Automated Storage and Retrieval Systems: An Attractive Solution for an Urban Warehouse’s Sustainable Development

Abstract

:1. Introduction

2. Research Context and Industrial Partnership

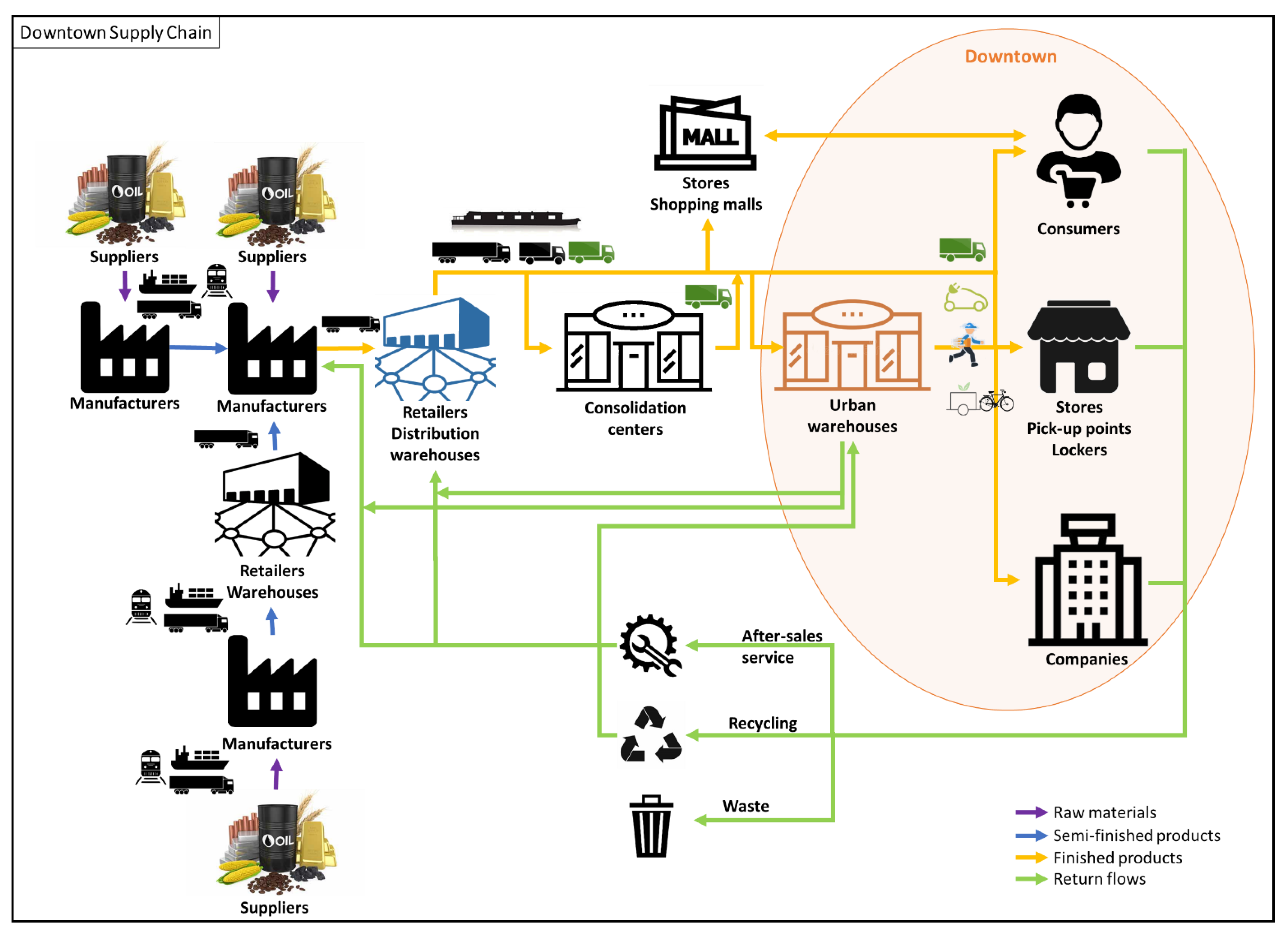

2.1. Urban Logistics: An Issue for Sustainable Logistics

