Abstract

Waste recycling has always been a priority in the paper industry. In this study, the potential of translating various wastes in papermaking into building materials was separately evaluated. For the first time, the improvement of flexibility and sample texture after translating wastes into cementitious materials was analyzed. The results showed that 20% of the waste in alkali-activated slag slurry is the best proportion for papermaking. In addition, paper sludge and wood chips significantly improved the slurry flexibility while lime mud and bottom ash did not have this effect. Considering the effect of adding wood chips on the optimization of the sample texture, the most appropriate proportion of the paper sludge was 5% when the wood chips in the mixture were 15%. The most suitable alkali equivalent was 6%, with a silicate modulus of 0.9. According to the experimental results, wastes in papermaking had great potential for exploitation and application as circular materials.

1. Introduction

In 2021, the global output of paper products was 90.2 million tons, which continues to grow due to the COVID-19 pandemic [1]. In addition, approximately 3 billion USD is spent each year on waste disposal from the paper industry and related expenses. For a medium-sized mill, the cost is close to 7 million USD [2]. The waste in papermaking includes many solid wastes such as chips from wood processing, lime muds from kraft pumping, bottom ash in the recovery boiler, and paper sludges from on-site sewage treatment [3,4]. Several programs have been developed to manage these wastes. For example, biomass materials such as wood chips and water treatment sludge could be partially added as fuel to fuel boilers of paper mills [5]. However, this process created additional air and water pollution while supplying electricity to the paper manufacturing process [6]. Some other solid wastes, such as lime sludge, were difficult to reuse as fuel. These materials were usually landfilled with the ashes from incineration [7], causing occupancy of the waste plant and posing the risk of soil and water contamination [8]. Therefore, it is necessary to select suitable resource-based methods to reprocess these wastes without increasing or shifting the environmental burden.

By investigating the main components of waste in papermaking [9], the conversion of waste into building materials could be a suitable solution [10]. Among the solid wastes, lime mud replaced the raw materials of ordinary Portland cement by calcination, with a maximum replacement ratio of 20% [11,12]. The paper sludge thermally activated at 600–750 °C replaced 10% of cement as the cementitious binder [13]. In addition, 15% of wood chip ash from paper mills could be used as a raw material for the cementitious binder [14]. Although these methods helped convert waste into building materials, they still caused some energy consumption and environmental impact [15]. In addition, some studies investigated the use of bottom ashes as aggregates [16].

Alkali-activated cementitious materials are formed by mixing aluminosilicate materials with alkali metal silicate solutions and alkali activators [17,18]. Among them, alkali-activated slag has received wide attention for its low CO2 emission, high compressive strength, durability, and fire resistance [19]. Recently, more emphasis has been placed on the potential for solidifying waste from alkali-activated blast furnace slag [20,21,22,23,24].

This study aimed to analyze the possibility of alkali-activating the mixture of wastes and blast furnace slag (BFS) in papermaking. Moreover, the effects of different wastes on the physical and mechanical properties of the slurry are discussed. In this study, different single-type papermaking wastes (SPW) were mixed with BFS and alkali-activated at ambient conditions. The compressive strengths and stress-time curves were used to analyze the optimized component and proportion of waste replacement BFS. On this basis, different types of wastes were selected as paper waste mixture (PWM) for further analysis to ensure a balance between the proportion of wastes in the mixtures, compressive strengths, and flexibilities. The effect of organic materials, such as wood chips, was also discussed. This study provided an appropriate alkali equivalent (AE) for the alkali activators.

2. Materials and Methods

The BFS used in this study was the experimental raw material provided by China Steel in Taiwan, with the label S6000, packed in 20 kg sealed bags. The papermaking wastes were provided by the Chung Hwa Paper Corporation in eastern Taiwan. Among them, lime mud was collected from the caustic kiln, paper sludge was collected during the sewage treatment process, and the bottom ash was collected from the recovery boilers. All the papermaking wastes were directly collected from the same batch of paper, with 150 kg samples of each material packed in six sealed bags. The sample of raw materials is shown in Figure 1. Those four materials were dried to constant weight at 110 °C and sieved with a mesh size of 0.282 mm. The main chemical components provided by the manufacturer are shown in Table 1.

Figure 1.

