Abstract

The focus of this research is to design a ground-mounted photovoltaic system at optimal tilt angle and interrow space to meet high demand of electrical energy. The Department of Electrical Engineering and Technology, GC University Faisalabad has been considered to perform the simulation test. This study is conducted using Meteonorm software for solar resource assessment. Furthermore, HelioScope software is used for modeling of a ground-mounted photovoltaic system, study of PV system’s performance in terms of annual generation, system losses and performance ratio and analysis of photovoltaic module’s performance, current-voltage and power-voltage curves for different irradiance levels. From SLD, it is seen that 11 strings are connected to each inverter and inverters output power are combined by using 20.0 A circuit interconnects. The performance of photovoltaic systems is impacted by tilt angle and interrow spacing. From simulation results of all cases, it is concluded that the PV system installed at 15° tilt angle with 4 feet interrow spacing are more efficient than the other installed PV systems, because total collector irradiance is maximum (1725.0 kWh/m2) as compared to other tilt angles. At 15° tilt angle, the annual production of photovoltaic system is 2.265 GWh and performance ratio of PV system is 82.0%. It is envisioned that this work will provide the guidance to energy system designers, planners and investors to formulate strategies for the installation of photovoltaic energy systems in Pakistan and all over the world.

1. Introduction

Energy is a necessary commodity for continuous economic growth and human development. Having enough affordable energy is critical for improving human health, eradicating hunger and raising living standards around the world [1]. Traditionally, fossil fuels have become the primary source of energy and have played a significant role to meet human energy demands. Renewable energy resources (hydropower solar, biomass, wind and geothermal) are more environmentally friendly than other types of energy resources. RES have the ability to generate energy while releasing zero or nearly zero emission and greenhouse gases into the atmosphere [2]. According to the energy outlook 2035 published by B.P. in January 2014, global primary energy demand will increase by 40% from 2012 to 2035, with 1.5% average annual growth rate. Residential and agricultural sectors will be the major electricity consumers [3].

Pakistan is an energy-scarce region, and most of the population does not have access to basic energy services such as electricity, natural and liquefied petroleum gas. Per capita primary energy consumption was 5.80 MWh, 5.70 MWh in 2010 and 2011, respectively, as compared to 37.30 MWh and 34.50 MWh in developed countries such as the United Kingdom for the same duration [4]. Pakistan relies on imports of oil and liquefied petroleum gas as its main energy source. The rise in crude oil prices in recent years has raised concerns about the rising cost of energy. This situation is worst as energy crisis has been continued since 2007 [5].

The National Electric Power Regulatory Authority published a report in 2020 on current energy situation. According to this report, under current planning and policy the crisis of energy shortage will be continued till 2025 [6]. Renewable energy is an alternative option for reducing Pakistan’s reliance on oil and LPG imports and meeting its energy needs by using available energy resources. Solar energy with appropriate potential (5.50–6.50 kWh/m2/day or 1850–2250 kWh/m2/year) is available across the Pakistan to meet public energy needs. This is the only resource in Pakistan that is unaffected by political, social and legal disputes [7,8]. Photovoltaic energy systems have attracted attention as a solution to decrease the consumption of fossil fuels [9]. Solar energy has a lot of potential, due to improvements in technology and its environmentally friendly nature. However, the major issues that solar energy face in the future are its unavailability all over the year, shortage of photovoltaic cell materials and high capital cost [10].

A photovoltaic system transforms sunlight directly into electricity. Photovoltaic devices have simple circuit design and they require relatively low maintenance. PV system have the benefit of being able to be used as both standalone and grid-connected systems. Photovoltaic systems vary in size from microwatts (mW) to megawatts (MW) [11,12]. Multi-junction cells and concentrating photovoltaic have efficiencies up to 43% in the lab, while the efficiency of PV modules available in the market is in the range of 16% [13]. The price of photovoltaic modules decreased from 32.0$/Watt (25.0 years ago) to less than 24.0 cent/Watt in 2021. Currently, silicon based PV modules are dominant with market-share of around 78% [14]. In the last two years, photovoltaic energy generation capacity has increased dramatically around the world. In 2020, more than 115.0 GW of power was added, bringing the total capacity of world to about 627.0 GW [15]. Photovoltaic share of energy production will rise to 960 TWh by 2035 that will increase from 0.41% to 2.61% of total world energy production, according to the International Energy Agency (IEA) new policies scenario [16].

To improve the performance of integrated PV system, various conditions and operating parameters are considered when evaluating PV system performance, including PV system orientation, solar irradiation intensity, time of month/year, and parameters variation and fluctuation throughout the day. The overall performance of traditional solar collectors has been improved significantly using a flat booster bottom reflector [17] and the optimum inclination of the collector and reflector [18]. The enhanced solar energy collection over the PV collector combined with the flat booster bottom reflector enhances energy production [19]. The evaluation of the PV systems was carried out by modelling and simulating the photovoltaic modules in the simulation software COMSOL Multiphysics. It was found that the total energy generation of the east-facing photovoltaic modules was 38.0% better than the conventional system [20]. Various environmental factors such as dust accumulation, shading and bird droppings affect the performance of photovoltaic system [21]. During designing of PV system, it is important to consider risk factors and objects that may causes shading, including high voltage power transmission lines, trees and buildings, that have considerable shading effects due to their height [22].

Hotspots/defects created by environment on the photovoltaic modules surface have unknown intensity, occurrence frequency and duration as well as they vary from area to area [23]. Photovoltaic cells operate as an electric load due to partial shading on photovoltaic modules, and the electric power is converted to heat. In this condition, photovoltaic cells can be considered of as current sources and when the currents of the cells connected in a series differ, significantly localized dissipation occurs. As a result, the temperatures in the photovoltaic cells rises, resulting in so-called hot spots [24]. In order to avoid the hot spot effect and make optimal use of the available space, not only the shading effects of high voltage power transmission lines poles but also those of the conductors between them must be taken into account [22].

Photovoltaic (PV) energy generation is reliable and have the potential to play an important role in reduction of carbon dioxide (CO2) emissions [25,26]. Photovoltaic (PV) is widely expected to become one of the most important future source of energy production, considering the potential of grid parity and cost reductions in Northern and Southern Europe by 2020 [27]. The rising demand for energy in the developing countries have caused energy security issues. Grid-connected photovoltaic systems have emerged as the most cost-effective large-scale renewable energy source. The performance analysis of these grid-connected photovoltaic (PV) energy generation systems will help to design, operate and maintain new grid-connected photovoltaic (PV) system [28]. The proper designing and sizing of a PV system avoids unnecessary costs due to oversized system and insufficient power supply due to undersized system [29].

Photovoltaic performance and output energy depend upon photovoltaic panel face angle, photovoltaic type (polycrystalline, monocrystalline, amorphous silicon and microamorphous silicon), system component efficiency, location and solar radiation, but location and solar radiation play an important role [30]. Feed-in tariff scheme is used to promote polycrystalline silicon and monocrystalline silicon photovoltaic system [31]. Quality certification and standards are essential for the successful implementation and optimal operation of photovoltaic energy generation system in smart cities [32]. Now-a-days photovoltaic energy generation system are become more complex and incorporate multiple technologies. HelioScope is one of the best simulation tool that capable of modelling these complex arrays [33]. Many software tools are available to assist renewable energy engineers in evaluating performance and designing of photovoltaic (PV) systems as shown in Table 1.

Table 1.

PV system simulation software [34].

The photovoltaic system has recently become the industry standard, estimate power generation taking into account losses due to environment, weather, shading, system component efficiencies, PV modules mismatches, wiring, clipping, reflection, soiling and aging, and also provide recommendation for system equipment and layout of PV array. However, HelioScope, a new software tool (introduced by Folsom Labs), provides all of photovoltaic system’s features as well as AutoCad’s design functionality, enabling system designers to do a complete design in one package [35,36].

