Abstract

In order to study the mechanical failure characteristics and energy evolution law of gas-bearing coal–rock composites under different gas pressures, a uniaxial mechanical loading experiment was carried out on an upper-rock lower coal binary coal–rock assembly under different gas pressures. The changes in parameters such as compressive strength and elastic energy of the coal–rock combination were analyzed, and the energy transfer in the failure process of the gas-bearing coal–rock assemblage was studied. The results showed that the compressive strength of the combined body decreased linearly with the increase in gas pressure, and the decreasing rate of compressive strength was 6.4%, 16.3%, and 21.4%. The elastic modulus of the combined body decreased with the increase in gas pressure in a power function relationship. The energy accumulated before the peak of the rock part of the composite body and the elastic energy released after the peak, the energy accumulated before the peak of the composite body, and the energy dissipated after the peak of the coal body part all decreased with the increase in gas pressure. The variation range of the indicators K1 and K2, which reflect the influence degree of the partially accumulated elastic energy of the rock on the failure of the assemblage, were 5.85~6.68% and 7.34~9.46%, respectively.

1. Introduction

With the increase in coal mining depth and intensity, the interaction between coal and gas, rock burst, and other dynamic disasters is more prominent, showing the frequent occurrence of compound disasters [1,2,3,4,5]. Deep coal seams have environmental characteristics such as “high in-situ stress, high gas pressure, and high gas content” [6,7,8]. Under these conditions, they are combined with the surrounding rock layers to form a “rock mass-coal mass” composite system structure [9,10,11]. The instability and failure of the overall structure is an intuitive manifestation of the occurrence of coal–rock composite dynamic disasters, and the overall structure strength is affected by conditions such as rock-layer strength, coal-seam strength, gas pressure, and special engineering geological environment, and its occurrence has enormous complexity. The deep environment causes the coal seam, roof, and floor and their combined structures to accumulate and store more elastic energy, and the protruding and impact risk of the coal seam and roof and floor is enhanced. The elastic energy stored in the coal–rock mass with shock tendency is an important energy source for coal–rock dynamic disasters [12,13]. The accumulation, transmission, and dissipation of elastic energy of coal seams and rock layers directly affect the inoculation, occurrence, and development of coal–rock dynamic disasters [14,15]. Therefore, it is particularly important to carry out research on the mechanical properties of the coal–rock system composed of interlayers of coal and rock, and the law of energy transfer between rock and coal, which has important practical significance for the prevention and control of deep coal–rock composite dynamic disasters.

At present, many scholars at home and abroad have carried out a lot of research on coal–rock assemblage. Jiang [16], Zuo [17,18], Chen [19], Liu [20], Cai [21], Li [22], Yang [23], and Du [24] studied the mechanical properties of conventional loading of coal–rock assemblies, and revealed the differences in deformation and strength between coal–rock assemblies and coal–rock individual bodies. Chen et al. [25] used an MTS 815 testing machine to conduct cyclic loading and unloading tests on coal–rock assemblies and analyzed the variation laws of elastic strain and residual strain during cyclic loading and unloading of coal–rock assemblies. Zhao et al. [26] carried out mechanical and energy characteristics experiments of the whole process of deformation and failure under uniaxial loading on coal–rock composite specimens with different coal thicknesses (11.11%, 20.00%, 33.33%, 50.00%, and 62.50%) and found that as the proportion of coal thickness increased, the fracturing form of the specimen changed from tensile failure to shear failure through tensile–shear composite failure. Yang et al. [27] investigated the mechanical response characteristics and energy partition evolution law of coal–rock combinations with different strength ratios and found that when the rock strength was lower than that of coal, the strength of the combination was similar to that of the rock. When the strengths of the two were similar, the strength of the assemblage was slightly higher than that of coal and rock. With the increase in the strength and stiffness of the rock, the strength and stiffness of the composite body also increased, and with an increase in the rock strength, the strain energy density of the coal–rock composite body increased rapidly and then decreased slowly. Dong et al. [28] found that with an increase in strain rate, the peak strain, peak strength, and crack number all showed an increasing trend. Chen et al. [29,30] studied the mechanical properties of binary and ternary combinations of 19 different coal–rock ratios and combinations and the energy transfer mechanism in the failure process and found that the composition of fine sandstone determined the mechanical properties and impact effects of the combination. The energy of coal and rock was mainly distributed in the weak coal and rock layers, and no matter what kind of combination, the proportion of coal–part energy was more than 50%. Shen et al. [31] studied the strength and deformation failure characteristics of coal–rock assemblages with different dip angles (0°, 15°, 30°, 45°, and 60°) of the coal–rock contact surface and found that for a dip angle below 30°, the cracks were mainly distributed in the coal body, the integrity of the rock mass was good, tensile shear failure occurred above a dip angle of 45°, cracks penetrated through the coal–rock mass, the coal mass cracks were numerous and dense, and the rock mass had deep cracks. In a study by Xia [32] and Zhang [33], as the coal inclination angle rose, the elastic modulus and peak strength gradually decreased, and the damage value gradually increased while the strain at the same damage value gradually decreased. Ma et al. [34] analyzed the effect of loading rate on the strength, deformation, and energy of coal–rock assemblage, and found that the strength, deformation, acoustic emission, and energy of coal–rock assemblage samples all had obvious loading rate effects, and the uniaxial compressive strength and elastic modulus showed an increasing trend with increasing loading rate.

