Hydrogen Production from Surplus Electricity Generated by an Autonomous Renewable System: Scenario 2040 on Grand Canary Island, Spain

Abstract

:1. Introduction

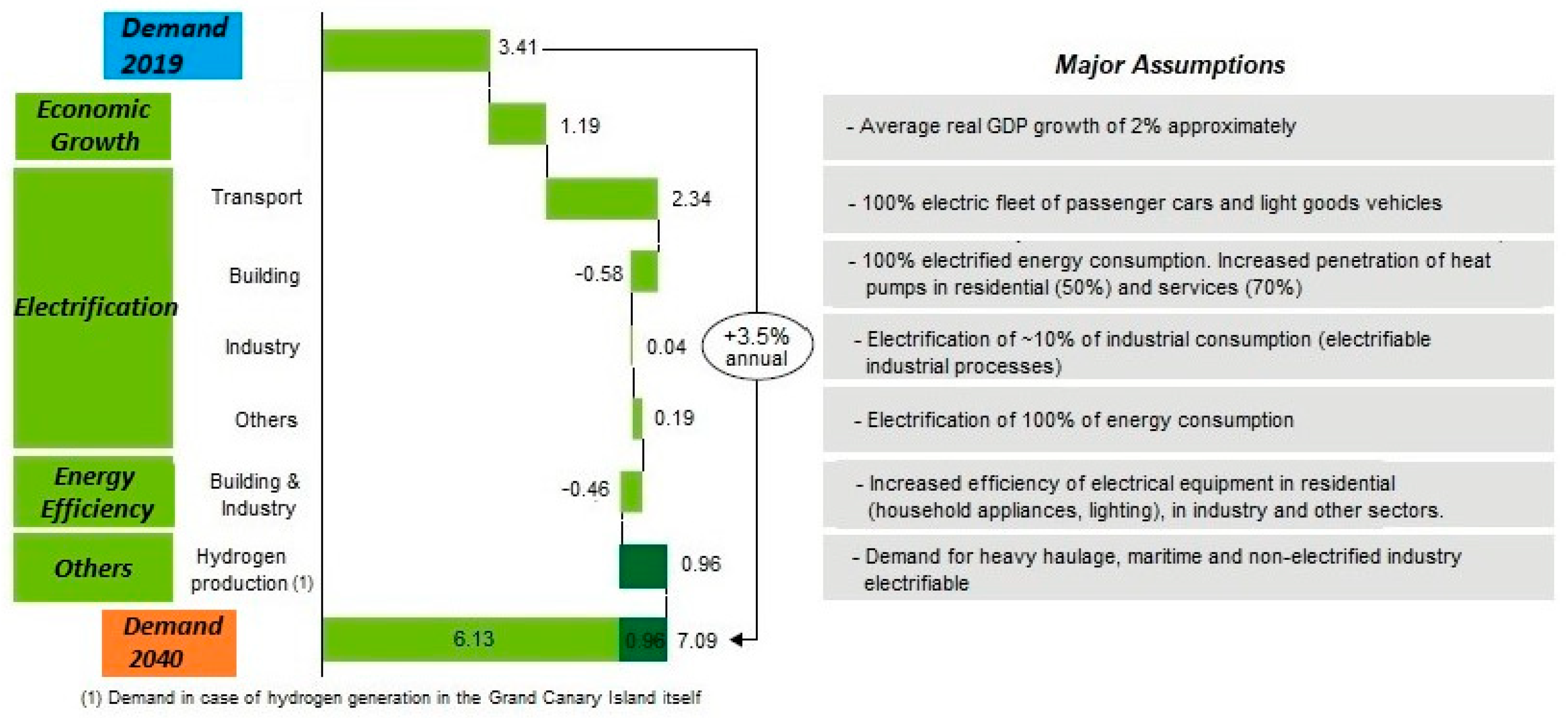

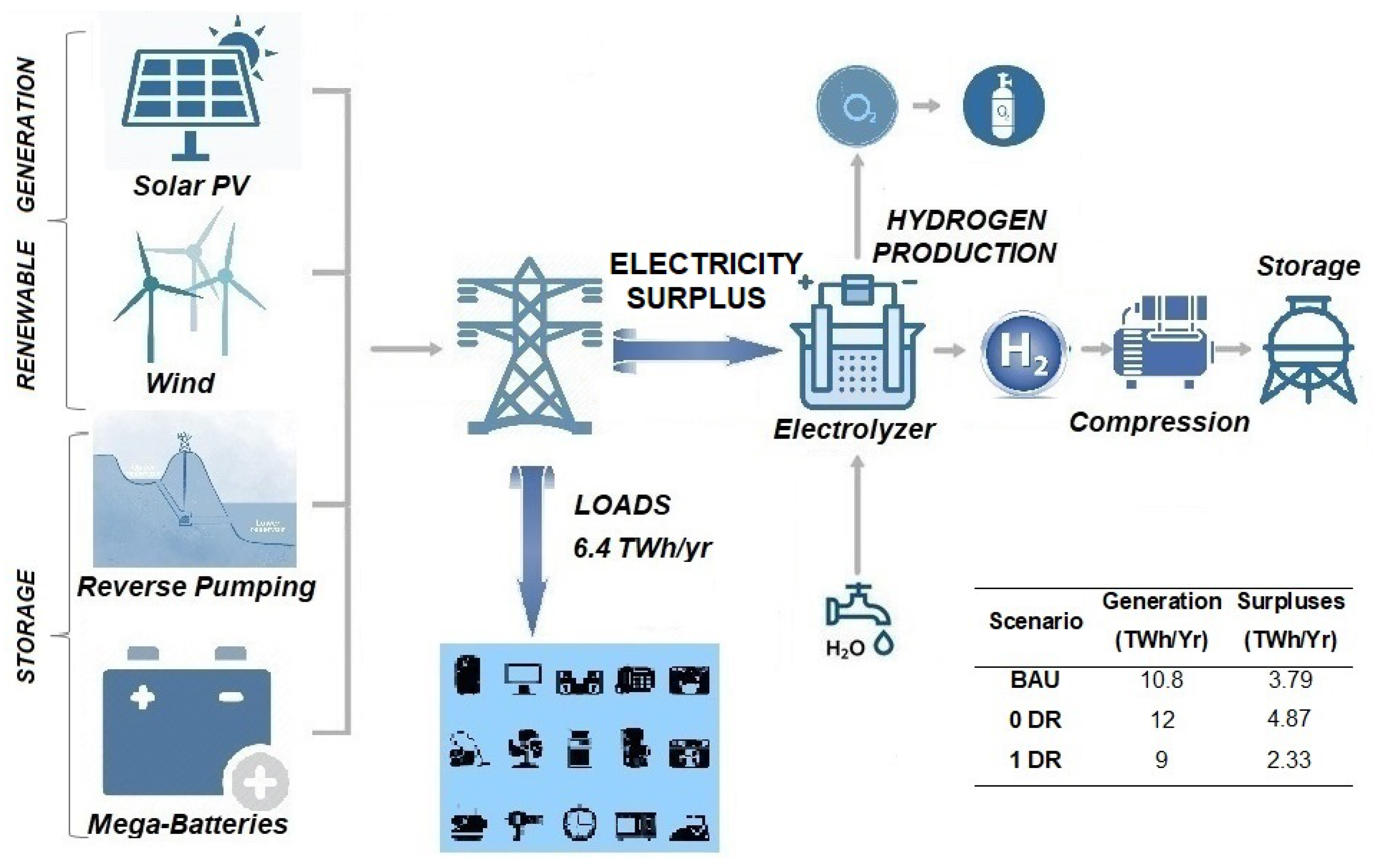

2. Future Generation–Demand Balance

3. The Renewable Generation

3.1. The Centralized Storage Systems

3.2. The Full Electrification of the Final Energy Consumptions

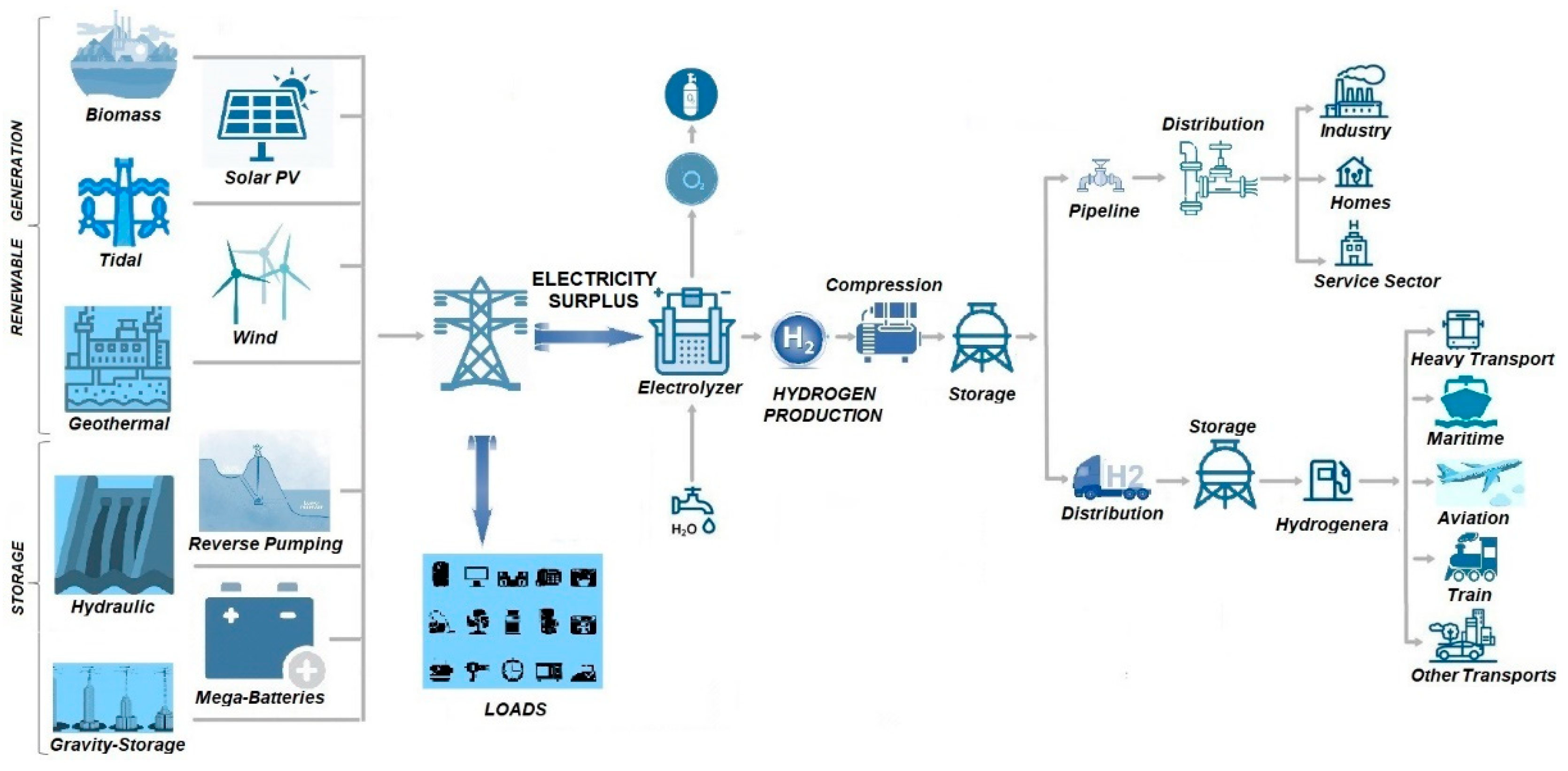

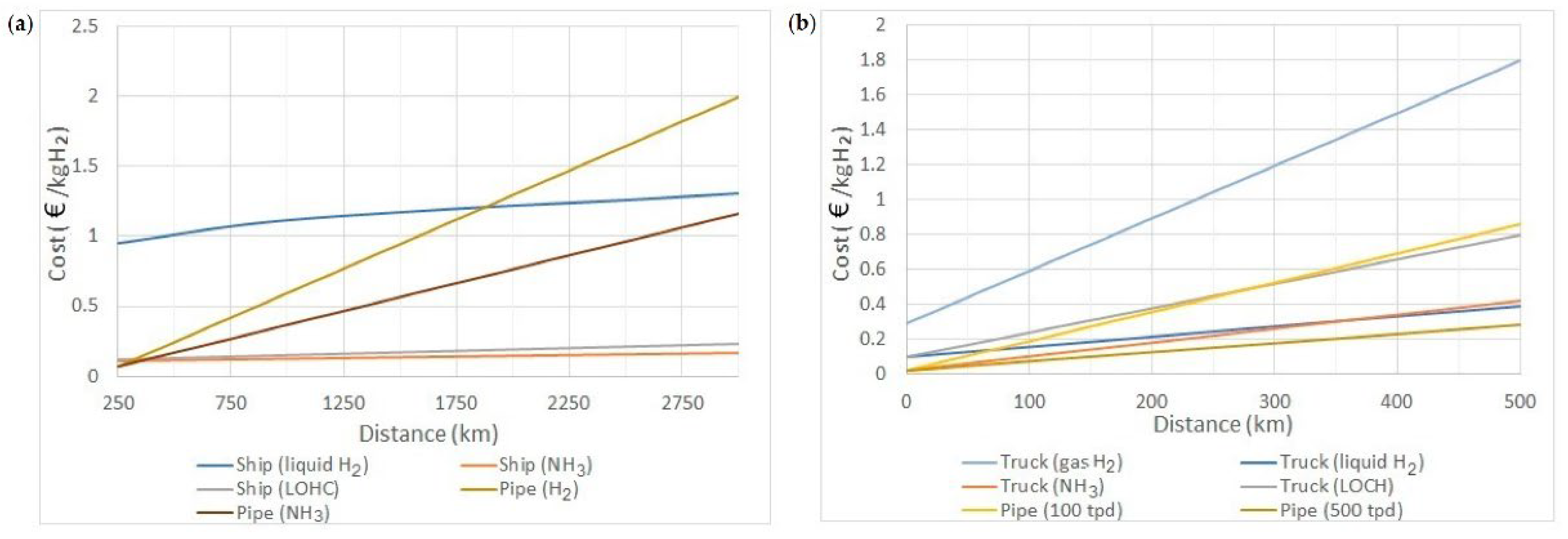

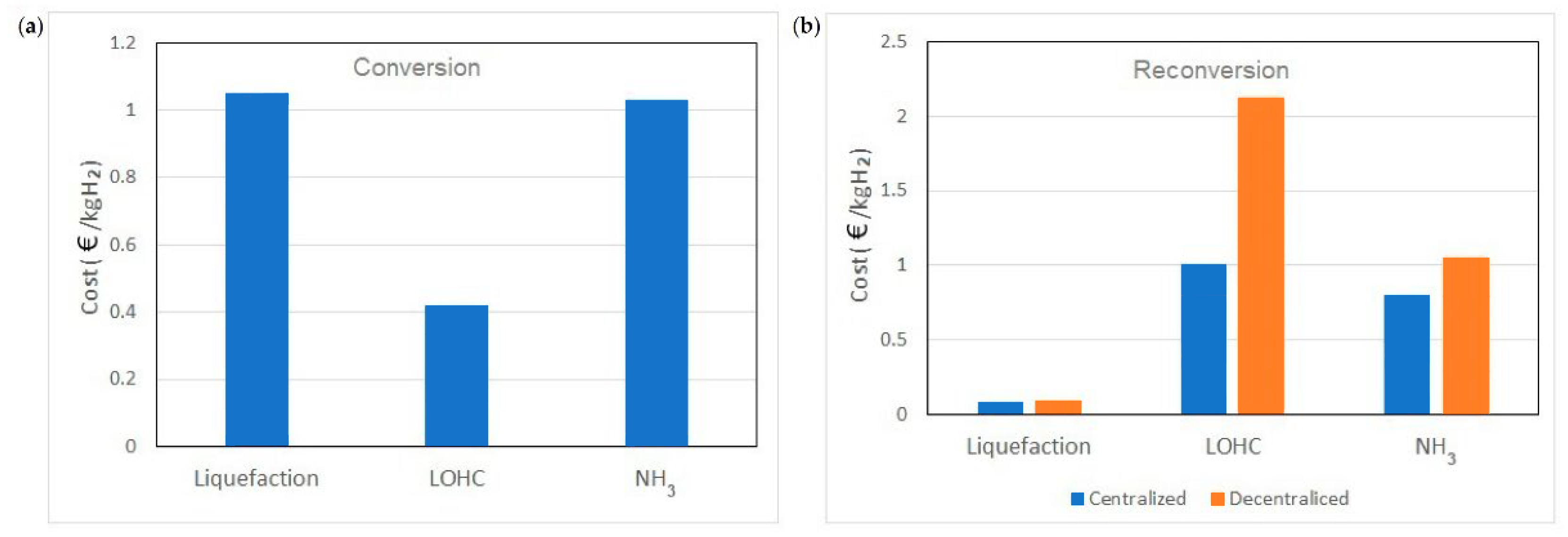

3.3. Hydrogen or Ammonia as Energy Vectors

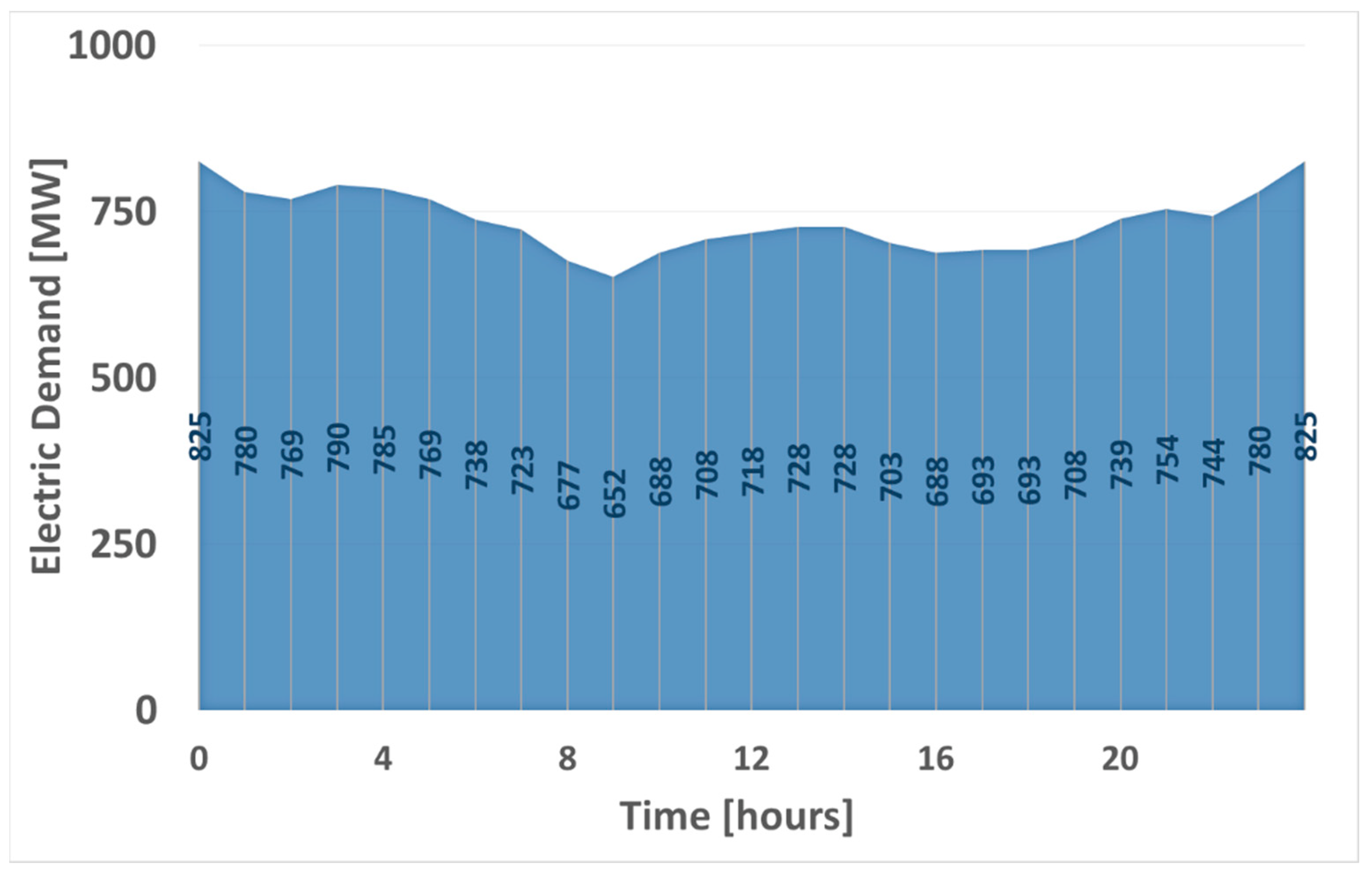

3.4. Smart Grids and Demand Management

- To strengthen and automate the network, improving its operation, quality indexes, and losses.

- To favor the integration of renewable energies, also improving the integration of intermittent renewable generation (mainly wind and solar photovoltaic) by developing new storage technologies and enhancing the existing ones.

