Feasibility of Applying Mel-Frequency Cepstral Coefficients in a Drive-by Damage Detection Methodology for High-Speed Railway Bridges

Abstract

1. Introduction

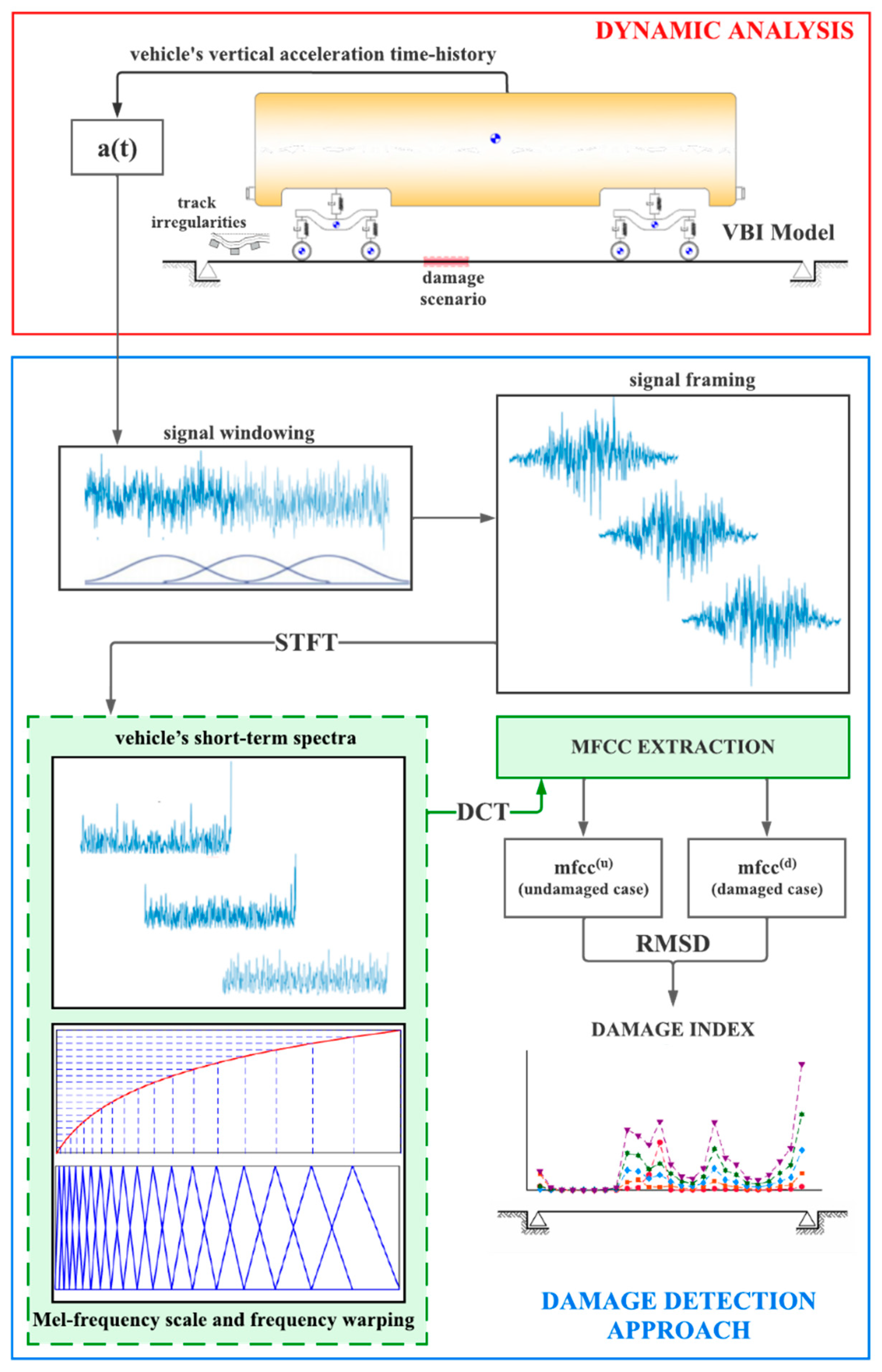

2. Methodology

2.1. Vehicle-Track-Bridge Dynamic Interaction System

2.1.1. Vehicle Model

2.1.2. Track Model

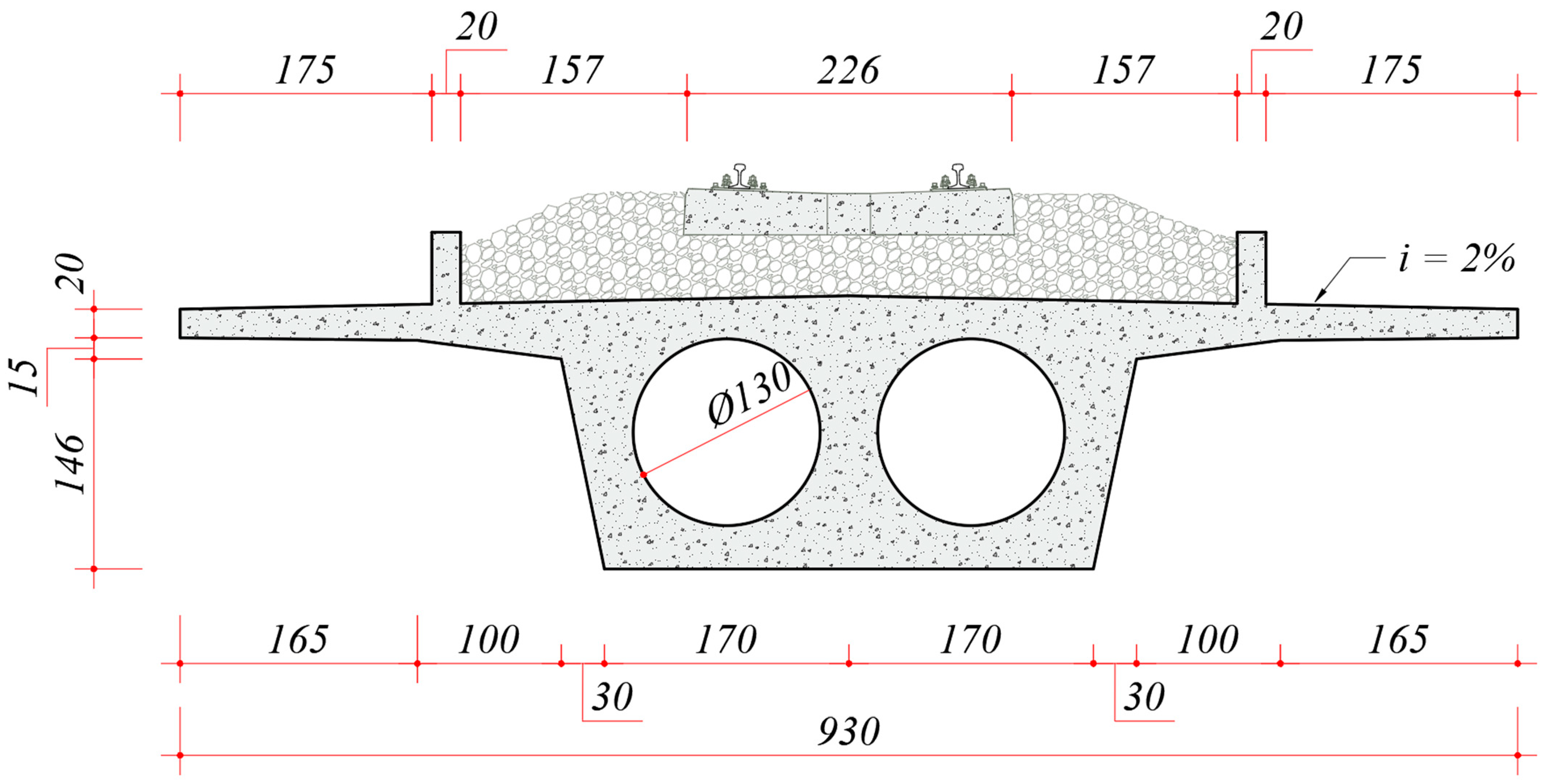

2.1.3. Bridge Model

2.1.4. Equations of Motion for the VTBI System

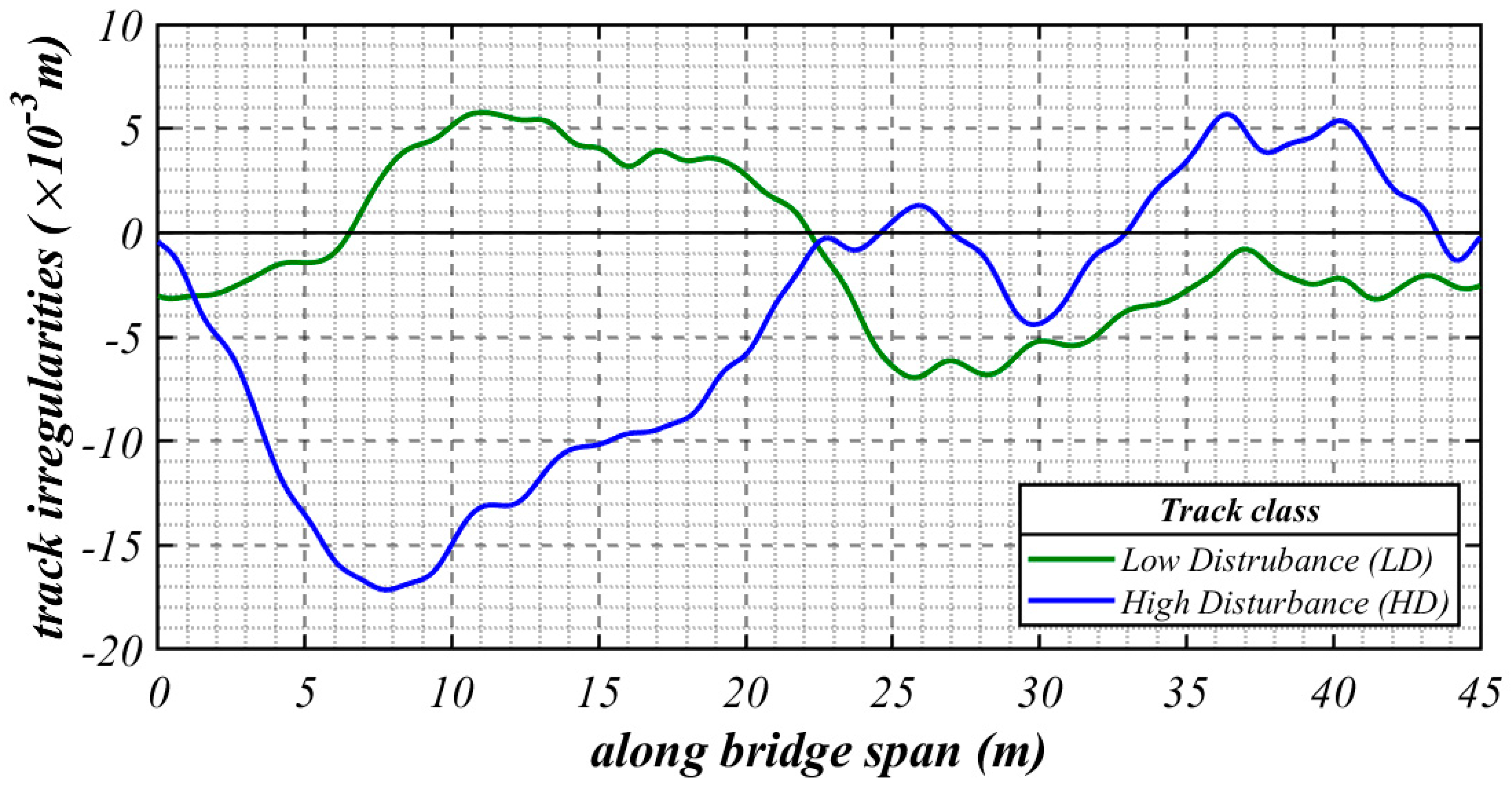

2.2. Irregularity of Track Vertical Profile

2.3. Drive-by Damage Detection Using MFCC

2.3.1. Vehicle’s Acceleration Segmentation Short-Term Spectra

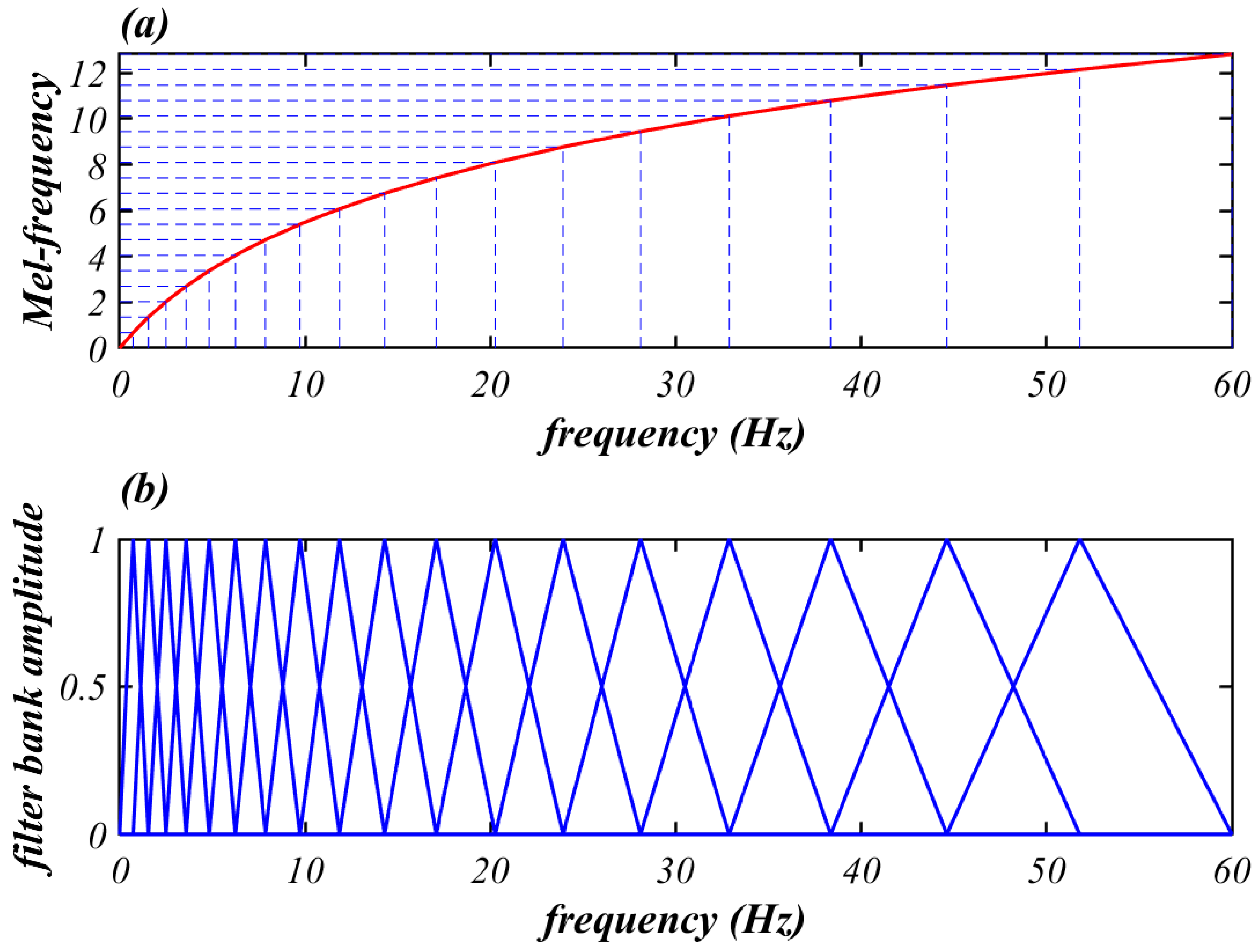

2.3.2. Adapted Mel-Frequency Scale and Frequency Warping

2.3.3. Mel-Frequency Cepstral Coefficients (MFCC)

2.3.4. Damage Index

3. Numerical Simulations: Results and Discussion

3.1. Dynamic Analysis

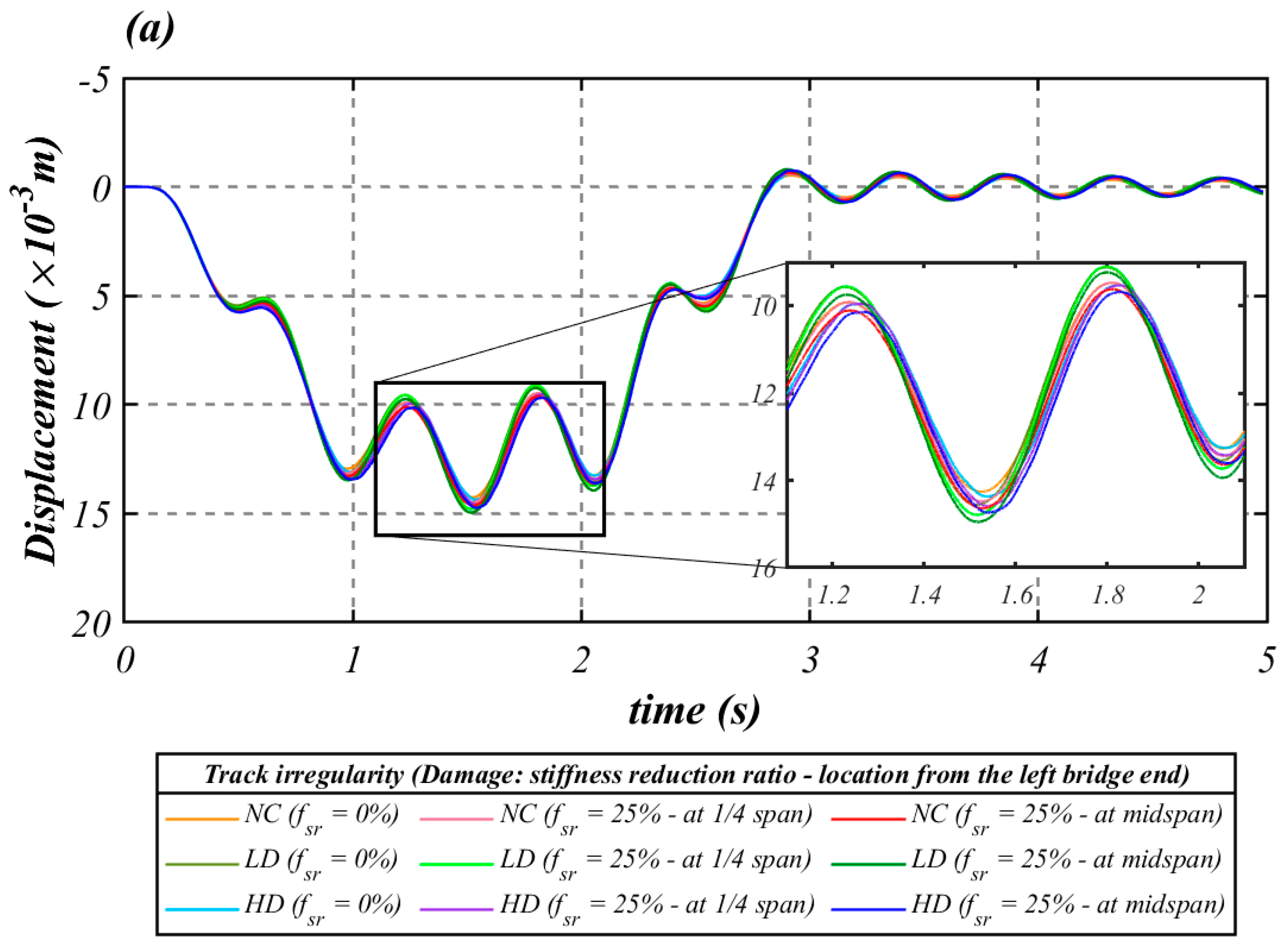

3.1.1. Bridge Response

3.1.2. Vehicle Response

