Review on the Application of Machine Vision in Defrosting and Decondensation on the Surface of Heat Exchanger

Abstract

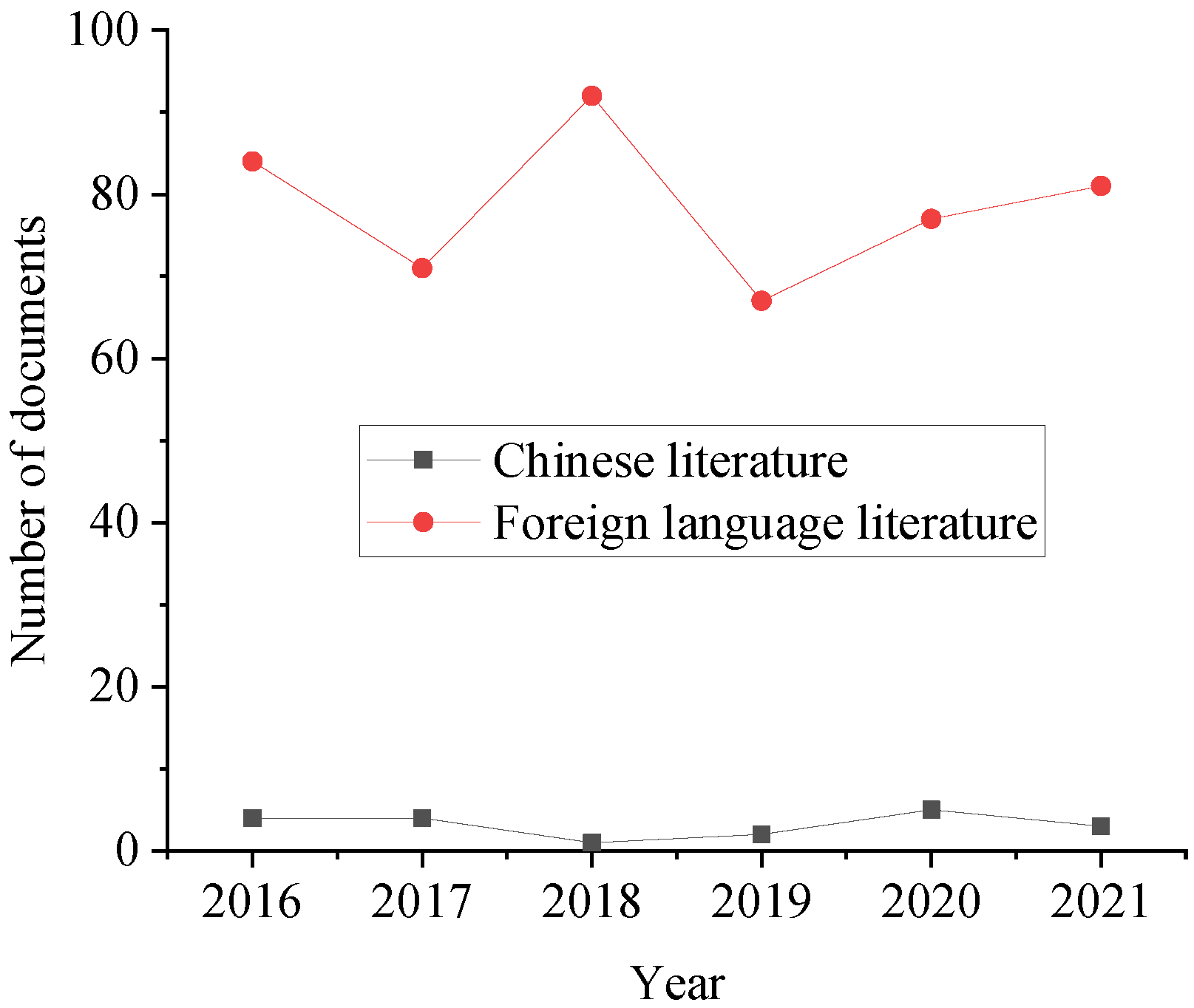

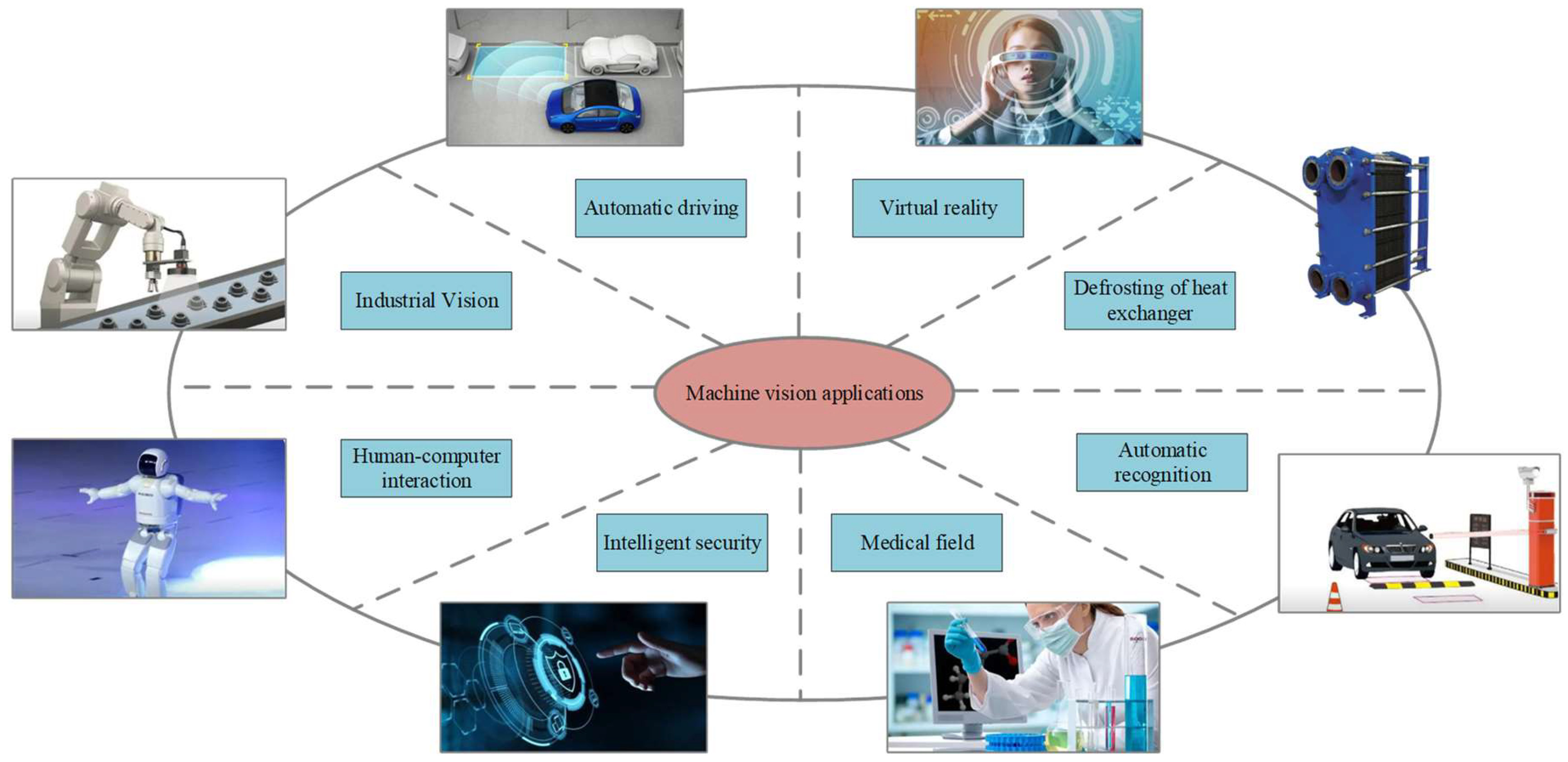

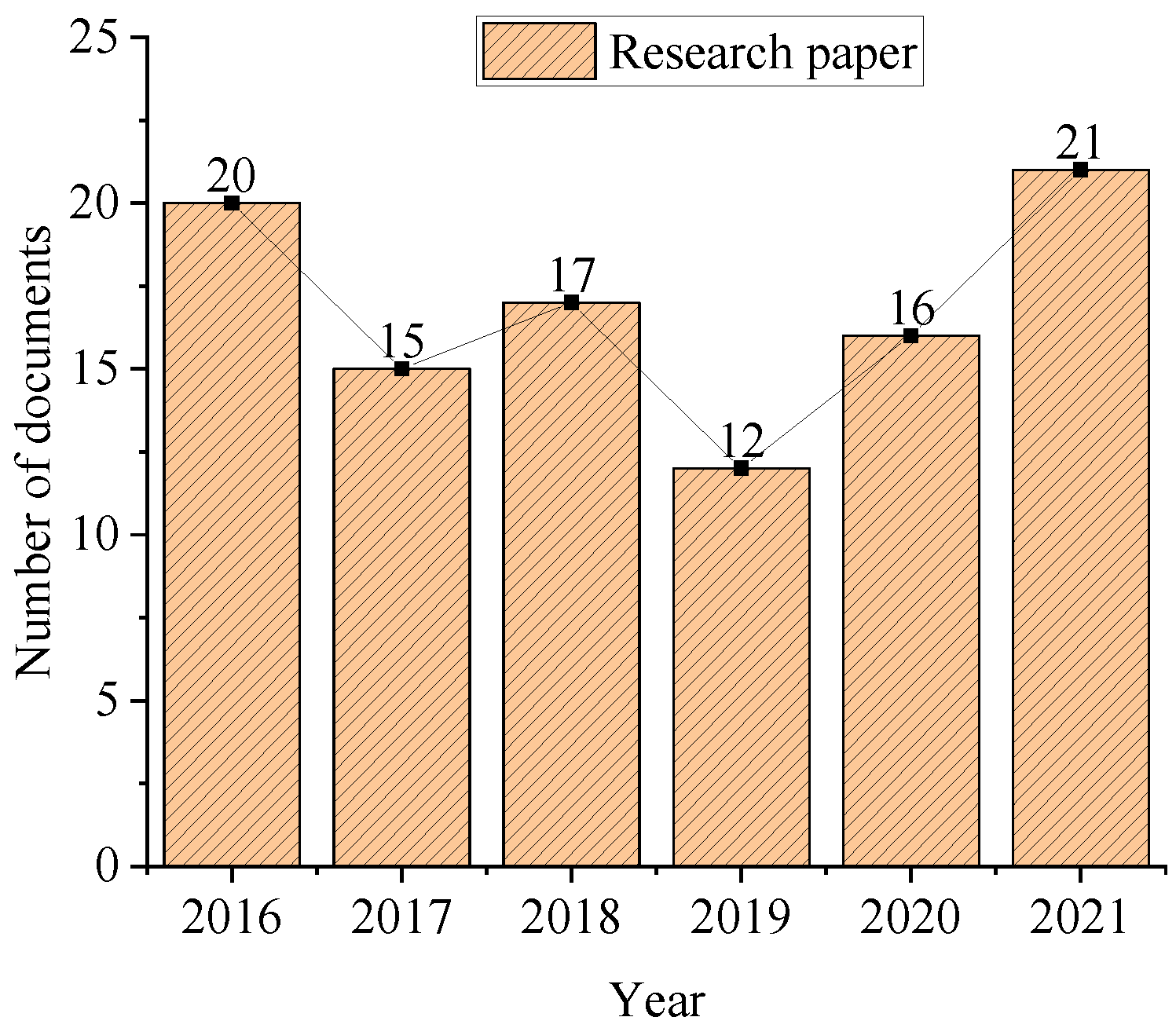

:1. Introduction

