Abstract

Natural wastes are widely used as composts for plant growth. However, wool waste has received little attention in this regard, despite its nitrogen-rich chemical structure owing to amide groups. A few studies have been conducted for soil amendment using wool, mostly in raw or pellet form. However, despite the possible consistent mixing and more uniform effect of powders inside soil, wool has never been implemented in powder form in soil for improving moisture. This study demonstrates the effectiveness of using wool as a powder, facilitating better mixing and spreading in soil. Results show that wool powders are more effective in retaining soil moisture compared to wool pellets and are comparable to commercial fertiliser. The findings further indicate that a balanced amount of wool is required to maintain a proper moisture level (not too wet or dry) to promote actual plant growth.

1. Introduction

Wool is a natural keratin fibre sourced from sheep in numerous countries, and more than 1.16 million tonnes are produced each year worldwide [1]. The countries that produce wool are widespread and from different continents, including Australia, New Zealand, China, the United States, the United Kingdom, Iran, Turkey, Argentina, and India. The estimated amount of wool production is mainly the total of the clean or traded wool, while the amount of waste wool is rarely counted. According to a report from 2019, it is predicted that around 10–15% of wool is wasted during its sorting and cleaning, and an added 12–15% is lost during spinning and weaving [2]. The annual combined generation of wool waste from the nine key countries listed above is estimated at around 317 thousand tonnes per year, which is mostly the pile of low-grade wool that is not possible to spin into textiles. These wastes are frequently discarded without any care, thus often causing environmental pollution. For example, the disposal of wool waste through incineration and landfilling causes air and soil pollution when the amount of wool is not wisely controlled [3,4].

To combat this pollution and utilise this massive waste as a resource, waste wool has been proposed over the years for numerous applications, such as insulation [5], building materials [6], adsorbents [7], and composites [8]. However, wool is rich in nitrogen due to its amide groups [1], and it possesses a moisture retention ability 3.5 times its weight [9]; both are beneficial for plant growth. There are some other resources that have been proposed for soil moisture retention, such as the use of biochar from coconut fibre [10], walnut shells [11], water hyacinths [12], mixed wood [13], superabsorbent nanocomposites from silica [14], Sphagnum moss [15], compost [16,17,18,19], and minerals including vermiculite [20], bentonite, and zeolite [21]. However, the advantage of wool in comparison with other resources is its amide structure, which can simultaneously benefit the soil with moisture retention, such as by nitrogen mineralisation. Wool is also biodegradable within six months in ideal conditions [22].

Though commercial fertilisers are widely used for plant cultivation, often, they include heavy metal impurities, such as cadmium, mercury, and lead [23], that can accumulate in the soil or even be transferred into the ultimate plant products [24]. Further, there is no previous evidence on the release of nitrogen oxides or nitric acid from wool to soil, while nitrogen is mainly transformed as non-hazardous nitrogen–ammonia (NO3–N) or ammonium nitrogen (NH4–N). Therefore, the use of wool for plant growth is sustainable and can benefit the soil if sensibly used, which can reduce the fertiliser amount to a minimum, if not totally replacing it. Each year, around 317 thousand tonnes of wool waste are discarded in major wool-growing countries around the world. The majority of these wool wastes (including consumed wool garments) currently enter landfill [25], and their proper use in plant cultivation has received little attention.

A few studies have previously shown the prospects of wool in soil amendment. An increased yield of basil, thorn apple, peppermint, and garden sage when using raw wool fibre was reported, where wool was found to raise the NH4–N and NO3–N content in soil, mainly related to the nitrogen mineralisation from wool [26]. Around 40 g wool waste was observed to be sufficient for 6 kg of soil, supporting 2–3 harvests. Further, nitrogen mineralisation in plant tissue was also evident, e.g., nitrogen in thorn apple and mint tissue increased from 19.5 to 44.3 g/kg and 13.2 to 30.3 g/kg, respectively, when using wool waste, and soil microbial biomass also increased [26]. Wool has also been reported as an organic fertiliser for tomato and broccoli in the form of pellets [9,27]. However, using wool in powder form is more advantageous than using its raw form (fibre) or pellets. The use of pellets can only provide a localised benefit in soil, while the fibres can hinder proper spreading in soil due to entanglement. The use of wool powders could deliver more convenient and consistent mixing in soil and evenly enhance the soil properties.

