Abstract

In this paper, a phase change microcapsule suspension MPCMS25 with a mass fraction of 10% was prepared with TH-ME25 as the phase change microcapsule particles and deionized water as the base fluid. The experimental benches of the Building Integrated Photovoltaic (BIPV) system and BIPV-MPCMS system were set up, and the comparative tests were carried out in Nanjing to study the optimization effect of phase change microcapsule suspension on the thermal and electrical properties of the BIPV system. The results show that MPCMS25 reduces the component temperature of the system by 8.8 °C and the backplane temperature by 11.1 °C. The optimization time of the component operating temperature and the backplane temperature is 9.5 h and 9.75 h, respectively. Delay appearance of peak module operating temperature by 114 min and peak backplane temperature by 125 min. In addition, the suspension can also improve the power conversion efficiency (PCE) of photovoltaic modules by 0~5%. After a simulation study on the energy consumption of a high-speed railway station, it is found that using the BIPV-MPCMS system as the building envelope can achieve an energy saving rate of about 8.5%.

1. Introduction

As a product of building energy conservation and comprehensive utilization of renewable energy, Building Integrated Photovoltaic uses solar energy to generate electricity. At the same time, BIPV becomes a part of the building by integrating solar photovoltaic cells into the surface of the building envelope or completely replacing the envelope, which contributes to energy conservation and emission reduction. However, in practical applications, only 15~20% of the solar energy absorbed by photovoltaic modules is used for power generation, and the rest is converted into internal energy, which leads to an increase in operating temperature [1] and can even reach up to 80 °C [2]. Related studies have shown that high module temperature will cause the saturation current of the cell to rise and the open circuit voltage to decrease, resulting in a decrease in net output power [3]. When the surface temperature of crystalline silicon cells is higher than the normal working temperature of 25 °C, the PCE will decrease at a rate of 0.4~0.6%/K [4]. Excessive temperature will also lead to permanent damage to the structure of photovoltaic modules and shorten the service life, so it is very important to effectively control the temperature of photovoltaic modules [5].

Currently, the more applied PV module surface cooling technology can be divided into Active Cooling and Passive Cooling. Active Cooling includes wind cooling [6] and water cooling [7], etc. The cooling fluid is mainly transported through the windpipe or pump to take away the heat through the surface of the photovoltaic module in a sensible way to achieve the effect of thermal management. However, the realization of Active Cooling requires additional equipment and consumes more energy. In contrast, Passive Cooling using phase change material (PCM) takes away heat in a latent heat manner and does not require additional power input in the cooling process, so it has higher efficiency and more uniform temperature distribution [8]. However, there are also some problems in the application of traditional PCM, such as low thermal conductivity, leakage caused by volume change during phase change, and obvious undercooling, which limit its application as an energy storage material to some extent. In order to solve these problems, some scholars proposed that the traditional PCM microcapsules were prepared into emulsions and microcapsules [9], which could not only make the PCM uniformly dispersed, solve the problems of volume change and leakage in the phase change process, but also increase the specific surface area of the PCM and improve their heat transfer efficiency. In addition, the microencapsulated PCM avoids direct contact between the phase change material and the external environment, which improves the long-term stability of the phase change material and prolongs the service life of the phase change material [10].

To verify the optimization of PCM for photovoltaic systems, many scholars have done research. Huang et al. [11] and Aelenei et al. [12] realized the purpose of controlling the working temperature of solar photovoltaic cells by installing PCM on the back of single crystal silicon solar cells. The superiority of the PV-PCM system was verified by establishing the numerical model and experimental system of the PV-PCM coupling system [13,14]. The theoretical and experimental results show that the total output efficiency of a PV-PCM system with a PCM is 2% to 3% higher than that of a single crystal silicon battery. Kibria et al. [15] used a finite difference scheme to discrete the energy balance equation and a fully implicit scheme to discrete the heat balance of the PCM module. Based on this, a transient one-dimensional energy balance model was developed to analyze the complex heat transfer characteristics of the PCM integrated photovoltaic cell system, and the model was verified by relevant experimental results. The results show that PCM can improve the PCE of photovoltaic systems by 5%. In order to further improve the output power of the system, Atki et al. [16] injected graphite into the PCM, making the power output increase by 7%.

In this paper, an experimental study was conducted to prepare a phase change microcapsule suspension (MPCMS) and encapsulate it on the back of the components of the conventional BIPV system. The BIPV-MPCMS system was set up and compared with the traditional BIPV system in Nanjing to study the performance optimization effect of phase change microcapsules suspension in the BIPV system. It is found that the BIPV-MPCMS system can not only reduce the energy consumption of the building but also achieve higher photovoltaic power generation, which is innovative to some extent. In Section 2, the preparation of MPCMS was described in detail. In Section 3, the experimental platform is built, and the data obtained from the experiment is processed and analyzed. Finally, the energy-saving effect of the BIPV-MPCMS system is simulated by software.

2. Preparation of Suspensions

2.1. Material Selection

Various factors should be taken into account when selecting materials. In the selection of microencapsulated PCM, the core material should satisfy the following conditions as much as possible: (1) Matching the phase change temperature range of the core material with the design temperature, (2) minimizing or avoiding the phenomenon of subcooling, (3) small phase change temperature range, (4) large heat transfer coefficient, (5) large specific heat, (6) small volume change during phase change, (7) stable material properties, (8) large latent heat, (9) good thermal conductivity, (10) low reactivity of the substance [17,18,19,20,21].

The shell should be selected according to the physical properties of the core material. If the core material is hydrophobic, the hydrophilic shell material is usually chosen, and vice versa. In addition, the following conditions should be met: (1) Good flexibility, (2) good sealing, (3) should be durable and somewhat elastic, (4) low reactivity, (5) high-temperature resistance [17,18,21].

According to the above principles, TH-ME25 from Hubei Thermal New Energy Technology Co., Ltd. was selected as the microcapsule material in this study, and deionized water was used as the suspension base solution. The specific parameters of the microcapsule particles are shown in Table 1.

Table 1.

Physical properties of TH-ME25.

2.2. Preparation Methods

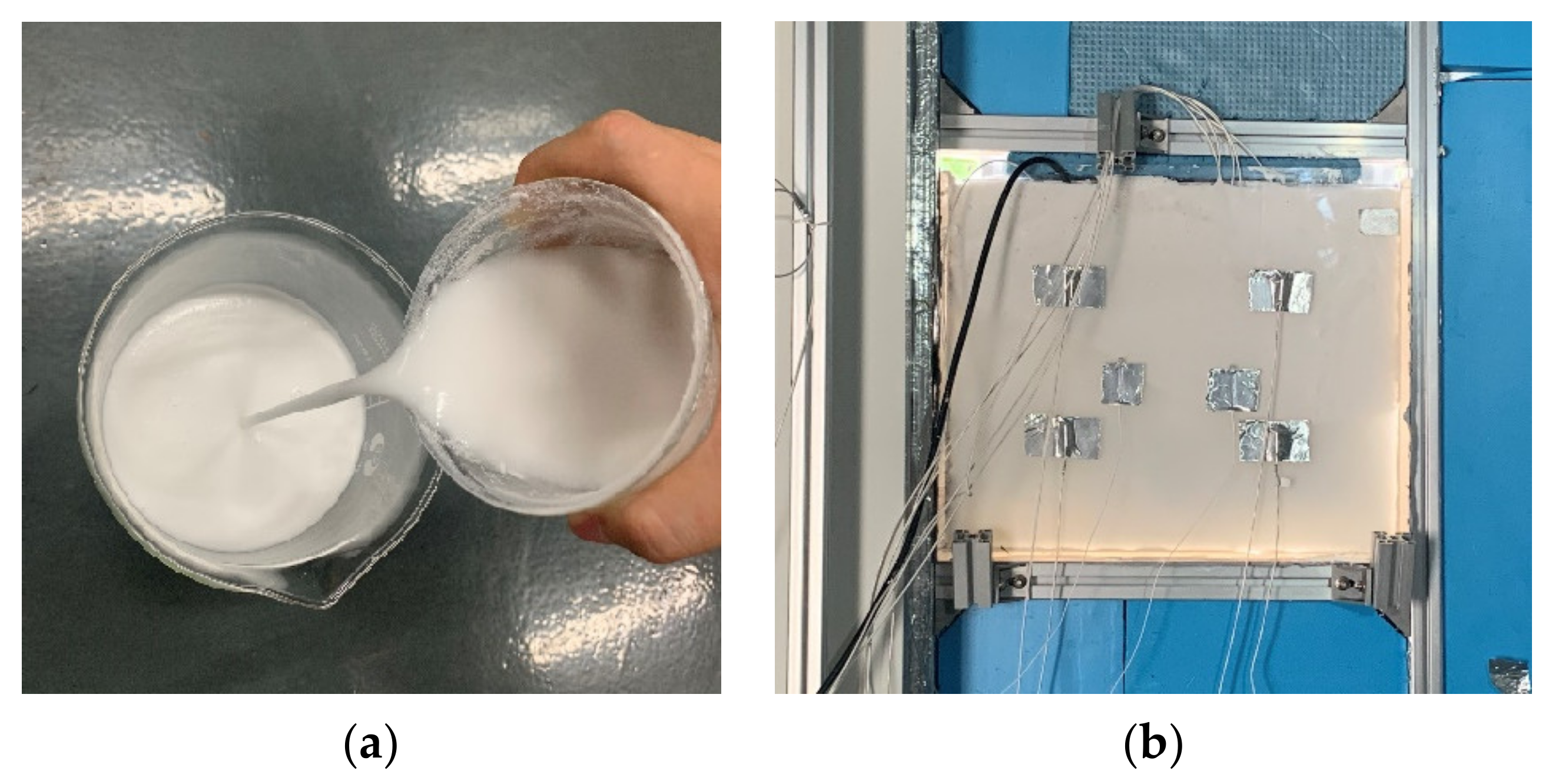

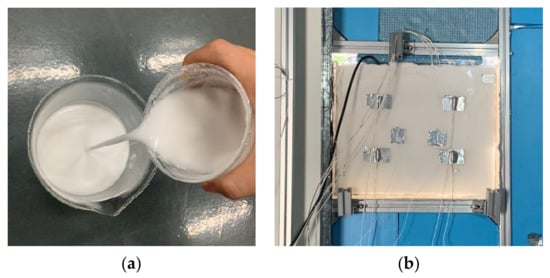

MPCMS25 with a 10% mass fraction was prepared and encapsulated on the back of BIPV system components. Figure 1 shows MPCMS25 with a mass fraction of 10% prepared using deionized water as a base solution and TH-ME25 as microcapsule particles. The density of deionized water is around 1.0 g/cm3, while the density of microcapsule particles is slightly larger. Because the suspension prepared in the experiment is mainly used for static heat storage, that is, natural convection heat transfer and no flow, a certain amount of xanthan gum is added to the deionized water to increase the stability of the suspension.

