Abstract

Eco-friendly sustainable construction materials with low carbon dioxide emissions and low energy consumption which utilize agricultural and industrial waste are widely recommended. Utilizing high-volume fly ash waste (FA) as a cement replacement will contribute to a reduction in the environmental problems related to cement production and landfill disposal. It is well known that the inclusion of high amounts of FA (up to 50%) as a cement replacement leads to low strength performance, especially at a concrete’s early age (below 7 days). In this study, a cement mortar with high-volume FA (60%) was developed with strength enhancement. With nanotechnology and nanomaterial benefits, nanoparticles from bottle glass waste (BGWNP) were produced and used to replace 2, 4, 6, 8, and 10% of cement–FA binder. The results showed that the compressive strength significantly improved with the inclusion of the BGWNP in a high-volume FA matrix and the strength trend increased from 21.3 to 328 MPa with increasing nanoparticle content from 0 to 6%. However, the results indicated that the inclusion of nanoparticles up to 6% led to a slight reduction in strength value. Similar trends were observed for other engineering and microstructure properties and the matrix containing 6% of BGWNP achieved the highest performance compared to that of the control sample. It is concluded that, with the utilization of BGWNP, there is an ability to produce high-volume FA-based cement with acceptable engineering properties as well as achieve sustainability goals by reducing pollution, recycling waste, and resolving landfill issues.

1. Introduction

Since its inception, concrete remains one of the primary construction materials and is widely exploited worldwide. Concrete is the soul of the modern construction industry with an annual demand of almost twelve billion tonnes [1,2,3]. Over the decades, concrete has been modified using different types of material in order to improve its properties, which has been useful for various applications in the construction sectors [4,5,6,7]. In accordance with the 2015 Paris Agreement, global carbon emissions from the cement industry must be reduced by at least 16% by 2030 if the Earth is to remain within the pre-global warming temperatures of 1.5 °C or 2 °C [8,9]. However, with continuous urban land expansion, population growth, and economic development, statistics indicate that global cement production will increase from the current 4.08 billion tonnes to 5 billion tonnes within the next 30 years [10,11]. Furthermore, in accordance with the Global Commission on the Economy and Environment (GCEE), if developing countries increase their infrastructure to the current global average levels, then the construction industry will emit 470 gigatonnes of CO2 into the atmosphere by 2050. At present, 1 tonne of cement produces approximately 1 tonne of CO2. Cement production currently accounts for 7.1% of global CO2 emissions and 2–3% of energy consumption [12,13]. Apart from producing massive amounts of greenhouse gases (e.g., CO2, Sox, and NOx emissions) and consuming high amounts of energy during the heating process, cement contributes to rapid landscape degradation, dust production during transportation, noise generation in quarries, and raw material exhaustion [14,15]. All of these conditions are major environmental issues that exert an impact on ecosystems that is critical to human well-being. Another environmental challenge is the generation of solid waste. The current global annual output of coal waste production is approximately 800 million tonnes, with fly ash (FA) accounting for approximately 75–80% of this amount [16]. The current annual reuse of ash worldwide ranges from 3% to 57%, depending on the country; however, it averages at approximately 16% [17], with the remainder sent to garbage dumps or landfills. Heavy metals, such as cadmium and lead, can easily leak from ash landfills into soil and groundwater, where they can remain as contaminants for thousands of years [18].

Several studies [19,20,21,22] have provided various solutions to overcome the reduction in strength of concrete with high-volume FA. Some studies have suggested increasing the fineness of FA in order to increase its surface area, accelerating the pozzolanic reaction and forcing the fine FA particles to act as seeds and fillers [23,24]. Other studies have proposed increasing the alkalinity of the concrete mixture by adding extra lime in order to catalyze FA particles and make them react faster [22,23,24]. Amongst all of these methods, nanomaterials have elicited the most interest due to their remarkable capability to fix concrete flaws at early ages, particularly those caused by FA. A wide range of nano-additives, such as nano-SiO2, Al2O3, Fe2O3, Fe3O4, ZnO2, ZrO2, Cu2O3, CuO, CaCO3, SF, and CTs [10,25,26,27,28], have been harnessed due to their remarkable effects on improving the strength properties and durability of nano-modified concrete. However, nearly all of these additives are rarely available or are expensive. In accordance with this principle, the utilization of industrial waste by-products as nano-additives may hold the key to multiple levels because they are low-cost waste materials that offer an environmentally friendly alternative to solid waste landfills. The presence of noncrystalline aluminium and silicon (with high amorphous silica content) in pulverized glass waste from bottles makes such waste an effective pozzolanic material [29]. Several studies on the use of glass waste as an aggregate in concrete have been recently conducted [30]. However, the results showed that concrete prepared with glass waste particles as coarse or fine aggregate performed poorly due to the damage caused by the alkali–silica reaction [31].

Bottle glass waste is one of the municipal solid wastes that end up in landfills or garbage dumps due to its non-biodegradable nature, posing severe environmental challenges. Every year, millions of tonnes of glass bottles are discarded worldwide [32]. Although some of these bottles are reused by glass producers through recycling, recycling all waste glass is difficult due to limitations, specifications, color variation, glass defects, and processing costs [33]. Soda-lime glass, with significant amounts of amorphous silica and a fixed chemical composition, accounts for approximately 82% of industrially processed glass [34]. Landfills are no longer considered an ideal solution because they are regarded as less environmentally sustainable given that glass is not a biodegradable material. With the environmental concerns surrounding cement and the challenges associated with industrial waste, adopting these industrial by-products in order to replace cement fully or partially may be environmentally and economically beneficial. Whilst most studies have focused on using industrial by-products, such as ash, granular furnace slag [35], rice husk ash [36], and silica fume [37], individually as cement alternatives, the synthesis of concrete using multiple types of these industrial by-products may be more efficient in the modified concrete production process. Several studies have highlighted the benefits of the general properties of concrete based on industrial by-products, such as FA, indicating that several properties of concrete, such as workability, durability, and strength, can be effectively improved at late ages [38]. However, the applicability of FA as an alternative source of Portland cement is regarded as a challenge due to the low mechanical performance of FA at early ages [39].

Meanwhile, when the fineness of the glass particles is reduced to less than 20 μm, the resulting glass powder exhibits favorable pozzolanic properties, and alkali–silica reaction is averted [40]. Thus, glass powder chemically reacts with calcium hydroxide (CH) to form extra calcium silicate hydrate (C–S–H) gel, avoiding the alkali–silica reaction [40]. This phenomenon opens up the possibility of using glass powder in concrete production as a partial substitute for Portland cement. Several studies [41] have shown that glass powder has adequate pozzolanic properties and using it as a partial substitute for cement improves several bulk properties of concrete. In previous studies [41,42], the researchers investigated the feasibility of using glass bottle powder as a partial substitute for cement with different levels ranging from 5% to 25% of the binder weight. Their findings showed a slight increase in compressive strength and improvements in flexural strength, water absorption, and chloride ion penetration, particularly with 15% cement replacement. However, all three studies reported a decrease in strength indexes at high replacement levels. Elaqra et al. [43] and Deng et al. [44] investigated the use of fine glass powder in various mixtures with and without coal ash. They recorded an increase in compressive, flexural and splitting tensile strengths, bending toughness, and deflection, with glass powder replacement levels ranging from 10 to 20 of the binder weight. Previous research has focused on using large amounts of glass powder as a cement substitute.

However, research on using it as a nanomaterial additive in order to improve the early strength properties of cement is still in its infancy. Huseien et al. [45] reported that adding bottle glass waste to nano-powder exerts a positive effect on the engineering properties of Geopolymer mortars. In accordance with the aforementioned studies [21,45], the improvement in strength and microstructure properties may be attributed to the pozzolanic reaction process, the production of extra C–S–H gel, and the physical filling effect of pores and cracks, which reflect positively on the strength properties, homogeneity, and compactness of cementitious systems.

This study aims to produce sustainable mortars for several applications in the construction sector with a reduction in environmental problems such as carbon dioxide emission, energy consumption, and landfill disposal, by replacing the cement with high-volume FA and BGWNP. The BGWNP was used to solve the early strength issue and enhance the engineering and microstructure properties at early and late ages. Several tests were conducted in order to evaluate the suggested mortar performance such as compressive strength, flexural, tensile, water absorption, and microstructures.

2. Methodology

2.1. Materials

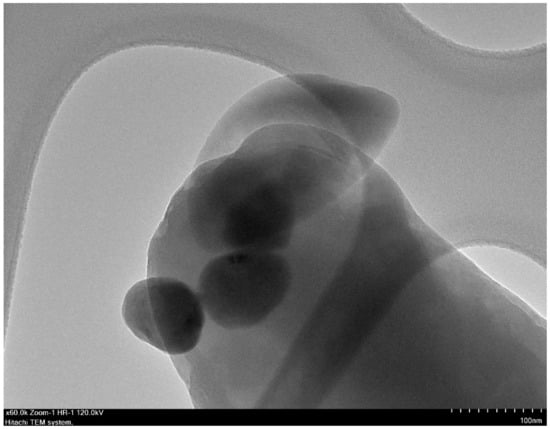

The suggested binders were synthesized from the resource materials: ordinary Portland cement (OPC), FA, and BGWNP. OPC that met the ASTM C150 requirements for cement Type I was obtained from a local cement producer and used as the primary source of calcium oxide (CaO). FA was collected as the primary resource of aluminium silicate from industry waste and used directly without any treatment except for the crushing of agglomerated particles. Bottle glass waste was collected from the food industry as waste material. The bottles were first cleaned with regular tap water in order to remove pollutants before being crushed with a crusher machine. Then, the crushed glass was ground for 3 h using a Los Angeles abrasion machine with a capacity of 25 kg in order to achieve a medium particle size of 25 µm. Thereafter, the obtained powder was heated at 110 °C for 1 h and then ground for another 7 h in a ball mill in order to achieve the nanosize (as shown in Figure 1). The stages of preparing BGWNP from glass waste are presented in Figure 2.

