Summary of the Transformational Relationship between Point Load Strength Index and Uniaxial Compressive Strength of Rocks

Abstract

1. Introduction

2. Point Load Calculation Method

2.1. Influencing Factor of Rock Point Load Failure

- ①

- The influence of the rock itself

- ②

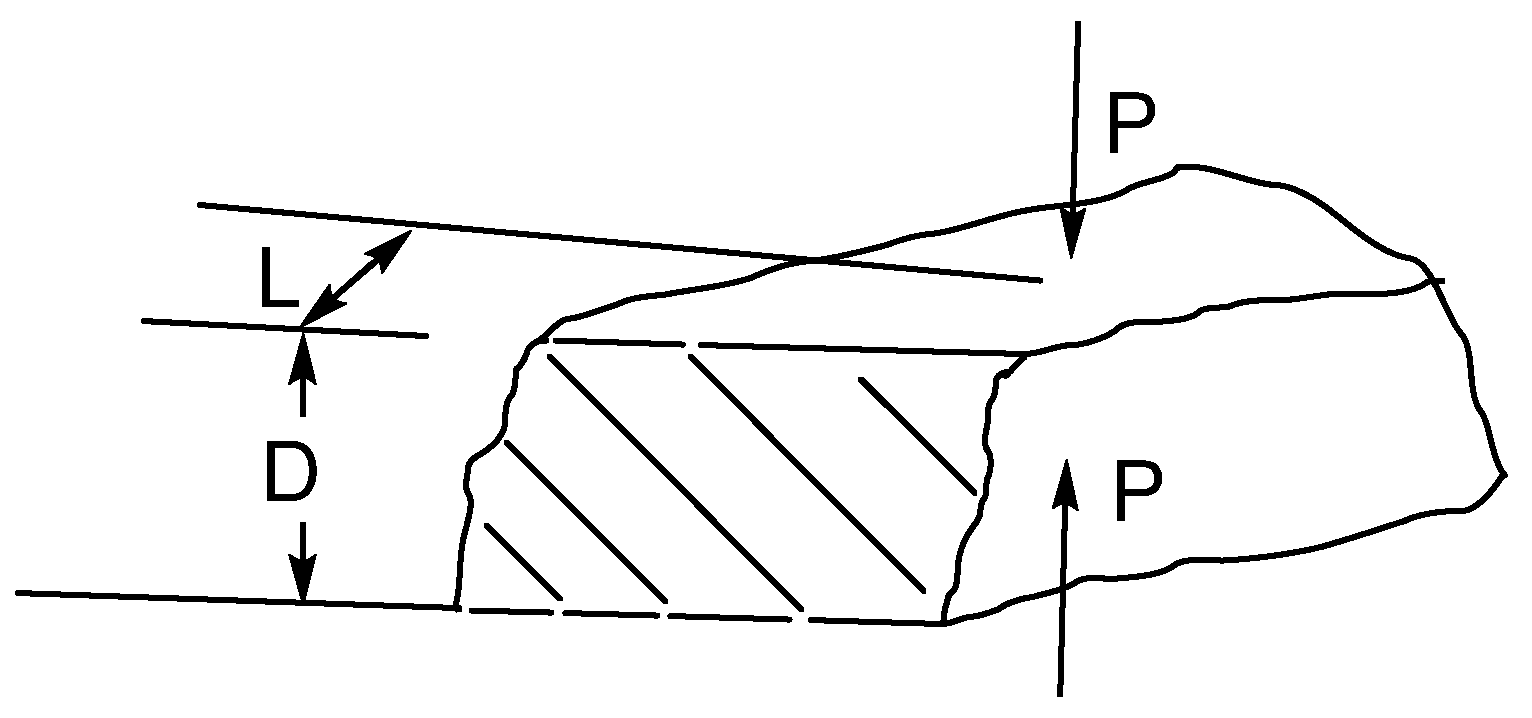

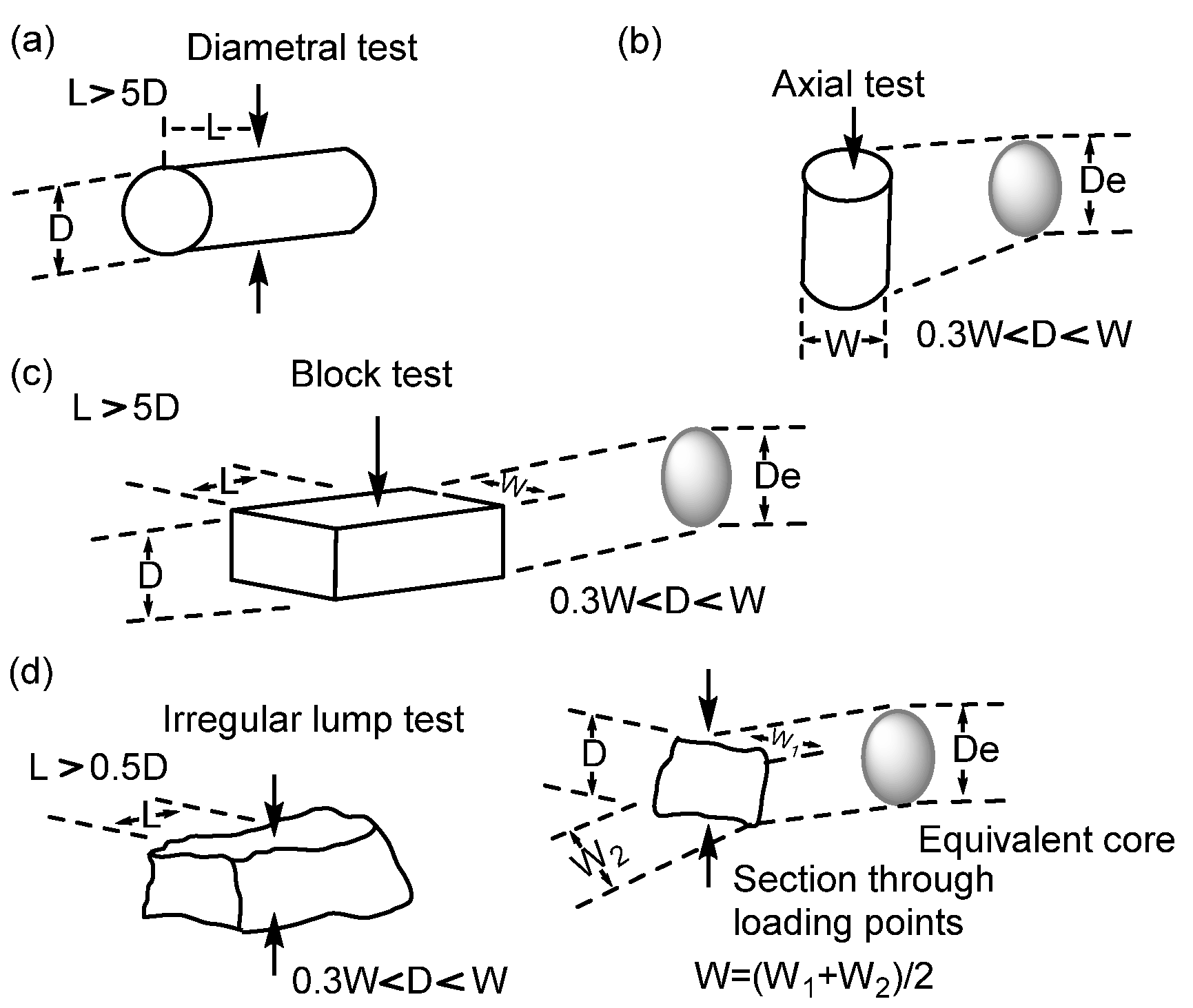

- The effect of sample shape

- ③

- The effect of sample size

- ④

- The effect of sample’s failure load area

2.2. Research on Failure Mechanism Using the Point Load Test

2.3. Research on Calculation Method of Point Loads

2.3.1. Calculation Formula

lgIs(50) = 0.256 + lgIs − 1.008·e−0.0274·D

2.3.2. Research Status of Correction Index

3. Study on Transformation between PLT and UCS

3.1. Linear Function Relationship

3.2. Other Functional Relationships

4. Discussions

5. Conclusions

- The failure of rock under point load is a gradual process. The failure starts at the upper and lower loading points, producing symmetrical local compressive stress. With the continuous loading, the compressive stress constantly decreases.

- Research is carried out regarding the fundamental problems of point load tests. Based on the analysis of the research progress, the calculation formulas and influencing factors of PLS of the rock are summarized, including the influences of rock size, shape, and compression cross-sectional areas on PLS. Meanwhile, the influences of rock properties and environments on PLT results were also discussed.

- The functional relationships between Is(50) and UCS were established according to the research results of previous researchers on different types of rocks by using mathematical statistics methods. However, to a certain extent, these functions are all relatively dispersed, when coupled with regional and other factors; therefore, the obtained functional relationships are of poor general applicability.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jalali, S.H.; Heidari, M.; Zarrinshoja, M.; Mohseni, N. Predicting of uniaxial compressive strength of some igneous and metamorphic rocks by block punch index and cylindrical punch index tests. Int. J. Rock Mech. Min. Sci. 2019, 119, 72–80. [Google Scholar] [CrossRef]