In the past, authors have demonstrated several methods of preparing powders from different keratin fibres, such as wool [1] and alpaca [28]. Powders have been prepared from these resources from a coarse level (particle size around 70 µm) to an ultra-fine size of particles, such as 2.6 µm [28]. To develop these powders, both mechanical [28] and chemical methods [1] were used. However, the preparation of ultra-fine powders from wool requires either prolonged mechanical processing, such as ball milling and air jet milling [28], or intensive chemical treatment [1]. Nevertheless, coarse powder preparation from wool is rather quick, sustainable, and less energy-intensive, while the prepared powders are still suitable for handling and uniform mixing with soil.

The aim of this preliminary work was to evaluate the effectiveness of coarse wool powder for soil moisture retention compared to wool pellets. The morphology of the powder and pellets was analysed and the moisture retention ability was observed over a 5-day period and compared with the results obtained with commercial fertiliser and non-fertilised soil. The further impact of these soil variants on the plant growth was also assessed by a 40-day experiment on actual plants.

2. Materials and Methods

Waste wool fibre sourced from a local farm was collected from the Commonwealth Scientific and Industrial Research Organisation (CSIRO), Geelong Waurn Ponds Campus, Australia. Garden soil mix (Australian Standard AS4454), all-purpose NPK fertiliser, and Stock Marionette (Matthiola incana) seedlings were purchased from the Bunnings Warehouse, Waurn Ponds, Australia.

Waste wool fibres were ground to a powder by a cutting mill (Pulverisette 19, Fritsch, Idar-Oberstein, Germany) using a 200 µm sieve. Part of the wool powder (WP) was converted into pellets using a hydraulic pellet press (Atlas Auto touch, Specac, Orpington, UK) using 8T pressure. The weight of each pellet was 165 ± 1 mg. The morphology of wool powder and pellets was observed using a DP71 optical microscope (Olympus, Tokyo, Japan).

Six separate 10 × 10 cm garden pots were each filled with around 150 ± 2 g soil. The soils differed in terms of mixing wool powder, wool pellets, and commercial fertiliser, and were named as per Table 1. One of the soil samples was kept untreated as the control. The amount of the fertiliser was chosen based on the recommended levels provided on the commercial fertiliser package (10 g per 40 cm pot).

Table 1.

Combinations of soil prepared with wool powder and pellets and commercial fertiliser, and control sample with no fertiliser.

The soils were watered until they all reached a moisture rating of 7 (measured by a soil moisture meter, Brunnings, Australia) [29]. The soil was then kept unwatered for the next 4 days and changes in the rating were measured. The overall process was conducted in three batches, and average and standard deviation values reported. The statistical significance of the difference in datasets was calculated using a two-tailed t test, where p ≤ 0.05 indicated a significant difference and p > 0.05 indicated no significant difference.

To investigate the impact of wool powder and pellets on plant growth, a further six soil samples were prepared using the same combinations as in Table 1 to identify the impact of the wool amount and form of wool in relation to no fertiliser and commercial fertiliser. Six Marionette seedlings of the same height (~7 cm) were planted and their growth up to 40 days was monitored. The plants were watered every 5 days, by spraying with water (20 ± 1 mL). The garden pots were kept indoors under a transparent roof, receiving ~2000 lumen during daytime. The average temperature was recorded at a maximum of 21–24 °C and a minimum of 11–13 °C. The average relative humidity and daylight hours were 68% and 12.3 h, respectively.