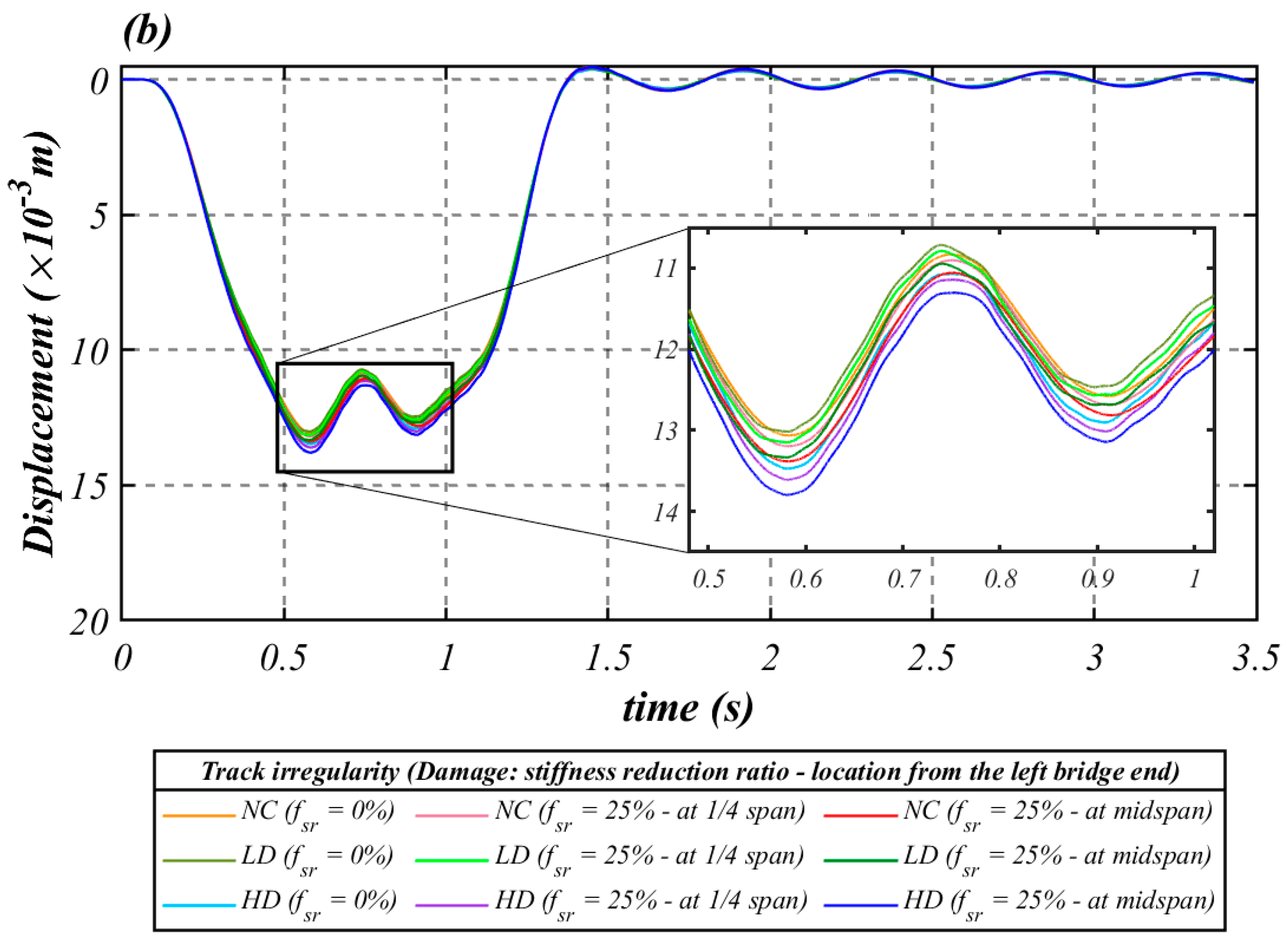

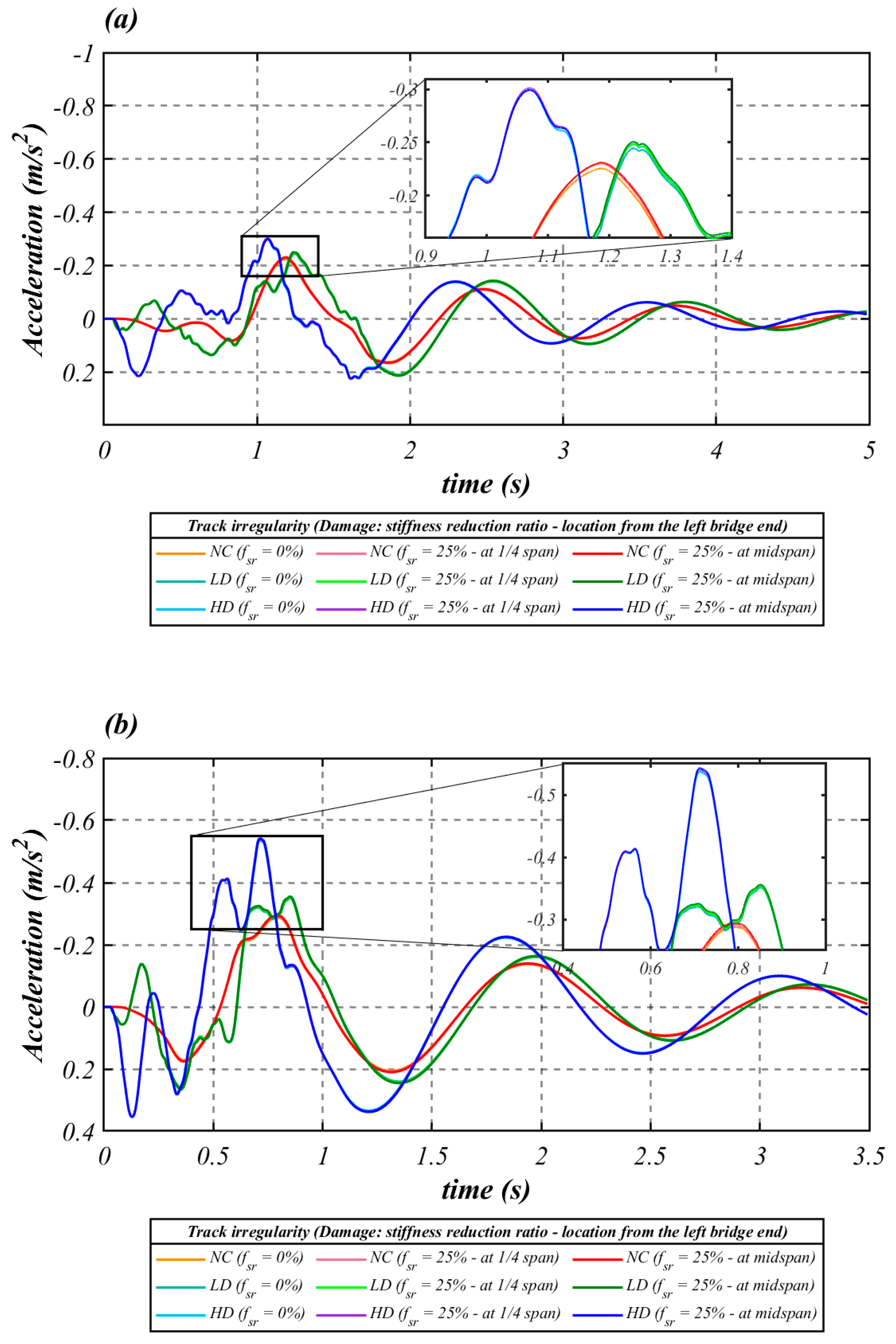

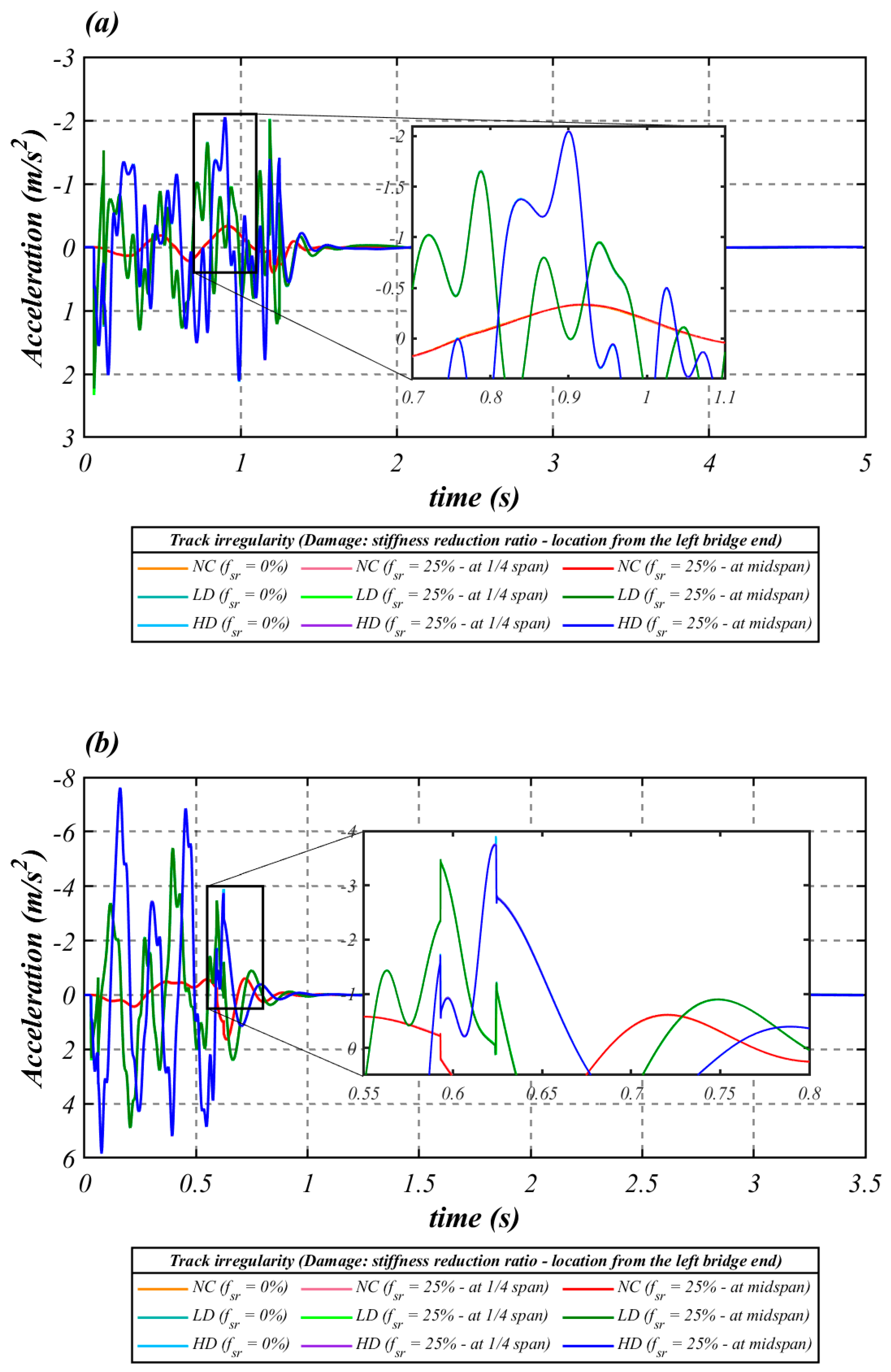

- As shown in Figure 9, different damage conditions are not visibly distinguished by the bogie responses. However, due to the reduction provided by the secondary suspension system in both the frequencies and the amplitude of the carbody’s responses relative to those of the bogie, different damage conditions were picked up by the car body’s vertical accelerations, albeit subtly. For this reason, the methodology proposed in this paper was applied, concerning the carbody accelerations.

- Figure 8a,b shows that the differences between the responses to damage severity become less apparent with increasing speed. This aspect represents the main challenge to be overcome in developing vibration-based drive-by damage detection methodologies for indirect SHM of HSR bridges.

3.2. Performance of the Proposed Drive-by Damage Detection Using MFCC

- The output dataset corresponding to the time-histories of the carbody’s vertical acceleration recorded at each case were corrupted by 5% white noise, to simulate the effect of measurement disturbances.

- No bandpass filters were used in the signal processing, since this procedure is already covered in the frequency warping stage, with the filter bank application.

- The filter bank was configured with 50 triangular filters, whose corresponding 50 frequency values in Hertz, equally spaced on a Mel-frequency scale, had a cut-off frequency of 60 Hz.

- For the segmentation/windowing of the carbody’s signal recorded, the STFT was set up with a window function length of samples (22 frames) to guarantee enough segments for damage identification on the bridge. Moreover, as the window functions taper off at the edges to avoid spectral ringing, the corresponding overlapping used was 34/64 of the windowing length.