- Liu, Q.S.; Zhao, Y.F.; Zhang, X.P. Case study: Using the point load test to estimate rock strength of tunnels constructed by a tunnel boring machine. Bull. Eng. Geol. Environ. 2019, 78, 1727–1734. [Google Scholar] [CrossRef]

- Mahtab, A.; Mostafa, M.; Mahmoud, Y. Correlation between uniaxial strength and point load index of rocks. In Proceedings of the 15th Asian Regional Conference on Soil Mechanics and Geotechnical Engineering, Kyushu, Japan, 9–13 November 2015; Japanese Geotechnical Society: Tokyo, Japan, 2015; Volume 2, pp. 504–507. [Google Scholar] [CrossRef]

- Li, S.; Wang, Y.; Xie, X. Prediction of Uniaxial Compression Strength of Limestone Based on the Point Load Strength and SVM Model. Minerals 2021, 11, 1387. [Google Scholar] [CrossRef]

- Kaya, A.; Karaman, K. Utilizing the strength conversion factor in the estimation of uniaxial compressive strength from the point load index. Bull. Eng. Geol. Environ. 2016, 75, 341–357. [Google Scholar] [CrossRef]

- Wen, J.L.; Li, H.S.; Jiang, F.X.; Yu, Z.X.; Mao, H.T.; Yang, X.L. Rock burst risk evaluation based on equivalent surrounding rock strength. Int. J. Min. Sci. Technol. 2019, 29, 571–576. [Google Scholar] [CrossRef]

- Liu, Q.S.; Wu, J.; Zhang, X.P.; Tang, L.X.; Bi, C.; Li, W.W.; Xu, J.L. Microseismic monitoring to characterize structure type rockburst: A case study of a TBM-excavated tunnel. Rock Mech. Rock Eng. 2020, 53, 2995–3013. [Google Scholar] [CrossRef]

- Guo, M.L. Discussion on adaptability of point load test of rocks. Rock Soil Mech. 2003, 24, 488–494. [Google Scholar] [CrossRef]

- Burbano, D.; García, T. Estimación empírica de la resistencia a compresión simple a partir del ensayo de carga puntual en rocas anisótropas (esquistos y pizarras). FIGEMPA 2016, 1, 13–16. [Google Scholar] [CrossRef]