- To favor the integration of hydrogen production, intermittent renewable generation and storage technologies aim to manage the generation–demand balance for both electric and hydrogen, using electric energy surpluses to produce hydrogen.

- Develop decentralized generation plants or systems, allowing for the operation of smaller installations closer to the final consumer, in harmony with the rest of the system (distributed generation), which would reduce losses.

- Active demand management, allowing consumers to manage their consumption more efficiently.

- Incentivize active demand management by promoting energy offers with hourly tariffs that encourage consumers to incentivize users to carry out smart recharging during off-peak hours.

- Integrate V2G technology, allowing the entry of a large amount of distributed and renewable energy and the active participation of customers in the electricity system. This technology allows bidirectional management of the grid since, on the one hand, it consumes energy from the grid, but, on the other hand, it can return it during peak demand hours. This allows advanced load control in smart grids. Even V2G policies could also be useful for supplying stationary demands, particularly home demand.

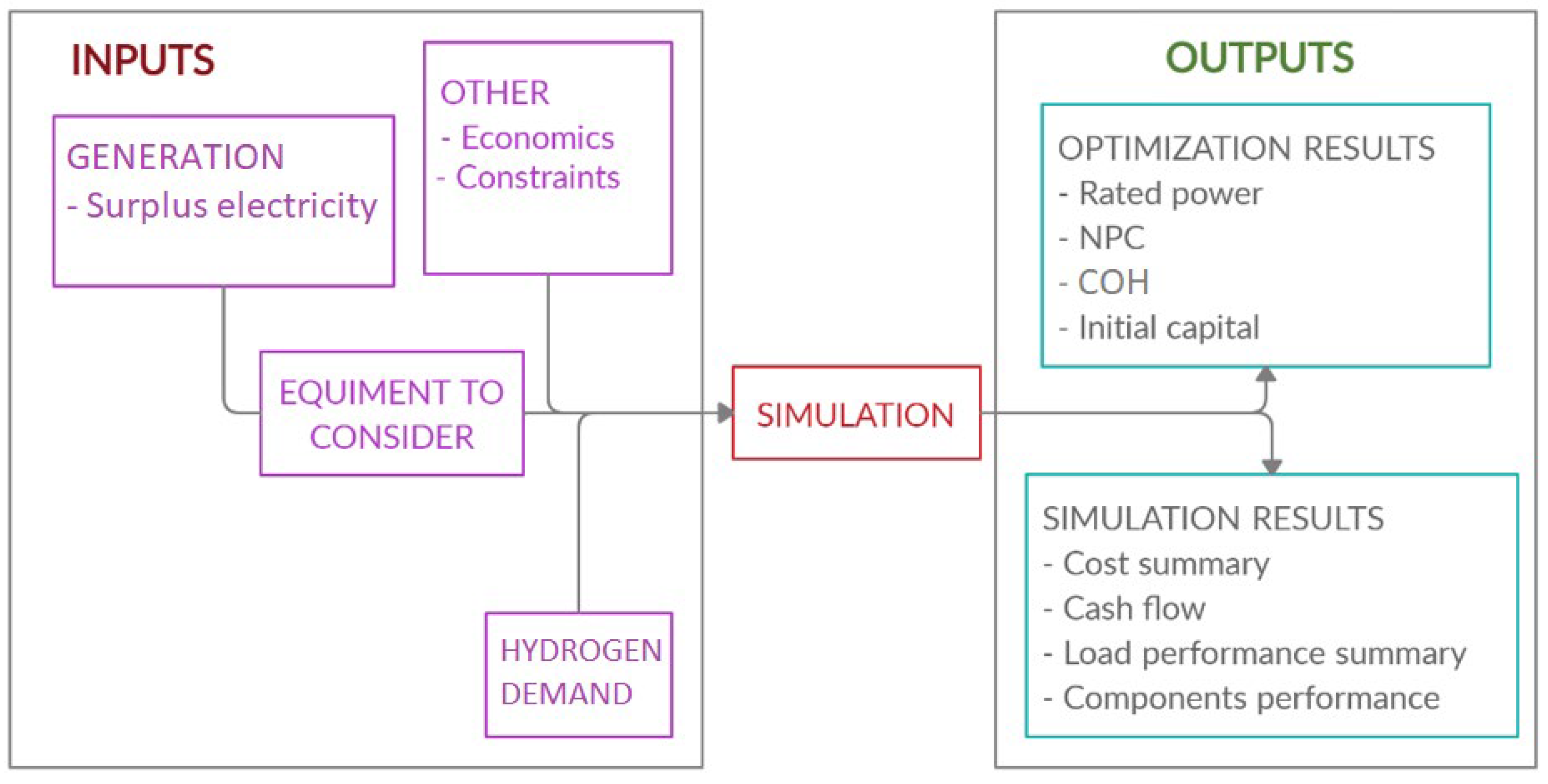

4. Methodology

- Available energy resources of each generation system (solar and wind resources available on Gran Canaria);

- Annual hourly energy demand data;

- Technical information of the renewable systems to be used;

- Cost of the generation system to be considered (in this case, photovoltaic and wind power plants);

- Technical information and price of the storage system (reversible pumping and EV batteries were analyzed);

- Other economic data (such as annual interest rate and lifetime of the project);

- Other costs of the generation and storage systems not considered in the previous points—an unforeseen expense (6%) was considered; this value includes the cost of the decommissioning facility (3%) when the plants reach the end of their useful life.

