1. Introduction

With technological development and the rise of industry, energy demand has increased. In recent years, combined energy system technologies have gained increasing attention due to their better performance, low production cost, energy security and reliability, and high efficiency. Integrated systems take advantage of the waste heat of an engine or a turbine that produces electricity [

1]. A combined cooling, heating, and power system (CCHP) is the integration of a prime mover, an absorption or compression chiller, a waste heat recovery system, and a heating unit. CCHP systems can produce heating, cooling, and electricity and have better performance compared to conventional systems. The energy efficiency of these systems can reach up to 60 to 90%, which is a 35% better performance than traditional plants [

1]. Furthermore, CCHP systems can be designed for different applications on diverse scales [

2]. Cogeneration and trigeneration systems are regarded as sustainable and environmentally friendly energy systems; therefore, the application of these systems has been promoted by the European Union and many other countries, along with the use of sustainable energy systems to achieve environmental targets and energy supply security [

3].

The prime mover in combined systems can take various forms, such as fuel cells [

4], the organic Rankine cycle [

5,

6], gas turbines [

7,

8], reciprocating engines, or a combination of them [

9,

10]. In addition, the system can be utilized using different types of fuel such as hydrocarbons and renewable energy sources [

11] or both [

12]. Many scholars have studied combined systems. Mohammadi et al. [

13] investigated the performance of an integrated system composed of an ORC cycle, an absorption refrigeration cycle, and a gas turbine. The proposed system provided 30 kW net power and 8 kW cooling with 67.6% efficiency. Javanshir et al. [

14] proposed a cycle that is a combination of a modified Kalina cycle and an absorption refrigeration cycle using an ammonia–water solution as the working fluid. The system was modelled, and the performance of the system was optimized for maximum exergy efficiency and minimum total product cost. Urbanucci and Testi [

15] proposed a trigeneration system that consisted of an internal combustion engine and an absorption heat pump that uses a water-ammonia mixture as the working pair. In order to investigate financial feasibility, a levelized cost of energy analysis was conducted.

Gas turbine prime movers are one of the favorable power utilization systems because of their low initial investment cost, lower environmental impacts, and acceleration in start-up [

16,

17]. Gas turbines are also known for having fuel flexibility. Among fuels, natural gas has a much lower impact on the environment in terms of greenhouse gas emissions [

18]. In addition to fossil fuels such as natural gas, cleaner energy sources such as biogas [

19,

20,

21] and hydrogen [

22,

23] can be used in gas turbines. Gas turbines experience a power drop and excessive increase in fuel consumption when working under partial load or high ambient temperatures [

24]. These two drawbacks can be overcome by cogeneration/trigeneration applications and inlet air cooling.

Gas turbines’ thermal efficiency is low due to significant heat loss through the high-temperature exhaust gas. The temperature of the exhaust gas is in the range of 450 to 600 °C, and it has great potential to be recovered [

16]. The development of thermodynamic cycles plays a vital role in enhancing the performance of power plants. For example, recuperation, intercooling, and various combined cycles have promoted gas turbine development [

25]. Simple gas turbine cycles are less efficient due to excessive heat loss through the exhaust gas. The work required to compress air between two specified pressures can be decreased by carrying out the compression process in multiple stages and cooling the gas between the processes [

26]. To reduce the energy loss and increase the power output, the intercooler between the compressing stages and the regeneration heat exchanger, which preheats the compressed air before the combustion process, can be utilized in gas turbine power cycles. The working fluid exits from the compressor at a lower temperature and enters the turbine at a higher temperature when intercooling and reheating are utilized [

26]. Various researchers investigated the performance enhancement of gas-turbine-cycle and combined-cycle power plants [

24,

27,

28,

29].

An extensive amount of primary energy can be saved with the use of integrated systems with gas turbine prime movers. These systems can produce thermal energy in the form of steam or hot water or cooling and electricity. Therefore, some scholars investigated integrated systems with gas turbine prime movers to recover the exhaust heat [

16,

30,

31,

32,

33]. Adhami et al. [

2] designed a portable micro-CCHP system based on a micro-gas turbine and micro-absorption chiller. The authors evaluated the proposed system under extremely hot and cold weather conditions. Ebrahimi and Majidi [

34] suggested a CCHP system based on a gas turbine prime mover. A LiBr–water absorption chiller was used for cooling production. A parametric analysis was conducted to understand the influence of the main design parameters on the system performance.

Since the world population continues to grow, refrigeration is essential to preserve perishable products such as vaccines and food [

35]. The most common refrigeration technologies are vapor compression cycles and absorption cycles. Since they are thermally driven, absorption refrigeration systems are commonly preferred for combined systems. One of the benefits of an ammonia–water absorption system is that water has a strong affinity for ammonia, and it works under broad operating conditions, such as low evaporating temperatures [

36]. However, LiBr–water systems could not work below 4–7 °C evaporator temperatures, since the water freezes. Therefore, for refrigeration applications, choosing an ammonia–water pair is more appropriate. Furthermore, an ammonia–water solution is highly stable. Ammonia does not harm the ozone layer. Unlike the LiBr–water pair, it has no crystallization or vacuum problem.

After the pandemic, the importance of refrigeration increased due to the vital need to preserve perishable products such as vaccines and food products that need to be stored below zero degrees. Ammonia–water absorption refrigeration systems can be used to keep perishable products, since they can work below zero degrees. Ammonia–water solutions are preferred in many energy conversion systems because of their variable boiling point (−60 to −10 °C), which results in lower exergy destructions in components [

14]. Therefore, integrating an absorption refrigeration system with a power cycle is beneficial for increasing energy efficiency and sustainability as well as reducing CO

2 emissions in the environment. However, there is no study in the literature regarding combined systems with ammonia refrigeration and a gas turbine prime mover with an intercooler.

