. https://doi.org/10.3390/su142113941

Ma S, Kang Y. Characteristics of Mining-Induced Slope Movement and Ground Behavior under Gully Landforms. Sustainability. 2022; 14(21):13941. https://doi.org/10.3390/su142113941

Chicago/Turabian StyleMa, Shaojie, and Yueming Kang. 2022. "Characteristics of Mining-Induced Slope Movement and Ground Behavior under Gully Landforms" Sustainability 14, no. 21: 13941. https://doi.org/10.3390/su142113941

APA StyleMa, S., & Kang, Y. (2022). Characteristics of Mining-Induced Slope Movement and Ground Behavior under Gully Landforms. Sustainability, 14(21), 13941. https://doi.org/10.3390/su142113941