Sustainable Management of Thickened Tailings in Chile and Peru: A Review of Practical Experience and Socio-Environmental Acceptance

Abstract

:1. Introduction

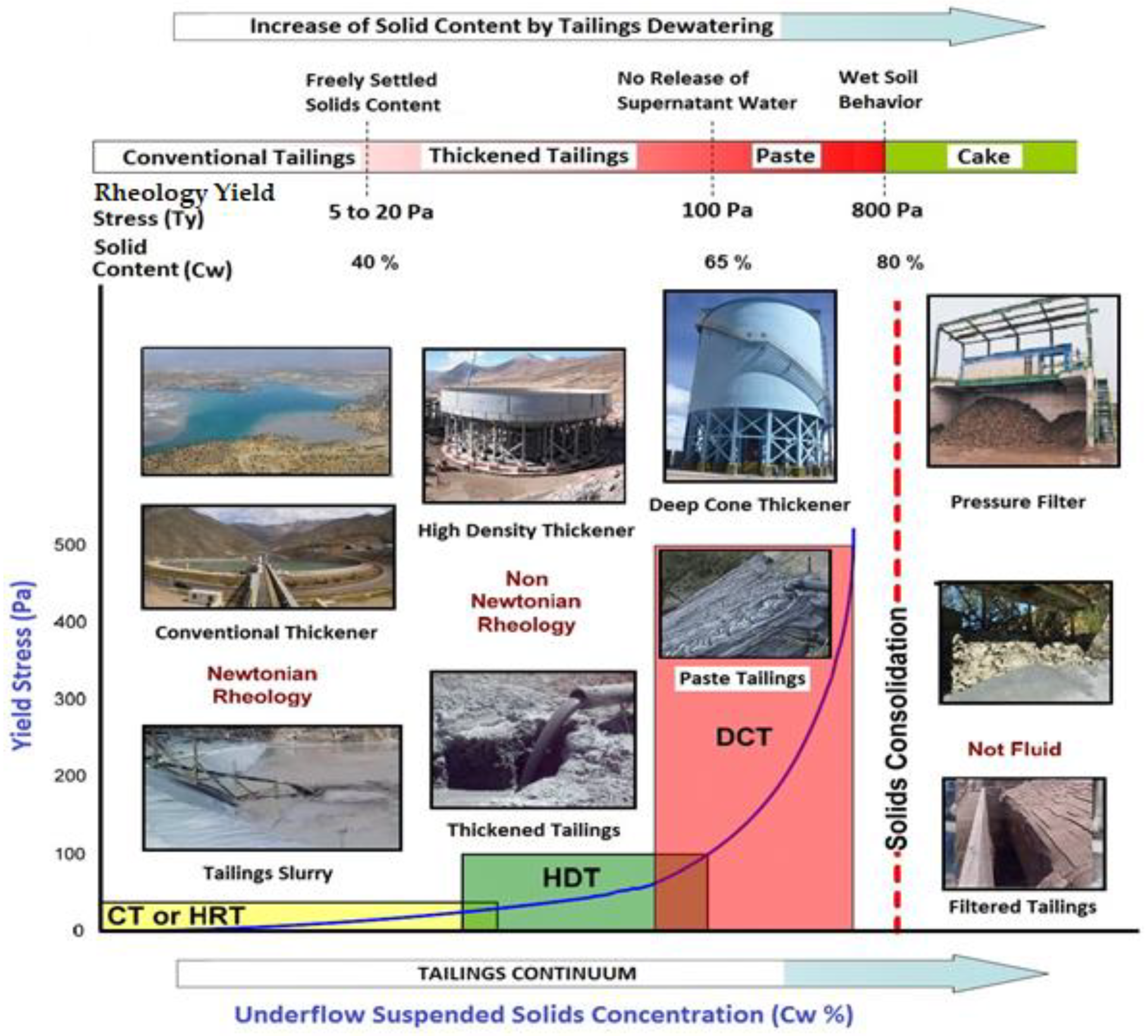

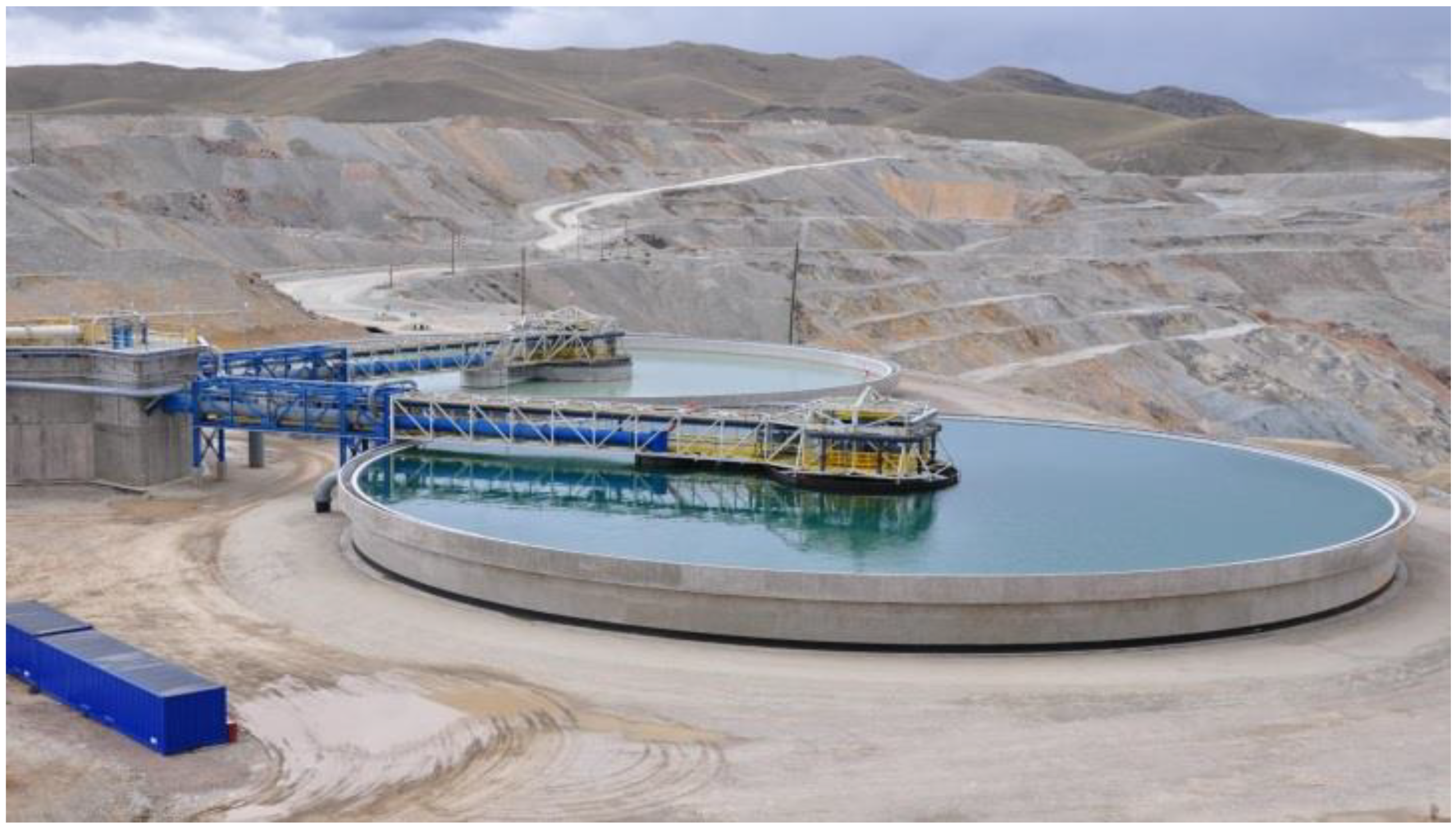

2. Tailings Thickening Plants Development and Advances

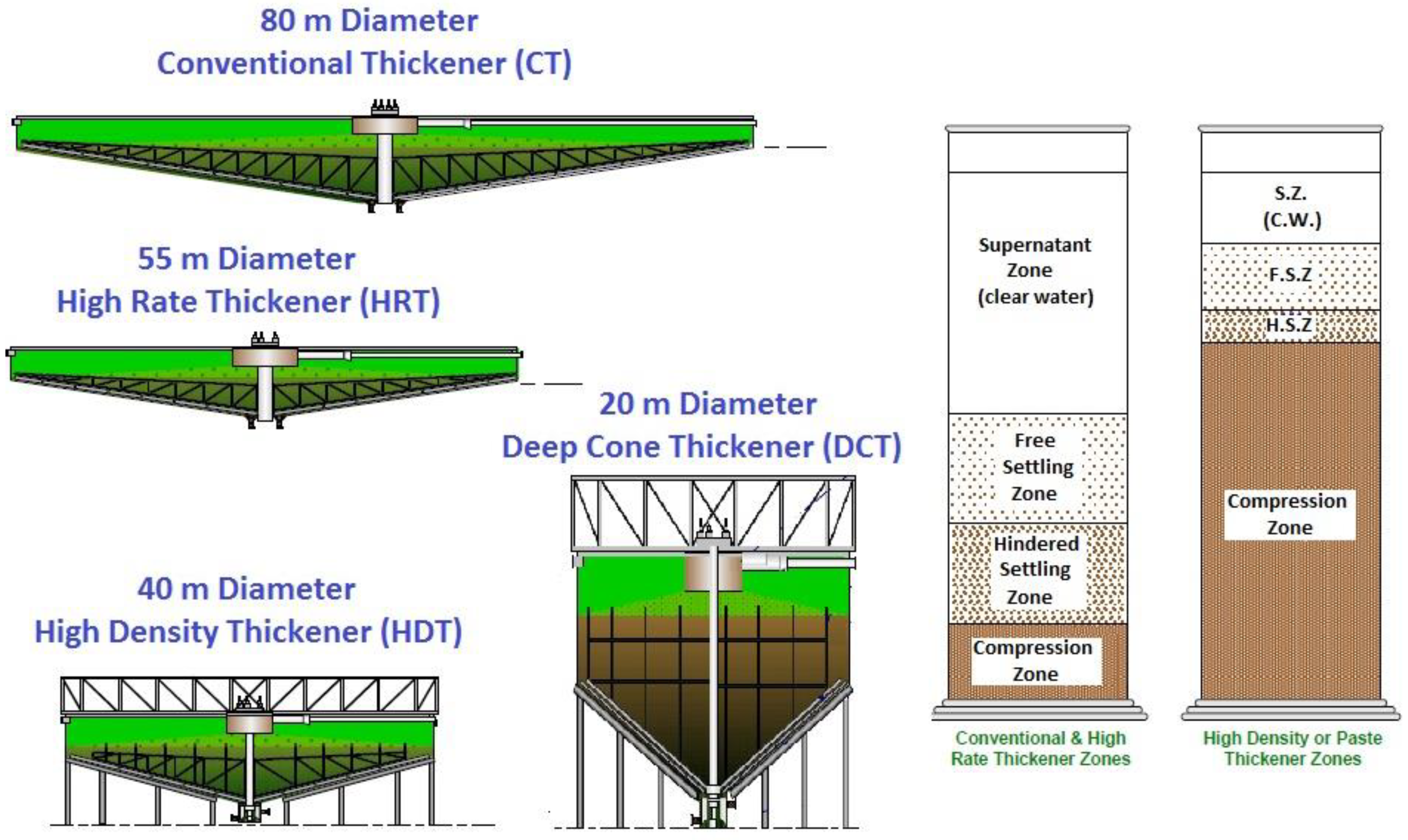

2.1. Conventional Thickeners (CT)

2.2. High Rate or High Capacity Thickeners (HRT)

2.3. High Density Thickeners (HDT) or High Compression Thickeners (HCT)

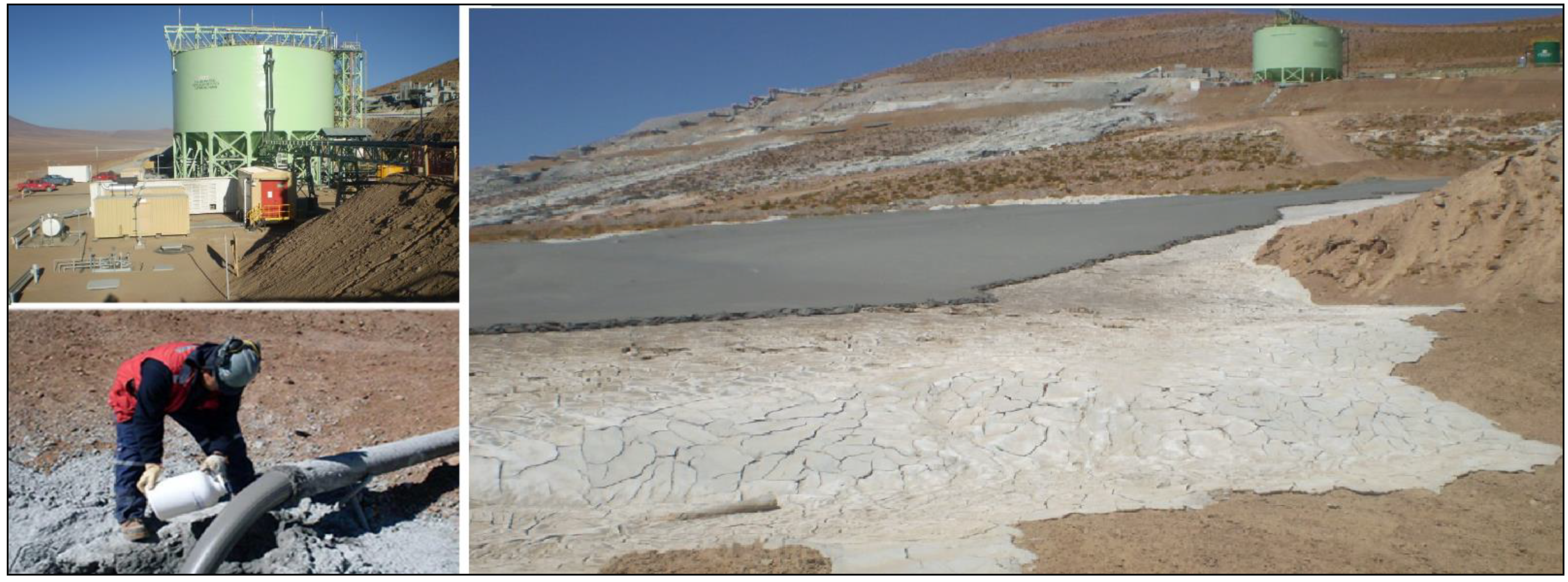

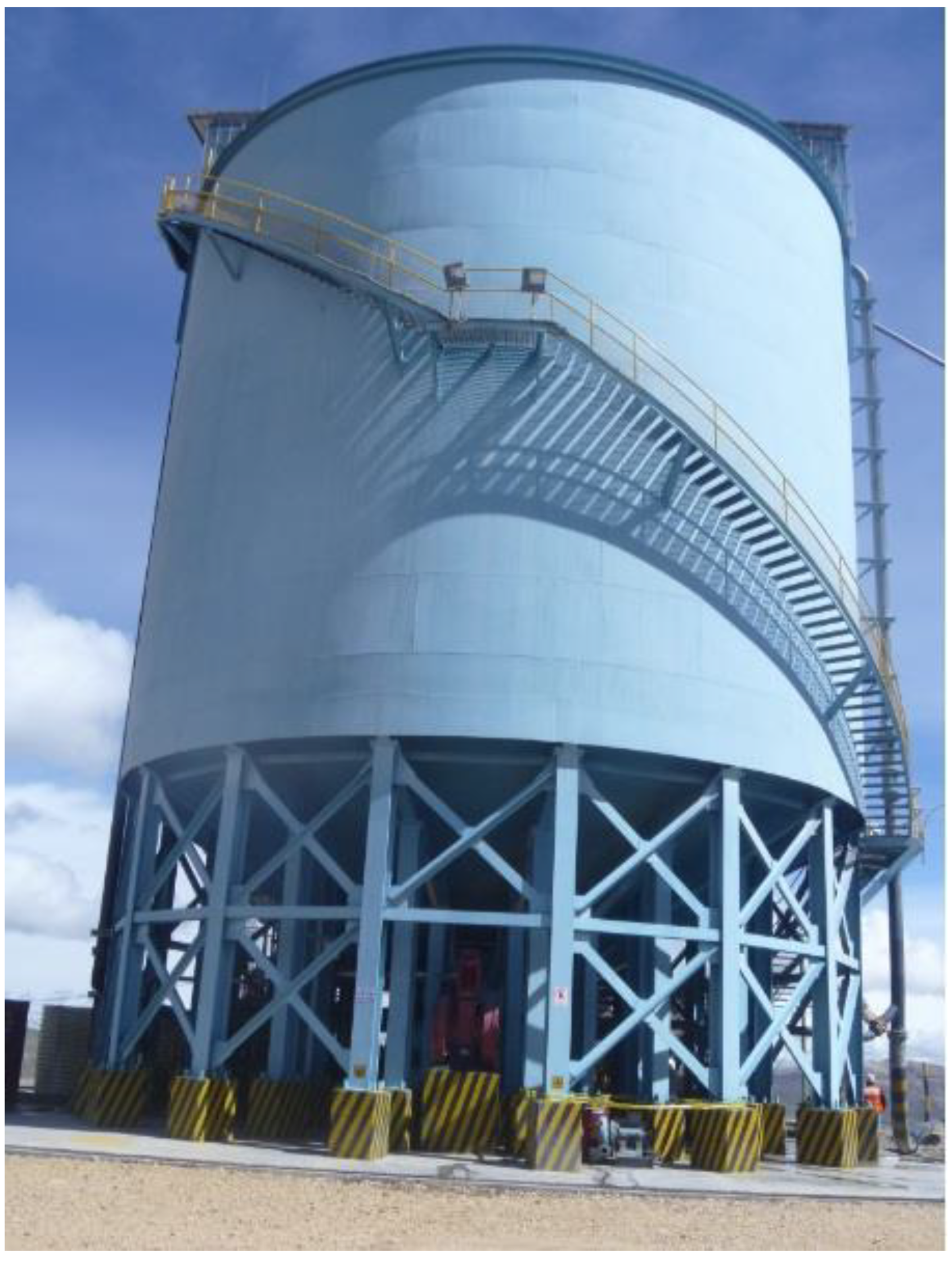

2.4. Paste or Deep Cone Thickeners (DCT)

3. Control and Performance of Tailings Thickening Plant

4. Thickened Tailings Transport

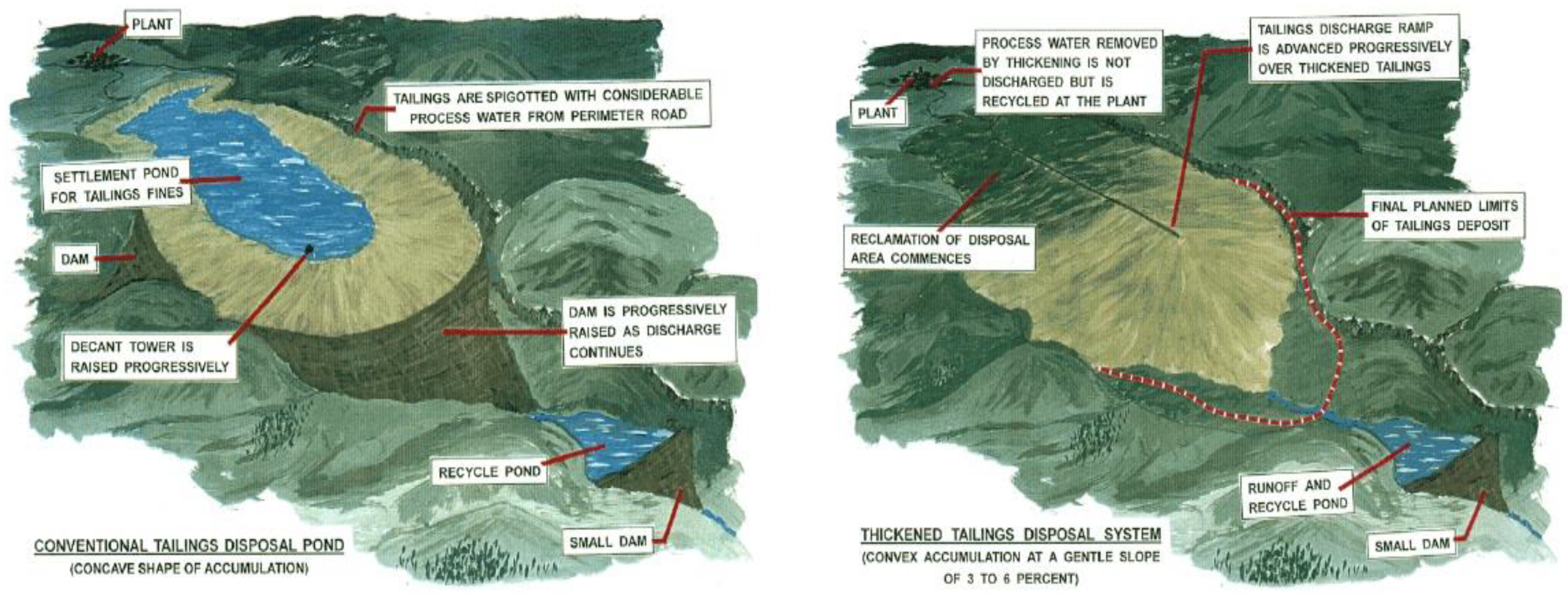

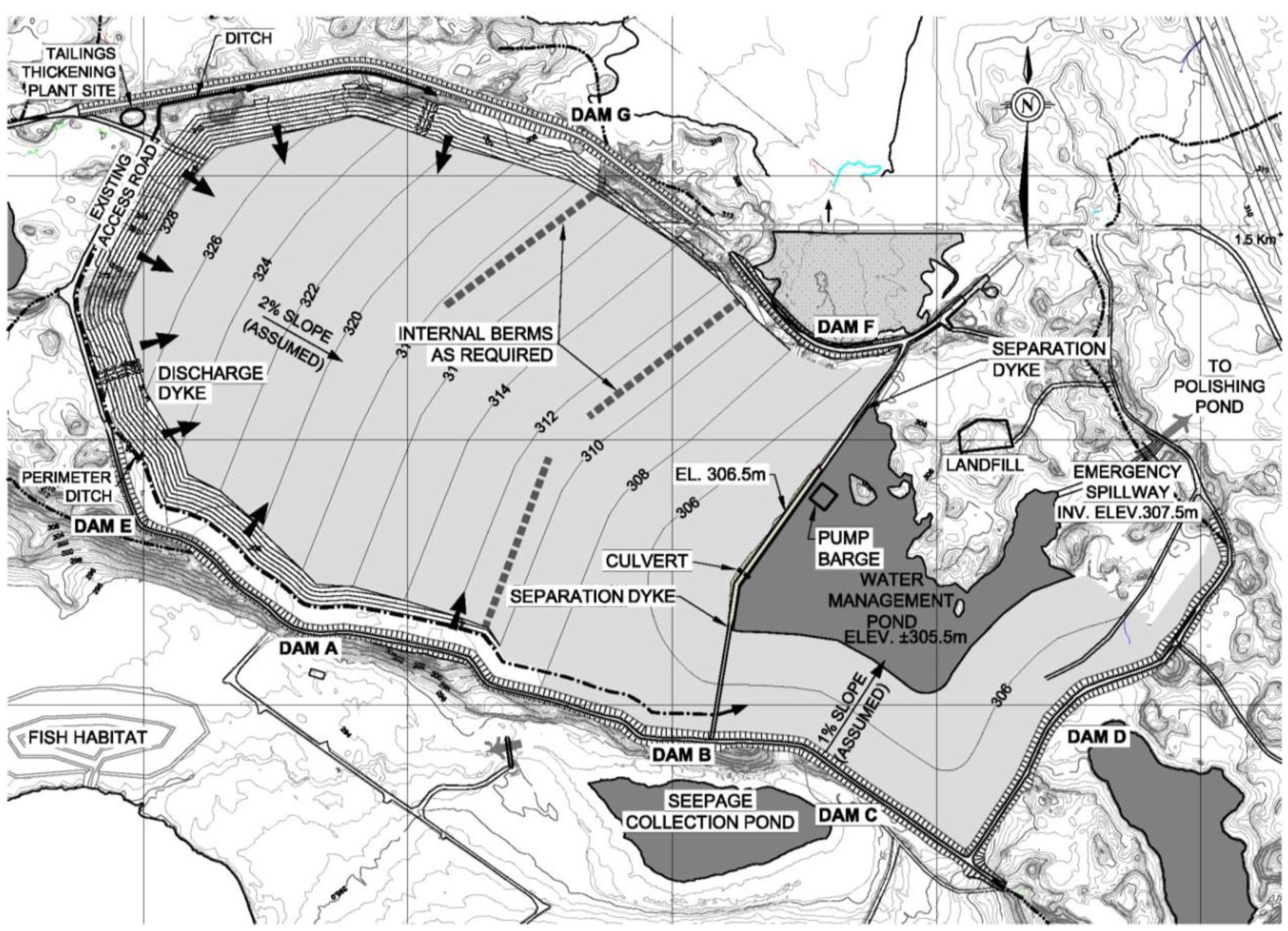

5. Thickened Tailings Disposal