Damage Detection Performance

4. Conclusions and Prospects

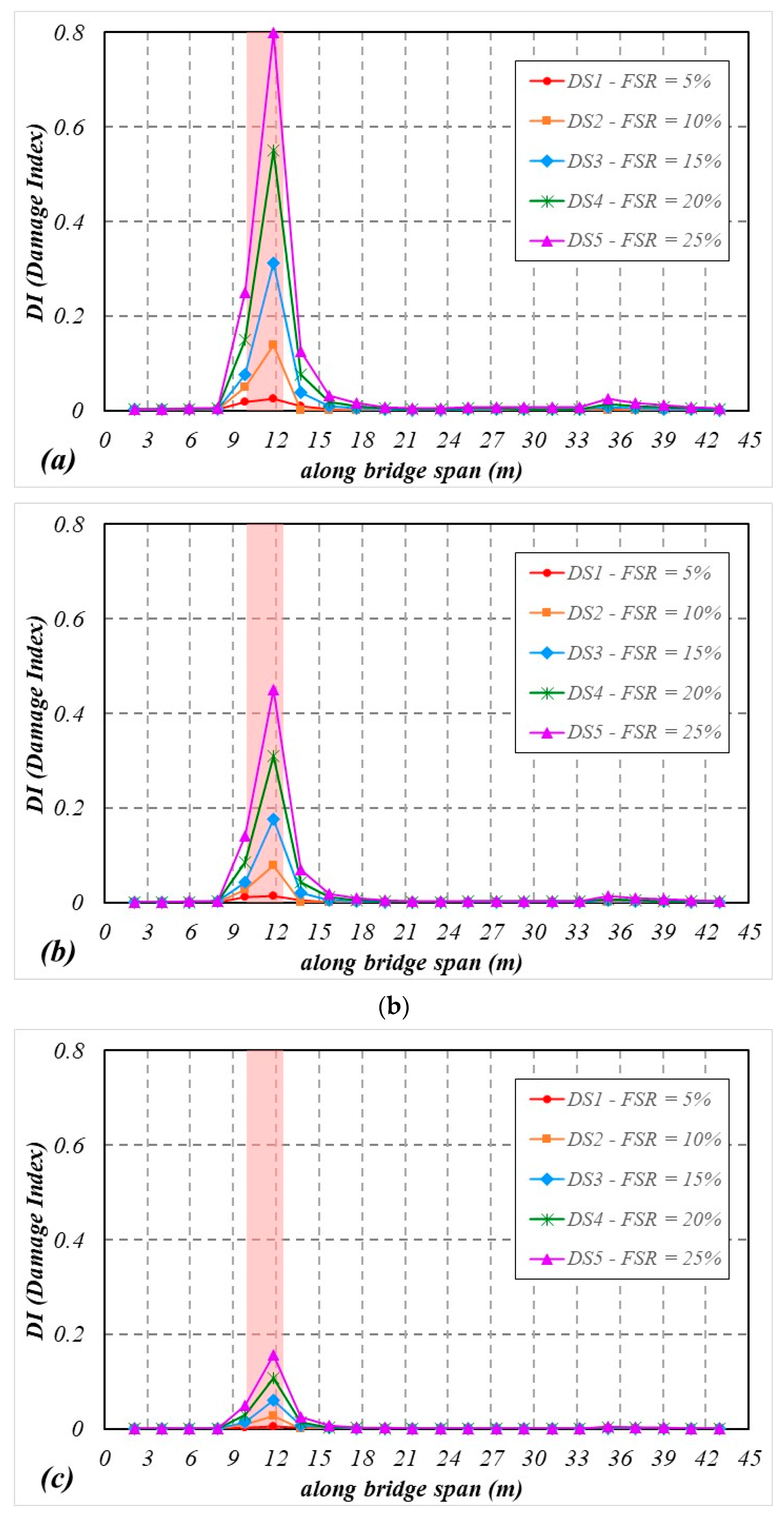

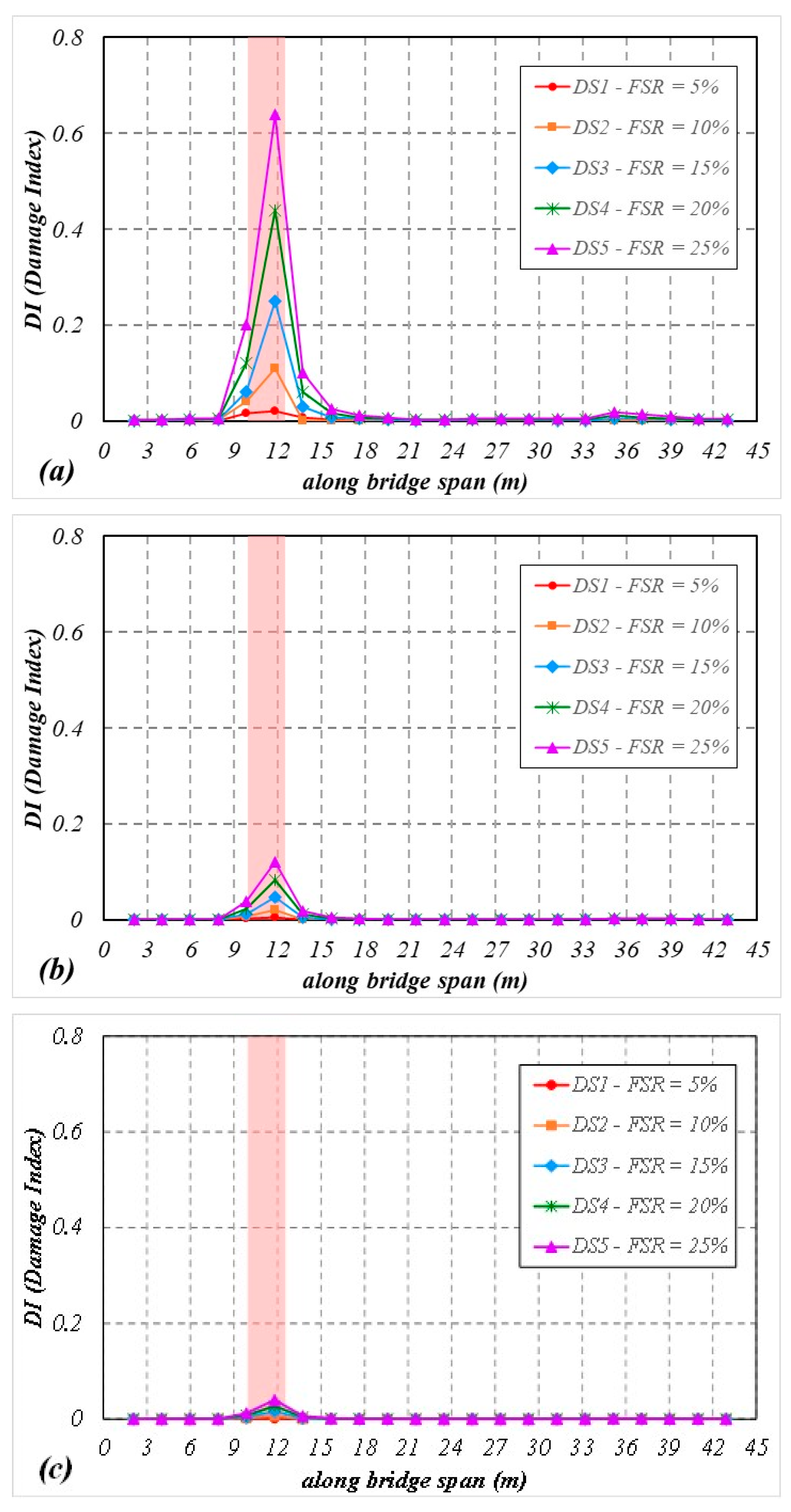

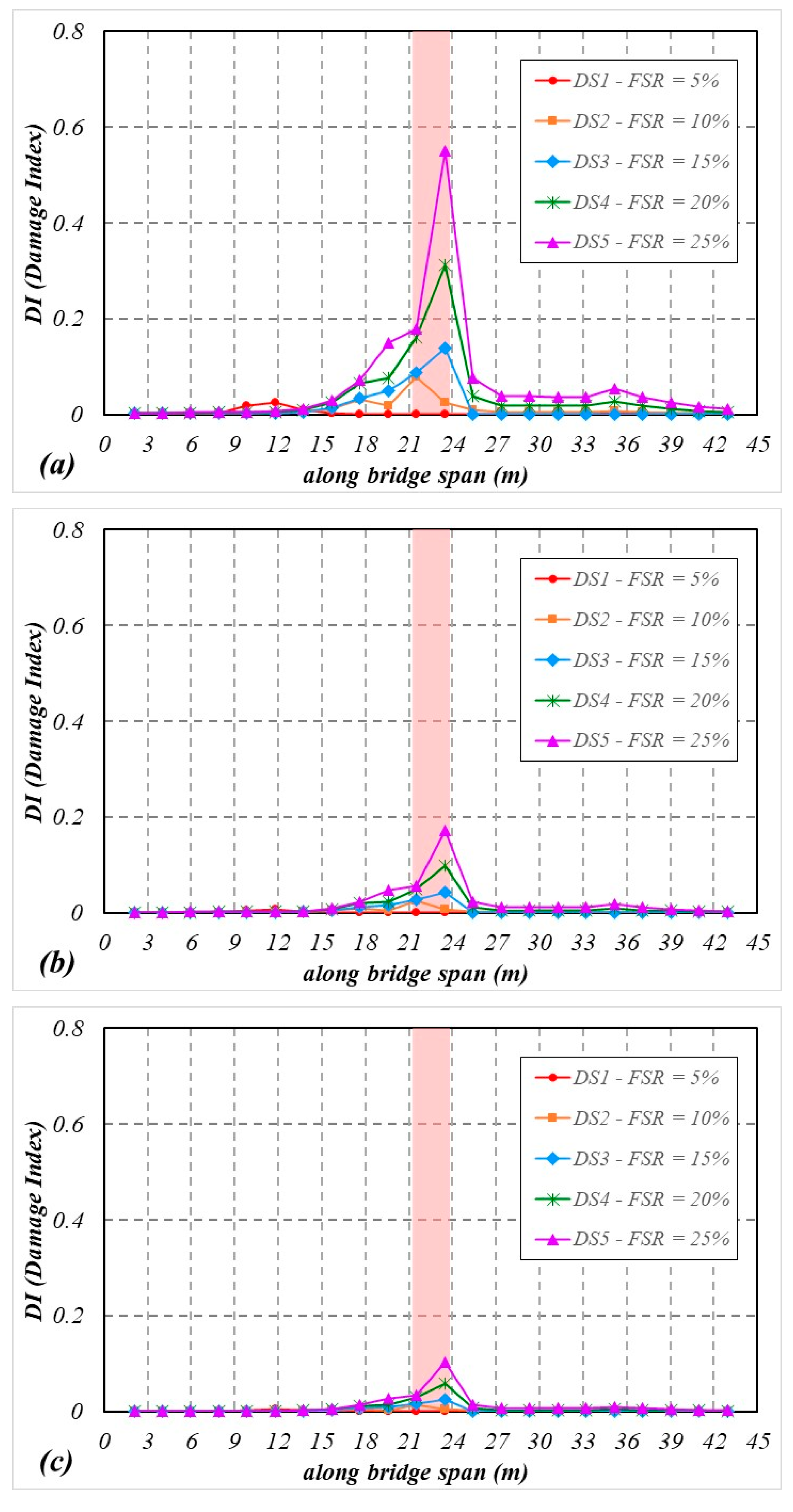

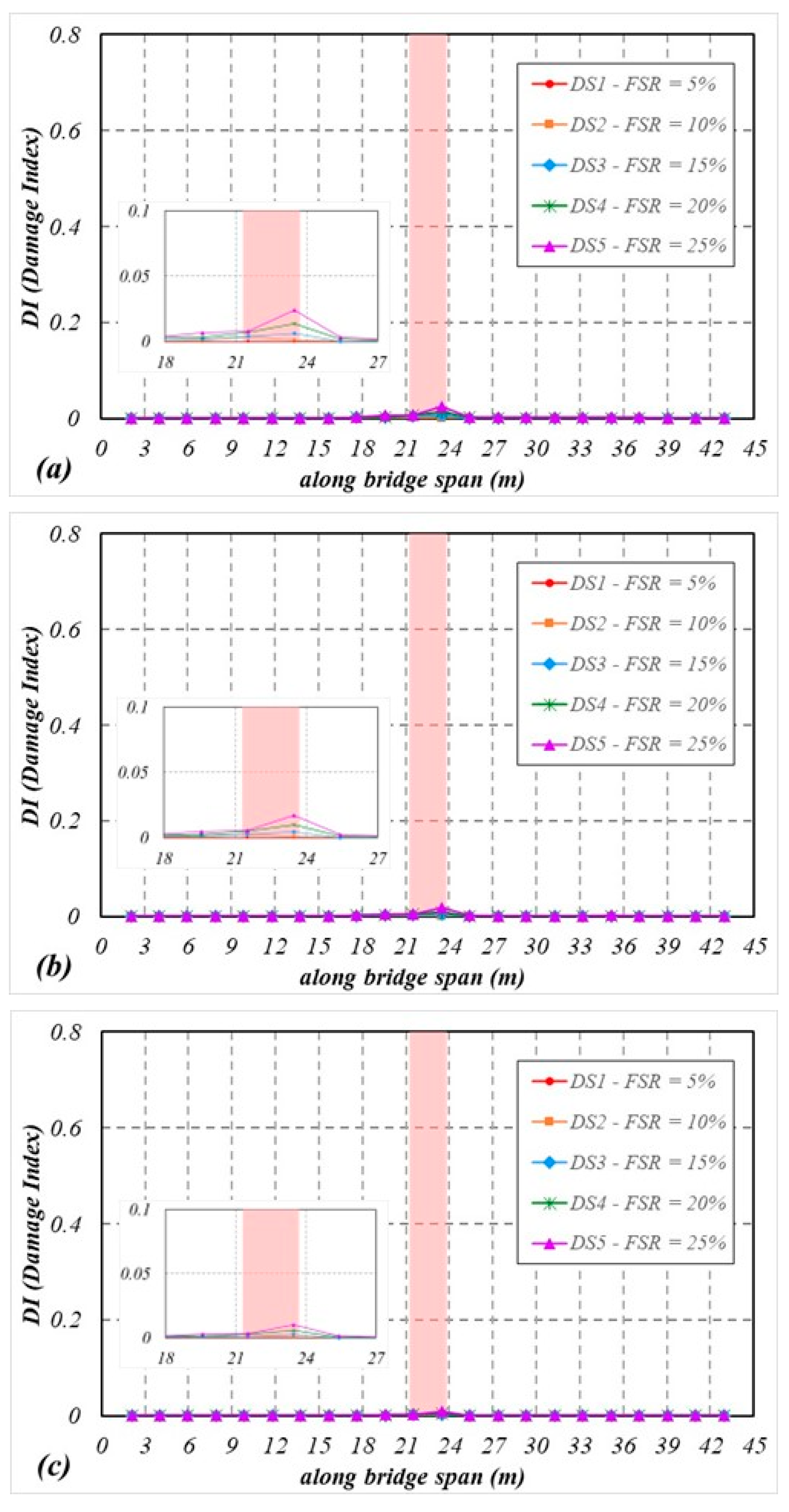

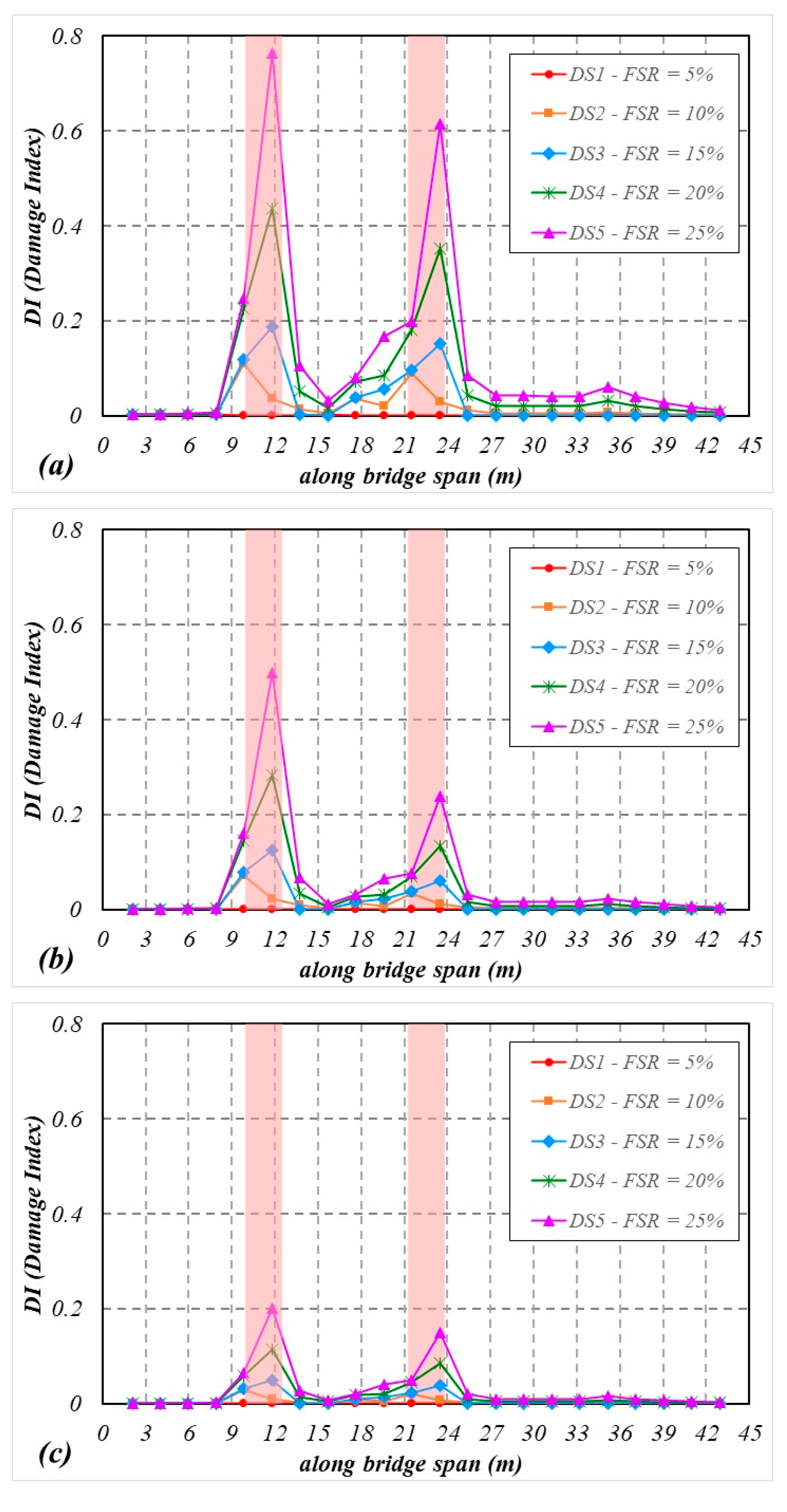

- The DI values acquired from MFCC offer robust information regarding the location of the damage. In all circumstances, the DI values reliably reflect the location and severity of the damage.

- The amplitude of the feature extracted from MFCC correlates with the vehicle’s speed over the bridge and the degree of track irregularities. The DI values are more sensitive to excitation sources caused by track irregularities than those induced by damage.

- The results indicate that the distribution patterns of DI differ concerning different damage locations, with a tendency to exhibit peaks near these damaged zones.

- In this paper, no attempt has been made to apply any dimensionality reduction techniques to the extracted features, such as principal component analysis, in which a linear mapping of the MFCC can be performed to extract the components more likely to be influenced by structural properties than by other excitation sources. Neither have more sophisticated techniques such as deep learning or time series analysis been applied, to compare the statistical distributions of the MFCC and extract damage location from them. These prospects will be investigated in the future.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, Z.; Li, S.; Lv, J.; Li, H. Condition Assessment for High-Speed Railway Bridges Based on Train-Induced Strain Response. Struct. Eng. Mech. 2015, 54, 199–219. [Google Scholar] [CrossRef]

- Montenegro, P.A.; Calçada, R.; Carvalho, H.; Bolkovoy, A.; Chebykin, I. Stability of a Train Running over the Volga River High-Speed Railway Bridge during Crosswinds. Struct. Infrastruct. Eng. 2020, 16, 1121–1137. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, P.; Tang, H.; Liu, X.; Xu, J.; Xiao, J.; Wu, J. Assessment and Prediction of High Speed Railway Bridge Long-Term Deformation Based on Track Geometry Inspection Big Data. Mech. Syst. Signal Process. 2021, 158, 107749. [Google Scholar] [CrossRef]