From the above research results, it can be seen that the previous studies on coal–rock assemblies mainly analyzed the influence of coal–rock combination method, coal–rock height ratio, strength ratio, dip angle, loading method, and other factors on the mechanical properties of coal–rock assembly. However, there are few studies on the effect of gas pressure on the mechanical properties of coal–rock assemblies. Because the deep coal–rock system is in a complex environment with high gas content and high gas pressure, the presence of gas has a significant impact on the coal–rock system. Therefore, in this paper, uniaxial mechanical loading experiments of coal–rock assemblies under different gas-pressure conditions are carried out to study the mechanical response characteristics and energy evolution laws of gas-bearing coal–rock assemblies under different gas-pressure conditions. It will provide a reference for research on the instability and failure mechanism of gas-bearing coal–rock systems in the stope environment of deep coal mines.

2. Uniaxial Compression Experiment of Gas-Bearing Coal–Rock Assemblage

The coal samples and rock samples required for this experiment were taken from the Yuyang Coal Mine M8 coal seam of Chongqing Songzao Coal and Electricity Co., Ltd. The M8 coal seam can be mined in the whole area, and the coal quality is anthracite. The thickness of the lower layer is 1.36~2.27 m, the average thickness of the lower layer is 1.64 m, the gangue is 0.3 m, and the thickness of the upper layer is 0.3 m. The roof of the coal seam is mudstone and sandy mudstone, the old roof is fine sandstone or siltstone, and the floor is gray claystone. The coal seam is buried at a depth of 670 m and belonged to a deep mine. The physical parameters, industrial analysis values, and adsorption analysis constants of the M8 coal seam samples are shown in Table 1.

Table 1.

Industrial analysis value and adsorption constant of coal sample of M8 coal seam in Yuyang Coal Mine.

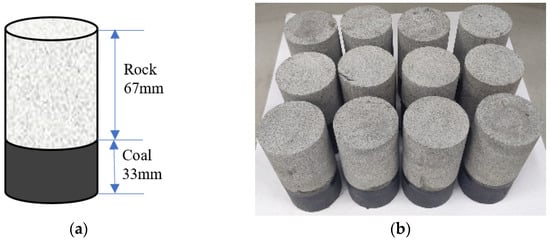

Based on the national standard GB/T23561.7-2009 for the determination of physical and mechanical properties of coal and rocks, the coal–rock assemblage was processed in a cylinder with a diameter of 50 mm × 100 mm (67 mm for the upper rock and 33 mm for the lower coal). Among them, siltstone was selected as the rock. The coal samples were made of similar materials with a cement ratio of 20%, a moisture content of 12%, a molding pressure of 25 MPa, a loading rate of 500 N/s, a pressure holding time of 15 min, a coal particle size of less than 0.18 mm, and a mass ratio of 0.18 mm to 0.25 mm of 1:1. The specific composite sample size is shown in Figure 1.

Figure 1.

The specific composite sample size. (a) Schematic diagram; (b) Physical diagram.

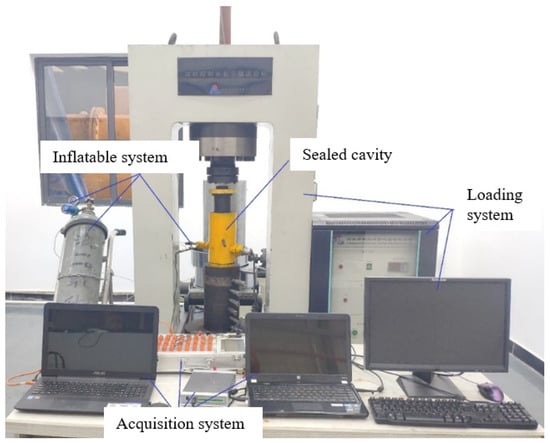

The experimental equipment was a TAW-2000 microcomputer-controlled electro-hydraulic servo rock triaxial testing machine (as shown in Figure 2). The experimental system consists of four parts, mainly including the sealing cavity, the loading system, the inflation system, and the data acquisition system. It can realize real-time monitoring of the stress–strain information of coal samples and rock samples and the pressure information in the cavity during the mechanical failure experiment of gas-bearing coal–rock assemblage at the same time. The uniaxial loading deformation failure experiment was carried out on the processed coal–rock composite specimen by means of displacement control loading, and the displacement loading rate was 0.48 mm/min.