Figure 1.

The MPCMS with a mass fraction of 10% was encapsulated on the back of the components of the BIPV system to build the BIPV-MPCMS system. Subgraph (a) microcapsule suspension with a mass fraction of 10%, (b) backside of the BIPV-MPCMS system after filling.

The specific preparation process is as follows.

- (1)

- According to the amount of the base solution and the mass fraction of the suspension to be prepared, the mass of the required microcapsule particles was calculated. The dried microcapsule particles were weighed with the FA2004 electronic balance and placed in the beaker.

- (2)

- According to the quality of microcapsule particles and the mass fraction of the suspension, the quality of deionized water was calculated. The beaker quantity was put in the jar, and DF101S constant temperature magnetic stirrer was used for low-speed stirring 20 min.

- (3)

- 0.2% mass fraction of xanthan gum was added to the solution and stirred vigorously for 30 min.

- (4)

- The stirred microcapsule suspension was put into an ultrasonic oscillator model KQ2200 F and oscillated at a constant temperature of 40 °C with a frequency of 37 kHz for 20 min.

- (5)

- We let it stand and observed whether the suspension appeared to be stratified.

3. Analysis of Experimental Results

3.1. Experimental Bench Construction

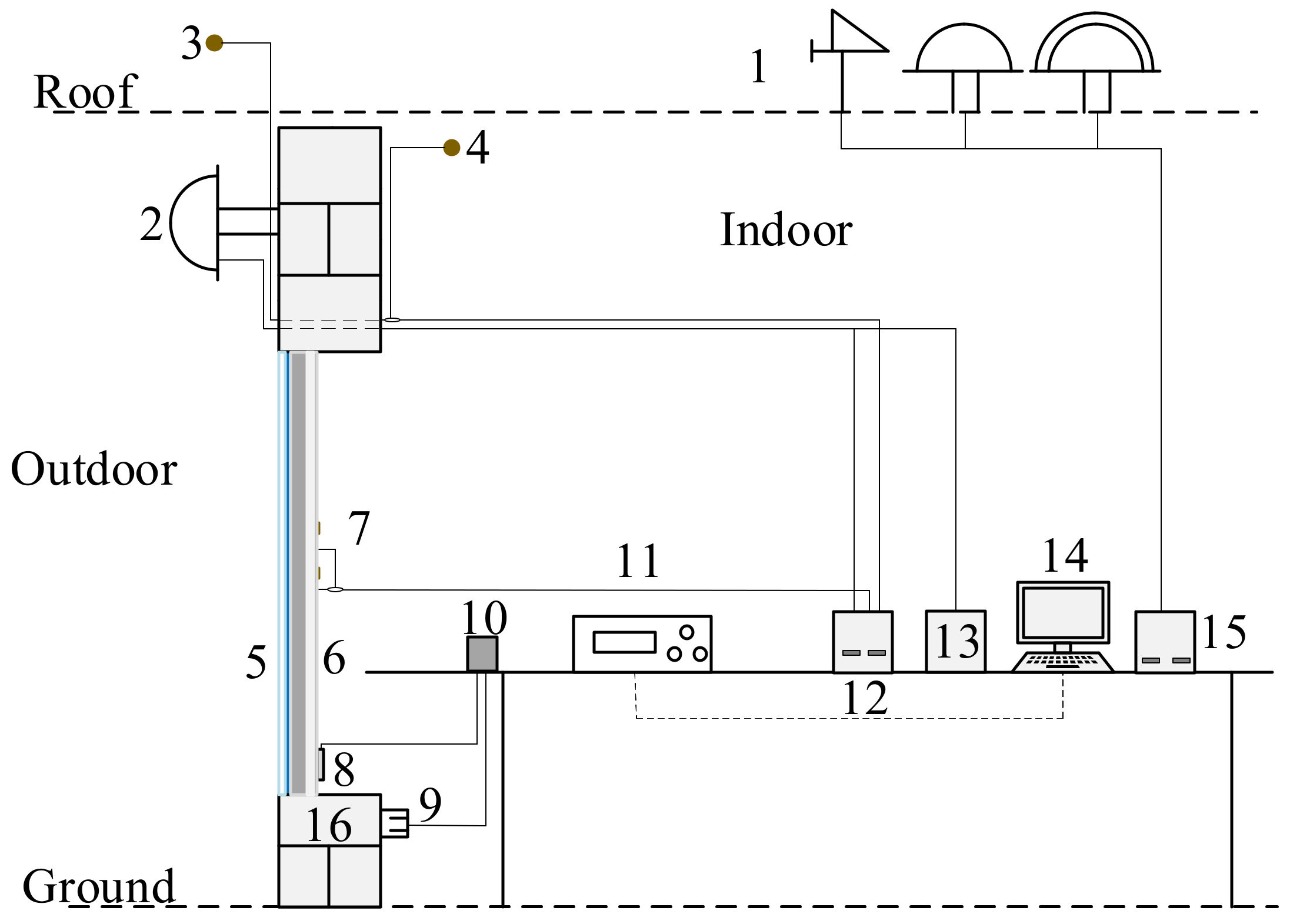

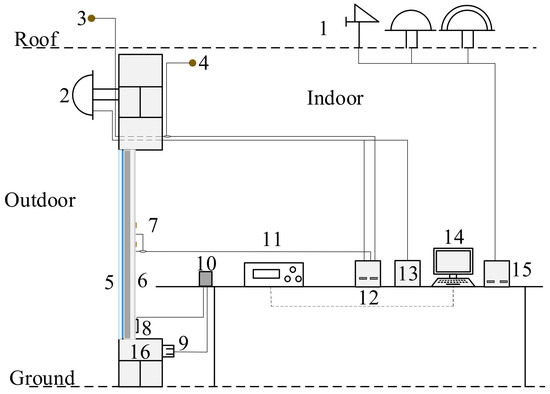

Established experimental platform, the structure of the BIPV-MPCMS25 experimental system is shown in Figure 2.

Figure 2.

Schematic diagram of the BIPV-MPCMS25 experimental system.1. Outdoor weather station; 2. Wall irradiation sensors; 3. Outdoor temperature sensor; 4. Indoor temperature sensor; 5. Photovoltaic modules; 6. MPCMS25; 7.RTD temperature probe; 8. PV module wiring port; 9. Inverter grid connection interface; 10. Micro Inverter; 11. DC electronic load; 12. Data logger; 13. Regulated power supply; 14. Computer; 15. Meteorological data logger; 16. Building walls.

In this study, the model SFM-30 monocrystalline silicon produced by SINGFO SOLAR ENERGY LTD was selected as the PV module of the system. Table 2 shows its specific parameters.

Table 2.

Detailed parameters of photovoltaic modules.

- (1)