- Yang, Y.B.; Xu, H.; Zhang, B.; Xiong, F.; Wang, Z.L. Measuring Bridge Frequencies by a Test Vehicle in Non-Moving and Moving States. Eng. Struct. 2020, 203, 109859. [Google Scholar] [CrossRef]

- Zhan, J.; Wang, Z.; Kong, X.; Xia, H.; Wang, C.; Xiang, H. A Drive-by Frequency Identification Method for Simply Supported Railway Bridges Using Dynamic Responses of Passing Two-Axle Vehicles. J. Bridge Eng. 2021, 26, 04021078. [Google Scholar] [CrossRef]

- Hester, D.; Gonzalez, A. A Discussion on the Merits and Limitations of Using Drive-by Monitoring to Detect Localised Damage in a Bridge. Mech. Syst. Signal Process. 2017, 90, 234–253. [Google Scholar] [CrossRef]

- Yang, Y.B.; Yang, J.; Zhang, B.; Wu, Y. Vehicle Scanning Method for Bridges; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2019; ISBN 9781119539582. [Google Scholar]

- Cheema, P.; Alamdari, M.M.; Chang, K.C.; Kim, C.W.; Sugiyama, M. A Drive-by Bridge Inspection Framework Using Non-Parametric Clusters over Projected Data Manifolds. Mech. Syst. Signal Process. 2022, 180, 109401. [Google Scholar] [CrossRef]

- Matsuoka, K.; Tanaka, H.; Kawasaki, K.; Somaschini, C.; Collina, A. Drive-by Methodology to Identify Resonant Bridges Using Track Irregularity Measured by High-Speed Trains. Mech. Syst. Signal Process. 2021, 158, 107667. [Google Scholar] [CrossRef]

- Yang, Y.-B.; Lin, C.W.; Yau, J.D. Extracting Bridge Frequencies from the Dynamic Response of a Passing Vehicle. J. Sound Vib. 2004, 272, 471–493. [Google Scholar] [CrossRef]

- Lin, C.W.; Yang, Y.B. Use of a Passing Vehicle to Scan the Fundamental Bridge Frequencies: An Experimental Verification. Eng. Struct. 2005, 27, 1865–1878. [Google Scholar] [CrossRef]

- Yang, Y.B.; Chang, K.C. Extracting the Bridge Frequencies Indirectly from a Passing Vehicle: Parametric Study. Eng. Struct. 2009, 31, 2448–2459. [Google Scholar] [CrossRef]