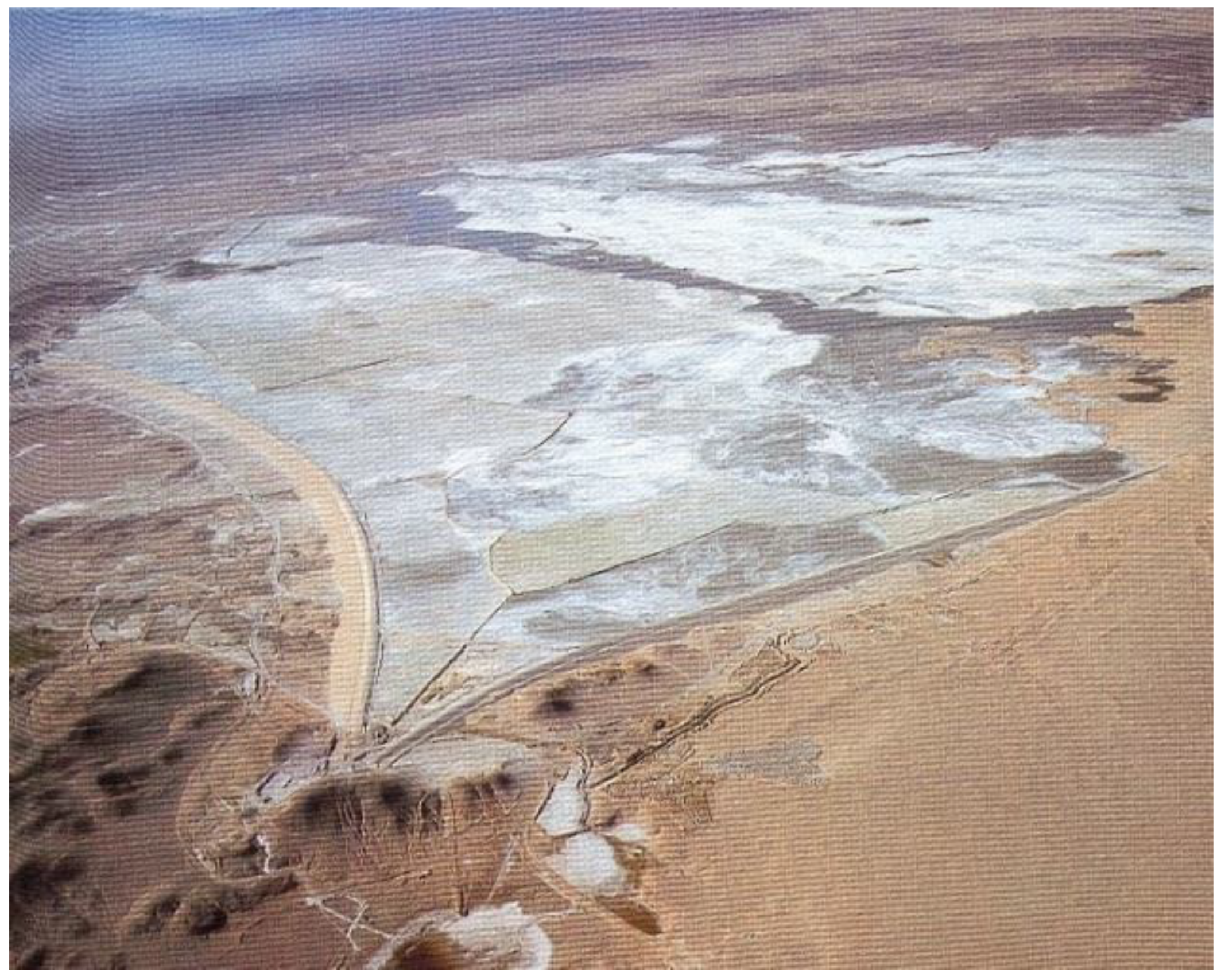

5.1. Down Valley Discharge (DVD)

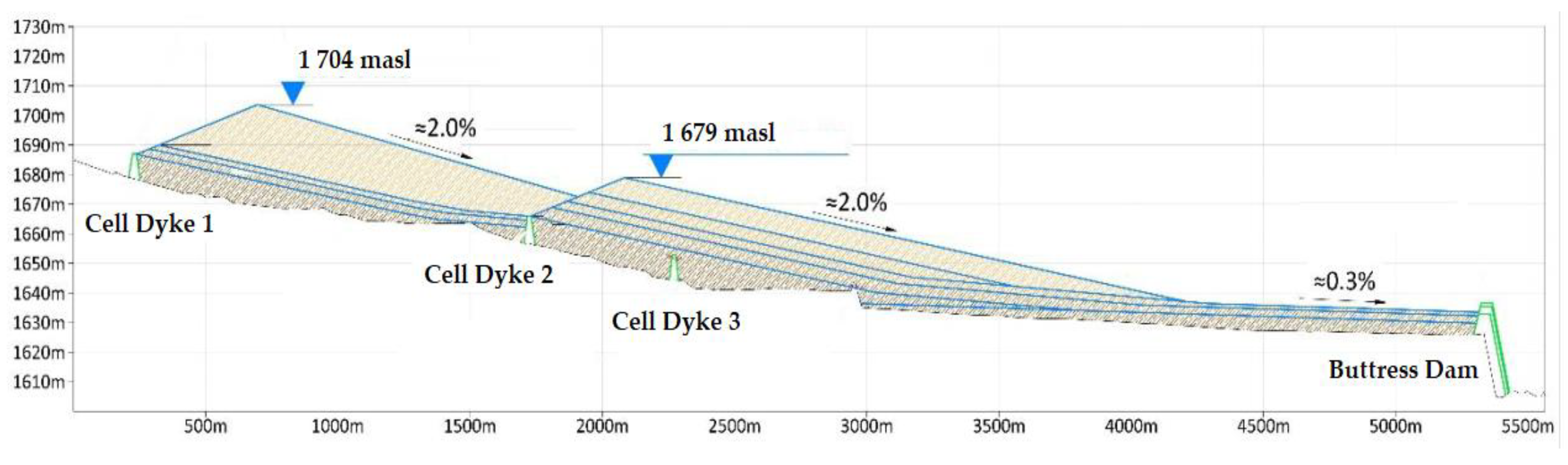

5.2. Cell Dyke Disposal (CDD)

6. Thickened Tailings Experiences—State of Practice

7. Successful Cases in Chile and Peru

7.1. Demo Plant Paste Tailings—Down Valley Discharge—Collahuasi—Chile

7.2. Las Cenizas Paste Tailings—Down Valley Discharge—Cabildo—Chile

7.3. Delta Paste Tailings—Down Valley Discharge—Ovalle—Chile

7.4. El Toqui Paste Tailings—Down Valley Discharge—Coyhaique—Chile

7.5. Alhué Paste Tailings—Down Valley Discharge—Yamana Gold—Chile

7.6. Centinela Thickened Tailings—Cell Dyke Disposal—Antofagasta Minerals—Chile

- Cells 1 and 2: Discharges from dykes to the upper sector of the TSF through spigots.

- Cell 3: Discharge from Chinese Wall 1 towards the J2 dyke basin through spigots.