- Abdul, K.; Zein, M.; Mutasim, A. Sandal. Estimation of the strength of Nubian sandstone formation from point load test index and other simple parameters. MATEC Web Conf. 2018, 149, 02024. [Google Scholar] [CrossRef][Green Version]

- Sheraz, A.M.; Emad, M.Z.; Shahzad, M.; Arshad, S.M. Relation between Uniaxial Compressive Strength, Point Load Index and Sonic Wave Velocity for Dolerite. Pak. J. Sci. 2014, 66, 1. [Google Scholar]

- Ali, K.; Candan, G. An assessment on the correlations between uniaxial compression strength and point load index. Arab. J. Geosci. 2022, 15, 268. [Google Scholar] [CrossRef]

- Brook, N. The equivalent core diameter method of size and shape correction in point load testing. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1985, 22, 61–70. [Google Scholar] [CrossRef]

- Diamantis, K.; Gartzos, E.; Migiros, G. Study on uniaxial compressive strength, point load strength index, dynamic and physical properties of serpentinites from Central Greece: Test results and empirical relations. Eng. Geol. 2009, 108, 199–207. [Google Scholar] [CrossRef]

- Azimian, A.; Ajalloeian, R.; Fatehi, L. An Empirical Correlation of Uniaxial Compressive Strength with P-wave Velocity and Point Load Strength Index on Marly Rocks Using Statistical Method. Geotech. Geol. Eng. 2014, 32, 205–214. [Google Scholar] [CrossRef]

- Karakul, H. Investigation of saturation effect on the relationship between compressive strength and Schmidt hammer rebound. Bull Eng. Geol. Environ. 2016, 4, 9–19. [Google Scholar] [CrossRef]

- María, E.G.; Ferry, B.P.; Víctor, M.-I.; José, B.S.; Carlos, H.-S.; Roberto, T. Predicting the Uniaxial Compressive Strength of a Limestone Exposed to High Temperatures by Point Load and Leeb Rebound Hardness Testing. Rock Mech. Rock Eng. 2022, 55, 1–17. [Google Scholar] [CrossRef]

- Rabat, Á.; Cano, M.; Tomás, R.; Tamayo, Á.E.; Alejano, L.R. Evaluation of Strength and Deformability of Soft Sedimentary Rocks in Dry and Saturated Conditions Through Needle Penetration and Point Load Tests: A Comparative Study. Rock Mech. Rock Eng. 2020, 53, 2707–2726. [Google Scholar] [CrossRef]

- Şahin, M.; Ulusay, R.; Karakul, H. Point Load Strength Index of Half-Cut Core Specimens and Correlation with Uniaxial Compressive Strength. Rock Mech. Rock Eng. 2020, 53, 3745–3760. [Google Scholar] [CrossRef]

- Yari, M.; Bagherpour, R. Investigating an innovative model for dimensional sedimentary rocks characterization using acoustic frequencies analysis during drilling. Rud.-Geološko-Naft. Zb. 2018, 33, 25. [Google Scholar] [CrossRef]

- Kumar, B.R.; Vardhan, H.; Govindaraj, M. Estimating rock properties using sound level during drilling: Field investigation. Int. J. Min. Miner. Eng. 2010, 2, 169–184. [Google Scholar] [CrossRef]

- Yari, M.; Bagherpour, R. Implementing acoustic frequency analysis for development the novel model of determining geomechanical features of igneous rocks using rotary drilling device. Geotech. Geol. Eng. 2018, 36, 1805–1816. [Google Scholar] [CrossRef]

- Yari, M.; Bagherpour, R.; Khoshouei, M. Developing a novel model for predicting geomechanical features of carbonate rocks based on acoustic frequency processing during drilling. Bull. Eng. Geol. Environ. 2019, 78, 1747–1759. [Google Scholar] [CrossRef]

- Kahraman, S. The determination of uniaxial compressive strength from point load strength for pyroclastic rocks. Eng. Geol. 2014, 170, 33–42. [Google Scholar] [CrossRef]

- Fan, J.Y.; Guo, Z.B.; Tao, Z.G.; Wang, F.N. Method of equivalent core diameter of actual fracture section for the determination of point load strength index of rocks. Bull. Eng. Geol. Environ. 2021, 80, 4575–4585. [Google Scholar] [CrossRef]

- Akbay, D.; Altindag, R. Reliability and evaluation of point load index values obtained from different testing devices. J. S. Afr. I. Min. Metall. 2020, 20, 181–190. [Google Scholar] [CrossRef]

- GBT50266-2013; National Standards of the People’s Republic of China. Standard for test methods of engineering rock mass. Administration of Quality Supervision, Inspection and Quarantine of People’s Republic of China; Standardization Administration of China: Beijing, China, 2013.

- Broch, E.; Franklin, J.A. The point-load strength test. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1972, 9, 669–676. [Google Scholar] [CrossRef]

- D’Andrea, D.V.; Fisher, R.L.; Fogelson, D.E. Prediction of compression strength from other rock properties. Colorad. Sch. Min. Q. 1964, 59, 623–640. [Google Scholar]

- Franklin, J.A. Suggested method for determining point load strength. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1985, 22, 51–60. [Google Scholar] [CrossRef]

- Taghipour, M.; Nikudel, M.R.; Farhadian, M.B. Engineering properties and durability of limestones used in Persepolis complex, Iran, against acid solutions. Bull. Eng. Geol. Environ. 2016, 75, 967–978. [Google Scholar] [CrossRef]

- Ghobadi, M.H.; Babazadeh, R. Experimental studies on the effects of cyclic freezing–thawing, salt crystallization, and thermal shock on the physical and mechanical characteristics of selected sandstones. Rock Mech. Rock Eng. 2015, 48, 1001–1016. [Google Scholar] [CrossRef]

