Independent User Circular Behaviors and Their Motivators and Barriers: A Review

Abstract

1. Introduction

2. Literature Review

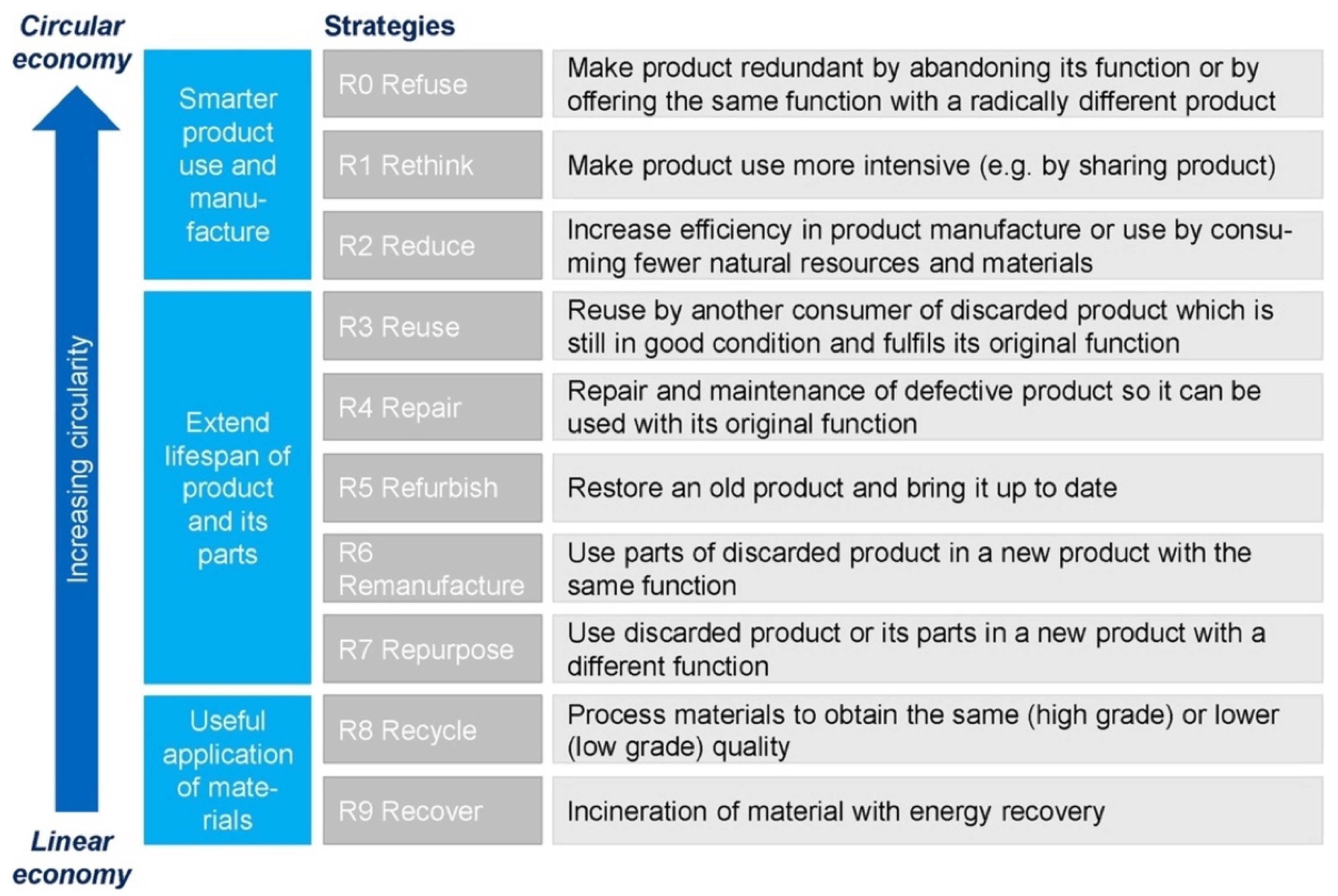

2.1. Behaviors Related to the R Frameworks

- During product use, users are expected to take care of the product by themselves or through engagement with the company’s after-sales services (such as life extension services). In addition, users are expected to provide the company with information about the state of the product at the start of its use (to confirm that the previous user left the product in a good condition) and during its use (to make the provider aware of any damage or need for maintenance). Wastling et al. [7] also identified two behaviors to be avoided: using the product for tasks other than the ones it was designed for (misuse), and any behavior that could destroy the product (damaging).

- At the end of use: it is desired that users return the product on time and in a satisfactory condition for the next use. Moreover, users’ assistance with reverse logistics might be required. For instance, instead of collecting the product from the user, the company might demand that the user take the product to a post office [7].