- Temperature acquisition system

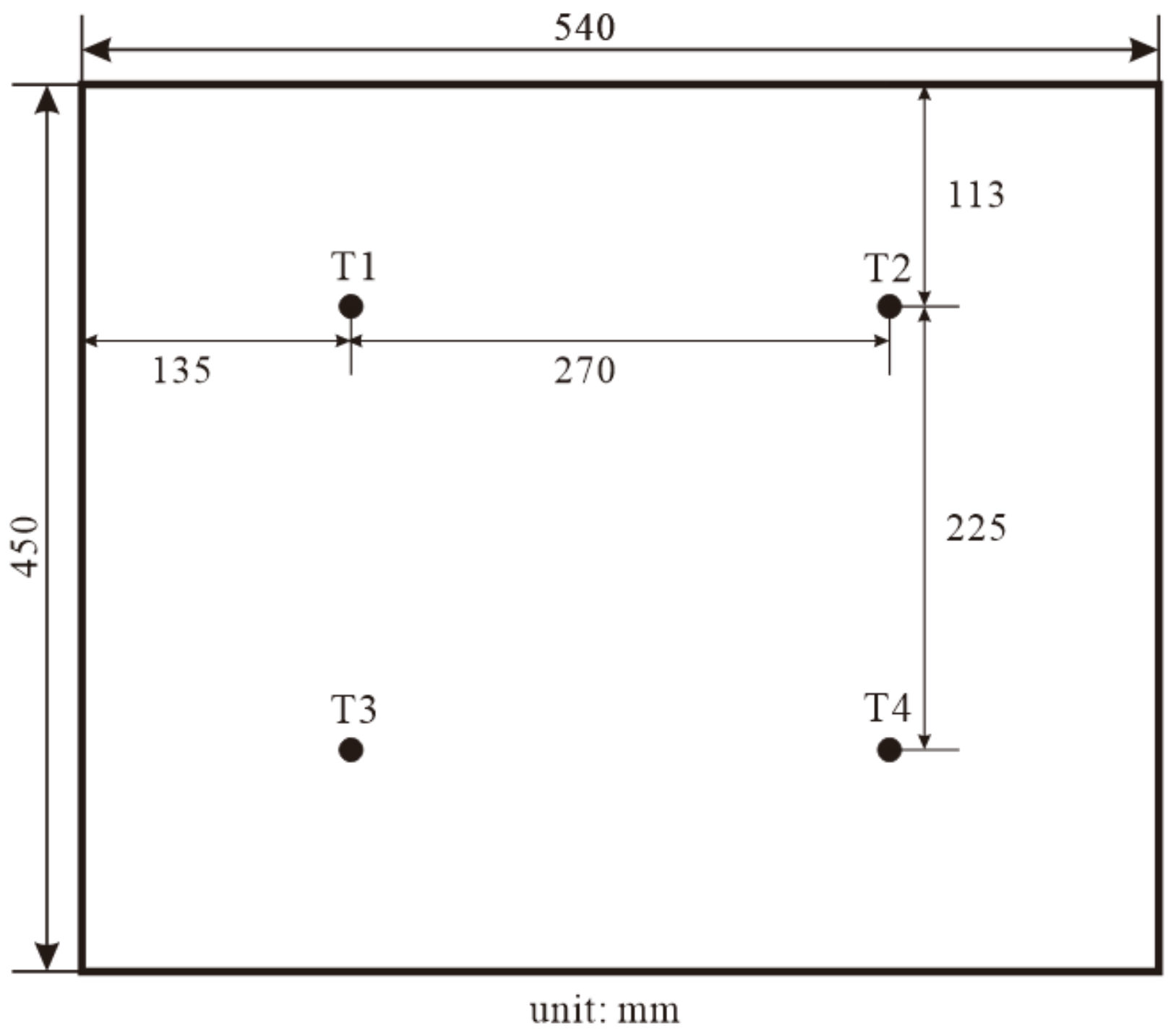

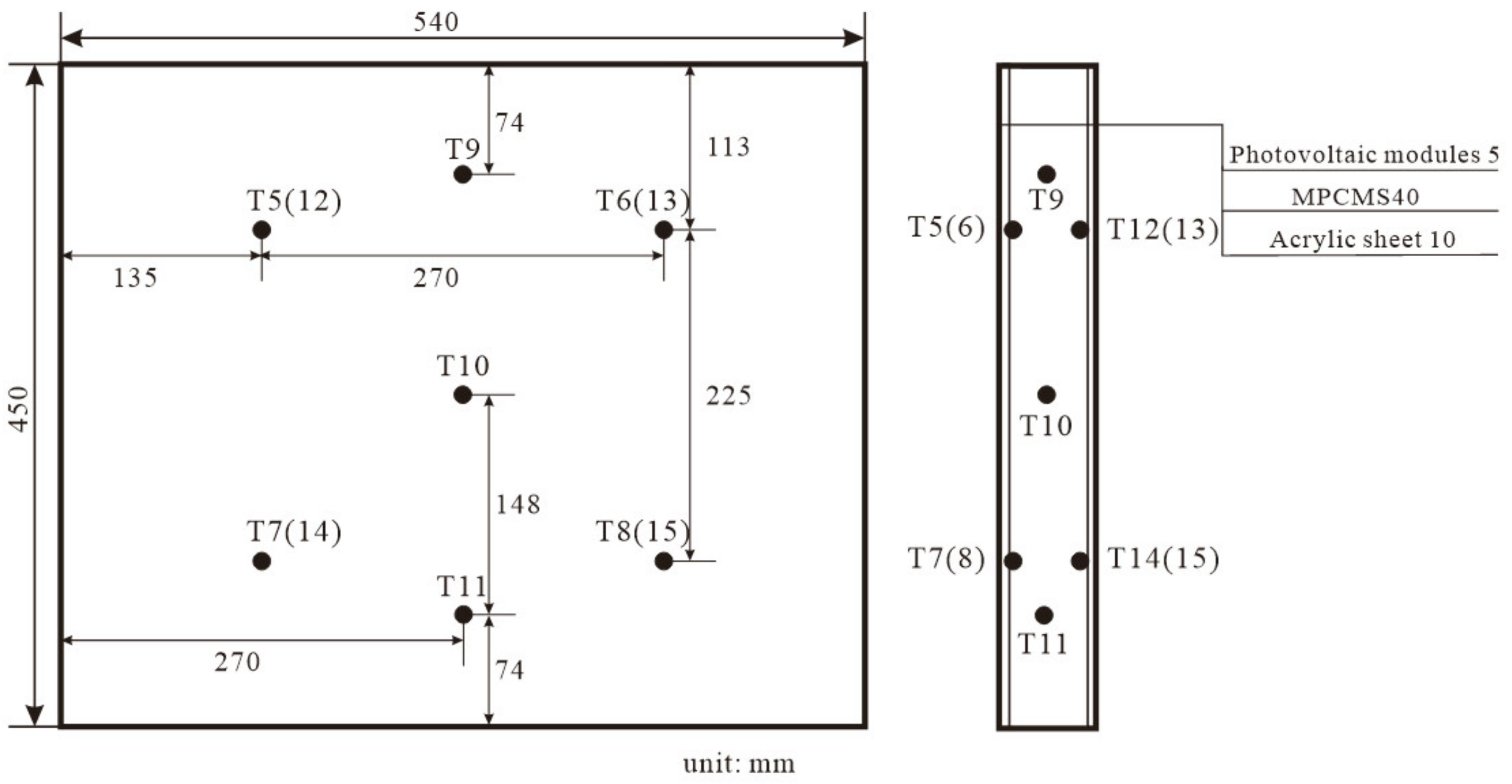

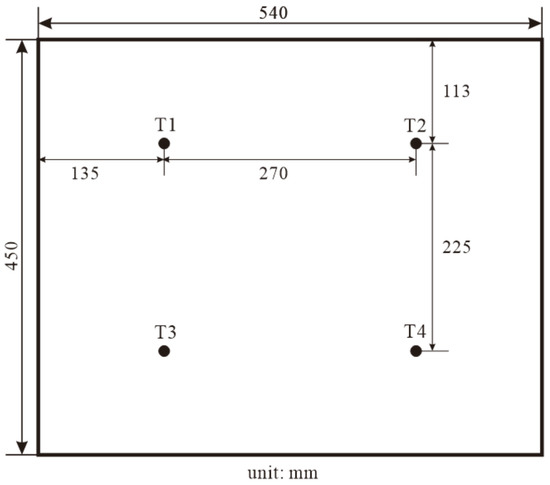

The size of the photovoltaic module was 540 × 450 mm, and the probe size of the temperature sensor was 8 × 25 mm. Because the temperature probe was smaller than the whole photovoltaic module, the temperature of a measuring point could not represent the overall temperature of the whole plane, so when arranging the temperature measuring points, 3~4 temperature measuring points were arranged on a plane, and the average value was taken to represent the overall temperature of the whole plane. The temperature measurement points of the blank BIPV system and the BIPV-MPCMS system comparison experimental group had a total of 15 points from T1-T15. Their specific layout locations are shown in Figure 3 and Figure 4.

Figure 3.

Temperature measurement point arrangement of the BIPV system.

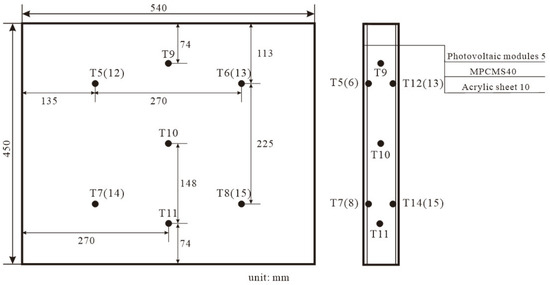

Figure 4.

Temperature measurement point arrangement of the BIPV-MPCMS system.

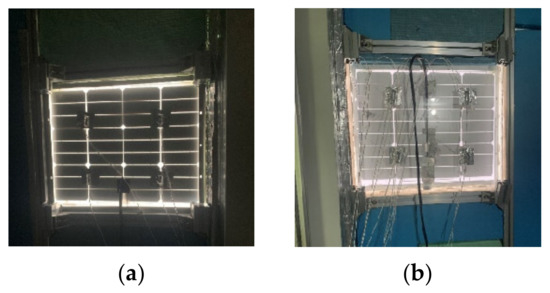

As shown in Figure 3, T1–T4 are the temperature measuring points on the back of the air-white photovoltaic module system. The whole photovoltaic module is divided into four regions on average, and a temperature measuring point is arranged at the center of the four regions. It is considered that the temperature of the measuring point represents the overall temperature of this region, and the average temperature of the four temperature measurement points is considered as the overall temperature of the backside of the PV module. Similarly, for the BIPV-MPCMS system shown in Figure 4, T5–T8, four temperature measuring points measure the operating temperature of photovoltaic modules in this system. T9–T11 measure the temperature of the suspension. In order to obtain the overall temperature of the suspension, the MPCMS layer of the system is divided into upper, middle, and lower parts on average at vertical height. A thermal resistance temperature sensor is placed at the center of each part, and the position is fixed by a waterproof adhesive. T12–T15 measured the backboard temperature of the system. Figure 5 shows a physical view of the temperature sensors arranged on the two systems.