The HelioScope simulation software has the feature to import high resolution and high quality maps of any geographic location from Google Earth. This software presents the exact layout or topography of any inspected location, edit and modify the images, and make PV models on it. Using HelioScope software, PV system designers can accurately estimate the shading effect of any object at any time. In addition, this software can also calculate the area of the proposed PV site. It uses physical characteristics of solar modules and inverters, weather information, shadow analysis, wire resistance and other factors to perform its simulation.

The HelioScope simulation software includes all the functionality of the PVSyst software, and adds the design functions of AutoCAD, so that energy system designers can use one software package to create a complete PV system design. Helioscope allows to use a single simulation software to perform energy estimation and 3D model designs. It can design photovoltaic systems from small scale to large scale and for any type of surface such as flat or uneven surfaces. Its advantage is that it can provide a high-precision estimate for the size of the photovoltaic system that can be installed at the proposed site, annually and monthly energy generation, expected energy generation (kWh/kWp), performance ratio (PR) of the system, number of photovoltaic modules and inverters, PV plant layout, single line diagram, PV system losses, voltage drop calculation, shading analysis, selection of system wiring, annual global horizontal irradiance, total collector irradiance, temperature metrics, SketchUp shading integration and computer-aided drawing (CAD) tools. HeliScope uses the Metronome [37], National Renewable Energy Laboratory (NREL) [38] and Solar Prospector [39] databases for weather data when creating models of PV plants. In the photovoltaic system design process, it is also possible to select system components (type and rating of PV modules and inverters), set the required tilt and azimuth angle, orientation, frame size, horizontal and vertical PV module mounting, row arrangement, interrow spacing and AC/DC electric cables.

Renewable energy is an easier and alternative way to reduce GHG emissions and can also help meet the growing demand for electricity. For the perspective of Pakistan, photovoltaic energy is one of the most feasible option. However, for a developing country such as Pakistan, the requirement of installation area/site is still a major problem. Therefore, the optimal number of PV modules, their orientation and interrow spacing have become an important factors which are considered for designing of large scale PV system. HelioScope simulation tool can help to answer this question to a certain extent. HelioScope is an innovative and novel simulation tool developed by Folsom Lab in the United States to plan and evaluate the performance of photovoltaic system as well as helps to find the maximum usage of available space. It uses physical characteristics of solar modules and inverters, weather information, shadow analysis, wire resistance and other factors to perform its simulation. The Department of Electrical Engineering and Technology, on GC University Faisalabad’s new campus has been considered for simulation testing and assessment of ground mounted PV system. A total of 129,201.6 ft2 of land are available for installation considering tilt angle of PV modules, shadow effect, solar irradiance, installation height, solar reflection and temperature. The goal of this research is to find the optimal title angle and interrow spacing of the PV modules in a given area to achieve the maximum solar energy production. The main contributions of the research are given below:

- (1)

- Modeling of a ground-mounted photovoltaic (PV) system to meet the high demand of electrical energy.

- (2)

- Analysis of photovoltaic module’s performance, current-voltage and power-voltage curves for different irradiance levels.

- (3)

- Solar resource assessment using Meteonorm software database.

- (4)

- Comparative study of the PV system is performed to identify the optimal interrow spacing for each tilt angle.

- (5)

- Performed analysis of the PV system installed at different tilt angles to find optimal tilt angle for proposed site.

- (6)

- Studied PV system’s performance in terms of annual generation, system losses and performance ratio.

- (7)

- Comparison of monthly energy generation (kWh) for different tilt angles.

- (8)

- Analysis of energy system losses under various conditions such as shading, reflection, soiling, irradiance, temperature, mismatch, wiring, and clipping, etc.

- (9)

- Total collector irradiance comparison of PV system for different tilt angles.

- (10)

- The proposed optimal tilt angle and interrow spacing can predict maximum PV output.

The remaining sections of this article are organized as follows: Section 2—Materials and Methods, discusses the climate conditions and solar resource assessment of proposed site. The PV system designing, proposed system components, photovoltaic module performance at different irradiance level, current-voltage and power-voltage curve of photovoltaic panels are also discussed in this section. Results are presented in Section 3. This section discusses monthly/annually energy production and system losses by photovoltaic system at different tilt angles, monthly energy production comparison, total collector irradiance comparison and performance ratio of the system. Finally, in Section 4, conclusions are drawn that highlight the key findings of this research.

2. Materials and Methods

A number of experiments were conducted out in this study to determine the optimal tilt angle and interrow spacing of photovoltaic modules and photovoltaic energy potential at a proposed location. We analyzed different tilt angle and interrow space to obtain maximum PV energy generation. The best technique to obtain maximum energy output from a photovoltaic (PV) array is to tilt it at optimum tilt angle, [40,41]. When PV modules are installed or placed in the opposite direction of the sun’s light, they produce the maximum energy. The experiment was divided into five different cases. It is found that the azimuth angle of 180° is better than other values of azimuth angle. Therefore, an azimuth angle of 180° was used in all five cases.

We used HelioScope software developed by Folsom Labs to perform detailed modeling such as system analysis, annual generation and system losses. The research was conducted under the following cases:

- Case 1: Energy production by photovoltaic system installed at 5° tilt angle;

- Case 2: Energy production by photovoltaic system installed at 10° tilt angle;

- Case 3: Energy production by photovoltaic system installed at 15° tilt angle;

- Case 4: Energy production by photovoltaic system installed at 20° tilt angle;

- Case 5: Energy production by photovoltaic system installed at 25° tilt angle.

2.1. Proposed Photovoltaic Plant Site Location

The proposed photovoltaic energy generation plant site is located in front of Department of Electrical Engineering and Technology, GC University Faisalabad new campus with latitude 31.3876587431 and longitude 73.026295403 in Punjab Province, Pakistan—as shown in Figure 1. The proposed site has 129,201.6 ft2 of land and it is come under the non-forest zone. The proposed site is well-connected to transportation options with convenient access to major highways and railways.

Figure 1.

Proposed photovoltaic plant site location.

Solar irradiation, gird station distance, road distance, distance from metropolitan areas, and land usage are all important considerations to consider when choosing a location for photovoltaic energy generation plant site. These criteria are employed in the optimal renewable energy management planning to assure the long-term development of energy production from PV system [42].

2.2. Climate Conditions for Modelling

The weather changes seasonally, from cold winter to hot summer, with a maximum temperature of 45.0 degrees Celsius. The monsoon season lasts from May to September and reaches its peak in July and August, about 65.0–70.0% of the annual rainfall. Throughout the year, there are an average of 7.5–8.5 h of clear sky every day and 2950.0 to 3350.0 h of sunshine per year.

Winds are generally low in the proposed area, with wind speeds less than 2.40 m/s. The wind speed increases during the monsoon season, specifically during the day. The meteorological station in Faisalabad have reported storm events with maximum gust wind speed of 15.0–25.0 m/s and the maximum single event is 30.0 m/s [43,44].

2.3. Solar Resource Assessment

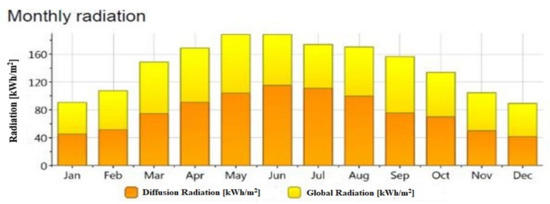

For the assessment of solar resource assessment, there are several professional tools available to obtain meteorological data from satellite imaging. The Meteonorm software and database were used in this research. Daily and monthly irradiation data, average, maximum and minimum temperatures, sunshine hours and precipitation were all important parameters to consider for PV output energy assessment.