2. Formation Mechanism of Frost and Dew; Application Status of Machine Vision in Defrosting and Dew Decondensation

2.1. Formation Mechanism of Dew and Frost

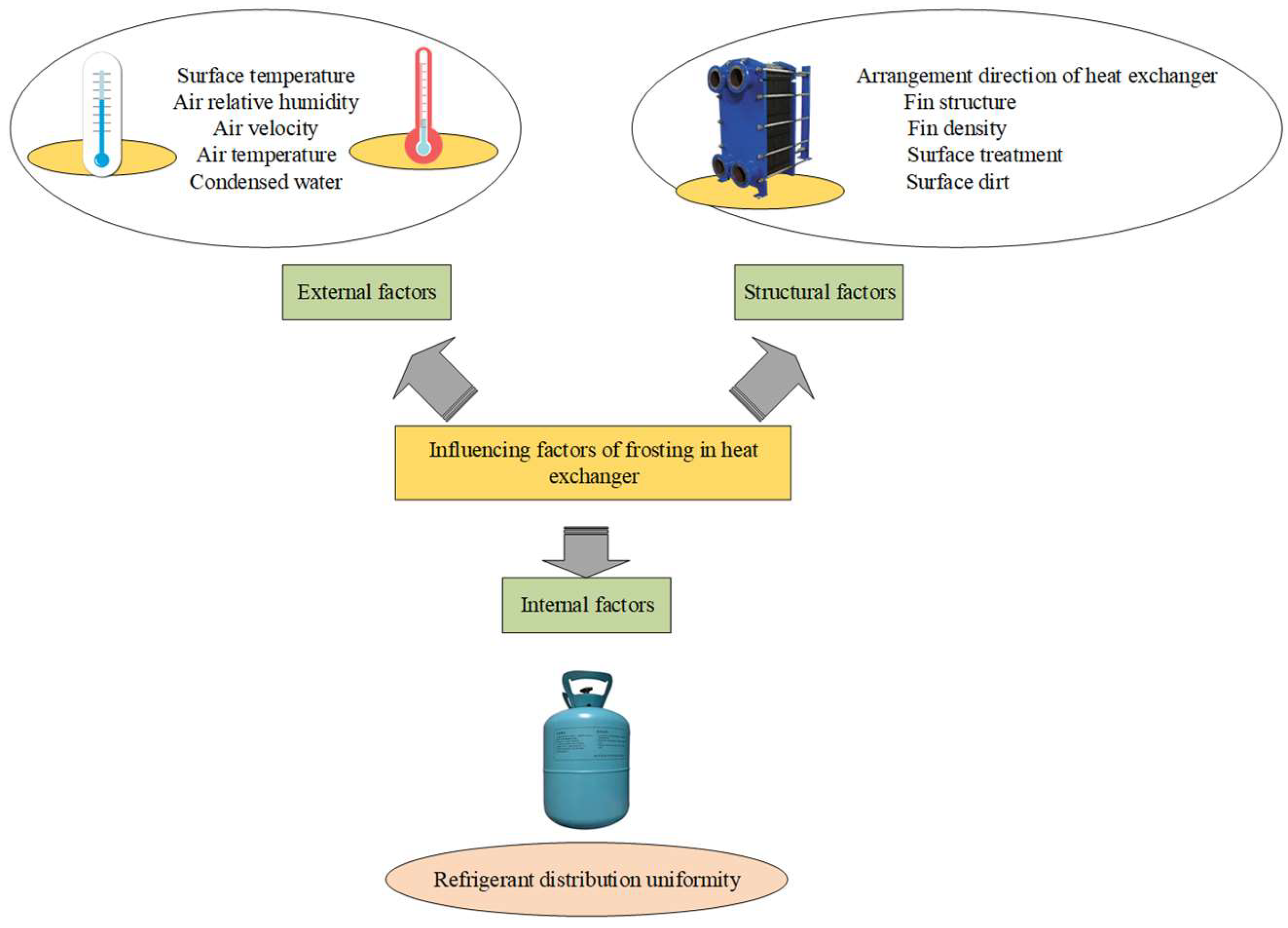

2.1.1. Surface Frosting Principle of the Exchanger

2.1.2. Growth Mechanism of Frosting on Exchanger Surface

2.2. Researching Defrosting and Decondensation on Exchanger Surface

2.2.1. Research Status of Surface Defrosting Methods for Heat Exchangers

- (1)

- Changing the inlet conditions of the Exchanger

- (2)

- Optimizing the structure and design of the Exchanger

- (3)