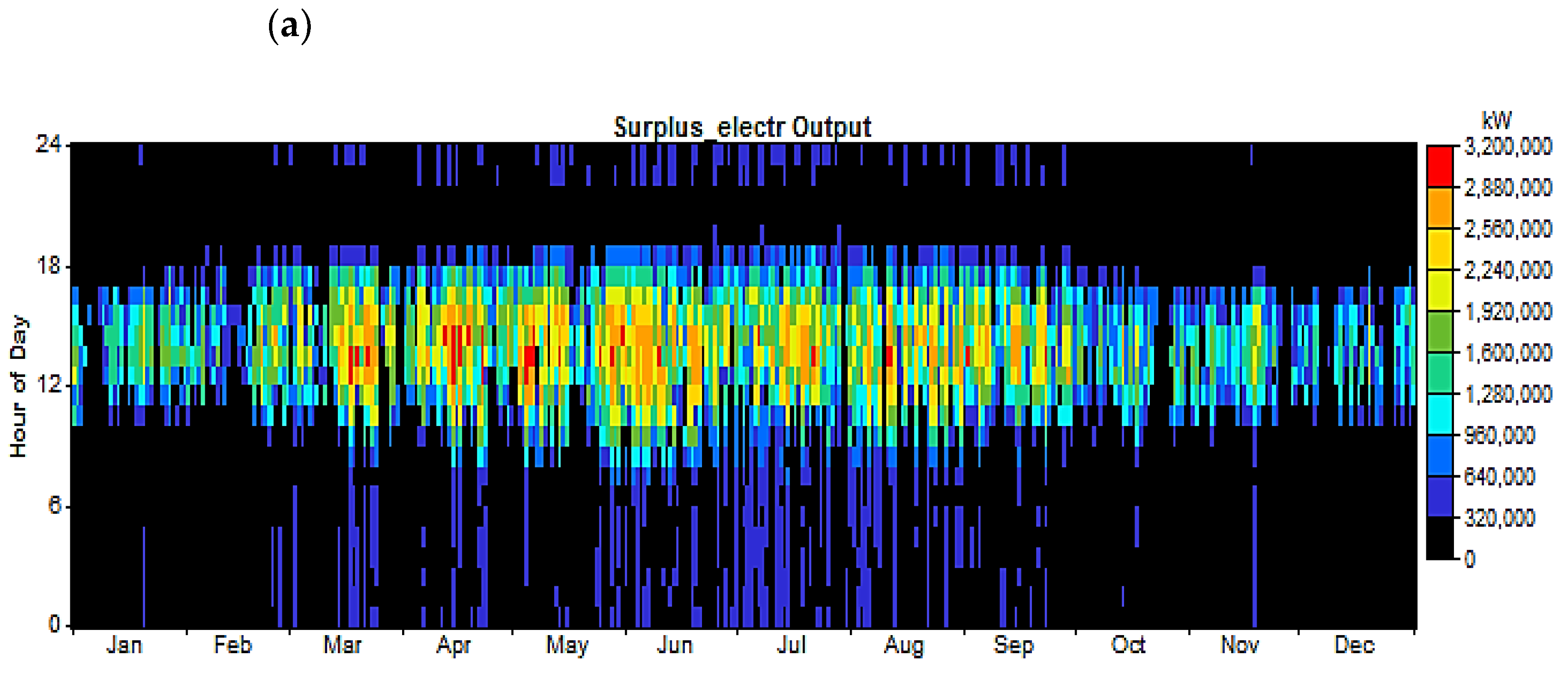

- The excess of energy: These were obtained from [46]. A wind generator and an hourly wind velocity curve were used to simulate the excess of power in HOMER. The results are shown in Section 6.1.

- The electrolyzer and the storage system: The excess energy is used to produce and store H2 to cover the demand. The electrolyzer and the storage system are described in Section 6.2.