2.2. The Industrial Partner: An Historical and Major Logistics Stakeholder

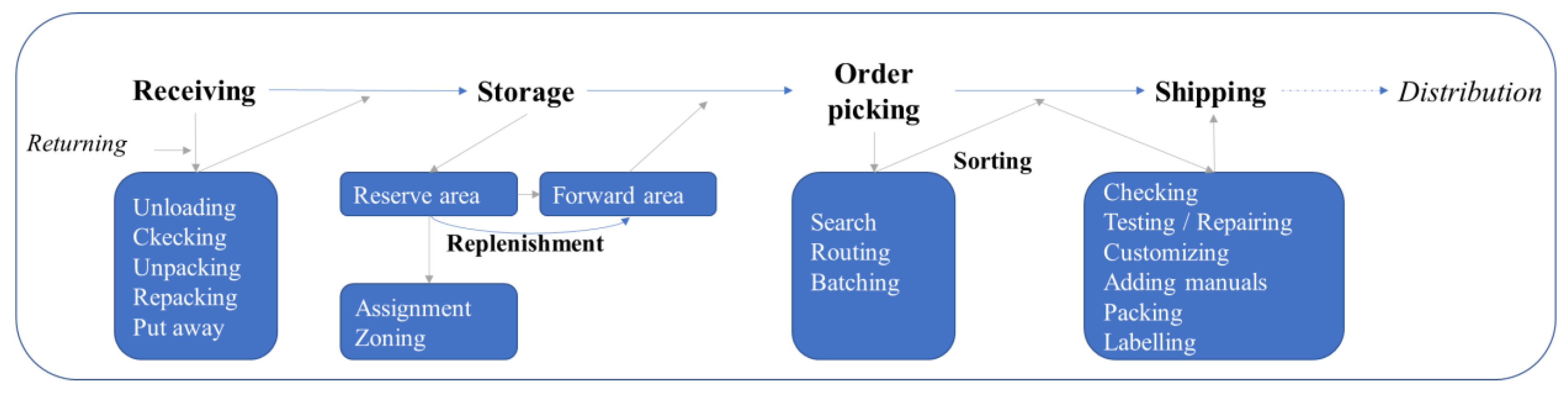

2.3. Urban Warehouses Characterization Regarding Traditional Warehousing

2.4. Urban Warehouses Challenges

3. Problem Statement: A Methodological Approach to Provide 4.0-Based Solutions to Improve the Performance of Urban Warehouses