Figure 2.

The experimental equipment.

3. Analysis of Mechanical Properties of Gas-Bearing Coal–Rock Combination

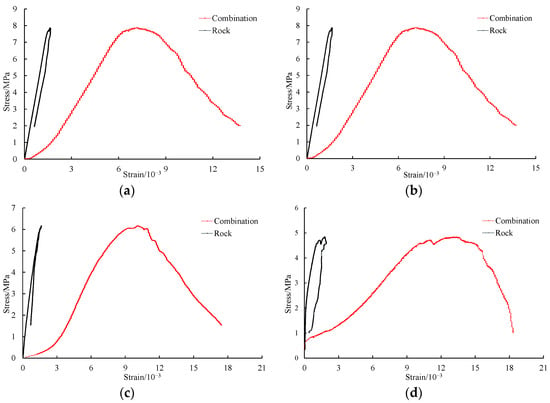

According to the above experimental scheme, the uniaxial loading deformation failure experiments of gas-bearing coal–rock assemblies under the conditions of gas pressures of 0.1 MPa, 0.3 MPa, 0.5 MPa, and 0.7 MPa were carried out. The stress–strain curve of the composite specimen obtained from the experiment is shown in Figure 3. The calculation results of each parameter of the composite specimen (peak strength, composite elastic modulus, rock elastic modulus, and rock peak strain) are shown in Table 2.

Figure 3.

The stress–strain curve of the composite specimen under different gas pressures. (a) 0.1 MPa; (b) 0.3 MPa; (c) 0.5 MPa; (d) 0.7 MPa.

Table 2.

The calculation results of each parameter of the composite specimen.

3.1. Comparative Analysis of Coal–Rock Assembly Strength

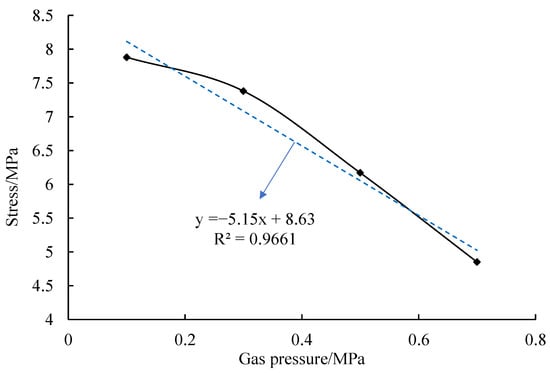

According to Figure 3 and Table 1, the relationship between compressive strength and gas pressure of the coal–rock assembly can be obtained as shown in Figure 4. It can be seen from Figure 4 that the compressive strength of the coal–rock assembly was related to the magnitude of the gas pressure. As the gas pressure increased from 0.1 MPa to 0.7 MPa, the compressive strength decreased from 7.88 MPa to 4.85 MPa. The decreasing rate of compressive strength was 6.4%, 16.3%, and 21.4%. By fitting the scatter plot of the compressive strength of the composite, it was found that there was a linear relationship between the two, and its expression is y = −5.15x + 8.63 (R2 = 0.9661).

Figure 4.

The relationship between compressive strength and gas pressure of the coal–rock assembly.

3.2. Comparative Analysis of Coal–Rock Assembly Elastic Modulus

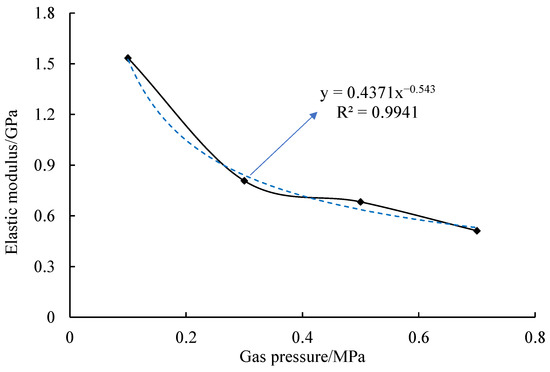

The relationship between the elastic model of the coal–rock assembly and the gas pressure is shown in Figure 5. It can be seen from Figure 5 that the elastic modulus of the coal–rock assembly was related to the gas pressure and decreased from 1.534 GPa to 0.512 GPa with the increase in the gas pressure from 0.1 MPa to 0.7 MPa. Meanwhile, the elastic modulus and gas pressure showed a power function relationship, and its expression is y = 0.4371x−0.543 (R2 = 0.9941).