- Cell 4: Discharge through tailings pipes inside the deposit towards the J1 dyke basin. The J1 dyke basin is subdivided into five sub-deposits by means of 4 dykes built inside it, which allow the deposition to be alternated. Work is constantly being carried out on installing spigots from the J2 dyke crest.

- Cell 5: Discharge through a tailings channel through the Caracoles sector to the South dike.

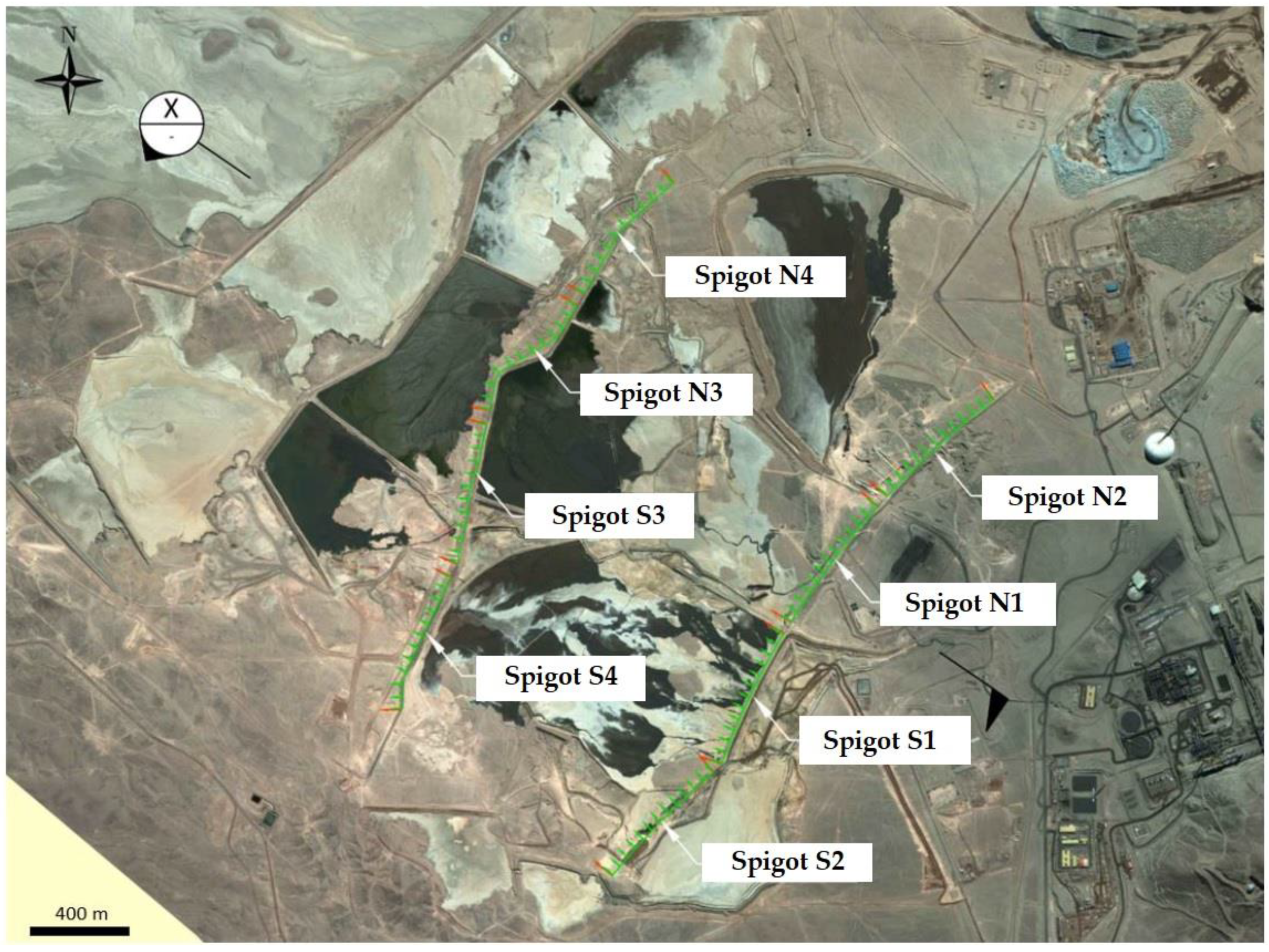

7.7. Sierra Gorda Thickened Tailings—Cell Dyke Disposal—KGHM—Chile

7.8. Spence Thickened Tailings—Cell Dyke Disposal—BHP—Chile

7.9. Talabre Thickened Tailings—Cell Dyke Disposal—Codelco—Chile

- Flocculent plant: facilities for the preparation of reagents and distribution and injection pumps to the tailings feed lines.

- Electrical room.

- Control and operation room, offices.

- Recirculating water reservoir (120,000 m3 capacity).

