1. Introduction

Among all the conditioning factors affecting food production and water supply, irrigation is one of the most important. Worldwide, irrigated agriculture accounts for 20% of total cultivated land and provides 40% of the food produced in the world [

1]. The impact of irrigation, however, varies in each region, depending on the conditions of the area and the use of the resources. In the European Union, Spain has the largest irrigated area, covering almost four million hectares, having increased by 14% in less than 20 years [

2]. In Spain, 77% of the irrigated area is irrigated by pressurized irrigation, in which sprinkler irrigation is of great importance (14.8% of the irrigated area) [

3]. The implementation of irrigation results in a large increase in productivity. Therefore, climate change is expected to favor the introduction of technologies that will improve water use efficiency. Specifically, in the case of developed countries, it is expected that in the near future the irrigated area will increase by 34% and the water used by 14% [

4].

The impact of irrigation is therefore enormous, both in terms of the benefit to society in relation to food production and the damage it causes. For example, it is estimated that irrigation accounts for 70% of all freshwater withdrawals worldwide [

1]. Therefore, the most important challenge will be to mitigate the negative impacts produced without reducing the benefits generated for society. This means that there is an increasing need to know how irrigation systems are performing in order to make them more effective and efficient. Effectiveness in an irrigation system consists of its capacity to provide the required quantity at the right time and the conditions necessary for the correct development of the plant. As for efficiency, it is the ability to use the available resources in the most productive way possible.

In this sense, when evaluating an irrigation system, distribution uniformity is one of the magnitudes that allows for both conditions to be assessed. The distribution uniformity is the parameter that characterizes the irrigation emitters’ relative distribution of irrigation water on the surface. Knowledge of this value will help characterize the irrigation system as a whole, as it is influenced by factors such as emitter layout, pumping, pipe routing, etc. Studies such as Eng et al. [

5] measured distribution uniformity for sprinklers under greenhouse conditions. As long as the needs are uniform over the entire surface, the water application will be the same throughout the field, i.e., maximum uniformity. A distribution uniformity of less than 100% will mean that there will be under- or over-irrigated areas, or both, which will negatively affect the effectiveness and efficiency of the irrigation system.

Emitter manufacturers often provide approximate distribution uniformity data depending on the model, sprinkler arrangement, and operating conditions. However, if reliable data are desired, it is in principle necessary to measure distribution uniformity directly under irrigation conditions. This need is due to the great dependence of the distribution uniformity on variables such as hydraulic pressure at the emitter, wind or topography, and the coefficient of variation of the microirrigation emitters which causes the distribution uniformity to vary significantly and easily, both spatially and temporally. Traditionally, this measurement has been made by placing a network of rain gauges or water collectors on the surface to be studied. The values thus obtained are used to calculate various coefficients that give an idea of the distribution uniformity. Although effective, this methodology is limited by the need for field data, which are often costly to obtain, especially if one wishes to study large areas. For this reason, in recent years, taking advantage of computer technology, models and tools have become available to simulate the behavior of sprinklers under different initial conditions and large surface areas, which in turn allows distribution uniformity to be estimated in an extended manner.

Most modeling studies on sprinkler water distribution have focused on simulating the behavior of a single sprinkler with a few input variables (Playán et al. [

6], Li, Bai, and Yan [

7] or Zhang, Merkley, and Pinthong [

8]). These investigations, however, only simulated uniformity for isolated sprinklers, and did not consider the effect of overlap on distribution uniformity. Other studies such as Chen et al. [

9] or Do Prado and Colombo [

10] succeeded in simulating distribution uniformity with several moving sprinklers using the commercial programming platform MATLAB, and the commercial program Si-mulasoft, respectively. Fukui, Nakanishi, and Okamura [

11] did the same but with stationary sprinklers. Apart from specific studies, commercial software has been developed that allows the distribution uniformity of sprinkler blocks to be known by using hydraulic simulations such as SPACE Pro [

12] or SIRIAS [

13].

However, the major limitation of the studies shown so far is the lack of spatial generalization of the results and the use of non-free software. These investigations and methodologies work adequately for certain conditions that do not represent, for example, what happens on an extensive farm but are limited to specific areas. Therefore, the main objective of this work was to propose and evaluate a methodology that allows the uniformity of the application of sprinkler irrigation in the whole area occupied by greenhouses on a given farm to be known without the need for direct measurements. The evaluation with field data of the proposed methodology was carried out at the level of irrigation sectors; this was a level of detail that we believed was sufficient at this stage of the study. This main objective required the previous fulfillment of others: (i) the determination of the pressures and flow rates in all the sprinklers of the installation using the free hydraulic simulation software EPANET; (ii) the determination of the distributed rainfall and flow rate curve as a function of pressure for the working sprinklers; (iii) assign to each location the precipitation corresponding to irrigation, which in turn would allow estimating the uniformity of the application, using the interaction between the free GIS program QGIS and EPANET. The uniformity thus obtained was compared with in situ measurements to evaluate the methodology’s validity.