Figure 5.

The relationship between the elastic model of the coal–rock assembly and gas pressure.

3.3. Comparative Analysis of Rock Peak Strain

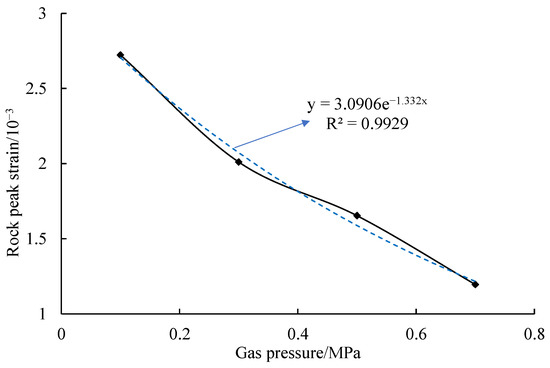

According to the uniaxial loading deformation failure experiment results of the gas-bearing coal–rock assemblies and Table 1, the relationship between the rock peak strain and the gas pressure was obtained as shown in Figure 6. It can be seen from Figure 6 that the gas pressure had a certain influence on the peak strain of the rock mass in the assemblage. With the increase in gas pressure from 0.1 MPa to 0.7 MPa, the peak strain of the rock mass decreased from 2.723 × 10−3 to 1.196 × 10−3. The rock peak strain and gas pressure showed an exponential function relationship, and its expression is y = 3.0906e−1.332x (R2 = 0.9929).

Figure 6.

The relationship between the rock peak strain and gas pressure.

4. Research on Energy Evolution Law of Coal–Rock Assemblage

4.1. Energy Calculation of Each Part in the Instability Failure Process of Coal–Rock Assembly

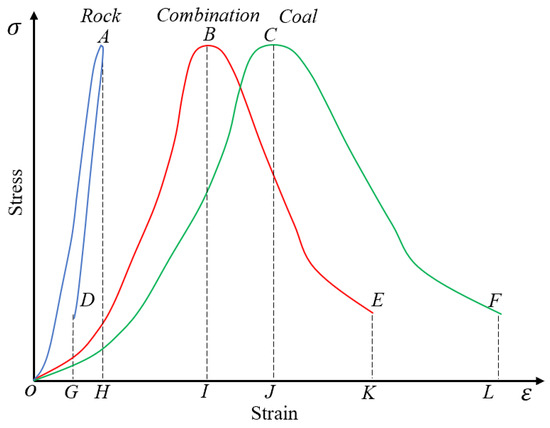

The “upper rock–lower coal” combination structure simulates that under the combined influence of in situ stress and gas pressure, the “roof–coal seam” system reaches the ultimate mechanical equilibrium state and breaks down under external loads [35,36,37,38]. When a coal–rock composite specimen is in the compression stage, both the coal and rock are deformed to compact the primary pores and fissures. Meanwhile, the coal and rock continuously accumulate energy and mainly exist in two ways. One is on the pores and fissures inside the specimen, causing irreversible deformation of the rock mass, coal mass, and composite body. The other causes elastic deformation of the rock mass, coal mass, and composite body, and is stored in the rock mass, coal mass, and composite body in the form of elastic energy. When the coal–rock composite specimen is unstable and damaged, the coal mass is damaged under the combined action of the external load and the elastic strain energy release of the rock mass. According to [15], the stress–strain curve of coal–rock assembly, rock mass, and coal mass can be drawn as shown in Figure 7.

Figure 7.

The stress–strain curve of coal–rock assembly, rock mass, and coal mass.

According to Figure 7 and [39,40], the total energy of rock mass pre-peak absorption (ER), the total energy of coal mass pre-peak absorption (Ec), the total energy of composite body pre-peak absorption (E), the releasable elastic energy of unloading after rock mass peak (EeR), the dissipated energy after coal mass failure peak (EdC), and the dissipated energy after composite body failure peak (Ed) can be acquired, as shown in Equation (1).

where, is the strain, is the stress, is the volume of the rock mass, is the volume of the coal mass, and .

4.2. Analysis of the Influence Degree of Rock Release Elastic Energy on Composite Failure

The total energy input before the peak of the coal–rock combination is divided into four parts: rock compaction dissipation energy, rock elastic energy, coal compaction dissipation energy, and coal elastic energy. When the composite body reaches its peak strength, the coal body is damaged due to its low strength, and the elastic energy of the rock and the coal are released. Referring to the definition method of the evaluation index of the impact tendency of coal [41,42,43], the releasable elastic energy of unload after the rock mass peak (EeR) is set as the index K1 compared with the total energy of the composite body pre-peak absorption (E), as shown in Equation (2). The K1 index reflects the ability of the rock part in the assemblage to accumulate elastic energy before the peak.