The monthly radiation data of proposed site is shown in Figure 2. From the figure it is shown that during the summer season of the year, the radiation level is highest especially for months of May and June. The average annual global horizontal irradiation (GHI) is 1722.0 kWh/m2 and horizontal diffuse irradiation is 932 kWh/m2 at the proposed site. GHI is total solar irradiation incident on the horizontal surface.

Figure 2.

Monthly radiation data for proposed photovoltaic plant site from Meteonorm.

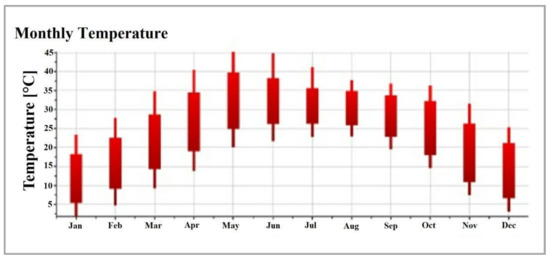

Monthly temperature data of proposed site is shown in Figure 3. From the figure it is shown that the air temperature of the site are increases during summer season and decreases during winter season. The monthly average air temperature is 24.0 °C as shown in Figure 3. This data indicates that there is an ample amount of reliable solar energy available that is harnessed by a photovoltaic energy generation system.

Figure 3.

Monthly temperature data for proposed photovoltaic plant site from Meteonorm.

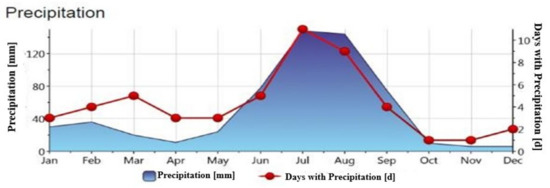

Precipitation data of proposed site are shown in Figure 4. The precipitation is generally high in all months of summer and it is low for winters except March. The monsoon season lasts from May to September and reaches its peak in July and August, about 65.0–70.0% of the annual rainfall.

Figure 4.

Precipitation data for proposed photovoltaic plant site from Meteonorm.

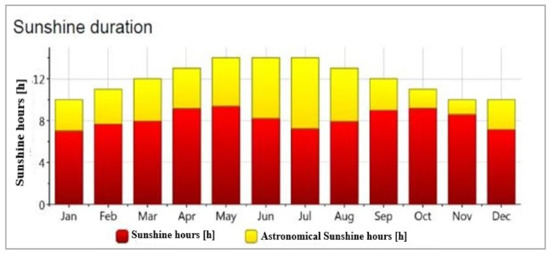

Sunshine hours of the proposed site are shown in Figure 5. The number of sunshine hours are important to understand the how much irradiance is required to produce the required output power. This parameter allows us to understand the maximum number of sunshine hours that proposed site will receive. Throughout the year, the sunshine hours vary from 7.0 to 13.0 h.

Figure 5.

Sunshine hours for proposed photovoltaic plant site from Meteonorm.

2.4. PV System Designing and Proposed System Components

HelioScope simulation tool are used for assessment of ground mounted PV system in front of Department of Electrical Engineering and Technology, GC University Faisalabad. The proposed site has 129,201.6 ft2 of land. Some input parameter for PV system simulation are shown in Table 2.

Table 2.

Input parameter for PV system simulation.

2.4.1. Photovoltaic Modules

The JA solar 535.0 Watt (JAM72 S30-535/MR) monocrystalline photovoltaic module was selected. Table 3 shows the specification of the photovoltaic module under consideration.

Table 3.

Photovoltaic module specification.

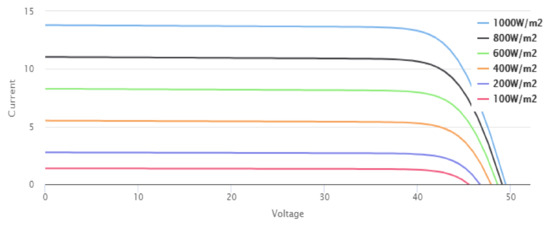

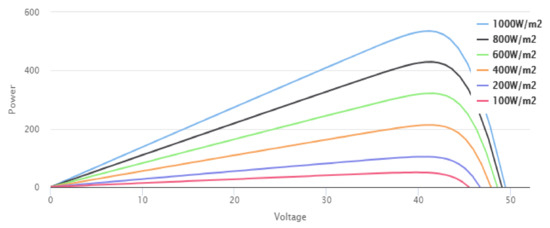

Photovoltaic module performances at different irradiance levels are shown in Table 4. The current–voltage curve of photovoltaic module in Figure 6 shows the simulation result for current (I) versus voltage (V) characteristics of the photovoltaic modules at different irradiance level (i.e., irradiance 1000 W/m2, irradiance 800 W/m2, irradiance 600 W/m2, irradiance 400 W/m2, irradiance 200 W/m2, and irradiance 100 W/m2). The current–voltage curve shows that as the radiation intensity level increases, the short-circuit current (ISC) of the PV modules increases. Similarly, the power–voltage curve of photovoltaic module in Figure 7 demonstrates power versus voltage characteristics at various levels of irradiance. The results show that as the radiation intensity level increases, the maximum power output of the photovoltaic modules also increases.

Table 4.

Photovoltaic module performance at different irradiance level.

Figure 6.

Current–voltage curve of photovoltaic module.

Figure 7.

Power–voltage curve of photovoltaic module.

2.4.2. Solar Inverter

A solar inverter, also known as a PV inverter, is described as an electrical converter that convert the variable direct current (DC) output of the photovoltaic module into alternating current (AC), which could be injected into utility grids or used by local or off-grid power grids. Table 5 shows the inverter specification.

Table 5.

Inverter specification.

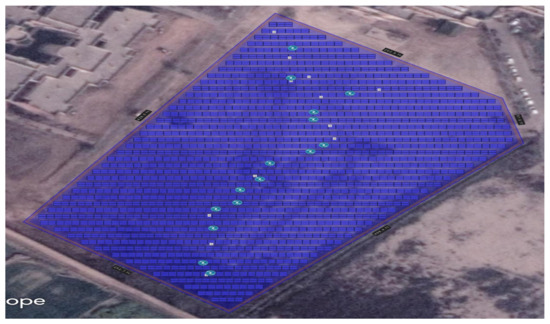

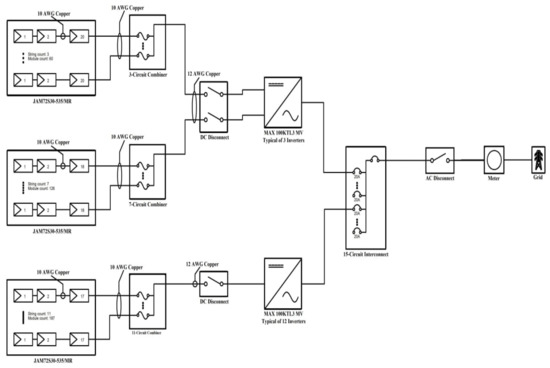

The layout design and single line diagram of the PV system is shown in Figure 8 and Figure 9, respectively. From SLD, we shown that 11 strings are connected to inverter (MAX 1000 KTL) and each string contain 17 PV modules. This configuration is used for 14 inverters. With inverter No. 15, 10 strings are connected (3 strings contain 20 PV modules and 7 strings contain 18 PV modules). Wiring configuration is very important for effective system installation, as it can reduce the system loss and improve the operational safety of the system. PV modules are connected in strings with 10 AWG DC cable. These strings are combined in combiner box. From combiner box to inverter we used a 12 AWG DC cable.