- Surface Modification and Frost Suppression of Exchanger

2.2.2. Effect of Surface Condensation on Exchanger

3. Application Status of MV in Defrosting and Dew Decondensation

3.1. Application of MV Technology in Exchanger System

3.1.1. Intelligent Defrosting Technology

3.1.2. ASHP

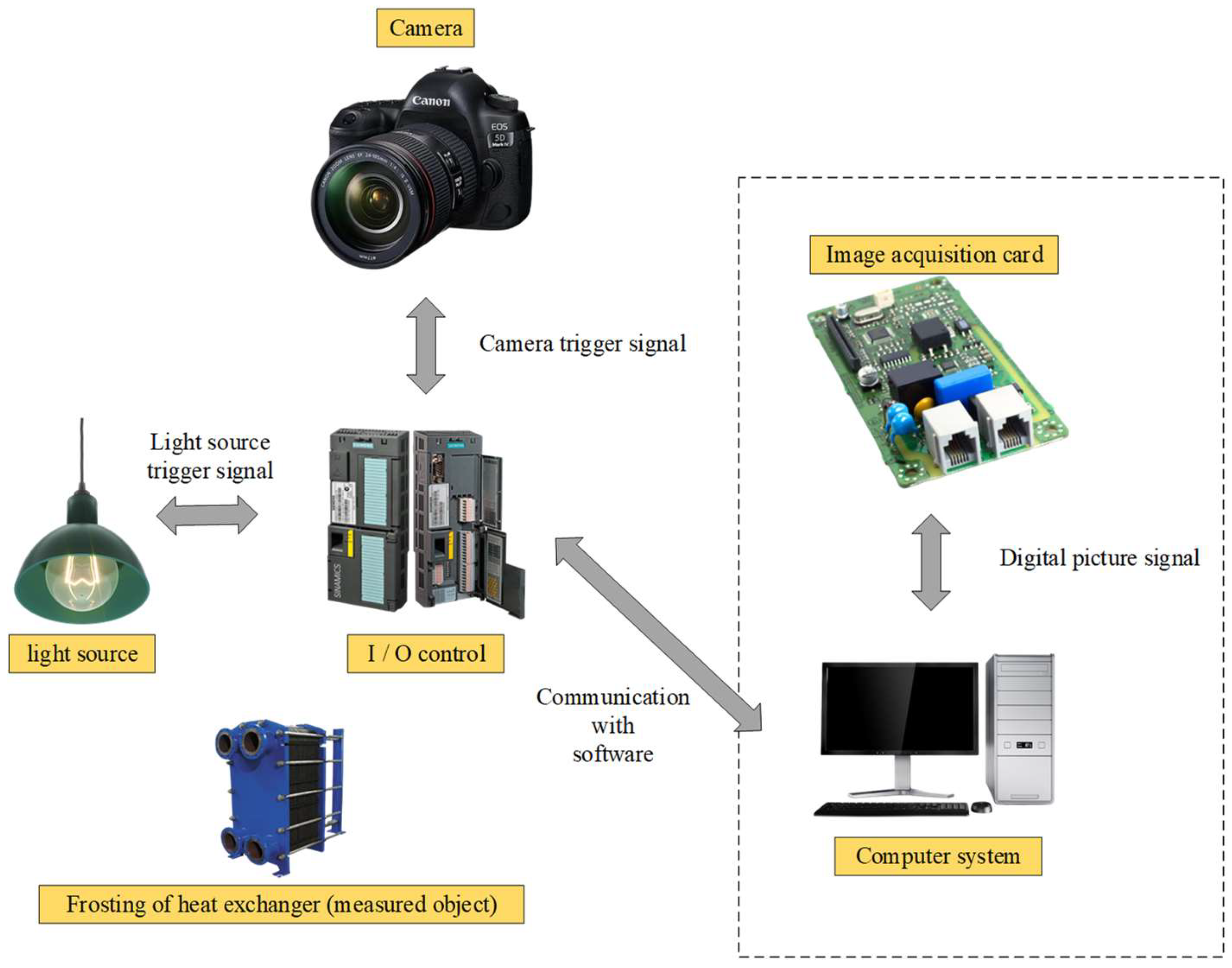

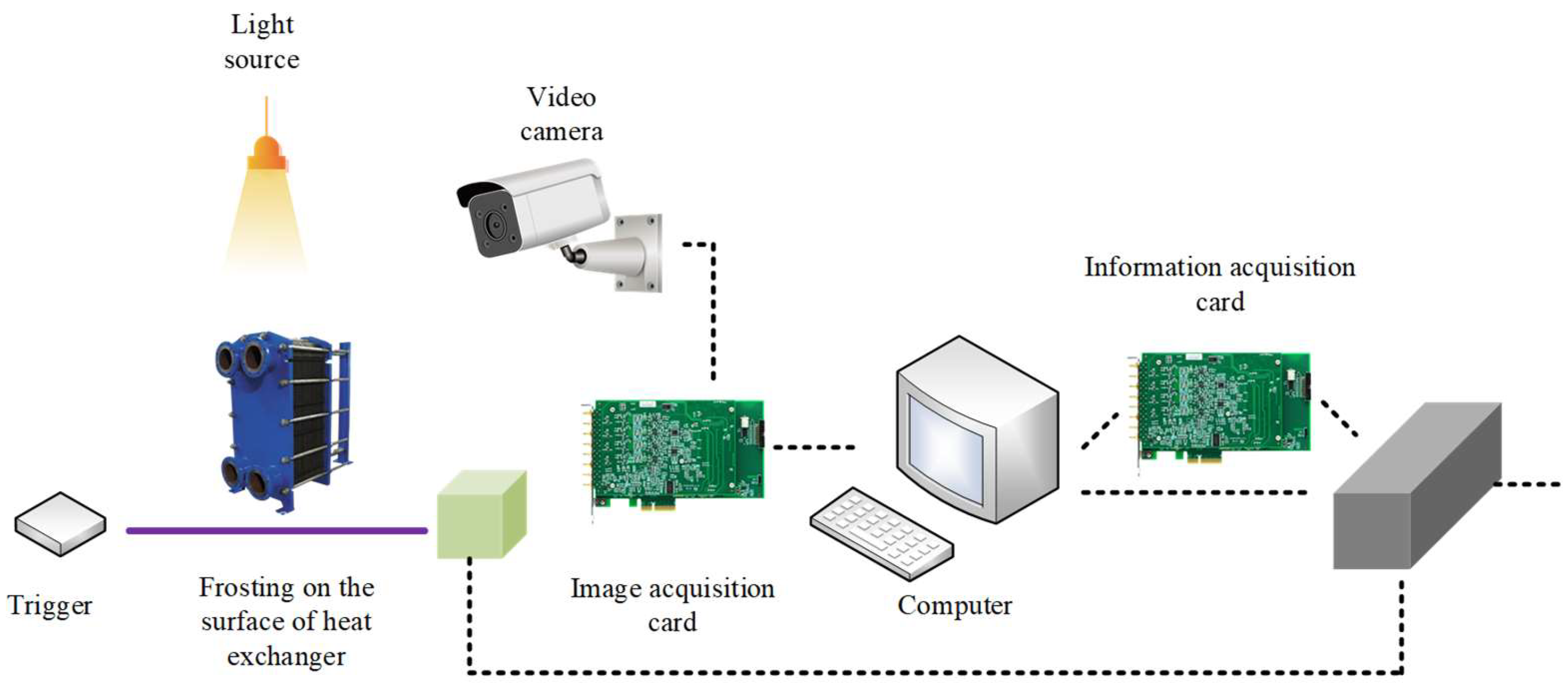

3.2. Application of MV in Defrosting System

3.3. Challenges and Prospects of Exchanger Defrosting Control

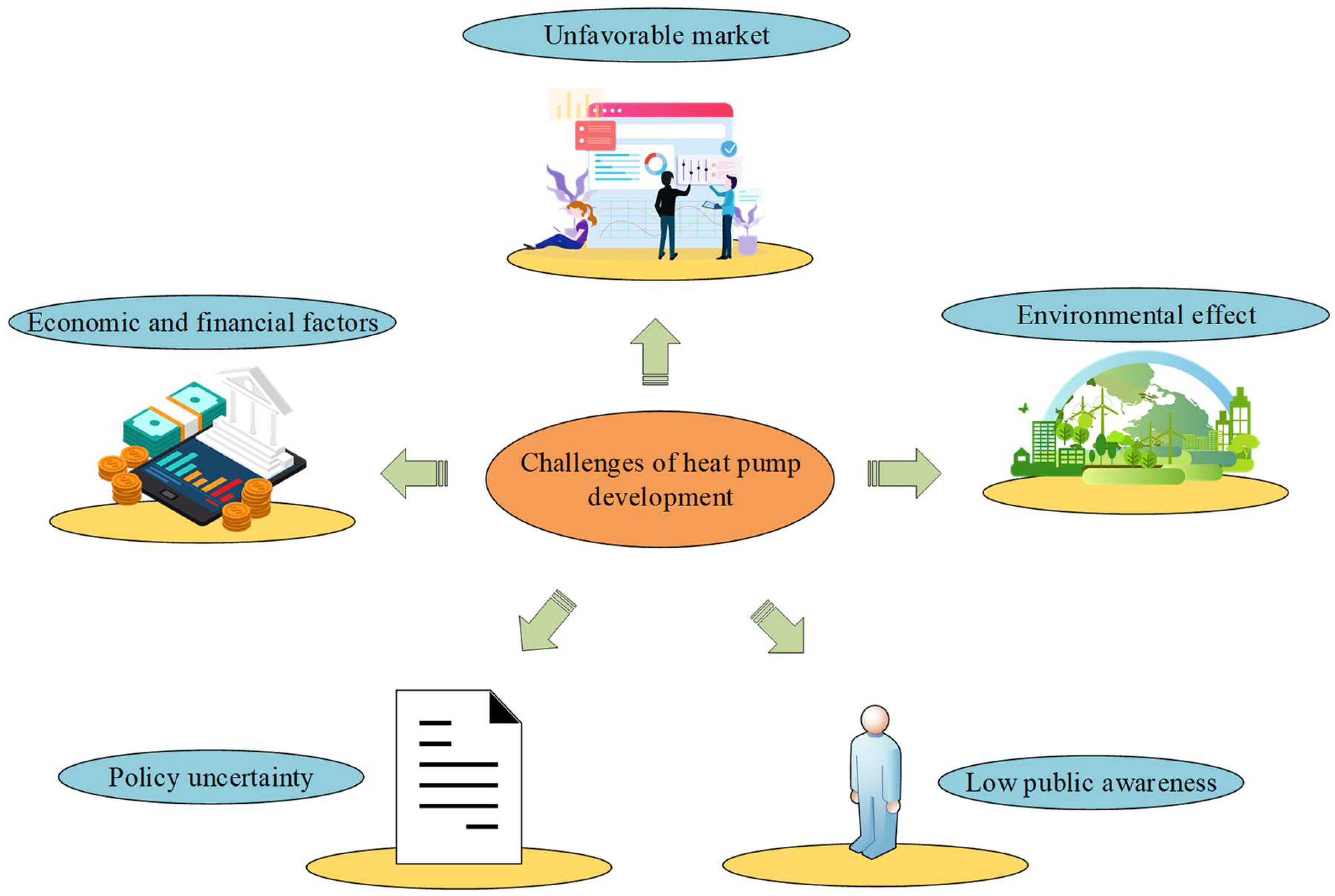

3.3.1. Challenges

3.3.2. Prospects

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, C.; Cheng, H.E. Dynamic Height-Detecting System for Growing Frost in a Tube. J. Shanghai Jiaotong Univ. 2001, 35, 1175–1177. [Google Scholar]