To the best of the author’s knowledge, there is not any published research on a combined system with ammonia refrigeration and a power sub-cycle with a gas turbine prime mover with double-stage compression and an intercooler. A novel trigeneration system is proposed in this study to produce electricity, refrigeration, and hot water. The system consists of a gas turbine, low-pressure and high-pressure compressors with an intercooler heat exchanger, a single-effect NH3–water absorption refrigeration unit, heat exchangers, a combustion chamber, and a cooling tower. The double-stage compression process with an intercooler is carried out to decrease the compression work and increase thermal efficiency. A portion of the released high-temperature exhaust gases from the turbine is used to heat the air at the combustion chamber inlet. The remaining part is used to drive the generator of the absorption refrigeration unit. Additionally, hot gases at the generator outlet are used to generate hot water. The thermodynamic states of every point in the cycle are presented. The thermodynamic performance of the whole system as well as each component of the system is analyzed. Design conditions and factors influencing the sub-cycles and the system as a whole are also examined.

The high initial investment cost is often a drawback behind the widespread adoption of the combined systems. The economy of combined systems may change drastically depending on many factors. Even though many studies in the literature regarding integrated energy systems have high energy efficiency, most of them do not evaluate the systems in terms of economic feasibility. However, financial feasibility is an important consideration and sometimes a drawback for real-world applications. Therefore, in addition to energy–environmental aspects, economic feasibility evaluations cannot be underestimated, presenting financial benefits to investors. In the present study, a financial analysis is also performed to investigate the levelized energy cost of the proposed system. Finally, a sensitivity study is conducted to understand the impact of operational parameters on the system performance.

2. System Description

The scheme of the designed power/refrigeration/hot water trigeneration system is presented in

Figure 1. The system consists of a turbine to produce power, a single-effect ammonia-water absorption chiller for refrigeration, and an additional waste heat recovery heat exchanger for hot water production. The complete system was modelled using the Engineering Equation Solver (EES) software. EES is an equation solver program with a thermodynamic database for hundreds of substances. EES automatically finds groups of equations that must be solved simultaneously. In addition, EES has many thermophysical property functions, so any thermodynamic property can be found from a built-in function call when two other properties are given. EES uses a variant of Newton’s method to solve systems of non-linear algebraic equations [

37]. The Jacobian matrix needed in Newton’s method is evaluated numerically at each iteration. The efficiency and convergence properties of the solution method are further improved by the step-size alteration and implementation of the Tarjan blocking algorithm, which breaks the problems into a number of more minor issues that are easier to solve [

37].

The power cycle part of the system consists of a low-pressure compressor, a high-pressure compressor, an intercooler heat exchanger between the two compressors, a combustion chamber, a turbine, and a generator coupled to the turbine. The fuel used in the system is natural gas. A recuperator is used to preheat the inlet air to the combustion chamber to reduce fuel consumption. Dry air at the ambient temperature enters the low-pressure compressor. After the initial compression, the air enters the intercooler, and its temperature is decreased. After that, the air enters the high-pressure compressor, and after the second compression process, the air enters the recuperator. In the recuperator, the air is heated by the hot flue gases coming from the turbine. Then, the air enters the combustion chamber, where the air and the fuel are combusted. The gases at high temperatures coming out of the combustion chamber run the turbine to convert kinetic energy into mechanical energy.

The absorption chillers are thermally driven chillers, which are very convenient for the use of exhaust heat from the prime movers [

38]. The main components of the refrigeration cycle are an evaporator, a generator, an absorber, a condenser, a pump, a refrigerant heat exchanger (RHX), a solution heat exchanger (SHX), expansion valves, and a rectifier. In the absorption chiller, ammonia is used as the refrigerant, and water is used as the absorbent. The chiller can work at two pressure levels. Gas turbine exhaust gas is the primary energy source for utilizing the absorption chiller.

Figure 1.

The scheme of the proposed system.

Figure 1.

The scheme of the proposed system.

5. Conclusions

Energy-efficient technologies such as trigeneration systems are among the solutions for transitioning to decarbonization. Ammonia refrigeration systems are crucial to preserving delicate products such as vaccines, since they can work below zero degrees. A novel trigeneration system with a regenerative gas turbine prime mover, a single-effect ammonia–water absorption refrigeration cycle, and a hot water production system is proposed and analyzed from thermodynamic and economic viewpoints. The energy required by the compressors is decreased by carrying out the compression process in multiple stages and cooling the air between the processes. Energy discharged from the gas turbine is utilized in the generator part of the absorption chiller and a hot water heat recovery heat exchanger. Such integration results in much higher efficiencies compared to a sole gas turbine cycle.