- Bhowmick, S.; Ram, B.K.; Monda, T.K. An Experimental Approach to Evaluate the Role of Rock Failure Modes in Mechanical Characterization of Metabasalts. Geotech. Geol. Eng. 2022, 40, 2867–2880. [Google Scholar] [CrossRef]

- Sarfarazi, V.; Asgari, K. Effect of Confining Pressure on Is(50) Obtained by Point Load Test. J. Min. Environ. 2021, 12, 1019–1028. [Google Scholar] [CrossRef]

- Xu, F.; Chen, Y.; Li, Y.J.; Wen, L. Study on the failure mode of spot load strength and its correlation with Uniaxial compressive strength. Min. Technol. 2019, 19, 80–83, 86. [Google Scholar]

- Zhu, J.J.; Luo, Q.; Zhan, X.Q.; Jiang, L.W.; Fang, D. An equivalent area method for evaluating the point load strength of irregular soft phyllite. Chin. J. Rock Mech. Eng. 2018, 38, 2762–2771. [Google Scholar]

- Hawkins, A.B. Aspects of rock strength. Bull. Eng. Geol. Environ. 1998, 57, 17–30. [Google Scholar] [CrossRef]

- Chau, K.T.; Wong, R.H.C. Uniaxial compressive strength and point load strength of rocks. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1996, 33, 183–188. [Google Scholar] [CrossRef]

- Wong, R.H.C.; Chau, K.T.; Yin, J.H.; Lai, D.T.W.; Zhao, G.S. Uniaxial compressive strength and point load index of volcanic irregular lumps. Int. J. Rock Mech. Min. Sci. 2017, 93, 307–315. [Google Scholar] [CrossRef]

- Mehdi, K.; Massoud, P. Evaluation of the Strength of Railway Ballast Using Point Load Test for Various Size Fractions and Particle Shapes. Rock Mech. Rock Eng. 2016, 49, 2655–2664. [Google Scholar] [CrossRef]

- Yao, H.Y.; Dai, L.; Liu, G.; Jia, Y.; Yuan, X.L. Experimental Investigation on the Point Load Strength of Red-Bed Silestone with Different Shapes. Acta Geodyn. Geomater. 2021, 18, 5–13. [Google Scholar] [CrossRef]

- Xiang, G.F.; Liang, H. On the Statistical Analysis of Data and Strength Determination in Point Load Tests of Rock. Chin. J. Rock Mech. Eng. 1986, 5, 173–186. [Google Scholar]

- Mehdi, K. Assessment of strength of individual ballast aggregate by conducting point load test and establishment of classification method. Int. J. Rock Mech. Min. Sci. 2021, 141, 104711. [Google Scholar] [CrossRef]

- Masoumi, H.; Roshan, H.; Hedayat, A.; Hagan, P.C. Scale-Size Dependency of Intact Rock under Point-Load and Indirect Tensile Brazilian Testing. Int. J. Geomech. 2018, 18, 04018006. [Google Scholar] [CrossRef]

- Min, W. Comparative analysis of rock point load test and uniaxial compression test. Geotech. Investig. Surv. 1989, 6, 18–20. [Google Scholar]

- Brook, N. The use of irregular specimens for rock strength tests. Int. J. Rock Mech. Min. Sci. 1977, 14, 193–202. [Google Scholar] [CrossRef]

- Gercek, H. Poisson’s ratio values for rocks. Int. J. Rock Mech. Min. Sci. 2007, 44, 1–13. [Google Scholar] [CrossRef]

- Gong, F.Q.; Luo, S.; Li, X.B.; Yan, J.Y. Linear energy storage and dissipation rule of red sandstone materials during the tensile failure process. Chin. J. Rock Mech. Eng. 2018, 37, 352–363. [Google Scholar]

- Reichmuth, D.R. Point load testing of brittle materials to determine tensile strength and relative brittleness. Rock Mech. 1969, 9, 134–159. [Google Scholar]

- Peng, S.S. Stress analysis of cylindrical rock discs subjected to axial double point load. Int. J. Rock Mech. Min. Sci. 1976, 13, 97–101. [Google Scholar] [CrossRef]

- Kaharaman, S.; Gunaydin, O. The effect of rock classes on the relation between uniaxial compressive strength and point load index. Bull. Eng. Geol. Environ. 2009, 68, 345–353. [Google Scholar] [CrossRef]

- Li, X.E.; Fu, X.M. A study on the point load test of irregular lump rocks. J. Oz Geotech. Eng. 1987, 9, 1–11. [Google Scholar]

- Hassani, F.P. Application of the point load index test to strength determination of rock and proposals for a new size-correction chart. In Proceedings of the 21st Symposium on Rock Mechanics Missouri-Rolla, Rolla, MO, USA, 27 May 1980. [Google Scholar]

- ISRM (International Society for Rock Mechanics). The Complete Suggested Methods for Rock Characterization, Testing and Monitoring: 1974–2006 ISRM. Suggested Methods Prepared by the Commission on Testing Methods; Ulusay, R., Hudson, J.A., Eds.; ISRM Turkish National Group: Ankara, Turkey, 2007. [Google Scholar]

- Yin, J.H.; Wong, R.H.C.; Chau, K.T.; Lai, D.T.W.; Zhao, G.S. Point load strength index of granitic irregular lumps: Size correction and correlation with uniaxial compressive strength. Tunn. Undergrad. Space Technol. 2017, 70, 388–399. [Google Scholar] [CrossRef]

- Li, H.P.; Wu, Y.Y.; Ge, C.; Dai, L.; Yao, H.Y. The Relation between Point Load Strength and Compressive and Tensile Strength of Marble. Sci. Technol. Eng. 2019, 19, 294–299. [Google Scholar]