- Abdulla, M.O.A.; Deniz, E.; Karagz, M.; Gürüf, G. An Experimental Study on A Novel Defrosting Method for Cold Room. Appl. Therm. Eng. 2021, 188, 116573. [Google Scholar] [CrossRef]

- Lee, W.J.; Bae, K.J.; Kwon, O.K. Effect of Super-Hydrophobic Coating on Frost/Defrost behavior in Fin-Tube Heat Exchangers. Korean J. Air-Cond. Refrig. Eng. 2021, 33, 122–129. [Google Scholar]

- You, Y.; Wang, S.; Lv, W.; Chen, Y.; Gross, U. A cfd model of frost formation based on dynamic meshes technique via secondary development of ansys fluent. Int. J. Heat Fluid Flow 2021, 89, 108807. [Google Scholar] [CrossRef]

- Chatterjee, R.; Beysens, D.; Anand, S. Anti-icing: Delaying ice and frost formation using phase-switching liquids (adv. mater. 17/2019). Adv. Mater. 2019, 31, 24. [Google Scholar] [CrossRef]

- Hayashi, Y.; Aoki, A.; Adachi, S.; Hori, K. Study of Frost Properties Correlating with Frost Formation Types. J. Heat Transf. 1977, 99, 239–245. [Google Scholar] [CrossRef]

- Zhang, Y.N. Experiments Study and Fractal Simulation on Frosting Growth; Southeast University: Nanjing, China, 2005. [Google Scholar]

- Hou, P.X. Experimental Study and Theory Analyse on Frost Fromation; Southeast University: Nanjing, China, 2006. [Google Scholar]