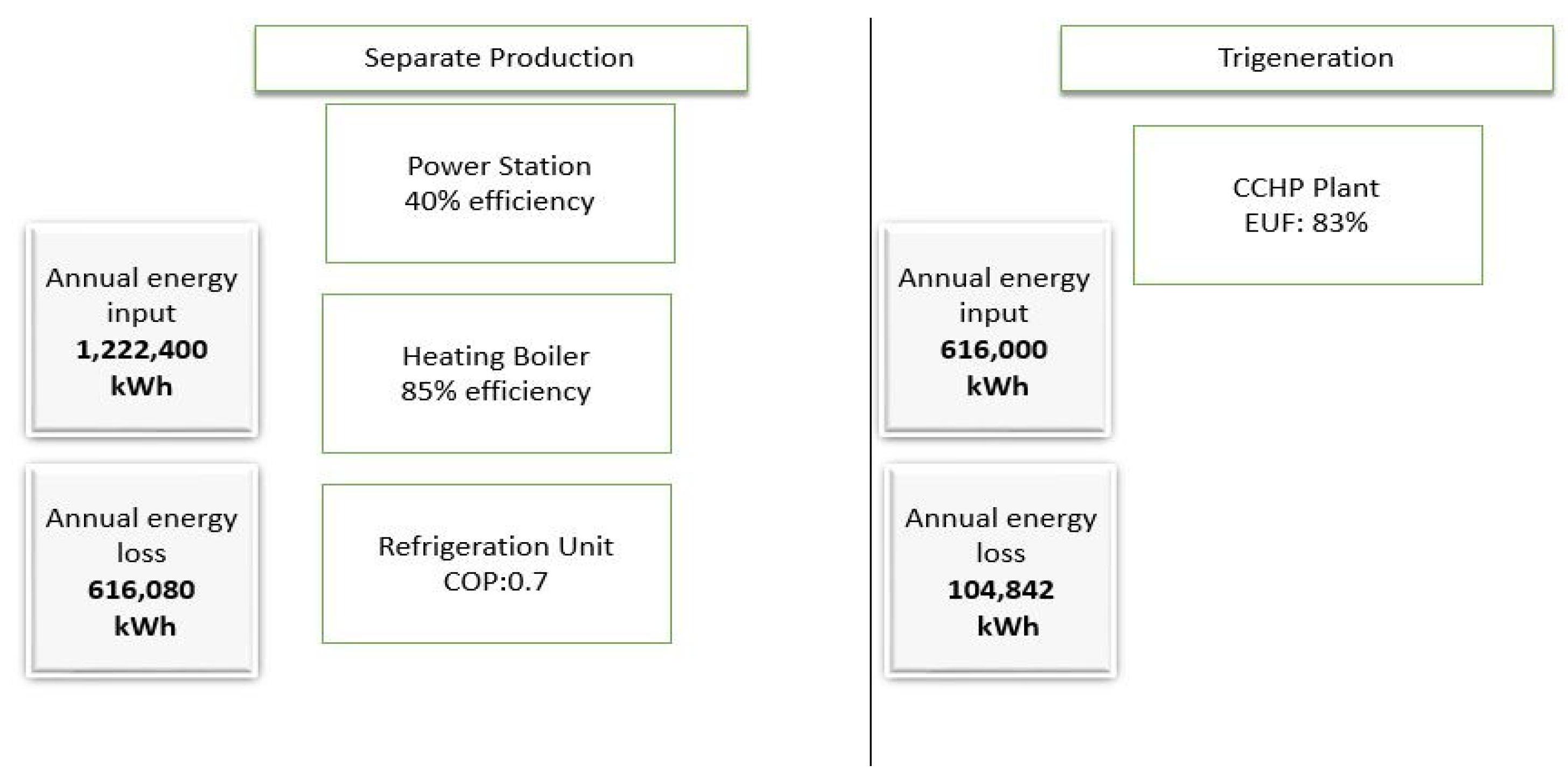

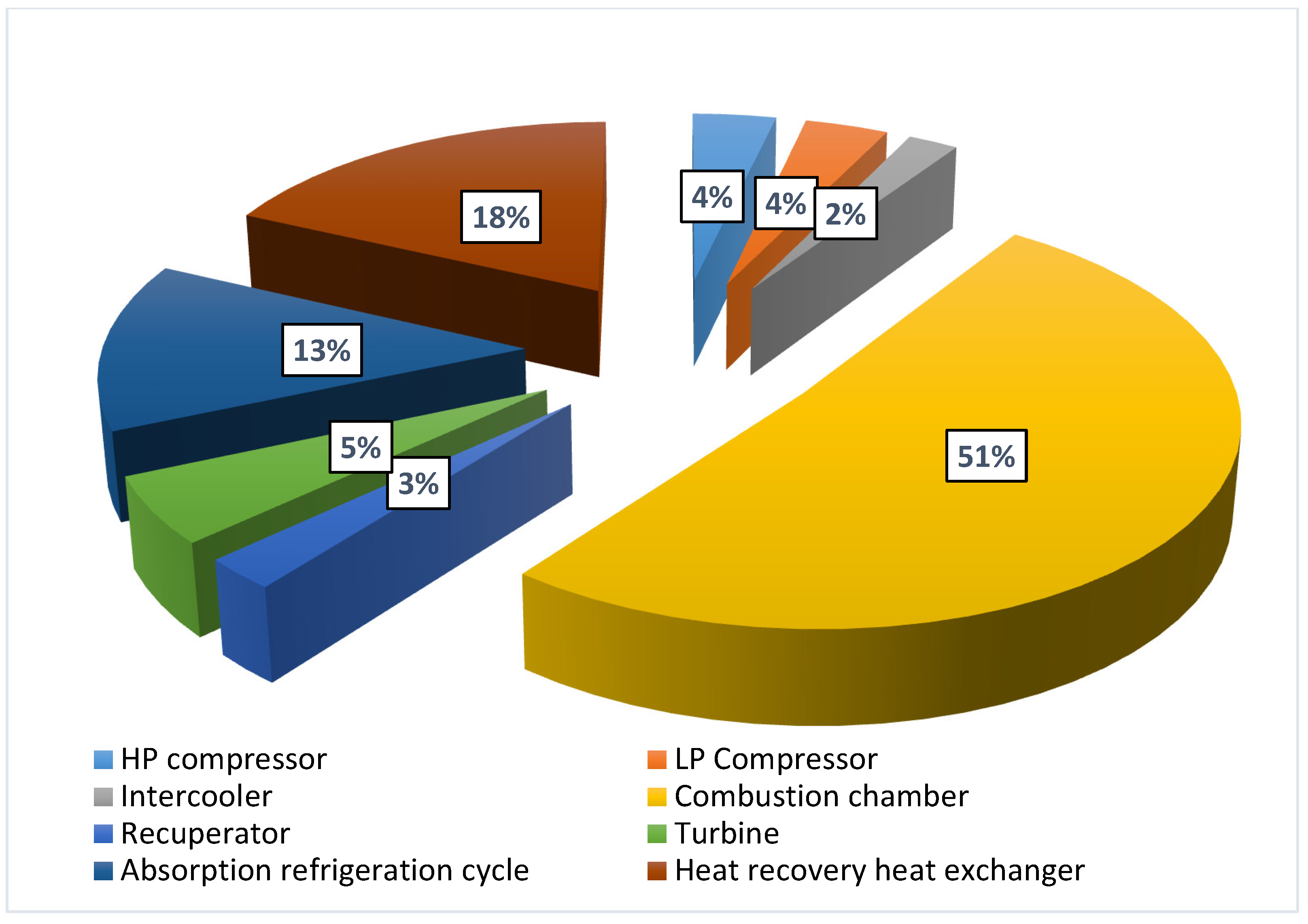

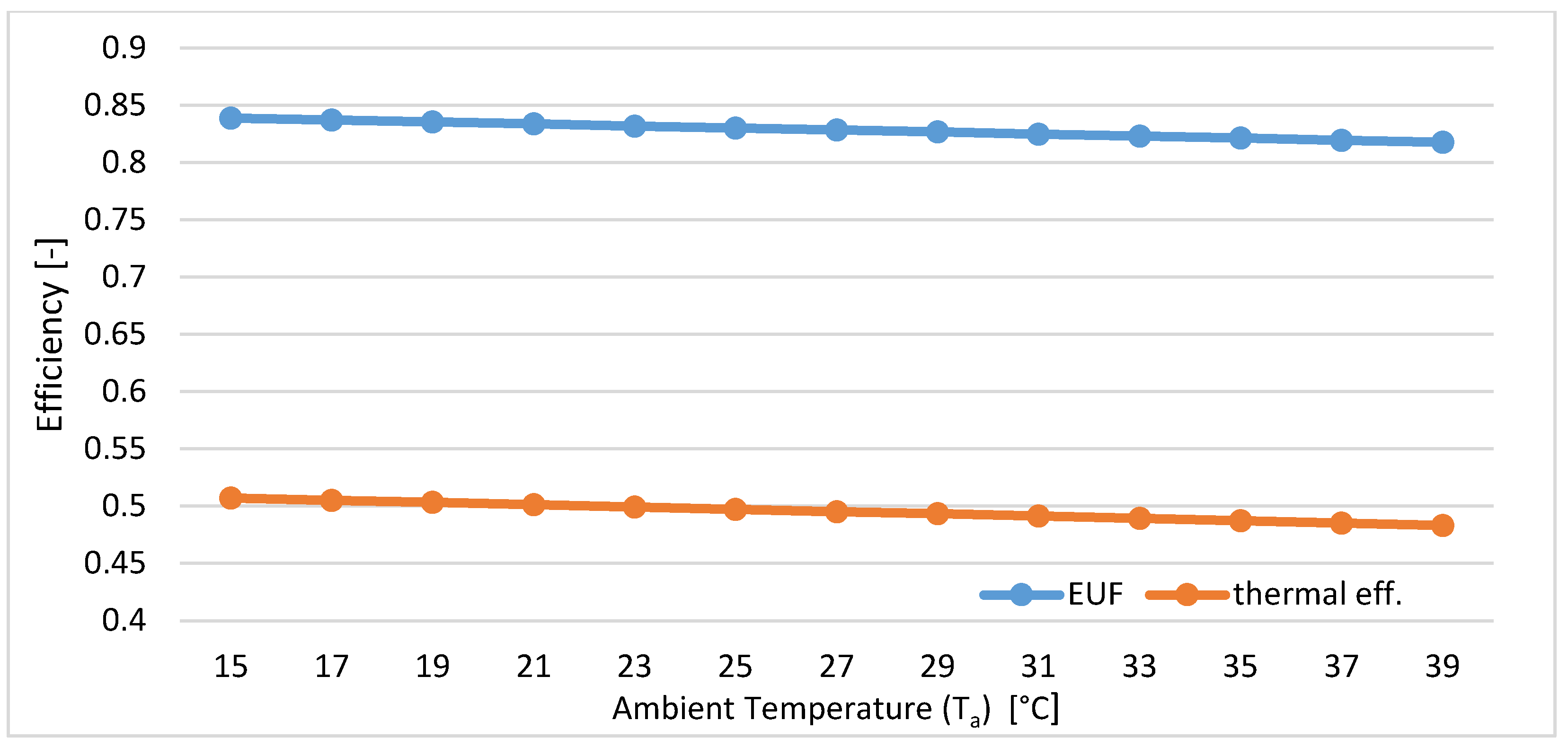

For the base case, the cycle efficiency of the gas turbine is 49.7%; on the other hand, the EUF of the trigeneration system is 83.0%. A major economic benefit for the application of trigeneration technology is generating energy at a lower cost than the cost of purchase from the local energy supplier. Results of the economic analysis show that with the implementation of the proposed combined system, the unit cost of the energy becomes much lower compared to the local grid. The LCOE of the system is around 0.02 $/kWh, whereas the unit price of the local electricity from the grid is 0.09 $/kWh. Compared to a separate production plant, a trigeneration system has 49% lower fuel input. In addition, energy losses through the plant with individual energy and power production are much higher compared to the trigeneration plant. The results of the exergy analysis show that the combustion chamber is the primary source of exergy destruction. Therefore, some measures can be taken to decrease the exergy destruction of that component.

A parametric study was also carried out to investigate the influence of some essential parameters on the system performance. The main findings are summarized below:

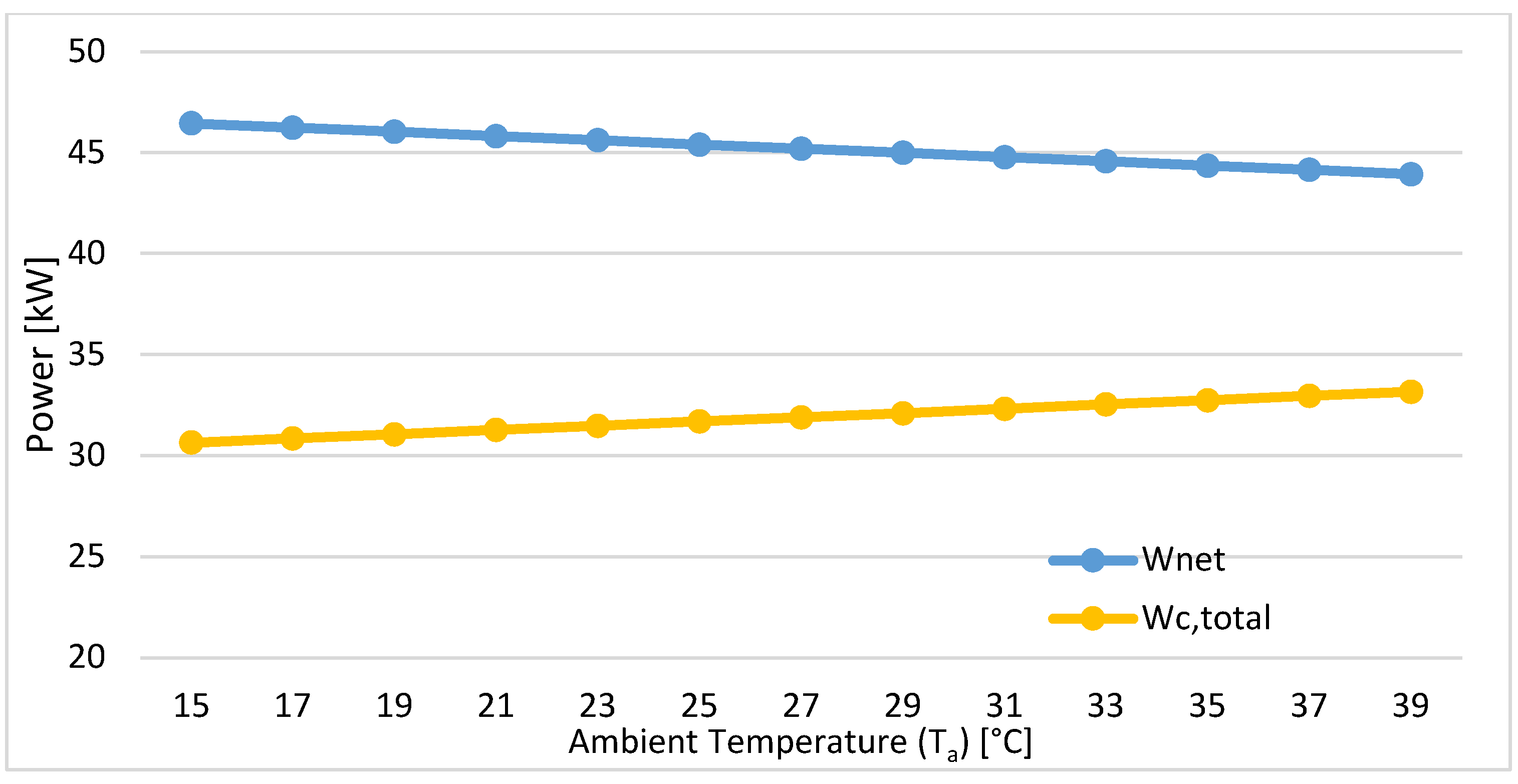

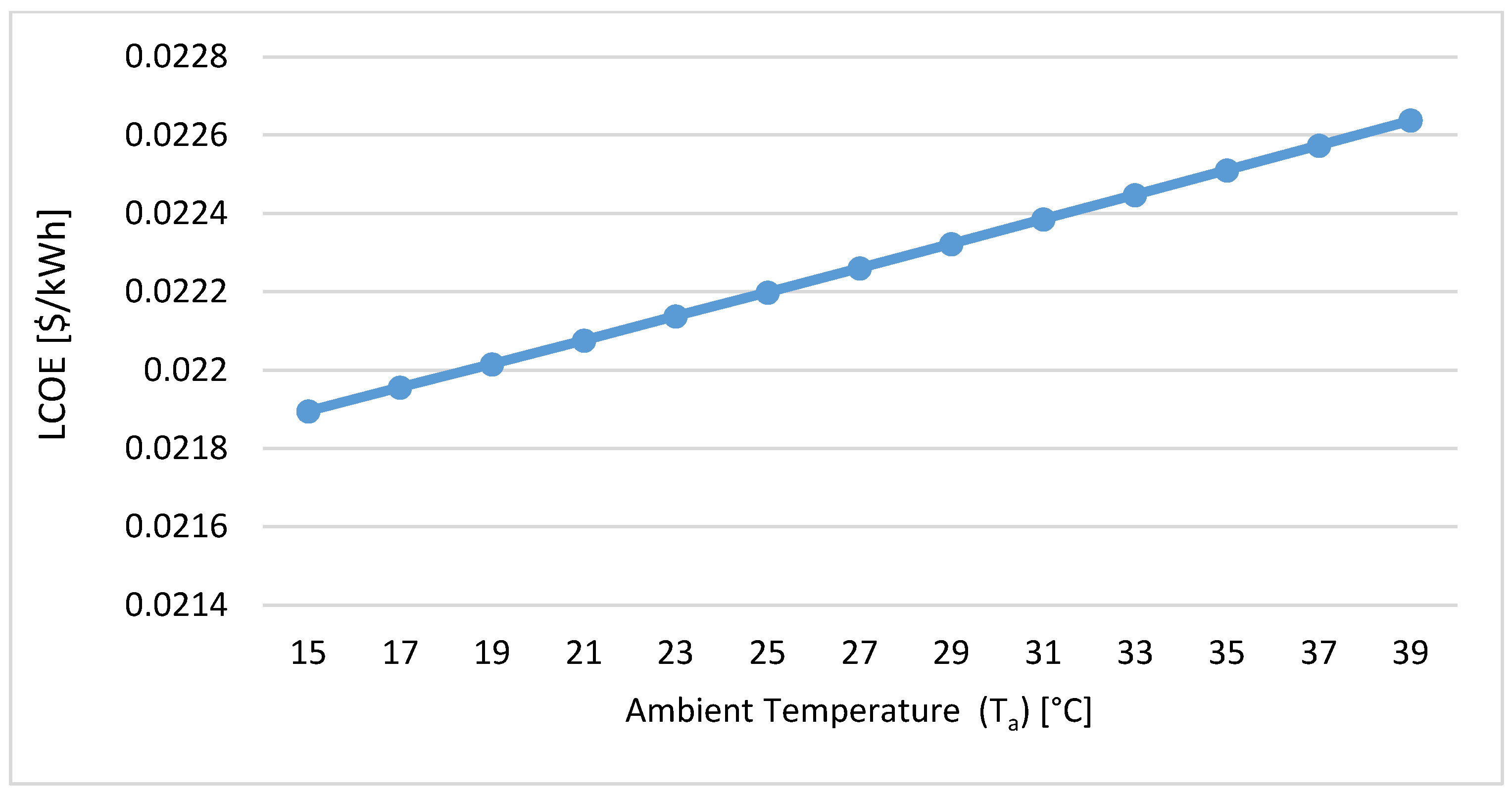

Results show that as the ambient temperature rises, the EUF and decrease, and the LCOE of the system increases. The LCOE of the system changes from 0.0219 to 0.0225 $/kWh between 15 and 39 °C ambient temperatures. Therefore, cooling the inlet compressor air with various technologies is an important consideration to improve the thermodynamic performance and financial feasibility of the system.