- Yao, J.L.; Yao, H.Y.; Dai, L.; Bian, H.B. Study on the Mechanical Characteristics of Anisotropic Gneiss under Point Load and Uniaxial Compression. Chin. J. Undergrad. Space Eng. 2021, 17, 1038–1044. [Google Scholar]

- Dai, L.; Yao, H.Y.; Pan, P.Z.; Wang, K.D.; Yao, J.L. Point Load Test and Analysis of Disc Rocks with Different Diameters. Water Resour. Power 2021, 39, 147–150. [Google Scholar]

- Protodyakonov, M.M. New methods of determining mechanical properties of rock. In Proceedings of the International Conference on Strata Control, Paris, France, 23 September 1960; pp. 187–195. [Google Scholar]

- Gunsallus, K.; Kulhawy, F.H. A comparative evaluation of rock strength measures. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1984, 2, 233–248. [Google Scholar] [CrossRef]

- Li, D.; Wong, L.N.Y. Point load test on meta-sedimentary rocks and correlation to USC and BTS. Rock Mech. Rock Eng. 2013, 46, 889–896. [Google Scholar] [CrossRef]

- Turk, N.; Dearman, W.R. Improvements in the determination of point load strength. Bull. Int. Assoc. Eng. Geol. 1985, 31, 137–142. [Google Scholar] [CrossRef]

- Panek, L.A.; Fannon, T.A. Size and shape effects in point load tests of irregular rock fragments. Rock Mech. Rock Eng. 1992, 25, 109–140. [Google Scholar] [CrossRef]

- Karaman, K.; Kesimal, A.; Ersoy, H. A comparative assessment of indirect methods for estimating the uniaxial compressive and tensile strength of rocks. Arab. J. Geosci. 2015, 8, 2393–2403. [Google Scholar] [CrossRef]

- Nagappan, K. Prediction of Unconfined Compressive Strength for Jointed Rocks Using Point Load Index Based on Joint Asperity Angle. Geotech. Geol. Eng. 2017, 35, 2625–2636. [Google Scholar] [CrossRef]

- Chen, X.D.; Feng, L.; Wang, J.J.; Guo, S.S.; Xu, Y.F. Cyclic triaxial test investigation on tuffs with different water content at Badantoru Hydropower Station in Indonesia. Eng. Geol. 2022, 300, 106554. [Google Scholar] [CrossRef]

- Wen, L.; Luo, Z.Q.; Yang, S.J.; Qin, Y.G.; Ma, S.W.; Jiang, H. A new method for evaluating the rock mass damage index based on the field point load strength. R. Soc. Open Sci. 2019, 6, 181591. [Google Scholar] [CrossRef] [PubMed]

- Kahraman, S. Valuation of simple methods for assessing the uniaxial compressive strength of rock. Int. J. Rock Mech. Min. Sci. 2001, 38, 981–994. [Google Scholar] [CrossRef]

- Cobanoglu, I.; Çelik, S.B. Estimation of uniaxial compressive strength from point load strength, Schmidt hardness and P-wave velocity. Bull. Eng. Geol. Environ. 2008, 67, 491–498. [Google Scholar] [CrossRef]

- Kohno, M.; Maeda, H. Relationship between point load strength index and uniaxial compressive strength of hydrothermally altered soft rocks. Int. J. Rock Mech. Min. Sci. 2012, 50, 147–157. [Google Scholar] [CrossRef]

- Ozturk, H.; Altinpinar, M. The estimation of uniaxial compressive strength conversion factor of trona and interbeds from point load tests and numerical modeling. J. Afr. Earth Sci. 2017, 131, 71–79. [Google Scholar] [CrossRef]

- Luo, Q.; Zhu, J.J.; Zhan, X.Q.; Cheng, M.; Li, C.B. Engineering Characteristics of Soft Phyllite and Its Applicability for Subgrade Filling. J. Railw. Eng. Soc. 2019, 250, 1–5. [Google Scholar]

- Feng, X.; Dai, L.; Yao, H.Y.; Hu, H.M.; Zhang, Z.F.; Li, H.G. Experimental study on anisotropic characteristics of gneiss. Sci. Technol. Eng. 2019, 19, 233–239. [Google Scholar]

- Sha, P.; Zhang, Q.T.; Lin, J.; Wu, F.Q. In-situ estimation of uniaxial compressive strength of igneous rock based on point load strength. Rock Soil Mech. 2020, 41, 1–10. [Google Scholar]

- Zheng, B.; Tang, M. The physical and mechanical properties of basalt in Mumbai Peninsula and internal correlations. Rock Soil Mech. 2020, 41, 1–11. [Google Scholar]

- Zhou, Z.; Chen, S.X.; Dai, Z.J.; Huang, K.; Yu, F. Study on strength softening law of Cenozoic red sandstone based on point load test. Rock Soil Mech. 2021, 42, 2997–3007. [Google Scholar]

- Li, Y.M.; Zhao, G.F. A numerical integrated approach for the estimation of the uniaxial compression strength of rock from point load tests. Int. J. Rock Mech. Min. Sci. 2021, 148, 104939. [Google Scholar] [CrossRef]

- Shahla, P.; Amin, J.; Ramin, S.; Artimes, G.D. The pH effect of sulfuric acid on the physico-mechanical properties of Atashkuh travertine. Cent. Iran 2022, 81, 159. [Google Scholar]

- Goulet, A.; Grenon, M.; Hadjigeorgiou, J. Understanding the Impact of Alteration on Rock Mass Strength. Geotech. Geol. Eng. 2022, 40, 2533–2552. [Google Scholar] [CrossRef]