Figure 8.

Layout design for PV system.

Figure 9.

Single line diagram of PV system.

The output power of the all inverters are combined by using 15 circuits interconnect (each circuit interconnect has 20.0 A rating). Two types of disconnecting switches are used in the system; AC disconnects are installed between utility grid and inverter, DC disconnects are installed between the PV modules and the inverter. After circuit interconnect, the service panels are installed. The connection between the AC wires coming from the national utility grid and the PV system is made through the electrical service panel.

The bidirectional meter consists of current and voltage measuring circuits, which measure instantaneous current and voltage, respectively. The processing unit is an Arduino Uno, and the net energy is displayed on an LCD display at regular intervals. The bidirectional meter can sense/detect the direction of current flow and records the information in a separate register. During the day, maximum loads are in off stage state, and the surplus energy generated by the photovoltaic system will be sent back to the utility grid (Export). At this time, the direction of current flow is reversed, and the bidirectional meter records the information in the export register. At night, there is no photovoltaic energy generation, and electricity is import from the utility grid to operate the load. Now, the direction of current flow is forward, and the bidirectional meter records the information in the import register.

3. Results

3.1. Case 1: Energy Production of Photovoltaic System Installed at 5° Tilt Angle

In Case 1 (as mentioned previously) we have selected 5° tilt angle. At an available space in front of department of electrical engineering and technology, first we perform the simulation study and compares output of PV system to find the most appropriate interrow spacing for 5° tilt angle. Table 6 shows the total installed capacity, annual production, performance ratio and load ratio with different interrow spacing.

Table 6.

Performance comparison of PV system at 5° tilt angle with different interrow spacing.

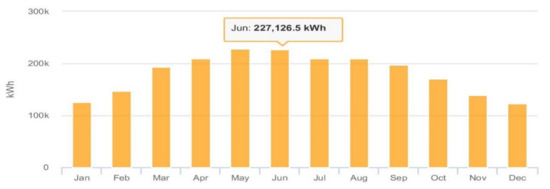

The PV system has interrow spacing 1 and 2 feet, and having low performance ratio, because system efficiency is decreased by shading effect on the PV modules. In case of PV system having 4 feet interrow spacing, the overall installed capacity of the photovoltaic energy generation system is decreased. The performance of ground mounted photovoltaic systems is impacted by interrow spacing. By increasing the interrow spacing of the PV modules, the shading effect on PV modules is reduced, but it also increases land and electric wiring costs. By comparison, we analyse that the PV system installed at a 5° tilt angle with 3 feet interrow spacing are more efficient. For this case, simulation result show that the annual production of PV system is 2.176 GWh, energy generated (kWh/kWp) is 1451.4 and performance ratio (PR) of the photovoltaic energy generation system is 82.6%. Figure 10 and Table 7 show the monthly energy generation of the photovoltaic system for 3 feet interrow spacing.

Figure 10.

Monthly energy generation of the photovoltaic system at 5° tilt angle.

Table 7.

Monthly energy generation of the photovoltaic system at 5° tilt angle.

Simulation results of Case 1 show that PV system produce maximum energy during summer season (May–June) and produce lowest energy during the winter season, November–January).

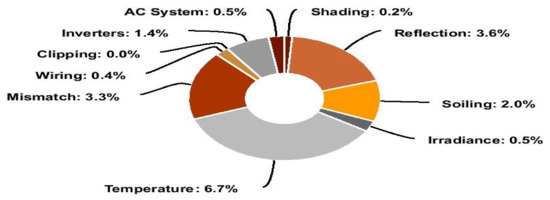

Figure 11 shows different PV system losses at a 5° tilt angle for 3 feet interrow spacing. In this figure, system losses such as A1C system, shading, reflection, soiling, irradiance, temperature, mismatch, wiring, clipping and inverters are highlighted. These losses are directly related to photovoltaic system output. For Case 1, the AC system losses are 0.5%, shading losses are 0.2%, reflection losses are 3.6%, soiling losses are 2.0%, irradiance losses are 0.5%, temperature losses are 6.7%, mismatch losses are 3.3%, wiring losses are 0.4%, clipping losses are 0.0% and inverters losses are 1.4%.

Figure 11.

PV system losses at 5° tilt angle.

The standard PV module working temperature is 25 °C. Temperature is the most important factor that affect the working performance of PV modules. However, the proposed PV site is located in hot climate area in Pakistan, so the ambient temperature () of PV module has increased too high. It can be calculated as [45]:

where

- : photovoltaic modules temperature (°C);

- : ambient temperature (°C);

- : wind speed;

- : solar radiation on the PV module (W/m2);

- : coefficient for the PV module’s upper temperature limit;

- : coefficient that determines how much the temperature of the PV module reduces when the wind speed increases.

By using Equation (1) for photovoltaic modules temperature, a 6.70% loss is calculated, and it is found that PV modules efficiency is reduced when photovoltaic modules temperature is increased.

When operating temperature of the PV system is increased, the performance of system decreased. This problem is reduced by using a passive cooling method. This method used combination of PCM and aluminum metal foam to regulate the temperature of the photovoltaic system [46].

The solar irradiance reflected from the surface of the photovoltaic modules are another reason for the loss of PV energy generation. These losses are calculated as [47]:

where

- : solar irradiance reflected from the surface of the photovoltaic modules (W/m2);

- : Albedo coefficient;

- : measured global irritation (W/m2);

- : collector tilt.

By using Equation (2) for solar irradiance reflected from the surface of the photovoltaic modules, 3.60% losses are calculated.

From the simulation result of Case 1, we found that the total irradiance of the collector was 1655.9 kWh/m2. The total amount of energy (kWh) that can be delivered to the utility grid was 2,175,683.7 kWh. The avg. operating ambient temp was 26.8 °C, whereas the avg. operating cell temp was 36.5 °C, as shown in Table 8.

Table 8.

PV system annual production result at 5° tilt angle.

3.2. Case 2: Energy Production of Photovoltaic System Installed at 10° Tilt Angle

In Case 2 we have selected a 10° tilt angle. At an available space in front of the Department of Electrical Engineering, first we perform the simulation study and compares PV system output to find the most appropriate interrow spacing for 10° tilt angle. Table 9 shows the total installed capacity, annual production, performance ratio and load ratio with different interrow spacing.

Table 9.

Performance comparison of pv system at 10° tilt angle with different interrow spacing.

The PV system, having interrow spacing 1 and 2 feet, and having a low performance ratio is because the system efficiency is decreased by the shading effect on the PV modules. In case of PV system having 4 feet interrow spacing, the overall installed capacity of the photovoltaic energy generation system is decreased. The performance of ground mounted photovoltaic systems is impacted by interrow spacing. By increasing the interrow spacing of the PV modules, the shading effect on PV modules is reduced, but it also increases land and electric wiring costs. By comparison, we analyze that the PV system installed at 10° tilt angle with 3 feet interrow spacing are more efficient. For this case, simulation result show that the annual production of PV system is 2.227 GWh, energy generated (kWh/kWp) is 1485.4 and performance ratio (PR) of the photovoltaic energy generation system is decreased to 82.3%. Figure 12 and Table 10 show the monthly energy generation of the photovoltaic system for 3 feet interrow spacing.

Figure 12.

Monthly energy generation of the photovoltaic system at a 10° tilt angle.

Table 10.

Monthly energy generation of the photovoltaic system at a 10° tilt angle.

Simulation results of Case 2 show that PV system produce maximum energy during summer season (May–June) and produce lowest energy during winter season (November–January).