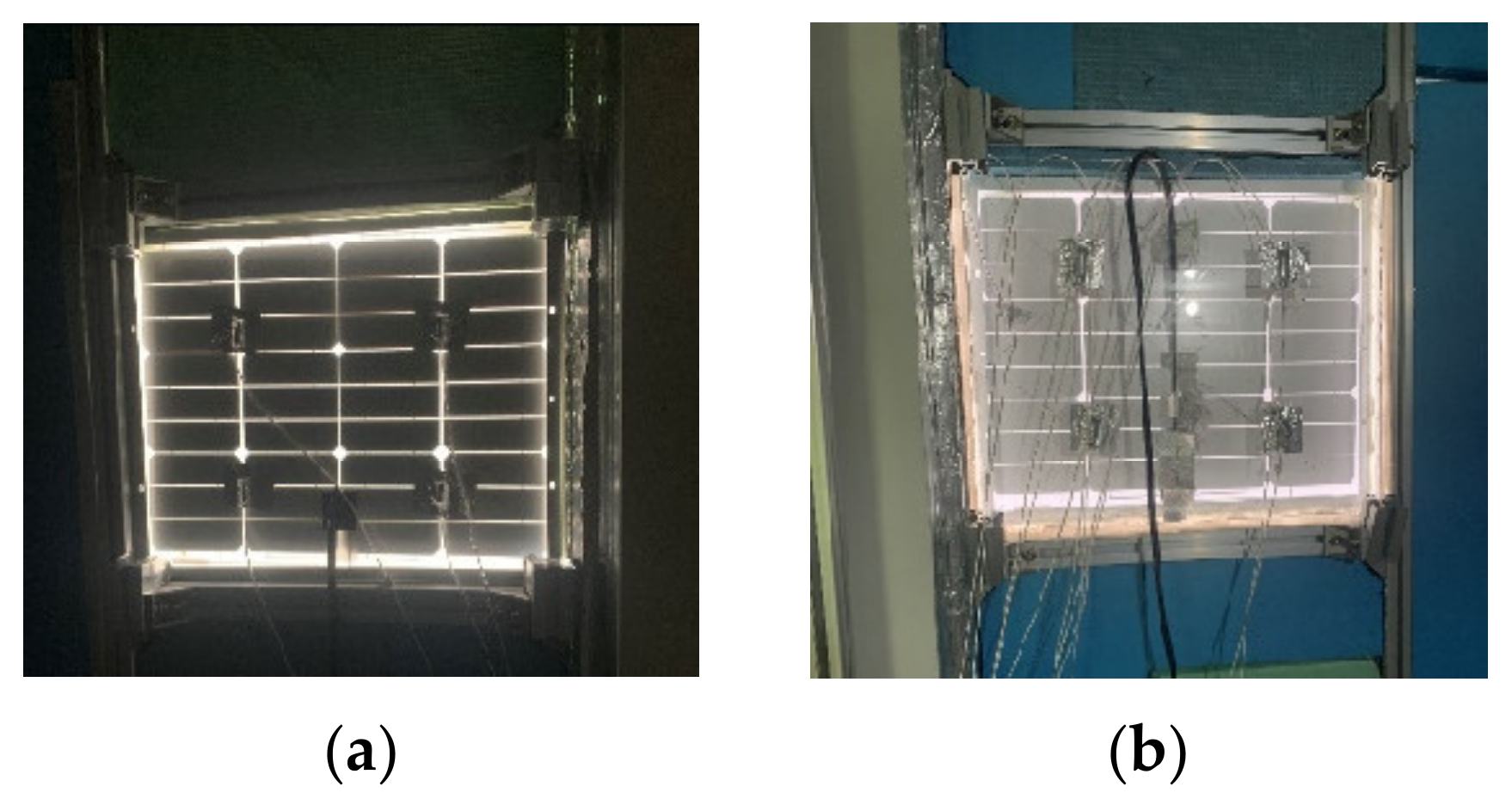

Figure 5.

The temperature sensor layout diagram. (a) Blank white photovoltaic modules, (b) BIPV-MPCMS system.

- (2)

- Power acquisition system

The experiment used a programmable DC electronic load model M9711 manufactured by Nanjing Maynuo Electronic Co., Ltd. to record power generation, which has six high-speed operation modes, such as constant current, constant resistance, constant voltage, and constant power, etc. The constant voltage test mode was mainly used to measure the real-time output power of PV modules in this experiment. The instrument offers a resolution of 0.1 mV, 0.01 mA during measurement (basic accuracy of 0.03%, basic current rise rate of 2.5 A/μs), as well as an automatic test function. After setting the running mode, the corresponding parameters, and the test delay time of the test process in the PC monitoring software M9700 with the M97 series load, the automatic test function could be realized. The test report could also be output to EXCEL for subsequent data storage and analysis.

In addition to power generation, it was necessary to measure the solar radiation intensity of the system’s environment. A thermoelectric TBQ solar radiation sensor was used in this experiment. The irradiation sensor was arranged on the aluminum profile on the wall where the photovoltaic module was located, and it was fixed on the same plane of the photovoltaic module by a screw to ensure that the measured irradiation data were the solar irradiation that the photovoltaic module could receive. The communication line of the irradiation sensor was connected to the data logger shown in Figure 2, the input signal of the channel was adjusted in the data logger as electric signal input, and the data acquisition frequency was adjusted to 1 time/min, so that the solar irradiation value could be displayed on the display screen of the paperless recorder. Before formally collecting data, it was necessary to calibrate it. In this experiment, the irradiation data were collected by the irradiation sensor at night when there was no solar irradiation by entering correction parameters to ensure its data collection was accurate.

3.2. Experimental Results and Analysis

The experimental results of the experimental platform were statistically analyzed to analyze the optimization effect of phase change microcapsule suspension on the thermal and electrical properties of the BIPV system. The BIPV-MPCMS system was filled with a mass fraction of 10% MPCMS25, and the blank BIPV system was fixed at the same height on the south facade wall of the building. A total of 24-h system operation test data from 0:00 on 24 May to 0:00 on 25 May 2021 was used for the analysis of the experimental results.

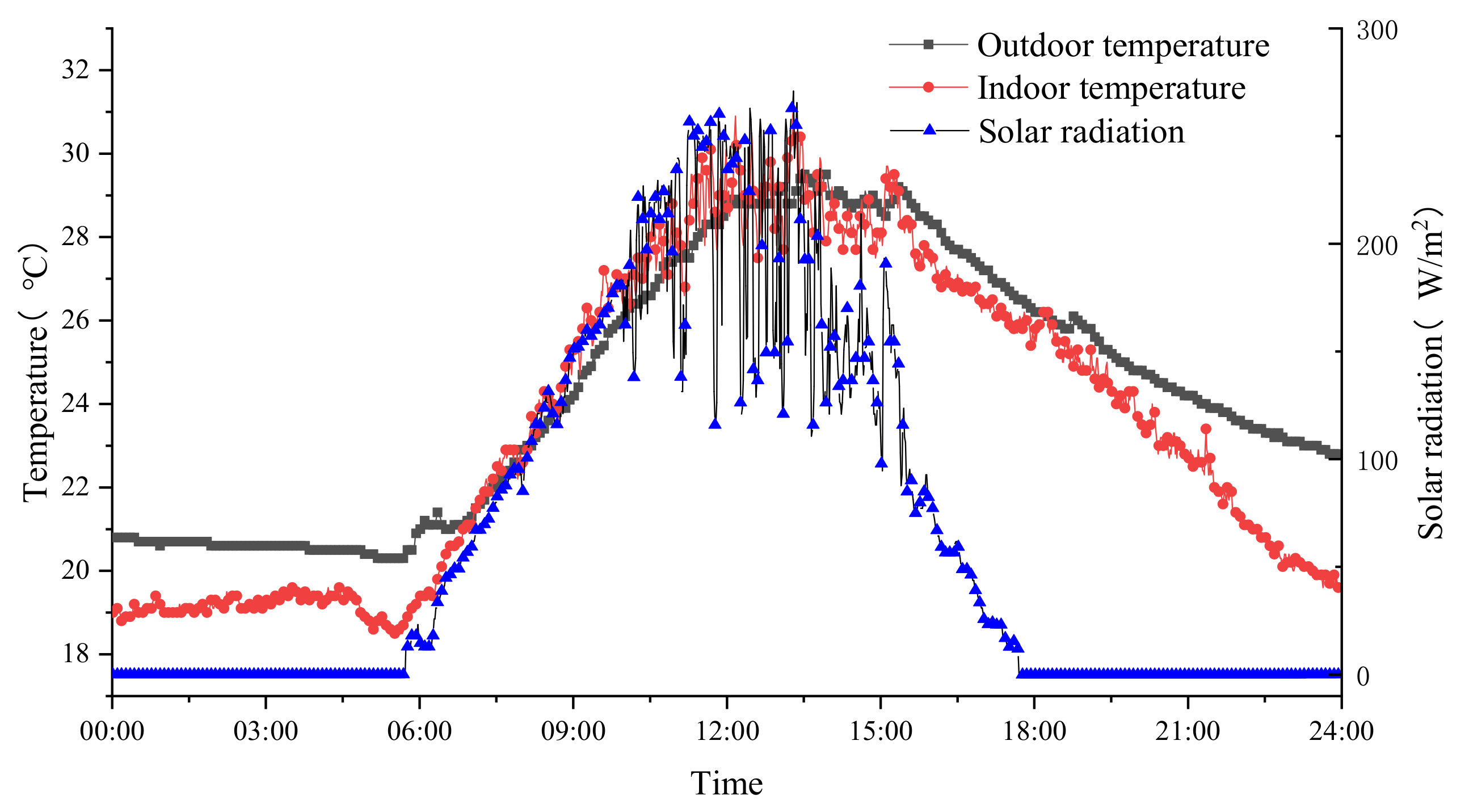

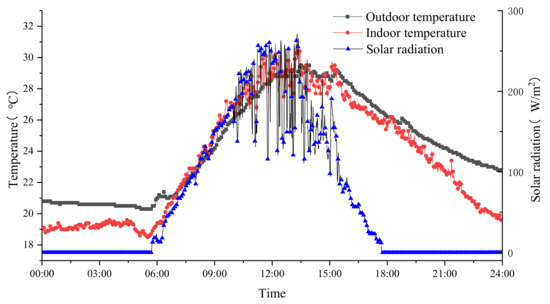

Figure 6 shows the outdoor meteorological parameter conditions on the day of the experiment. It can be seen that the outdoor temperature was around 18 °C when the system started to operate on that day, while the indoor temperature reached around 21 °C, slightly higher than the outdoor temperature due to the closeness of the building cabin and the heat dissipation of the indoor experimental equipment. Then over time, the intensity of solar radiation began to increase, the indoor and outdoor temperatures also began to rise. The outdoor temperature and solar radiation intensity reached the maximum value of the day at about 13:20. The maximum solar irradiation was 271 W/m2, and the maximum outdoor temperature reached 31.1 °C. While the existence of thermal inertia of the building led to a slower increase in indoor temperature than outdoor temperature, there was a delay. The peak indoor temperature was 29.6 °C at 14:00. After reaching the peak, solar radiation intensity and outdoor temperature began to decrease, and the decrease of indoor temperature was gentler than that of outdoor temperature. The indoor temperature was higher than the outdoor temperature at 15:00 and remained so until the end of the day.

Figure 6.

Details of indoor and outdoor ambient temperatures and solar radiation intensity on 24 May 2021. Temperature and solar radiation present similar functional curves: Rising from 6:00, reaching a maximum at about 12:00, and then gradually decreasing.