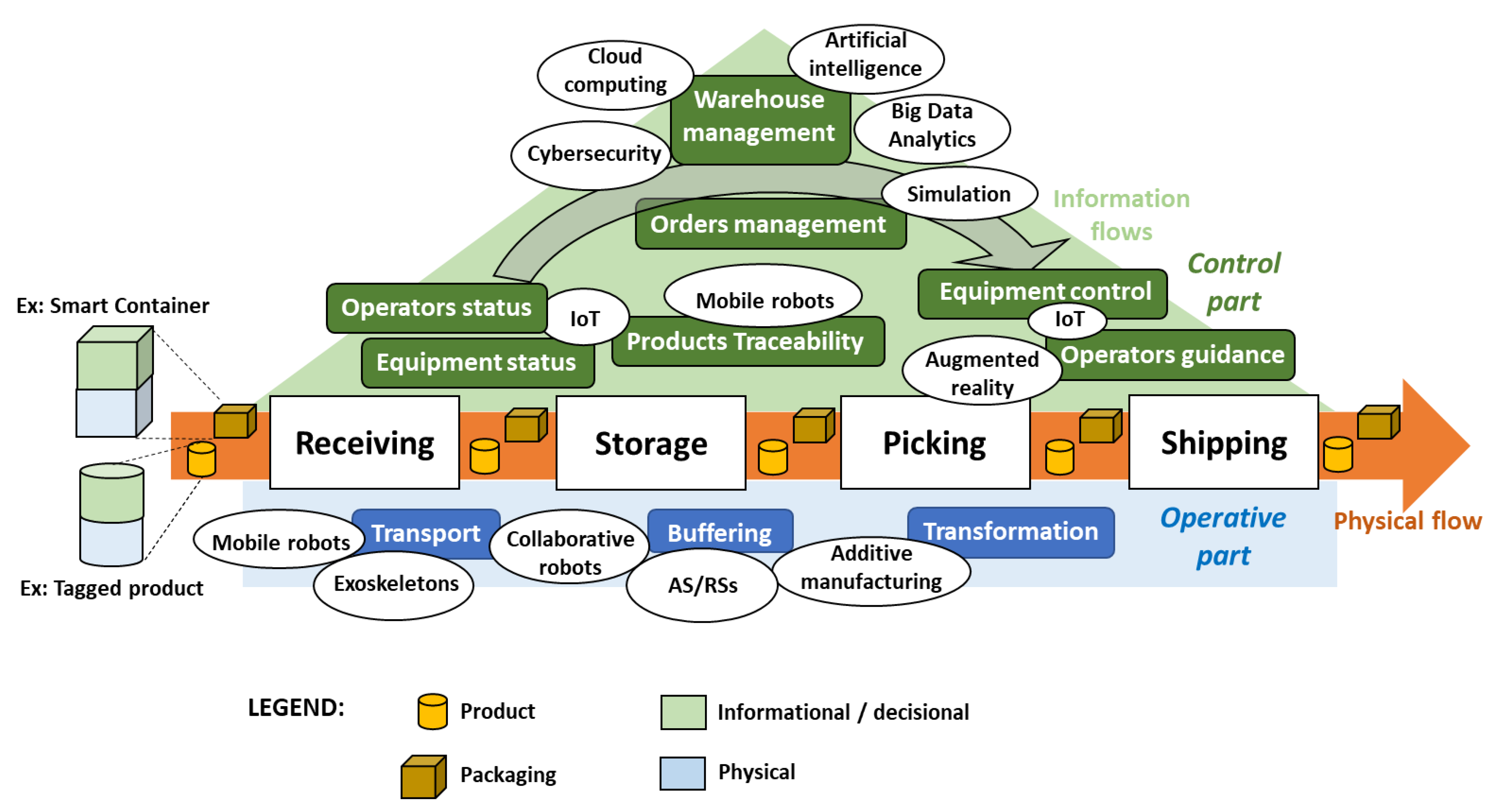

3.1. 4.0. and Urban Warehouse: How to Improve the Performance of the Logistic Process?

- The macro-processes of warehousing that encompass the activities presented in Section 2.3;

- Le Moigne’s model [28], which proposes to break down an organization into three systems: decision (headquarters of the decision centers), information, and operating (headquarters of the load centers), inducing a physical part and an informational part.

- Evaluating the impact of 4.0 technologies regarding the performance of urban warehouse

- Designing logistics solutions combining 4.0 technologies to adjust the urban warehouse logistic.

3.2. Intelligent Storage and Retrieval Systems for Urban Warehouses Based on 4.0 Technologies: Issues and Methodology

4. Case Study: An Intelligent ASRS System to Improve the Urban Logistics of a Large Range of Automotive Repair and Maintenance Items