7.10. Los Corralillos Thickened Tailings—Down Valley Discharge—Cerro Negro Norte CMP—Chile

7.11. Carmen de Andacollo Thickened Tailings—Down Valley Discharge—Teck—Chile

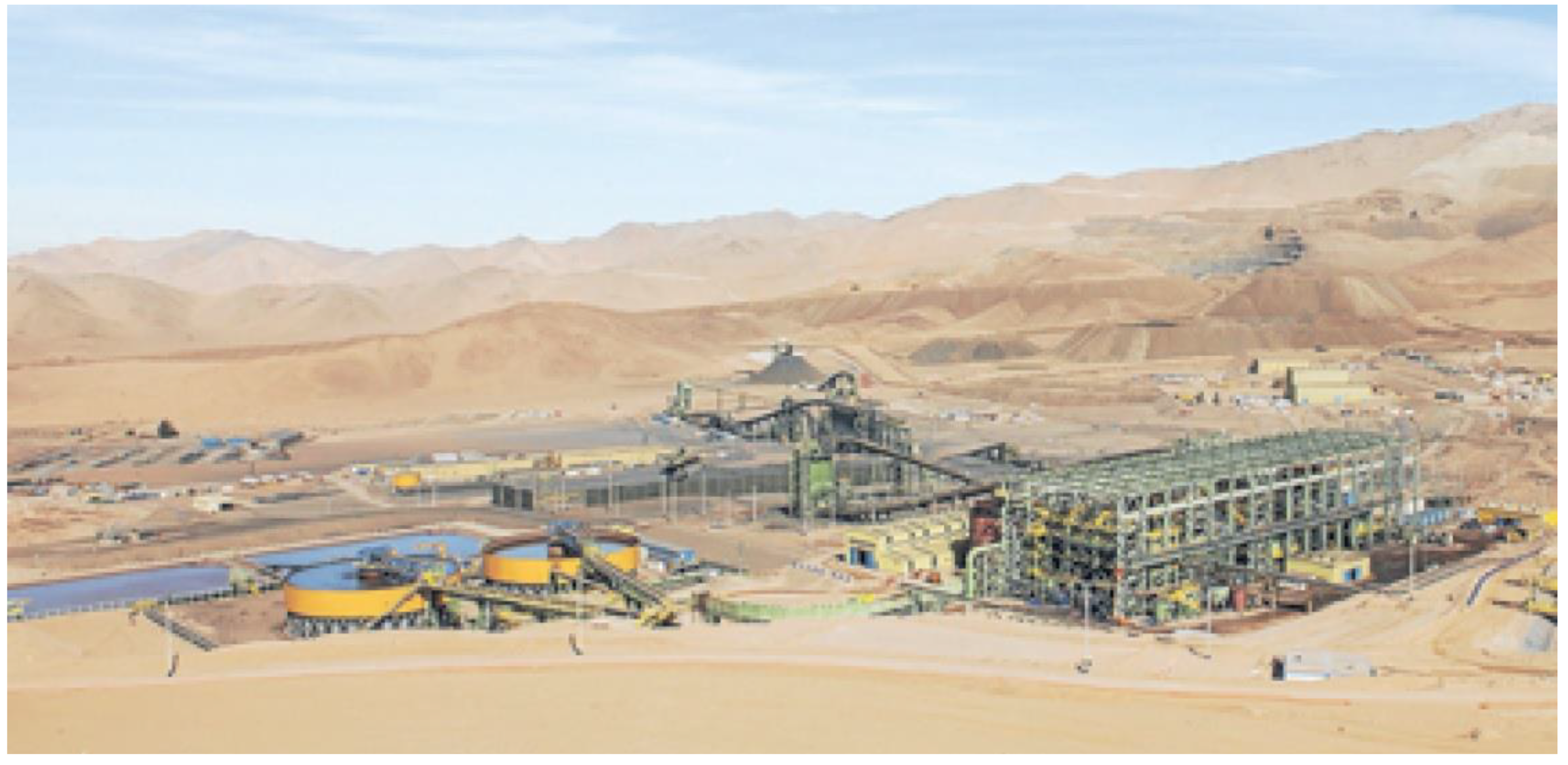

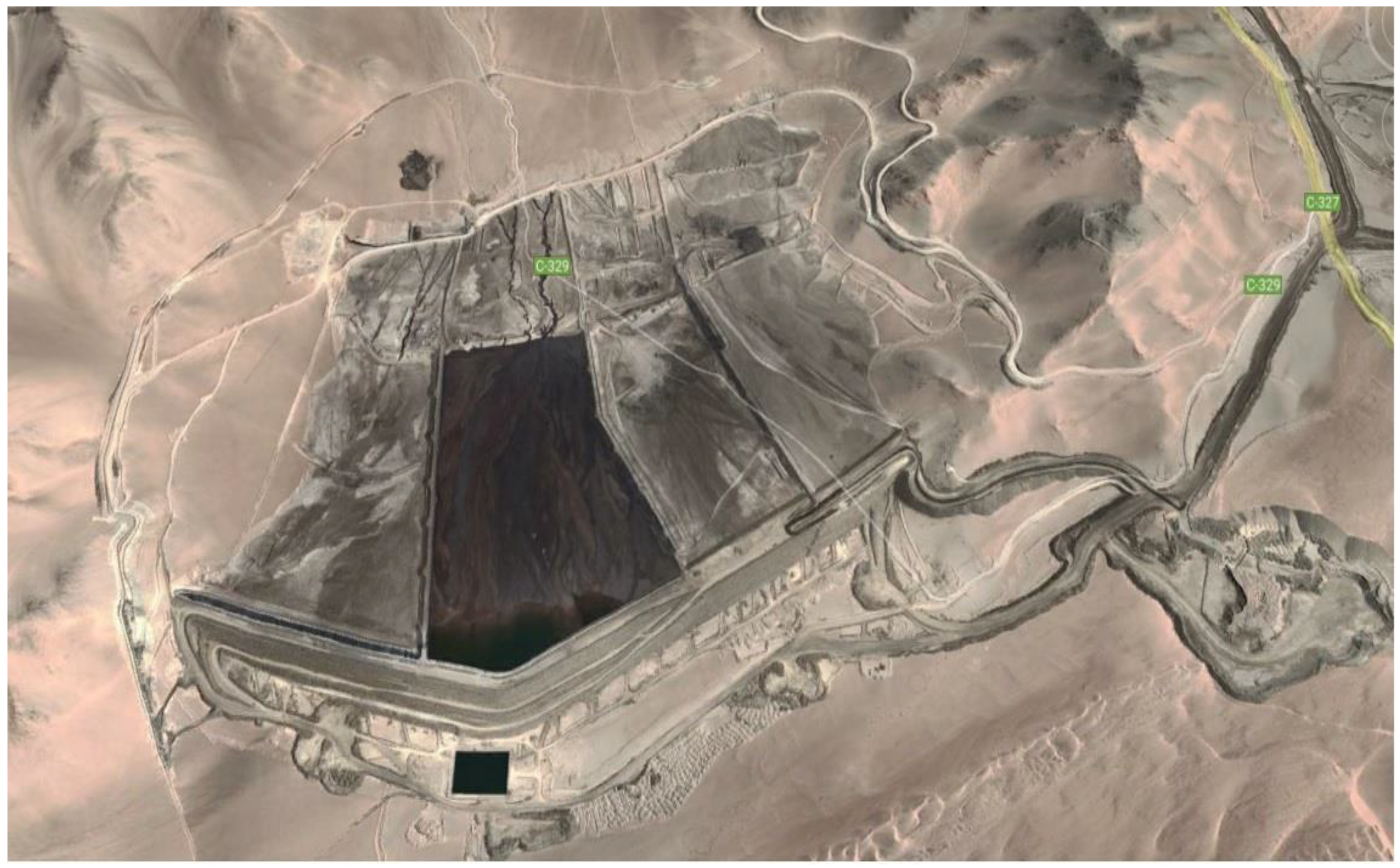

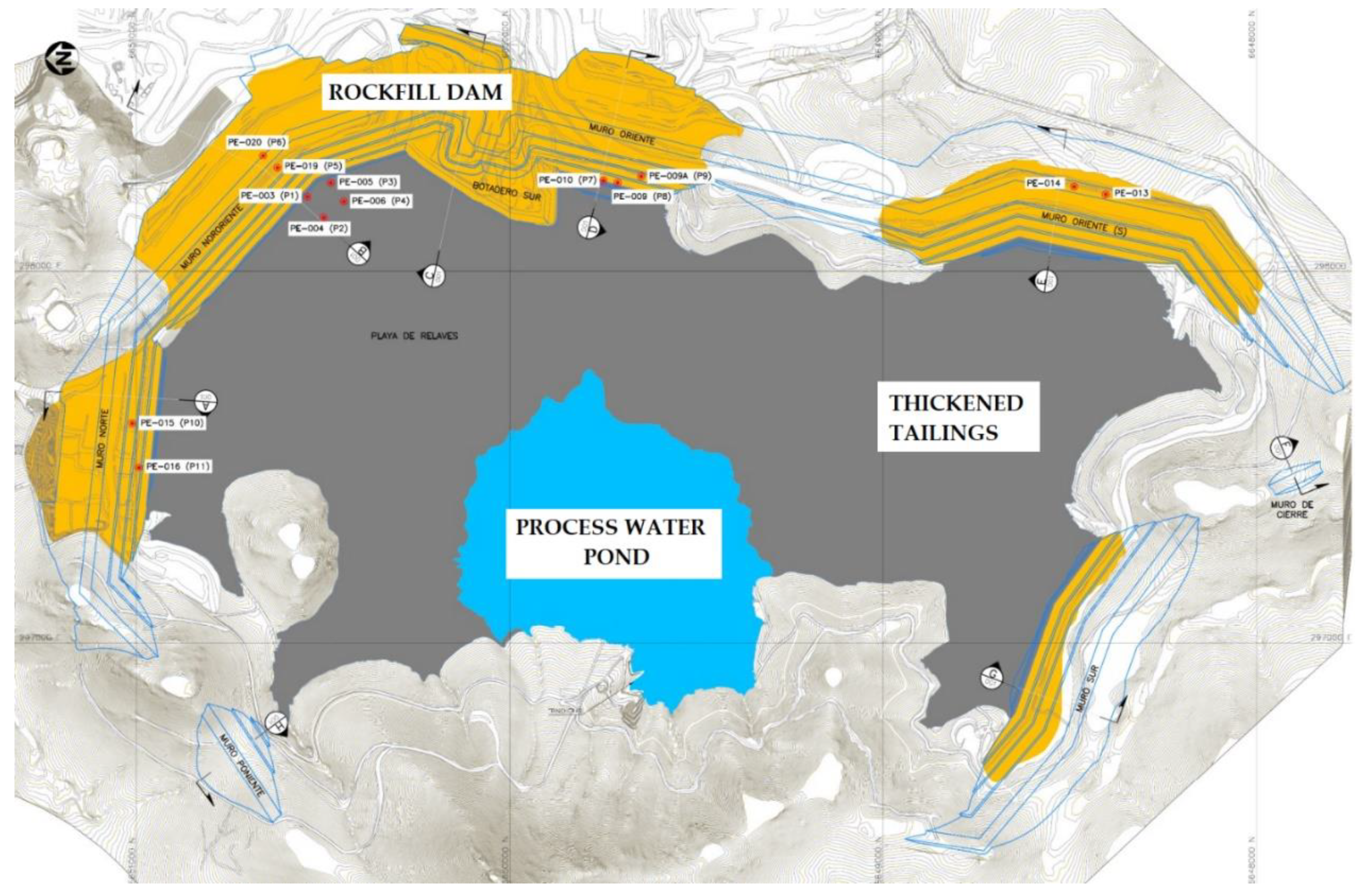

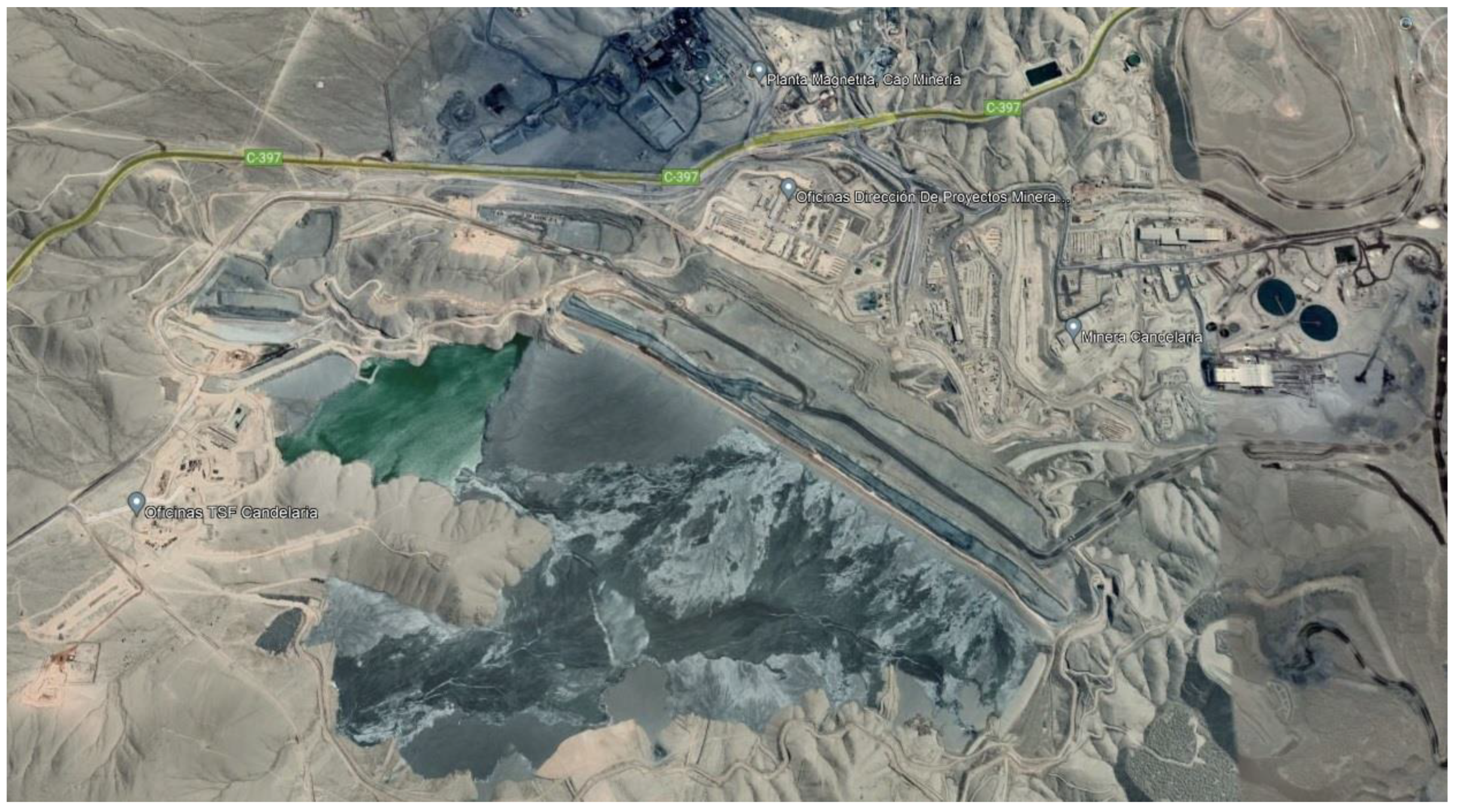

7.12. Los Diques Thickened Tailings—Down Valley Discharge—Candelaria—Chile

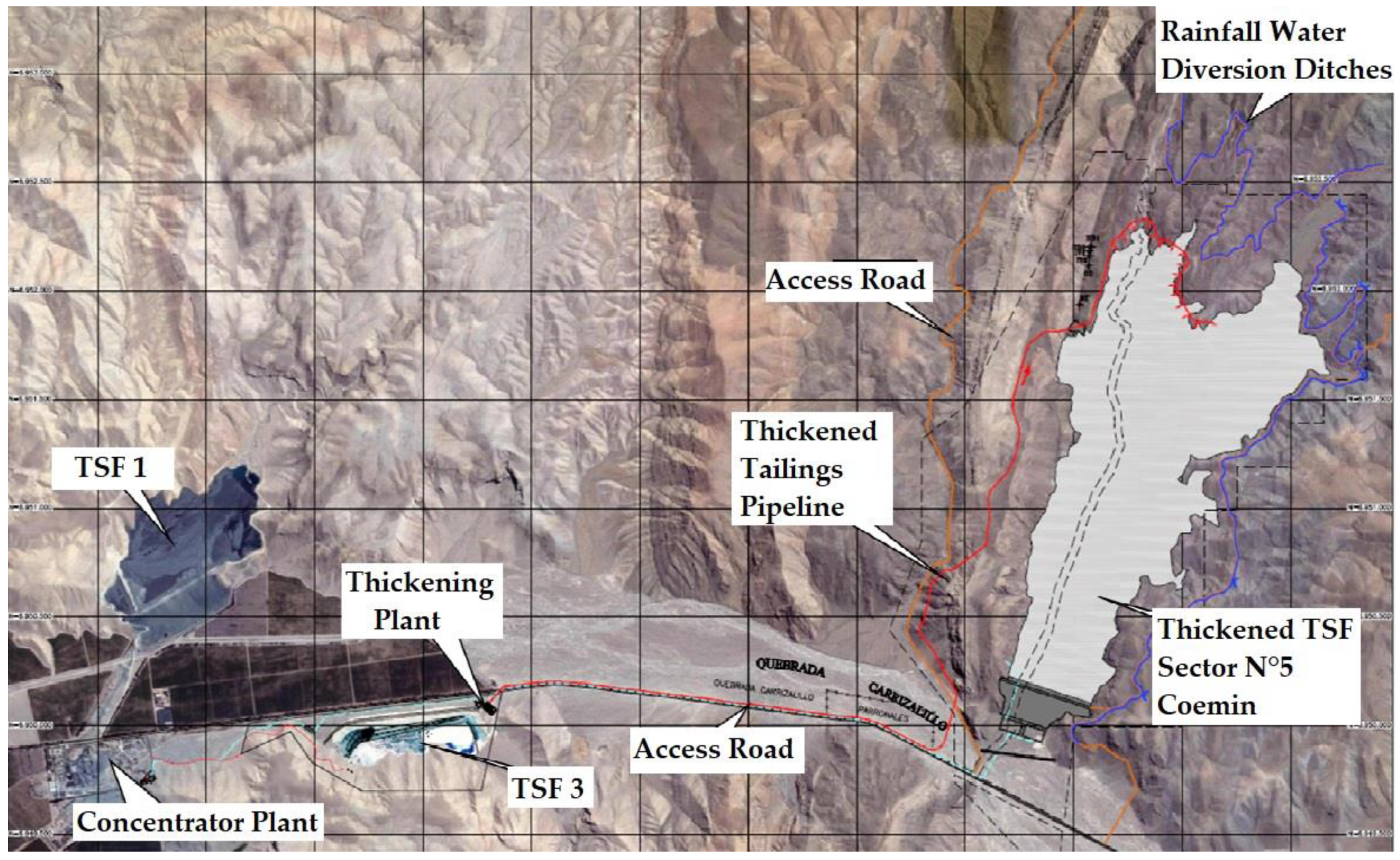

7.13. Sector N°5 Paste Tailings—Down Valley Discharge—Coemin—Chile

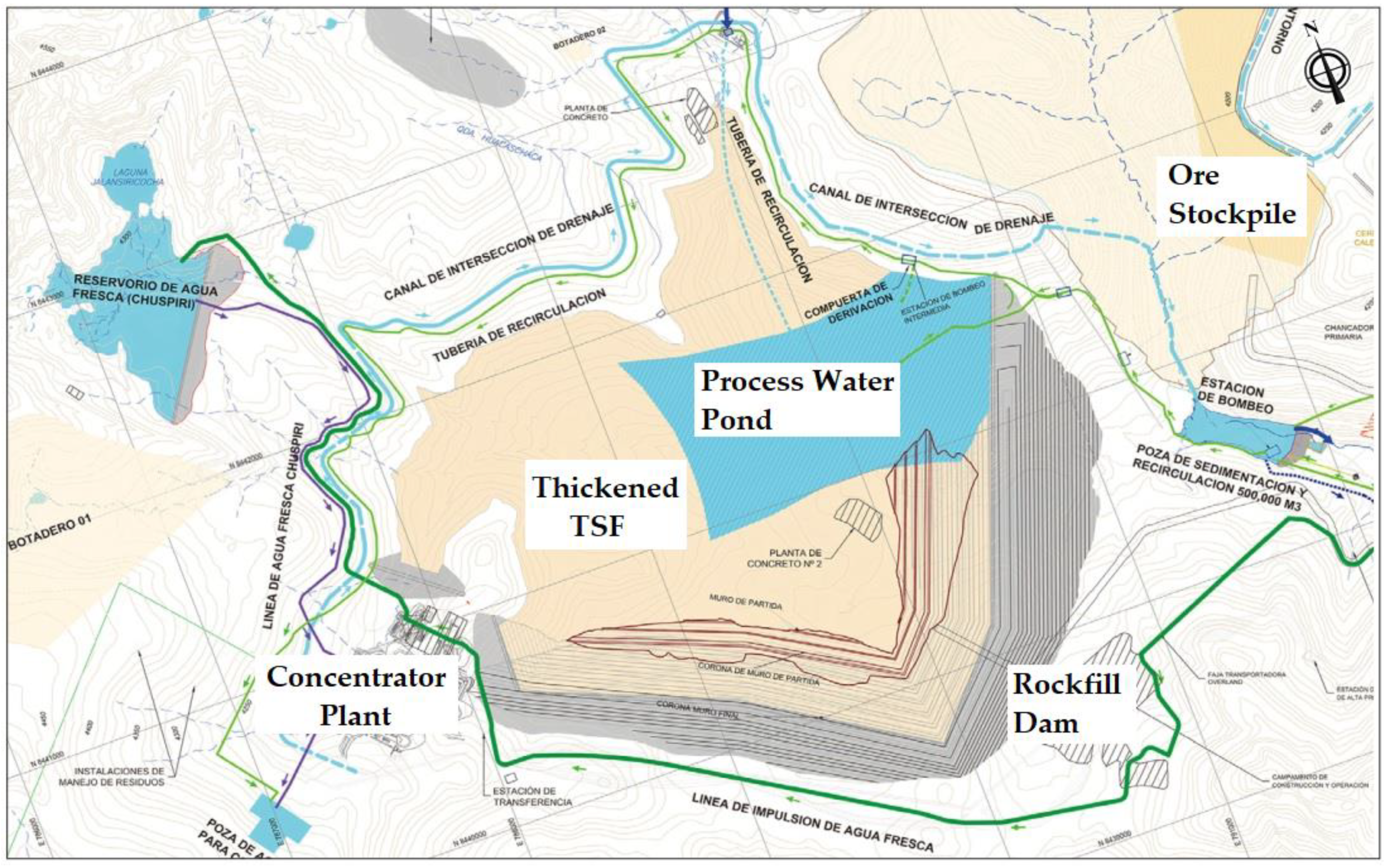

7.14. Toromocho Thickened Tailings—Down Valley Discharge—Chinalco—Peru

- The tailings pond is small and easy to manage during operations and upon closure;

- A homogeneous tailings deposit has lower susceptibility to oxidation due to a higher degree of saturation maintained in the tailings deposit;

- Lower seepage rates from the base of the facility because of the homogeneity and density of the tailings;

- A lower overall dam height; and

- Significantly reduced risk compared with the other alternatives because there is no pond trapped on top of the tailings to transport the tailings long distances in the event of a dam failure.