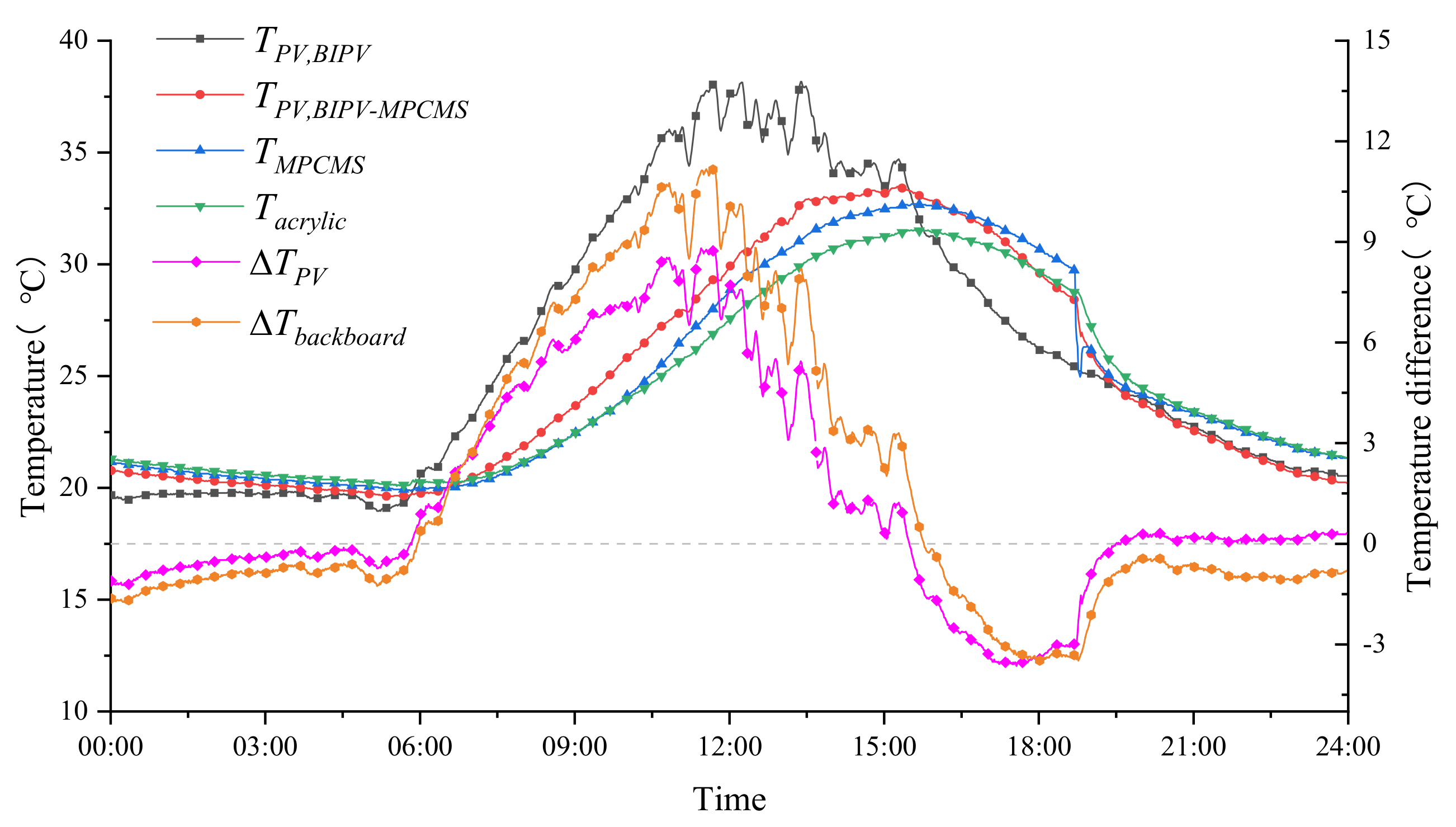

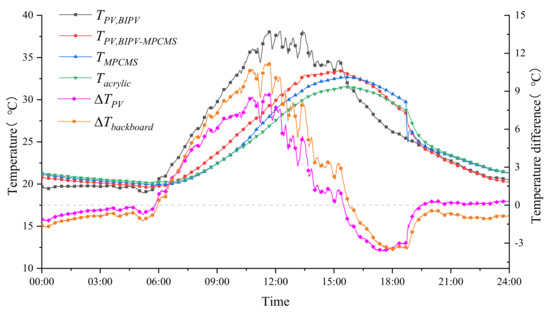

In Figure 7, is the difference between the component temperature of the BIPV system and the component temperature of the BIPV-MPCMS system, and is the difference in backplane temperature between the two systems. From the diagram, it can be seen that the temperature relationship between the temperature of the PV module, the temperature of the suspension and the temperature of the backboard at the beginning of the operation of the system: is the highest, is the second and is the lowest, but the difference between the three temperatures is not significant. This phenomenon is because the backboard of the system contacts with the indoor environment, and the outer surface of the photovoltaic module contacts with the outdoor environment. From Figure 6, it can be seen that the indoor temperature is about 3 °C higher than the outdoor temperature at the beginning, so the temperature gradient of the suspension system is caused. With the increase in solar irradiation intensity and outdoor temperature, the temperature of the PV module started to rise rapidly. It took 30 min to exceed the temperature of the suspension and backboard and it reached the maximum temperature of 33.5 °C at 15:15. The temperature of the suspension is mainly determined by the temperature of the PV module and the temperature of the backboard. The temperature of the suspension is mainly determined by the temperature of the photovoltaic module and the temperature of the backplane. In the early stage, it was greatly affected by the temperature of the photovoltaic module, and the temperature rises rapidly, reaching a maximum temperature of 32.7 °C at 15:35. During this period, the suspension transferred part of the heat to the acrylic backboard, resulting in a rise in the temperature of the acrylic backboard. The backboard also reached the maximum temperature of 31.5 °C at 15:35. After that, the temperature began to decline. During the decline process, the temperature of the suspension and backplane was greatly affected by the indoor temperature, and the decline rate was low. The PV module was mainly influenced by the outdoor environment, and the temperature dropped faster. The temperature started to be lower than the suspension temperature at 16:00, the temperature started to be lower than the backboard temperature after 18:00.

Figure 7.

Temperature comparison between the BIPV system and the BIPV-MPCMS25 system. After a period of system operation, the temperature changes of the photovoltaic module, suspension, and backplane are different, but all reach a peak at about 12:00.

By comparing and analyzing the temperature changes of the BIPV system and the BIPV-MPCMS system. It can be seen that the temperature rise rate caused by the increase of solar radiation intensity in the BIPV-MPCMS system during 6:00–11:00 is much lower than that of the BIPV system, and the temperature trend is more subdued, this is mainly due to the phase transition of suspension to absorb a large amount of latent heat. The temperature rise rate increased slightly after 11:00 because the phase change microcapsules in the suspension had completely completed the phase change process. After that, the suspension reduced the heating rate of photovoltaic modules by absorbing sensible heat. Compared to the two systems, the temperature of the blank BIPV system peaked at 13:22 at 38.17 °C. At this time, the difference in module operating temperature between the two systems was 5.44 °C, and the difference in backboard temperature was 8.19 °C. Since then, the temperature of the blank BIPV system began to decrease. Due to the presence of the suspension, the temperature of the BIPV-MPCMS system increased slowly. The component temperature reached the peak at 15:16, and the backboard temperature reached the peak at 15:27. The peak delay of the component temperature was 114 min, and the peak delay of the backplane temperature was 125 min. After the peak, the temperature began to decrease. Since the blank BIPV system directly heats the environment, the cooling rate is also fast. The suspension in the BIPV-MPCMS system has a certain heat capacity, and the phase change microcapsules will release heat when the temperature is reduced to the phase change temperature. These factors will reduce the cooling rate of the system. In this experiment, the temperature of the BIPV system was reduced to lower than that of the BIPV-MPCMS system after 15:30. Overall, the component operating temperature difference between the blank BIPV system and the BIPV-MPCMS system reached a maximum at 11:26, which was 8.8 °C, while the backplane temperature of the two systems was more different, reaching 11.1 °C at 11:41. After that, the temperature difference between the two systems began to decrease gradually, and the temperature difference between the components and the backplane decreased to negative after 15:29 and 15:46, respectively. It can be seen that the temperature control effect of suspension on photovoltaic modules can reach 9.5 h, and the temperature control effect on the backboard of the system can reach 9.75 h.