Figure 1.

TEM image of prepared BGWNP.

Figure 2.

BGWNP preparation stages using a ball mill grinding machine.

X-ray fluorescence spectroscopy (XRF) was used to determine the chemical compositions of OPC, FA, and BGWNP, as indicated in Table 1. CaO and aluminium silica oxides were found in 89.97% of OPC, 91.17% of FA, and 86.16% of BGWNP. The OPC included a significant amount of CaO (approximately 62.4%) whilst the FA contained a relatively small amount (5.16%). The percentage of K2O was less than 1% in OPC, FA, and BGWNP. Meanwhile, the percentage of iron oxide (Fe2O3) was remarkably similar in the OPC (3.35%) and FA (3.67%). In general, the XRF test indicated that the OPC had a high calcium weight, FA had a high aluminium weight, and BGWNP had a high silicon weight. Table 1 also provides the physical characteristics of the OPC, FA, and BGWNP, such as specific gravity, color, and average size. The specific gravity of the OPC, FA, and BGWNP was 3.15, 2.20, and 1.02, respectively. Moreover, the OPC had a dark grey color, FA had a grey appearance, and BGWNP was light grey. The transmission electron microscopy (TEM) of BGWNP is shown in Figure 2. The average size particle of BGWNP was approximately 80–120 nm.

Table 1.

Chemical compositions of OPC obtained from XRF analyses.

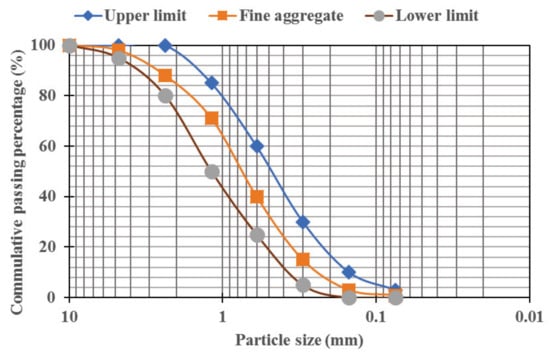

In the mix design, natural siliceous river sand was utilized as fine aggregates wherein the sand was cleaned as per ASTM C117 requirements in order to eliminate silts and impurities. Next, it was oven-dried (60 °C) for a day for moisture control. Care was taken to ensure that the aggregates were free from organic matters such as dry mud, leaves, and other harmful materials. The physical properties of the fine and coarse aggregates (such as density, specific gravity, degree of voids, evaporable moisture content, and water absorption) were recorded according to the method described in ASTM C128. These parameters fulfilled the conditions needed to produce the normal mortar and the highest-allowed limit required by ASTM C33 stipulation. The percentage passing the 600 μm sieve was also found as 40% to be used in the mix design calculations. The bulk density of the oven-dried fine aggregates and specific gravity on the saturated surface dry (SSD) condition were 1730 kg/m3 and 2.70, respectively. Figure 3 shows the grading outcomes of fine aggregates obtained from the sieve analysis. The grading of the different sizes of the fine aggregates occurred within the upper and lower limits specified by ASTM C33. The nominal highest size and fineness modulus of the fine aggregates were 4.75 mm and 2.3, respectively. Generally, the well-graded aggregates showed less water demand and segregation tendency, and were, thus, responsible for the overall properties’ enhancement of the proposed concrete mixes.

Figure 3.

Particle size distribution of the fine aggregates.

2.2. Mixes’ Design and Specimens’ Preparation

Table 2 provides the proportions of the suggested mortars’ mix design. The control mix was then calibrated to achieve a compressive strength of 30 MPa after 28 days of curing age. FA was used to replace 60% of the OPC by weight and was considered as a control sample. Then, varied amounts of BGWNP (2%, 4%, 6%, 8%, and 10%, by weight of binder) were included as an OPC-FA binder replacement. First, the binder was prepared by mixing the OPC, FA, and BGWNP for 3 min in order to be homogenous. Then, the fine aggregates were added and mixed for another 4 min. Finally, the water was added and the mixture was mixed for another 5 min. Then, the prepared mortars were cast into the molds which was achieved using a two-layers pouring method. In this process, each layer was subjected to vibration for a period of 20 s in order to eliminate any air pockets within the mixture. Once the casting process was completed, the casted mortar specimens were cured for 24 h in an ambient atmosphere (temperature 27 ± 1.5 °C, relative humidity 50%) before the demolding process. The specimens were demolded after 1 day and cured at atmosphere temperature (27 °C) until the test day.

Table 2.

Details of the normal and optimized self-curing concrete mixtures.

2.3. Test Procedure

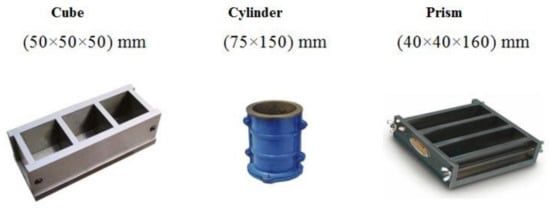

The workability of the proposed mortars was evaluated in terms of a flow test in order to provide an assessment of the ease of handling the mortar in its fresh state in accordance with ASTM C143, as shown in Figure 4. To evaluate the engineering properties of prepared high-volume fly ash mortars, three types of molds, namely, cubes (50 mm × 50 mm × 50 mm), cylinders (75 mm × 150 mm), and prisms (40 mm × 40 mm × 160 mm) were used (as shown in Figure 5). A compressive strength test was conducted in accordance with ASTM C109 specifications. Three specimens from each age were tested and the average value was considered. Flexural strength and splitting tensile strength were tested in accordance with ASTM C78 and ASTM C496, respectively. Modulus of elasticity (MOE) was examined in accordance with ASTM C469/C469M. Following ASTM C 642, a specification water absorption test was performed. X-ray diffraction (XRD), scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDS), and thermogravimetric analysis (TGA) were conducted in order to monitor the microstructural properties of the designed specimens. To perform XRD and TGA/differential thermal analysis (DTA) tests, a small part of the interior of the tested specimen was taken for compressive strength and ground tests to pass through a 125 nm sieve. The surface morphology of the tested specimens was examined using SEM. The samples prepared for the SEM test were taken from specimens tested for compressive strength at 7 and 28 days. The samples were then sown onto two cellophane sheets before being attached to a coin. For SEM imaging, each sample was placed in a sample holder (brass stub type) and dried for 5 min with ionizing radiation before being coated with gold using a Blazers sputter coater. The resulting patterns were studied at a voltage of 120 kV and a magnification of 1000×. After selecting a relatively high image magnification, significant morphological images were captured immediately.

Figure 4.

Procedure for measuring the prepared mortar’s flowability.

Figure 5.

Various steel molds used in the preparation of high-volume FA specimens.

3. Results and Discussion

3.1. Workability

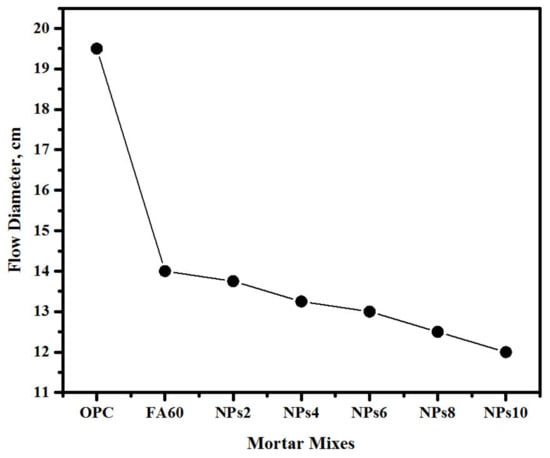

Figure 6 shows the measured flow diameter values of various mortar mixes. It can be clearly observed that the mortar’s workability is obviously influenced by the FA and BGWNP content. The flow diameter values of the mix prepared with the FA as an OPC replacement was monotonically decreased with an increase in FA contents. The flow value of the OPC (control sample) was dropped from 19.5 cm to 14 cm with the inclusion of FA (60% as OPC replacement). The results of the flow test of the designed mixtures are presented in Figure 4, which illustrates the influence of FA on reducing the workability of mortar mixtures by approximately 28% with a 0.55 water-to-cement (w/c) ratio. The high surface area and water demand of FA particles resulted in a reduction in the prepared mortar’s workability [46]. Meanwhile, adding BGWNP resulted in a slight decrease in workability. With the inclusion of BGWNP as an OPC-FA binder replacement, the flow diameter value was dropped from 14 cm to 13.75, 13.25, 12.5, and 12 cm, with increasing nanoparticle content from 0% to 2, 4, 6, 8, and 10%, respectively. Such findings may be attributed to the role of nanomaterials in increasing blended viscosity. This result can be ascribed to the inclusion of high specific surface area nanoparticles, which require more water to become wet [45]. In contrast with the spherical shape of the FA particles, the angular and irregular shape of the BGWNP particles may increase intermolecular friction, limiting workability [47]. Furthermore, BGWNP tends to occupy the interspace between mixture particles, reducing the area available for particle dynamics, and, thus, a high amount of water is required to lubricate the mixture in order to provide it with sufficient workability [48].

Figure 6.