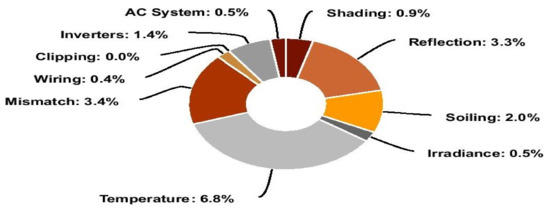

Figure 13 shows different PV system losses at a 10° tilt angle for 3 feet interrow spacing. For Case 2, the AC system losses are 0.5%, shading losses are 0.9%, reflection losses are 3.3%, soiling losses are 2.0%, irradiance losses are 0.5%, temperature losses are 6.8%, mismatch losses are 3.4%, wiring losses are 0.4%, clipping losses are 0.0% and inverters losses are 1.4%.

Figure 13.

PV system losses at 10° tilt angle.

From the simulation result of Case 2, we found that the total irradiance of the collector was 1696.0 kWh/m2. The total amount of energy (kWh) that can be delivered to the utility grid was 2,226,761.7 kWh. The avg. operating ambient temp was 26.8 °C, whereas the avg. operating cell temp was 36.8 °C, as shown in Table 11.

Table 11.

PV system annual production result at 10° tilt angle.

3.3. Case 3: Energy Production of Photovoltaic System Installed at 15° Tilt Angle

In Case 3, we have selected 15° tilt angle. At available space in front of department of electrical engineering, first we perform the simulation study and compares PV system output to find the most appropriate interrow spacing for 15° tilt angle. Table 12 shows the total installed capacity, annual production, performance ratio and load ratio with different interrow spacing.

Table 12.

Performance comparison of PV system at 15° tilt angle with different interrow spacing.

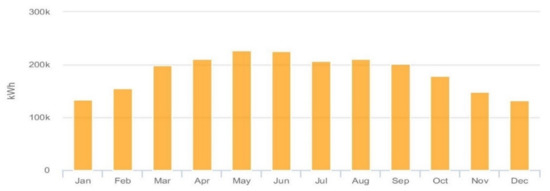

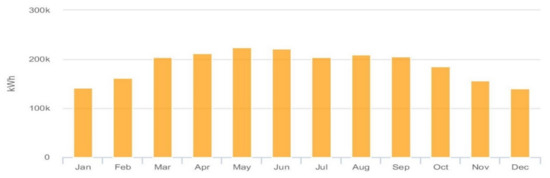

PV system having interrow spacing 1, 2 and 3 feet having low performance ratio, because system efficiency is decreased by shading effect on the PV modules. By comparison, we analyze that PV system installed at 15° tilt angle with 4 feet interrow spacing are more efficient. For this case, simulation result show that the annual production of PV system is 2.265 GWh, energy generated (kWh/kWp) is 1510.6 and performance ratio (PR) of the photovoltaic energy generation system is decreased to 82.0%. Figure 14 and Table 13 show the monthly energy generation of the photovoltaic system for 4 feet interrow spacing.

Figure 14.

Monthly energy generation of the photovoltaic system at 15° tilt angle.

Table 13.

Monthly energy generation of the photovoltaic system at 15° tilt angle.

Simulation results of Case 3 show that PV system produce maximum energy during summer season (May–June) and produce lowest energy during winter season (November–January).

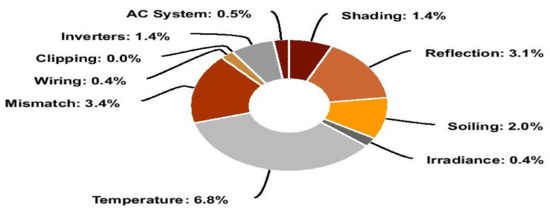

Figure 15 shows different PV system losses at a 15° tilt angle for 4 feet interrow spacing. For Case 3, the AC system losses are 0.5%, shading losses are 1.4%, reflection losses are 3.1%, soiling losses are 2.0%, irradiance losses are 0.4%, temperature losses are 6.8%, mismatch losses are 3.4%, wiring losses are 0.4%, clipping losses are 0.0% and inverters losses are 1.4%.

Figure 15.

PV system losses at 15° tilt angle.

From the simulation result of Case 3, we found that the total irradiance of the collector is 1725.0 kWh/m2. The total amount of energy (kWh) that can be delivered to the utility grid is 2,264,509.0 kWh. The avg. operating ambient temp is 26.8 °C, whereas the avg. operating cell temp is 37.0 °C as shown in figure Table 14.

Table 14.

PV system annual production result at 15° tilt angle.

3.4. Case 4: Energy Production of Photovoltaic System Installed at 20° Tilt Angle

In Case 4, we have selected 20° tilt angle. At available space in front of department of electrical engineering, first we perform the simulation study and compares PV system output to find the most appropriate interrow spacing for 20° tilt angle. Table 15 shows the total installed capacity, annual production, performance ratio and load ratio with different interrow spacing.

Table 15.

Performance comparison of PV system at 20° tilt angle with different interrow spacing.

The PV system has interrow spacing of 1, 2 and 3 feet and a low performance ratio, because the system efficiency is decreased by the shading effect on the PV modules. By comparison, we found that a PV system installed at a 20° tilt angle with a 4 feet interrow spacing are more efficient. For this case, the simulation result showed that the annual production of PV system is 2.257 GWh, energy generated (kWh/kWp) is 1505.4 performance ratio (PR) of the photovoltaic energy generation system is decreased to 80.5%. Figure 16 and Table 16 show the monthly energy generation of the photovoltaic system for 4 feet interrow spacing.

Figure 16.

Monthly energy generation of the photovoltaic system at 20° tilt angle.

Table 16.

Monthly energy generation of the photovoltaic system at 20° tilt angle.

Simulation results of Case 4 show that PV system produce maximum energy during summer season (May–June) and produce lowest energy during winter season (November–January).

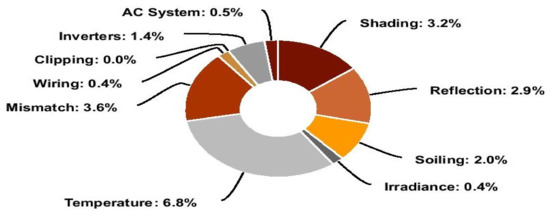

Figure 17 shows different PV system losses at a 20° tilt angle for 4 feet interrow spacing. For Case 4, the AC system losses are 0.5%, shading losses are 3.2%, reflection losses are 2.9%, soiling losses are 2.0%, irradiance losses are 0.4%, temperature losses are 6.8%, mismatch losses are 3.6%, wiring losses are 0.4%, clipping losses are 0.0% and inverters losses are 1.4%.

Figure 17.

PV system losses at 20° tilt angle.

From the simulation result of Case 4, we found that the total irradiance of the collector is 1722.5 kWh/m2. The total amount of energy (kWh) that can be delivered to the utility grid is 2,256,751.6 kWh. The avg. operating ambient temp is 26.8 °C, whereas the avg. operating cell temp is 37.0 °C, as shown in Table 17.

Table 17.

PV system annual production result at 20° tilt angle.

3.5. Case 5: Energy Production of Photovoltaic System Installed at 25° Tilt Angle

In Case 5, we have selected a 25° tilt angle. At available space in front of department of electrical engineering, first we perform the simulation study and compares the PV system output to find the most appropriate interrow spacing for 25° tilt angle. Table 18 shows the total installed capacity, annual production, performance ratio and load ratio with different interrow spacing.

Table 18.

Performance comparison of PV system at 25° tilt angle with different interrow spacing.