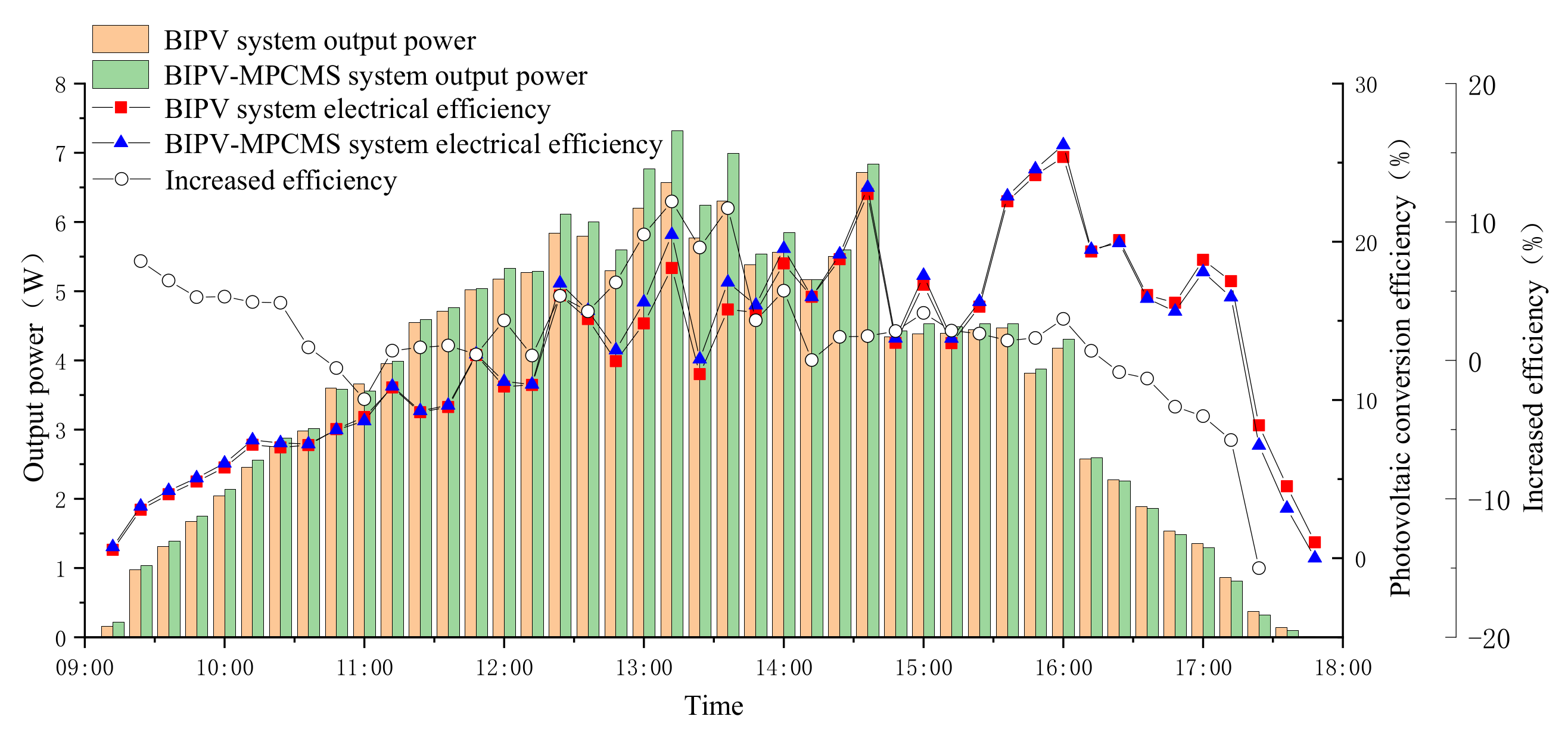

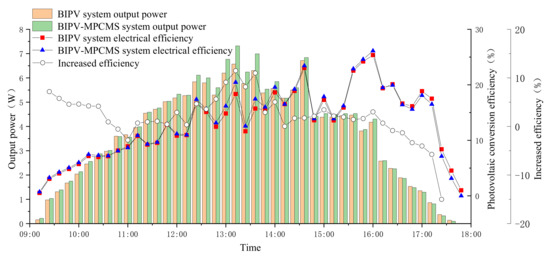

Figure 8 shows the output power of the two systems on 24 May. The analysis results show that from the beginning of the test, with the increase of solar irradiation intensity, the output power also gradually increased. Solar radiation intensity peaked at about 13:00, and output power peaked at 12:36. The maximum output power of the BIPV system is 6.92 W, and the PCE is 14.8%. The maximum output power of the BIPV-MPCMS system is 7.23 W, and the PCE is 15.5%. PCE increased by 4.8%. After reaching the peak, the solar radiation intensity began to decrease, and the output power decreased accordingly. Before 15:36, the output power of the BIPV-MPCMS system is higher than that of the BIPV system. After that, the output power of the BIPV system starts to overtake. This phenomenon is analyzed because before 15:36, the operating temperature of photovoltaic modules in the BIPV-MPCMS system is lower than that in the BIPV system, and the PCE of photovoltaic modules is inversely proportional to its own temperature. Therefore, under the same solar irradiation, the lower the temperature is, the higher the output power of photovoltaic modules is. After 15:36, the operating temperature of the photovoltaic modules in the BIPV system is relatively low, so the output power is reversed, which corresponds to the changing trend of the operating temperature of the two system modules shown in Figure 8.

Figure 8.

Comparison of the electrical power of the two systems.

The PCE and efficiency improvement percentage of the two systems are analyzed, where the efficiency improvement percentage indicates the percentage improvement of the PCE of the BIPV-MPCMS system over the BIPV system. The analysis results show that the PCE of the BIPV system fluctuates between 10.89% and 15.52%, while that of the BIPV-MPCMS system is between 9.8% and 15.81%. The percentage of efficiency improvement removes the maximum and minimum values, and most of them are distributed between 0 and 5%. The PCE of the two systems is relatively low within two hours after the start of measurement and two hours before the end of the measurement and the PCE is slightly higher in the middle. Compared with the blank BIPV system, the PCE of the BIPV-MPCMS system is higher from 6:00 to 15:36, and the efficiency is improved in the range of 0~5%, while the PCE of the BIPV system is relatively higher after 15:36. Overall, compared to the optimization of the thermal performance of the system, the effect of the electrical performance is relatively less effective, and the increase in output power is not as obvious as the effect of temperature reduction.

4. Energy Consumption Simulation

To study the specific energy-saving effect of the BIPV-MPCMS system, the energy consumption simulation of the building with phase change photovoltaic as building envelope was carried out using DesignBuilder (DB) simulation software to analyze and verify the results. The simulation work mainly focuses on the comparison of common envelope, BIPV system envelope, and BIPV-MPCMS system envelope.

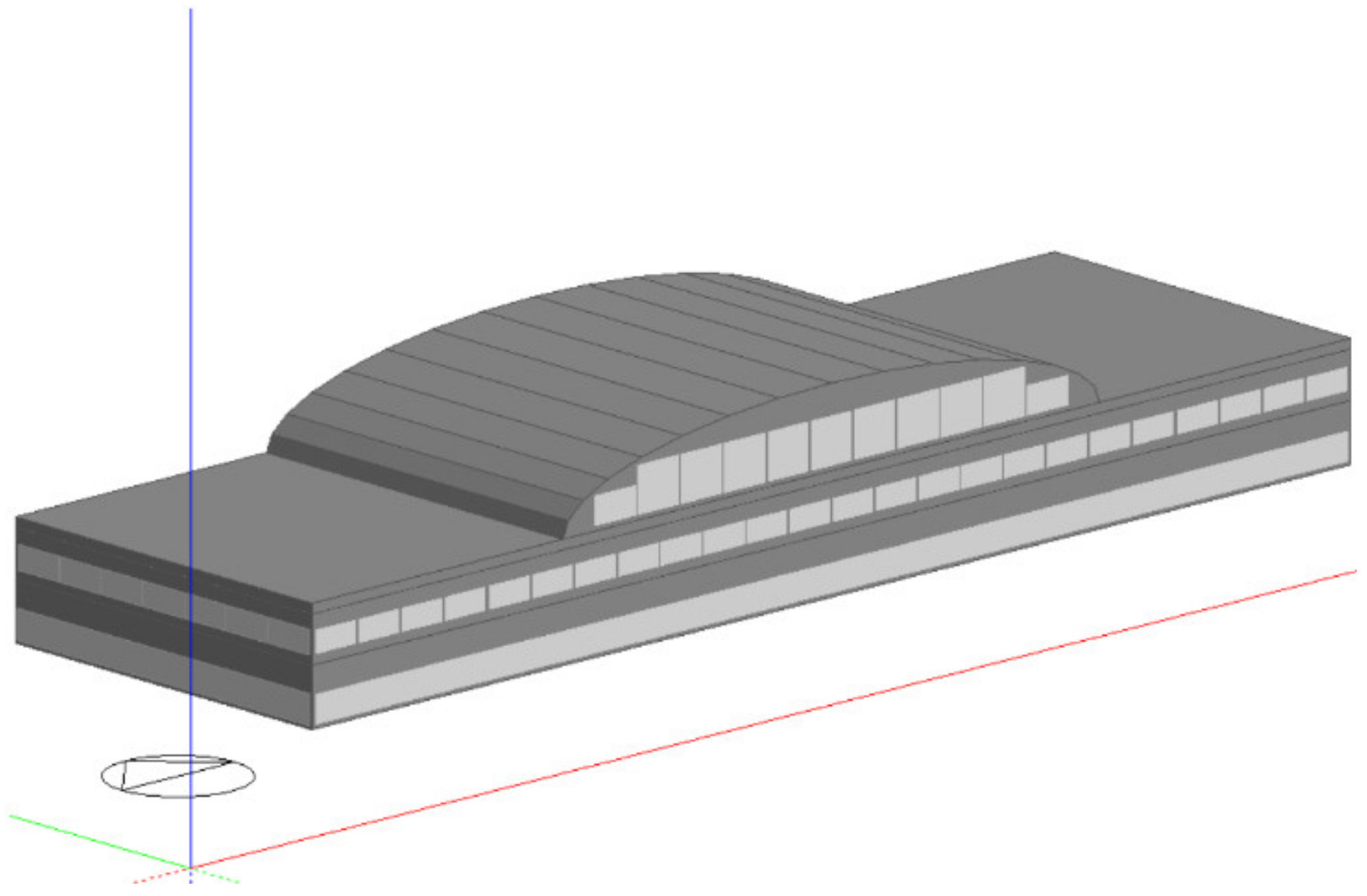

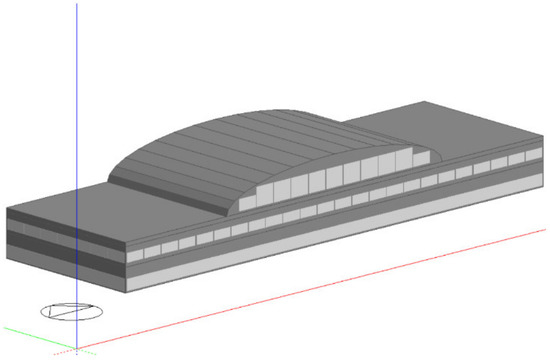

DB is a comprehensive user-graphic interface simulation software developed by UK DesignBuilder for EnergyPlus, a dynamic simulation program for building energy consumption. It has a powerful database for full energy simulation analysis and economic analysis of building heating, cooling, lighting, ventilation, and lighting. The version selected in this article is Designbuilder V6. The building model is a high-speed railway station in hot summer and cold winter area. The building construction area is about 8000 m2, two floors above ground, the highest point of the building body height is 20 m, the window wall ratio is 0.5. Figure 9 shows the high-speed railway station model established in DB software. Some modeling details of high-speed railway stations are shown in Table 3. Considering the functional factors of a high-speed railway station, the air conditioning equipment is set to run for 24 h.

Figure 9.

A high-speed rail station model. The red line, green line and blue line are the x-axis, y-axis and z-axis respectively.

Table 3.

Modeling details of high-speed railway station.