At higher turbine inlet temperatures, fuel mass flow rate and the net power generation increase.

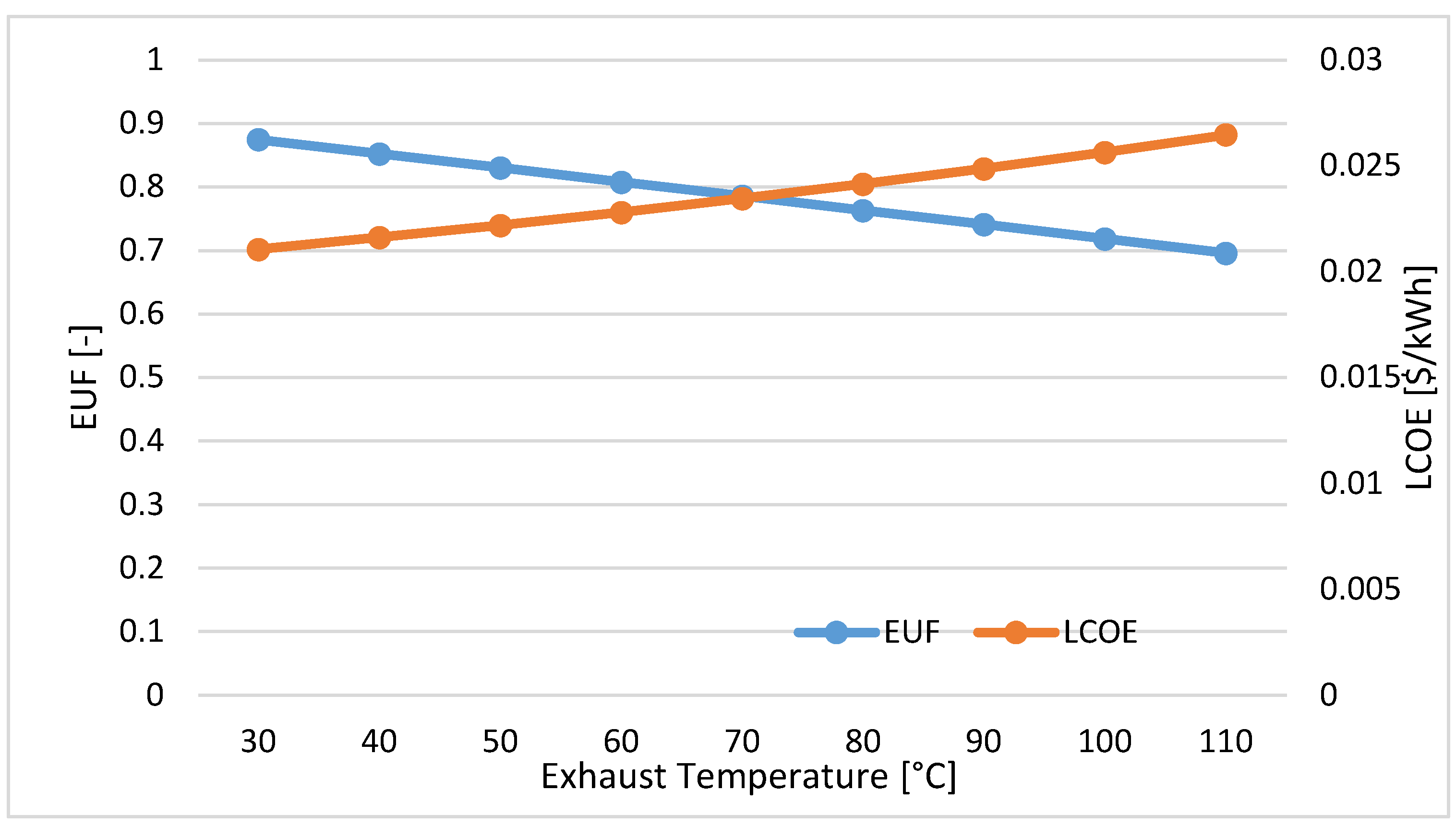

Increasing the exhaust temperature decreases the EUF and increases the LCOE. At 30 °C exhaust temperature, the LCOE is at 0.0210 $/kWh, and at 110 °C exhaust temperature, it is at 0.0264 $/kWh. As a result, it is necessary to benefit from the potential of the high-temperature exhaust gas before rejecting it.