7.15. Antapaccay Thickened Tailings—In Pit Tailings Disposal—Tintaya—Peru

7.16. Las Bambas Thickened Tailings—Down Valley Discharge—MMG—Peru

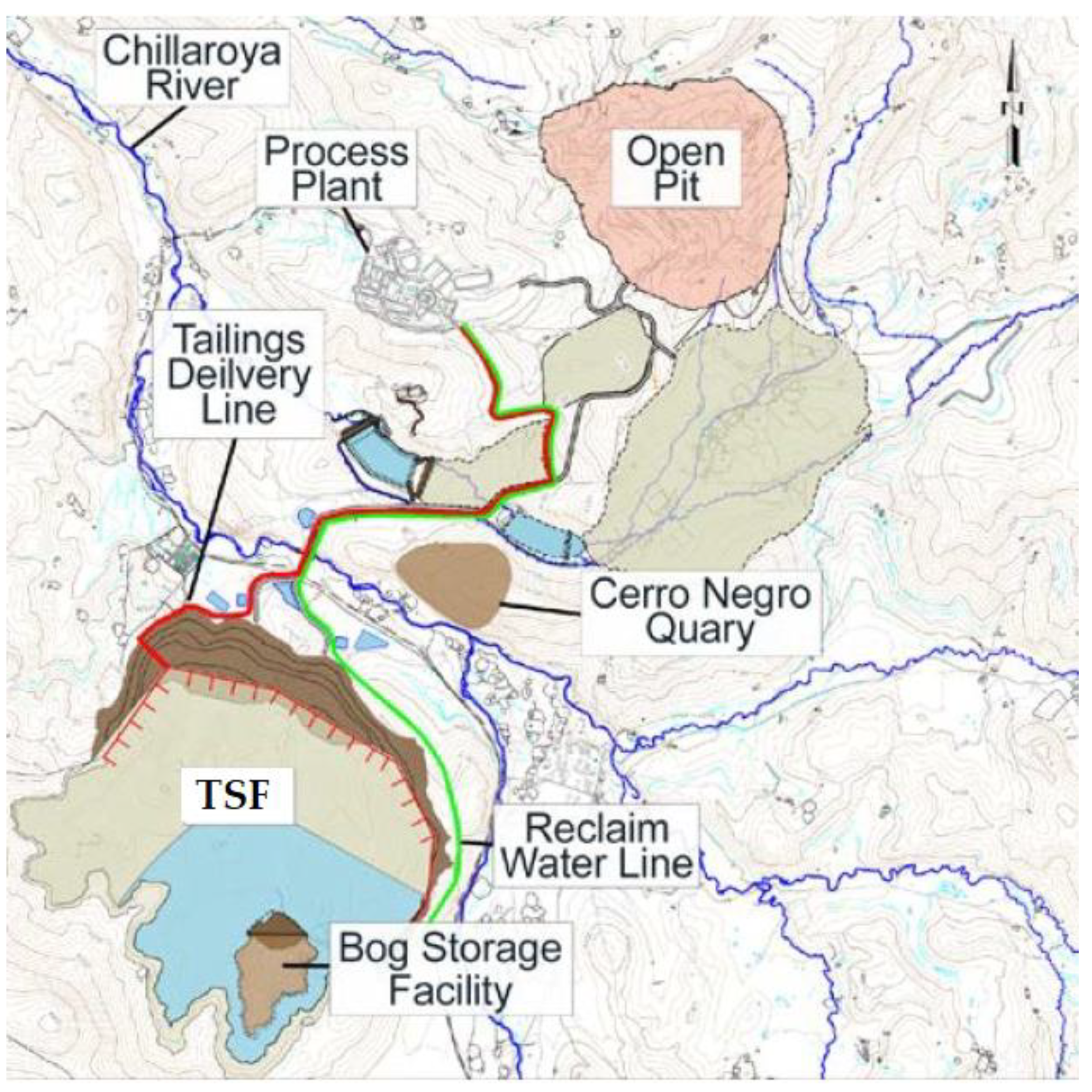

7.17. Constancia Thickened Tailings—Down Valley Discharge—Hudbay—Peru

7.18. Chungar Paste Tailings—Down Valley Discharge—Volcan—Peru

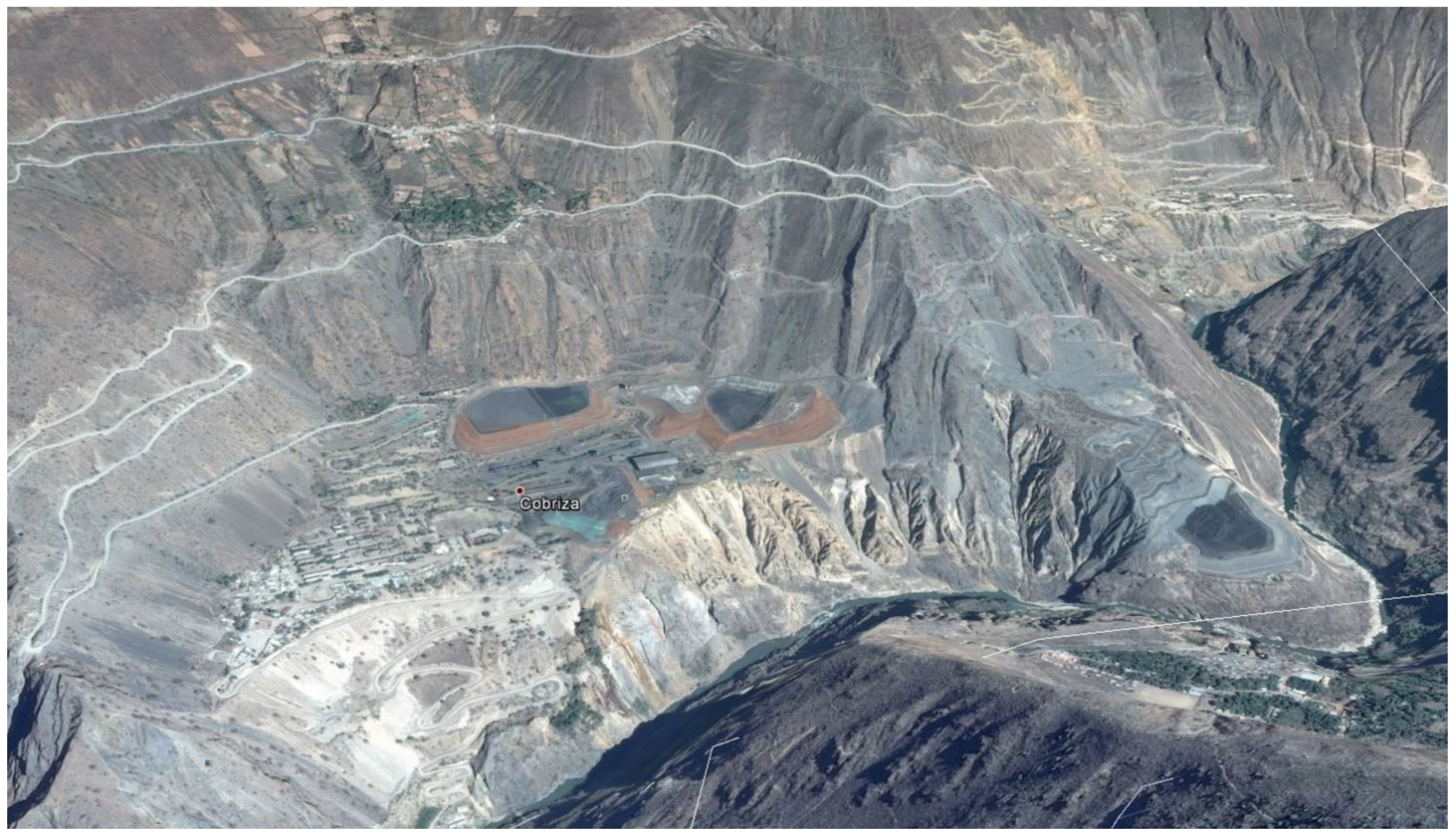

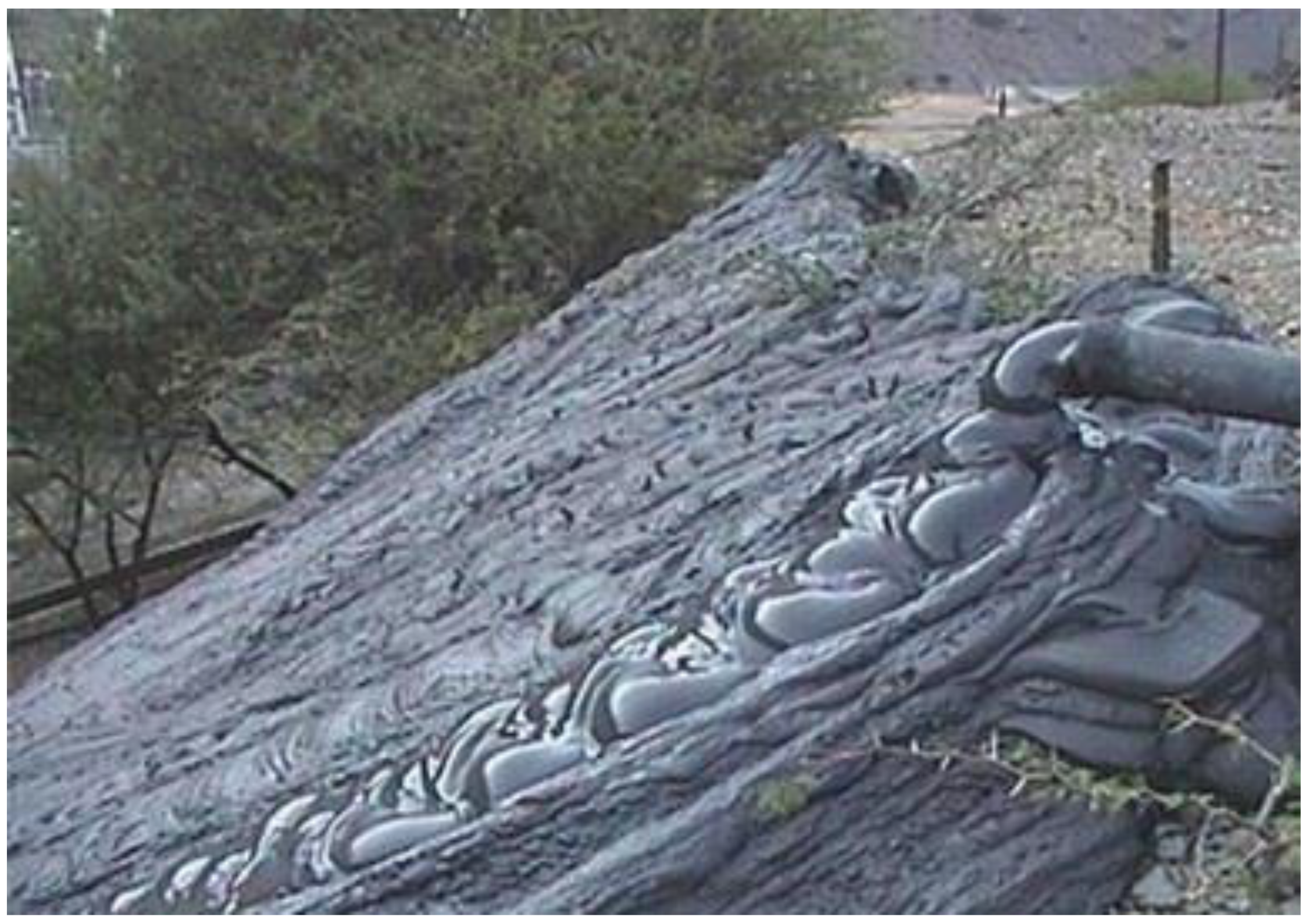

7.19. Cobriza Paste Tailings—Down Valley Discharge—Doe Run—Peru

7.20. Rumichaca Paste Tailings—Down Valley Discharge—Volcan—Peru

7.21. Huachuacaja Thickened Tailings—Down Valley Discharge—El Brocal—Peru

- Tajo Norte: Open-Pit Mine—produces minerals such as Ag, Pb, Zn, and Cu

- Marca Punta Norte: Underground Mine—produces Cu

- Tailings depositional slope of 2.0%

- Tailings discharged from west side of the valley and from tailings dam

- 28 discharge tailing points, which were built every 200 m approx. (Figure 61)

- Dry tailings deposition density of 1.59 t/m3

- Average production of tailings: 16,740 mtpd

- Annual average volume of the deposit tailing pond: 3.0 million m3

- Capacity: 123 million tons

- Estimated lifetime: 20 years

- Spigots (every 200 m) of diameter of 8” from HDPE SDR-13

7.22. Cerro Corona Thickened Tailings—Down Valley Discharge—GoldFields—Peru

7.23. La Quinua Thickened Tailings—Down Valley Discharge—Newmont—Peru

- Pipe material: Steel

- Pipe diameter: 300 mm

- Pipeline Length: 4 km

- Pump station: Centrifugal pumps

- Solid concentration by weight (Cw): 65 to 71%

- Yield stress: 8.5 Pa

8. Opportunities for Tailings Management Improvement in Chile, Peru and Worldwide

9. Discussions—Strengths and Limitations of Thickened Tailings from Practical Experiences Presented

9.1. Strengths

- Higher water recovery during processing, less water to be managed at the TSF.

- May be non-segregating, producing a tailings product with potentially low hydraulic conductivity.

- Thickened and paste tailings can be more easily closed as a “dry” facility than a conventional TSF.

- Failure if it occurs, would likely be local slumping and consequences would be restricted to the local area.

9.2. Limitations

- High-density thickeners require operational attention and are subject to system “upsets” from tailings variability, gradation or operator error.

- It could take months to years to optimize the thickening system to produce a consistent tailings product and the achieved solids content (Cw) is often at least 5% lower than the design target.

- Positive displacement pumps (PD Pumps) may be required for tailings transportation, which are more expensive and more challenging to operators.

- Beach slopes are difficult to predict and will vary depending on operational practices, tailings properties and weather.

- Significant drying time (if required for physical stability) is often not achieved in wet climates and may require a large drying area and rotation of the tailings discharge points (spigots).

10. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| TSF | Tailings Storage Facility |

| BATs | Best Available Technologies |

| TTD | Thickened Tailings Disposal |

| PTD | Paste Tailings |

| CT | Conventional Thickener |

| HRT | High Rate Thickener |

| HDT | High Density Thickener |

| HCT | High Compression Thickener |

| DCT | Deep Cone Thickener |

| Cw | Slurry tailings solids content by weight |

| mtpd | Metric tonnes per day |

| DVD | Down Valley Discharge |

| CDD | Cell Dyke Disposal |

| PD Pumps | Positive Displacement Pumps |

| masl | Meters above sea level |

| U/F | Thickener Underflow |

| FR | Thickener Feed Solid Rate |

| FD | Thickener Flocculent Dosage |

References

- Barrera, S.; Cacciuttolo, C.; Caldwell, J. Reassessment of Best Available Tailings Management Practices. In Proceedings of the 19th International Conference on Tailings and Mine Waste T&MW 2015, Vancouver, BC, Canada, 30 January 2015. [Google Scholar]

- Cacciuttolo, C.; Tabra, K.; Sandoval, M. Efficient Use of Water in Tailings Management: New Methodologies for the Future. In Proceedings of the Water Week Latinoamerica 2015 Congress, Viña del Mar, Chile, 24–27 March 2015. [Google Scholar]

- Cacciuttolo Vargas, C.; Perez Campomanes, G. Practical Experience of Filtered Tailings Technology in Chile and Peru: An Environmentally Friendly Solution. Minerals 2022, 12, 889. [Google Scholar] [CrossRef]

- Watson, A.H.; Corser, P.G.; Garces Pardo, E.E.; Lopez Christian, T.E.; Vandekeybus, J. A comparison of alternative tailings disposal methods—The promises and realities. In Proceedings of the First International Seminar on the Reduction of Risk in the Management of Tailings and Mine Waste, Perth, Australia, 29 September–1 October 2010; Jewell, R., Fourie, A.B., Eds.; pp. 499–514. [Google Scholar] [CrossRef]

- Diez, A. Experiencia de los Relaves en Pasta de Delta. In Proceedings of the 3rd Paste Tailings Seminar, RELPAS, Santiago, Chile, 2011; Available online: http://www.relpas.cl/neo_2011/pdf/2011/M3/03%20Alejandro%20Diez.pdf (accessed on 12 March 2016).

- Schoenberger, E. Environmentally sustainable mining: The case of tailings storage facilities. Resour. Policy 2016, 49, 119–128. [Google Scholar] [CrossRef]

- Williams, D.J. Lessons from Tailings Dam Failures—Where to Go from Here? Minerals 2021, 11, 853. [Google Scholar] [CrossRef]

- Global Tailings Review. Towards Zero Harm: A compendium of papers. Chapter ii Mine Tailings Facilities: Overview and Industry Trends. 2022. Available online: https://globaltailingsreview.org/compendium/ (accessed on 3 August 2022).

- East, D.; Fernandez, R. Managing Water to Minimize Risk in Tailings Storage Facility Design, Construction, and Operation. Mine Water Environ. 2021, 40, 36–41. [Google Scholar] [CrossRef]

- Wu, D. Solutions for Surface Disposal of Mine Tailings. In Mine Waste Management in China: Recent Development; Springer: Singapore, 2020. [Google Scholar] [CrossRef]

- Edraki, M.; Baumgartl, T.; Manlapig, E.; Bradshaw, D.; Franks, D.M.; Moran, C.J. Designing mine tailings for better environmental, social and economic outcomes: A review of alternative approaches. J. Clean. Prod. 2014, 84, 411–420. [Google Scholar] [CrossRef]

- Cacciuttolo, C.; Valenzuela, F. Efficient Use of Water in Tailings Management: New Technologies and Environmental Strategies for the Future of Mining. Water 2022, 14, 1741. [Google Scholar] [CrossRef]

- Cacciuttolo, C.; Barrera, S.; Caldwell, J.; Vargas, W. Filtered Dry Stacked Tailings: Developments and New Trends. In Proceedings of the 2nd International Seminar on Tailings Management, Antofagasta, Chile, 6–8 August 2014. [Google Scholar]

- Schoenbrunn, F.; Laros, T. Design features and types of sedimentation equipment. Miner. Process. Plant Des. Pract. Control. Proc. 2002, 2, 1331. [Google Scholar]

- Schoenbrunn, F. Dewatering to higher densities. In Proceedings of the 14th International Seminar on Paste and Thickened Tailings, Perth, Australia, 5–7 April 2011. [Google Scholar]

- Jewell, R.J.; Fourie, A.B. (Eds.) Paste and Thickened Tailings—A Guide, 3rd ed.; The Australian Centre of Geotechnics (ACG) and the University of Western Australia: Perth, Australia, 2015. [Google Scholar]

- Slottee, J.S.; Johnson, J. Paste Thickener Design and Operation Selected to Achieve Downstream Requirements. In Proceedings of the 12th International Seminar on Paste and Thickened Tailings, Viña Del Mar, Chile, 21–24 April 2009. [Google Scholar]

- AVA Montajes. Espesador High Rate de Relaves Collahuasi. Available online: https://www.ava.cl/proyectos-en-ejecucion/proyecto-collahuasi (accessed on 15 July 2022).

- Schoenbrunn, F.; Laros, T. Dry Tailings Disposal Using Hi-Density Thickening. In Proceedings of the Fourth International Conference on Tailings and Mine Waste ‘97, Fort Collins, CO, USA, 13–17 January 1997; pp. 357–363. [Google Scholar]

- Pulgar, F.; Jeldres, R.; Concha, F.; Toledo, P. Uso de Agua de Mar en Minería Avances en el Espesamiento de Relaves Ricos en Arcillas; Centro de Recursos Hídricos para la Agricultura y la Minería CRHIAM, Universidad de Concepción: Concepcion, Chile, 2022. [Google Scholar]

- Cochilco, Comisión Chilena del Cobre. Informe de Actualización del Consumo Energético de la Minería del Cobre al año 2018. Ministerio de Minería. 2019. Available online: https://www.cochilco.cl/Mercado%20de%20Metales/Informe%20de%20Consumo%20de%20Energ%C3%ADa%202018.pdf (accessed on 15 August 2022).

- ASTM C143/C143M-00; Standard Test Method for Slump of Hydraulic-Cement Concrete. Annual Book of ASTM Standards, Vol. 04.02. American Society for Testing and Materials: West Conshohocken, PA, USA, 2003.