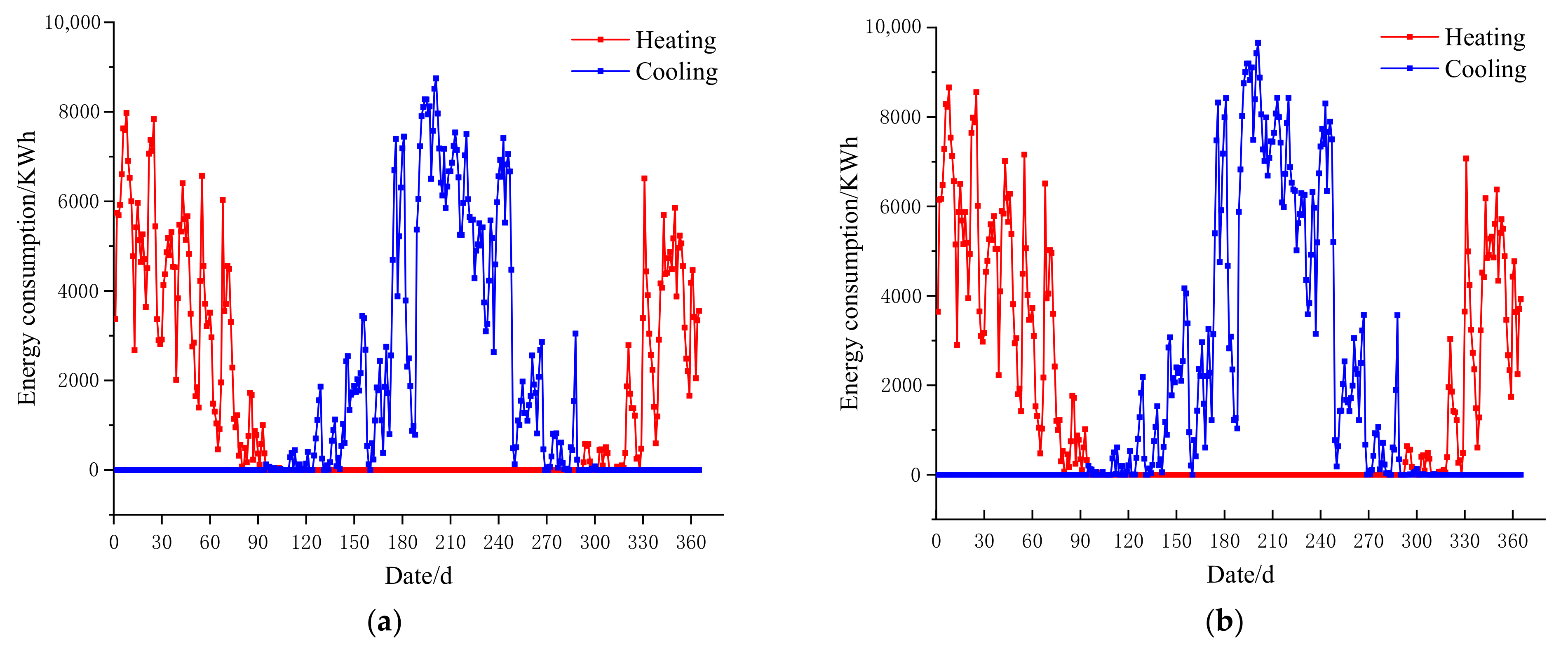

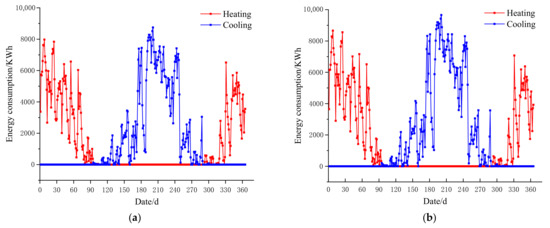

Firstly, the building curtain wall is set as an ordinary curtain wall, and the simulation results are shown in Figure 10a using DB software. The analysis results show that the total annual cooling energy consumption of this high-speed railway station is 620.7 MWh, and the total heating energy consumption is 532.3 MWh. The cooling time period is mainly from April to October, with the highest cooling energy consumption of 209.8 MWh in July. The heating time period is mainly from November to March, with the highest heating energy consumption of 182.8 MWh in January. In addition to the outdoor environment, building energy consumption is mainly influenced by the density of indoor people. July and January are both peak periods for passenger traffic, especially in January, when passenger traffic peaks due to the Spring Festival, which leads to a very rapid increase in the density of people in the high-speed railway station and a significant increase in energy consumption for building heating.

Figure 10.

Energy consumption of buildings with BIPV system curtain wall and BIPV-MPCMS system curtain wall. (a) BIPV system curtain wall, (b) BIPV-MPCMS system curtain wall.

Replace the ordinary curtain wall with a BIPV system curtain wall. Since the north façade of the building in this area is not exposed to sunlight all year round, BIPV curtain walls are mainly installed on the south, east and west walls of the building, and the curtain wall area is set to one-half of the wall area. The total installation area of the façade PV is about 948 m2, and the local average annual total solar radiation is 1207 kWh/m2. 490 W high power polycrystalline PV module is selected, panel size is 2187 mm × 1102 mm, the comprehensive efficiency coefficient of PV curtain wall is 80%, the tilt angle discount factor is taken as 0.8, and the installed PV capacity is estimated to be 183 kW. Set the BIPV curtain wall in DB software with the same thermal performance as the original curtain wall, and the PCE is constant at 15%. Simulation is performed again: After installing the BIPV system curtain wall, the annual cooling and heating energy consumption of the high-speed railway station is unchanged, and considering the energy conversion loss, the annual power generation capacity of PV is 141.6 MWh.

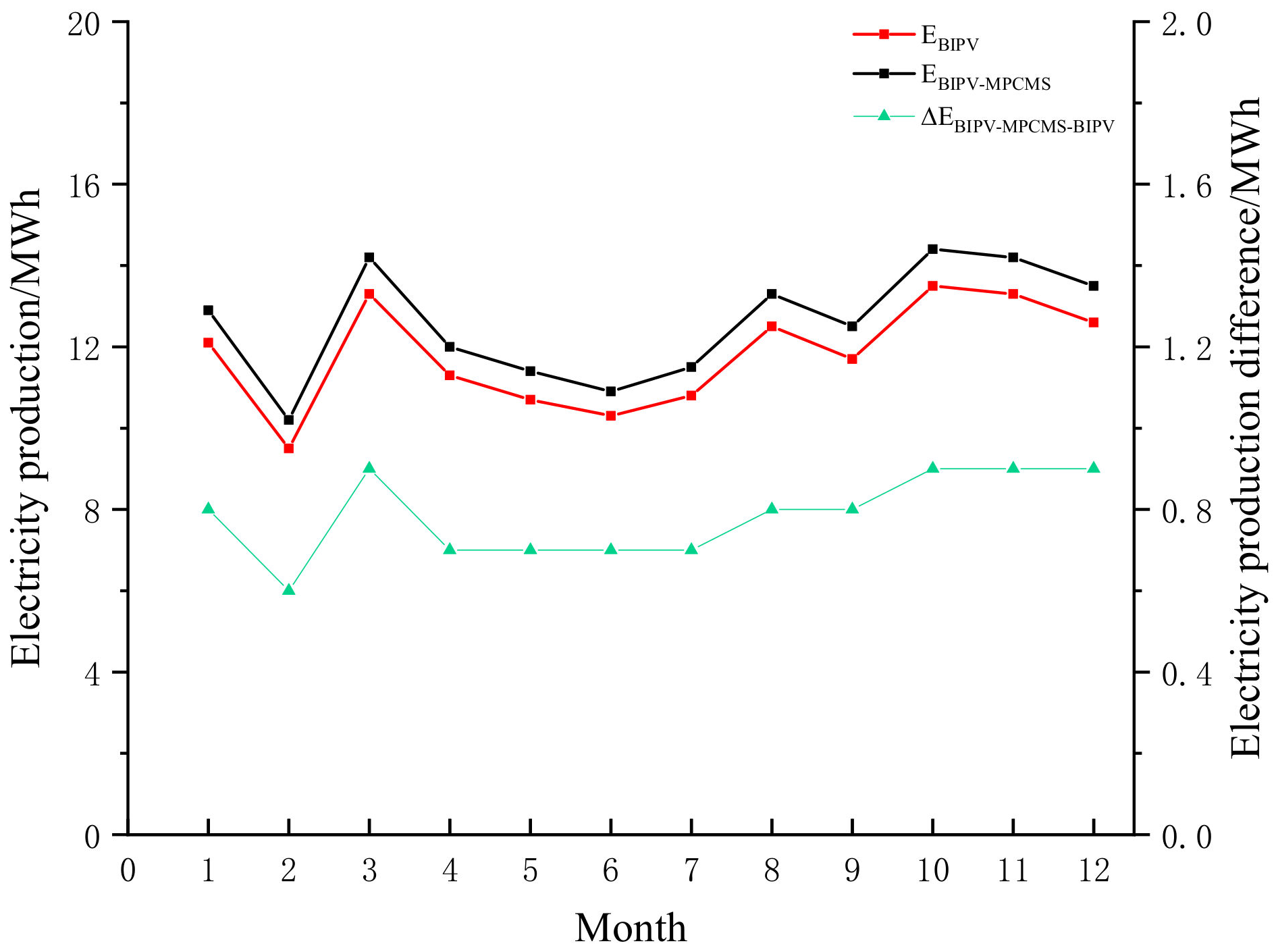

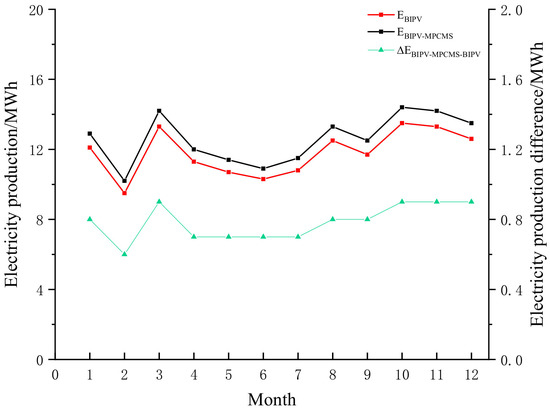

Further improve the energy saving rate by replacing the BIPV system curtain wall with a BIPV-MPCMS system curtain wall. The thickness of the phase change layer is set to 20 mm, the thermal conductivity of the phase change material is 0.2 W/(m2K), and the phase change photovoltaic PCE is constant at 16%. Figure 10b shows the energy consumption graph of a curtain wall building with a BIPV-MPCMS system installed. It can be seen from the figure that: the total annual cooling energy consumption of the high-speed railway station is 545.4 MWh, the total heating energy consumption is 490.8 MWh, and the annual photovoltaic power generation is 151.0 MWh after considering the energy conversion loss. Figure 11 represents the ratio of the power production of the curtain wall of the BIPV system to the curtain wall of the BIPV-MPCMS system.