The material diagram. (a) BFS. (b) Lime mud. (c) Paper sludge. (d) Bottom ash.

Table 1.

Chemical composition of paper industrial wastes and BFS.

Considering the simplification of the alkali-activated cementitious material production and the convenience of storage and transportation, sodium silicate powder was used to prepare activators. The composition of sodium silicate powder was 46.07% of SiO2 and 51.35% of Na2O. The AE of the activators was 10%, the silicate modulus (Ms) of the activators was 0.93, and the water-binder ratio (W/B) was 0.5.

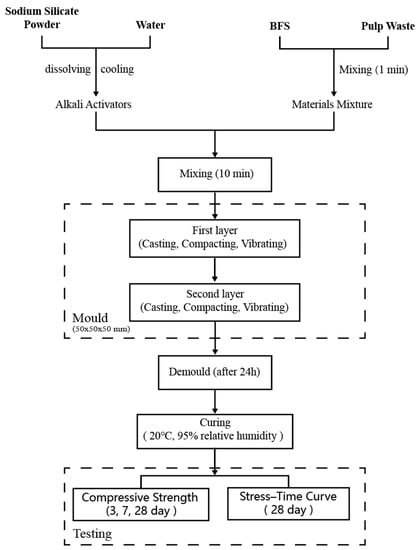

The experimental procedures included the preparation of the activator or material mixture, preparation of slurry, casting of specimens, and testing. Firstly, the alkali activator solution was prepared by mixing sodium silicate powder and water, then sealed and cooled to room temperature. Meanwhile, the raw materials were weighed in the required quantity and thoroughly mixed for 1 min. Subsequently, the mixture of dry materials was added to an alkali activator and mixed for another 10 min to finish the slurry. According to ASTM C109, the specimens for compressive strength tests were cast in 50 mm × 50 mm × 50 mm molds with two layers of mortar, followed by compaction and vibration to eliminate air bubbles. After the initial setting, specimens were sealed with plastic films to prevent moisture loss. In this study, samples were de-molded after 24 h of casting and stored in a control box at 20 °C and 95% relative humidity. Considering the experimental design and the number of samples, three of each experimental series were separately tested on the compressive strengths at 3, 7, and 28 days; the stress-time curves at day 28 were recorded. The specific steps and test parameters are shown in Figure 2 and the experiment’s process records in the laboratory are shown in Figure 3.

Figure 2.

Experimental steps and test item.

Figure 3.

The experiments process record in the laboratory. (a) The material mixing process. (b) The performance test.

3. Results and Discussion

This study classified the BFS substitution from wastes in papermaking into two pathways: SPW substitution and PWM substitution. In both pathways, the effects of these wastes on mechanical properties and texture were investigated. The suitable AE values were also analyzed.

3.1. Effect of Single-Type Paper Waste (SPW) Substitution Proportion

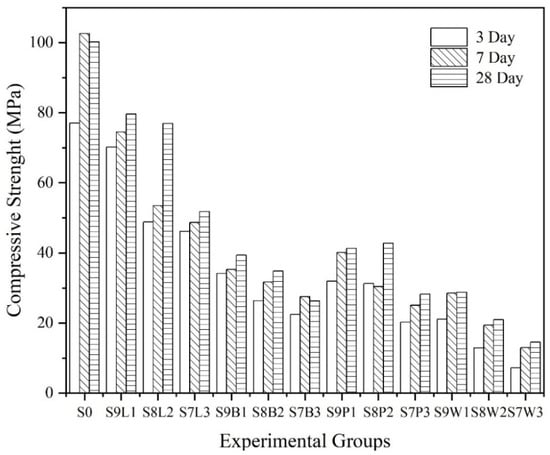

The experiment parameters of the SPW substitution are shown in Table 2 and the compressive strengths of samples are illustrated in Figure 4. The compressive strengths for different experimental series ranged from 14.5 MPa to 73.7 MPa after 28 days of curing. In terms of the SPW substitution proportion, the highest compressive strength was 73.7 MPa, in which BFS was partially substituted by 10% of the lime mud. The weakest compressive strength was 14.5 MPa, in which wood chips partially replaced 30% of BFS. Under the same substitution ratio, the compressive strength of lime mud, paper sludge, bottom ash, and wood chips sequentially decreased. The early strength illustrated that the compressive strengths of the sample increased rapidly from 0 to 7 days, almost exceeding 85% of the final strength. Except for the decrease in the compressive strength values of samples with the addition of sawdust from 7 to 28 days, the trend of strength development remained relatively constant, with some values fluctuating.