2.2. Behaviors beyond the 9R Framework

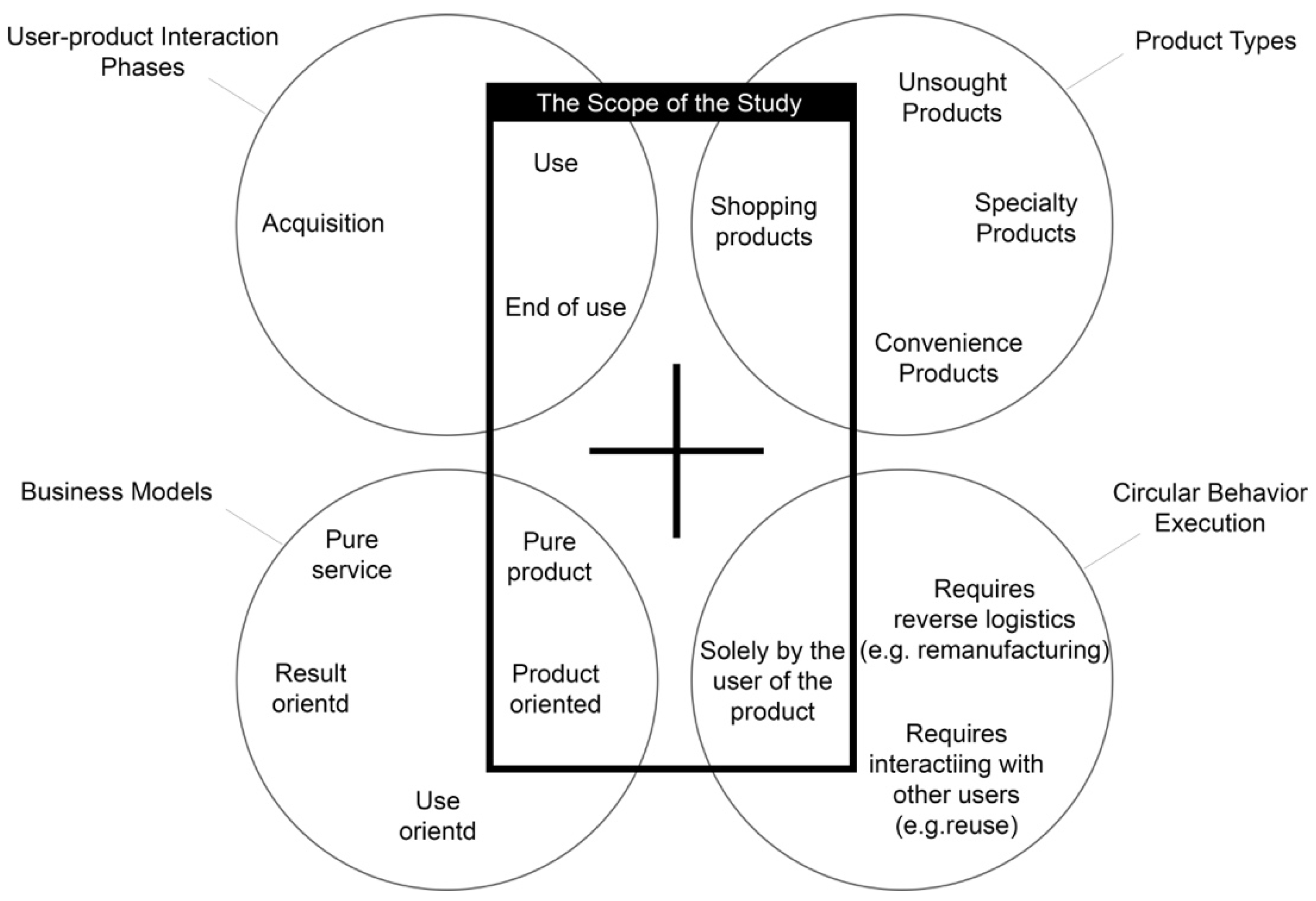

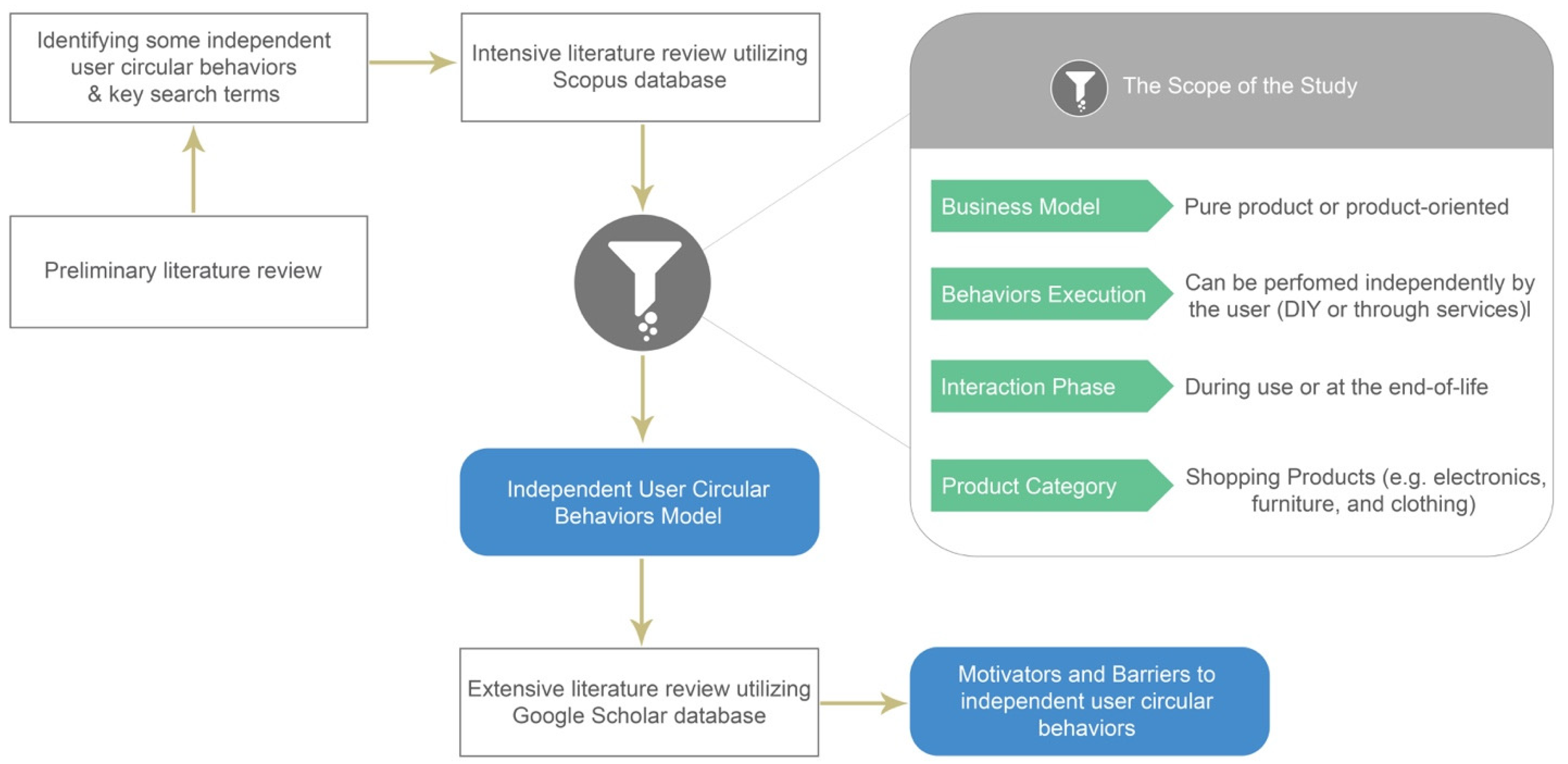

3. Methods

3.1. Independent User Circular Behaviors

- Care: to conduct maintenance, repair, or any preventive or protective measure aiming to prolong the product’s lifespan [31,42]. We decided to use ‘care’ instead of the activities it includes (mainly repair and maintenance), to have our work aligned with the recent research by Ackermann [31], Ackermann et al. [42], and Ackermann et al. [49] who took a user perspective approach to explore product care within the realm of a Circular Economy. We believe that building on their work would contribute to the coherence and the convergence of the Circular Economy terminology. Moreover, by using the term ‘care’ we aim to avoid the confusion that may arise from using the activities it encompasses (repair and maintenance) instead. That is because in the 9R framework and the butterfly diagram, “maintenance” is not a proactive action—but ‘maintain’, the user behavior, is [5,22].

- Appreciate: to continue using a functioning, energy-efficient product as is. It is important to mention that we are proposing this new concept to describe this specific behavior to distinguish it from (a) the behavior of postponing product replacement through care or upgrade, and (b) the environmentally undesirable retention of energy-guzzling products [50]. To appreciate the product is basically to resist phycological obsolescence, which arises when the user ceases to find a symbolic or aesthetic value in the product [50] because of a change in the perceived needs of the user [41].

- Repurpose: to reuse the product, its materials, or components, as is or after transformation, to serve a new purpose when the product can no longer fulfill its original purpose. It should be noted that this definition includes only end-of-life repurposing.