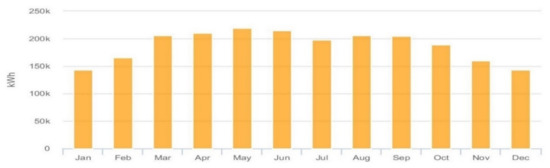

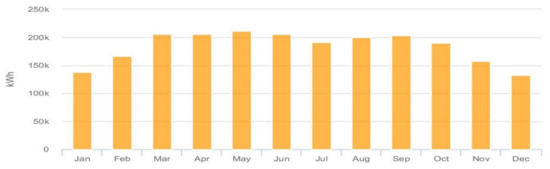

PV system having interrow spacing 1, 2 and 3 feet having low performance ratio, because system efficiency is decreased by shading effect on the PV modules. By comparison we analyze that PV system installed at 25° tilt angle with 4 feet interrow spacing are more efficient. For this case, simulation result show that the annual production of PV system is 2.206 GWh, energy generated (kWh/kWp) is 1471.3 and performance ratio (PR) of the photovoltaic energy generation system is decreased to 78.0%. Figure 18 and Table 19 show the monthly energy generation of the photovoltaic system for 4 feet interrow spacing.

Figure 18.

Monthly energy generation of the photovoltaic system at a 25° tilt angle.

Table 19.

Monthly energy generation of the photovoltaic system at a 25° tilt angle.

Simulation results of Case 5 show that PV system produce maximum energy during summer season (May–June) and produce lowest energy during winter season (November–January).

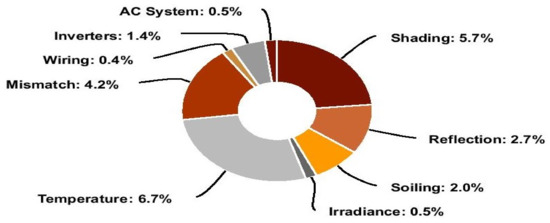

Figure 19 shows different PV system losses at a 25° tilt angle for 4 feet interrow spacing. For Case 5, the AC system losses are 0.5%, shading losses are 5.7%, reflection losses are 2.7%, soiling losses are 2.0%, irradiance losses are 0.5%, temperature losses are 6.7%, mismatch losses are 4.2%, wiring losses are 0.4%, clipping losses are 0.0% and inverters losses are 1.4%.

Figure 19.

PV system losses at 25° tilt angle.

From the simulation result of Case 5, we found that the total irradiance of the collector was 1694.2 kWh/m2. The total amount of energy (kWh) that can be delivered to the utility grid was 2,205,644.3 kWh. The avg. operating ambient temperature was 26.8 °C, whereas the avg. operating cell temp is 36.8 °C as shown in Table 20.

Table 20.

PV system annual production result at 25° tilt angle.

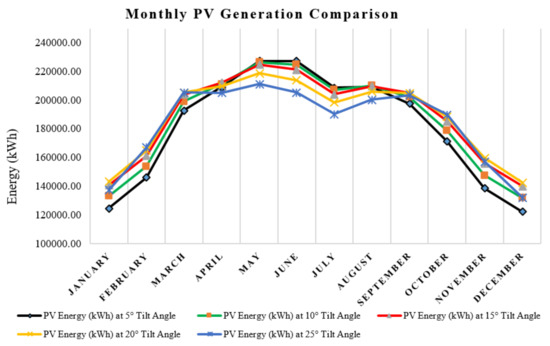

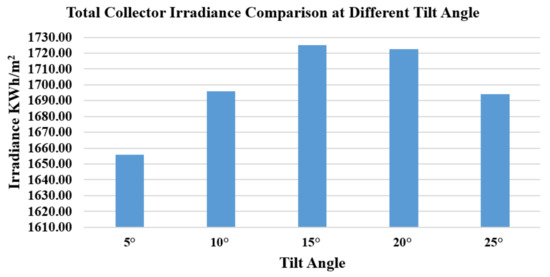

Comparison of monthly PV energy (kWh) generation installed at different tilt angle (5° to 25°) are shown in the Figure 20 and comparison of total collector irradiance are shown in Figure 21. The PV energy production is influenced by plane of array (POA). When we look at the plane of array (POA) irradiation for each case, we can see that the plane of array loss increased as the tilt angle of the PV system increased.

Figure 20.

Monthly PV energy (kWh) generation comparison at different tilt angle.

Figure 21.

Comparison of total collector irradiance.

4. Discussions

The performance of ground mounted photovoltaic systems is impacted by tilt angle and interrow spacing. By increasing the interrow spacing of the PV modules, the shading effect on PV modules is reduces, but it also increases land and electric wiring costs. Finally, if we analyze the results of the experiments, we can see that for Case 1, at a 5° tilt angle annual production of PV system is 2.176 GWh and performance ratio of the PV system is 82.6% with 3 feet interrow spacing. For Case 2, we use 10° tilt angle, the annual production of PV system is 2.227 GWh and performance ratio (PR) of the photovoltaic energy generation system is 82.3% with 3 feet interrow spacing. For Case 3, we use a 15° tilt angle, the annual production of PV system is 2.265 GWh and performance ratio of the PV system is 82.0% with 4 feet interrow spacing. For Case 4, we use 20° tilt angle, the annual production of PV system is 2.257 GWh and performance ratio (PR) of the photovoltaic energy generation system is 80.5% with 4 feet interrow spacing. For Case 4, we use 25° tilt angle, the annual production of PV system is 2.206 GWh and performance ratio of the PV system is 78.0% with 4 feet interrow spacing. In all five cases, we seen that tilt angle and interrow spacing has an impact on the PV output energy generation. When we look at the plane of array (POA) irradiation for each case, we can see that the plane of array loss increased as the tilt angle of the PV system increased. The PV energy production is influenced by plane of array (POA).

From simulation result of all cases, we concluded that the PV system installed at 15° angle are more efficient than the PV system installed at other tilt angle, because total collector irradiance is maximum (1725.0 kWh/m2) at 15° tilt angle as shown in Figure 21 and performance ratio of the photovoltaic system is also higher. In addition, at this tilt angle, the PV system produces maximum annual output energy (2,264,509.0 kWh).

The main goal of this study is to create a valid model that will help energy system designers, planners and investors especially in developing countries such as Pakistan where the requirement of installation area/site is still a major problem. Therefore, the optimal number of PV modules, their orientation and interrow spacing have become the important factors which are considered for designing of large scale PV system. Although, it is impossible to create a model with universal validity, but this research explores the technical approaches and methodologies, and software solutions that can provide technical assistance to developing countries in formulating suitable photovoltaic power plant designing and installation strategies.

5. Conclusions

HelioScope software is used to design ground-mounted photovoltaic systems and predict the plant performance at different tilt angles and interrow spacing in order to select the optimal angle and row space to meet the demand of electrical energy for the GC University Faisalabad. The Faisalabad district was selected for this research because it represents the overall climatic condition and the main population of Pakistan. According to a climatic and geographical study, Pakistan has a huge solar energy potential, with an average value of 1800.0 to 2200.0 kWh/m2 per year or 5.0 to 6.0 kWh/m2 per day. Overall, the system has showed potential and proved its feasibility to meet the energy demands of GC University.

By analyzing the results of the experiments, we concluded that the PV system installed at 15° angle with 4 feet interrow spacing are more efficient than the PV system installed at other tilt angle with different interrow space, because total collector irradiance is maximum (1725.0 kWh/m2) at 15° tilt angle and performance ratio of photovoltaic system is also higher. In addition, at this tilt angle PV system produces maximum annual output energy (2,264,509.0 kWh). System losses such as AC system, shading, reflection, soiling, irradiance, temperature, mismatch, wiring, clipping and inverters are highlighted during simulation results. For PV system installed at a 15° tilt angle with 4 feet interrow spacing, the AC system losses are 0.5%, shading losses are 1.4%, reflection losses are 3.1%, soiling losses are 2.0%, irradiance losses are 0.4%, temperature losses are 6.8%, mismatch losses are 3.4%, wiring losses are 0.4%, clipping losses are 0.0% and inverters losses are 1.4%.