Table 2.

Experimental parameters of SPW substitution proportion.

Figure 4.

The compressive strength of SPW substitution proportion.

When paper sludge and wood chips were used as partial substitutes for BFS, the highest 28-day compressive strengths were 41.1 MPa and 28.8 MPa, respectively. This result could be attributed to the high content of organic impurities, which disrupted the polymerization of the cement [25]. In addition, the highest compressive strength of bottom ash was 39.4 MPa, which substituted BFS after 28 days of curing. Compared to other wastes, bottom ash had some volume expansion except for the reduction in the w/b ratio of the slurry [21]. Although the volume expansion reduced the self-shrinkage of the slurry, cracks were also generated in this process, degrading the mechanical properties of the material [16].

In S8L2 and S8P2, the development of compressive strengths from 7 to 28 days approached 20% of the final strength. Since the reactivity of the lime mud and the paper sludge is poorer than BFS, the weakening of compressive strength was reflected by the decreased development rate of compressive strength with an increasing ratio. Furthermore, the strengths on day 28 showed a significant decrease of more than 10 MPa in the comparison between S8M2 and S7M3 or S8P2 and S7P3 (11.5 MPa and 14.0 MPa, respectively). This result indicated that if the total proportion of lime mud and the paper sludge exceeded 20%, the polymerization in cementitious materials was incomplete [26], significantly decreasing the compressive strength. This result was similar to previous reports [11,12]. However, the other reports have expressed different opinions [27,28] due to different pretreatment of slurry raw materials. Therefore, a total weight of 20% could be considered a suitable proportion, which allowed the partial substitution of the lime mud or paper sludge for BFS.

Considering the optimization of compressive strength, the stress-time curve of BFS replaced by 20% of the waste was selected as the study object. According to Figure 5, the stress-time curves for partial substitution of BFS with lime mud or bottom ash showed the characteristics of brittle materials. Moreover, the shapes of the curves were similar, with a linear increase in yield strength and a sharp decrease at the peak. This variation suggested that the samples were crushed and lost the stress intensity at the peak. Only the peak points of the curves differed between them, indicating that lime mud or bottom ash could not change the characteristics of brittle materials, resulting in the alkali activation of BFS. In the partial substitution of BFS with paper sludge or wood chips, the curves decreased slowly at the peak. This change indicated that the samples still exceeded the yield strength in some respects. Based on these results, paper sludge or wood chips could significantly change the properties of alkali-activated BFS from brittle to ductile [29].

Figure 5.

The stress curve of the slurry with the 20% proportion of SPW substituted for BFS.

3.2. Effect of Paper Waste Mixture (PWM) Proportion

Due to the experimental results of the partial substitution of BFS with SPW, the lime mud and paper sludge were considered suitable materials for partial substitution. The experiment parameters of the PWM substitution are shown in Table 3. The effect of the proportion of various waste mixtures on compressive strength was discussed in this section. Based on the results, the proportion of BFS in the mixed powder can be further reduced.

Table 3.

Experimental parameters of PWM substitution proportion.

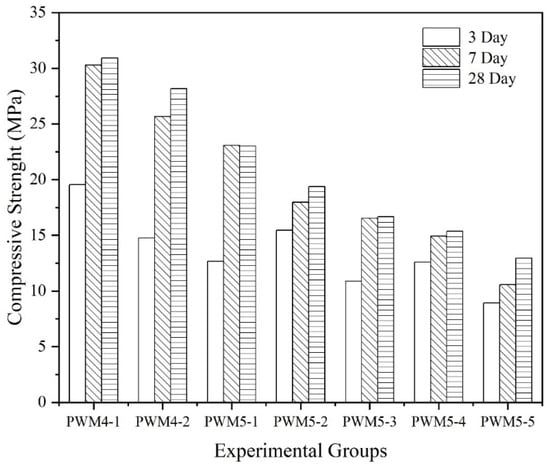

As shown in Figure 6, the compressive strengths of BFS substituted with waste mixtures showed a similar trend to that of BFS substituted with SPW. The compressive strength rapidly increased to a maximum around day 7 and fluctuated from 7 to 28 days. When the BFS was substituted by waste mixtures with a weight proportion of 50%, the highest compressive strength was 23.1 MPa. It was evident that the compressive strength decreased with decreasing proportion of lime mud in the waste mixtures. For every 5% reduction in the proportion of lime mud, the average compressive strength decreased by nearly 2.5 MPa.