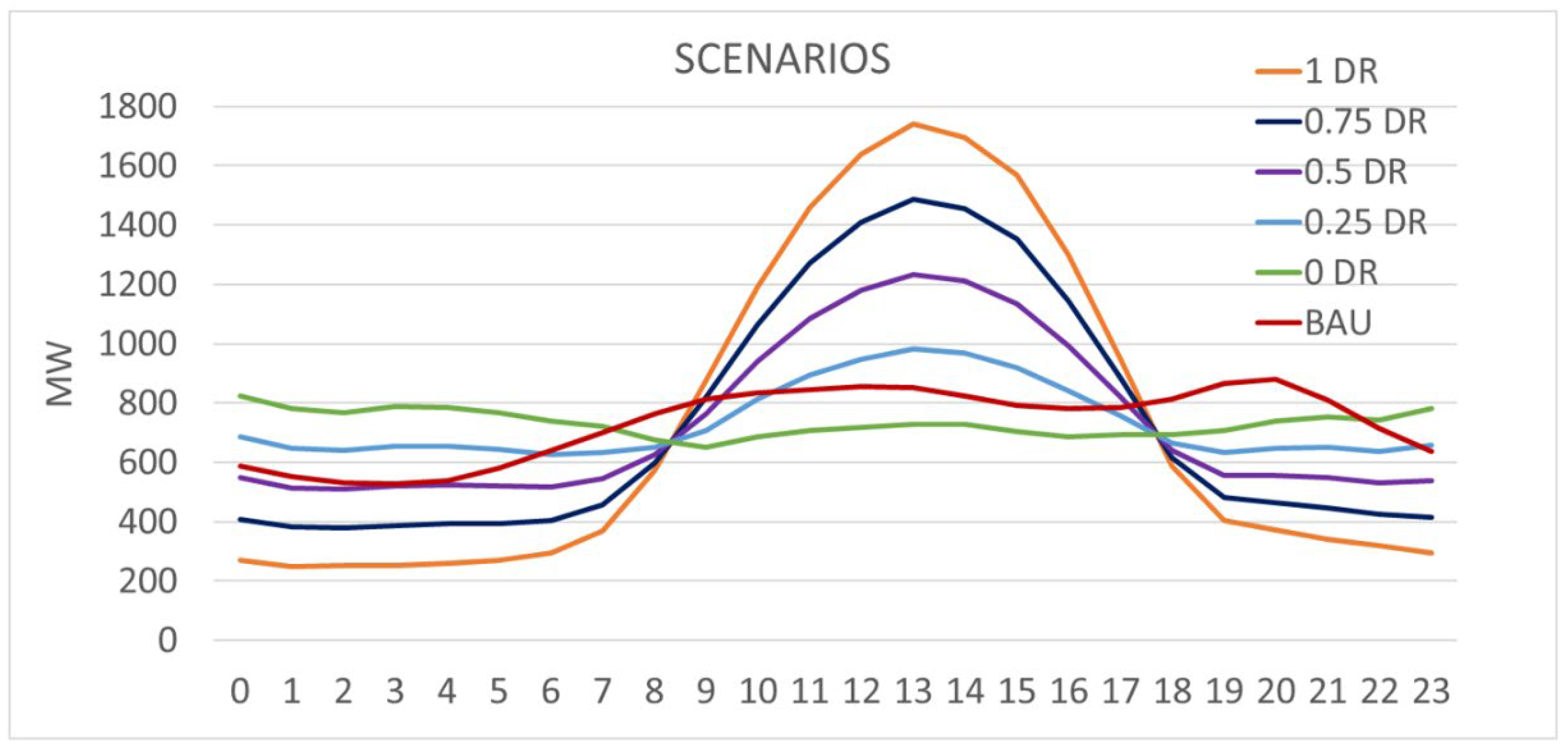

5. Analyzed Scenarios

6. Hydrogen Production System Simulation

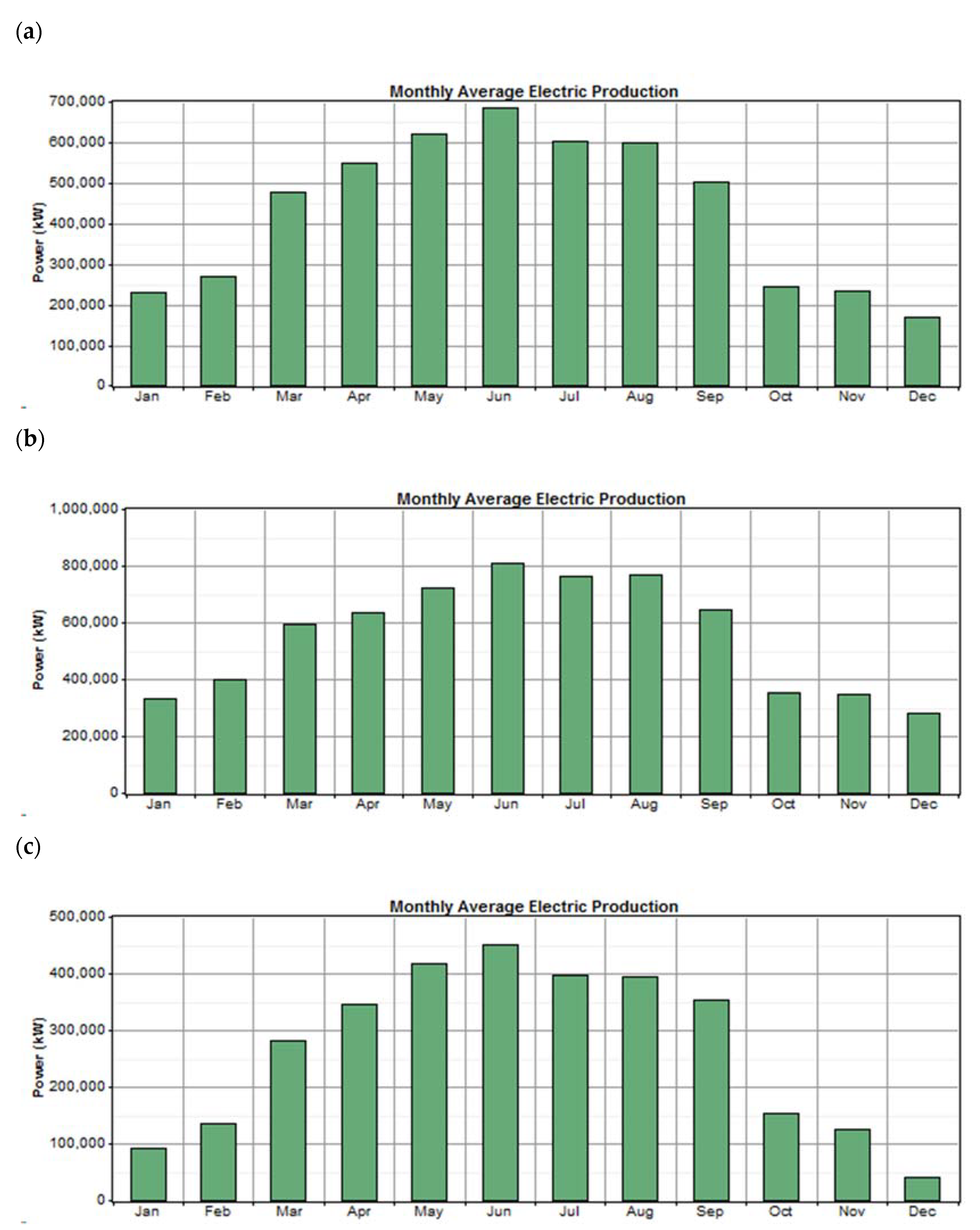

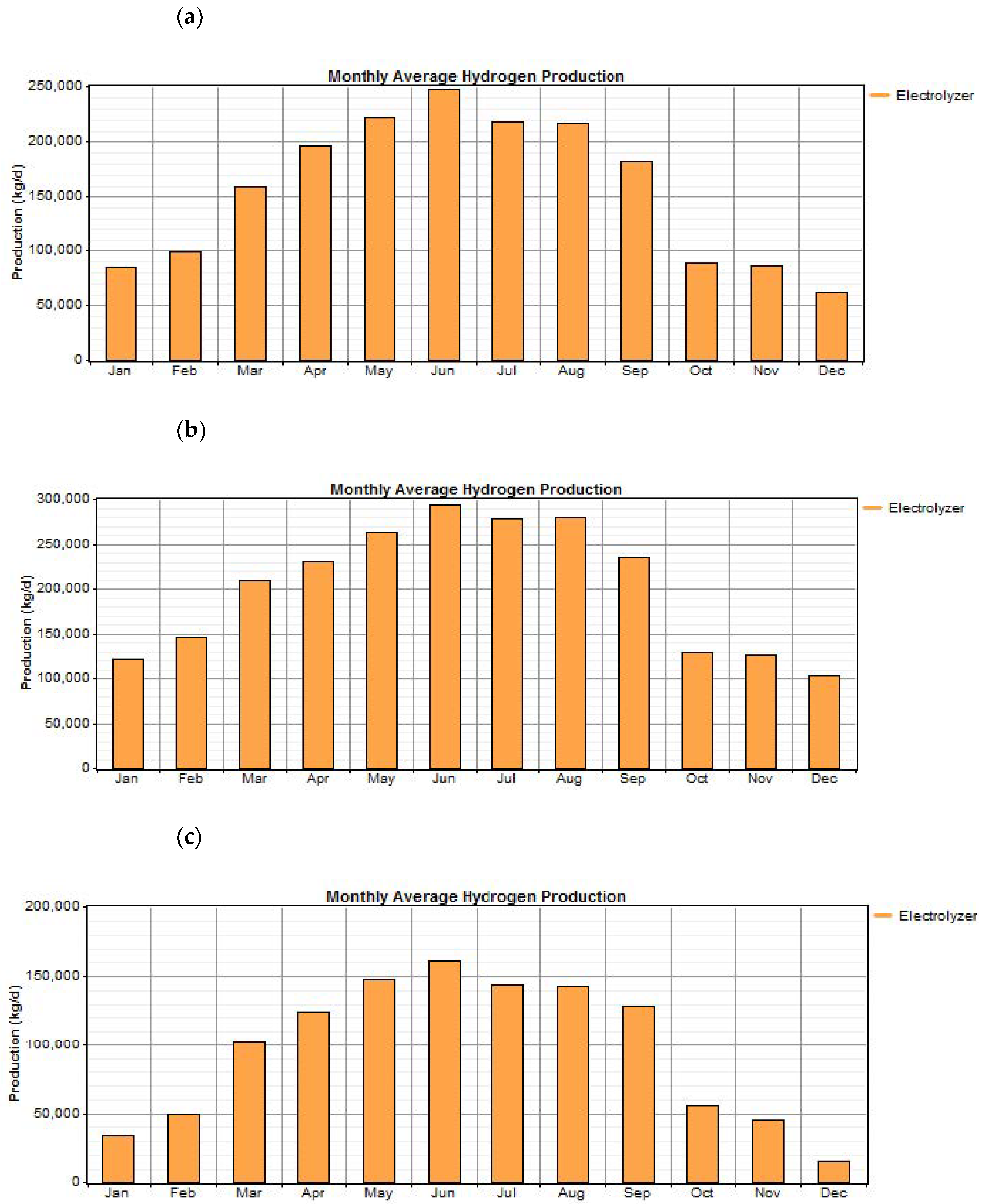

6.1. Surplus Electricity Used for Hydrogen Production

6.2. Electrolyzer and Hydrogen Storage Systems

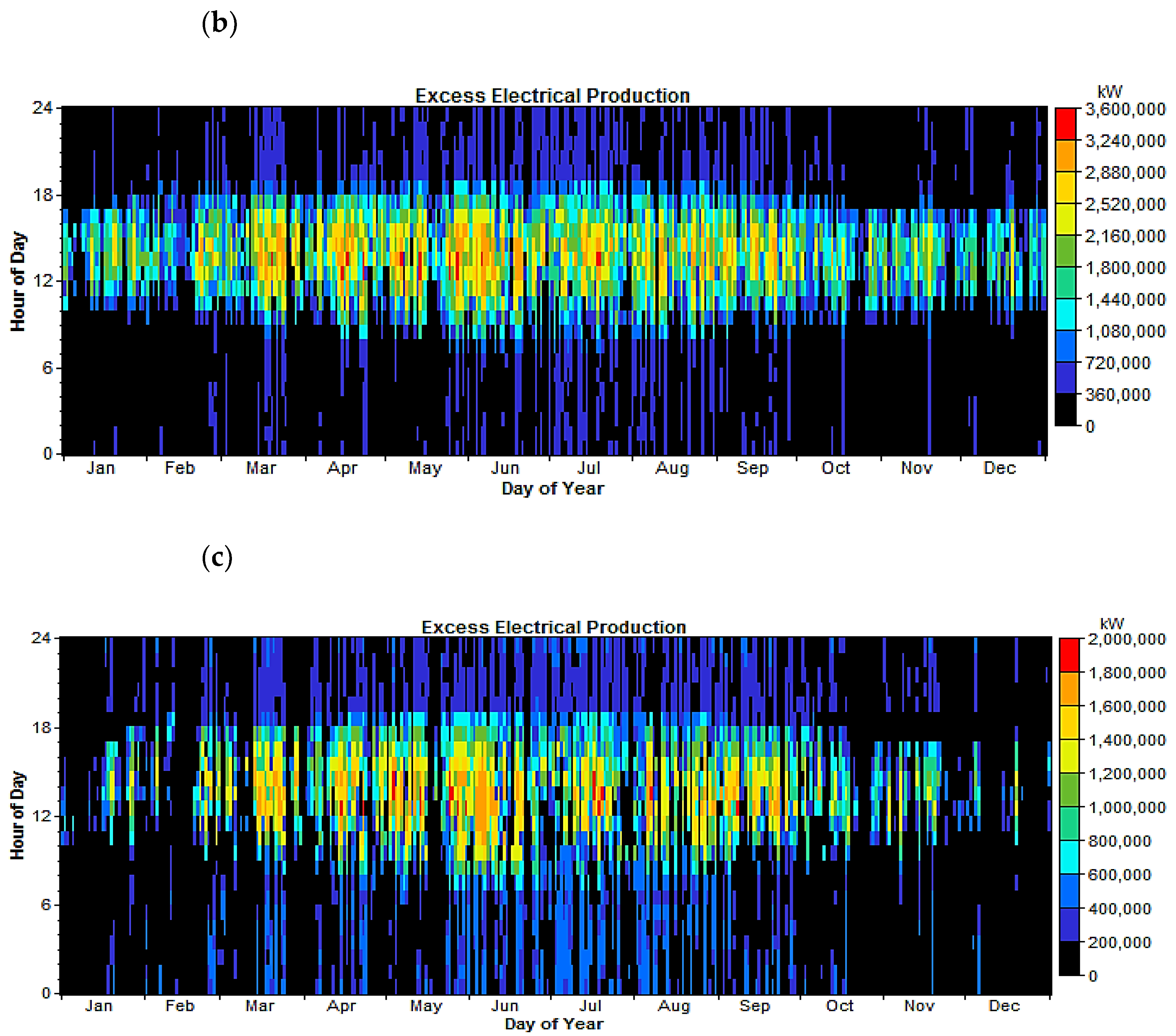

6.3. Hydrogen Load

7. Results

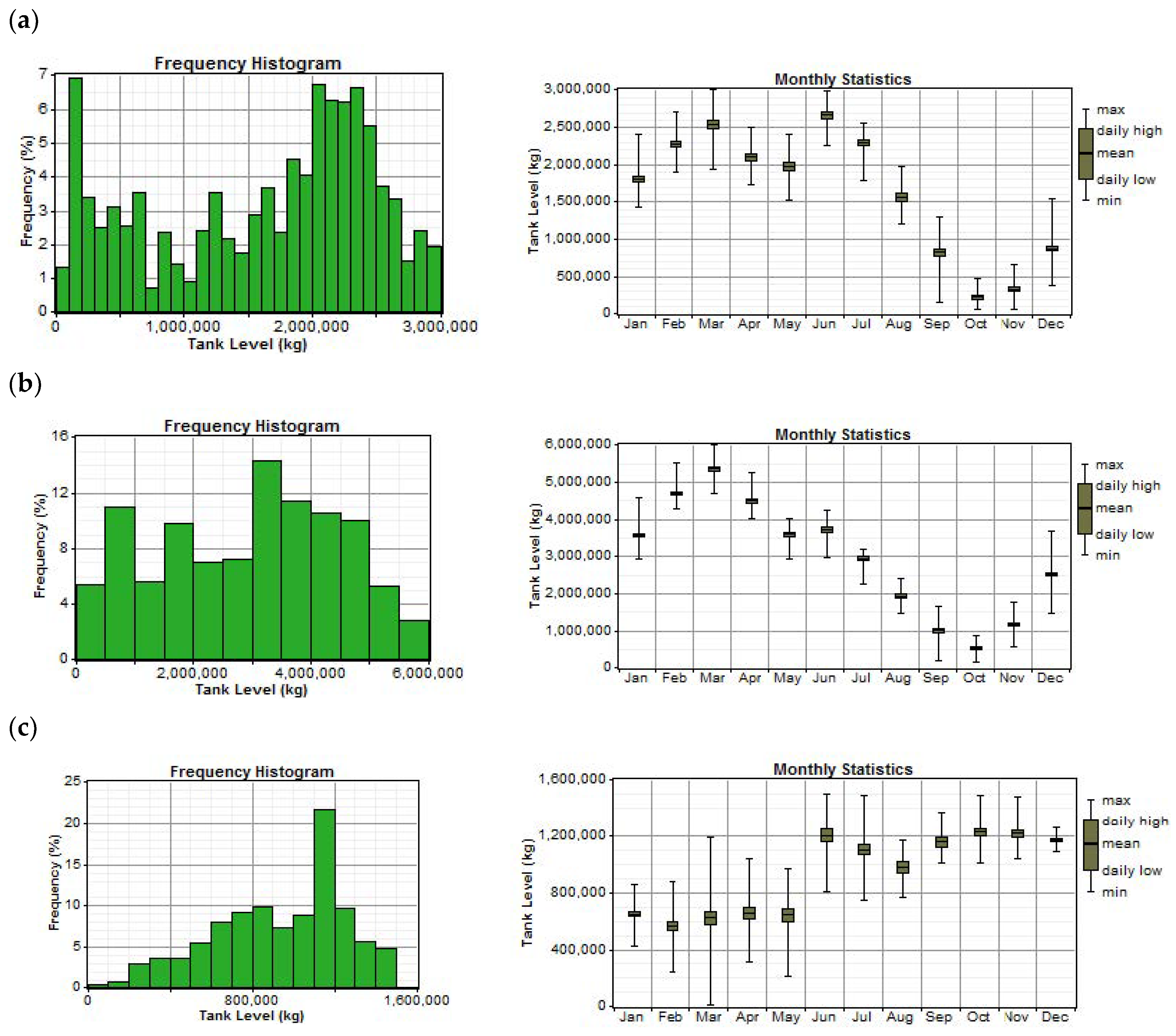

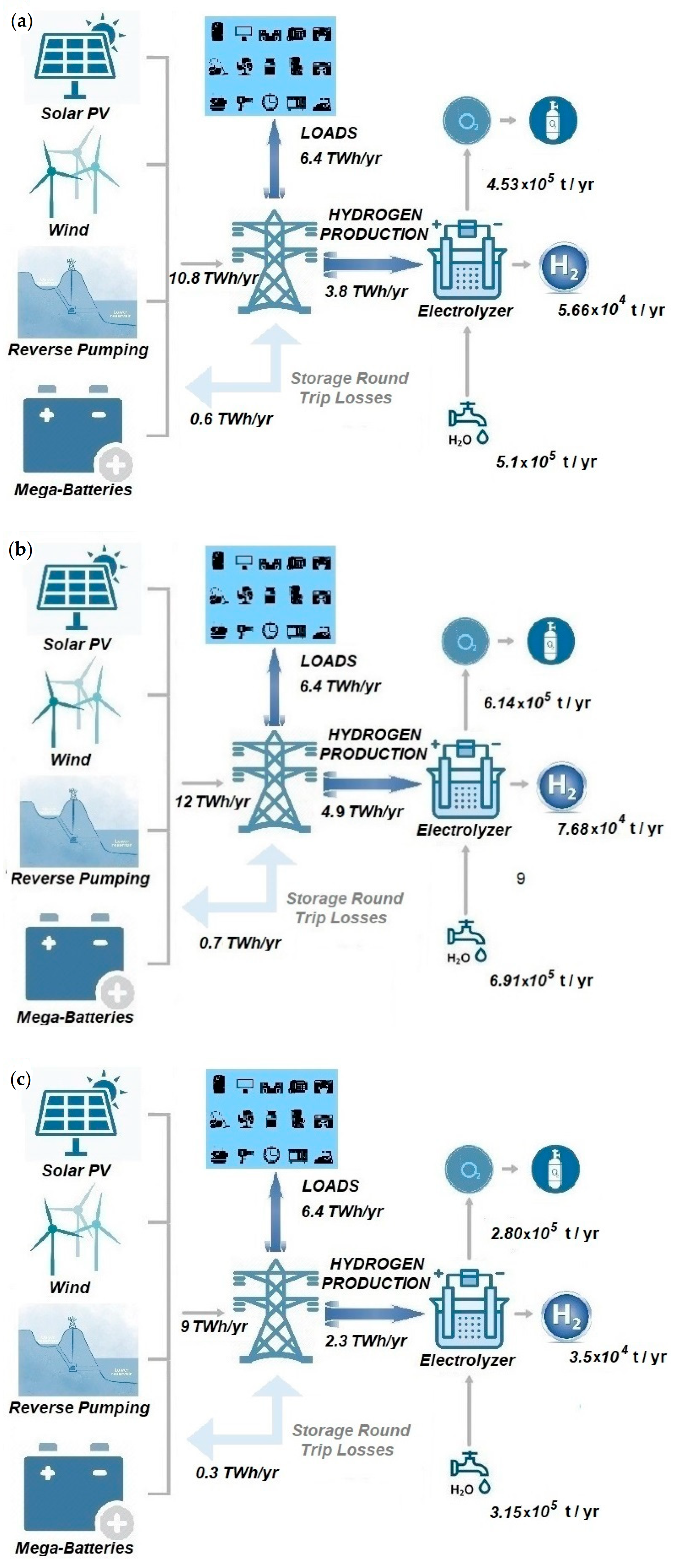

- BAU scenario: In this scenario, there is an excess of 3.8 TWh/year, able to produce 56,600 t of hydrogen per year, equivalent to 1.9 TWh/year (in terms of lower heating values). The power required in the electrolyzer set is 250 MW. To store hydrogen profitably, a storage system with a capacity of 3000 t is needed (see Table 2). The required initial investment is EUR 2400 M; the O&M costs are around EUR 59 M/year, the COH is EUR 4.54/kg, and there is a total NPC cost of EUR 3150 M (See Table 3).

- 0 DR scenario: In this scenario, there is an excess of 4.9 TWh, able to produce 76,600 t of hydrogen per year, equivalent to 5.56 TWh/year. The power required by the electrolyzer set is 300 MW. To store hydrogen profitably, a storage system with a capacity of 6000 t is needed (See Table 2). The required initial investment is EUR 3600 M; the O&M costs are around EUR 81 M/year, the COH is EUR 4.92/kg, and there is a total NPC cost of EUR 4600 M (See Table 3).