Flow diameter values of the proposed mortar mixes.

3.2. Compressive Strength

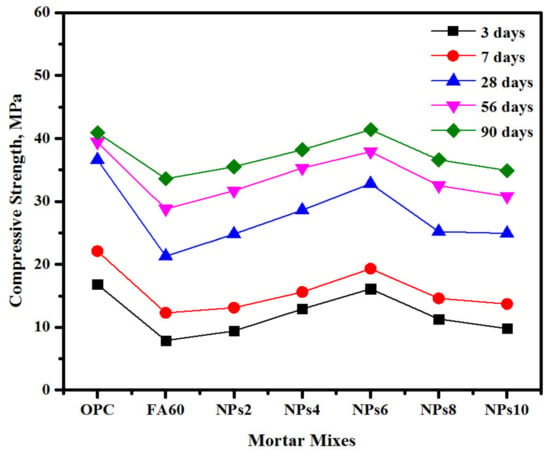

Figure 7 illustrates the compressive strength of the prepared mortars after 3, 7, 28, 56, and 90 days of curing age. With regard to the specimens containing 60% of FA, and compared to the OPC control sample, the results showed a significant reduction in early compressive strength, particularly at 3, 7, and 28 days. Nevertheless, the compressive strength of the high-volume FA specimens was close to that of the control sample at 90 days. The results showed a drop in compressive strength replacing 60% of the OPC by the FA from 16.1, 22.1, 36.5, 39.4, 40.9 MPa to 7.9, 12.2, 21.3, 28.8, 33.7 MPa, at 3, 7, 28, 56, and 90 days, respectively. When 60% of the OPC was replaced by the FA, the Ca(OH)2 formed by cement hydration became insufficient for activating all of the FA contents to trigger a pozzolanic reaction [49]. Consequently, many unreacted FA particles remained in the paste, increasing the pore size and the total porosity of the matrix and reducing its compressive strength [19]. After 28 days, more Ca(OH)2 content was precipitated around the unreacted FA particles and the unreacted FA particles reacted and formed extra C–S–H/C−A−S−H gel [50]. This phenomenon was demonstrated in this work by comparing the compressive strength of the high-volume FA and control samples at 90 days, i.e., 39.7 MPa for the FA60 specimens and 42.1 MPa for the control samples. Several authors [51] have reported similar patterns for a high-volume FA-based cement binder, i.e., generally exhibiting significant increases in compressive strength that is either equal to or exceeds that of normal concrete at late ages.

Figure 7.

Compressive strength development of designed mortars.

For the specimens prepared with BGWNP as an OPC-FA binder replacement, the results showed an enhancement in strength development. At an early age (3 days), the inclusion of 2, 4, and 6% of BGWNP in the modified cement matrix led to an increase in compressive strength from 7.9 MPa to 9.4, 12.9, and 16.1 MPa, respectively. However, the increasing level of replacement to 8 and 10% resulted in a drop in strength to 11.3 and 9.8 MPa, respectively. A similar trend of results was observed at 7 days of curing age and the inclusion of 6% BGWNP as an OPC-FA binder replacement significantly improved the strength development compared to the other levels. At 28, 56, and 90 days of curing age, the results indicated that replacing the OPC-FA binder by 6% led to an improvement in compressive strength to 32.8, 37.9, and 41.4 MPa, respectively. A higher improvement in compressive strength was recorded in NPs6 at 90 days of age, which achieved a slightly higher performance when compared to the control sample (OPC). Meanwhile, the performance of the NPS4 specimens was close to those of the control sample (OPC) and NPs6, recording a compressive strength of 28.6, 35.4, and 38.2 MPa at age of 28, 56, and 90 days, respectively. However, the NPs2, NPs8, and NPs10 specimens exhibited a lower performance when compared to the control sample. In general, the mixtures with 6% of BGWNP achieved the targeted design strength at 28 days, which has a compressive strength value of 32.8 MPa.

Two factors may work together and contribute to the enhancement of the matrix’s compressive strength due to nano-additives at early ages [52]. The first factor is the physical effect, in which micropores are filled up to reduce the porosity of the matrix. The second factor is the chemical effect due to the consumption of Ca(OH)2 and the formation of more C–S–H gel, which enhances strength performance [48]. On this basis, BGWNP, which have a size of less than 120 nm and high contents of CaO, SiO2, and Al2O3 (3.16%, 69.14%, and 13.86%, respectively), can explain the increment in compressive strength. Nevertheless, the strength of the nanomaterials-modified concrete increases as the percentage of nano-additives increases, but compressive strength decreases beyond the optimal content of the nanomaterials. Such a decrease in the compressive strength of mortar beyond the optimum dosage of nanomaterials is primarily due to the creation of agglomerates, producing weak zones and points within the concrete matrix [53]. This phenomenon can explain the low compressive strength of NPs8 and NPs10. Furthermore, with an increase in nanoparticle content, antiparticle distances decrease to an extent that can hinder the formation of Ca(OH)2 crystals. Consequently, the decrease in Ca(OH)2 crystals can reduce strength properties because these crystals are essential components responsible for reacting with the added nanoparticles that generate excess C–S–H gel in the concrete [54]. At later ages of 56 and 90 days, the compressive strength of the specimens’ NPs6 exceeded that of the normal concrete sample (OPC), with values of 41.4 MPa compared to 40.9 MPa, respectively. The improvement in the compressive strength of the specimens containing 6% of BGWNP may be largely attributed to the following reasons: (1) the pozzolanic reaction of BGWNP and FA particles at the ages of 28, 56, and 90 days and (2) the role of BGWNP in filling pores and increasing the compactness of the samples.

However, the low performance of mortar specimens containing 8 and 10% of BGWNP (NPs8 and NPs10) can be attributed to the high surface area of nanoparticles which assisted in the reduction of the compressive strength performance. However, the lower performance of NPs10 compared to the other mixtures was attributed to decreasing the internal space required to form hydration products which resulted in lower strength values. With increasing nanoparticle percentage, the space between the nanoparticles is reduced to the point wherein the formation of Ca(OH)2 crystals is inhibited. The Ca(OH)2 was considered as the major molecule that reacts with nanoparticles to generate extra C–S–H gel. At the late ages of 56 and 90 days, the pozzolanic reaction of the FA particles started to accelerate, enhancing the strength performance of specimens.

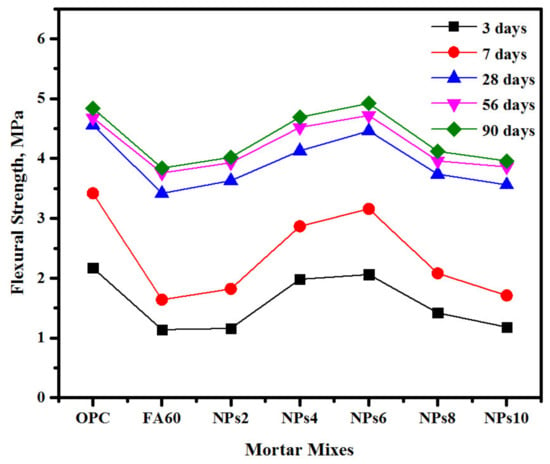

3.3. Flexural Strength

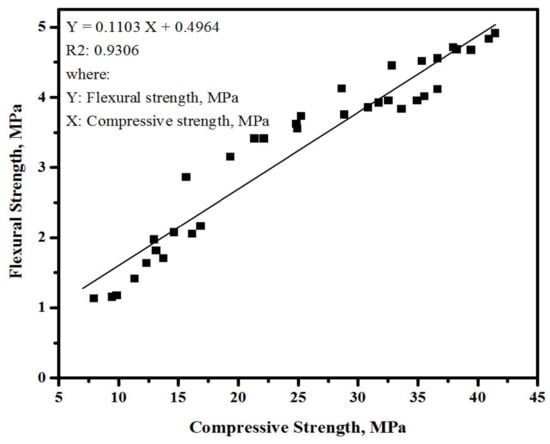

Figure 8 illustrated the effect of FA and BGWNP content on the OPC mortar’s flexural performance. For this purpose, the prepared specimens were evaluated after 3, 7, 28, 56, and 90 days of curing ages. From the reported results, it can be clearly observed that the flexural strength value was significantly influenced by the FA content and the strength values were dropped for all ages. At ages 3, 7, 28, 56, and 90 days, the inclusion of 60% FA as an OPC replacement resulted in a drop in flexural strength value from 2.17, 3.42, 4.56, 4.68, and 4.84 MPa to 1.14, 1.64, 3.42, 3.76, and 3.82 MPa, respectively. However, with the inclusion of BGWNP as a partially replaced OPC-FA binder led to an improvement in flexural strength performance. The results showed that the 6% of BGWNP achieved the optimum level of replacement and significantly improved strength compared to that of the control sample. For the specimens containing 6% of BGWNP, the flexural strength values increased from 2.07 MPa to 3.16, 4.46, 4.72, and 4.92 MPa, with an increasing curing age from 3 days to 7, 28, 56, and 90 days, respectively. The increment in flexural strength values at early ages with the inclusion of BGWNP can be largely attributed to the presence of fine BGWNP that serve as seeds, providing additional nucleation sites and expediting the hydration process within the mixture. The BGWNP reacted with the Ca(OH)2 to produce extra C–S–H gel and improved the strength performance. This observation was attributed to two factors related to nano-additives. Firstly, once the amorphous silica in BGWNP dissolved in water, it formed H2SiO4 which reacted with the Ca2+, forming C–S–H gel. Secondly, the presence of BGWNP acted as seeds inside pores, providing more nucleation sites and enhancing pozzolanic reaction. These two mechanisms may improve bonds between hydration and pozzolanic products and aggregates due to refined micro-cracks, decreased porosity, and the conversion of Ca(OH)2 to C–S–H gel [55]. Figure 9 displays the relationship between flexural strength and the compressive strength of modified mortars. A linear regression method was applied to correlate the experimental data, with R2 values between 0.9306, which signified good confidence for the relationships.