In the coal–rock assemblage, the rock mass will release elastic energy during the failure of the coal mass, part of the elastic energy will participate in the coal-failure process, and the other part of the elastic energy can restore the strain of the rock mass. Part of the dissipated energy after the coal mass failure peak (EdC) comes from the rock mass, and the other part comes from the elastic energy accumulated by itself. The releasable elastic energy of unloading after the rock mass peak (EeR) is defined as the index K2 compared to the dissipated energy after the coal mass failure peak (EdC), as shown in Equation (3).

The K2 index reflects the proportion of the energy contributed by the elastic energy of the rock in the composite body when the composite body is destroyed. Both indexes K1 and K2 can reflect the degree of influence of rock accumulation elastic energy on the failure of the composite to a certain extent.

4.3. Calculation Results and Discussion

According to the definitions in Section 4.1 and Section 4.2, the calculation results of each energy index were obtained as shown in Table 3. The relationship expression between each index and gas pressure is shown in Table 4.

Table 3.

The calculation results of each index.

Table 4.

The relationship expression between each index and gas pressure.

It can be seen from Table 3 and Table 4 that the total energy of the rock mass pre-peak absorption (ER), the releasable elastic energy of unloading after the rock mass peak (EeR), the total energy of the composite body pre-peak absorption €, and the dissipated energy after the coal mass failure peak (EdC) all decreased with the increase in gas pressure from 0.1 MPa to 0.7 MPa. ER and gas pressure had a linear negative relationship, and the fitting coefficient R2 was 0.9949. EeR, E, EdC, and gas pressure had a quadratic polynomial relationship, and the fitting coefficients were 0.9955, 0.9775, and 0.9933, respectively. When the gas pressure went from 0.1 MPa to 0.7 MPa, the variation range of indicator K1 was 5.85~6.68% and the variation range of indicator K2 was 7.34~9.46%. It shows that with the increase in gas pressure, the energy releases after the rock peak had a greater aggravating effect on the failure of the coal–rock assemblage. When gas-containing coal seams and rock formations were destabilized and damaged, the limit of accumulated energy in the coal seams decreased and the elastic energy accumulated in the rock formations promoted the destruction of the coal seams.

This is because with the increase in gas pressure, when the combination reaches equilibrium of adsorption and desorption, the gas pressure partially adsorbed by the coal will be larger, and the adsorbed gas will weaken the mechanical properties of the coal and cause a slight volume expansion of the coal. Ultimately, the overall mechanical properties of the composite body are reduced, and the energy limit value of the composite body when it is destroyed is reduced. Therefore, the higher the gas pressure, the smaller the energy value accumulated before the peak of each part of the combination. With the increase in gas pressure, the ratio of the energy released after the peak of the rock mass to the accumulated energy before the peak increases, indicating that with the increase in gas pressure, the ability of the rock mass to release energy decreases, and the energy acting on itself to generate plastic deformation increases. The ratio of the elastic energy released after the partial peak of the rock to the energy dissipated after the partial peak of the coal mass decreases with the increase in the gas pressure, indicating that the energy effect of the rock mass on the instability and failure of the partial coal body decreases and the required energy for the failure of the coal mass decreases. The energy comes more from the strain energy accumulated before the peak of the coal mass.

5. Conclusions

In this paper, uniaxial loading deformation failure experiments of gas-bearing coal–rock assemblies under the conditions of gas pressures of 0.1 MPa, 0.3 MPa, 0.5 MPa, and 0.7 MPa were carried out. The following conclusions were mainly obtained:

- (1)

- As the gas pressure increased from 0.1 MPa to 0.7 MPa, the compressive strength of the combined body decreased linearly from 7.88 MPa to 4.85 MPa, and the decreasing rate of compressive strength was 6.4%, 16.3%, and 21.4%. The elastic modulus of the combined body decreased from 1.534 GPa to 0.512 GPa with the increase in gas pressure in a power-function relationship. The peak strain of the rock mass decreased from 2.723 × 10−3 to 1.196 × 10−3 in an exponential-function relationship with the increase in gas pressure.

- (2)

- The total energy of the rock mass pre-peak absorption (ER), the releasable elastic energy of unloading after the rock mass peak (EeR), the total energy of the composite body pre-peak absorption €, and the dissipated energy after the coal mass failure peak (EdC) all decreased with the increase in gas pressure from 0.1 MPa to 0.7 MPa. ER and gas pressure had a linear negative relationship, and EeR, E, EdC, and gas pressure had a quadratic polynomial relationship.