Although this is not the first time that the interaction of both programs has been used, it is the first time it has been used to simulate a system with a pressure-dependent demand. So far, the studies that have integrated both programs have done so for supply networks with fixed flow rates, such as the studies of Pérez-Padillo et al. [

14], Muller et al. [

15], Safitri et al. [

16], Estong et al. [

17] and Nagarajan and Charhate [

18]. Other studies used GIS and hydraulic simulation programs for flood hazard zoning [

19] or used GIS tools to determine shoreline morphological changes [

20]. The only study that used a GIS program with EPANET was the EPANET study of Pérez Urrestarazu et al. [

21] for failure and problem area monitoring in different irrigation sectors. Therefore, it will be the first time that QGIS and EPANET have been used together to geospatially represent rainfall and calculate distribution uniformity in a system with a pressure-dependent demand.

2. Materials and Methods

2.1. Description of the Hydraulic Systems in the Greenhouses Studied

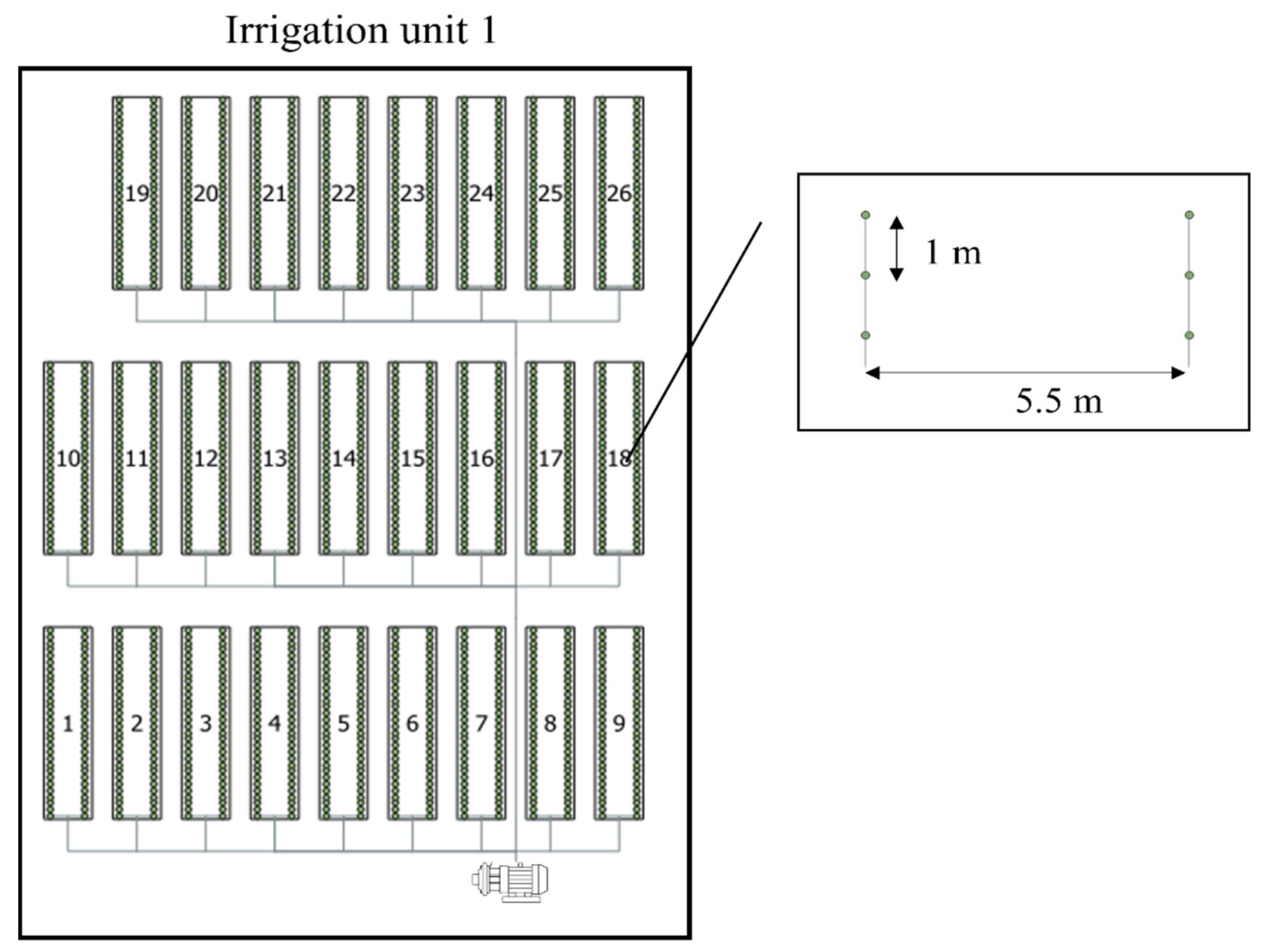

A greenhouse agricultural facility was chosen for this study. The irrigation system was sprinkler irrigation. The sprinklers were located along the length and width of the greenhouses at a height of about 1.8 m above the ground. The agricultural facility had 26 greenhouses. The sectors had an almost flat slope. The irrigation unit was sized to irrigate three irrigation sectors simultaneously. The sprinkler arrangement was 5.5 × 1.0 m with the Green Spin 120 model of NaanDanJain company (

Figure 1). The nominal flow rate of the sprinklers was 120 L/h with a nominal pressure of 2 bar. The surface area in each sector was different, varying from 500 m