Figure 8.

Flexural strength development of designed mortars.

Figure 9.

Relationship between compressive strength and flexural strength of modified mortars.

3.4. Splitting Tensile Strength

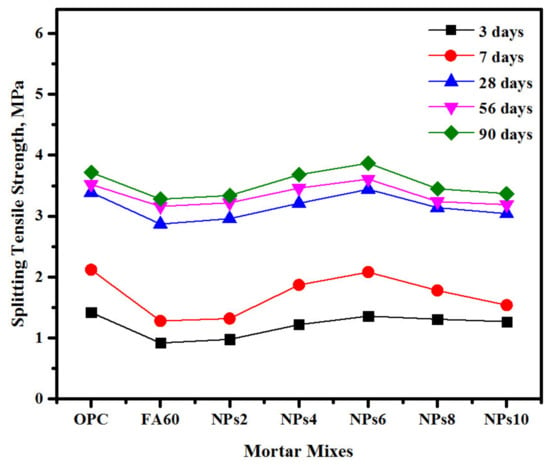

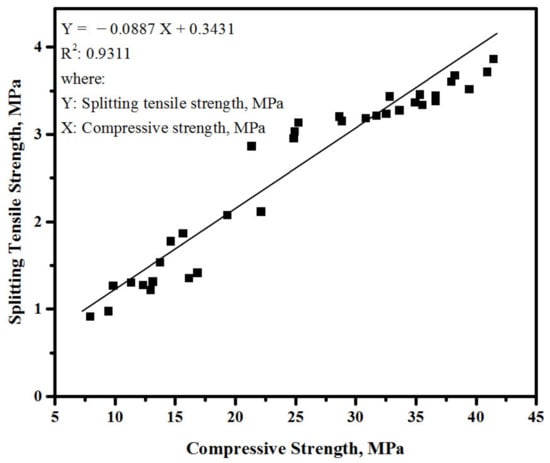

The average values of the proposed mortar’s splitting tensile strength tested at 3, 7, 28, 56, and 28 days are presented in Figure 10. The splitting tensile strength of the control sample (OPC) was 1.42, 2.12, 3.39, 3.52, and 3.72 MPa at 3, 7, 28, 56, and 90 days, respectively. With the inclusion of 60% of the FA as an OPC replacement, the splitting tensile strength value was dropped to 0.92, 1.28, 2.87, 3.16, and 3.28 MPa after 3, 7, 28, 56, and 90 days of curing age, respectively. Similar to results reported in Section 3.2 and Section 3.3, the reduction in splitting tensile strength due to the inclusion of a high-volume of FA (60%) as an OPC replacement was generally remarkable. The reduction in splitting tensile strength values can be attributed to the slow pozzolanic reaction of the FA content and the lack of OPC content required to bond aggregate particles. The inclusion of BGWNP in the mortar matrix demonstrated a better performance in terms of splitting tensile strength. After 3 days of curing age, the splitting tensile strength of the specimen containing 2, 4, 6, 8, and 10% of BGWNP recorded strengths of 0.98, 1.22, 1.36, 1.31, and 1.27 MPa, respectively. The specimens prepared with 6% of BGWNP as an OPC-FA binder replacement recorded the highest splitting tensile strength compared to the other levels of replacement, with an increasing curing age of 3 days to 7, 28, 56, and 90 days for the splitting tensile strength value trend which increased from 1.36 MPa to 2.08, 3.44, 3.61, and 3.87 MPa, respectively. Several studies have attributed the role of nanoparticles in strength improvement indexes to two factors: their pozzolanic properties and their high surface area reactivity [56]. Elaqra et al. [43] investigated the use of fine glass powder in various mixtures with and without bottom ash and recorded an increase in splitting tensile strength at approximately all curing ages. In accordance with their findings, the increase in tensile strength might be due to a reduction in pore size as the pozzolanic reaction progressed, and in the production of denser C–S–H. The pozzolanic reaction between the SiO2 and CaO contents of glass powder, which occurs in the pore solution and in Ca(OH)2, may explain the increment in splitting tensile strength caused by BGWNP [43]. Similar to other pozzolanic nano-additives, such as nano-silica, BGWNP serve as seeds, providing additional nucleation sites and expediting the hydration process in the mixture. In addition, BGWNP reacts with lime to produce extra C–S–H gel due to its pozzolanic properties. Furthermore, BGWNP act as seeds and fillers inside pores and small cracks, providing more nucleation sites, increasing the compactness of the matrix, and decreasing porosity; these phenomena reflect positively on strength properties [57]. A linear regression method was applied to correlate the experimental data of compressive strength and splitting tensile strength as shown in Figure 11, with R2 values between 0.9311, which signified good confidence for the relationships.

Figure 10.

Splitting tensile strength development of designed mortars.

Figure 11.

Relationship between splitting tensile strength and compressive strength.

3.5. Modulus of Elasticity

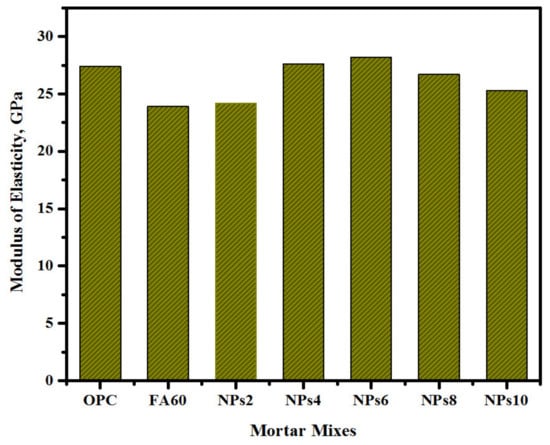

At the age of 28 days, the modulus of elasticity (MoE) was measured and the obtained results are illustrated in Figure 12. The results indicated that the value of the MoE was significantly influenced by FA and BGWNP content. With the inclusion of 60% of FA as an OPC replacement in a modified mortar mixture, the MoE value dropped sharply from 27.4 GPa to 23.9 GPa, respectively. However, with the inclusion of 2, 4, and 6% of BGWNP as an OPC-FA binder replacement slightly increased the MoE values to 24.2, 27.6, and 28.2 GPa, respectively. Unlike the results shown, increasing the BGWNP content to 8 and 10% negatively affected the MoE values which dropped to 26.7 and 25.3 GPa, respectively. The reduction of MoE values with a high amount of FA (60%) can be ascribed to the delayed pozzolanic process of the FA content. Several studies [58,59,60] have found that high-volume FA mixtures have lower MoE values than traditional cement mixtures. Furthermore, previous studies have reported that increasing FA content in the cement matrix resulted in a sharp reduction in strength properties including the MoE. For strength enhancement with the inclusion of BGWNP in the mortar matrix, several studies [47,61,62] have been conducted on the use of glass powder as a substitute for cement, but no significant increase in MoE has been reported, particularly in early ages. These studies ascribed the lack of a marked increase in MoE to the low pozzolanic reaction of glass powder at early ages. However, by increasing glass powder fineness to within a nanoscale, the role of nanoparticles, even from different sources, in filling pores and providing more nucleation sites to consume Ca(OH)2, dominating Ca(OH)2 crystal orientation growth, and reducing total crystal size, improves MoE. Controlling the growth of Ca(OH)2 crystals (with hexagonal platelet morphology) reduces the probability of forming cracks at the interfacial transition zone (ITZ); such cracks are considered essentially responsible for the failure of mechanical properties, including MoE (weak zones) [14]. In addition, the inclusion of nanoparticles decreases the probability of Ca(OH)2 crystal growth. This reduction is ascribed to the strong reactivity and high surface area of the nanoparticles included in the concrete matrix. A conclusion was drawn that incorporating various nanoparticles into the OPC matrix possibly slows down the growth rate of Ca(OH)2 crystals in the simulated transition regions; this phenomenon is responsible for the creation of more C–S–H gel, which acts as gap/pore filling agent in the OPC matrix, enhancing mechanical properties, including MoE [63].

Figure 12.

Modulus of Elasticity development of designed mortars.