For Pakistan, this study discusses the designing and energy estimation of photovoltaic energy generation system installed at optimal tilt angle and interrow spacing. This study evaluates the performance of photovoltaic system as well as helps to find the maximum usage of available space that is important for photovoltaic power plant investments. Currently, there is no research study available in Pakistan that is related to methodologies and finding presented in this study. While some international researchers have touched this research area in certain aspects such as Khan et al., 2020 [48]; Hartner et al., 2015 [49]; Babatunde et al., 2018 [50]). In addition, the findings of this research can help the energy system designers, planners and investors to formulate strategies for photovoltaic energy system installation in Pakistan and all-around the world.

The most important global validity of this research is to design the ground-mounted photovoltaic systems and predict the plant performance at different tilt angles and interrow spacing. This is to select the optimal angle and row space in order to avoids unnecessary costs of oversized systems and to utilize the available space in an optimal way.

Author Contributions

Conceptualization, M.T. and S.H.; methodology, M.T. and S.H.; software, S.H., A.R.B., A.D.B. and A.B.A.; validation, E.M.A., S.H. and A.R.B., formal analysis, E.M.A., S.H. and A.D.B. and A.B.A.; investigation, M.T. and S.H.; resources, S.H. and E.M.A.; writing—original draft preparation, M.T. and S.H.; writing—review and editing, M.T., E.M.A., A.D.B. and A.B.A. and S.H.; visualization, A.R.B., A.D.B., A.B.A. and E.M.A.; supervision, A.R.B., S.H. and E.M.A.; project administration, E.M.A. and S.H.; funding acquisition, E.M.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is already contained within this article.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| AWG | American wire gauge |

| AC | Alternating current (A) |

| CO2 | Carbon dioxide (CO2) |

| DC | Direct current (A) |

| GWh | Gigawatt hour |

| GHI | Global horizontal irradiance |

| Isc | Short circuit current |

| Imp | Maximum power current |

| kWh | Kilowatt hour |

| MWh | Megawatt hour |

| PR | Performance ratio |

| PV | Photovoltaic |

| POA | Plane of array |

| SLD | Single line diagram |

| Vmp | Maximum power voltage |

| Voc | Open circuit voltage |

References

- Muneer, T.; Asif, M.; Munawwar, S. Sustainable production of solar electricity with particular reference to the Indian economy. Renew. Sustain. Energy Rev. 2005, 9, 444–473. [Google Scholar] [CrossRef]

- Muneer, T.; Asif, M. Prospects for secure and sustainable electricity supply for Pakistan. Renew. Sustain. Energy Rev. 2007, 11, 654–671. [Google Scholar] [CrossRef]

- BP Energy Outlook 2035. 2020. Available online: https://www.bp.com/en/global/corporate/energy-economics/energy-outlook.html (accessed on 3 January 2021).

- Salam, R.A.; Amber, K.P.; Ratyal, N.I.; Alam, M.; Akram, N.; Muñoz, C.Q.G.; Márquez, F.P.G. An Overview on Energy and Development of Energy Integration in Major South Asian Countries: The Building Sector. Energies 2020, 13, 5776. [Google Scholar] [CrossRef]

- Qasim, M.; Kotani, K. An empirical analysis of energy shortage in Pakistan. Asia-Pac. Dev. J. 2014, 21, 137–166. [Google Scholar] [CrossRef]

- National Electric Power Regulatory Authority (NEPRA), Pakistan. State of Industry Report 2019–2020. Available online: http://www.nepra.org.pk/industryreports.htm (accessed on 14 February 2021).

- Sher, H.A.; Murtaza, A.F.; Addoweesh, K.E.; Chiaberge, M. Pakistan’s progress in solar PV based energy generation. Renew. Sustain. Energy Rev. 2015, 47, 213–217. [Google Scholar] [CrossRef]

- Farooqui, S.Z. Prospects of renewables penetration in the energy mix of Pakistan. Renew. Sustain. Energy Rev. 2014, 29, 693–700. [Google Scholar] [CrossRef]

- Duhirwe, P.N.; Hwang, J.K.; Ngarambe, J.; Kim, S.; Kim, K.; Song, K.; Yun, G.Y. A novel deep learning-based integrated photovoltaic, energy storage system and electric heat pump system: Optimising energy usage and costs. Int. J. Energy Res. 2021, 45, 9306–9325. [Google Scholar] [CrossRef]

- Hayat, M.B.; Ali, D.; Monyake, K.C.; Alagha, L.; Ahmed, N. Solar energy—A look into power generation, challenges, and a solar-powered future. Int. J. Energy Res. 2019, 43, 1049–1067. [Google Scholar] [CrossRef]

- Tyagi, V.V.; Rahim, N.A.; Rahim, N.A.; Jeyraj, A.; Selvaraj, L. Progress in solar PV technology: Research and achievement. Renew. Sustain. Energy Rev. 2013, 20, 443–461. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, G.; Lv, G.Z.; Zhang, A.N.; Wang, R.Z. Performance study of a solar photovoltaic air conditioner in the hot summer and cold winter zone. Sol. Energy 2015, 117, 167–179. [Google Scholar] [CrossRef]

- Razykov, T.M.; Ferekides, C.S.; Morel, D.; Stefanakos, E.; Ullal, H.S.; Upadhyaya, H.M. Solar photovoltaic electricity: Current status and future prospects. Sol. Energy 2011, 85, 1580–1608. [Google Scholar] [CrossRef]

- World Energy Council London. World Energy Resources. 2020. Available online: https://www.worldenergy.org/assets/images/imported/2020/10/WEC_Resources_summary-final_180314_TT.pdf (accessed on 29 February 2021).

- REN21. Renewables 2020 Global Status Report (Paris: REN21 Secretariat). ISBN 9783948393007. 2020. Available online: https://www.ren21.net/wp-content/uploads/2019/05/gsr_2020_full_report_en.pdf (accessed on 7 March 2021).

- IEA. World Energy Outlook 2020, IEA, Paris. 2020. Available online: https://www.iea.org/reports/world-energy-outlook-2020 (accessed on 21 March 2021).

- Baccoli, R.; Frattolillo, A.; Mastino, C.; Curreli, S.; Ghiani, E. A comprehensive optimization model for flat solar collector coupled with a flat booster bottom reflector based on an exact finite length simulation model. Energy Convers. Manag. 2018, 164, 482–507. [Google Scholar] [CrossRef]

- Baccoli, R.; Mastino, C.C.; Innamorati, R.; Serra, L.; Curreli, S.; Ghiani, E.; Ricciu, R.; Marini, M. A mathematical model of a solar collector augmented by a flat plate above reflector: Optimum inclination of collector and reflector. Energy Procedia 2015, 81, 205–214. [Google Scholar] [CrossRef] [Green Version]

- Baccoli, R.; Kumar, A.; Frattolillo, A.; Mastino, C.; Ghiani, E.; Gatto, G. Enhancing energy production in a PV collector–Reflector system supervised by an optimization model: Experimental analysis and validation. Energy Convers. Manag. 2021, 229, 113774. [Google Scholar] [CrossRef]

- Al-Zareer, M.; Dincer, I.; Rosen, M.A. Performance improvement study of an integrated photovoltaic system for offshore power production. Int. J. Energy Res. 2021, 45, 772–785. [Google Scholar] [CrossRef]