- Mehdi, K.; Massoud, P. Mechanical Properties of Clayey Soil Reinforced with PET Considering the Influence of Lime-Stabilization. Transp. Geotech. 2022, 33, 100726. [Google Scholar] [CrossRef]

- Palchik, V.; Hatzor, Y.H. The Influence of Porosity on Tensile and Compressive Strength of Porous Chalks. Rock Mech. Rock Eng. 2004, 37, 331–341. [Google Scholar] [CrossRef]

- Bieniawski, Z.T. The point load test in geotechnical practice. Eng. Geol. 1975, 9, 1–11. [Google Scholar] [CrossRef]

- Read, J.R.L.; Thornien, P.N.; Regan, W.M. A rational approach to the point load test. In Proceedings of the Third Australia-New Zealand Conference on Geomechanics, Wellington, New Zealand, 12–16 May 1980; pp. 35–39. [Google Scholar]

- Forster, I.R. The influence of core sample geometry on the axial point-load test. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1983, 20, 291–295. [Google Scholar] [CrossRef]

- Vallejo, L.E.; Welsh, R.A.; Robinson, M. Correlation between unconfined compressive and point load strengths for appalachian rocks. In Proceedings of the 30th US Symposium on Rock Mechanics (USRMS), Morgantown, WV, USA, 19–22 June 1989. [Google Scholar]

- Ghosh, D.K.; Srivastava, M. Point load strength: An index for classification of rock material. Bull. Int. Assoc. Eng. Geol. 1991, 44, 27–33. [Google Scholar] [CrossRef]

- Smith, H.J. The point load test for weak rock in dredging applications. Int. J. Rock Mech. Min. Sci. 1997, 34, 291–295. [Google Scholar] [CrossRef]

- Tugrul, A.; Zarif, I.H. Correlation of mineralogical and textural, characteristics with engineering properties of selected granitic rocks from Turkey. Eng. Geol. 1999, 51, 303–317. [Google Scholar] [CrossRef]

- Quane, S.L.; Russell, J.K. Rock strength as a metric of welding intensity in pyroclastic deposits. Eur. J. Mineral. 2003, 15, 855–864. [Google Scholar] [CrossRef]

- Tsiambaos, G.; Sabatakakis, N. Considerations on strength of intact sedimentary rocks. Eng. Geol. 2004, 72, 261–273. [Google Scholar] [CrossRef]

- Kahraman, S.; Gunaydin, O.; Fener, M. The effect of porosity on the relation between uniaxial compressive strength and point load index. Int. J. Rock Mech. Min. Sci. 2005, 42, 584–589. [Google Scholar] [CrossRef]

- Sabatakakis, N.; Koukis, G.; Tsiambaos, G.; Papanaklia, S. Index properties and strength variation controlled by microstructure for sedimentary rocks. Eng. Geol. 2008, 97, 80–90. [Google Scholar] [CrossRef]

- Singh, T.N.; Kainthola, A.; Venkatesh, A. Correlation between point load index and uniaxial compressive strength for different rock types. Rock Mech. Rock Eng. 2012, 45, 259–264. [Google Scholar] [CrossRef]

- Mishra, D.A.; Basu, A. Estimation of uniaxial compressive strength of rock materials by index tests using regression analysis and fuzzy inference system. Eng. Geol. 2013, 160, 54–68. [Google Scholar] [CrossRef]

- Woo, I. Correlation Between the Point-Load Strength and the Uniaxial Compressive Strength of Korean Granites. J. Eng. Geol. 2014, 24, 101–110. [Google Scholar] [CrossRef][Green Version]

- Amr, F.E. The use of point load test for Dubai weak calcareous sandstones. J. Rock Mech. Geotech. Eng. 2015, 7, 452–457. [Google Scholar] [CrossRef]

- Jiang, Q.; Cui, J.; Feng, X.T.; Liu, G.F.; Wang, B.L.; Liu, T.; LÜ, Y.G. Stochastic statistics and probability distribution estimation of mechanical parameters of basalt. Rock Soil Mech. 2017, 38, 784–792. [Google Scholar]

- Singh, R.; Umrao, R.K.; Ahmad, M.; Ansari, M.K.; Sharma, L.K.; Singh, T.N. Prediction of geomechanical parameters using soft computing and multiple regression approach. Measurement 2017, 99, 108–119. [Google Scholar] [CrossRef]

- Xie, W.Q.; Zhang, X.P.; Liu, Q.S.; Tang, S.H.; Li, W.W. Experimental investigation of rock strength using indentation test and point load test. Int. J. Rock Mech. Min. Sci. 2021, 139, 104647. [Google Scholar] [CrossRef]

- Feijoo, P.; Peralta, A.; Tamayo, A.; Feijoo, B. Rock material particle size and its correlation with the point load test index. Multidiscip. J. Sci. Res. 2022, 3, 78–88. [Google Scholar] [CrossRef]

- Deere, D.U.; Miller, R.P. Engineering Classification and Index Properties for Intact Rocks; Air Force Weapons Lab, Wright-Patterson Air Force Base: Fairborn, OH, USA, 1966; p. 301. [Google Scholar]

- Cargill, J.S.; Shakoor, A. Evaluation of empirical methods for measuring the uniaxial compressive strength of rock. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1990, 27, 495–503. [Google Scholar] [CrossRef]

- Grasso, P.; Xu, S.; Mahtab, A. Problems and Promises of Index Testing of Rocks. Rock Mech. 1992, 33, 879–888. [Google Scholar]

- Ulusay, R.K.; Türeli Ider, M.H. Prediction of engineering properties of a selected litharenite sandstone from its petrographic characteristics using correlation and multivariate statistical techniques. Eng. Geol. 1994, 38, 135–157. [Google Scholar] [CrossRef]