3. Results

3.1. Surface Morphology of Wool Powder and Pellets

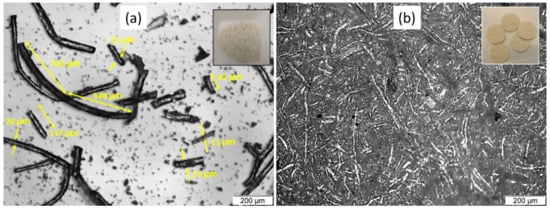

Figure 1 shows the surface morphology of the wool powder and the prepared pellet. The wool powder (Figure 1a) retained the fibrous structure of the wool, although there was a combination of random lengths. The diameter of the wool mostly remained similar (mostly around 20–23 µm), though some fibres at a lower limit were also seen (such as 11 µm). The length of the fibre widely varied due to the cutting operation, starting from around 82 µm to 690 µm. On the other hand, the morphology of the wool pellet (Figure 1b) showed a dense, fibrous structure, where ribbon-shaped fibres were attached to each other. The aggregation of the particles in the pellet was presumably much higher, compared to the randomly distributed fibres in the wool powder.

Figure 1.

Morphology of the prepared (a) wool powder and (b) wool pellet under optical microscope.

3.2. Moisture Retention Ability of Wool Powder and Pellets

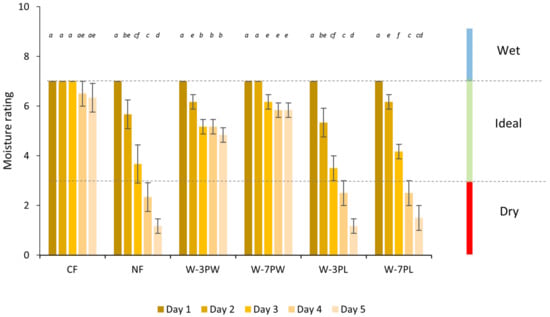

Figure 2 shows the moisture rating of the soil prepared with the samples over a 5-day period. The moisture meter provides data on three regions: wet, moist, and dry. The wet region (moisture rating 8–10) is suitable for aquatic plants, the dry region (moisture rating 0–3) is suitable for low-water plants such as Cactus and Sanseviera, and the moist region (moisture rating 4–7) is ideal for most common plants [29]. The results showed that the commercial fertiliser (CF) was more effective in holding the moisture and remained in the ideal region even after 5 days. This was probably because of some chemical elements present in the composition, such as ammonium (7.8%) [24], responsible for the high hygroscopicity [30]. Both the wool powders (W-3PW and W-7PW) also retained the moisture in the ideal region for all 5 days, although the amount was lower than CF. The moisture gained in soil due to the presence of wool powders was probably related to the lower particle size and higher surface area of the powders. Powders prepared from keratinous resources commonly show a higher moisture absorption ability compared to raw fibres (an 18% increase was reported), due to the enhanced surface area, which provides more space for the moisture to accumulate [28]. A smaller size leads to a higher surface area and thus can accumulate more moisture. In the current experiment, the soil with no fertiliser or wool (NF) radically dried up over this period and mostly stayed in the dry region in the last 3 days, identical to the result obtained from three wool pellets (W-3PL). Comparing the wool pellets and wool powder, powders were more effective in moisture retention, while the pellets allowed the soil to reach to dry region mostly after 2–3 days. This was probably because the wool powder was spread throughout the soil and completely mixed with it, while the pellets were mainly concentrated in specific places. The decrease in the soil moisture was found insignificant (p > 0.05) among days 3, 4, and 5 for W-3PW and W-7PW samples, showing a consistent water-holding ability. However, the samples with wool pellets, as well as the NF sample, showed a drastic soil moisture reduction over the 5-day period (p ≤ 0.05). A higher amount of wool in either powder or pellet form was more effective in moisture retention compared with a lower amount of wool. For example, W-7PW maintained the soil moisture at an average rating of 5.8 after 5 days, while W-3PW was at the average rating of 4.8 after the same period.

Figure 2.