2 to 650 m

2. A single vertical centrifugal pump drove the water.

2.2. In Situ Measurement of Distribution Uniformity

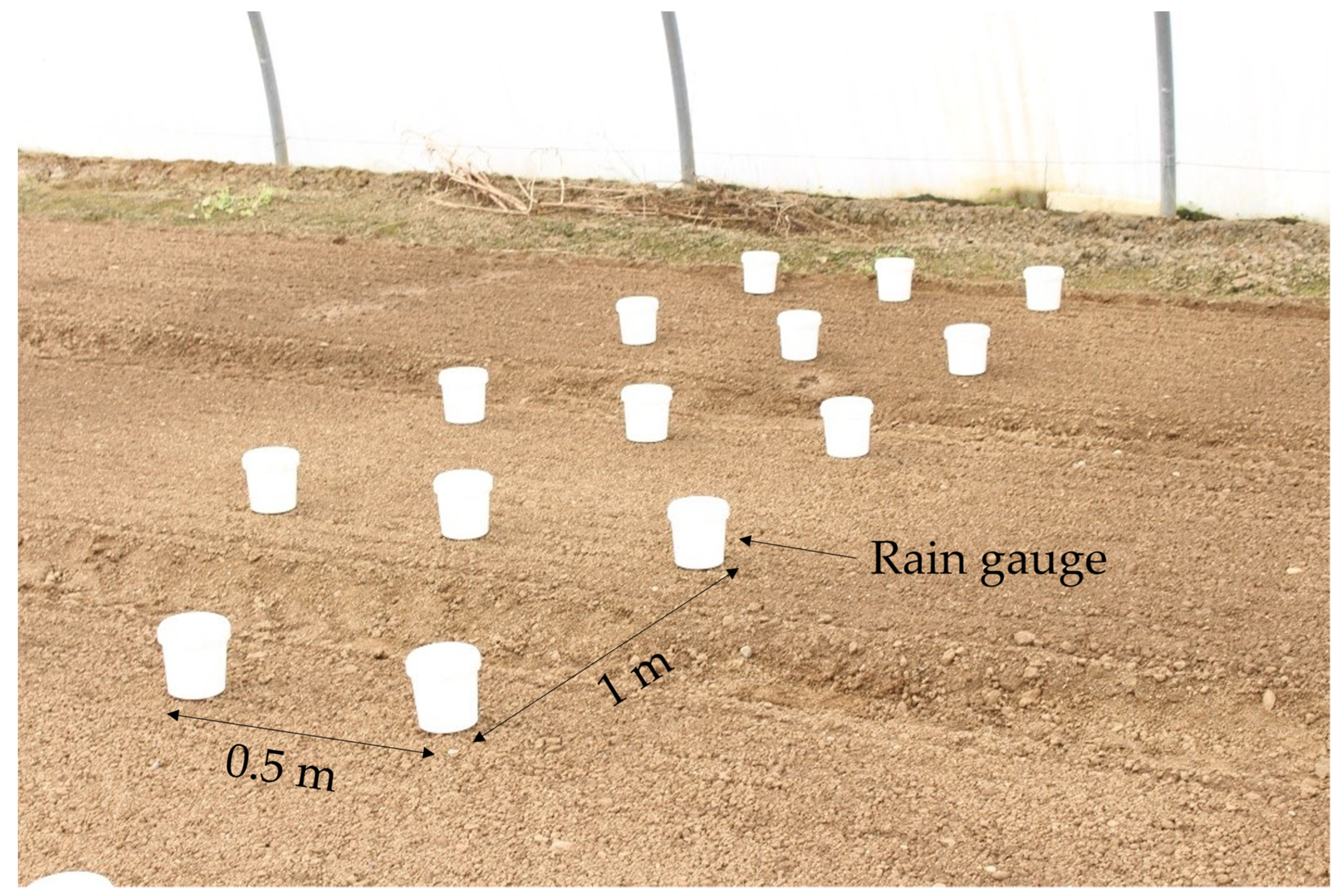

As already discussed, the main objective of this work was to quantify water application in the different areas of an installation by sprinklers to calculate the distribution uniformity. The simulation would allow an estimation of the distribution uniformity without the need to take data in the field. However, a distribution uniformity study with the classical methodology was necessary to evaluate the simulations correctly and to determine if they gave correct results. This way, the simulation results could be compared with those obtained in the study and whether the proposed methodology yielded adequate results could be checked. For this purpose, several rain gauges were placed in sectors 5 and 23, and irrigation was applied for 30 min. In each trial, 24 rain gauges were placed at a frame of 0.5 × 1 m, covering an area of 7 m

2 (

Figure 2). The dimensions of the catch can array were based on the sector’s width and the sprinklers’ arrangement. While irrigation was in operation, data on the maximum and minimum pressures of the sector in which the study was conducted were obtained manually.

To obtain the distribution uniformity, for this experiment the Christiansen’s uniformity coefficient proposed by Christiansen (1942) [

22] at the University of California (1) was used for this experiment:

where

is the amount of water collected by each catch rain gauge (in mm),

is the average value collected by the gauges, and n is the total number of rain gauges.

The value obtained from (1) reported the distribution uniformity of the studied area, i.e., 7 m

2. To extrapolate this value to that of the sector in which it is being measured, Equation (2) was used that takes into account the pressure differences of the sprinklers in the sector [

23]:

where

is the uniformity coefficient of the system or sector, CU is the uniformity coefficient of the measurement area.,

is the minimum pressure in the system and

is the average pressure of the system. For this purpose, the maximum and minimum sprinkler pressure was measured in the two sectors where uniformity was measured.

2.3. Sprinkler Evaluation: Flow vs. Pressure Relationship and Depth of Water Application Distribution vs. Pressure

In order to proceed with the simulations, it was necessary to have the flow vs. pressure relationship of the sprinkler, which was the Green Spin 120 model (NaanDanJain) and also the water application distribution vs. pressure. One of the particularities of this simulation was that the sprinkler water supply would depend on the incoming pressure. Therefore, if one wanted to know the water delivery of each sprinkler (“demand”), one would have to know the flow vs. pressure relationship of the sprinkler (

Figure 3). The flow vs. pressure relationship was defined by the discharge coefficient and the discharge exponent (3).

where q is the emitter flow rate, k is the discharge coefficient, h is the pressure at the emitter inlet, and x is the discharge exponent.

These values were obtained in a hydraulics laboratory by measuring the flow rate at different pressures and performing a geometric regression process.

The discharge coefficient and discharge exponent obtained were as follows (

Table 1).