- (3)

- When the gas pressure went from 0.1 MPa to 0.7 MPa, the variation range of the indexes K1 and K2 were 5.85%~6.68% and 7.34%~9.46%, respectively. K1 and K2 can reflect the degree of influence of rock accumulation elastic energy on the failure of the composite to a certain extent.

- (4)

- This paper obtained the effect of gas pressure on the mechanical failure characteristics and energy evolution law of gas-bearing coal–rock composites, and it could provide a useful reference for the systematic instability of a coal–rock combination system and the analysis of energy evolution law in the process of deep coal-mining resources.

Author Contributions

Conceptualization, L.D.; methodology, L.D., Z.Z. and H.S.; validation, L.D., Z.Z. and H.S.; formal analysis, L.D.; investigation, L.D., H.S. and H.G.; resources, L.D.; data curation, L.D. and H.G.; writing—original draft preparation, L.D., H.S. and H.G.; writing—review and editing, L.D., Z.Z. and H.S.; visualization, L.D. and H.G.; supervision, Z.Z.; project administration, L.D.; funding acquisition, L.D. and H.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (No. 51874348, No. 51974358, No. 52104239), the Chongqing Science Fund for Distinguished Young Scholars (No. cstc2019jcyjjqX0019), the Natural Science Foundation of Chongqing (No. cstc2020jcyj-msxmX1052), the Science and Technology Innovation and Entrepreneurship Fund of China Coal Technology Engineering Group (No. 2019-TD-QN040), and the Science and Technology Project of Chongqing Jiulongpo District (No. 2020-02-008-Y), which are gratefully acknowledged.

Institutional Review Board Statement

The study did not require ethical approval.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

All data and/or models used in the study appear in the submitted article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Xiao, Z.M.; Gu, S.T.; Zhang, Y.Z.; Wang, H. A coal seam-roof-floor coupling destressing control method of fault coal bursts induced by deep coal seam mining. Energy Sci. Eng. 2022, 10, 2170–2190. [Google Scholar] [CrossRef]

- Wang, K.; Li, K.N.; Du, F. Study on prediction of coal-gas compound dynamic disaster based on GRA-PCA-BP model. Geofluids 2021, 2021, 3508806. [Google Scholar] [CrossRef]

- Du, F.; Wang, K.; Guo, Y.Y.; Wang, G.D.; Wang, L.; Wang, Y.H. The mechanism of rockburst-outburst coupling disaster considering the coal–rock combination: An experiment study. Geomech. Eng. 2020, 22, 255–264. [Google Scholar]

- Chen, X.J.; Li, L.Y.; Wang, L.; Qi, L.L. The current situation and prevention and control countermeasures for typical dynamic disasters in kilometer-deep mines in China. Saf. Sci. 2019, 115, 229–236. [Google Scholar] [CrossRef]

- Pan, Y.S. Integrated study on compound dynamic disaster of coal-gas outburst and rockburst. J. China Coal Soc. 2016, 41, 105–112. (In Chinese) [Google Scholar]

- Yuan, L. Research progress of mining response and disaster prevention and control in deep coal mines. J. China Coal Soc. 2021, 46, 716–725. (In Chinese) [Google Scholar]

- Xie, H.P.; Zhu, J.B.; Zhou, T.; Zhang, K.; Zhou, C.T. Conceptualization and preliminary study of engineering disturbed rock dynamics. Geomech. Geophys. Geo-Energy Geo-Resour. 2020, 6, 34. [Google Scholar] [CrossRef]

- Dai, L.C.; Liu, Y.B.; Cao, J.; Yang, X.L.; Sun, H.T.; Wen, G.C.; Wang, B. A Study on the energy condition and quantitative analysis of the occurrence of a coal and gas outburst. Shock. Vib. 2019, 2019, 8651353. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Wang, J.H.; Lu, C.P.; Wang, C.; Xie, H.D.; Yan, X.Y. Research on instability characteristics and precursory effect of coal–rock parting-coal structures. Sci. Rep. 2022, 12, 12091. [Google Scholar] [CrossRef] [PubMed]

- Zuo, J.P.; Chen, Y.; Sun, Y.J.; Jiang, G.H.; Wang, J.T. Investigation on whole failure nonlinear model for deep coal–rock combined bodies. J. Min. Sci. Technol. 2017, 2, 17–24. (In Chinese) [Google Scholar]

- Feng, G.R.; Bai, J.W.; Shi, X.D.; Qi, T.Y.; Wang, P.F.; Guo, J.; Wang, S.Y.; Kang, L.X. Key pillar theory in the chain failure of residual coal pillars and its application prospect. J. China Coal Soc. 2021, 46, 164–179. (In Chinese) [Google Scholar]