3.2. The Motivators and the Barriers

3.2.1. Identification

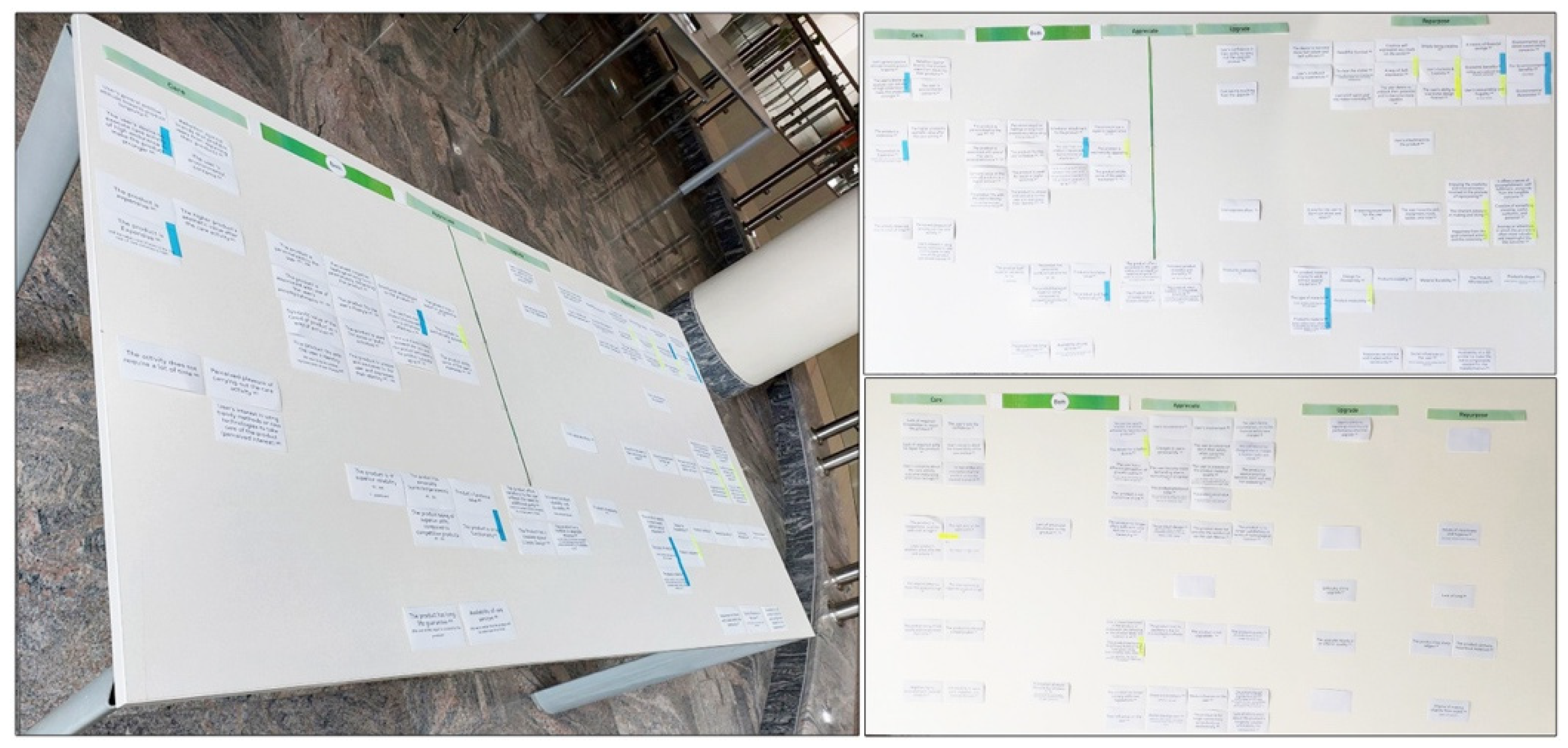

3.2.2. Clustering and Synthesis

4. Results and Discussion

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Galvão, G.D.A.; Nadae, J.; Clemente, D.; Chinen, G.; de Carvalho, M.M. Circular Economy: Overview of Barriers. Procedia CIRP 2018, 73, 79–85. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The circular economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A Review on Circular Economy: The Expected Transition to a Balanced Interplay of Environmental and Economic Systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation (EMF), 2013, Towards the Circular Economy, Volume 1. Available online: https://emf.thirdlight.com/link/x8ay372a3r11-k6775n/@/preview/1?o (accessed on 5 February 2022).