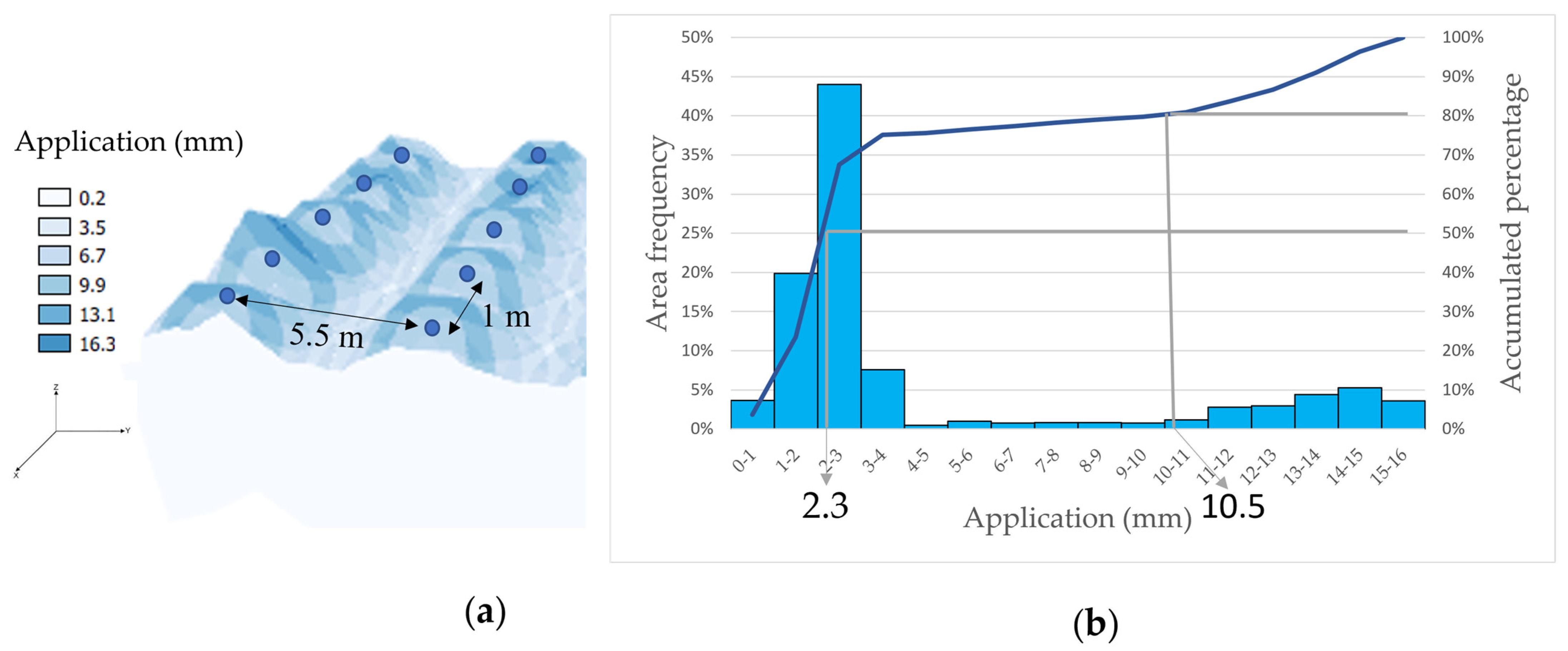

Equation (3) reports the total flow delivered depending on the incoming pressure but does not show how it was distributed in the space. Therefore, a sprinkler was placed in the same laboratory at the same height as in the greenhouses, and six rain gauges were placed 0.5 m apart along the same radius of the jet so that they were arranged along the 3 m. The precipitation in each rain gauge was determined at different pressures (1.1 bar and 2.4 bar) and by means of a geometric regression process, the characteristic curve was determined (ec. 4).

where

p is the precipitation rate (mm/h) at each sampled distance (

d),

k and

x are fitted parameters at each distance. The characteristic curve was as follows (

Table 2).

Negative values of xd indicate that at higher pressure the application at that distance is lower. Values of zero indicate that the pressure does not affect the water applied at that distance.

2.4. Pressure Simulation

The programs used for rainfall simulation were the QGIS 3.10 [

24] and EPANET 2.2. QGIS is an open-source Geographic Information System and EPANET is a program for the analysis of hydraulic behavior in pressurized pipeline networks developed by the U.S. Environmental Protection Agency [

25]. It is currently the most widely used hydraulic modeling software in the world and allows simulations over long periods of time of the hydraulic behavior and the evolution of water quality in pressurized supply networks. It is also widely used for the optimization of distribution networks [

26] or for the evaluation of irrigation systems from the point of view of energy needs [

27].

The simulation consisted of two parts. First, a simulation was performed in EPANET to determine the pressure reaching the sprinklers, an exercise that required the support of QGIS, as explained below. Subsequently, another simulation was performed in QGIS to obtain and geospatially represent the applied water height (

Figure 3). For the hydraulic simulation in EPANET, the first step was to characterize the irrigation facilities in the QGIS GIS program: characterization and spatial representation of the pipes (lengths, diameters, roughness), sprinklers (flow vs. pressure relationship), nodes, pump, and reservoir placement. Once all the elements related to the irrigation facilities had been spatially characterized, they were simulated in the hydraulic simulation program EPANET. However, for the integration of both programs, i.e., for EPANET to use the QGIS information, it was necessary to use the QWater 3.1.8 plugin. QWater is the add-on that allows the creation of the INP file, a file format that EPANET could recognize from QGIS layers.