- Valdebenito, R.; Paredes, L. Recent experiences on TTD thickened tailings in Chile. In Proceedings of the 1st International Seminar on Tailings Management, Santiago, Chile, 1–3 August 2013. [Google Scholar]

- Pornillos, E. A technique for measuring the reduction of yield stress of thickened tailings. In Proceedings of the 14th International Seminar on Paste and Thickened Tailings, Perth, Australia, 5–7 April 2011; Jewell, R., Fourie, A.B., Eds.; Australian Centre for Geomechanics: Perth, Australia, 2011; pp. 167–174. [Google Scholar]

- Robinsky, E.I. Tailings disposal by the thickened discharge method for improved economy and environmental control. Tailings Disposal Today. In Proceedings of the 2nd International Tailings Symposium, Denver, CO, USA, May 1978. [Google Scholar]

- Robinsky, E.I. Thickened Tailing Disposal in any Topography. In Essential Readings in Light Metals; Donaldson, D., Raahauge, B.E., Eds.; Springer: Cham, Germany, 2016. [Google Scholar] [CrossRef]

- MacNamara, L.; Khoshniaz, N.; Hashemi, S. The Sarcheshmeh thickened tailings disposal projectin. In Proceedings of the 14th International Seminar on Paste and Thickened Tailings, Perth, Australia, 5–7 April 2011; Jewell, R., Fourie, A.B., Eds.; Australian Centre for Geomechanics: Perth, Australia, 2011; pp. 237–243. [Google Scholar] [CrossRef] [Green Version]

- Roshdieh, A.; Williams, P.; Seddon, K.D. The Sarcheshmeh thickened tailings scheme—A case study. In Proceedings of the 18th International Seminar on Paste and Thickened Tailings, Cairns, Australia, 5–7 May 2015; Jewell, R., Fourie, A.B., Eds.; Australian Centre for Geomechanics: Perth, Australia, 2015; pp. 587–595. [Google Scholar] [CrossRef]

- McPhail, G.; Bello, F.; Engels, J. Beach Profile Modeling at Centinela Mine, Chile. In Proceedings of the 4th International Seminar on Tailings Management TAILINGS 2017, Santiago, Chile, 8 July 2017. [Google Scholar]

- Engels, J.; Gonzalez, H.; Aedo, G.; McPhail, G.I. Implementation of spigot discharge systems for high-density tailings at Sierra Gorda Sociedad Contractual Minera, Chile. In Proceedings of the 21st International Seminar on Paste and Thickened Tailings, Perth, Australia, 11–13 April 2018; Jewell, R.J., Fourie, A.B., Eds.; Australian Centre for Geomechanics: Perth, Australia, 2018; pp. 389–400. [Google Scholar] [CrossRef]

- SEA (Servicio de Evaluación Ambiental). Estudio de Impacto Ambiental “Minerales primarios Minera Spence”. 2022. Available online: https://seia.sea.gob.cl/documentos/documento.php?idDocumento=2130577305 (accessed on 30 July 2022).

- Verdugo, R.; Echevarría, J.; Peters, G.; Caro, G. Feasibility Evaluation of Converting a Conventional Tailings Disposal in a Thickened Tailings Deposit. Paste and Thickened Tailings International Conference 2014, Vancouver Canada. 2014. Available online: http://www.cmgi.cl/publicaciones-web/peters/feasibility%20evaluation%20of%20converting%20a%20conventional%20tailings%20disposal%20in%20a%20thickened%20tailings%20deposit.pdf (accessed on 30 July 2022).

- Barrera, S.; Hills, R. Cerro Negro—Assessment of Beach Slope and Indetermination of the Operational Limits of Centrifugal Pumps. In Proceedings of the Twelfth International Seminar on Paste and Thickened Tailings, Viña del Mar, Chile, 21–24 April 2009; Jewell, R., Fourie, A.B., Barrera, S., Wiertz, J., Eds.; Australian Centre for Geomechanics: Perth, Australia, 2009; pp. 337–344. [Google Scholar] [CrossRef]

- Consejo Minero Teck. Plataforma Relaves Mineros Teck Carmen de Andacollo. 2022. Available online: https://consejominero.cl/comunicaciones/plataforma-de-relaves/teck/ (accessed on 14 April 2022).

- Sotil, A.; Soto, V.; Brouwer, K. Reducing Long Term Risk at the Candelaria Tailings Storage Facility. In Proceedings of the Tailings and Mine Waste 2020, Keystone, CO, USA, 15–18 November 2020; Available online: https://www.knightpiesold.com/sites/en/assets/File/TWM%202020%20-%20Reducing%20Long%20Term%20Risk%20at%20the%20Candelaria%20TSF.pdf (accessed on 12 April 2022).

- Valdebenito, R. Tranques de relaves espesados y en pasta en Chile. In Proceedings of the FLSmidth Tailings Disposal Seminar, Santiago, Chile, May 2012. [Google Scholar]

- Valdebenito, R. Webinar Relaves Espesados con Tecnologia Thickened Tailings Disposal (TTD). 2022. Available online: https://www.youtube.com/watch?v=C_b_dNY9rC4 (accessed on 12 June 2022).

- SEA (Servicio de Evaluación Ambiental). EIA: Depósito de Relaves en Pasta Minera Florida. 2015. Available online: http://seia.sea.gob.cl/documentos/documento.php?idDocumento=7889337 (accessed on 5 December 2015).

- Gridley, N.; Salcedo, S. Cemented Paste for Ore Recovery. In Proceedings of the 16th International Seminar on Paste and Thickened Tailings, Belo Horizonte, Brazil, 17–19 June 2013. [Google Scholar]

- Gutierrez, M.A. Tesis de Pregrado Operación de la Presa de Relaves del Proyecto Toromocho. Universidad Nacional de San Agustin, Arequipa, Peru. 2015. Available online: http://repositorio.unsa.edu.pe/bitstream/handle/UNSA/2671/IMgucoma.pdf?sequence=1&isAllowed=y (accessed on 12 April 2022).

- SENACE (Servicio Nacional de Certificación Ambiental para las Inversiones Sostenibles). Resumen Ejecutivo MEIA Antapaccay Expansión Tintaya Integración Coroccohuayco. 2018. Available online: https://www.senace.gob.pe/download/comunicaciones/eia-meia/antapaccay/Resumen-Ejecutivo_Antapaccay.pdf (accessed on 12 April 2022).

- Runge Pincock Minarco. Competent Person’s Report Las Bambas Mining Project. 2014. Available online: https://www1.hkexnews.hk/listedco/listconews/sehk/2014/0630/01208_1970351/e119.pdf (accessed on 12 April 2022).

- Ridlen, P.; Kerr, T.; Dominquez, G.; Varnier, J.B.; Toro, J. Design of a Centerline Method Tailings Dam using Mine Waste Rockfill in Peru. In Proceedings of the Tailings and Mine Waste 2018, Keystone, CO, USA, 30 September–2 October 2018. [Google Scholar]

- Lara, J.L.; Maldonado, R. Design and Operational Experience of the Animon High Density Tailings Deposit-Peru. In Proceedings of the 19th International Seminar on Paste and Thickened Tailings, Santiago, Chile, 3–6 July 2016. [Google Scholar]

- Gonzales, V. Cobriza’s cu Tailings Surface Stacking A Successful story. In Proceedings of the International Seminar on Paste and Thickened Tailings, Santiago, Chile, 20–22 April 2005; Jewell, R., Barrera, S., Eds.; Australian Centre for Geomechanics: Perth, Australia, 2005; pp. 261–270. [Google Scholar] [CrossRef]

- SENACE (Servicio Nacional de Certificación Ambiental para las Inversiones Sostenibles). INFORME N° 00931-2019-SENACE-PE/DEAR. Evaluación del Cuarto Informe Técnico Sustentatorio de la Unidad Minera Carahuacra, Presentado Por Volcan Compañía Minera S.A.A. 2019. Available online: https://cdn.www.gob.pe/uploads/document/file/1221404/inf-DEAR-931-2019-RD-18620200808-2289235-1102ruy.pdf (accessed on 12 April 2022).

- Pezo, J. Tailings Management and Operational Control in Huachuacaja RCF. In Proceedings of the 19th International Seminar on Paste and Thickened Tailings, Santiago, Chile, 3–6 July 2016. [Google Scholar]

- Corser, P.; Rogers, J.; Misiewicz, J.; Ross-Watt, D.; Gutierrez, J. Design, Construction and Operation of a Centerline Rockfill Tailing Dam with Low Permeability Core Zone. In Proceedings of the Tailings and Mine Waste 2011, Vancouver, Canada, 6–9 November 2011. [Google Scholar]

- Kerr, T.F.; Duryea, P.D.; Grobbelaar, W.; Hackney, K. Design of a Thickened Mill Sands Management System within a Heap Leach Pad. In Proceedings of the Tenth International Seminar on Paste and Thickened Tailings, Perth, Australia, 13–15 March 2007; Jewell, R., Fourie, A.B., Eds.; Australian Centre for Geomechanics: Perth, Australia, 2007; pp. 361–372. [Google Scholar]

- Loan, C.; Villanueva, M.L.; Saldía, N. Collahuasi paste thickener—Pilot and full scale results. In Proceedings of the 14th International Seminar on Paste and Thickened Tailings, Perth, Australia, 5–7 April 2011. [Google Scholar]

- Flores, I. Disposición de relaves en pasta Faena Cabildo. In Proceedings of the 3rd Paste Tailings Seminar, RELPAS, Santiago, Chile, 2011; Available online: http://www.relpas.cl/neo_2011/pdf/2011/M3/02%20Ivar%20Flores.pdf (accessed on 4 March 2016).

- Galaz, J. Estado del Arte en la Disposición de Relaves Espesados. In Proceedings of the 3rd Paste Tailings Seminar, RELPAS, Santiago, Chile, 2011; Available online: http://www.relpas.cl/neo_2011/pdf/2011/M1/01%20Juanita%20Galaz.pdf (accessed on 23 March 2016).

- Martin, J.; Lopez, A.; Barrera, S.; Jara, C. Mixed system of tailings disposal. In Proceedings of the 3rd International Seminar on Tailings Management, Santiago, Chile, 19–21 August 2015. [Google Scholar]

- Yamana Gold. Paste Tailings Disposal at Compañia Minera Florida Alhue, Chile. 2016. Available online: https://www.youtube.com/watch?v=m6EYsbmb0gQ (accessed on 12 June 2022).

- Consejo Minero Antofagasta Minerals. Plataforma Relaves Mineros Antofagasta Minerals Centinela. 2022. Available online: https://consejominero.cl/comunicaciones/plataforma-de-relaves/antofagasta-minerals-3/ (accessed on 14 April 2022).

- Barrera, S.; Engels, J. High-density thickening for large production rates: Main challenges. In Proceedings of the 21st International Seminar on Paste and Thickened Tailings, Perth, Australia, 11–13 April 2018; Jewell, R.J., Fourie, A.B., Eds.; Australian Centre for Geomechanics: Perth, Australia, 2018; pp. 35–42. [Google Scholar] [CrossRef]

- Martínez, J.; Franco, E. Propuesta de modelo de optimización de tiempo de vida útil de depósito de relaves espesados. Ingeniare Rev. Chil. Ing. 2019, 27, 236–245. [Google Scholar] [CrossRef]

- Consejo Minero KGHM. Plataforma Relaves Mineros KGHM Sierra Gorda. 2022. Available online: https://consejominero.cl/comunicaciones/plataforma-de-relaves/kghm-3/ (accessed on 14 April 2022).

- Servicio de Evaluación Ambiental (SEA). Declaración de Impacto Ambiental Ajustes Constructivos a Instalaciones de Relaves Espesados Proyecto Radomiro Tomic Codelco. 2022. Available online: https://infofirma.sea.gob.cl/DocumentosSEA/MostrarDocumento?docId=56/f2/eeb30796ef7365a8f0d0cf93fca9677d5fc2 (accessed on 30 July 2022).

- Consejo Minero CMP. Plataforma Relaves Mineros CAP Los Corralillos. 2022. Available online: https://consejominero.cl/comunicaciones/plataforma-de-relaves/cmp-2/ (accessed on 14 April 2022).

- CMP. Descripción Proyecto Minero Cerro Negro Norte CMP. 2008. Available online: http://www.plataformacaldera.cl/biblioteca/589/articles-64617_documento.pdf (accessed on 13 April 2022).

- TECK. INFORME TÉCNICO Inspección de Seguridad (DSI 2018) Compañía Minera TECK—Carmen de Andacollo (TECK-CDA). 2018. Available online: https://www.teck.com/media/DSI-2018-CDA.pdf (accessed on 12 April 2022).

- Lundin Mining. Presentation Minera Candelaria Tailings Storage Facilities Transition Experience. 2019. Available online: https://www.ecometales.cl/ecometales/site/docs/20191111/20191111114704/7_lundin_mining_candelara.pdf (accessed on 12 April 2022).

- Lundin Mining. Technical Report for the Candelaria Copper Mining Complex, Atacama Region, Region III, Chile. 2018. Available online: https://lundinmining.com/site/assets/files/3641/candelaria_2018_tr.pdf (accessed on 12 April 2022).

- SMA (Superintendencia del Medio Ambiente). Proyecto Deposito de Relaves en Pasta Sector 5, COEMIN S.A. 2021. Available online: https://ssa.sma.gob.cl/Documento/Descargar/269881 (accessed on 12 April 2022).

- Paterson, A.J.C. The pipeline transport of high density slurries—A historical review of past mistakes, lessons learned and current technologies. In Proceedings of the 14th International Seminar on Paste and Thickened Tailings, Perth, Australia, 5–7 April 2011. [Google Scholar]

- CHINALCO. Resumen Ejecutivo Modificación del Estudio de Impacto Ambiental Para el Proyecto de Expansión de la Unidad Minera Toromocho A 170 000 TPD. 2020. Available online: https://www.chinalco.com.pe/sites/default/files/meia/1.0%20Resumen%20Ejecutivo%20MEIA%20Toromocho.pdf (accessed on 12 April 2022).

- Johnson, J.; Vizcarra, J. Modernization of Chinalco Toromocho Copper Tailings Thickeners. In Proceedings of the 23rd International Conference on paste Thickened and Filtered Tailings, Santiago, Chile, 12 November 2020. [Google Scholar]

- CHINALCO. Entrevista al Gerente General Gerald Wolff en Convención Minera Perumin. 2009. Available online: https://www.youtube.com/watch?v=MbaM0rsRGQo (accessed on 19 June 2022).

- OEFA (Organismo de Evaluación y Fiscalizacion Ambiental). Plan de Evaluacion Ambiental en el Area de Influencia de la Unidad Minera Antapaccay en el año. 2018. Available online: http://visorsig.oefa.gob.pe/datos_de/PM0201/PM020102/01/PA/PA_180-2018-OEFA-DEAM-STEC.pdf (accessed on 12 April 2022).