4.1. The Context of La Poste and the End-Customer Issue

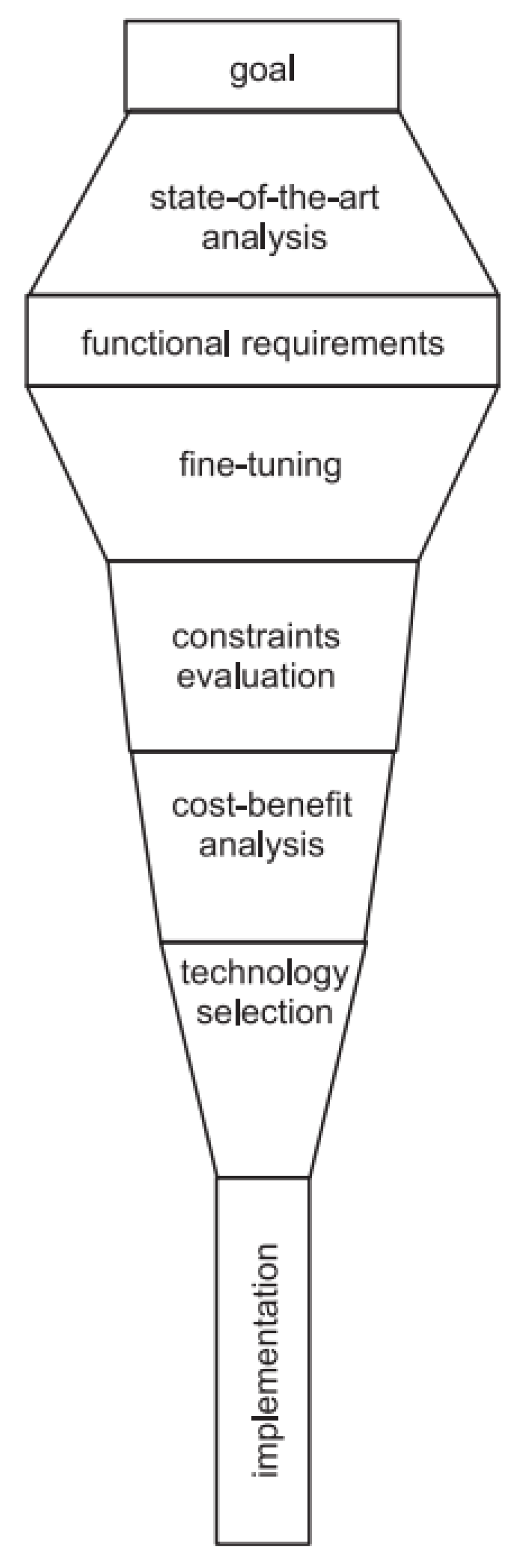

4.2. The Methodology Followed

- Define the objective of the intelligent sysstem.

- 2.

- Analyze the state of the art.

- 3.

- Define the essential functional requirements for the planned system.

- 4.

- Refine the contextual elements.

- 5.

- Evaluate the constraints.

- 6.

- Conduct a cost-benefit analysis.

- 7.

- Choose the technology.

- 8.

- Carry out the implementation of the intelligent system.

4.3. Application of the Methodology and Results

- Goal

- 2.

- State of the art analysis

- Pallet handling systems (“AS/RS pallets” or “AS/RS unit loads”), used to store and retrieve products stored on pallets in single or double-deep racking aisles. Carts are used to transport the units from the storage location to the picking area and back. There is one cart per aisle. Once the products have been removed from the pallet, the pallet must be returned to storage. Therefore, this system is ideal for low throughput and high density or weight inventory requirements. Generally, these are systems that require the building to be built around them and therefore cannot easily be configured within an existing building.

- Miniload systems designed for storage and retrieval of small items stored in bins or drawers. They work in the same way as an AS/RS with pallets. However, the racks can go up to four depths.

- Shuttle systems, with one or two storage depths, managing boxes or bins, and with more shuttles than aisles. These systems have a very high throughput.

- The AS/RS unit, one of the latest emerging technologies, has been introduced by the company Autostore, who are its only manufacturer. It is based on five components: an aluminum grid that holds stacked bins in which products are stored and serves as rails for robots that run on its surface driving, collecting and delivering the bins to workstations (ports) where order fulfillment and replenishment is performed. Finally, the controller is the “brain” of the system. Connected to the warehouse management system, it controls traffic, tracks inventory, controls robots, plans and schedules tasks and keeps track of everything. These systems offer unmatched storage density.

- AS/RS based on automated guided vehicles (AGVs), which move the whole racking system (with mobile shelves) or the pallets to the fixed workstation of the order picker.

- 3.

- Functional requirements

- Accommodate the maximum number of references (number, size and weight) (3),

- Adapt to change (2),

- Move products efficiently and accurately (4),

- Respond to order peaks (10),

- Allow storage and picking operations to be carried out throughout the warehouse’s opening hours (11),

- Reduce labor overhead, while increasing throughput capabilities (7),

- Simplify product storage while improving inventory organization (5),

- Achieve higher storage density in the warehouse footprint (1),

- Improve warehouse and user safety through optimized material flow and improved ergonomics (8),

- Track flow of all goods (6),

- Provide low energy consumption or sustainability benefits (9).

- 4.

- Fine-tuning

- 5.

- Constraints evaluation

- 6.