- Parajuly, K.; Fitzpatrick, C.; Muldoon, O.; Kuehr, R. Behavioral change for the circular economy: A review with focus on electronic waste management in the EU. Resour. Conserv. Recycl. X 2020, 6, 100035. [Google Scholar] [CrossRef]

- Wastling, T.; Charnley, F.; Moreno, M. Design for Circular Behaviour: Considering Users in a Circular Economy. Sustainability 2018, 10, 1743. [Google Scholar] [CrossRef]

- Gainforth, H.L.; Sheals, K.; Atkins, L.; Jackson, R.; Michie, S. Developing interventions to change recycling behaviors: A case study of applying behavioral science. Appl. Environ. Educ. Commun. 2016, 15, 325–339. [Google Scholar] [CrossRef]

- Hazen, B.; Mollenkopf, D.A.; Wang, Y. Remanufacturing for the Circular Economy: An Examination of Consumer Switching Behavior. Bus. Strat. Environ. 2016, 26, 451–464. [Google Scholar] [CrossRef]

- Terzioğlu, N. Repair motivation and barriers model: Investigating user perspectives related to product repair towards a circular economy. J. Clean. Prod. 2021, 289, 125644. [Google Scholar] [CrossRef]

- Testa, F.; Iovino, R.; Iraldo, F. The circular economy and consumer behaviour: The mediating role of information seeking in buying circular packaging. Bus. Strat. Environ. 2020, 29, 3435–3448. [Google Scholar] [CrossRef]

- Corsini, F.; Gusmerotti, N.; Frey, M. Consumer’s Circular Behaviors in Relation to the Purchase, Extension of Life, and End of Life Management of Electrical and Electronic Products: A Review. Sustainability 2020, 12, 10443. [Google Scholar] [CrossRef]

- Bucklin, L.P. Retail Strategy and the Classification of Consumer Goods. J. Mark. 1963, 27, 50–55. [Google Scholar] [CrossRef]

- Claessens, M. 4 Types of Consumer Products and Marketing Considerations—Convenience, Shopping, Specialty and Unsought Products. Marketing-Insider. 2017. Available online: https://marketing-insider.eu/4-types-of-consumer-products/ (accessed on 21 February 2022).

- Tukker, A. Eight types of product–service system: Eight ways to sustainability? Experiences from SusProNet. Bus. Strat. Environ. 2004, 13, 246–260. [Google Scholar] [CrossRef]

- Cramer, J. Moving towards a Circular Economy in The Netherlands: Challenges and Directions. Proceedings van The HKIE Environmental Division Annual Forum, The Future Directions and Breakthroughs of Hong Kong’s Environmental Industry. 2015. Available online: https://openresearch.amsterdam/image/2020/6/11/moving_towards_a_circular_economy_in_the_netherlands_april2015.pdf (accessed on 4 March 2022).

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain Policy Report. 2017. Available online: https://www.pbl.nl/sites/default/files/downloads/pbl-2016-circular-economy-measuring-innovation-in-product-chains-2544.pdf (accessed on 2 March 2022).

- Mangla, S.K.; Börühan, G.; Ersoy, P.; Kazancoglu, Y.; Song, M. Impact of information hiding on circular food supply chains in business-to-business context. J. Bus. Res. 2021, 135, 1–18. [Google Scholar] [CrossRef]

- Malinauskaite, J.; Jouhara, H.; Czajczyńska, D.; Stanchev, P.; Katsou, E.; Rostkowski, P.; Thorne, R.; Colón, J.; Ponsá, S.; Al-Mansour, F.; et al. Municipal solid waste management and waste-to-energy in the context of a circular economy and energy recycling in Europe. Energy 2017, 141, 2013–2044. [Google Scholar] [CrossRef]

- Ragossnig, A.M.; Schneider, D.R. Circular economy, recycling and end-of-waste. Waste Manag. Res. J. Sustain. Circ. Econ. 2019, 37, 109–111. [Google Scholar] [CrossRef]

- Marino, A.; Pariso, P. Comparing European countries’ performances in the transition towards the Circular Economy. Sci. Total Environ. 2020, 729, 138142. [Google Scholar] [CrossRef]

- Morseletto, P. Targets for a circular economy. Resour. Conserv. Recycl. 2020, 153, 104553. [Google Scholar] [CrossRef]

- Konietzko, J.; Bocken, N.; Hultink, E.J. Circular ecosystem innovation: An initial set of principles. J. Clean. Prod. 2020, 253, 119942. [Google Scholar] [CrossRef]

- Michelini, G.; Moraes, R.N.; Cunha, R.N.; Costa, J.M.; Ometto, A.R. From Linear to Circular Economy: PSS Conducting the Transition. Procedia CIRP 2017, 64, 2–6. [Google Scholar] [CrossRef]

- Yan, J.; Feng, C. Sustainable design-oriented product modularity combined with 6R concept: A case study of rotor laboratory bench. Clean Technol. Environ. Policy 2014, 16, 95–109. [Google Scholar] [CrossRef]

- Sihvonen, S.; Ritola, T. Conceptualizing ReX for Aggregating End-of-life Strategies in Product Development. Procedia CIRP 2015, 29, 639–644. [Google Scholar] [CrossRef]

- Nasr, N.; Thurston, M. Remanufacturing: A Key Enabler to Sustainable Product Systems. 2006. Available online: https://www.mech.kuleuven.be/lce2006/key4.pdf (accessed on 18 March 2022).