Once the INP file was created, it was then exported into EPANET. The next step was to provide EPANET with information regarding the facility’s operation. As previously mentioned, three sectors (individual greenhouses) were irrigated simultaneously. This resulted in a large casuistry, with numerous possible combinations of opening between sectors. The rainfall depends on the pressure (non-linear relationship), which depends on the irrigation sectors that are irrigated simultaneously. Indeed, in each combination of sectors, the characteristics of the pipes used changed, as well as the number of sprinklers, etc. Considering that the simulation provided information on the distribution uniformity of water application, it did not make sense to simulate all possible combinations of tunnel openings, since in many of them the results will not vary significantly. Thus, it was considered that, in each tunnel, uniformity would only be simulated for the most and least favorable combinations, understanding as such those with the highest and lowest average arrival pressure at the sprinklers, respectively. Therefore, each tunnel was simulated with the combination that made the average pressure of arrival to its emitters the highest and the lowest. To identify these combinations, all possible combinations were simulated first to determine these average pressures. After having identified the most and least favorable tunnel associations, the distribution uniformity simulation was performed for this collection of combinations.

Each simulation run in EPANET was made with a different combination of sector openings. In a supply network with constant demands, the opening could be studied with demand patterns assigned to the emitters. In this case, being a “pressure-driven analysis”, the configuration was different. Before the inlet of each sector, a node was placed with a time pattern, and a Rule-Based control was created to open and close the inlet pipe. The corresponding INP file was attached to the

Supplementary Materials File to see how the controls and the simulation work.

Once the pressure–demand relationship was applied for all emitters, the pump characteristic curve was added, and all possible sector combinations were simulated for each sector. This simulation also made it possible to know the total flow provided by the pump in each combination of sector opening. Knowing the relationship between the pump efficiency and the flow rate delivered, it was possible to obtain the pump efficiency for each combination of sector opening.