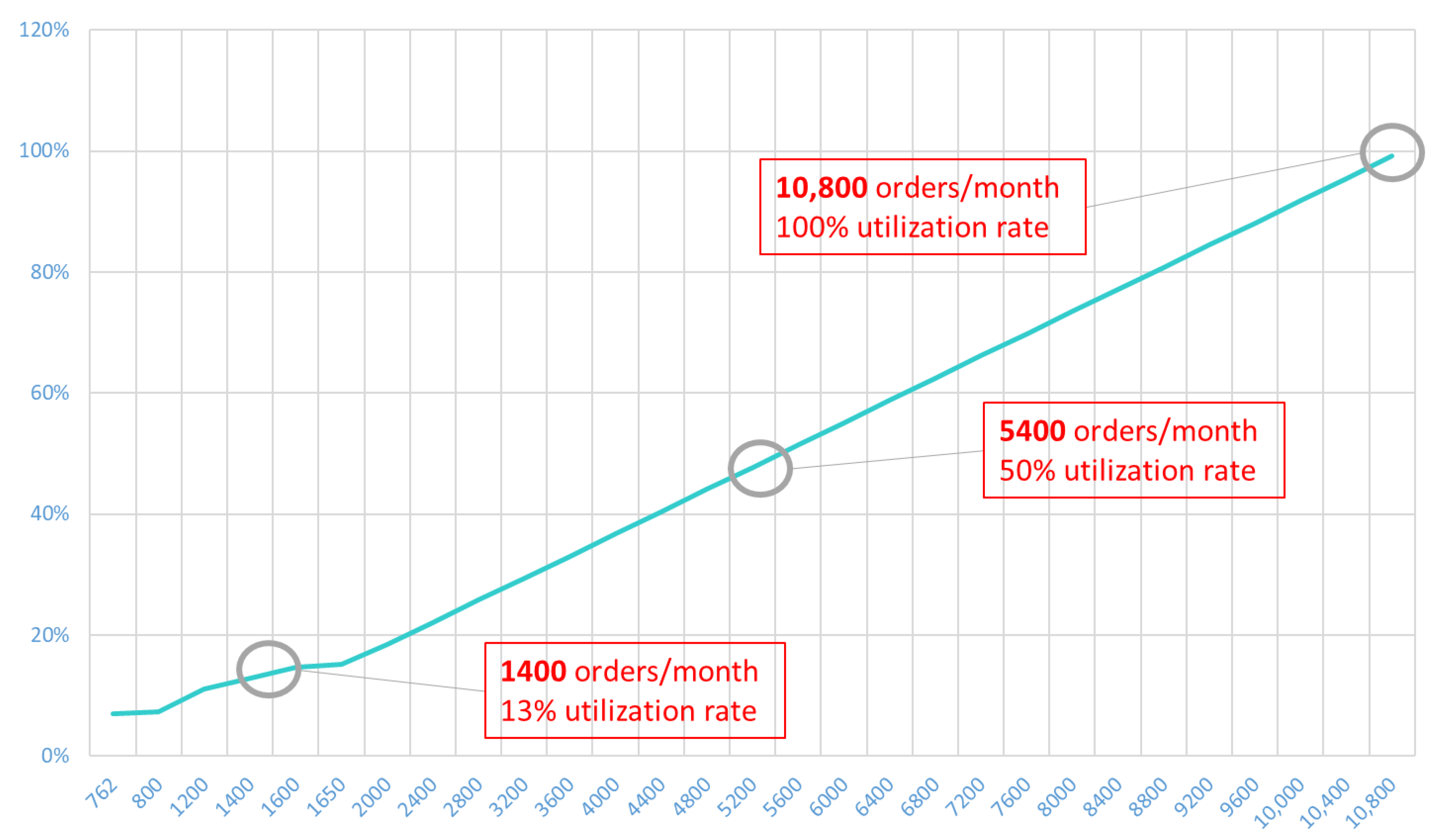

- Cost-benefit analysis and technology choice

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- United Nations. The Paris Agreement. 2016. Available online: https://www.un.org/en/climatechange/paris-agreement (accessed on 1 January 2022).

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development. 2017. Available online: https://sdgs.un.org/2030agenda (accessed on 1 January 2022).