- Yang, Y.B.; Chang, K.C.; Li, Y.C. Filtering Techniques for Extracting Bridge Frequencies from a Test Vehicle Moving over the Bridge. Eng. Struct. 2013, 48, 353–362. [Google Scholar] [CrossRef]

- Kim, C.W.; Isemoto, R.; Toshinami, T.; Kawatani, M.; McGetrick, P.J.; O’Brien, E.J. Experimental Investigation of Drive-by Bridge Inspection. In Proceedings of the SHMII-5 2011—5th International Conference on Structural Health Monitoring of Intelligent Infrastructure, Cancun, Mexico, 11–15 December 2011. [Google Scholar]

- Cerda, F.; Chen, S.; Bielak, J.; Garrett, J.H.; Rizzo, P.; KovaČević, J. Indirect Structural Health Monitoring of a Simplified Laboratory-Scale Bridge Model. Smart Struct. Syst. 2014, 13, 849–868. [Google Scholar] [CrossRef]

- Chang, K.-C.; Kim, C.-W.; Kawatani, M. Feasibility Investigation for a Bridge Damage Identification Method through Moving Vehicle Laboratory Experiment. Struct. Infrastruct. Eng. 2014, 10, 328–345. [Google Scholar] [CrossRef]

- Kim, C.W.; Isemoto, R.; Mcgetrick, P.J.; Kawatani, M.; Obrien, E.J. Drive-by Bridge Inspection from Three Different Approaches. Smart Struct. Syst. 2014, 13, 775–796. [Google Scholar] [CrossRef]

- Yang, Y.B.; Wang, Z.-L.; Shi, K.; Xu, H.; Wu, Y.T. State-of-the-Art of Vehicle-Based Methods for Detecting Various Properties of Highway Bridges and Railway Tracks. Int. J. Struct. Stab. Dyn. 2020, 20, 2041004. [Google Scholar] [CrossRef]

- Elhattab, A.; Uddin, N.; OBrien, E. Drive-by Bridge Damage Monitoring Using Bridge Displacement Profile Difference. J. Civ. Struct. Health Monit. 2016, 6, 839–850. [Google Scholar] [CrossRef]

- Locke, W.; Sybrandt, J.; Redmond, L.; Safro, I.; Atamturktur, S. Using Drive-by Health Monitoring to Detect Bridge Damage Considering Environmental and Operational Effects. J. Sound Vib. 2020, 468, 115088. [Google Scholar] [CrossRef]

- Elhattab, A.; Uddin, N.; OBrien, E. Drive-By Bridge Frequency Identification under Operational Roadway Speeds Employing Frequency Independent Underdamped Pinning Stochastic Resonance (FI-UPSR). Sensors 2018, 18, 4207. [Google Scholar] [CrossRef]