Figure 6.

The compressive strength of PWM substitution proportion.

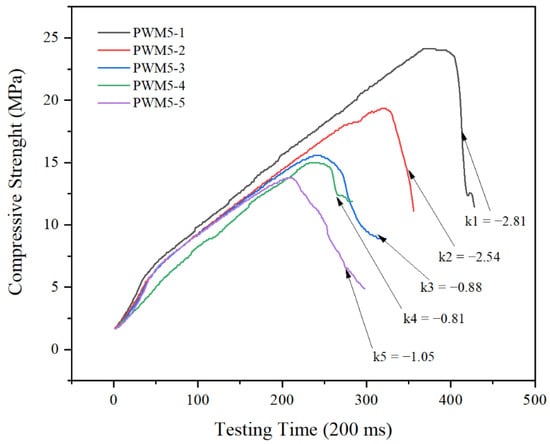

In Figure 7, the stress-time curves did not drop abruptly at the peak in the substitution of BFS with mixed wastes. When the proportion of the lime mud in waste mixtures exceeded 10% of the total weight, curve optimization was performed. As the proportion of paper sludge in waste mixtures increased, the slope of the curve flattened out at the yield stress, suggesting that the flexibility of samples was optimized with the increase of paper sludge. When the proportion of paper sludge increased to 1% of the total weight, the slope of the curve over the yield point changed from −2.5 to −1, indicating a prominent enhancement of flexibility. Therefore, the stress-time curve was optimized when the paper sludge accounted for 20% of the total mixture weight.

Figure 7.

The stress curve of the slurry with the 50% proportion of PWM substituted for BFS.

3.3. Texture Change of PWM Slurry

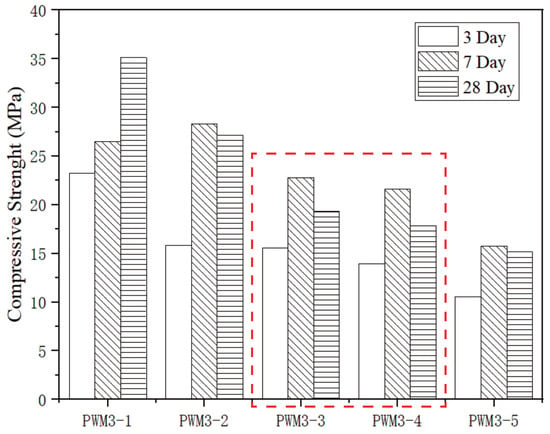

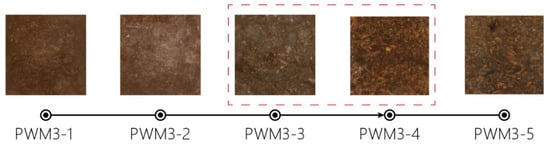

Considering the optimization of slurry texture and compressive strength, the wood chips were added to the slurry as seen in Table 4. Both wood chips and paper sludge improved the property of the stress-time curve. In addition, 5% of wood chips were used to gradually replace the paper sludge in the mixing proportion of up to 20% of the total weight. It can be seen from Figure 8 that when wood chips were added from 10% (PWM3-3) to 15% (PWM3-4) of the total weight, the compressive strength was at a steady stage (nearly 25 MPa), with both stony and woody textures starting to appear clearly on the surface of the mud (Figure 9). Considering the possibility of adding wood chips as decoration materials, it is appropriate to add 15% of wood chips and 5% of paper sludge to the mixture.

Table 4.

Experimental parameters of PWM3 series substitution proportion.

Figure 8.

The compressive strength of PWM3 series.

Figure 9.

The change of texture in terms of PWM.