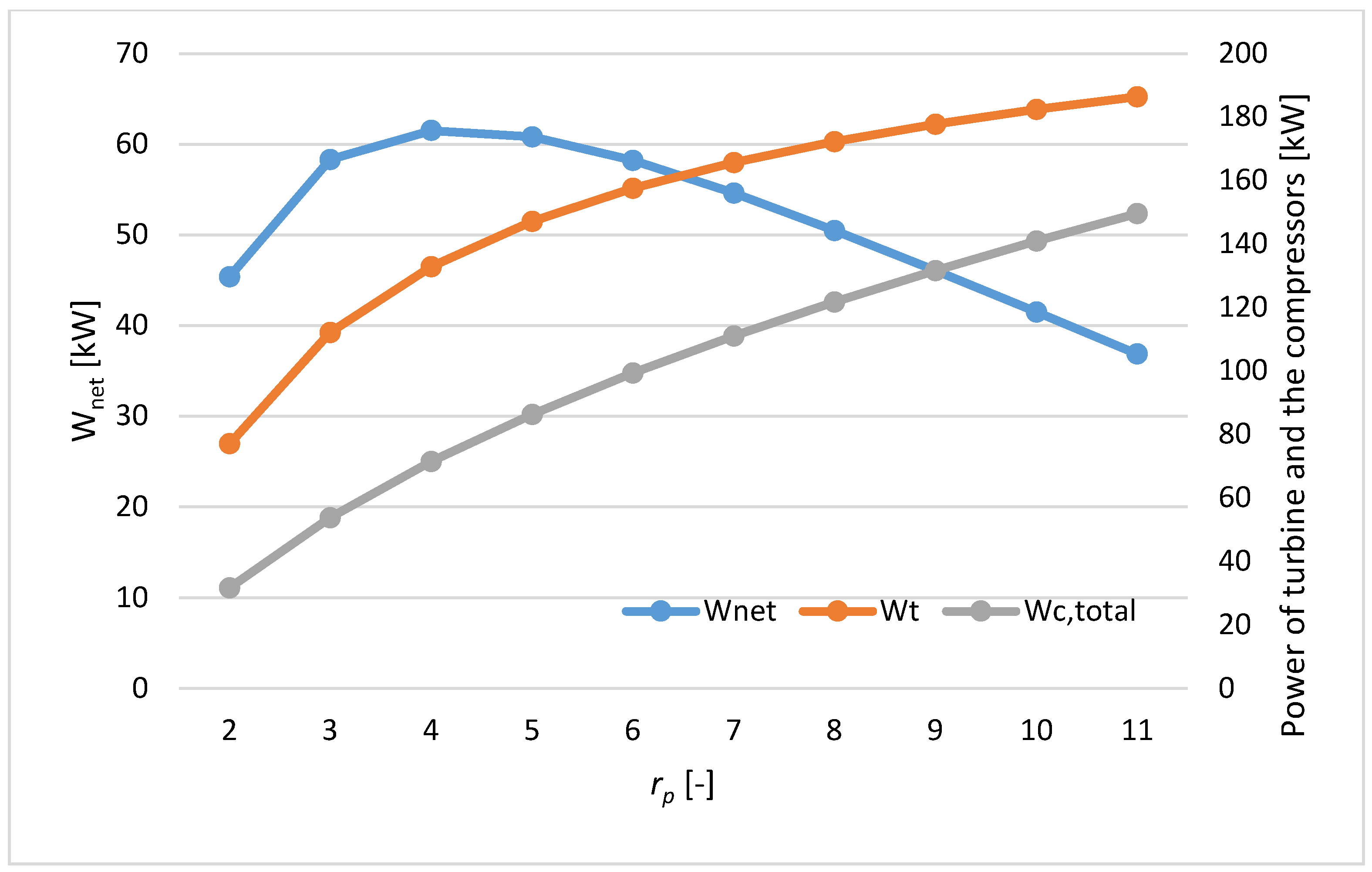

When the pressure ratio increases, both turbine and compressor power increase, but after a specific rp value, increments in the compressors’ power consumption are more significant than those for the turbine; as a result, the net power output decreases. The net power utilization of the system is maximum when the rp is 4, for each compressor.