- Wang, H.; Nagayama, T.; Nakasuka, J.; Zhao, B.; Su, D. Extraction of Bridge Fundamental Frequency from Estimated Vehicle Excitation through a Particle Filter Approach. J. Sound Vib. 2018, 428, 44–58. [Google Scholar] [CrossRef]

- Reksowardojo, A.P.; Nagayama, T.; Su, D.; Mizutani, T. Bridge Natural Frequency Estimation by Extracting the Common Vibration Component from the Responses of Two Vehicles. Eng. Struct. 2017, 150, 821–829. [Google Scholar] [CrossRef]

- He, Y.; Yang, J.P. Using Acceleration Residual Spectrum from Single Two-Axle Vehicle at Contact Points to Extract Bridge Frequencies. Eng. Struct. 2022, 266, 114538. [Google Scholar] [CrossRef]

- Malekjafarian, A.; OBrien, E.J. Identification of Bridge Mode Shapes Using Short Time Frequency Domain Decomposition of the Responses Measured in a Passing Vehicle. Eng. Struct. 2014, 81, 386–397. [Google Scholar] [CrossRef]

- Li, J.; Zhu, X.; Law, S.; Samali, B. Indirect Bridge Modal Parameters Identification with One Stationary and One Moving Sensors and Stochastic Subspace Identification. J. Sound Vib. 2019, 446, 1–21. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, L.; Zhao, H.; Lie, S.T. Extraction of Mode Shapes of Beam-like Structures from the Dynamic Response of a Moving Mass. Acta Mech. Sin./Lixue Xuebao 2019, 35, 664–673. [Google Scholar] [CrossRef]

- Yang, Y.B.; Li, Z.; Wang, Z.L.; Shi, K.; Xu, H.; Qiu, F.Q.; Zhu, J.F. A Novel Frequency-Free Movable Test Vehicle for Retrieving Modal Parameters of Bridges: Theory and Experiment. Mech. Syst. Signal Process. 2022, 170, 108854. [Google Scholar] [CrossRef]

- Wang, Z.L.; Yang, J.P.; Shi, K.; Xu, H.; Qiu, F.Q.; Yang, Y.B. Recent Advances in Researches on Vehicle Scanning Method for Bridges. Int. J. Struct. Stab. Dyn. 2022, 2230005. [Google Scholar] [CrossRef]

- Nguyen, K.V.; Tran, H.T. Multi-Cracks Detection of a Beam-like Structure Based on the on-Vehicle Vibration Signal and Wavelet Analysis. J. Sound Vib. 2010, 329, 4455–4465. [Google Scholar] [CrossRef]

- Bowe, C.; Quirke, P.; Cantero, D.; Obrien, E.J. Drive-by Structural Health Monitoring of Railway Bridges Using Train-Mounted Accelerometers. In Proceedings of the COMPDYN 2015—5th ECCOMAS Thematic Conference on Computational Methods in Structural Dynamics and Earthquake Engineering, Crete Island, Greece, 25–27 May 2015; Papadrakakis, M., Papadopoulos, V.P.V., Eds.; National Technical University of Athens: Athens, Greece, 2015; pp. 1652–1663. [Google Scholar]

- Carnevale, M.; Collina, A.; Peirlinck, T. A Feasibility Study of the Drive-by Method for Damage Detection in Railway Bridges. Appl. Sci. 2019, 9, 160. [Google Scholar] [CrossRef]

- Micu, E.A.; Obrien, E.J.; Bowe, C.; Fitzgerald, P.; Pakrashi, V. Bridge Damage and Repair Detection Using an Instrumented Train. J. Bridge Eng. 2022, 27, 05021018. [Google Scholar] [CrossRef]

- Li, Z.; Au, F.T.K. Damage Detection of Bridges Using Response of Vehicle Considering Road Surface Roughness. Int. J. Struct. Stab. Dyn. 2015, 15, 1450057. [Google Scholar] [CrossRef]

- OBrien, E.J.; Malekjafarian, A.; González, A. Application of Empirical Mode Decomposition to Drive-by Bridge Damage Detection. Eur. J. Mech. A/Solids 2017, 61, 151–163. [Google Scholar] [CrossRef]

- Tan, C.; Elhattab, A.; Uddin, N. “Drive-by” Bridge Frequency-Based Monitoring Utilizing Wavelet Transform. J. Civ. Struct. Health Monit. 2017, 7, 615–625. [Google Scholar] [CrossRef]

- Yang, Y.B.; Yang, J.P. State-of-the-Art Review on Modal Identification and Damage Detection of Bridges by Moving Test Vehicles. Int. J. Struct. Stab. Dyn. 2017, 18, 1850025. [Google Scholar] [CrossRef]

- Yang, Y.B.; Wang, Z.L.; Shi, K.; Xu, H.; Mo, X.Q.; Wu, Y.T. Two-Axle Test Vehicle for Damage Detection for Railway Tracks Modeled as Simply Supported Beams with Elastic Foundation. Eng. Struct. 2020, 219, 110908. [Google Scholar] [CrossRef]

- An, Y.; Chatzi, E.; Sim, S.-H.; Laflamme, S.; Blachowski, B.; Ou, J. Recent Progress and Future Trends on Damage Identification Methods for Bridge Structures. Struct. Control Health Monit. 2019, 26, e2416. [Google Scholar] [CrossRef]

- He, Y.; Yang, J.P.; Li, Y.-F. A Three-Stage Automated Modal Identification Framework for Bridge Parameters Based on Frequency Uncertainty and Density Clustering. Eng. Struct. 2022, 255, 113891. [Google Scholar] [CrossRef]

- Qiao, L.; Esmaeily, A. An Overview of Signal-Based Damage Detection Methods. Appl. Mech. Mater. 2011, 94–96, 834–851. [Google Scholar] [CrossRef]

- Babajanian Bisheh, H.; Ghodrati Amiri, G.; Nekooei, M.; Darvishan, E. Damage Detection of Bridges Based on Combining Efficient Cepstral Coefficients. J. Vib. Control 2021, 27, 2279–2290. [Google Scholar] [CrossRef]

- Kong, X.; Cai, C.S.; Kong, B. Damage Detection Based on Transmissibility of a Vehicle and Bridge Coupled System. J. Eng. Mech. 2015, 141, 04014102. [Google Scholar] [CrossRef]

- Malekjafarian, A.; Golpayegani, F.; Moloney, C.; Clarke, S. A Machine Learning Approach to Bridge-Damage Detection Using Responses Measured on a Passing Vehicle. Sensors 2019, 19, 4035. [Google Scholar] [CrossRef] [PubMed]

- Bernardini, L.; Carnevale, M.; Somaschini, C.; Matsuoka, K.; Collina, A. A Numerical Investigation of New Algorithms for the Drive-by Method in Railway Bridge Monitoring. In Proceedings of the Proceedings of the International Conference on Structural Dynamic, EURODYN; Papadrakakis, M., Fragiadakis, M.P.C., Eds.; European Association for Structural Dynamics: Bochum, Germany, 2020; Volume 1, pp. 1033–1043. [Google Scholar]

- Hajializadeh, D. Deep-Learning-Based Drive-by Damage Detection System for Railway Bridges. Infrastructures 2022, 7, 84. [Google Scholar] [CrossRef]

- Hajializadeh, D. Deep Learning-Based Indirect Bridge Damage Identification System. Struct. Health Monit. 2022, 3. [Google Scholar] [CrossRef]

- Souza, E.F.; Bittencourt, T.N.; Ribeiro, D.; Carvalho, H. Development of Damage Detection Methodologies in Bridges Using Drive-by Methods and Machine Learning Algorithms: A Systematic Review of the Literature. In EUROSTRUCT 2021. Lecture Notes in Civil Engineering: Proceedings of the 1st Conference of the European Association on Quality Control of Bridges and Structures; Springer: Cham, Switzerland, 2022; Volume 200, pp. 123–131. [Google Scholar] [CrossRef]

- Li, H.; Wang, T.; Yang, J.P.; Wu, G. Deep Learning Models for Time-History Prediction of Vehicle-Induced Bridge Responses: A Comparative Study. Int. J. Struct. Stab. Dyn. 2022, 2350004. [Google Scholar] [CrossRef]

- Smith, W.A.; Randall, R.B. Cepstrum-Based Operational Modal Analysis Revisited: A Discussion on Pole–Zero Models and the Regeneration of Frequency Response Functions. Mech. Syst. Signal Process. 2016, 79, 30–46. [Google Scholar] [CrossRef]

- Randall, R.B.; Antoni, J.; Smith, W.A. A Survey of the Application of the Cepstrum to Structural Modal Analysis. Mech. Syst. Signal Process. 2019, 118, 716–741. [Google Scholar] [CrossRef]

- Dackermann, U.; Smith, W.A.; Randall, R.B. Damage Identification Based on Response-Only Measurements Using Cepstrum Analysis and Artificial Neural Networks. Struct. Health Monit. 2014, 13, 430–444. [Google Scholar] [CrossRef]

- Dackermann, U.; Smith, W.A.; Li, J.; Randall, R.B. On the Use of the Cepstrum and Artificial Neural Networks to Identify Structural Mass Changes from Response-Only Measurements. In Proceedings of the ISMA 2014—International Conference on Noise and Vibration Engineering and USD 2014—International Conference on Uncertainty in Structural Dynamics, Leuven, Belgium, 15–17 September 2014; Sas, P., Moens, D.D.H., Eds.; KU Leuven: Leuven, Belgium, 2014; pp. 3739–3750. [Google Scholar]

- Morgantini, M.; Betti, R.; Balsamo, L. Structural Damage Assessment through Features in Quefrency Domain. Mech. Syst. Signal Process. 2021, 147, 107017. [Google Scholar] [CrossRef]

- Randall, R.B. Cepstral Methods of Operational Modal Analysis. In Encyclopedia of Structural Health Monitoring; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2009; ISBN 9780470061626. [Google Scholar]