- Fener, M.; Kahraman, S.; Bilgil, A.; Gunaydin, O. A comparative evaluation of indirect methods to estimate the compressive strength of rocks. Rock Mech. Rock Eng. 2005, 38, 329–343. [Google Scholar] [CrossRef]

- Akram, M.; Bakar, M.Z.A. Correlation between Uniaxial Compressive Strength and Point Load Index for Salt-range Rocks. Pak. J. Eng. Appl. Sci. 2007, 1, 1–8. [Google Scholar]

- Kilic, A.; Teymen, A. Determination of mechanical properties of rocks using simple methods. Bull. Eng. Geol. Environ. 2008, 67, 237–244. [Google Scholar] [CrossRef]

- Yilmaz, I. A new testing method for indirect determination of the unconfined compressive strength of rocks. Int. J. Rock Mech. Min. Sci. 2009, 46, 1349–1357. [Google Scholar] [CrossRef]

- Basu, A.; Kamran, M. Point load test on schistose rocks and its applicability in predicting uniaxial compressive strength. Int. J. Rock Mech. Min. Sci. 2010, 47, 823–828. [Google Scholar] [CrossRef]

- Heidari, M.; Khanlari, G.R.; Torabi, K.M.; Kargarian, S. Predicting the uniaxial compressive and tensile strengths of gypsum rock by point load testing. Rock Mech. Rock Eng. 2012, 45, 265–273. [Google Scholar] [CrossRef]

- Fu, Z.L.; Wang, L. Comparative experimental research on point load strength, uniaxial compressive strength and tensile strength for rocks in roof and floor of coal seam. Chin. J. Rock Mech. Eng. 2013, 32, 88–96. [Google Scholar]

- Lin, J.; Sha, P.; Wu, F. Correlation Between Point Loading Index and Uniaxial Compression Strength of Rock-like Material Based on Size Effect. J. Yangtze River Sci. Res. Inst. 2018, 35, 34–44. [Google Scholar]

- Li, S.Q.; Zhao, Z.N.; Wu, J. Study on the correlation between uniaxial compressive strength and point load strength of limestone. China Min. Mag. 2021, 30, 189–194. [Google Scholar]

- Santi, P.M. Field methods for characterizing weak rock for engineering. Environ. Eng. Geosci. 2006, 12, 1–11. [Google Scholar] [CrossRef]

- ASTM C1721-09; Standard Guide for Petrographic Examination of Dimension Stone. ASTM International: West Conshohocken, PA, USA, 2009.

- Chen, J.Q.; Wei, Z.A. Comparison of rock strength from different point load tests and the uniaxial compressive strength. Chin. J. Geol. Hazard Control 2018, 29, 78–83. [Google Scholar]

- Guevara-Lopez, F.; Jimenez, R.; Gardoni, P.; Asem, P. Probabilistic prediction of intact rock strength using point load tests using a Bayesian formulation. Georisk 2020, 14, 206–215. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, G.F.; Wei, X.; Li, H. A multifrequency ultrasonic approach to extracting static modulus and damage characteristics of rock. Int. J. Rock Mech. Min. Sci. 2021, 148, 104925. [Google Scholar] [CrossRef]

- Liu, G.; Peng, J.; Zhang, Z.; Wang, Z.; Yang, Y. Numerical investigation of fluid-driven crack propagation and coalescence in granite specimen with two preexisting flaws. J. Nat. Gas Sci. Eng. 2020, 75, 103132. [Google Scholar] [CrossRef]

- Kadir, K.; Ayberk, K.; Ayhan, K. Use of the point load index in estimation of the strength rating for the RMR system. J. Afr. Earth Sci. 2015, 106, 40–49. [Google Scholar] [CrossRef]

- Muhammad, Z.J.; Muhammad, S.K. Establishment of Correlation Between Los Angeles Abrasion Loss and Strength Determined through Point Load Index and Schmidt Rebound Hammer. Sci. Int. 2014, 26, 767–770. [Google Scholar]

- Gholam-Reza, K.; Mojtaba, H.; Ali-Asghar, S.; Davood, F. Quantification of strength anisotropy of metamorphic rocks of the Hamedan province, Iran, as determined from cylindrical punch, point load and Brazilian tests. Eng. Geol. 2014, 169, 80–90. [Google Scholar] [CrossRef]

- Pouyan, A.; Paolo, G. A generalized Bayesian approach for prediction of strength and elastic properties of rock. Eng. Geol. 2021, 289, 106187. [Google Scholar] [CrossRef]

- Li, H.R.; Qiao, Y.F.; Shen, R.X.; He, M.C.; Cheng, T.; Xiao, Y.M.; Tang, J. Effect of water on mechanical behavior and acoustic emission response of sandstone during loading process: Phenomenon and mechanism. Eng. Geol. 2021, 294, 106386. [Google Scholar] [CrossRef]

- Sobhey, M.; Shahien, M.; Sawwaf, M.; Farouk, A. Point Load Index of Rocks Exposed to High Thermal Effect. J. Eng. Res. 2021, 5, 38–42. [Google Scholar]

- Didem, E.S.; Engin, O. Determining point load strength loss from porosity, Schmidt hardness, and weight of some sedimentary rocks under freeze–thaw conditions. Environ. Earth Sci. 2018, 77, 62. [Google Scholar] [CrossRef]

- Zhou, Z.L.; Wu, Z.B.; Li, X.B.; Li, X.; Ma, C.D. Mechanical behavior of red sandstone under cyclic point loading. Nonferrous Met. Soc. China 2015, 25, 2708–2717. [Google Scholar] [CrossRef]

- Marzouk, M.A.A.; Li, D.; Ren, G.F. Evaluation of Point Load Test Effectiveness in Estimation of Long-Term Durability of Some Chinese Limestone Rocks Due to Frost Action. Iran. J. Sci. Technol. Trans. Sci. 2020, 44, 1393–1406. [Google Scholar] [CrossRef]