3.4. Effect of Declining Alkali Equivalent

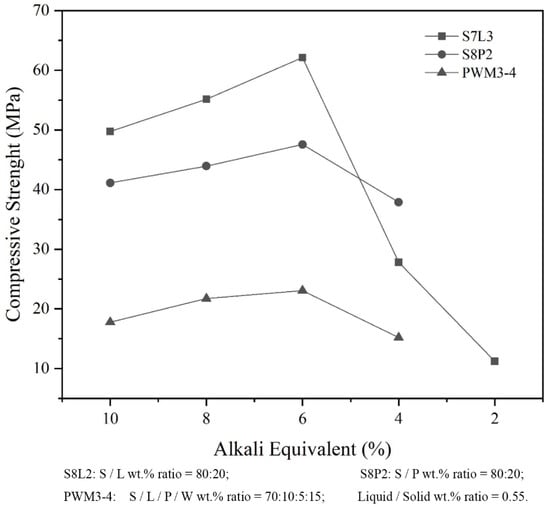

Given the simplified process for producing alkali-activated cementitious materials and the convenience of storing and transporting raw materials, only sodium silicate powder was used to prepare alkali activators in this study. Therefore, the silicate modulus (Ms) of alkali activators was a constant value and the ingredient of alkali activators could only be adjusted by AE. Considering the pulp waste proportion, the compressive strength, and the optimization of slurry texture, three kinds of slurries were selected as the samples to investigate the most suitable value of AE. Based on the results of the BFS substitution with waste mixtures in papermaking, the lime mud significantly improved the compressive strength of the slurry. Moreover, two SPW test groups and one PWM test group were used for AE adjustment. The waste substitutions were S7L3, S8L2, and PWM3-4. The content of AE in the activator decreased from 10% to 2%.

The effects of AE on the compressive strengths are shown in Figure 10. When the content of AE exceeded 6%, the compressive strength increased as the AE decreased. The reason was the presence of excessive hydroxyl ions in the slurry, which could form carbonate on the sample surface by evaporation of water [19]. In addition, this reaction led to the destruction of the colloidal structure. With 6% of AE, the compressive strength reached its peak. This result is consistent with the best AE interval in a previous study [30]. However, S8L2 and PWM3-4 failed to harden after 24 h and could not be de-molded. This result suggested that the alkalinity of the activator was not sufficient to fully stimulate the activity of the BFS and lime mud, resulting in a dramatic decrease in compressive strength. Since the AE was 6%, the compressive strength could approach more than 65 MPa after 28 days of curing.

Figure 10.

The effect of different AE on the compressive strength.

4. Conclusions

This study evaluated the potential of various wastes in papermaking to be alkali-activated as cementitious materials in terms of mechanical properties, flexibility, and sample texture. The results expanded the knowledge boundary of paper waste reuse and demonstrated the potential advantages of using papermaking wastes as building materials (e.g., toughness enhancement and wood texture). Some experimental data (e.g., 6% AE, 20% waste addition) can also be used as a reference for the actual transformation of wastes in papermaking. However, the experimental findings have limitations in terms of generalization because the compositions of papermaking wastes from different sources vary considerably. The conclusions of this study are as follows:

- (1)

- According to the experimental results, the compressive strength showed a huge span of 14.5~73.7 MPa after curing for 28 days. When the BFS was partially substituted by the same proportion of wastes, the compressive strength decreased sequentially from the lime mud, paper sludge, bottom ash, and wood chips. The effect of the mixture of the lime mud and paper sludge on the compressive strength showed that for every 5% reduction in the proportion of lime mud, the strength decreased by nearly 2.5 MPa.

- (2)

- From the stress-time curves, neither the lime mud nor the bottom ash contributed to the flexibility of the slurry. On the contrary, the paper sludge and wood chips significantly optimized the slurries. In order to strike a balance between the compressive strength and the flexibility proportion, 20% of the waste substitution should be preliminarily determined as the suitable proportion.

- (3)

- Considering the possibility of adding wood chips as decoration materials, 15% of wood chips and 5% of paper sludge are appropriate proportions in the mixture.

- (4)

- For the alkali-activated mixture of wastes and BFS, 6% of AE was the best ratio for the activator with the silicate modulus (Ms) fixed at 0.9.

Author Contributions

T.Y.: Conceptualization, Methodology, Formal analysis, Investigation, Data curation, Writing—original draft. S.-R.L.: Funding acquisition, Project administration, Supervision, Resources, Writing—review and editing. W.-Y.K.: Supervision, Resources, Writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Ministry of Education of Taiwan, grant number H108-AA09.