- Bochud, N.; Gomez, A.M.; Rus, G.; Carmona, J.L.; Peinado, A.M. Robust Parametrization for Non-Destructive Evaluation of Composites Using Ultrasonic Signals. In Proceedings of the ICASSP, IEEE International Conference on Acoustics, Speech and Signal Processing—Proceedings, Prague, Czech Republic, 22–27 May 2011; pp. 1789–1792. [Google Scholar]

- Zhang, G.; Harichandran, R.S.; Ramuhalli, P. Application of Noise Cancelling and Damage Detection Algorithms in NDE of Concrete Bridge Decks Using Impact Signals. J. Nondestruct. Eval. 2011, 30, 259–272. [Google Scholar] [CrossRef]

- Balsamo, L.; Betti, R.; Beigi, H. A Structural Health Monitoring Strategy Using Cepstral Features. J. Sound Vib. 2014, 333, 4526–4542. [Google Scholar] [CrossRef]

- Tronci, E.M.; Beigi, H.; Feng, M.Q.; Betti, R. Damage Assessment in Structural Systems through Transfer Learning from Audio Domains. In Proceedings of the International Conference on Structural Health Monitoring of Intelligent Infrastructure: Transferring Research into Practice, SHMII; International Society for Structural Health Monitoring of Intelligent Infrastructure ISHMII: Brussels, Belgium, 2021; Volume 2021, pp. 805–811. [Google Scholar]

- Tronci, E.M.; Beigi, H.; Feng, M.Q.; Betti, R. Transfer Learning from Audio Domains a Valuable Tool for Structural Health Monitoring. In Proceedings of the Conference Proceedings of the Society for Experimental Mechanics Series; Grimmelsman, K., Ed.; Springer: Berlin/Heidelberg, Germany, 2022; pp. 99–107. [Google Scholar]

- Tronci, E.M.; Beigi, H.; Feng, M.Q.; Betti, R. A Transfer Learning SHM Strategy for Bridges Enriched by the Use of Speaker Recognition X-Vectors. J. Civ. Struct. Health Monit. 2022, 12. [Google Scholar] [CrossRef]

- Mei, Q.; Gül, M.; Boay, M. Indirect Health Monitoring of Bridges Using Mel-Frequency Cepstral Coefficients and Principal Component Analysis. Mech. Syst. Signal Process. 2019, 119, 523–546. [Google Scholar] [CrossRef]

- Yu, Z.; Shao, S.; Deng, G.; Zhou, Z. A Damage Detection Method of Bridges Utilizing Vehicle Vibration Time History Signal. In European Workshop on Structural Health Monitoring; Springer: Cham, Switzerland, 2021; Volume 127, pp. 367–377. [Google Scholar] [CrossRef]

- MATLAB Release Notes (R2022a); MATLAB: Natick, MA, USA, 2022.

- Zhai, W.; Han, Z.; Chen, Z.; Ling, L.; Zhu, S. Train–Track–Bridge Dynamic Interaction: A State-of-the-Art Review. Veh. Syst. Dyn. 2019, 57, 984–1027. [Google Scholar] [CrossRef]

- Zhai, W.; Xia, H.; Cai, C.; Gao, M.; Li, X.; Guo, X.; Zhang, N.; Wang, K. High-Speed Train–Track–Bridge Dynamic Interactions—Part I: Theoretical Model and Numerical Simulation. Int. J. Rail Transp. 2013, 1, 3–24. [Google Scholar] [CrossRef]

- Iwnicki, S.; Spiryagin, M.; Cole, C.; McSweeney, T. (Eds.) Handbook of Railway Vehicle Dynamics, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Nguyen, K.; Goicolea, J.M.; Galbadón, F. Comparison of Dynamic Effects of High-Speed Traffic Load on Ballasted Track Using a Simplified Two-Dimensional and Full Three-Dimensional Model. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit. 2014, 228, 128–142. [Google Scholar] [CrossRef]

- Quirke, P.; Bowe, C.; OBrien, E.J.; Cantero, D.; Antolin, P.; Goicolea, J.M. Railway Bridge Damage Detection Using Vehicle-Based Inertial Measurements and Apparent Profile. Eng. Struct. 2017, 153, 421–442. [Google Scholar] [CrossRef]

- Cantero, D.; Arvidsson, T.; OBrien, E.; Karoumi, R. Train–Track–Bridge Modelling and Review of Parameters. Struct. Infrastruct. Eng. 2016, 12, 1051–1064. [Google Scholar] [CrossRef]

- Lou, P.; Au, F.T.K. Finite Element Formulae for Internal Forces of Bernoulli–Euler Beams under Moving Vehicles. J. Sound Vib. 2013, 332, 1533–1552. [Google Scholar] [CrossRef]

- Zhai, W. Vehicle–Track Coupled Dynamics: Theory and Applications; Springer: Berlin/Heidelberg, Germany, 2020; ISBN 978-981-32-9282-6. [Google Scholar]

- Lou, P. Finite Element Analysis for Train–Track–Bridge Interaction System. Arch. Appl. Mech. 2007, 77, 707–728. [Google Scholar] [CrossRef]

- Lei, X.; Noda, N.-A. Analyses of Dynamic Response of Vehicle and Track Coupling System with Random Irregularity of Track Vertical Profile. J. Sound Vib. 2002, 258, 147–165. [Google Scholar] [CrossRef]

- Podwórna, M. Modelling of Random Vertical Irregularities of Railway Tracks. Int. J. Appl. Mech. Eng. 2015, 20, 647–655. [Google Scholar] [CrossRef]

- Lee, J.; Choi, H.; Park, D.; Chung, Y.; Kim, H.-Y.; Yoon, S. Fault Detection and Diagnosis of Railway Point Machines by Sound Analysis. Sens. 2016, 16, 549. [Google Scholar] [CrossRef] [PubMed]

- Calçada, R.; Delgado, R.; Campos e Matos, A. (Eds.) Bridges for High-Speed Railways: Revised Papers from the Workshop, Porto, Portugal, 3–4 June 2004, 1st ed.; CRC Press: Boca Raton, FL, USA, 2008; ISBN 9780429207396. [Google Scholar]

| Track Class | |||

|---|---|---|---|

| Low disturbance | 0.8246 | 0.0206 | 4.032 × 10−7 |

| High disturbance | 0.8246 | 0.0206 | 1.080 × 10−6 |

| Properties | Notation | Value | Unit | |

|---|---|---|---|---|

| Deck | Reinforced concrete density | 2500 | kg/m3 | |

| Reinforced concrete area | 6.0191 | m2 | ||

| Ballast [72] | Ballast density | 1750 | kg/m3 | |

| Ballast area | 3.6315 | m2 | ||

| Sleeper [72] | Sleeper mass (half) | 170 | kg | |

| Sleeper spacing (half) | 0.60 | m | ||

| Rail [72] | Rail mass per unit length (per rail seat) | 60.64 | kg/m | |

| Euler-Bernoulli beam: | ||||

| Mass per unit length | 13,350 | kg/m | ||

| Modulus of elasticity | 39 | GPa | ||

| Cross-section moment of inertia | 2.60 | m4 | ||

| Span length | 45 | m | ||

| Properties | Notation | Value | Unit | |

|---|---|---|---|---|

| Concentrated masses | Carbody | 47,800 | kg | |

| Bogies | 3500 | kg | ||

| Wheelsets | 1800 | kg | ||

| Rotary inertia | Carbody | 1.96 × 106 | kg·m2 | |

| Bogies | 1715 | kg·m2 | ||

| Stiffness coefficient (*) | Primary suspension | 2.40 × 106 | N/m | |

| Secondary suspension | 2.00 × 104 | N·s/m | ||

| Damping coefficient (*) | Primary suspension | 7.00 × 105 | N/m | |

| Secondary suspension | 4.00 × 104 | N·s/m | ||

| Distances | ||||

| Distance between bogie centers in one car | 17.375 | m | ||

| Distance between wheelset axles in one bogie | 2.50 | m | ||

| Distance between bogie centers from adjacent cars | 7.40 | m | ||

| Vertical bending mode | 1st | 2nd | 3rd | 4th | 5th | 6th | 7th | 8th |

| Frequency (Hz) | 2.14 | 8.55 | 19.24 | 34.21 | 53.45 | 76.96 | 104.75 | 136.82 |

| Mode | Frequency (Hz) | ||

|---|---|---|---|

| Carbody | Front Bogie | Rear Bogie | |

| Vertical (bouncing) | 0.804 | 6.317 | 6.323 |

| Pitching | 1.089 | 10.525 | 10.525 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Souza, E.F.; Bittencourt, T.N.; Ribeiro, D.; Carvalho, H. Feasibility of Applying Mel-Frequency Cepstral Coefficients in a Drive-by Damage Detection Methodology for High-Speed Railway Bridges. Sustainability 2022, 14, 13290. https://doi.org/10.3390/su142013290

de Souza EF, Bittencourt TN, Ribeiro D, Carvalho H. Feasibility of Applying Mel-Frequency Cepstral Coefficients in a Drive-by Damage Detection Methodology for High-Speed Railway Bridges. Sustainability. 2022; 14(20):13290. https://doi.org/10.3390/su142013290

Chicago/Turabian Stylede Souza, Edson Florentino, Túlio Nogueira Bittencourt, Diogo Ribeiro, and Hermes Carvalho. 2022. "Feasibility of Applying Mel-Frequency Cepstral Coefficients in a Drive-by Damage Detection Methodology for High-Speed Railway Bridges" Sustainability 14, no. 20: 13290. https://doi.org/10.3390/su142013290

APA Stylede Souza, E. F., Bittencourt, T. N., Ribeiro, D., & Carvalho, H. (2022). Feasibility of Applying Mel-Frequency Cepstral Coefficients in a Drive-by Damage Detection Methodology for High-Speed Railway Bridges. Sustainability, 14(20), 13290. https://doi.org/10.3390/su142013290