- SENACE (Servicio Nacional de Certificación Ambiental para las Inversiones Sostenibles). Resumen Ejecutivo de la Tercera Modificación del Estudio de Impacto Ambiental de la Unidad Minera Las Bambas. 2016. Available online: http://ceropapel.senace.gob.pe/share/s/f7Zx6K39RmCIGnbrscekNw (accessed on 12 April 2022).

- Lozano, F.; Llaury, J.; Lara, F. Uso de Tecnologia de Punta en la Disposicion de Relaves Espesados en la Unidad Chungar. In Proceedings of the Congreso Nacional de Mineria, Lima, Peru, 10 November 2012. [Google Scholar]

- Schoenbrunn, F. High Tonnage Surface Stacking Impediments to Implementation. In Proceedings of the 8th International Seminar on Paste and Thickened Tailings, Santiago, Chile, 20–22 April 2005. [Google Scholar]

- Lara, J.L. Presentacion de Relaves Espesados y Filtrados en Perú, Instituto de Ingenieros de Minas, Jueves Minero. 2013. Available online: https://www.youtube.com/watch?v=0vcYR2gSPjk (accessed on 12 April 2022).

- Rogers, J.; Weber, C.; Corser, P.; MWH Canada; Gutierrez, J. Influence of tailings deposition environment on deposit homogeneity and interpretation of cone penetration test data: A case study from the Cerro Corona Mine. In Proceedings of the Tailings and Mine Waste 2015, Vancouver, BC, Canada, 6–9 November 2015. [Google Scholar]

- Franks, D.M.; Boger, D.V.; Cote, C.M.; Mulligan, D.R.Y. Sustainable Development Principles for the Disposal of Mining and Mineral Processing Wastes. J. Resour. Policy 2011, 36, 114–122. [Google Scholar] [CrossRef]

- Kinnunen, P.; Karhu, M.; Yli-Rantala, E.; Kivikytö-Reponen, P.; Mäkinen, J. A review of circular economy strategies for mine tailings. Clean. Eng. Technol. 2022, 8, 100499. [Google Scholar] [CrossRef]

- Beylot, A.; Bodénan, F.; Guezennec, A.; Muller, S. LCA as a support to more sustainable tailings management: Critical review, lessons learnt and potential way forward. Resour. Conserv. Recycl. 2022, 183, 106347. [Google Scholar] [CrossRef]

- Department of Industry, Tourism and Resources (DITR). Tailings Management, Leading Practice Sustainable Development Program (LPSDP) for the Mining Industry; Department of Industry, Tourism and Resources: Canberra, Australia, 2007. [Google Scholar]

- Araya, N.; Ramírez, Y.; Cisternas, L.A.; Kraslawski, A. Use of real options to enhance water-energy nexus in mine tailings management. Appl. Energy 2021, 303, 117626. [Google Scholar] [CrossRef]

- Cacciuttolo, C. Review of tailings management in Chile: Lessons learned, incipient progress of a holistic management, and future challenges in reducing socio-environmental impacts. In Proceedings of the 3rd International Seminar on Environmental Issues in Mining, Lima, Peru, 2–4 December 2015. [Google Scholar]

- Smith, L. Hydrogeology and Mineral Resource Development; The Groundwater Project: Guelph, ON, Canada, 2021. [Google Scholar]

| Parameter | Units | CT | HRT | HCT or HDT | Paste or DCT |

|---|---|---|---|---|---|

| Solid loading | tph/m2 | (0.02–2.0) | (0.35–1.5) | (0.4–1.0) | (0.3–0.8) |

| Maximum diameter | m | 125 | 100 | 80 | 30 |

| Flocculent dosing use | g/ton | No use | 10–15 | 20–30 | 30–50 |

| Tank thickener height | m | 1–3 | 3–5 | 4–8 | >8 |

| Cone angle | ° | 2–5 | 5 | 5–15 | 15–30 |

| U/F Solid content by weight | % | 30–45 | 45–60 | 60–65 | 65–75 |

| Tailings Bed Depth | m | <1 | 1–2 | 3–4 | 4–10 |

| Residence Time | h | 0.5–1 | 1–2 | 3–6 | 6–12 |

| Yield Stress | Pa | 0 | 0–30 | 30–50 | 50–300 |

| Torque K Factor | kN/m | <50 | <50 | <125 | >200 |

| Shear Thinning System | - | No | No | No–Yes | Yes |

| Manufacturer | Flocculent Name |

|---|---|

| SNF | Floerger 913-SH |

| Floerger 923-SH | |

| Tec-2050 | |

| BASF | Magnafloc 1011 |

| Magnafloc 155 | |

| Magnafloc 2025 | |

| Magnafloc 333 | |

| Rheomax 1050 | |

| Orica | Orifloc AP 2020 |

| Kemira | Superfloc A-110 |

| Tailings Storage Facility Name | Mining Company Name | Country | TSF Disposal Parameters | Reference | |||

|---|---|---|---|---|---|---|---|

| Production Rate (mtpd) | PSD d50 (µm) | Solids Content Cw (%) | Tailings Disposal Method | ||||

| Sarcheshmeh TSF | National Iranian Copper Industries Company | Iran | 96,000 | 57 | 60 (TT) | TTD | [27,28] |

| Kidd Creek TSF | Glencore | Canada | 8000 | 45 | 63 (TT) | TTD | [4] |

| Kimberley TSF | De Beers | South Africa | 25,000 | 45 | 55 (TT) | TTD | [4] |

| Ernest Henry TSF | Evolution | Australia | 20,000 | 55 | 75 (TT) | PTD | [4] |

| Century TSF | New Century Resources | Australia | 12,000 | 60 | 58 (TT) | TTD | [4] |

| Sunrise TSF | BHP | Australia | 10,000 | 50 | 64 (TT) | TTD | [4] |

| Osborne TSF | Ivanhoe Limited’s | Australia | 4500 | 55 | 74 (TT) | PTD | [4] |

| Centinela TSF | Antofagasta Minerals | Chile | 95,000 | 45 | 65 (TT) | TTD | [29] |

| Sierra Gorda TSF | KGHM | Chile | 110,000 | 40 | 60 (TT) | TTD | [30] |

| Spence TSF | BHP | Chile | 95,000 | 55 | 52 (TT) | TTD | [31] |

| Talabre TSF | Codelco | Chile | 200,000 | 60 | 57 (TT) | TTD | [32] |

| Talabre TTD TSF (*) | Codelco | Chile | 400,000 | 60 | 67 (TT) | TTD | [32] |

| Los Corralillos TSF | Cerro Negro Norte CMP | Chile | 20,000 | 75 | 65 (TT) | TTD | [33] |

| Carmen Andacollo TSF | Teck | Chile | 55,000 | 70 | 58 (TT) | TTD | [34] |

| Los Diques TSF | Lunding | Chile | 75,000 | 65 | 50 (TT) | TTD | [35] |

| Demo Plant | Collahuasi | Chile | 6000 | 74 | 65 (TT) | PTD | [36] |

| Chinchorro TSF | Las Cenizas | Chile | 2500 | 65 | 70 (TT) | PTD | [36] |

| Delta Plant TSF | ENAMI | Chile | 2000 | 71 | 67 (TT) | PTD | [36] |

| Sector 5 TSF | Coemin | Chile | 8000 | 68 | 70 (TT) | PTD | [37] |

| Alhue TSF | Yamana Gold | Chile | 3000 | 75 | 65 (TT) | PTD | [38] |

| El Toqui TSF | Nyrstar | Chile | 1500 | 68 | 72 (TT) | PTD | [39] |

| Toromocho TSF | Chinalco | Peru | 140,000 | 69 | 65 (TT) | TTD | [40] |

| Antapaccay TSF | Tintaya | Peru | 75,000 | 75 | 58 (TT) | TTD | [41] |

| Las Bambas TSF | MMG | Peru | 140,000 | 75 | 62 (TT) | TTD | [42] |

| Constancia TSF | Hudbay | Peru | 90,000 | 70 | 58 (TT) | TTD | [43] |

| Chungar TSF | Volcan | Peru | 5500 | 60 | 70 (SL) | PTD | [44] |

| Cobriza TSF | Doe Run | Peru | 5000 | 65 | 70 (TT) | PTD | [45] |

| Rumichaca TSF | Volcan | Peru | 6000 | 60 | 65 (SL) | PTD | [46] |

| Huachuacaja TSF | El Brocal | Peru | 18,000 | 65 | 65 (TT) | TTD | [47] |

| Cerro Corona TSF | GoldFields | Peru | 22,000 | 78 | 55 (TT) | TTD | [48] |

| La Quinua TSF | Newmont | Peru | 17,000 | 67 | 67 (TT) | TTD | [49] |

| Paste Thickening Process Parameters | Cu Tailings Characterization | ||||

|---|---|---|---|---|---|

| Parameter | Value | Units | Parameter | Value | Units |

| Tailings throughput | 6000 | tpd | Particle size distribution (P80) | 115 | µm |

| DCT diameter | 22 | m | Fines content (<#200 ASTM) | 65 | % |

| DCT height | 20 | m | Solid Gravity (Gs) | 2.76 | - |

| Solid loading | 0.658 | tph/m2 | Feed solid content (Cw) | 47–53 | % |

| Flocculent dosing use | 20–25 | g/ton | Underflow Solid Content (Cw) | 57–67 | % |

| Overflow water recovery | 127 | m3/h | Unsheared/sheared yield stress | 260/130 | Pa |

| Paste Thickening Process Parameters | Cu Tailings Characterization | ||||

|---|---|---|---|---|---|

| Parameter | Value | Units | Parameter | Value | Units |

| Tailings throughput | 2500 | tpd | Particle size distribution (P80) | 110 | µm |

| DCT diameter | 17 | m | Fines content (<#200 ASTM) | 60 | % |

| DCT height | 16 | m | Solid Gravity (Gs) | 2.82 | - |

| Solid loading | 0.460 | tph/m2 | Feed solid content (Cw) | 55–60 | % |

| Flocculent dosing use | 25–30 | g/ton | Underflow Solid Content (Cw) | 68–72 | % |

| Overflow water recovery | 45 | m3/h | Unsheared/sheared yield stress | 120/60 | Pa |

| Paste Thickening Process Parameters | Cu Tailings Characterization | ||||

|---|---|---|---|---|---|

| Parameter | Value | Units | Parameter | Value | Units |

| Tailings throughput | 2000 | tpd | Particle size distribution (P80) | 105 | µm |

| DCT diameter | 12 | m | Fines content (<#200 ASTM) | 70 | % |

| DCT height | 8 | m | Solid Gravity (Gs) | 2.90 | - |

| Solid loading | 0.737 | tph/m2 | Feed solid content (Cw) | 30–35 | % |

| Flocculent dosing use | 15–20 | g/ton | Underflow Solid Content (Cw) | 65–70 | % |

| Overflow water recovery | 114 | m3/h | Unsheared/sheared yield stress | 90/45 | Pa |

| Paste Thickening Process Parameters | Zn, Au, Pb, Ag and Cu Tailings Characterization | ||||

|---|---|---|---|---|---|

| Parameter | Value | Units | Parameter | Value | Units |

| Tailings throughput | 1500 | tpd | Particle size distribution (P80) | 160 | µm |

| DCT diameter | 14 | m | Fines content (<#200 ASTM) | 60 | % |

| DCT height | 10 | m | Solid Gravity (Gs) | 3.20 | - |

| Solid loading | 0.406 | tph/m2 | Feed solid content (Cw) | 30–35 | % |

| Flocculent dosing use | 25–35 | g/ton | Underflow Solid Content (Cw) | 70–75 | % |

| Overflow water recovery | 103 | m3/h | Unsheared/sheared yield stress | 150/75 | Pa |

| Paste Thickening Process Parameters | Au and Zn Tailings Characterization | ||||

|---|---|---|---|---|---|

| Parameter | Value | Units | Parameter | Value | Units |

| Tailings throughput | 3000 | tpd | Particle size distribution (P80) | 125 | µm |

| DCT diameter | 17 | m | Fines content (<#200 ASTM) | 55 | % |

| DCT height | 12 | m | Solid Gravity (Gs) | 2.72 | - |

| Solid loading | 0.550 | tph/m2 | Feed solid content (Cw) | 20–25 | % |

| Flocculent dosing use | 25–35 | g/ton | Underflow Solid Content (Cw) | 60–70 | % |

| Overflow water recovery | 320 | m3/h | Unsheared/sheared yield stress | 130/65 | Pa |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cacciuttolo Vargas, C.; Marinovic Pulido, A. Sustainable Management of Thickened Tailings in Chile and Peru: A Review of Practical Experience and Socio-Environmental Acceptance. Sustainability 2022, 14, 10901. https://doi.org/10.3390/su141710901

Cacciuttolo Vargas C, Marinovic Pulido A. Sustainable Management of Thickened Tailings in Chile and Peru: A Review of Practical Experience and Socio-Environmental Acceptance. Sustainability. 2022; 14(17):10901. https://doi.org/10.3390/su141710901

Chicago/Turabian StyleCacciuttolo Vargas, Carlos, and Alex Marinovic Pulido. 2022. "Sustainable Management of Thickened Tailings in Chile and Peru: A Review of Practical Experience and Socio-Environmental Acceptance" Sustainability 14, no. 17: 10901. https://doi.org/10.3390/su141710901

APA StyleCacciuttolo Vargas, C., & Marinovic Pulido, A. (2022). Sustainable Management of Thickened Tailings in Chile and Peru: A Review of Practical Experience and Socio-Environmental Acceptance. Sustainability, 14(17), 10901. https://doi.org/10.3390/su141710901