Figure 11.

BIPV system curtain wall power production and BIPV-MPCMS system curtain wall power production.

The simulation results show that after the installation of the BIPV-MPCMS system curtain wall, compared with the ordinary curtain wall, building cooling and heating energy consumption is significantly reduced, respectively. Cooling energy consumption decreased by 12.1%, heating energy consumption decreased by 7.8%. At the same time, because the PCE of the BIPV-MPCMS curtain wall is 6.7% higher than that of the BIPV system curtain wall, the annual power yield will increase by 6.7%. It can be found that the total energy saved after installing a BIPV-MPCMS system curtain wall reaches 8.5%. Therefore, it is feasible to install a BIPV-MPCMS system curtain wall in this building, which can not only increase the PV power generation but also reduce the building energy consumption required by the building itself.

5. Conclusions

In this paper, a comparative experimental platform of the BIPV system and the BIPV-MPMS system is built. The thermal performance data and electrical performance data of the two systems running on 24 May 2021 in the Nanjing area are collected and compared. Taking a high-speed railway station building as an experimental object, the energy-saving effect of the BIPV-MPMS system is simulated. The analysis results show that:

- (1)

- The presence of suspension causes the module temperature and backboard temperature of the BIPV-MPCMS system to be reduced compared with the BIPV system. The maximum is 8.8 °C, and the maximum temperature of the backboard can be reduced by 11.1 °C. The optimization time of the operating temperature of the photovoltaic module can reach 9.5 h, and the control of the backplane temperature can reach 9.75 h. The suspension can also delay the peak temperature of the system. Compared with the blank BIPV system, the peak operating temperature of the components in the BIPV-MPCMS system was delayed by 114 min, and the peak temperature of the backboard was delayed by 125 min, delaying the peak temperature from noon to afternoon.

- (2)

- In addition to the thermal performance, MPCMS25 has a certain optimization effect on the power generation capacity of BIPV. The PCE of the BIPV system on that day ranged from 10.89% to 15.52%, while the efficiency of the BIPV-MPCMS system was between 9.8% to 15.81%. The solar irradiation intensity peaked at around 13:00, and the output power values of the two systems reached a maximum at 12:36. The maximum output power of the BIPV system was 6.92 W, with a PCE of 14.8%, and the maximum output power of the BIPV-MPCMS system was 7.23 W, with a PCE of 15.5%, an efficiency improvement of 4.8%. After 15:36, the power generation capacity of the BIPV-MPCMS system starts to be weaker than that of the BIPV system, but at this time, the solar irradiation intensity is smaller and the power generation capacity of PV modules is weaker, so the difference in output power is also relatively small.

- (3)

- Using the BIPV-MPCMS system as the outer envelope of some buildings can have an effective energy-saving effect. Compared with ordinary curtain walls, BIPV-MPCMS system curtain walls can reduce the annual cooling energy consumption of buildings by 12.1% and heating energy consumption by 7.8%. Considering that the BIPV-MPCMS system has higher PCE than the BIPV system, the annual power yield of buildings can be greatly improved. Buildings installed with BIPV-MPCMS system curtain walls can achieve a total energy saving rate of 8.5%.

The experimental results clearly show that MPCMS25 has a good optimization effect on the thermoelectric performance of the BIPV system, and the performance of the BIPV-MPCMS system is much better than that of the BIPV system. For buildings using the BIPV-MPCMS system as the external envelope can not only reduce the energy consumption of the building but also achieve higher photovoltaic power generation so as to achieve a higher energy saving rate.

The BIPV-MPCMS system integrated with PCM is more complex than the BIPV system, which inevitably increases the cost. In the future, it would be a meaningful study to compare the cost of an integrated PCM with the additional energy-saving benefits brought by the BIPV-MPCMS system. The feasibility and possible actual benefits of an integrated PCM can be found by comparison. In fact, PCM will have some additional effects on the characteristics of photovoltaic modules, such as increasing the weight of the module, changing the service life, changing the structural stability, and taking into account the safety factors, such as waterproof and fireproof, which will more or less increase the cost of integrated PCM. However, given the great potential of the BIPV-MPCMS system, with the progress of technology, the BIPV-MPCMS system may be widely used in fields, such as the construction industry.

Author Contributions

Methodology, Y.Z. (Yu Zheng) and W.Z.; Resources, F.H.; Software, K.W.; Supervision, X.L. (Xiaoge Li); Writing—original draft, X.L. (Xiaoming Li) and Y.Z. (Yuqiang Zhao); Writing—review & editing, X.L. (Xiaoming Li) All authors have read and agreed to the published version of the manuscript.

Funding

National Natural Science Foundation of China Youth Science Foundation Project (No. 51908287) and Jiangsu Provincial Natural Science Foundation Project (No. BK20180484).

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rahman, M.M.; Hasanuzzaman, M.; Rahim, N.A. Effects of various parameters on PV-module power and efficiency. Energy Convers. Manag. 2015, 103, 348–358. [Google Scholar] [CrossRef]

- Hasan, A.; McCormack, S.J.; Huang, M.J.; Norton, B. Evaluation of phase change materials for thermal regulation enhancement of building integrated photovoltaics. Sol. Energy 2010, 84, 1601–1612. [Google Scholar] [CrossRef]

- Radziemska, E.; Klugmann, E. Thermally affected parameters of the current–voltage characteristics of silicon photocell. Energy Convers. Manag. 2002, 43, 1889–1900. [Google Scholar] [CrossRef]

- Radziemska, E. The effect of temperature on the power drop in crystalline silicon solar cells. Renew. Energy 2003, 28, 1–12. [Google Scholar] [CrossRef]

- Martín-Chivelet, N.; Polo, J.; Sanz-Saiz, C.; Núñez Benítez, L.T.; Alonso-Abella, M.; Cuenca, J. Assessment of PV Module Temperature Models for Building-Integrated Photovoltaics (BIPV). Sustainability 2022, 14, 1500. [Google Scholar] [CrossRef]

- Teo, H.G.; Lee, P.S.; Hawlader, M.N.A. An active cooling system for photovoltaic modules. Appl. Energy 2012, 90, 309–315. [Google Scholar] [CrossRef]

- Schiro, F.; Benato, A.; Stoppato, A.; Destro, N. Improving photovoltaics efficiency by water cooling: Modelling and experimental approach. Energy 2017, 137, 798–810. [Google Scholar] [CrossRef]

- Bahaidarah, H.M.S.; Baloch, A.A.B.; Gandhidasan, P. Uniform cooling of photovoltaic panels: A review. Renew. Sustain. Energy Rev. 2016, 57, 1520–1544. [Google Scholar] [CrossRef]

- Peng, G.; Dou, G.; Hu, Y.; Sun, Y.; Chen, Z. Phase change material (PCM) microcapsules for thermal energy storage. Adv. Polym. Technol. 2020, 2020, 9490873. [Google Scholar] [CrossRef]

- Awad, M.M.; Ahmed, O.K.; Ali, O.M.; Alwan, N.T.; Yaqoob, S.J.; Nayyar, A.; Abouhawwash, M.; Alrasheedi, A.F. Photovoltaic Thermal Collectors Integrated with Phase Change Materials: A Comprehensive Analysis. Electronics 2022, 11, 337. [Google Scholar] [CrossRef]

- Huang, M.J.; Eames, P.C.; Norton, B. Phase change materials for limiting temperature rise in building integrated photovoltaics. Sol. Energy 2006, 80, 1121–1130. [Google Scholar] [CrossRef]

- Aelenei, L.; Pereira, R.; Gonçalves, H.; Athienitis, A. Thermal Performance of a Hybrid BIPV-PCM: Modeling, Design and Experimental Investigation. Energy Procedia 2014, 48, 474–483. [Google Scholar] [CrossRef]

- Huang, M.J.; Eames, P.C.; Norton, B. Thermal regulation of building-integrated photovoltaics using phase change materials. Int. J. Heat Mass Transf. 2004, 47, 2715–2733. [Google Scholar] [CrossRef]

- Huang, M.J.; Eames, P.C.; Hewitt, N.J. The application of a validated numerical model to predict the energy conservation potential of using phase change materials in the fabric of a building. Sol. Energy Mater. Sol. Cells 2006, 90, 1951–1960. [Google Scholar] [CrossRef]

- Kibria, M.A.; Saidur, R.; Al-Sulaiman, F.A.; Aziz, M.M.A. Development of a thermal model for a hybrid photovoltaic module and phase change materials storage integrated in buildings. Sol. Energy 2016, 124, 114–123. [Google Scholar] [CrossRef]

- Atkin, P.; Farid, M.M. Improving the efficiency of photovoltaic cells using PCM infused graphite and aluminium fins. Sol. Energy 2015, 114, 217–228. [Google Scholar] [CrossRef]

- Hasan, A.; McCormack, S.J.; Huang, M.J.; Norton, B. Characterization of phase change materials for thermal control of photovoltaics using Differential Scanning Calorimetry and Temperature History Method. Energy Convers. Manag. 2014, 81, 322–329. [Google Scholar] [CrossRef]

- Chen, Z.; Fang, G. Preparation and heat transfer characteristics of microencapsulated phase change material slurry: A review. Renew. Sustain. Energy Rev. 2011, 15, 4624–4632. [Google Scholar] [CrossRef]

- Huang, L.; Petermann, M.; Doetsch, C. Evaluation of paraffin/water emulsion as a phase change slurry for cooling applications. Energy 2009, 34, 1145–1155. [Google Scholar] [CrossRef]

- Zhao, C.Y.; Zhang, G.H. Review on microencapsulated phase change materials (MEPCMs): Fabrication, characterization and applications. Renew. Sustain. Energy Rev. 2011, 15, 3813–3832. [Google Scholar] [CrossRef]

- Zhang, P.; Ma, Z.W.; Wang, R.Z. An overview of phase change material slurries: MPCS and CHS. Renew. Sustain. Energy Rev. 2010, 14, 598–614. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).