Data Availability Statement

Acknowledgments

We thank the CHP for materials provision, and NCKU C-Hub for space and instruments.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| BFS | blast furnace slag |

| SPW | the single-type papermaking wastes |

| PWM | the paper waste mixture |

| AE | alkali equivalent |

| Ms | silicate modulus |

| W/B | water-binder ratio |

| wt.% | weight percentage |

References

- Lombard, B. Cepi Preliminary Statistics Report 2021; Confederation of European Paper Industries: Brussels, Belgium, 2022; p. 2. Available online: https://www.cepi.org/statistics/ (accessed on 23 February 2022).

- Kilinc, M.B. Epicellulyse XT (Xerophilic Technology)-Paper Mill Sludge (Waste) to Energy & amp; Organic Fertilizer. Available online: https://sdgs.un.org/partnerships/epicellulyse-xt-xerophilic-technology-paper-mill-sludge-waste-energyorganic-fertilizer (accessed on 18 September 2022).

- Suhr, M.; Klein, G.; Kourti, I.; Gonzalo, M.R.; Santonja, G.G.; Roudier, S.; Sancho, L.D. Best Available Techniques (Bat) Reference Document for the Production of Pulp, Paper and Board; Publications Office of the European Union: Luxembourg, 2015; Volume 906. [Google Scholar]

- Monte, M.C.; Fuente, E.; Blanco, A.; Negro, C. Waste management from pulp and paper production in the European Union. Waste Manag. 2009, 29, 293–308. [Google Scholar] [CrossRef] [PubMed]

- Gavrilescu, D. Energy from biomass in pulp and paper mills. Environ. Eng. Manag. J. 2008, 7, 537–546. [Google Scholar] [CrossRef]

- Tarnawski, W. Emission factors for combustion of biomass fuels in the pulp and paper mills. Czas. Fibres Text. East. Eur. 2004, 12, 91–95. [Google Scholar]

- van Ewijk, S.; Park, J.Y.; Chertow, M. Quantifying the system-wide recovery potential of waste in the global paper life cycle. Resour. Conserv. Recycl. 2018, 134, 48–60. [Google Scholar] [CrossRef]

- Kaur, R.; Tyagi, R.D.; Zhang, X. Review on pulp and paper activated sludge pretreatment, inhibitory effects and detoxification strategies for biovalorization. Environ. Res. 2020, 182, 109094. [Google Scholar] [CrossRef] [PubMed]

- Martins, F.M.; Martins, J.M.; Ferracin, L.C.; da Cunha, C.J. Mineral phases of green liquor dregs, slaker grits, lime mud and wood ash of a Kraft pulp and paper mill. J. Hazard. Mater. 2007, 147, 610–617. [Google Scholar] [CrossRef]

- de Azevedo, A.R.G.; Alexandre, J.; Pessanha, L.S.P.; Manhães, R.d.S.T.; de Brito, J.; Marvila, M.T. Characterizing the paper industry sludge for environmentally-safe disposal. Waste Manag. 2019, 95, 43–52. [Google Scholar] [CrossRef]

- Buruberri, L.H.; Seabra, M.P.; Labrincha, J.A. Preparation of clinker from paper pulp industry wastes. J. Hazard. Mater. 2015, 286, 252–260. [Google Scholar] [CrossRef]

- Singh, S.K.; Singh, A.; Singh, B.; Vashistha, P. Application of thermo-chemically activated lime sludge in production of sustainable low clinker cementitious binders. J. Clean. Prod. 2020, 264, 121570. [Google Scholar] [CrossRef]

- Ferreiro, S.; Frías, M.; Vigil de la Villa, R.; Sánchez de Rojas, M.I. The influence of thermal activation of art paper sludge on the technical properties of blended Portland cements. Cem. Concr. Compos. 2013, 37, 136–142. [Google Scholar] [CrossRef]

- Ukrainczyk, N.; Vrbos, N.; Koenders, E.A.B. Reuse of woody biomass ash waste in cementitious materials. Chem. Biochem. Eng. Q. 2016, 30, 137–148. [Google Scholar] [CrossRef]