- Schöder, D.; Ding, F.; Campos, J.K. The Impact of E-Commerce Development on Urban Logistics Sustainability. Open J. Soc. Sci. 2016, 4, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Lagorio, A.; Pinto, R.; Golini, R. Research in urban logistics: A systematic literature review. Int. J. Phys. Distrib. Logist. Manag. 2016, 46, 908–931. [Google Scholar] [CrossRef]

- Barreto, L.; Amaral, A.; Pereira, T. Industry 4.0 implications in logistics: An overview. Procedia Manuf. 2017, 13, 1245–1252. [Google Scholar] [CrossRef]

- Cimini, C.; Lagorio, A.; Romero, D.; Cavalieri, S.; Stahre, J. Smart logistics and the logistics operator 4.0. IFAC-PapersOnLine 2020, 53, 10615–10620. [Google Scholar] [CrossRef]

- Kang, S. Why do warehouses decentralize more in certain metropolitan areas? J. Transp. Geogr. 2020, 88, 102330. [Google Scholar] [CrossRef]

- Diziain, D.; Ripert, C.; Dablanc, L. How can we bring logistics back into cities? The case of Paris metropolitan area. Procedia-Soc. Behav. Sci. 2012, 39, 267–281. [Google Scholar] [CrossRef] [Green Version]

- Aljohani, K.; Thompson, R.G. Impacts of logistics sprawl on the urban environment and logistics: Taxonomy and review of literature. J. Transp. Geogr. 2016, 57, 255–263. [Google Scholar] [CrossRef]

- Dablanc, L. E-commerce trends and implications for urban logistics. In Urban Logistics: Management, Policy and Innovation in a Rapidly Changing Environment; Browne, M., Behrends, S., Woxenius, J., Giuliano, G., Holguin-Veras, J., Eds.; Kogan Page: London, UK, 2019; pp. 167–195. [Google Scholar]

- Settey, T.; Gnap, J.; Beňová, D.; Pavličko, M.; Blažeková, O. The growth of e-commerce due to COVID-19 and the need for urban logistics centers using electric vehicles: Bratislava case study. Sustainability 2021, 13, 5357. [Google Scholar] [CrossRef]

- Taniguchi, E.; Thompson, R.G. Modeling city logistics. Transp. Res. Rec. J. Transp. Res. Board 2002, 1790, 45–51. [Google Scholar] [CrossRef]

- Cour des Comptes. Rapport D’observations de la Cour des Comptes sur les Nouveaux Services de Proximité de La Poste—Exercices 2014–2019. 2021. Available online: https://www.ccomptes.fr (accessed on 8 May 2022).

- La Poste. Plan Stratégique La Poste 2030, Engagée Pour Vous (Press Pack). 2021. Available online: https://www.lapostegroupe.com/fr/actualite/lancement-du-nouveau-plan-strategique-la-poste-2030-engagee-pour-vous (accessed on 8 May 2022).

- Carneiro Freire, S.M.; Corban, C.; Ehrlich, D.; Florczyk, A.; Kemper, T.; Maffenini, L.; Melchiorri, M.; Pesaresi, M.; Schiavina, M.; Tommasi, P. Atlas of the Human Planet 2019: A Compendium of Urbanisation Dynamics in 239 Countries; Publications Office of the European Union: Brussels, Belgium; Luxembourg, 2020; ISBN 978-92-76-17418-9. [Google Scholar]

- Beamon, B.M. Designing the green supply chain. Logist. Inf. Manag. 1999, 12, 332–342. [Google Scholar] [CrossRef] [Green Version]

- Wang, K. Logistics 4.0 Solution—New Challenges and Opportunities. In Proceedings of the 6th International Workshop of Advanced Manufacturing and Automation, Fort Worth, TX, USA, 21–22 August 2016; Atlantis Press: Manchester, UK, 2016. [Google Scholar]

- Khanzode, V.; Shah, B. A comprehensive review of warehouse operational issues. Int. J. Logist. Syst. Manag. 2017, 26, 346. [Google Scholar] [CrossRef]

- Dablanc, L.; Rakotonarivo, D. The impacts of logistics sprawl: How does the location of parcel transport terminals affect the energy efficiency of goods’ movements in Paris and what can we do about it? Procedia-Soc. Behav. Sci. 2010, 2, 6087–6096. [Google Scholar] [CrossRef] [Green Version]