- 1 DR scenario. In this scenario, there is an electricity excess of 2.3 TWh, able to produce 35,000 t of hydrogen per year, equivalent to 1.17 TWh/year. The power required in the electrolyzer set is 150 MW. To store hydrogen profitably, a storage system with a capacity of 1800 t is needed (See Table 2). The required initial investment is EUR 1500 M; the O&M costs are around EUR 34 M/year, the COH is EUR 4.06/kg, and there is a total NPC cost of EUR 1817 M (See Table 3).

7.1. Energy Analysis

7.2. Storage System

7.3. Economic Analysis

7.4. Water Use and Oxygen Production Analysis

8. Conclusions and Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- IEA (International Energy Agency). World Energy Outlook 2020—Analysis; IEA: Paris, France, 2020; Available online: https://www.iea.org/reports/world-energy-outlook-2020 (accessed on 20 October 2021).

- IEA (International Energy Agency). Global Energy Review 2021—Analysis; IEA: Paris, France, 2021; Available online: https://www.iea.org/reports/global-energy-review-2021 (accessed on 20 October 2021).

- IEA (International Energy Agency). SDG7: Data and Projections; IEA: Paris, France, 2020; Available online: https://www.iea.org/reports/sdg7-data-and-projections (accessed on 17 May 2022).