- Yi, T.; Liou, S.-R.; Kuo, W.-Y. The Interaction Effects of the Parameters on Optimization Design in Paper Production Waste Usage on Alkali-Activated Slag with Taguchi Method. J. Renew. Mater. 2022, 10, 1753–1772. [Google Scholar] [CrossRef]

- Wyrzykowski, M.; Ghourchian, S.; Sinthupinyo, S.; Chitvoranund, N.; Chintana, T.; Lura, P. Internal curing of high performance mortars with bottom ash. Cem. Concr. Compos. 2016, 71, 1–9. [Google Scholar] [CrossRef]

- Wang, S.-D.; Scrivener, K.L.S. Hydration products of alkali activated slag cement. Cem. Concr. Res. 1995, 25, 561–571. [Google Scholar] [CrossRef]

- Xu, H.; Van Deventer, J.S.J. The geopolymerisation of alumino-silicate minerals. Int. J. Miner. Process. 2000, 59, 247–266. [Google Scholar] [CrossRef]

- Chen, J.-H. Silicon-Contained Waste as a Raw Material of Inorganic Polymers. Ph. D. Thesis, National Cheng Kung University, Tainan City, Taiwan, 2009. [Google Scholar]

- Huang, K.; Fan, X.; Gan, M.; Ji, Z. Use of Municipal Solid Waste Incinerator (MSWI) Fly Ash in Alkali Activated Slag Cement. In Characterization of Minerals, Metals, and Materials 2019; Springer: Berlin/Heidelberg, Germany, 2019; pp. 401–410. [Google Scholar]

- Gao, X.; Yuan, B.; Yu, Q.L.; Brouwers, H.J.H. Characterization and application of municipal solid waste incineration (MSWI) bottom ash and waste granite powder in alkali activated slag. J. Clean. Prod. 2017, 164, 410–419. [Google Scholar] [CrossRef]

- Kang, S.-P.; Kwon, S.-J.J.C.; Materials, B. Effects of red mud and alkali-activated slag cement on efflorescence in cement mortar. Constr. Build. Mater. 2017, 133, 459–467. [Google Scholar] [CrossRef]

- Liu, G.; Florea, M.; Brouwers, H.J.H. Waste glass as binder in alkali activated slag–fly ash mortars. Mater. Struct. 2019, 52, 101. [Google Scholar] [CrossRef]

- Long, W.-J.; Tan, X.-W.; Xiao, B.-X.; Han, N.-X.; Xing, F. Effective use of ground waste expanded perlite as green supplementary cementitious material in eco-friendly alkali activated slag composites. J. Clean. Prod. 2019, 213, 406–414. [Google Scholar] [CrossRef]

- Choi, H.; Choi, Y.C. Setting characteristics of natural cellulose fiber reinforced cement composite. Constr. Build. Mater. 2021, 271, 121910. [Google Scholar] [CrossRef]

- Dai, X.; Aydin, S.; Yücel Yardimci, M.; Qiang, R.E.N.; Lesage, K.; De Schutter, G. Rheology, early-age hydration and microstructure of alkali-activated GGBFS-Fly ash-limestone mixtures. Cem. Concr. Compos. 2021, 124, 104244. [Google Scholar] [CrossRef]

- de Azevedo, A.R.G.; Alexandre, J.; Xavier, G.d.C.; Pedroti, L.G. Recycling paper industry effluent sludge for use in mortars: A sustainability perspective. J. Clean. Prod. 2018, 192, 335–346. [Google Scholar] [CrossRef]

- Saeli, M.; Senff, L.; Tobaldi, D.M.; Carvalheiras, J.; Seabra, M.P.; Labrincha, J.A. Unexplored alternative use of calcareous sludge from the paper-pulp industry in green geopolymer construction materials. Constr. Build. Mater. 2020, 246, 118457. [Google Scholar] [CrossRef]

- Silva, G.; Kim, S.; Bertolotti, B.; Nakamatsu, J.; Aguilar, R.J.C.; Materials, B. Optimization of a reinforced geopolymer composite using natural fibers and construction wastes. Constr. Build. Mater. 2020, 258, 119697. [Google Scholar] [CrossRef]

- Shi, C.; Roy, D.; Krivenko, P. Alkali-Activated Cements and Concretes; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).