3.6. Water Absorption

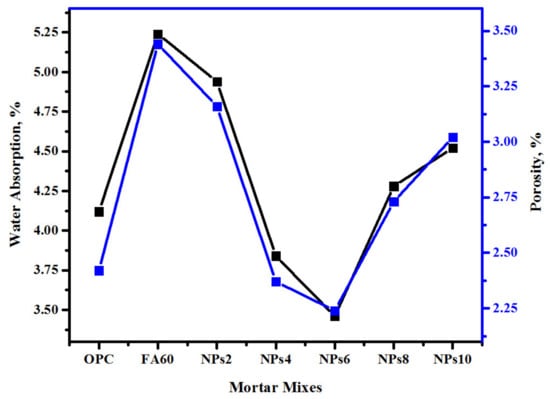

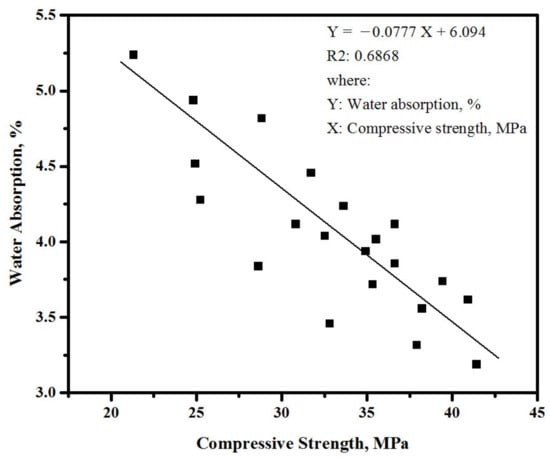

Figure 13 displays the water absorption (WA) and the porosity of the prepared high-volume FA specimens after 28 days of curing age. The FA60 specimen exhibited a higher WA percentage (5.24%) than that of the one reordered with the control sample (4.12%). This increment can be attributed to the slow pozzolanic reaction of the FA content, leaving a considerable number of capillary pores that allow water to diffuse into the mortar’s structure. However, the microstructure of the prepared mortars was improved with the inclusion of BGWNP and the ratio of water absorption trend decreased. In the case of adding BGWNP, the NPs6 sample expectedly exhibited the lowest WA ratio (3.46%). This finding may be attributed to the ideal hydration condition that is associated with 6% BGWNP, which demonstrated optimum performance in all of the tested performance indexes. With the inclusion of 2 and 4% BGWNP, the results recorded a decrease in WA% and achieved 4.94 and 3.84% compared to 5.24%, respectively. To evaluate the actual reduction due to the addition of BGWNP, however, the increasing content of BGWNP on the mortar matrix up to 6% (8 and 10%) led to a slight increase in the WA value from 3.46% to 4.28 and 4.52%, respectively. Likewise, the porosity of the evaluated specimens was influenced by the BGWNP content. The results showed that the inclusion of 6% of BGWNP significantly reduced the porosity value of tested specimens. Several studies [64,65,66] have reported that incorporating glass nanoparticles into the cement matrix reduces the permeability, and, consequently, the WA percentage. The mechanism for the improvement of the mortar’s porosity due to BGWNP inclusion can be attributed to the uniform dispersion of BGWNP into the mortar’s matrix and the equal interparticle distribution. With an optimum content and regular distribution of BGWNP, distribution is assumed to be homogeneous for uniform gel production throughout the mortar matrix, regulating the distribution, morphology, and structures of the pores. In addition, the strong reactivity and high surface area of BGWNP helps to promote the hydration process in the cement paste. Consequently, the microstructures of the concrete mixes are enhanced, regulating their porosity (pore distribution and size) in the matrix and reducing water intake. The linear regression method was applied to correlate the experimental data as shown in Figure 14, with an R2 value of 0.6868. This signified good confidence for the relationships.

Figure 13.

Effect of nanoparticles’ content on high-volume fly ash mortar’s water absorption and porosity.

Figure 14.

Effect of nanoparticles’ content on high-volume fly ash mortar’s water absorption.

3.7. XRD Patterns

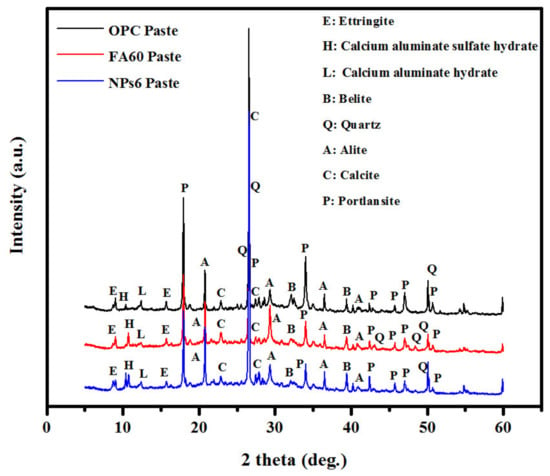

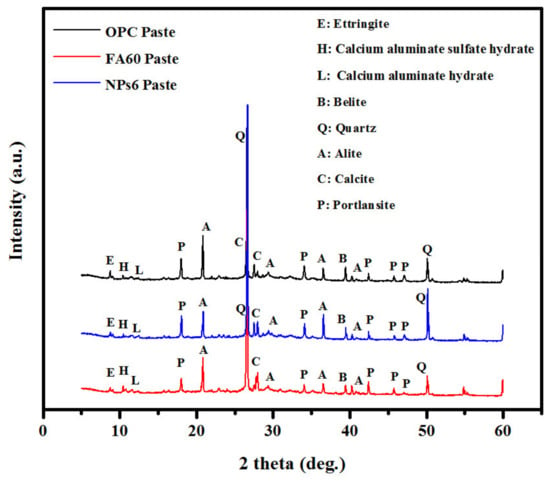

Figure 15 and Figure 16 presented the X-ray diffraction (XRD) of modified cement pastes at 7 and 28 days, respectively. At 7 days of age (Figure 13), the intensity of the Ca(OH)2 peak trend decreased with an inclusion of 60% of FA as an OPC replacement as shown at 17.8°, 34.1°, and 46.9°. A similar trend of results was observed for paste prepared with 6% of BGWNP as an OPC-FA binder replacement and the intensity of Ca(OH)2 peaks dropped. This slight reduction can be attributed to the pozzolanic reaction between the amorphous silica atoms in BGWNP and Ca(OH)2 generated during the first hydration process. The peaks of C–S–H were observed mostly in calcite, alite, and belite. In general, the replacement of cement by FA resulted in a significant decrease in Ca(OH)2 (Portlandite) and C–S–H peaks, and this finding was attributed to the lack of calcium content in the modified mixtures. At 28 days, the intensity of Portlandite, alite, and Belite improved for modified cement containing FA and BGWNP which explained the enhancement observed in strength values at 28 days of curing age.

Figure 15.

Effect of FA and BGWNP on the structures of prepared mortar at 7 days of age.

Figure 16.

Effect of FA and BGWNP on the structures of prepared mortar at 28 days of age.

3.8. SEM Analyses

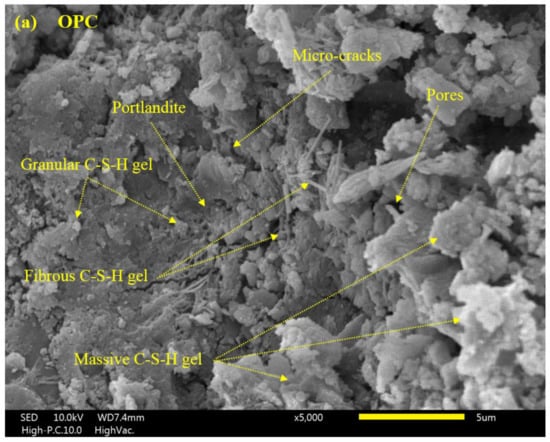

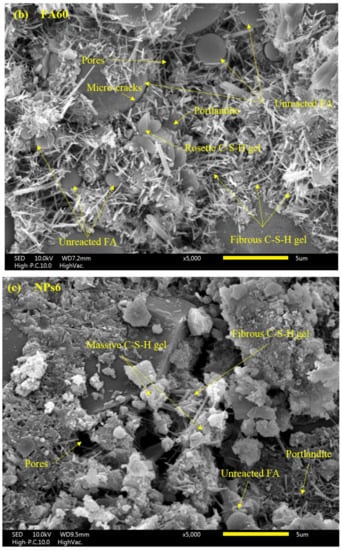

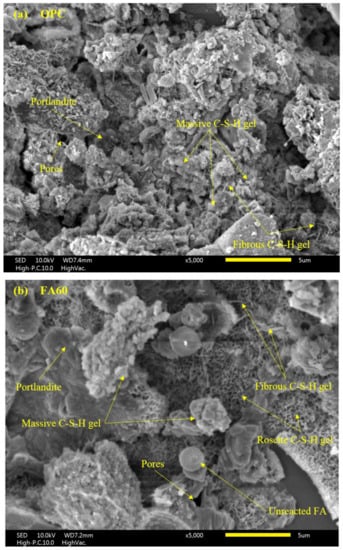

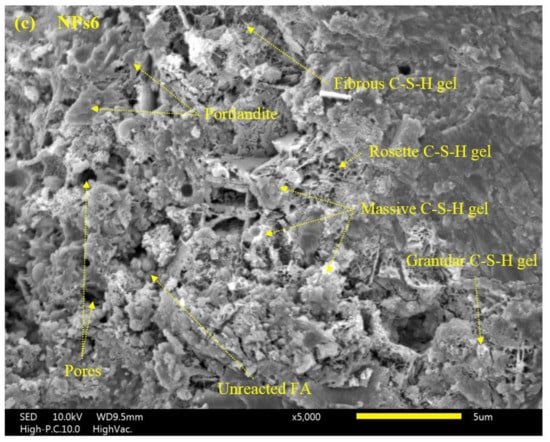

Figure 17 and Figure 18 illustrate the scanned electronic microscopy image (SEM) of the prepared mortars at 7 and 28 days, respectively. At an early age (7 days), with the replacement of the OPC by 60% FA, the change in microstructure was distinctly evident and more unreacted FA appeared with more pores as shown in Figure 17b. In general, the microstructure of the specimens prepared with 60% FA as an OPC replacement was less dense compared to the OPC matrices (Figure 17a) due to the lack of C–S–H gel formation. By contrast, the inclusion of 6% of BGWNP as an OPC-FA binder replacement led to an enhancement of the hydration process, forming more hydration products (Figure 17c). In all of the specimens prepared with FA and BGWNP, three major morphological features were evident, with an extremely small amount of non-reacted particles observed with increasing BGWNP content. At 28 days of curing age, the control specimens (OPC) exhibited a uniform dense C–S–H gel, which is consistent with the observed high compressive strength. However, the microstructure of the sample with only OPC was less dense than the other matrices due to the high void content associated with the nature of the rapid reaction of cement and the high w/c ratio. The replacement of OPC-FA by 6% BGWNP produced a remarkable change in microstructure, with the 6% BGWNP specimen showing a denser microstructure than that of the OPC and FA60 (Figure 18a,b) due to the filling effect and provided more nucleation sites in transition zones and pores (Figure 18c). Furthermore, the ongoing hydration and pozzolanic reactions formed more C–S–H gel, which increased packing density in the microstructure. Such an effect is evident through the observation of some FA particles firmly embedded into the microstructure. This result is attributed to the slow reactivity of FA particles. Incorporating BGWNP into the blended mixes significantly increased FA reactivity, decreasing the amount of unreacted/partially reacted FA spheres after 28 days of curing and enhancing the strength development.