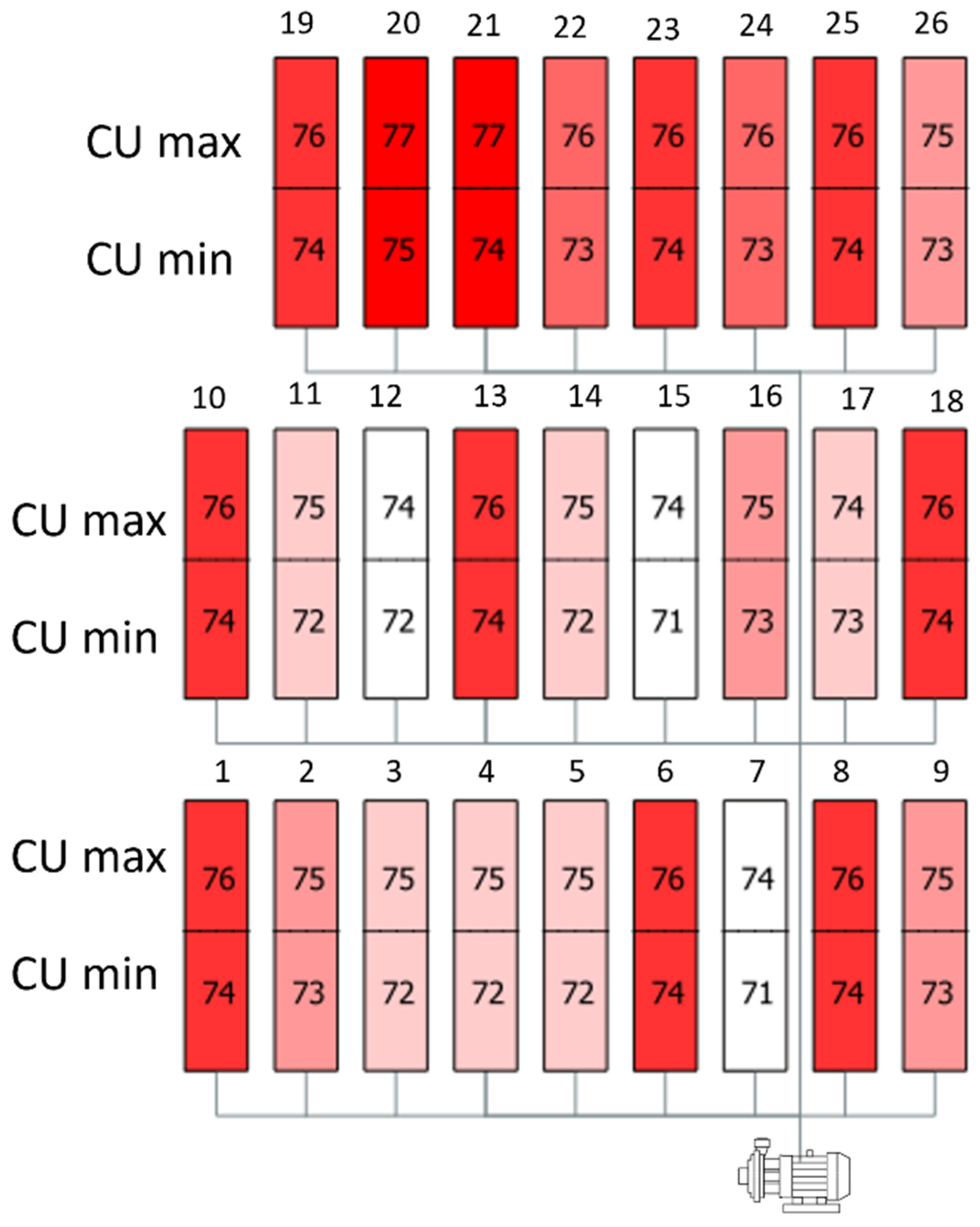

Through this simulation, once identified for each sector, the sector combinations that made the maximum and minimum pressure of the emitters, these combinations were simulated to obtain the distribution uniformity. In this way we obtained the information for all the emitters of each sector of what is the maximum and minimum arrival pressure depending on the combination of sector opening.

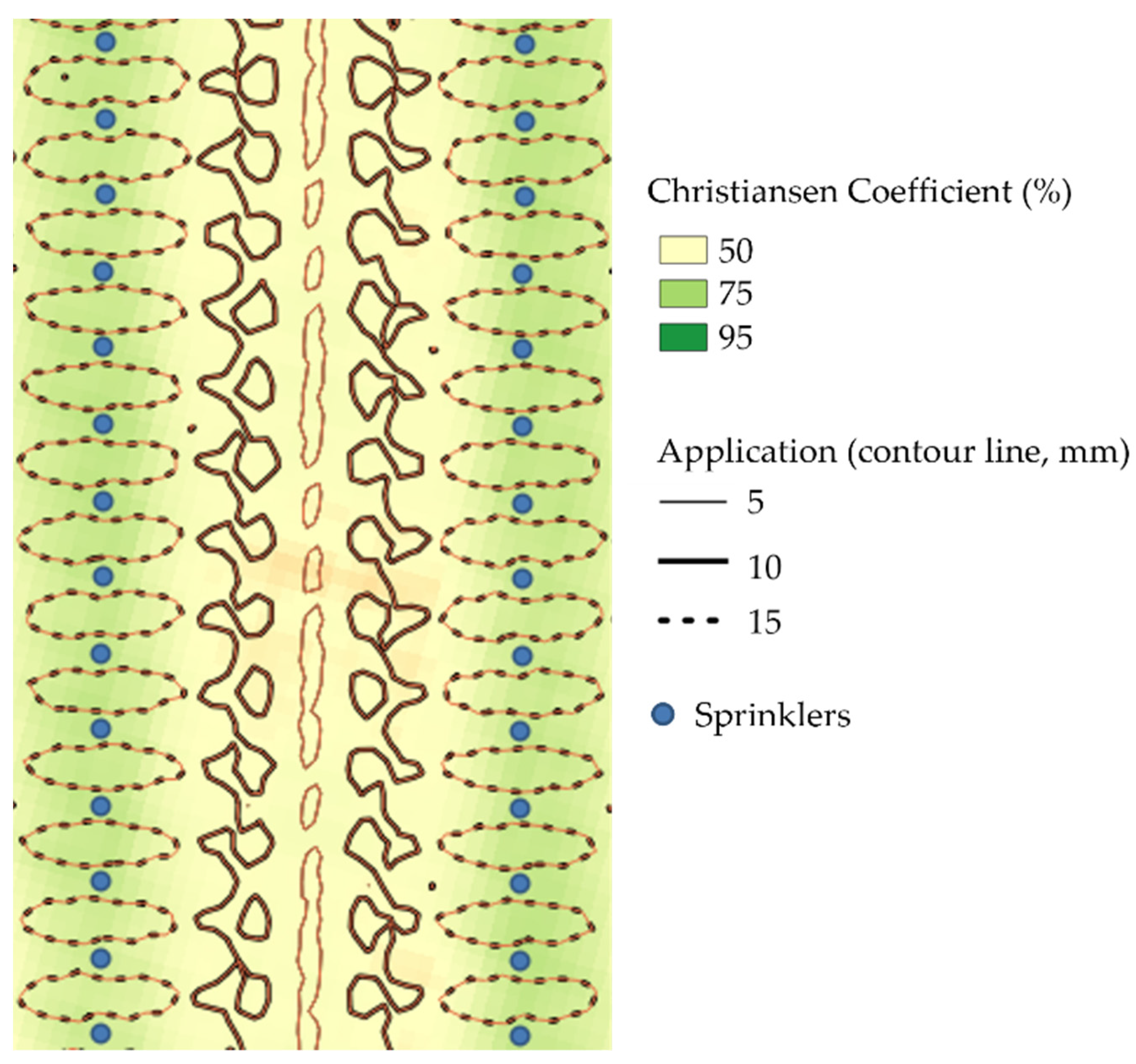

2.5. Simulation of the Spatial Distribution of Rainfall and Calculation of the Uniformity Coefficient

So far, EPANET allowed us to know the minimum and maximum pressure of each sprinkler depending on the combination of sector openings. QGIS was used to geospatially represent the rainfall, which would be useful to know the uniformity of all the sectors. Again, to link the two programs, a QGIS plugin, in this case, the QGISRed plugin, was used. This plugin allowed the INP file created to be imported and the the installations with the conditions stipulated in EPANET to be re-simulated.