- Vargas-Salgado, C.; Berna-Escriche, C.; Escrivá-Castells, A.; Díaz-Bello, D. Optimization of All-Renewable Generation Mix According to Different Demand Response Scenarios to Cover All the Electricity Demand Forecast by 2040: The Case of the Grand Canary Island. Sustainability 2022, 14, 1738. [Google Scholar] [CrossRef]

- Nzotcha, U.; Nsangou, J.C.; Kenfack, J.; Ngohe-Ekam, P.S.; Hamandjoda, O.; Bignom, B. Combining electric energy storage and deep-lake degassing by means of pumped hydropower. Appl. Energy 2021, 304, 117839. [Google Scholar] [CrossRef]

- Berna-Escriche, C.; Pérez-Navarro, Á.; Escrivá, A.; Hurtado, E.; Muñoz-Cobo, J.L.; Moros, M.C. Methodology and application of statistical techniques to evaluate the reliability of electrical systems based on the use of high variability generation sources. Sustainability 2021, 13, 10098. [Google Scholar] [CrossRef]

- Meng, Y.; Zhou, R.; Dinçer, H.; Yüksel, S.; Wang, C. Analysis of inventive problem-solving capacities for renewable energy storage investments. Energy Rep. 2021, 7, 4779–4791. [Google Scholar] [CrossRef]

- Bataille, C.; Nilsson, L.J.; Jotzo, F. Industry in a net-zero emissions world: New mitigation pathways, new supply chains, modelling needs and policy implications. Energy Clim. Chang. 2021, 2, 100059. [Google Scholar] [CrossRef]

- Çabukoglu, E.; Georges, G.; Küng, L.; Pareschi, G.; Boulouchos, K. Fuel cell electric vehicles: An option to decarbonize heavy-duty transport? Results from a Swiss case-study. Transp. Res. Part D Transp. Environ. 2019, 70, 35–48. [Google Scholar] [CrossRef]

- Bach, H.; Bergek, A.; Bjørgum, Ø.; Hansen, T.; Kenzhegaliyeva, A.; Steen, M. Implementing maritime battery-electric and hydrogen solutions: A technological innovation systems analysis. Transp. Res. Part D Transp. Environ. 2020, 87, 102492. [Google Scholar] [CrossRef]

- Xiang, H.; Ch, P.; Nawaz, M.A.; Chupradit, S.; Fatima, A.; Sadiq, M. Integration and economic viability of fueling the future with green Hydrogen: An integration of its determinants from renewable economics. Int. J. Hydrogen Energy 2021, 46, 38145–38162. [Google Scholar] [CrossRef]

- Chiefari, J.; Hornung, C. Mobile hydrogen reformers as a novel approach to decarbonise the transport sector. Curr. Opin. Chem. Eng. 2021, 34, 100756. [Google Scholar] [CrossRef]

- Fan, L.; Tu, Z.; Chan, S.H. Recent development of Hydrogen and fuel cell technologies: A review. Energy Rep. 2021, 7, 8421–8446. [Google Scholar] [CrossRef]

- Cagalitan, D.D.T.F.; Abundo, M.L.S. A review of biohydrogen production technology for application towards hydrogen fuel cells. Renew. Sustain. Energy Rev. 2021, 151, 111413. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, F.; He, J.; Wu, M.; Ke, Y. Obstacle identification, analysis and solutions of hydrogen fuel cell vehicles for application in China under the carbon neutrality target. Energy Policy 2021, 159, 112643. [Google Scholar] [CrossRef]

- Shet, S.P.; Priya, S.S.; Sudhakar, K.; Tahir, M. A review on current trends in potential use of metal-organic framework for hydrogen storage. Int. J. Hydrogen Energy 2021, 46, 11782–11803. [Google Scholar] [CrossRef]

- Cesaro, Z.; Ives, M.; Nayak-Luke, R.; Mason, M.; Bañares-Alcántara, R. Ammonia to power: Forecasting the levelized cost of electricity from green ammonia in large-scale power plants. Appl. Energy 2021, 282, 116009. [Google Scholar] [CrossRef]

- Cardoso, J.S.; Silva, V.; Rocha, R.C.; Hall, M.J.; Costa, M.; Eusébio, D. Ammonia as an energy vector: Current and future prospects for low-carbon fuel applications in internal combustion engines. J. Clean. Prod. 2021, 296, 126562. [Google Scholar] [CrossRef]

- Sustainability Report 2021|Yara International. n.d. Available online: https://www.yara.com/this-is-yara/sustainability/sustainability-reporting/latest-sustainability-report/ (accessed on 22 June 2022).

- MARITIME FORECAST TO 2050, Energy Transition Outlook 2019. n.d. Available online: https://eto.dnv.com/2021/maritime-forecast-2050/about#:~:text=Offers%20shipowners%20practical%20advice%20and,demands%20from%20investors%20and%20institutions (accessed on 22 June 2022).

- Monitor Deloitte, Los Territorios no Peninsulares Descarbonizados en 2040, Deloitte. 2021. Available online: https://www2.deloitte.com/es/es/pages/strategy/articles/territorios-no-peninsulares-descarbonizados-2040.html (accessed on 20 October 2021).

- Gobierno de Canarias (GCAN); Ministerio para la Transición Energética y el Reto Demográfico (MITECO); Instituto para la Diversificación y Ahorro de la Energía (IDAE). Estrategia de Energía Sostenible en las Islas Canarias; Gobierno de Canarias (GCAN); Ministerio para la Transición Energética y el Reto Demográfico (MITECO); Instituto para la Diversificación y Ahorro de la Energía (IDAE): Madrid, Spain, 2022; Available online: https://www.lamoncloa.gob.es/serviciosdeprensa/notasprensa/transicion-ecologica/Documents/2022/160222_EstrategiaSostenible_Canarias.pdf (accessed on 5 July 2022).

- Gobierno de Canarias, I.T.d.C.-G. Estrategia del Vehículo Eléctrico de Canarias. 2021. Available online: https://www.gobiernodecanarias.org/energia/descargas/SDE/Portal/Planificacion/Estrategias/D3_Estrategia_Vehiculo_Electrico.pdf (accessed on 5 July 2022).

- European Commission. PHOTOVOLTAIC GEOGRAPHICAL INFORMATION SYSTEM—PVGIS. n.d. Available online: https://re.jrc.ec.europa.eu/pvg_tools/en/#PVP (accessed on 17 June 2022).

- MERRA-2. n.d. Available online: https://gmao.gsfc.nasa.gov/reanalysis/MERRA-2/docs/ (accessed on 18 May 2021).

- Dirección General de Energía del Gobierno de Canarias. Estrategia de Almacenamiento Energético. 2021. Available online: https://www.gobiernodecanarias.org/energia/descargas/SDE/Portal/Planificacion/Estrategias/D2_Estrategia_Almacenamiento.pdf (accessed on 5 July 2022).

- Letcher, T.M. Storing Energy: With Special Reference to Renewable Energy Sources; Elsevier: Amsterdam, The Netherlands, 2022; Available online: https://books.google.com/books/about/Storing_Energy.html?id=d7SBzgEACAAJ (accessed on 20 October 2021).

- Menéndez, J.; Fernández-Oro, J.M.; Galdo, M.; Loredo, J. Efficiency analysis of underground pumped storage hydropower plants. J. Energy Storage 2020, 28, 101234. [Google Scholar] [CrossRef]

- Gobierno de Canarias, ANUARIO ENERGÉTICO DE CANARIAS 2019. 2020. Available online: http://www.gobiernodecanarias.org/istac/jaxi-istac/menu.do?uripub=urn:uuid:131cf873-66a9-408d-8cfa-537d6be05067 (accessed on 14 June 2022).

- Denmark and Norway Team Up to Build World’s Largest Hydrogen Ferry–EURACTIV.com. n.d. Available online: https://www.euractiv.com/section/energy/news/denmark-and-norway-team-up-to-build-worlds-largest-hydrogen-ferry/ (accessed on 22 June 2022).

- Burton, N.A.; Padilla, R.v.; Rose, A.; Habibullah, H. Increasing the efficiency of hydrogen production from solar powered water electrolysis. Renew. Sustain. Energy Rev. 2021, 135, 110255. [Google Scholar] [CrossRef]

- The Future of Hydrogen—Analysis—IEA. n.d. Available online: https://www.iea.org/reports/the-future-of-hydrogen (accessed on 22 June 2022).

- Brändle, G.; Schönfisch, M.; Schulte, S. Estimating long-term global supply costs for low-carbon hydrogen. Appl. Energy 2021, 302, 117481. [Google Scholar] [CrossRef]

- Planta de hidrógeno verde de Puertollano—Iberdrola. n.d. Available online: https://www.iberdrola.com/conocenos/lineas-negocio/proyectos-emblematicos/puertollano-planta-hidrogeno-verde (accessed on 22 June 2022).

- Enagás y Naturgy Estudian Producir Hidrógeno verde a Partir de 350 MW de Energía Eólica en Asturias. n.d. Available online: www.enagas.es (accessed on 22 June 2022).

- Power to Green Hydrogen Mallorca|ACCIONA|Business as Unusual. n.d. Available online: https://www.acciona.com/es/proyectos/power-to-green-hydrogen-mallorca/?_adin=01833301559 (accessed on 22 June 2022).

- El Nuevo Hub de Hidrógeno Verde En Canarias. Available online: https://hidrogeno-verde.es/el-nuevo-hub-de-hidrogeno-verde-en-canarias/ (accessed on 13 September 2022).