- Hou, P.X.; Cai, L.; Wei-Ping, Y.U. Experimental Study and Fractal Analysis of Ice Crystal Structure at Initial Period of Frost Formation. J. Appl. Sci. 2007, 25, 193–197. [Google Scholar]

- Liu, Y.M.; Liu, Z.L.; Huang, L.Y.; Sun, J. Fractal model for simulation of frost formation and growth. Sci. China Technol. Sci. 2010, 53, 807–812. [Google Scholar] [CrossRef]

- Liu, Y.M.; Liu, Z.L.; Huang, L.Y. Improved computation method of box dimension and its application in frost formation. Beijing Gongye Daxue Xuebao 2012, 38, 1724–1730. [Google Scholar]

- Liu, Y.; Liu, Z.; Huang, L. Experimental and theoretical investigations of the fractal characteristics of frost crystals during frost formation process. Exp. Therm. Fluid Sci. 2012, 36, 217–223. [Google Scholar] [CrossRef]

- Liu, Y.M. A Fractal Model and Experimental Study of Frost Deposition on Cold Surface; Beijing University of Technology: Beijing, China, 2012. [Google Scholar]

- Chen, S.; Yao, S.; Xie, F.; Han, H.; Chang, Z. Thermal conductivity of frost layer on finned-tube vaporizer based on fractal theory. CIESC J. 2012, 63, 3855–3860. [Google Scholar]

- Yao, S.; Chen, S.; Liu, Y.; Ren, J. Heat transfer analysis of frosting under cryogenic condition. Cryogenics 2013, 6, 15–20. [Google Scholar]

- Yao, S.P. Study on Heat Transfer of Frosting on Air-heating Finned-tube Vaporizer Based on Fractal Theory; Lanzhou University: Lanzhou, China, 2013. [Google Scholar]

- Hang, Y. Research on Defrosting Control Method of Air Source Heat Pump Based on Image Processing Technology; Tianjin University: Tianjin, China, 2017. [Google Scholar]

- Boreyko, J.B.; Hansen, R.R.; Murphy, K.R.; Nath, S.; Retterer, S.T.; Collier, C.P. Controlling Condensation and Frost Growth with Chemical Micropatterns. Sci. Rep. 2016, 6, 19131. [Google Scholar] [CrossRef] [PubMed]

- Tan, B.; Cai, J. An improved model based on real gas state equation and fog formation for condensation heat and mass transfer. Nucl. Eng. Des. 2020, 372, 110968. [Google Scholar] [CrossRef]

- Gafner, Y.Y.; Gafner, S.L.; Nomoev, A.V. Computer simulation of the formation process of cu-au nanoparticles by condensation. Solid State Phenom. 2020, 310, 96–100. [Google Scholar] [CrossRef]

- Zhu, J.H.; Sun, Y.Y.; Wang, W.; Ge, Y.; Li, L.; Liu, J.A. Novel Temperature–Humidity–Time Defrosting Control Method Based on a Frosting Map for Air-source Heat Pumps. Int. J. Refrig. 2015, 54, 45–54. [Google Scholar] [CrossRef]

- Wang, W.; Liu, J.; Sun, Y.; Wu, X.; Bai, X.; Zhu, J.; Ge, Y. Experimental study on two new efficient defrosting control methods of air source heat pump. Refrig. Air-Cond. 2017, 3, 314. [Google Scholar]

- Peng, K.; Wang, X.; Song, G.; Liu, M. Analysis of the influence of the tubes constrained structure of contra-flow vertical shell and tube heat exchanger on heat transfer ability with natural circulation. J. Phys. Conf. Ser. 2021, 1985, 012064. [Google Scholar] [CrossRef]

- Park, J.S.; Kim, D.R.; Kwan-Soo, L. Frosting Behavior and Thermal Performance of Louvered Fins with Unequal Louver Pitch. Int. J. Heat Mass Transf. 2016, 95, 499–505. [Google Scholar] [CrossRef]

- Liu, J.C.; Wei, X.T.; Zhou, Z.Y.; Wei, Z. Numerical analysis on interactions between fluid flow and structure deformation in plate-fin heat exchanger by Galerkin method. Heat Mass Transf. 2018, 54, 2835–2844. [Google Scholar] [CrossRef]

- Wang, F.; Liang, C.; Zhang, X.; Zhang, Y. Effects of surface wettability and defrosting conditions on defrosting performance of fin-tube heat exchanger. Exp. Therm. Fluid Sci. 2018, 93, 334–343. [Google Scholar] [CrossRef]

- Dong, W.; Li, Y. Investigation on Exergy in The Process of Heat Exchanger Defrosting. IOP Conf. Ser. Earth Environ. Sci. 2020, 514, 042033. [Google Scholar] [CrossRef]

- Du, Y.J.; Wu, J.H.; Wang, C.; Lei, B.W. Comparison of Two Reverse-cycle Defrosting Methods for a R290 Split Room Air Conditioner. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1180, 012048. [Google Scholar] [CrossRef]