- Van den Berg, J.P.; Zijm, W.H.M. Models for warehouse management: Classification and examples. Int. J. Prod. Econ. 1999, 59, 519–528. [Google Scholar] [CrossRef]

- Observatoire Régional de l’Immobilier d’Entreprise en Ile-de-France. La Logistique Urbaine, un Enjeu Stratégique Pour le Territoire Francilien-Note Semestrielle de l’ORIE; Observatoire Régional de L’immobilier D’entreprise: Paris, France, 2018; p. 20. [Google Scholar]

- Bartholdi, J.J.; Hackman, S.T. Warehouse and Distribution Science—Mathematical Models to Optimize Management of Time and Space in a Warehouse. 2019. Available online: https://www.warehouse-science.com/ (accessed on 15 June 2022).

- Bréchemier, D.; Schillaci, G.; Prévost, X.; Migne, C.; Ogée, B. La Logistique Urbaine Face aux défis Économiques et Environnementaux; Roland Berger: Munich, Germany, 2020. [Google Scholar]

- Pfeiffer, S. The vision of “Industrie 4.0” in the making-a case of future told, tamed, and traded. NanoEthics 2017, 11, 107–121. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moeuf, A.; Pellerin, R.; Lamouri, S.; Tamayo-Giraldo, S.; Barbaray, R. The industrial management of SMEs in the era of Industry 4.0. Int. J. Prod. Res. 2018, 56, 1118–1136. [Google Scholar] [CrossRef] [Green Version]

- Winkelhaus, S.; Grosse, E.H. Logistics 4.0: A systematic review towards a new logistics system. Int. J. Prod. Res. 2020, 58, 18–43. [Google Scholar] [CrossRef]

- Radivojević, G.; Milosavljević, L. The Concept of Logitics 4.0; Logic: Belgrade, Serbia, 2019; p. 10. [Google Scholar]

- Le Moigne, J.-L. La théorie du système général: Théorie de la modélisation. Presses Univ. De Fr. 1977, 1, 162. [Google Scholar]

- Roodbergen, K.J.; Vis, I.F. A survey of literature on automated storage and retrieval systems. Eur. J. Oper. Res. 2009, 194, 343–362. [Google Scholar] [CrossRef] [Green Version]

- Porter, M.E.; Heppelmann, J.E. How Smart, Connected Products Are Transforming Competition. Technology and Analytics. Harvard Business Review, 23 November 2014; 7. [Google Scholar]

- Fritz, W.; García Martínez, R.; Blanqué, J.R.; Adobbati, R.; Rama, A.; Sarno, M. The autonomous intelligent system. Robot. Auton. Syst. 1989, 5, 109–125. [Google Scholar] [CrossRef]

- Bauer, C.; Dey, A.K. Considering context in the design of intelligent systems: Current practices and suggestions for improvement. J. Syst. Softw. 2016, 112, 26–47. [Google Scholar] [CrossRef]

- Turner, A. Evaluation of Automated Storage and Retrieval in a Distribution Center. Master’s Thesis, MIT Sloan School of Management Department of Mechanical Engineering, University of California Santa Barbara, Santa Barbara, CA, USA, 2020. [Google Scholar]

- France Supply Chain by Aslog. Guide de L’Intralogistique en France 2020–2021—Mécanisation, Automatisation, Robotisation; ASLOG: Paris, France, 2021; ISBN 978-2-915311-02-0. [Google Scholar]

- Modula Comparaison des Systèmes de Stockage Automatiques: Différences, Avantages et Désavantages. Available online: https://www.modula.eu/blog/fr/comparaison-des-systemes-de-stockage-automatiques-differences-avantages-et-desavantages/ (accessed on 8 May 2022).