- Wang, X.; Palazoglu, A.; El-Farra, N.H. Operational optimization and demand response of hybrid renewable energy systems. Appl. Energy 2015, 143, 324–335. [Google Scholar] [CrossRef]

- Suresh, G.; Prasad, D.; Gopila, M. An efficient approach based power flow management in smart grid system with hybrid renewable energy sources. Renew. Energy Focus 2021, 39, 110–122. [Google Scholar] [CrossRef]

- Dawood, F.; Shafiullah, G.M.; Anda, M. Stand-Alone Microgrid with 100% Renewable Energy: A Case Study with Hybrid Solar PV-Battery-Hydrogen. Sustainability 2020, 12, 2047. [Google Scholar] [CrossRef]

- González, I.; Calderón, A.J.; Portalo, J.M. Innovative Multi-Layered Architecture for Heterogeneous Automation and Monitoring Systems: Application Case of a Photovoltaic Smart Microgrid. Sustainability 2021, 13, 2234. [Google Scholar] [CrossRef]

- Balasubramanian, S.; Balachandra, P. Effectiveness of demand response in achieving supply-demand matching in a renewables dominated electricity system: A modelling approach. Renew. Sustain. Energy Rev. 2021, 147, 111245. [Google Scholar] [CrossRef]

- Wang, J.; Li, D.; Lv, X.; Meng, X.; Zhang, J.; Ma, T.; Pei, W.; Xiao, H. Two-Stage Energy Management Strategies of Sustainable Wind-PV-Hydrogen-Storage Microgrid Based on Receding Horizon Optimization. Energies 2022, 15, 2861. [Google Scholar] [CrossRef]

- Cecilia, A.; Carroquino, J.; Roda, V.; Costa-Castelló, R.; Barreras, F. Optimal Energy Management in a Standalone Microgrid, with Photovoltaic Generation, Short-Term Storage, and Hydrogen Production. Energies 2020, 13, 1454. [Google Scholar] [CrossRef]

- Vargas-Salgado, C.; Aparisi-Cerdá, I.; Alfonso-Solar, D.; Gómez-Navarro, T. Can Photovoltaic Systems Be Profitable in Urban Areas? Analysis of Regulation Scenarios for Four Cases in Valencia City (Spain). Sol. Energy 2022, 233, 461–477. [Google Scholar] [CrossRef]

- Berna-Escriche, C.; Vargas-Salgado, C.; Alfonso-Solar, D.; Escrivá-Castells, A. Can a fully renewable system with storage cost-effectively cover the total demand of a big scale standalone grid? Analysis of three scenarios applied to the Grand Canary Island, Spain by 2040. J. Energy Storage 2022, 52, 104774. [Google Scholar] [CrossRef]

- Schmidt, O.; Gambhir, A.; Staffell, I.; Hawkes, A.; Nelson, J.; Few, S. Future cost and performance of water electrolysis: An expert elicitation study. Int. J. Hydrogen Energy 2017, 42, 30470–30492. [Google Scholar] [CrossRef]

- E4tech Sàrl with Element Energy Ltd., Development of Water Electrolysis in the European Union Final Report. 2014. Available online: www.e4tech.com (accessed on 15 June 2022).

- McPherson, M.; Johnson, N.; Strubegger, M. The role of electricity storage and hydrogen technologies in enabling global low-carbon energy transitions. Appl. Energy 2018, 216, 649–661. [Google Scholar] [CrossRef]

- Marocco, P.; Ferrero, D.; Lanzini, A.; Santarelli, M. The role of Hydrogen in the optimal design of off-grid hybrid renewable energy systems. J. Energy Storage 2022, 46, 103893. [Google Scholar] [CrossRef]

- Guinot, B.; Champel, B.; Montignac, F.; Lemaire, E.; Vannucci, D.; Sailler, S.; Bultel, Y. Techno-economic study of a PV-hydrogen-battery hybrid system for off-grid power supply: Impact of performances’ ageing on optimal system sizing and competitiveness. Int. J. Hydrogen Energy 2015, 40, 623–632. [Google Scholar] [CrossRef]

- Silva, S.B.; Severino, M.M.; de Oliveira, M.A.G. A standalone hybrid photovoltaic, fuel cell and battery system: A case study of Tocantins, Brazil. Renew. Energy 2013, 57, 384–389. [Google Scholar] [CrossRef]

- IRENA, Innovation Trends in Electrolysers for Hydrogen Production. 2021, 37. Available online: https://www.irena.org/publications/2022/May/Innovation-Trends-in-Electrolysers-for-Hydrogen-Production (accessed on 19 July 2022).

- Christensen, A. Assessment of Hydrogen Production Costs from Electrolysis: United States and Europe, International Council on Clean Transportation (ICCT). 2020, pp. 1–73. Available online: https://theicct.org/sites/default/files/publications/final_icct2020_assessment_of%20_hydrogen_production_costs%20v2.pdf (accessed on 19 July 2022).

- Terlouw, T.; Bauer, C. Environmental Science electrolysis: A techno-economic and environmental assessment. Energy Environ. Sci. 2022, 15, 3583–3602. [Google Scholar] [CrossRef]

- IRENA. Green Hydrogen Cost Reduction, 2020. Available online: https://www.irena.org/publications/2020/Dec/Green-hydrogen-cost-reduction (accessed on 19 July 2022).

- Huhtanen, S. Optimal Electricity Source Mix for Hydrogen Production in an Electrolyzer. Master’s Thesis, Aalto University, School of Electrical Engineering, Espoo, Finland, 2022. [Google Scholar]

| Value | Units | ||

|---|---|---|---|

| Electrolyzer | Cost | 600 | EUR/kW |

| O&M | 60 | EUR/year kW | |

| Lifetime | 95,000 | h | |

| Operation time | 3700–4260 | h/year | |

| H2 Storage tank 1 | Cost | 300 | EUR/kg |

| O&M | 4.5 | EUR/year kg | |

| Lifetime | 25 | Year | |

| Total efficiency 2 | 60 | (%) |

| Scenario | PElectrolyzer | H2 Tank Capacity | H2 Tank Capacity | Available Energy for Producing H2 | H2 Production | Energy Content in the H2 Produced |

|---|---|---|---|---|---|---|

| (GW) | (t) | (GWh) | (GWh/yr) | (t/yr) | (TWh/yr) | |

| BAU | 2.5 | 3000 | 100 | 3792 | 56,613 | 1.89 |

| 0 DR | 3.0 | 6000 | 200 | 4873 | 76,658 | 2.56 |

| 1 DR | 1.5 | 1800 | 60 | 2332 | 35,003 | 1.17 |

| Scenario | Capital Costs (EUR M) | NPC Costs (EUR M) | O&M Costs (EUR M/yr) | COH (EUR/kg) |

|---|---|---|---|---|

| BAU | 2400 | 3148 | 59 | 4.54 |

| 0 DR | 3600 | 4636 | 81 | 4.92 |

| 1 DR | 1380 | 1817 | 34 | 4.06 |

| BAU | 0 DR | 1 DR | ||

|---|---|---|---|---|

| Available energy (from excess electricity) | 3792 | 4873 | 2332 | GWh/year |

| Electrolyzer load | 3722 | 4842 | 2301 | GWh/year |

| Lost electricity | 70 | 31 | 31 | GWh/year |

| % Lost electricity | 1.9% | 0.6% | 1.3% |

| Component | Capital (EUR M) | O&M (EUR M) | Total (EUR M) | |

|---|---|---|---|---|

| BAU | Surplus_electr | 0 | 0 | 0 |

| Electrolyzer | 1500 | 575 | 2075 | |

| Hydrogen Tank | 900 | 173 | 1073 | |

| System | 2400 | 748 | 3148 | |

| 0DR | Surplus_electr | 0 | 0 | 0 |

| Electrolyzer | 1800 | 690 | 2490 | |

| Hydrogen Tank | 1800 | 345 | 2145 | |

| System | 3600 | 1036 | 4636 | |

| 1DR | Surplus_electr | 0 | 0 | 0 |

| Electrolyzer | 900 | 345 | 1245 | |

| Hydrogen Tank | 600 | 115 | 715 | |

| System | 1500 | 460 | 1960 |

| Scenario | H2O Demand | O2 Produced | H2 Produced |

|---|---|---|---|

| (t/yr) | (t/yr) | (t/yr) | |

| BAU | 509,517 | 452,904 | 56,613 |

| 0 DR | 690,822 | 614,064 | 76,758 |

| 1 DR | 315,027 | 280,024 | 35,003 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Berna-Escriche, C.; Vargas-Salgado, C.; Alfonso-Solar, D.; Escrivá-Castells, A. Hydrogen Production from Surplus Electricity Generated by an Autonomous Renewable System: Scenario 2040 on Grand Canary Island, Spain. Sustainability 2022, 14, 11884. https://doi.org/10.3390/su141911884

Berna-Escriche C, Vargas-Salgado C, Alfonso-Solar D, Escrivá-Castells A. Hydrogen Production from Surplus Electricity Generated by an Autonomous Renewable System: Scenario 2040 on Grand Canary Island, Spain. Sustainability. 2022; 14(19):11884. https://doi.org/10.3390/su141911884

Chicago/Turabian StyleBerna-Escriche, César, Carlos Vargas-Salgado, David Alfonso-Solar, and Alberto Escrivá-Castells. 2022. "Hydrogen Production from Surplus Electricity Generated by an Autonomous Renewable System: Scenario 2040 on Grand Canary Island, Spain" Sustainability 14, no. 19: 11884. https://doi.org/10.3390/su141911884

APA StyleBerna-Escriche, C., Vargas-Salgado, C., Alfonso-Solar, D., & Escrivá-Castells, A. (2022). Hydrogen Production from Surplus Electricity Generated by an Autonomous Renewable System: Scenario 2040 on Grand Canary Island, Spain. Sustainability, 14(19), 11884. https://doi.org/10.3390/su141911884