- Chu, F.Q.; Wen, D.S.; Wu, X.M. Frost Self-Removal Mechanism during Defrosting on Vertical Superhydrophobic Surfaces: Peeling Off or Jumping Off. Langmuir 2018, 34, 14562–14569. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Wu, X.; Sun, Y.; Liu, J.; Bai, X. Experimental study on the influence of different defrosting cycles on the operation performance of air source heat pump. Heat. Vent. Air Cond. 2018, 48, 8. [Google Scholar]

- Kang, J.; Kim, H.; Bak, J.; Limb, S.; Yuna, B. Condensation of steam mixed with non-condensable gas on vertical heat exchanger tubes in circumstances with free convection. Int. J. Heat Mass Transf. 2021, 169, 120925. [Google Scholar] [CrossRef]

- Reda, M.N.; Spinnler, M.; Al-Kayiem, H.H.; Sattelmayera, T. Assessment of condensation and thermal control in a photovoltaic panel by PV/T and ground heat exchanger. Sol. Energy 2021, 221, 502–511. [Google Scholar] [CrossRef]

- Ali, A.; Muneer, A. Experimental Steam Condensation Enhancement on Metal Foam Filled Heat Exchanger. J. Mech. Eng. Res. Dev. 2021, 44, 145–167. [Google Scholar]

- Shamirzaev, A.S. An experimental investigation on condensation of R134a refrigerant in microchannel heat exchanger. J. Phys. Conf. Ser. 2018, 1105, 012060. [Google Scholar] [CrossRef]

- Li, X.T.; Zendehboudi, A.; Wang, B. Application of smart models for prediction of the frost layer thickness on vertical cryogenic surfaces under natural convection. Appl. Therm. Eng. 2017, 115, 1128–1136. [Google Scholar]

- Li, Z.; Wang, W.; Sun, Y.; Wang, S.; Deng, S.; Lin, Y. Applying image recognition to frost built-up detection in air source heat pumps. Energy 2021, 5, 121004. [Google Scholar] [CrossRef]

- Li, Z.; Deng, S.M. Steady state ANN model of operating characteristics of variable speed direct expansion air conditioning system. J. Refrig. 2017, 38, 7. [Google Scholar]

- Zheng, X.; Shi, R.; You, S.; Han, Y.; Shi, K. Experimental study of defrosting control method based on image processing technology for air source heat pumps. Sustain. Cities Soc. 2019, 51, 101667. [Google Scholar] [CrossRef]

- Ye, Z.; Shi, J.; Chen, J. Frosting behavior of louvered-fin and tube heat exchanger after surface treatment: Experimental analysis. Appl. Therm. Eng. 2021, 194, 117066. [Google Scholar] [CrossRef]

- Miao, H.; Yang, X.; Yin, D.; Zheng, W.; Zhang, H.; Zhang, S.; Liu, Z. A novel defrosting control strategy with image processing technique and fractal theory. Int. J. Refrig. 2022, 138, 259–269. [Google Scholar] [CrossRef]

- Radcliffe, J.; Cox, J.; Bulanon, D.M. Machine vision for orchard navigation. Comput. Ind. 2018, 98, 165–171. [Google Scholar] [CrossRef]

- He, Y.; Deng, B.; Wang, H.; Cheng, L.; Zhou, K.; Cai, S.; Ciampa, F. Infrared machine vision and infrared thermography with deep learning: A review. Infrared Phys. Technol. 2021, 116, 103754. [Google Scholar] [CrossRef]

- Ding, L.; Noborio, K.; Shibuya, K.; Tamura, Y. Frost forecast-a practice of machine learning from data. Int. J. Reason.-Based Intell. Syst. 2021, 13, 1. [Google Scholar] [CrossRef]

- Liu, S.C.; Li, X.Q.; Shen, M.J.; Li, H.; Sun, Z. Experimental investigation on drying performance of an existed enclosed fixed frequency air source heat pump drying system. Appl. Therm. Eng. 2018, 130, 735–744. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, B.; Zhu, X.; Liu, M.; Lv, Z. Review on the Application of Machine Vision in Defrosting and Decondensation on the Surface of Heat Exchanger. Sustainability 2022, 14, 11606. https://doi.org/10.3390/su141811606

Yang B, Zhu X, Liu M, Lv Z. Review on the Application of Machine Vision in Defrosting and Decondensation on the Surface of Heat Exchanger. Sustainability. 2022; 14(18):11606. https://doi.org/10.3390/su141811606

Chicago/Turabian StyleYang, Bin, Xin Zhu, Minzhang Liu, and Zhihan Lv. 2022. "Review on the Application of Machine Vision in Defrosting and Decondensation on the Surface of Heat Exchanger" Sustainability 14, no. 18: 11606. https://doi.org/10.3390/su141811606

APA StyleYang, B., Zhu, X., Liu, M., & Lv, Z. (2022). Review on the Application of Machine Vision in Defrosting and Decondensation on the Surface of Heat Exchanger. Sustainability, 14(18), 11606. https://doi.org/10.3390/su141811606