- Lüdeke-Freund, F.; Gold, S.; Bocken, N.M.P. A Review and Typology of Circular Economy Business Model Patterns. J. Ind. Ecol. 2018, 23, 36–61. [Google Scholar] [CrossRef]

- Schenkel, M.; Caniëls, M.; Krikke, H.; van der Laan, E. Understanding value creation in closed loop supply chains—Past findings and future directions. J. Manuf. Syst. 2015, 37, 729–745. [Google Scholar] [CrossRef]

- Bakker, C.; den Hollander, M.; Hinte, V. Products That Last, 1st ed.; BIS Publishers B.V.: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Ackermann, L. Design for Product Care: Enhancing Consumers’ Repair and Maintenance Activities. Des. J. 2018, 21, 543–551. [Google Scholar] [CrossRef]

- Haines-Gadd, M.; Chapman, J.; Lloyd, P.; Mason, J.; Aliakseyeu, D. Emotional Durability Design Nine—A Tool for Product Longevity. Sustainability 2018, 10, 1948. [Google Scholar] [CrossRef]

- Aguirre, D. Design for Repurposing: A Sustainable Design Strategy for Product Life and Beyond. 2010. Available online: https://www.idsa.org/sites/default/files/DesignForRepurposing.pdf (accessed on 6 April 2022).

- Ali, M.I.M.; Shaukat, M.M.; Merah, N.; Pashah, S. Product repurposing: Typology and design considerations. J. Innov. Sustain. RISUS 2020, 11, 18–32. [Google Scholar] [CrossRef]

- Scott, K.A.; Weaver, S.T. The Intersection of Sustainable Consumption and Anticonsumption: Repurposing to Extend Product Life Spans. J. Public Policy Mark. 2018, 37, 291–305. [Google Scholar] [CrossRef]

- Bridgens, B.; Powell, M.; Farmer, G.; Walsh, C.; Reed, E.; Royapoor, M.; Gosling, P.; Hall, J.; Heidrich, O. Creative upcycling: Reconnecting people, materials and place through making. J. Clean. Prod. 2018, 189, 145–154. [Google Scholar] [CrossRef]

- Sung, K.; Candidate Cooper, T.; Kettley, S. Individual Upcycling Practice: Exploring the Possible Determinants of Upcycling Based on a Literature Review—Kyungeun Sung. 2014. Available online: http://irep.ntu.ac.uk/id/eprint/2559/1/217970_1133.pdf (accessed on 9 April 2022).

- Lai, S.-L.; Shu, L. Do-it-yourselfers as Lead users for Environmentally Conscious Behavior. Procedia CIRP 2014, 15, 431–436. [Google Scholar] [CrossRef][Green Version]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Mugge, R.; Schoormans, J.P.L.; Schifferstein, H.N.J. Design Strategies to Postpone Consumers’ Product Replacement: The Value of a Strong Person-Product Relationship. Des. J. 2005, 8, 38–48. [Google Scholar] [CrossRef]

- Khan, M.A.; Mittal, S.; West, S.; Wuest, T. Review on upgradability—A product lifetime extension strategy in the context of product service systems. J. Clean. Prod. 2018, 204, 1154–1168. [Google Scholar] [CrossRef]

- Ackermann, L.; Mugge, R.; Schoormans, J. Consumers’ perspective on product care: An exploratory study of motivators, ability factors, and triggers. J. Clean. Prod. 2018, 183, 380–391. [Google Scholar] [CrossRef]

- Laitala, K.; Klepp, I.G.; Haugrønning, V.; Throne-Holst, H.; Strandbakken, P. Increasing repair of household appliances, mobile phones and clothing: Experiences from consumers and the repair industry. J. Clean. Prod. 2021, 282, 125349. [Google Scholar] [CrossRef]

- Siddaway, A.P.; Wood, A.M.; Hedges, L.V. How to Do a Systematic Review: A Best Practice Guide for Conducting and Reporting Narrative Reviews, Meta-Analyses, and Meta-Syntheses. Annu. Rev. Psychol. 2019, 70, 747–770. [Google Scholar] [CrossRef]

- Paul, J.; Lim, W.M.; O’Cass, A.; Hao, A.W.; Bresciani, S. Scientific procedures and rationales for systematic literature reviews (SPAR-4-SLR). Int. J. Consum. Stud. 2021, 45, O1–O16. [Google Scholar] [CrossRef]