- Wang, K.; Du, F. Coal-gas compound dynamic disasters in China: A review. Process Saf. Environ. Prot. 2020, 133, 1–17. [Google Scholar] [CrossRef]

- Du, F.; Wang, K.; Zhang, X.; Xin, C.P.; Shu, L.Y.; Wang, G.D. Experimental study of coal-gas outburst: Insights from coal–rock structure, gas pressure and adsorptivity. Nat. Resour. Res. 2020, 29, 2481–2493. [Google Scholar] [CrossRef]

- Xiao, X.C.; Fan, Y.F.; Wu, D.; Ding, X.; Wang, L.; Zhao, B.Y. Energy dissipation feature and rock burst risk assessment in coal–rock combinations. Rock Soil Mech. 2019, 40, 4203–4212+4219. (In Chinese) [Google Scholar]

- Sun, H.T.; Dai, L.C.; Liu, Y.B.; Jin, H.W. Critical conditions and energy transfer characteristics of the failure process of coal–rock combination systems in deep mines. Geofluids 2021, 2021, 6655443. [Google Scholar] [CrossRef]

- Jiang, Y.D.; Wang, T.; Song, Y.M.; Wang, X.; Zhang, W. Experimental study on the stick-slip process of coal–rock composite samples. J. China Coal Soc. 2013, 38, 177–182. (In Chinese) [Google Scholar]

- Zuo, J.P.; Chen, Y.; Cui, F. Investigation on mechanical properties and rock burst tendency of different coal–rock combined bodies. J. China Univ. Min. Technol. 2018, 47, 81–87. (In Chinese) [Google Scholar]

- Zuo, J.P.; Chen, Y.; Song, H.Q. Study progress of failure behaviors and nonlinear model of deep coal–rock combined body. J. Cent. South Univ. Sci. Technol. 2021, 52, 2510–2521. (In Chinese) [Google Scholar]

- Chen, Y.L.; Zuo, J.P.; Liu, D.J.; Wang, Z.B. Deformation failure characteristics of coal–rock combined body under uniaxial compression: Experimental and numerical investigations. Bull. Eng. Geol. Environ. 2019, 78, 3449–3464. [Google Scholar] [CrossRef]

- Liu, W.R.; Yuan, W.; Yan, Y.T.; Wang, X. Analysis of acoustic emission characteristics and damage constitutive model of coal–rock combined body based on particle flow code. Symmetry 2019, 11, 1040. [Google Scholar] [CrossRef] [Green Version]

- Cai, Y.B.; Wang, K.; Xu, C. Comparative experimental study on deformation and damage characteristics of single coal rock and primary coal–rock combination. J. Min. Sci. Technol. 2020, 5, 278–283. (In Chinese) [Google Scholar]

- Li, C.J.; Xu, Y.; Feng, M.M.; Pan, B. Deformation law and failure mechanism of coal–rock-like combined body under uniaxial loading. J. China Coal Soc. 2020, 45, 1773–1782. (In Chinese) [Google Scholar]

- Yang, S.; Wang, J.; Ning, J.G.; Qiu, P.Q. Experimental study on mechanical properties, failure behavior and energy evolution of different coal–rock combined specimens. Appl. Sci. 2019, 20, 4427. [Google Scholar] [CrossRef] [Green Version]

- Du, Y.L.; Feng, G.R.; Kang, H.P.; Zhang, Y.J.; Zhang, X.H. Effects of different pull-out loading rates on mechanical behaviors and acoustic emission responses of fully grouted bolts. J. Cent. South Univ. 2021, 28, 2052–2066. [Google Scholar] [CrossRef]

- Chen, Y.; Zuo, J.P.; Song, H.Q.; Feng, L.L.; Shao, G.Y. Deformation and crack evolution of coal–rock combined body under cyclic loading-unloading effects. J. Min. Saf. Eng. 2018, 35, 826–833. (In Chinese) [Google Scholar]

- Zhao, P.X.; He, Y.C.; Li, S.G.; Lin, H.F.; Jia, Y.Y.; Yang, E.H. Coal thickness effect on mechanics and energy characteristics of coal–rock combination model. J. Min. Saf. Eng. 2020, 37, 1067–1076. (In Chinese) [Google Scholar]

- Yang, L.; Gao, F.Q.; Wang, X.Q. Mechanical response and energy partition evolution of coal–rock combinations with different strength ratios. Chin. J. Rock Mech. Eng. 2020, 39, 3297–3305. (In Chinese) [Google Scholar]

- Dong, S.N.; Li, A.; Ji, Y.D.; Yang, Y.X.; Mu, Q. Mechanical and failure characteristics of rock-coal–rock combined body under different strain rates: A numerical study from micro perspective. Geotech. Geol. Eng. 2021, 39, 185–191. [Google Scholar] [CrossRef]