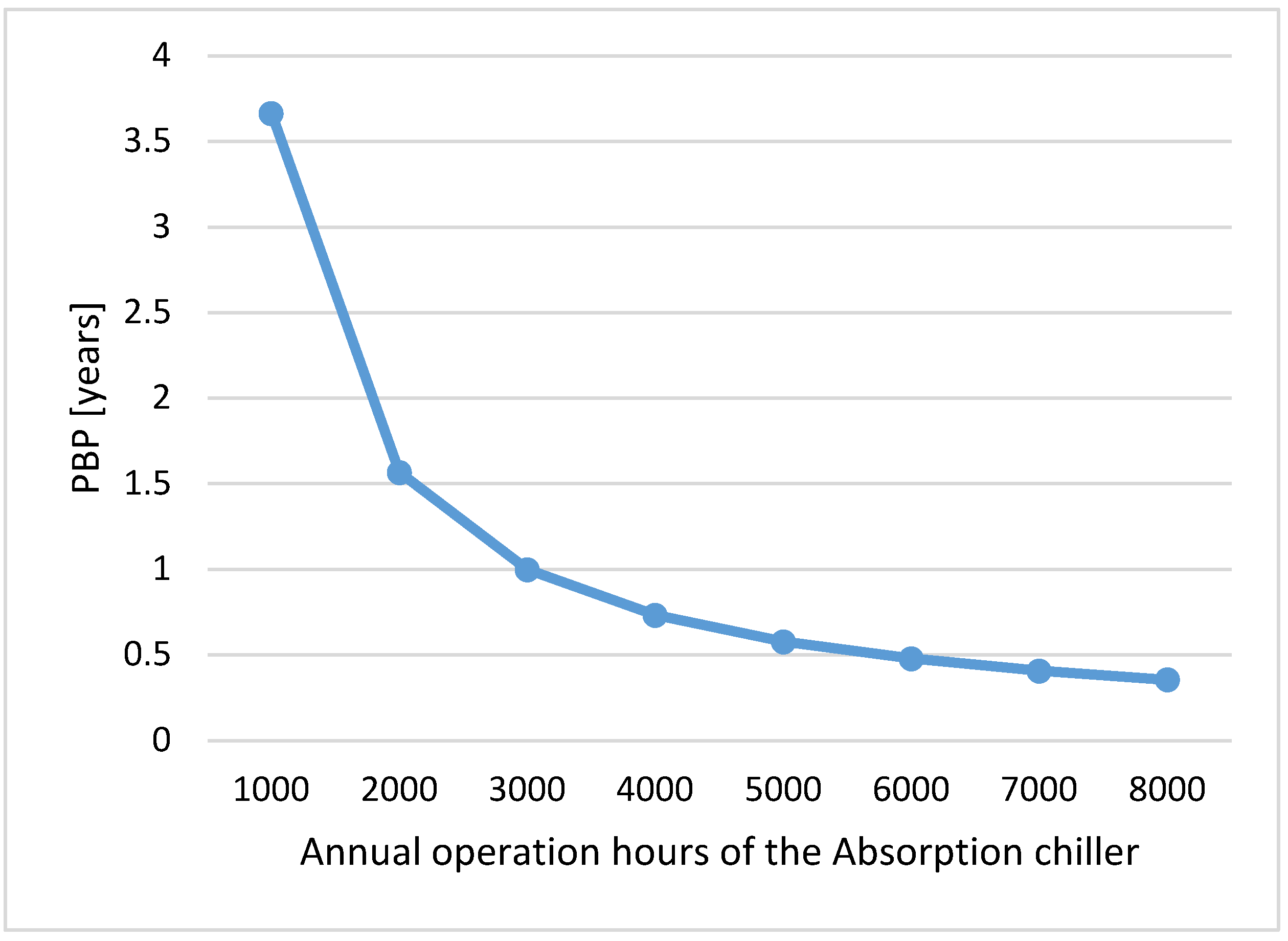

The effect of the annual operation hours of the absorption chiller on the payback period of the chiller is investigated. Results show that the integration of an absorption chiller is more beneficial financially when the cooling requirement is high, stable, and continuous. When the annual operation time is 1000 h, the PBP of the chiller is 3.6 years, and it decreases to 4 months when the operation time becomes 8000 h.

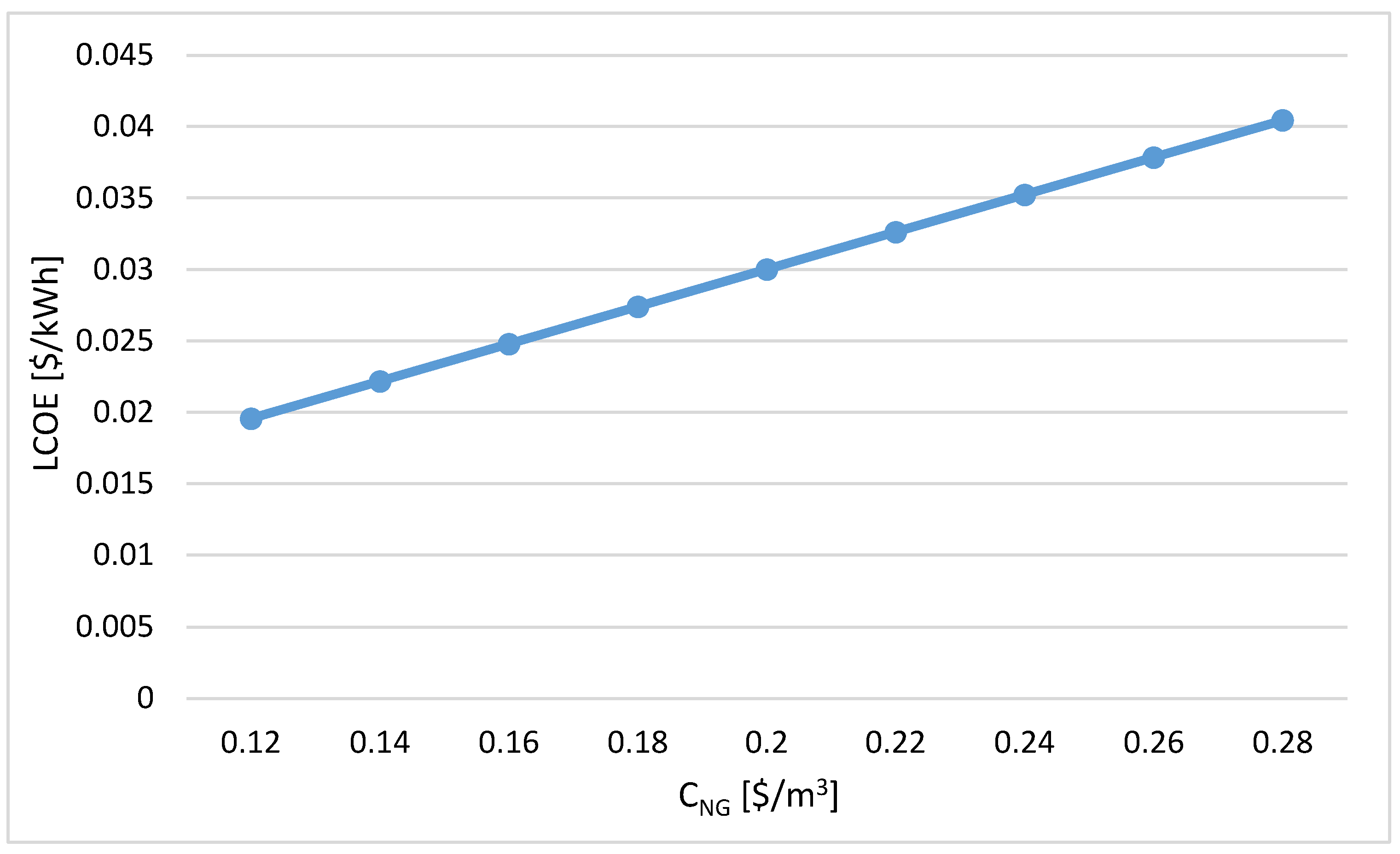

Fuel costs have a larger uncertainty in the future market. To reduce the risks, it is important to make accurate fuel price predictions. The effect of the natural gas cost on the LCOE is analyzed. Results show that the LCOE of the combined cycle is very sensitive to the price fluctuations of natural gas. However, even for the most expensive natural gas cost rate scenario, the LCOE of the system is much lower compared to the local electricity rate.

Local incentives should be enhanced by regulations to broaden the combined system applications, as the high investment cost is an economic barrier.