Figure 17.

SEM images of proposed mortar at 7 days (a) OPC (b) FA60 and (c) 6% BGWNP.

Figure 18.

SEM images of proposed mortar at 28 days (a) OPC (b) FA60 and (c) 6% BGWNP.

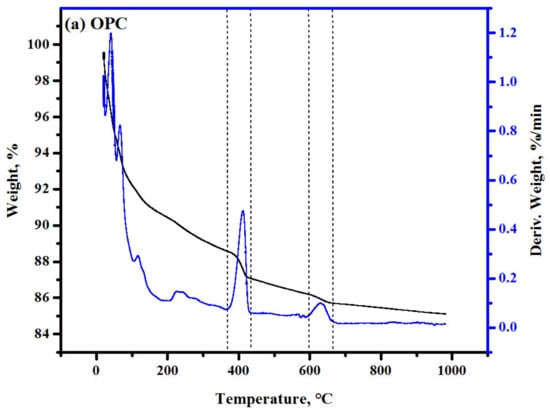

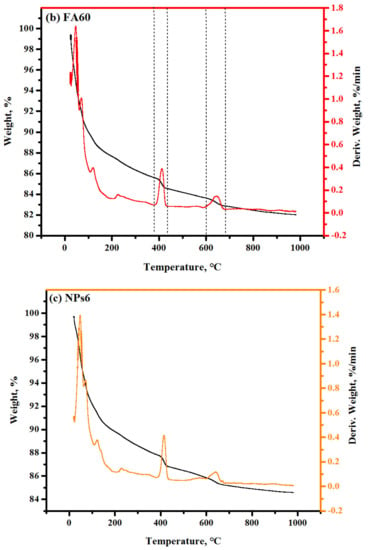

3.9. TGA and DTG Results

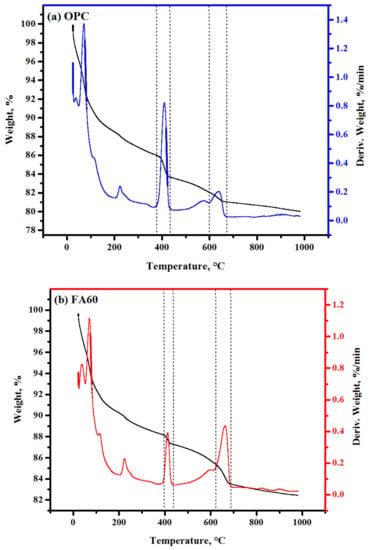

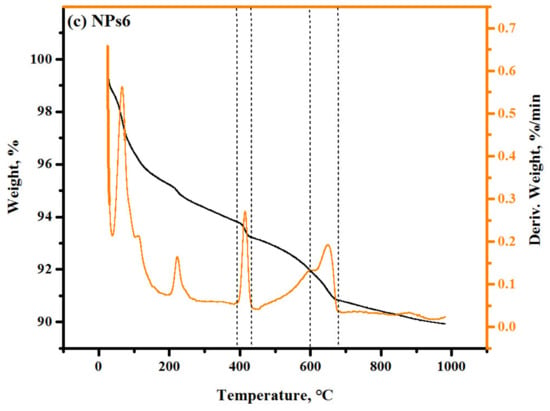

Figure 19 and Figure 20 illustrated the thermal stability of high-volume FA-BGWNP modified cement binder at temperatures ranging from 29 °C to 1000 °C after 7 and 28 days of age, respectively. The phases of Ca(OH)2 and CaCO3 decomposition were within the ranges of 390–460 °C and 580–690 °C, respectively. All of these reverse reactions are depicted on the DTA curves as peaks, whilst weight losses are illustrated on the TGA curves. The most widely used technique for assessing the degree of reaction of the OPC is the evaluation of the bound water content on the basis of the weight loss of samples between (typically) 105 °C and 1000 °C. However, the situation becomes more complicated when supplementary cementitious materials (SCMs) are used, making the separation of the bound water unrealistic due to the reaction of the SCMs caused by the reaction of the clinker phases. The release of water-bound atoms may also occur within 80–170 °C due to the chemical nature and multiple composition phases of calcium silicate hydrate (C–S–H). The TGA and DTA results were adopted to determine the weight loss percentage of the concrete specimens. The percentages of Ca(OH)2 and C–S–H were calculated using Equations (1) and (2), respectively:

where WL(CH) is the weight loss due to CH dehydration, MW(CH) is the molecular weight of CH (74 g·mol−1), and MW(H) is the molecular weight of water (18 g·mol−1).

CH (%) = WL CH (%) × [MW CH/MW H]

C–S–H gel (%) = Total LOI − LOI CH − LOI CC

Figure 19.

TGA and DTG curves of modified mortar at 7 days of age (a) OPC (b) FA60 and (c) NPs6.

Figure 20.

TGA and DTG curves of modified mortar at 28 days of age (a) OPC (b) FA60 and (c) NPs6.

Table 3 displays the TGA results of the designed modified mortar specimens with FA and BGWNP at 7 and 28 days of curing age. The analysis results of TGA and DTA indicated that the percentage of C–S–H gel in the specimens with 60% FA as the OPC replacement recorded lower values (4.9 and 9.7%) than the C–S–H gel percentage calculated with the OPC specimens (7.9 and 13.8%) at 7 and 28 days, respectively. Furthermore, the percentage of Ca(OH)2 was calculated and the results indicated the low percentage of Ca(OH)2 in specimens with 60% FA (2.9 and 4.2%) compared with 5.4 and 6.4% in the OPC specimens at 7 and 28 days of age, respectively. The low stability of mortar specimens with 60% FA and the low amounts of C–S–H gel and Ca(OH)2 clearly showed that the high amount of silica and low calcium oxide from FA negatively affected dense gel formation and led to the non-homogeneous microstructure properties of mortar specimens at 7 and 28 days and resulted in a decrement on compressive strength from 22.1 MPa to 12.3 MPa at 7 days and from 36.6 MPa to 21.3 MPa at 28 days with the replacement of OPC by 60% FA. The hydration process trend improved with the inclusion of BGWNP as an OPC-FA binder replacement and more dense gels were produced. The results showed that with the inclusion of 6% BGWNP, the content of C–S–H gels increased from 4.9% to 6.8%, resulted in an increment in strength from 12.3 MPa to 19.3 MPa at 7 days. At 28 days, the inclusion of 6% BGWNP increased the content of C–S–H gels from 9.7% to 13.3%, and led to an increase in compressive strength from 21.3 MPa to 32.8 MPa, respectively. It is clear from the TGA and DTG observed that the inclusion of BGWNP as an OPC-FA replacement significantly improved the hydration process and improved the strength development at an early and late age.

Table 3.

C–S–H and Ca(OH)2 content on modified cement at 7 and 28 days of age.

4. Conclusions

The current study investigated the integration of nanoparticles derived from bottle glass waste in boosting the early strength properties of high-volume FA- (60%) based cement mortars. The results showed a significant improvement in strength development with the inclusion of BGWNP in the high-volume FA-based cement matrix. The major findings are listed as follows:

- Modified cement workability was significantly improved by the inclusion of FA and BGWNP content. The flow diameter was dropped from 19.5 cm to 12 cm with the inclusion of a high amount of FA and BGWNP in the cement matrix.

- The inclusion of high-volume FA (60%) as an OPC replacement resulted in a drop in the strength performance of prepared mortars at an early age.

- The results indicated that the inclusion of 6% BGWNP as an OPC-FA binder replacement produced higher compressive strength at all curing ages compared with the other percentages. However, the results showed that the compressive strength of the specimens with 6% BGWNP exhibited higher strength than the control sample (OPC) at 90 days of curing age.

- Similar to the compressive strength results, a trend was observed for flexural, splitting tensile strength, and modulus of elasticity, and the strength significantly improved with the inclusion of 6% of BGWNP as an OPC-FA replacement in the mortar matrix.

- The inclusion of nanoparticles from bottle glass waste significantly improved the microstructure of prepared mortar and led to a reduction in the total pores and porosity of tested specimens. The lower water absorption was obtained with specimens containing 6% of BGWNP as an OPC-FA replacement.

- With regard to the XRD results, the replacement of OPC by 60% of FA resulted in a significant decrease in the C–S–H peaks, and this decrease was attributed to the lack of calcium content in the modified mixtures. However, the inclusion of 6% of BGWNP led to an improvement in the hydration process and an enhancement in the intensity of the C-S-H and Ca(OH)2 peaks with strength improvement.

- The surface morphology of the modified mortar with a high-volume FA significantly improved with fewer pores and micro-cracks with the inclusion of 6% of BGWNP in the mortar matrix.