Once the layer of points with all the emitters represented geospatially and with the maximum and minimum pressure data were created, to move from this point layer with the pressure data to the geospatial representation of the final water height, a QGIS model was created. The QGIS model was the automation of a sequence of processes. This QGIS model allowed the processing of the sprinkler point layer with the associated pressure and sprinkler evaluation data and the creation of the raster with the geospatial representation of the rainfall. The sprinkler data used in this evaluation were the characteristic curve obtained in the sprinkler evaluation (depth of water application distribution vs. pressure). From the layer of points, the model was used to create several buffers around the sprinklers to represent the application area. In these buffers, the pressure, the distance from the buffer to the emitter, the irrigation time, and the water application depth were calculated, taking into account the data from the sprinkler evaluation. Next, the overlapping areas were obtained and summed depending on how many times they overlapped. Finally, the obtained polygon was rasterized to obtain a raster with the water application information.

The model would therefore provide the emitter layer and also the raster of the geospatial representation of the applied water height. To calculate the uniformity from here, a point per square meter was designated in the sectors, emulating rain gauges, which were assigned the height relative to where they were located. Finally, these data were used to calculate the Christiansen’s uniformity coefficient and compared with those obtained in the distribution uniformity study. The complete simulation process is shown in

Figure 3.

4. Discussion

This work aimed to simulate the precipitation applied by sprinklers in greenhouse facilities and to know in detail the uniformity of this precipitation. For this, the integration of two computer tools such as QGIS and EPANET, was proposed. The simulation developed in this study obtained results similar to those in reality. Furthermore, it has been shown that the distribution uniformity of a sector calculated by using rain gauges in one area and extrapolating them to the whole sector can be simulated by means of the tools and methodology proposed.

Unlike previous studies, this simulation effort made it possible to adapt to the peculiarities of a given irrigation installation. Compared to other established models, the integration between EPANET and QGIS was much more flexible. Among other things, it has made it possible to obtain distribution uniformity at various scales. It has also made it possible to rank the combination of sector openings based on distribution uniformity. In addition, using a hydraulic simulation program such as EPANET, other important variables for hydraulic evaluations such as pump efficiency have been calculated, and the combination of sector openings can again be ordered according to pump efficiency. This work therefore opens the way for new projects that aim to determine the behavior of the irrigation system from hydraulic simulations.

The methodology proposed in this article is susceptible to incorporating a series of improvements related to the evaluation of the sprinklers and the evaluation of the simulations with an in situ experimentation. This could be performed mainly by increasing the number of laboratory sprinkler evaluations and using several sprinklers. In addition, a larger number of sectors could be compared between simulated and measured data, which would help to improve the model more accurately. However, the idea of simulating the hydraulic behavior of a complete greenhouse sprinkler irrigation system by integrating GIS and hydraulic simulation tools using open-source software could become a very valuable tool for evaluating irrigation systems. In addition, this avoids the rigidity of the input data of previous studies where there was hardly any possibility of adding the particularities of a specific installation. Estimating the distribution uniformity over the entire surface without the need to measure it directly saves a lot of effort and resources and allows on many occasions to know data that otherwise would be very difficult to obtain. In short, we believe that the methodology proposed in this article can be very useful to improve the management of sprinkler irrigation systems, particularly those in which distribution uniformity is of special importance, as is the case of high value-added crops, which are frequently grown in greenhouses. It has been shown that it is possible to accurately estimate distribution uniformity in different areas of a facility. This will allow actions such as: (i) assigning the areas with greater uniformity to the most demanding or cost-effective crops; (ii) identifying areas where an improvement of the facilities would be desirable; (iii) identifying the tunnel opening combinations that improve uniformity in each of them. These improvements in management could also result in savings in water and other inputs, which are becoming increasingly important in the current context of climate change and the reduction in the impact of agriculture on the environment. Finally, similar studies could be carried out with the same tools for other pressurized irrigation systems, such as sprinkler irrigation outside greenhouses and drip irrigation.