Moisture rating over 5-day period for soils prepared from wool powder (PW) and pellets (PL) of different amounts, 165 mg (3) and 385 mg (7), compared to commercial fertiliser (CF) and no fertiliser (NF). Error bars show standard deviation; different superscripts indicate that data are significantly different (p ≤ 0.05).

3.3. Effect on Actual Plant Growth by Wool Powder and Pellets

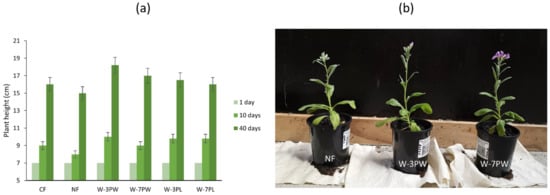

Figure 3 shows the growth of plants over 40 days using the six types of soil. Common plants such as stock flowers need a balanced, moist soil for appropriate growth. In line with the findings in Figure 2, although the moisture retention from W-3PW was lower than that of W-7PW and CF, it showed a more balanced effect (not excessive low/high moisture retention). This could be the reason that W-3PW showed the greatest influence on the plant growth (around 43% increase in 10 days and around 160% increase over 40 days), compared to other samples. The lowest value was obtained for NF, which showed around a 14% increase in 10 days and around a 114% increase in 40 days. The samples with pelletised wool, CF and W-7PW, showed moderate growth. It is probable that the pelletised wool was not as effective as the wool powders in terms of moisture retention and allowed the sample to dry up sooner. However, the lower value for CF and W-7PW, compared to W-3PW, was probably related to the higher moisture in the soil, caused by greater moisture retention. Although this plant growth process was not replicated in simultaneous batches, the positive impact of wool was steady for all the wool-included samples, and it was consistent with the soil moisture retention findings and with the literature [26]. The difference achieved in the plant height data for the W-3PW sample after 40 days was more than 5%, except for CF and NF (error bars in Figure 3a). The higher impact observed with a lower amount of wool could be explained by the similar result noted for the wool pellets as well. Based on these initial findings, future trials using multiple batches of plants and different species should be performed to further validate this impact.

Figure 3.

Plant height (a) from first day to up to 40 days, affected by commercial fertiliser (CF), no fertiliser (NF), and wool powders (PW) and pellets (PL) of different amounts, and (b) photograph of plant growth after 40 days, when comparing NF with the samples prepared with wool powders of two different amounts, 3PW (165 mg) and 7PW (385 mg). Error bars show 5% deviation of actual data.

4. Summary

Due to the nitrogen and protein content of wool waste and its moisture retention ability, its use can lead to sustainable cultivation, partly or fully replacing common fertilisers that possess the risk of transferring heavy metal impurities to both soil and plants. Wool waste can achieve reasonable use in soil as a low-cost, feasible, and environmentally friendly option. This is likely to be an industrially applicable solution, given the amount of wool waste generated worldwide. This can also potentially eliminate the current additional costs related to waste wool disposal. This study presents the usefulness of using wool powder for soil moisture retention compared to wool pellets and commercial fertilisers. The morphology of wool powders showed the fibrous structure of wool, with a combination of random lengths and widths, while the pellets showed a dense, fibrous surface. In 150 g soil, the moisture retention performance of both 165 and 385 mg wool powders was comparable to that of the commercial fertiliser. However, the plant height after 40 days was observed to be higher when using a lower amount of wool (165 mg), due to its balanced moisture retention ability. Therefore, the results show that the use of an optimised amount of wool powder can be effective for both moisture retention ability in soil and the promotion of plant growth. This initial study indicates the potential of wool powders for soil amendment, which should encourage future research, such as changes in the characteristics of particles and pellets by hydration and the presumable nutritional benefits for the soil and plants.