- Chen, G.B.; Qin, Z.C.; Zhang, G.H.; Li, T.; Li, J.K. Law of energy distribution before failure of a loaded coal–rock combined body. Rock Soil Mech. 2020, 41, 1–13. (In Chinese) [Google Scholar]

- Chen, G.B.; Li, T.; Yang, L.; Zhang, G.H.; Li, J.W.; Dong, H.J. Mechanical properties and failure mechanism of combined bodies with different coal–rock ratios and combinations. J. Min. Strat. Control. Eng. 2021, 3, 80–90. (In Chinese) [Google Scholar]

- Shen, W.B.; Yu, W.J.; Pan, B. Rock mechanics test and failure characteristics of coal–rock Combination with different dip angles. Miner. Eng. Res. 2021, 36, 1–8. (In Chinese) [Google Scholar]

- Xia, Z.G.; Liu, S.; Bian, Z.; Song, J.H.; Feng, F.; Jiang, N. Mechanical properties and damage characteristics of coal–rock combination with different dip angles. KSCE J. Civ. Eng. 2021, 25, 1687–1699. [Google Scholar] [CrossRef]

- Zhang, C.L.; Dong, Y.; Feng, R.M.; Peng, N.B.; Zhang, J.H.; Wu, J.K.; Shen, W. Crack propagation law and failure characteristics of coal–rock combined body with the different inclination angle of prefabricated fissure. Geofluids 2021, 2021, 4348912. [Google Scholar] [CrossRef]

- Ma, Q.; Tan, Y.L.; Liu, X.S.; Zhao, Z.H.; Fan, D.Y.; Purev, L. Experimental and numerical simulation of loading rate effects on failure and strain energy characteristics of coal–rock composite samples. J. Cent. South Univ. 2021, 28, 3207–3222. [Google Scholar] [CrossRef]

- Li, X.; Li, H.; Yang, Z.; Sun, Z.X.; Zhuang, J.Y.; Song, C.X.; Wang, X. Experimental study on triaxial unloading failure of deep composite coal–rock. Adv. Civ. Eng. 2021, 2021, 6687051. [Google Scholar] [CrossRef]

- Li, T.; Chen, G.B.; Li, Q.H.; Cao, B.; Li, Y.H. The effect of crack characteristics on the mechanical properties and energy characteristics of coal–rock composite structure. Acta Geodyn. Geomater. 2022, 19, 127–142. [Google Scholar] [CrossRef]

- Shi, X.D.; Bai, J.W.; Feng, G.R.; Wang, K.; Cui, B.Q.; Guo, J.; Yang, X.Y.; Song, C. Crack propagation law at the interface of FRP wrapped coal-backfilling composite structure. Constr. Build. Mater. 2022, 344, 128229. [Google Scholar] [CrossRef]

- Gao, L.; Zhan, X.Y.; Zhang, P.D.; Wen, Z.J.; Ma, Z.Q.; Kong, D.Z.; Kang, X.T.; Han, S. Study on the dip angle effect of asymmetric deformation and failure of the gob-side coal–rock roadway in gently inclined coal seam. Sustainability 2022, 14, 7299. [Google Scholar] [CrossRef]

- Zhang, L.M.; Gao, S.; Ren, M.Y.; Wang, Z.Q.; Ma, S.Q. Rock elastic strain energy and dissipation strain energy evolution characteristics under conventional triaxial compression. J. China Coal Soc. 2014, 39, 1238–1242. (In Chinese) [Google Scholar]

- Chen, G.Q.; Wu, J.C.; Jiang, W.Z.; Li, S.J.; Qiao, Z.B.; Yang, W.B. An evaluation method of rock brittleness based on the whole process of elastic energy evolution. Chin. J. Rock Mech. Eng. 2020, 39, 901–911. (In Chinese) [Google Scholar]

- Ju, W.J.; Lu, Z.G.; Gao, F.Q.; Zhao, Y.X.; Li, W.Z.; Sun, Z.Y.; Hao, X.J. Research progress and comprehensive quantitative evaluation index of coal rock bursting liability. Chin. J. Rock Mech. Eng. 2021, 40, 1839–1856. (In Chinese) [Google Scholar]

- Qi, Q.X.; Li, H.T.; Li, X.P. Qualitative and quantitative evaluation of impact risk in underground mine. Coal Sci. Technol. 2021, 49, 12–19. (In Chinese) [Google Scholar]

- Gong, F.Q.; Zhao, Y.J.; Wang, Y.L.; Peng, K. Research progress of coal bursting liability indices and coal burs “Human-Coal-Environment” three elements mechanism. J. China Coal Soc. 2022, 47, 1974–2010. (In Chinese) [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).