- Hussain, S.; Maher, O.; Abdallah, S. Estimating Unconfined Compressive Strength of Sedimentary Rocks in United Arab Emirates from Point Load Strength Index. J. Appl. Math. Phys. 2014, 2, 296–303. [Google Scholar] [CrossRef]

| Serial No. | PLS Index Formula | Correlation Coefficient (R2) | Rock Type |

|---|---|---|---|

| 1 | Is = −0.516De + 31.423 | 0.897 | Basalt |

| 2 | Is = −0.824De + 50.364 | 0.835 | Dolomite |

| 3 | Is = −0.137De + 11.776 | 0.764 | Limestone |

| 4 | Is = −0.105De + 9.209 | 0.782 | Marl |

| 5 | Is = −0.414De + 25.710 | 0.828 | Quartzite |

| 6 | Is = −0.606De + 38.694 | 0.892 | Lava |

| Functional Relationship Type | Author | Functional Relationship | Major Rock Type | Remarks |

|---|---|---|---|---|

| Quadratic function | Tugrul et al. [88] | UCS = 3.86(Is(50))2 + 5.65Is(50) | Magmatic rock | — |

| Quane et al. [89] | UCS = 3.86(Is(50))2 + 5.56Is(50) | — | — | |

| Sha Peng et al. [74] | UCS = 0.31(Is(50))2 + 7.01Is(50) (R = 0.966) | Tuff | — | |

| UCS = −0.94(Is(50))2 + 24.56Is(50) (R = 0.966) | Diorite | — | ||

| Sha P. et al. [76] | UCS = 0.14(Is(50))2 + 13.25Is(50) (R = 0.3) | Igneous rock | — | |

| Exponential function | Diamanti et al. [14] | UCS = 16.45exp(0.39Is(50)) | — | — |

| Sheraz et al. [11] | UCS = 85.52exp(0.718Is) (R = 67%) | Dolomite | — | |

| Kahraman [24] | UCS = 1.99exp(1.18Is(50)) (R = 0.92) | Pyroclastic rock | Saturated | |

| UCS = 2.27exp(1.04Is(50)) (R = 0.93) | Natural | |||

| UCS = 2.68exp(0.93Is(50)) (R = 0.93) | Dry | |||

| Li Shao Qian et al. [113] | UCS = 6.46exp(0.56Is(50)) | Limestone | Axial | |

| UCS = 9.80exp(0.47Is(50)) | Diametral | |||

| Power function | Tsiambaos et al. [90] | UCS = 7.3(Is(50))1.71 (R2 = 0.906) | — | — |

| Santi et al. [114] | UCS = 12.25(Is(50))1.50 (R2 = 0.985) | — | — | |

| Diamanti et al. [14] | UCS = 17.81(Is(50))1.06 (R2 = 0.906) | — | — | |

| ASTM [115] | UCS = 17.81Is(50)1.06 | Serpentinite | — | |

| Ministry of Water Resources of the People’s Republic of China [27] | UCS = 22.82(Is(50))0.75 (R2 = 0.90) | — | — | |

| Sheraz et al. [11] | UCS = 202.71Is0.633 (R = 80%) | Dolomite | — | |

| Kahraman [24] | UCS = 7.73(Is(50))1.25 (R = 0.910) | Pyroclastic rock | Dry | |

| UCS = 8.61(Is(50))0.95 (R = 0.910) | Saturated | |||

| UCS = 8.66(Is(50))1.03 (R = 0.922) | Natural | |||

| Chen Jiaqi et al. [116] | UCS = 22.72Is(50)0.82 (R2 = 0.860) | Sandstone, mudstone, and limestone | Irregular | |

| UCS = 26.24IS(50)0.72 (R2 = 0.860) | Regular | |||

| Logarithmic function | Grasso et al. [103] | UCS = 100lnIs(50) + 13.9 | — | — |

| UCS = 17.04lnIs(50) + 9.29 | — | — | ||

| Kilic et al. [107] | UCS = 100ln(Is(50)) + 13.9 (R = 0.990) | — | — | |

| Kahraman [24] | UCS = 17.04ln(Is(50)) + 9.29 (R = 0.750) | Pyroclastic rock | Dry | |

| UCS = 7.27ln(Is(50)) + 11.7 (R = 0.750) | Saturated | |||

| UCS = 10.28ln(Is(50)) + 12.32 (R = 0.730) | Natural |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, M.; Xu, W.; Chen, D.; Li, J.; Mu, H.; Mi, J.; Wu, Y. Summary of the Transformational Relationship between Point Load Strength Index and Uniaxial Compressive Strength of Rocks. Sustainability 2022, 14, 12456. https://doi.org/10.3390/su141912456

Wang M, Xu W, Chen D, Li J, Mu H, Mi J, Wu Y. Summary of the Transformational Relationship between Point Load Strength Index and Uniaxial Compressive Strength of Rocks. Sustainability. 2022; 14(19):12456. https://doi.org/10.3390/su141912456

Chicago/Turabian StyleWang, Meiqian, Wei Xu, Dakun Chen, Jianguo Li, Hongyuan Mu, Jian Mi, and Yonghong Wu. 2022. "Summary of the Transformational Relationship between Point Load Strength Index and Uniaxial Compressive Strength of Rocks" Sustainability 14, no. 19: 12456. https://doi.org/10.3390/su141912456

APA StyleWang, M., Xu, W., Chen, D., Li, J., Mu, H., Mi, J., & Wu, Y. (2022). Summary of the Transformational Relationship between Point Load Strength Index and Uniaxial Compressive Strength of Rocks. Sustainability, 14(19), 12456. https://doi.org/10.3390/su141912456