Author Contributions

Conceptualization, M.N.; methodology, A.N.M.A.H.; formal analysis, A.N.M.A.H.; investigation, A.N.M.A.H.; writing—original draft preparation, A.N.M.A.H.; writing—review and editing, M.N.; visualization, A.N.M.A.H.; supervision, M.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Acknowledgments

The authors would like to acknowledge the contributions of the late Isuru Jeewantha.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Haque, A.N.M.A.; Naebe, M.; Mielewski, D.; Kiziltas, A. Thermally stable micro-sized silica-modified wool powder from one-step alkaline treatment. Powder Technol. 2022, 404, 117517. [Google Scholar] [CrossRef]

- Sharma, S.; Sahoo, A.; Chand, R. Potential use of waste wool in agriculture: An overview. Indian J. Small Rumin. 2019, 25, 1–12. [Google Scholar] [CrossRef]

- Kumawat, T.K.; Sharma, A.; Sharma, V.; Chandra, S. Keratin waste: The biodegradable polymers. In Keratin; IntechOpen: London, UK, 2018. [Google Scholar]

- Marchelli, F.; Rovero, G.; Curti, M.; Arato, E.; Bosio, B.; Moliner, C. An integrated approach to convert lignocellulosic and wool residues into balanced fertilisers. Energies 2021, 14, 497. [Google Scholar] [CrossRef]

- Cai, Z.; Al Faruque, M.A.; Kiziltas, A.; Mielewski, D.; Naebe, M. Sustainable lightweight insulation materials from textile-based waste for the automobile industry. Materials 2021, 14, 1241. [Google Scholar] [CrossRef]

- Buratti, C.; Belloni, E.; Merli, F. Water vapour permeability of innovative building materials from different waste. Mater. Lett. 2020, 265, 127459. [Google Scholar] [CrossRef]

- El-Geundi, M.S. Adsorbents for industrial pollution control. Adsorpt. Sci. Technol. 1997, 15, 777–787. [Google Scholar] [CrossRef]

- Remadevi, R.; Al Faruque, M.A.; Zhang, J.; Naebe, M. Electrically conductive honeycomb structured graphene composites from natural protein fibre waste. Mater. Lett. 2020, 264, 127311. [Google Scholar] [CrossRef]

- Ordiales, E.; Gutiérrez, J.I.; Zajara, L.; Gil, J.; Lanzke, M. Assessment of utilization of sheep wool pellets as organic fertilizer and soil amendment in processing tomato and broccoli. Mod. Agric. Sci. Technol. 2016, 2, 20–35. [Google Scholar]

- Guarnieri, S.F.; Nascimento, E.C.d.; Costa Junior, R.F.; Faria, J.L.B.d.; Lobo, F.d.A. Coconut fiber biochar alters physical and chemical properties in sandy soils. Acta Sci. Agron. 2021, 43, e51801. [Google Scholar] [CrossRef]

- Wang, D.; Li, C.; Parikh, S.J.; Scow, K.M. Impact of biochar on water retention of two agricultural soils—A multi-scale analysis. Geoderma 2019, 340, 185–191. [Google Scholar] [CrossRef]

- Xing, X.; Liu, Y.; Garg, A.; Ma, X.; Yang, T.; Zhao, L. An improved genetic algorithm for determining modified water-retention model for biochar-amended soil. Catena 2021, 200, 105143. [Google Scholar] [CrossRef]

- Ulyett, J.; Sakrabani, R.; Kibblewhite, M.; Hann, M. Impact of biochar addition on water retention, nitrification and carbon dioxide evolution from two sandy loam soils. Eur. J. Soil Sci. 2014, 65, 96–104. [Google Scholar] [CrossRef]

- Olad, A.; Zebhi, H.; Salari, D.; Mirmohseni, A.; Tabar, A.R. Slow-release NPK fertilizer encapsulated by carboxymethyl cellulose-based nanocomposite with the function of water retention in soil. Mater. Sci. Eng. C 2018, 90, 333–340. [Google Scholar] [CrossRef]

- Waddington, J.; Lucchese, M.; Duval, T. Sphagnum moss moisture retention following the re-vegetation of degraded peatlands. Ecohydrology 2011, 4, 359–366. [Google Scholar] [CrossRef]