- Green, B.N.; Johnson, C.D.; Adams, A. Writing narrative literature reviews for peer-reviewed journals: Secrets of the trade. J. Chiropr. Med. 2006, 5, 101–117. [Google Scholar] [CrossRef]

- Thelwall, M.; Sud, P. Scopus 1900–2020: Growth in articles, abstracts, countries, fields, and journals. Quant. Sci. Stud. 2022, 3, 37–50. [Google Scholar] [CrossRef]

- Moreno, M.; De los Rios, C.; Rowe, Z.; Charnley, F. A Conceptual Framework for Circular Design. Sustainability 2016, 8, 937. [Google Scholar] [CrossRef]

- Ackermann, L.; Schoormans, J.P.; Mugge, R. Measuring consumers’ product care tendency: Scale development and validation. J. Clean. Prod. 2021, 295, 126327. [Google Scholar] [CrossRef]

- van Nes, N.; Cramer, J. Influencing product lifetime through product design. Bus. Strat. Environ. 2005, 14, 286–299. [Google Scholar] [CrossRef]

- Jensen, P.B.; Laursen, L.N.; Haase, L.M. Barriers to product longevity: A review of business, product development and user perspectives. J. Clean. Prod. 2021, 313, 127951. [Google Scholar] [CrossRef]

- Mugge, R.; Schifferstein, H.N.J.; Schoormans, J.P.L. A longitudinal study of product attachment and its deter-minants. ACR Eur. Adv. 2005, 7, 641. Available online: https://www.acrwebsite.org/volumes/13712/eacr/vol7/E-07 (accessed on 16 April 2022).

- Ülkü, S.; Dimofte, C.V.; Schmidt, G.M. Consumer Valuation of Modularly Upgradeable Products. Manag. Sci. 2012, 58, 1761–1776. [Google Scholar] [CrossRef]

- Kuusinen, K.; Sørensen, M.K.; Frederiksen, N.M.; Laugesen, N.K.; Juul, S.H. From Startup to scaleup: An interview study of the development of user experience work in a data-intensive company. In Human-Centered Software Engineering; Springer International Publishing: Berlin/Heidelberg, Germany, 2019; pp. 3–14. [Google Scholar] [CrossRef]

- Merriam-Webster Dictionary. Definition of CURA. Available online: https://www.merriam-webster.com/dictionary/cura (accessed on 23 May 2022).

- Shah, V. The Circular Economy’s Trillion-Dollar Opportunity. Eco-Business. 2014. Available online: https://www.eco-business.com/news/circular-economys-trillion-dollar-opportunity (accessed on 20 May 2022).

| Independent User Circular Behavior | Papers |

|---|---|

| Care | Ackermann’s [31]; Ackermann et al.’s [42]; Terzioğlu’s [10]; Laitala et al.’s [43] |

| Appreciate | Mugge et al.’s [40]; Mugge et al.’s [52]; Haines-Gadd et al.’s [32]; van Nes and Cramer’s [50]; Jensen et al.’s [51] |

| Upgrade | Ülkü et al.’s [53] |

| Repurpose | Aguirre’s [33], Lai and Shu’s [38], Bridgens et a.’s [36], Sung et al.’s [37], Scott and Weaver’s [35] |

| Factors | Independent User Circular Behaviors | |||||

|---|---|---|---|---|---|---|

| Care | Appreciate | Upgrade | Repurpose | |||

| User-related | Motivators | Positive attitude towards product longevity and the desire to achieve it through care activities | ||||

| Rebellion against brand policies that restrain users from performing some care activities on their own | ||||||

| The user is environmentally conscious | ||||||

| The user is confident in their ability to make the upgrade | ||||||

| The user is economical | ||||||

| User’s desire to become more self-reliant | ||||||

| Necessity | ||||||

| For self-expression | ||||||

| User’s creativity | ||||||

| User’s childhood experiences of making things | ||||||

| A way to clear the clutter | ||||||

| The user’s DIY spirit | ||||||

| Barriers | The user lacks confidence in his or her ability to perform the care activity | |||||

| User’s concerns about the irreversibility of the care method | ||||||

| User’s concerns about the outcome endurance and future damages | ||||||

| User’s assumption that the product cannot be cared of | ||||||

| User’s innovativeness | ||||||

| Changes in user’s personal life | ||||||

| Changes in user’s financial ability | ||||||

| The user desires have changed due to technological progress and changes in fashion trends | ||||||

| The user does not appreciate the product’s aging look | ||||||

| The product has become aesthetically unappealing | ||||||

| User’s concerns about the product’s reliability after the upgrade | ||||||

| Factors | Independent User Circular Behaviors | |||||

|---|---|---|---|---|---|---|

| Care | Appreciate | Upgrade | Repurpose | |||

| User-product related | Motivators | The product is expensive | ||||

| The increase in the perceived aesthetic value of the product after the care activity | ||||||