- Similarly, TGA and DTA showed that the inclusion of BGWNP improved the hydration process with more gel products. Specimens containing FA and BGWNP displayed high chemical stability under high temperatures.

- Sustainable mortar with acceptable compressive strength and lower carbon dioxide emission was produced for several applications in the construction industry using FA and glass waste.

- Through systematic preparation of new high-volume FA blends and their thorough characterizations, it was demonstrated that such ternary blends can offer the flexibility needed to achieve good mechanical properties and durability in order to meet the required specifications of construction industries. It is established that the exploitation of this new high-volume FA blend could promote both economic and environmental sustainability within the construction industry.

Author Contributions

Y.R.A.: Conceptualization, validation, writing—review and editing, visualization, and supervision. A.A.A.: Conceptualization, methodology, validation, writing—original draft preparation, visualization, supervision, project administration, verified the manuscript structure, and supervised the overall research. All authors have read and agreed to the published version of the manuscript.

Funding

The authors extend their appreciation to Researchers Supporting Project number (RSP-2021/271), King Saud University, Riyadh, Saudi Arabia.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| BGWNPs | Bottle glass waste nanoparticles |

| CS | Compressive strength |

| STS | Splitting tensile strength |

| FS | Flexural strength |

| C–S–H | Calcium silicate hydrate |

| CH | Portlandite (Ca(OH)2) |

| CO2 | Carbon dioxide |

| OPC | Ordinary Portland cement |

| SSD | Saturated surface dry |

| XRD | X-ray diffraction |

| SEM | Scanning electronic image |

References

- Kurtis, K.; Nanko, H.; Mohr, B. Methods for Internally Curing Cement-Based Materials and Products Made Therefrom. U.S. Patent Application 11/738,906, 25 October 2007. [Google Scholar]

- Huseien, G.F.; Mirza, J.; Ismail, M.; Ghoshal, S.; Hussein, A.A. Geopolymer mortars as sustainable repair material: A comprehensive review. Renew. Sustain. Energy Rev. 2017, 80, 54–74. [Google Scholar] [CrossRef]

- Huseien, G.F.; Sam AR, M.; Algaifi, H.A.; Alyousef, R. Development of a sustainable concrete incorporated with effective microorganism and fly Ash: Characteristics and modeling studies. Constr. Build. Mater. 2021, 285, 122899. [Google Scholar] [CrossRef]

- Wang, J.; Liu, E.; Li, L. Characterization on the recycling of waste seashells with Portland cement towards sustainable cementitious materials. J. Clean. Prod. 2019, 220, 235–252. [Google Scholar] [CrossRef]

- Xie, J.; Fang, C.; Lu, Z.; Li, Z.; Li, L. Effects of the addition of silica fume and rubber particles on the compressive behaviour of recycled aggregate concrete with steel fibres. J. Clean. Prod. 2018, 197, 656–667. [Google Scholar] [CrossRef]

- Xie, J.; Wang, J.; Rao, R.; Wang, C.; Fang, C. Effects of combined usage of GGBS and fly ash on workability and mechanical properties of alkali activated geopolymer concrete with recycled aggregate. Compos. Part B Eng. 2019, 164, 179–190. [Google Scholar] [CrossRef]

- Alyousef, R.; Ebid, A.A.K.; Huseien, G.F.; Mohammadhosseini, H.; Alabduljabbar, H.; Ngian, S.P.; Mohamed, A.M. Effects of Sulfate and Sulfuric Acid on Efficiency of Geopolymers as Concrete Repair Materials. Gels 2022, 8, 53. [Google Scholar] [CrossRef]

- Watts, J. Concrete: The most destructive material on Earth. Guardian 2019, 25, 1–9. [Google Scholar]

- Huseien, G.F.; Saleh, A.T.; Ghoshal, S.K. Effective Microorganism Solution and High Volume of Fly Ash Blended Sustainable Bio-Concrete. Biomimetics 2022, 7, 65. [Google Scholar] [CrossRef]

- Shah, K.W.; Huseien, G.F.; Kua, H.W. A State-of-the-art review on core–shell pigments nanostructure preparation and test methods. Micro 2021, 1, 55–85. [Google Scholar] [CrossRef]

- Mhaya, A.M.; Baharom, S.; Baghban, M.H.; Nehdi, M.L.; Faridmehr, I.; Huseien, G.F.; Algaifi, H.A.; Ismail, M. Systematic Experimental Assessment of POFA Concrete Incorporating Waste Tire Rubber Aggregate. Polymers 2022, 14, 2294. [Google Scholar] [CrossRef]

- Coppola, L.; Coffetti, D.; Crotti, E.; Gazzaniga, G.; Pastore, T. An Empathetic Added Sustainability Index (EASI) for cementitious based construction materials. J. Clean. Prod. 2019, 220, 475–482. [Google Scholar] [CrossRef]

- Mhaya, A.M.; Baharom, S.; Huseien, G.F. Improved strength performance of rubberized Concrete: Role of ground blast furnace slag and waste glass bottle nanoparticles amalgamation. Constr. Build. Mater. 2022, 342, 128073. [Google Scholar] [CrossRef]

- Onaizi, A.M.; Huseien, G.F.; Lim, N.H.A.S.; Amran, M.; Samadi, M. Effect of nanomaterials inclusion on sustainability of cement-based concretes: A comprehensive review. Constr. Build. Mater. 2021, 306, 124850. [Google Scholar] [CrossRef]

- Huseien, G.F.; Faridmehr, I.; Nehdi, M.L.; Abadel, A.A.; Aiken, T.A.; Ghoshal, S. Structure, morphology and compressive strength of Alkali-activated mortars containing waste bottle glass nanoparticles. Constr. Build. Mater. 2022, 342, 128005. [Google Scholar] [CrossRef]

- Bhatt, A.; Priyadarshini, S.; Mohanakrishnan, A.A.; Abri, A.; Sattler, M.; Techapaphawit, S. Physical, chemical, and geotechnical properties of coal fly ash: A global review. Case Stud. Constr. Mater. 2019, 11, e00263. [Google Scholar] [CrossRef]

- Ahmaruzzaman, M. A review on the utilization of fly ash. Prog. Energy Combust. Sci. 2010, 36, 327–363. [Google Scholar] [CrossRef]

- Essienubong, I.A.; Okechukwu, E.P.; Ejuvwedia, S.G. Effects of waste dumpsites on geotechnical properties of the underlying soils in wet season. Environ. Eng. Res. 2019, 24, 289–297. [Google Scholar] [CrossRef]

- Herath, C.; Gunasekara, C.; Law, D.W.; Setunge, S. Performance of high volume fly ash concrete incorporating additives: A systematic literature review. Constr. Build. Mater. 2020, 258, 120606. [Google Scholar] [CrossRef]

- Li, G. Properties of high-volume fly ash concrete incorporating nano-SiO2. Cem. Concr. Res. 2004, 34, 1043–1049. [Google Scholar] [CrossRef]

- Onaizi, A.M.; Lim, N.H.A.S.; Huseien, G.F.; Amran, M.; Ma, C.K. Effect of the addition of nano glass powder on the compressive strength of high volume fly ash modified concrete. Mater. Today Proc. 2022, 48, 1789–1795. [Google Scholar] [CrossRef]

- Huseien, G.F.; Joudah, Z.H.; Khalid, N.H.A.; Sam, A.R.M.; Tahir, M.M.; Lim, N.H.A.S.; Alyousef, R.; Mirza, J. Durability performance of modified concrete incorporating fly ash and effective microorganism. Constr. Build. Mater. 2021, 267, 120947. [Google Scholar] [CrossRef]

- Nath, S.; Kumar, S. Role of particle fineness on engineering properties and microstructure of fly ash derived geopolymer. Constr. Build. Mater. 2020, 233, 117294. [Google Scholar] [CrossRef]

- Huseien, G.F.; Shah, K.W.; Sam, A.R.M. Sustainability of nanomaterials based self-healing concrete: An all-inclusive insight. J. Build. Eng. 2019, 23, 155–171. [Google Scholar] [CrossRef]

- Ng, D.S.; Paul, S.C.; Anggraini, V.; Kong, S.Y.; Qureshi, T.S.; Rodriguez, C.R.; Liu, Q.-F.; Šavija, B. Influence of SiO2, TiO2 and Fe2O3 nanoparticles on the properties of fly ash blended cement mortars. Constr. Build. Mater. 2020, 258, 119627. [Google Scholar]

- Liu, M.; Tan, H.; He, X. Effects of nano-SiO2 on early strength and microstructure of steam-cured high volume fly ash cement system. Constr. Build. Mater. 2019, 194, 350–359. [Google Scholar] [CrossRef]

- Rashad, A.M. Effects of ZnO2, ZrO2, Cu2O3, CuO, CaCO3, SF, FA, cement and geothermal silica waste nanoparticles on properties of cementitious materials–A short guide for Civil Engineer. Constr. Build. Mater. 2013, 48, 1120–1133. [Google Scholar] [CrossRef]

- Zhang, R.; Cheng, X.; Hou, P.; Ye, Z. Influences of nano-TiO2 on the properties of cement-based materials: Hydration and drying shrinkage. Constr. Build. Mater. 2015, 81, 35–41. [Google Scholar] [CrossRef]

- Samadi, M.; Shah, K.W.; Huseien, G.F.; Lim, N.H.A.S. Influence of glass silica waste nano powder on the mechanical and microstructure properties of alkali-activated mortars. Nanomaterials 2020, 10, 324. [Google Scholar] [CrossRef]