- Zemánek, P. Evaluation of compost influence on soil water retention. Acta Univ. Agric. Silvic. Mendel. Brun. 2011, 59, 227–232. [Google Scholar] [CrossRef]

- Neugebauer, M.; Jakubowski, T.; Sołowiej, P.; Wesołowski, M. A fuzzy model of the composting process with simultaneous heat recovery and aeration rate control. In Renewable Energy Sources: Engineering, Technology, Innovation; Springer: Berlin/Heidelberg, Germany, 2018; pp. 151–160. [Google Scholar]

- Mbah, B.N.; Odili, P.N. Changes in moisture retention properties of five waste materials during short-term mesophilic composting. Compost Sci. Util. 1998, 6, 67–73. [Google Scholar] [CrossRef]

- Mylavarapu, R.; Zinati, G. Improvement of soil properties using compost for optimum parsley production in sandy soils. Sci. Hortic. 2009, 120, 426–430. [Google Scholar] [CrossRef]

- Lai, W.; Ahmad, W.W.; Jasni, J.; Ab Kadir, M. A review on the usage of Zeolite, Perlite and Vermiculite as natural enhancement materials for grounding system installations. In Proceedings of the IEEE 15th Student Conference on Research and Development (SCOReD), Wilayah Persekutuan Putrajaya, Malaysia, 13–14 December 2017; pp. 338–343. [Google Scholar]

- Amani, E.; Ghasemi, A.R.; Nouri, M.R.; Motaghian, H. Effect of Vermiculite, Bentonite and Zeolite on Evaporation and Soil Characteristic Moisture Curve. J. Water Soil Conserv. 2021, 28, 83–101. [Google Scholar]

- Swan, P. Wool is biodegradable. International Wool Textile Organisation. Available online: https://iwto.org/wp-content/uploads/2020/04/IWTO_Wool-is-Biodegradable.pdf (accessed on 19 August 2022).

- Oyedele, D.; Asonugho, C.; Awotoye, O. Heavy metals in soil and accumulation by edible vegetables after phosphate fertilizer application. Electron. J. Environ. Agric. Food Chem. 2006, 5, 1446–1453. [Google Scholar]

- Brunnings, All Purpose NPK Fertiliser: Analysis. Brunnings Garden Products, Australia. 2022. Available online: https://brunnings.com.au/product/all-purpose-npk-fertiliser-500g/ (accessed on 1 March 2022).

- Wiedemann, S.; Biggs, L.; Nebel, B.; Bauch, K.; Laitala, K.; Klepp, I.; Swan, P.; Watson, K. Environmental impacts associated with the production, use, and end-of-life of a woollen garment. Int. J. Life Cycle Assess. 2020, 25, 1486–1499. [Google Scholar] [CrossRef]

- Zheljazkov, V.D. Assessment of wool waste and hair waste as soil amendment and nutrient source. J. Environ. Qual. 2005, 34, 2310–2317. [Google Scholar] [CrossRef] [PubMed]

- Böhme, M.H. Use of bio-waste as fertiliser for the protected vegetable cultivation. J. Vietnam. Environ. 2018, 10, 27–32. [Google Scholar] [CrossRef]

- Al Faruque, M.A.; Remadevi, R.; Wang, X.; Naebe, M. Preparation and characterisation of mechanically milled particles from waste alpaca fibres. Powder Technol. 2019, 342, 848–855. [Google Scholar] [CrossRef]

- Brunnings, 3 in 1 Soil Meter: Direction of Use. Brunnings Garden Products, Australia. 2022. Available online: https://brunnings.com.au/product/3-in-1-soil-meter/ (accessed on 1 March 2022).

- Elzaki, B.I.; Zhang, Y.J. Anti-hygroscopic surface modification of ammonium nitrate (NH4NO3) coated by surfactants. Arab. J. Chem. 2020, 13, 3460–3473. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).