- Mustafa, R.J.; Gomaa, M.R.; Al-Dhaifallah, M.; Rezk, H. Environmental Impacts on the Performance of Solar Photovoltaic Systems. Sustainability 2020, 12, 608. [Google Scholar] [CrossRef] [Green Version]

- Zsiborács, H.; Baranyai, N.H.; Vincze, A.; Pintér, G. An Economic Analysis of the Shading Effects of Transmission Lines on Photovoltaic Power Plant Investment Decisions: A Case Study. Sensors 2021, 21, 4973. [Google Scholar] [CrossRef]

- Ahmed, W.; Sheikh, J.A.; Farjana, S.H.; Mahmud, M.A.P. Defects Impact on PV System GHG Mitigation Potential and Climate Change. Sustainability 2021, 13, 7793. [Google Scholar] [CrossRef]

- Djordjevic, S.; Parlevliet, D.; Jennings, P. Detectable faults on recently installed solar modules in Western Australia. Renew. Energy 2014, 67, 215–221. [Google Scholar] [CrossRef] [Green Version]

- Nawaz, I.; Tiwari, G.N. Embodied energy analysis of photovoltaic (PV) system based on macro-and micro-level. Energy Policy 2006, 34, 3144–3152. [Google Scholar] [CrossRef]

- Ayompe, L.M.; Duffy, A.; McCormack, S.J.; Conlon, M. Measured performance of a 1.72 kW rooftop grid connected photovoltaic system in Ireland. Energy Convers. Manag. 2011, 52, 816–825. [Google Scholar] [CrossRef] [Green Version]

- Gielen, D.; Boshell, F.; Saygin, D.; Bazilian, M.D.; Wagner, N.; Gorini, R. The role of renewable energy in the global energy transformation. Energy Strategy Rev. 2019, 24, 38–50. [Google Scholar] [CrossRef]

- Kumar, B.S.; Sudhakar, K. Performance evaluation of 10 MW grid connected solar photovoltaic power plant in India. Energy Rep. 2015, 1, 184–192. [Google Scholar] [CrossRef] [Green Version]

- Quiles, E.; Roldán-Blay, C.; Escrivá-Escrivá, G.; Roldán-Porta, C. Accurate Sizing of Residential Stand-Alone Photovoltaic Systems Considering System Reliability. Sustainability 2020, 12, 1274. [Google Scholar] [CrossRef] [Green Version]

- Charan, C.R.; Laxmi, A.J.; Sangeetha, P. Optimized energy efficient solution with stand alone PV system. MATTER Int. J. Sci. Technol. 2017, 3, 16–27. [Google Scholar] [CrossRef] [Green Version]

- Shi, K.; Li, C.; Koo, C. A Techno-Economic Feasibility Analysis of Mono-Si and Poly-Si Photovoltaic Systems in the Rooftop Area of Commercial Building under the Feed-In Tariff Scheme. Sustainability 2021, 13, 4709. [Google Scholar] [CrossRef]

- Sarkar, S.; Bhaskar, M.S.; Rao, K.U.; Prema, V.; Almakhles, D.; Subramaniam, U. Solar PV network installation standards and cost estimation guidelines for smart cities. Alex. Eng. J. 2022, 61, 1277–1287. [Google Scholar] [CrossRef]

- Goel, S.; Sharma, R. Analysis of measured and simulated performance of a grid-connected PV system in eastern India. Environ. Dev. Sustain. 2020, 23, 451–476. [Google Scholar] [CrossRef]

- Guittet, D.L.; Freeman, J.M. Validation of Photovoltaic Modeling Tool HelioScope Against Measured Data (No. NREL/TP-6A20-72155). National Renewable Energy Lab.(NREL), Golden, CO (United States). 2018. Available online: https://www.nrel.gov/docs/fy19osti/72155.pdf (accessed on 27 March 2021).

- Li, H.X.; Zhang, Y.; Edwards, D.; Hosseini, M.R. Improving the energy production of roof-top solar PV systems through roof design. Build. Simul. 2020, 13, 475–487. [Google Scholar] [CrossRef]

- Behi, B.; Baniasadi, A.; Arefi, A.; Gorjy, A.; Jennings, P.; Pivrikas, A. Cost–Benefit Analysis of a Virtual Power Plant Including Solar PV, Flow Battery, Heat Pump, and Demand Management: A Western Australian Case Study. Energies 2020, 13, 2614. [Google Scholar] [CrossRef]

- Meteonorm Software. Worldwide Irradiation Data. Available online: https://meteonorm.com/en/ (accessed on 11 April 2021).

- National Renewable Energy Laboratory. PVWatts Calculator. Available online: https://pvwatts.nrel.gov/ (accessed on 13 April 2021).

- Solar Prospector. Solar Resource Data. Available online: https://www.pvsyst.com/help/meteo_import_solar_prospector.htm (accessed on 15 April 2021).

- Hailu, G.; Fung, A.S. Optimum Tilt Angle and Orientation of Photovoltaic Thermal System for Application in Greater Toronto Area, Canada. Sustainability 2019, 11, 6443. [Google Scholar] [CrossRef] [Green Version]

- Liu, W.; Li, J.; Li, S.; Luo, J.; Jiang, X. Research on optimum tilt angle of photovoltaic module based on regional clustering of influencing factors of power generation. Int. J. Energy Res. 2021, 45, 11002–11017. [Google Scholar] [CrossRef]

- Rediske, G.; Siluk, J.C.M.; Gastaldo, N.G.; Rigo, P.D.; Rosa, C.B. Determinant factors in site selection for photovoltaic projects: A systematic review. Int. J. Energy Res. 2019, 43, 1689–1701. [Google Scholar] [CrossRef]

- Khan, S.; Hasan, M. Climate classification of Pakistan. Int. J. Econ. Environ. Geol. 2019, 10, 60–71. [Google Scholar] [CrossRef]

- Shahid, M.; Cong, Z.; Zhang, D. Understanding the impacts of climate change and human activities on streamflow: A case study of the Soan River basin, Pakistan. Theor. Appl. Climatol. 2018, 134, 205–219. [Google Scholar] [CrossRef]

- Kim, M.; Kim, H.; Jung, J.H. A Study of Developing a Prediction Equation of Electricity Energy Output via Photovoltaic Modules. Energies 2021, 14, 1503. [Google Scholar] [CrossRef]

- Sharaf, M.; Huzayyin, A.S.; Yousef, M.S. Performance enhancement of photovoltaic cells using phase change material (PCM) in winter. Alex. Eng. J. 2021, 61, 4229–4239. [Google Scholar] [CrossRef]

- Umer, F.; Aslam, M.S.; Rabbani, M.S.; Hanif, M.J.; Naeem, N.; Abbas, M.T. Design and optimization of solar carport canopies for maximum power generation and efficiency at Bahawalpur. Int. J. Photoenergy 2019, 2019, 6372503. [Google Scholar] [CrossRef] [Green Version]

- Khan, T.Y.; Soudagar, M.E.M.; Kanchan, M.; Afzal, A.; Banapurmath, N.R.; Akram, N.; Mane, S.D.; Shahapurkar, K. Optimum location and influence of tilt angle on performance of solar PV panels. J. Therm. Anal. Calorim. 2020, 141, 511–532. [Google Scholar] [CrossRef]

- Hartner, M.; Ortner, A.; Hiesl, A.; Haas, R. East to west–The optimal tilt angle and orientation of photovoltaic panels from an electricity system perspective. Appl. Energy 2015, 160, 94–107. [Google Scholar] [CrossRef]

- Babatunde, A.A.; Abbasoglu, S.; Senol, M. Analysis of the impact of dust, tilt angle and orientation on performance of PV Plants. Renew. Sustain. Energy Rev. 2018, 90, 1017–1026. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).