- Khan, N.N.; Saha, A.K.; Sarker, P.K. Reuse of waste glass as a supplementary binder and aggregate for sustainable cement-based construction materials: A review. J. Build. Eng. 2020, 28, 101052. [Google Scholar] [CrossRef]

- Bueno, E.T.; Paris, J.M.; Clavier, K.A.; Spreadbury, C.; Ferraro, C.C.; Townsend, T.G. A review of ground waste glass as a supplementary cementitious material: A focus on alkali-silica reaction. J. Clean. Prod. 2020, 257, 120180. [Google Scholar] [CrossRef]

- Hamzah, H.K.; Joudah, Z.H.; Georgescu, D.P.; Khalid, N.H.A.; Huseien, G.F. Laboratory evaluation of alkali-activated mortars modified with nanosilica from glass bottle wastes. Mater. Today Proc. 2021, 46, 2098–2104. [Google Scholar] [CrossRef]

- Matos, A.M.; Sousa-Coutinho, J. Durability of mortar using waste glass powder as cement replacement. Constr. Build. Mater. 2012, 36, 205–215. [Google Scholar] [CrossRef]

- Larsen, A.W.; Merrild, H.; Christensen, T.H. Recycling of glass: Accounting of greenhouse gases and global warming contributions. Waste Manag. Res. 2009, 27, 754–762. [Google Scholar] [CrossRef] [PubMed]

- Mehta, A.; Siddique, R.; Ozbakkaloglu, T.; Shaikh, F.; Belarbi, R. Fly ash and ground granulated blast furnace slag-based alkali-activated concrete: Mechanical, transport and microstructural properties. Constr. Build. Mater. 2020, 257, 119548. [Google Scholar] [CrossRef]

- Thomas, B.S. Green concrete partially comprised of rice husk ash as a supplementary cementitious material—A comprehensive review. Renew. Sustain. Energy Rev. 2018, 82, 3913–3923. [Google Scholar] [CrossRef]

- Nasr, M.; Hussain, T.; Kubba, H.; Shubbar, A. Influence of using high volume fraction of silica fume on mechanical and durability properties of cement mortar. J. Eng. Sci. Technol. 2020, 15, 2494–2506. [Google Scholar]

- De Maeijer, P.K.; Craeye, B.; Snellings, R.; Kazemi-Kamyab, H.; Loots, M.; Janssens, K.; Nuyts, G. Effect of ultra-fine fly ash on concrete performance and durability. Constr. Build. Mater. 2020, 263, 120493. [Google Scholar] [CrossRef]

- Siad, H.; Lachemi, M.; Sahmaran, M.; Mesbah, H.A.; Hossain, K.M.A. Use of recycled glass powder to improve the performance properties of high volume fly ash-engineered cementitious composites. Constr. Build. Mater. 2018, 163, 53–62. [Google Scholar] [CrossRef]

- Schwarz, N.; Cam, H.; Neithalath, N. Influence of a fine glass powder on the durability characteristics of concrete and its comparison to fly ash. Cem. Concr. Compos. 2008, 30, 486–496. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Abd Elmoaty, A.E.M.; Aboshama, A.Y. Utilization of waste glass powder in the production of cement and concrete. Constr. Build. Mater. 2016, 124, 866–877. [Google Scholar] [CrossRef]

- Jain, K.L.; Sancheti, G.; Gupta, L.K. Durability performance of waste granite and glass powder added concrete. Constr. Build. Mater. 2020, 252, 119075. [Google Scholar] [CrossRef]

- Elaqra, H.; Rustom, R. Effect of using glass powder as cement replacement on rheological and mechanical properties of cement paste. Constr. Build. Mater. 2018, 179, 326–335. [Google Scholar] [CrossRef]

- Deng, Y.; Yan, C.; Zhang, J.; Yin, L.; Liu, S.; Yan, Y. Preparation and mechanical characterization of engineered cementitious composites with high-volume fly ash and waste glass powder. J. Clean. Prod. 2022, 333, 130222. [Google Scholar] [CrossRef]

- Huseien, G.F.; Hamzah, H.K.; Sam, A.R.M.; Khalid, N.H.A.; Shah, K.W.; Deogrescu, D.P.; Mirza, J. Alkali-activated mortars blended with glass bottle waste nano powder: Environmental benefit and sustainability. J. Clean. Prod. 2020, 243, 118636. [Google Scholar] [CrossRef]

- Huseien, G.F.; Shah, K.W. Durability and life cycle evaluation of self-compacting concrete containing fly ash as GBFS replacement with alkali activation. Constr. Build. Mater. 2020, 235, 117458. [Google Scholar] [CrossRef]

- Arowojolu, O.; Fina, J.; Pruneda, A.; Ibrahim, A.; Mahmoud, E. Feasibility study on concrete performance made by partial replacement of cement with nanoglass powder and fly ash. Int. J. Civ. Eng. 2019, 17, 1007–1014. [Google Scholar] [CrossRef]

- Hisseine, O.A.; Tagnit-Hamou, A. Development of ecological strain-hardening cementitious composites incorporating high-volume ground-glass pozzolans. Constr. Build. Mater. 2020, 238, 117740. [Google Scholar] [CrossRef]

- Berry, E.; Hemmings, R.; Cornelius, B. Mechanisms of hydration reactions in high volume fly ash pastes and mortars. Cem. Concr. Compos. 1990, 12, 253–261. [Google Scholar] [CrossRef]

- Aydin, E.; Arel, H.Ş. Characterization of high-volume fly-ash cement pastes for sustainable construction applications. Constr. Build. Mater. 2017, 157, 96–107. [Google Scholar] [CrossRef]

- Yu, J.; Lu, C.; Leung, C.K.; Li, G. Mechanical properties of green structural concrete with ultrahigh-volume fly ash. Constr. Build. Mater. 2017, 147, 510–518. [Google Scholar] [CrossRef]

- Praveenkumar, T.; Vijayalakshmi, M.; Meddah, M. Strengths and durability performances of blended cement concrete with TiO2 nanoparticles and rice husk ash. Constr. Build. Mater. 2019, 217, 343–351. [Google Scholar] [CrossRef]

- Li, H.; Zhang, M.-H.; Ou, J.-P. Abrasion resistance of concrete containing nano-particles for pavement. Wear 2006, 260, 1262–1266. [Google Scholar] [CrossRef]

- Lim, N.H.A.S.; Mohammadhosseini, H.; Tahir, M.; Samadi, M.; Sam, A.R.M. Microstructure and strength properties of mortar containing waste ceramic nanoparticles. Arab. J. Sci. Eng. 2018, 43, 5305–5313. [Google Scholar] [CrossRef]

- Samadi, M.; Huseien, G.F.; Lim, N.H.A.S.; Mohammadhosseini, H.; Alyousef, R.; Mirza, J.; Rahman, A.B.A. Enhanced performance of nano-palm oil ash-based green mortar against sulphate environment. J. Build. Eng. 2020, 32, 101640. [Google Scholar] [CrossRef]

- Kamali, M.; Ghahremaninezhad, A. An investigation into the hydration and microstructure of cement pastes modified with glass powders. Constr. Build. Mater. 2016, 112, 915–924. [Google Scholar] [CrossRef]

- Patil, B.H. Utilization of Waste Glass Powder as a Replacement of Cement in Concrete. Int. J. Res. Eng. Sci. Manag. 2020, 3, 466–468. [Google Scholar]

- Kayali, O.; Ahmed, M.S. Assessment of high volume replacement fly ash concrete—Concept of performance index. Constr. Build. Mater. 2013, 39, 71–76. [Google Scholar] [CrossRef]

- Durán-Herrera, A.; Juárez, C.; Valdez, P.; Bentz, D. Evaluation of sustainable high-volume fly ash concretes. Cem. Concr. Compos. 2011, 33, 39–45. [Google Scholar] [CrossRef]

- Yoon, S.; Monteiro, P.J.; Macphee, D.E.; Glasser, F.P.; Imbabi, M.S.-E. Statistical evaluation of the mechanical properties of high-volume class F fly ash concretes. Constr. Build. Mater. 2014, 54, 432–442. [Google Scholar] [CrossRef]

- Jiang, Y.; Ling, T.C.; Mo, K.H.; Shi, C. A critical review of waste glass powder–Multiple roles of utilization in cement-based materials and construction products. J. Environ. Manag. 2019, 242, 440–449. [Google Scholar] [CrossRef]

- Bostanci, L. Effect of waste glass powder addition on properties of alkali-activated silica fume mortars. J. Build. Eng. 2020, 29, 101154. [Google Scholar] [CrossRef]

- Ren, J.; Lai, Y.; Gao, J. Exploring the influence of SiO2 and TiO2 nanoparticles on the mechanical properties of concrete. Constr. Build. Mater. 2018, 175, 277–285. [Google Scholar] [CrossRef]

- Parghi, A.; Alam, M.S. Physical and mechanical properties of cementitious composites containing recycled glass powder (RGP) and styrene butadiene rubber (SBR). Constr. Build. Mater. 2016, 104, 34–43. [Google Scholar] [CrossRef]

- Kunther, W.; Ferreiro, S.; Skibsted, J. Influence of the Ca/Si ratio on the compressive strength of cementitious calcium-silicate-hydrate binders. J. Mater. Chem. A 2017, 5, 17401–17412. [Google Scholar] [CrossRef]

- Hamzah, H.K.; Huseien, G.F.; Asaad, M.A.; Georgescu, D.P.; Ghoshal, S.; Alrshoudi, F. Effect of waste glass bottles-derived nanopowder as slag replacement on mortars with alkali activation: Durability characteristics. Case Stud. Constr. Mater. 2021, 15, e00775. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).