| The product is personalized to the user | ||||||

| Perceived negative feelings from premature product discard | ||||||

| The product is aesthetically appealing | ||||||

| The product is associated with one of the user’s accomplishments | ||||||

| The product represents the user’s lifestyle | ||||||

| The symbolic value of the cared of product as a way of activism | ||||||

| The product is used for social or joyful activities | ||||||

| The product’s graceful aging which embodies the user-product history | ||||||

| The product evokes some of the user’s memories | ||||||

| The product is of high utility | ||||||

| User’s emotional attachment to the product | ||||||

| Barriers | The product is inexpensive, and the care cost is high | |||||

| The decrease in the perceived aesthetic value of the product after the care activity | ||||||

| The product is unfashionable | ||||||

| Lack of emotional attachment to the product | ||||||

| The user finds no social value in the product | ||||||

| The product design is inferior to competitive products | ||||||

| The product does not provide the comfort of use the user desires | ||||||

| Avoiding the interaction with a contaminated product | ||||||

| Factors | Independent User Circular Behaviors | |||||

|---|---|---|---|---|---|---|

| Care | Appreciate | Upgrade | Repurpose | |||

| User-process-related | Motivators | User’s interest in using trendy methods or new technologies to take care of the product | ||||

| The perceived pleasure from performing the activity | ||||||

| The activity does not require a lot of time | ||||||

| The required effort is low | ||||||

| The user has the required resources to perform the behavior | ||||||

| To reduce stress and relax | ||||||

| To learn something new | ||||||

| Barriers | A sense of accomplishment from creating something original and personal | |||||

| The user does not have the time required | ||||||

| The user does not have the required knowledge for the care activity | ||||||

| The required effort is high | ||||||

| The upgrade process is difficult to execute | ||||||

| Factors | Independent User Circular Behaviors | |||||

|---|---|---|---|---|---|---|

| Care | Appreciate | Upgrade | Repurpose | |||

| Product-related | Motivators | The product is of high reliability | ||||

| The product has personality | ||||||

| The product is of high functionality | ||||||

| The product is new | ||||||

| The product material ages gracefully | ||||||

| The product can be configured in various ways without needing extra parts | ||||||

| The product is highly durable | ||||||

| The product has a classic design | ||||||

| The product is modular | ||||||

| The product material is easy to work with | ||||||

| The product is designed for disassembly | ||||||

| The product is portable | ||||||

| Product affordances | ||||||

| Barriers | The product is of low quality | |||||

| The product is of low reliability | ||||||

| The product is old | ||||||

| The product quality is inferior to competitive products | ||||||

| The upgrade results in a product of an inferior quality | ||||||

| The product has sharp edges | ||||||

| The product contains hazardous materials or components | ||||||

| Factors | Independent User Circular Behaviors | |||||

|---|---|---|---|---|---|---|

| Care | Appreciate | Upgrade | Repurpose | |||

| Situational | Motivators | The product has a long-life guarantee or warranty | ||||

| Availability of care services | ||||||

| Sharing and/or trading resources within the community is facilitated | ||||||

| Social influences on the user | ||||||

| Availability of a 3D printer to make the extra components | ||||||

| Barriers | Inaccessibility to original spare parts, materials, and methods required to exhibit care behavior | |||||

| The stigma associated with repaired products | ||||||

| Low cost of new products | ||||||

| Promotion of frequent replacements by the selling company | ||||||

| The product no longer complies with new legislations | ||||||

| Media influence on the user | ||||||

| Social influences on the user | ||||||

| Advances in the market and the introduction of new, similar products with more features and better designs | ||||||

| The product is no longer satisfactory symbolically | ||||||

| lack of information about the product’s lifetime | ||||||

| The stigma toward making objects from waste | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, M.I.M.; Choe, P. Independent User Circular Behaviors and Their Motivators and Barriers: A Review. Sustainability 2022, 14, 13319. https://doi.org/10.3390/su142013319

Ali MIM, Choe P. Independent User Circular Behaviors and Their Motivators and Barriers: A Review. Sustainability. 2022; 14(20):13319. https://doi.org/10.3390/su142013319

Chicago/Turabian StyleAli, Mohammed I. M., and Pilsung Choe. 2022. "Independent User Circular Behaviors and Their Motivators and Barriers: A Review" Sustainability 14, no. 20: 13319. https://doi.org/10.3390/su142013319

APA StyleAli, M. I. M., & Choe, P. (2022). Independent User Circular Behaviors and Their Motivators and Barriers: A Review. Sustainability, 14(20), 13319. https://doi.org/10.3390/su142013319