| Features | Traditional Warehouses | Urban Warehouses | |

|---|---|---|---|

| Type of activities | Volumes stored (in no. of references) | Millions | A few thousand |

| Volume of orders processed | High | Medium | |

| Order processing time | H+, D, D + 1, D + 2, D + 4 | H+, D, D + 1 | |

| Product storage time | Low (a few hours to a few days) | Medium (a few hours to a few weeks) | |

| Modes of entry transportation | Trucks (super trucks, trucks, carriers) | Straight trucks | |

| Modes of exit transportation | Straight trucks, light commercial vehicles (electric or thermal cars and electric or thermal vans) | Light commercial vehicles (cars and electric vans), cargo bikes, walking | |

| Number of customers | Multiple clients | Few clients | |

| Operating Expense Costs | Mediums | Very high | |

| Exploited areas | Large spaces (several thousand m2) | Small spaces (a few hundred to a few thousand m2) | |

| Exploited space typology | Main storage equipment | Pallet racks, shelves | Shelves |

| Location | Outside the cities | Downtown | |

| Geographic coverage | Urban peripheries, suburbs, downtown | Downtown | |

| Main type of construction | New | Rehabilitated | |

| Type of clients | Targets | All | Luxe, urgence, niche |

| Types of orders | Nb of items/order | From 1 unit to hundreds | 1 to 3 units |

| Processing times | Medium, fast | Fast, express | |

| Majority handling units | Pallets, boxes/bins | Products, boxes/bins | |

| Types of products | Dimensions | Small, medium, large | Small, medium |

| Weight | Low, medium, high | Low, medium (max 30 kg) | |

| Hazardousness | Possible | Complex | |

| Pallets | Miniload | Shuttle | Autostore | AGVs Based AS/RS | ||

|---|---|---|---|---|---|---|

| Visual |  |  |  |  |  | |

| Speed | 85 cycles/hour/carriage (60 for the double depth ones) | 120 to 200 cycles/hr/carriage | 500 cycles/hr/alley | Speed of 1.6 m/s and 30 bins/hour/robot | ||

| Flow rate | Low (single input/output position) | Low (single input/output position) | High (5 times higher than miniload) | Medium | High (3 times more order lines processed per hour than a traditional storage system) | |

| Supported weights | Between 230 and 1815 kg | Maximum 230 kg | Maximum 90 kg | Maximum 30 kg | Between 450 and 1360 kg | |

| Maximum height | Very high (max 50 m) | Very high | Medium | Medium (max 7 m, between 4 and 16 bin heights) | Very low (maximum 2 m) | |

| Type of products | Heavy and bulky | Small and medium weights | Small and light | Small and light | Small | |

| Installation costs | High | High | High | Medium | Low | |

| Operating costs | Medium (high maintenance costs due to poor reliability but low infrastructure costs due to high rack storage) | Medium | Medium | Low (high reliability) | High (decried reliability, need for floor space) | |

| Density | Average (8 times higher than a traditional storage system) | Medium | Medium | High | Medium (removes traffic lanes but does not use height) | |

| System flexibility | Very low | Low | High | High | High | |

| Ease of installation | Low | Low | Medium | High | High | |

| Adaptability | Very low | Low | Low | Medium | Low | |

| 3a: Client physical constraints | |

| Number of references | 5741 |

| Average number of orders/month | 762 |

| Average number of items/order | 1.3 |

| Average weight of an item (kg) | 2 |

| Maximum weight (kg) | 22.54 |

| Minimum weight (kg) | 0.001 |

| Average dimensions (L × W × H) (mm) | 248 × 138 × 73 |

| Maximum dimensions (L × W × H) (mm) | 980 × 581 × 590 |

| Minimum dimensions (L × W × H) (mm) | 10 × 1 × 1 |

| 3b: Selected site physical constraints | |

| Geometry |  |

| Surface area (m2) | 98 |

| Height under exploitable ceiling (m) | 5.5 |

| Slab resistance (kg/m2) | 600 |

| Surface area (m2) | 66 |

| Number of bin locations | 1600 |

| Breathing coefficient | 15% |

| Number of available bins | 1360 |

| Number of robots | 5 |

| Number of operator stations | 1 |

| Average rate (bins/h) | 103 |

| External bin dimensions (mm) | 550 × 450 × 330 |

| Inner bin dimensions (mm) | 500 × 400 × 330 |

| Max weight/bin (kg) | 30 |

| Number of possible compartments/bin | 32 |

| Number of References (Article Data Base) | 5741 | |||

|---|---|---|---|---|

| A | Number of available bins | 2040 | ||

| B | No. of out-of-gauge references | 695 | ||

| No. of items stored/reference | 3 | 2 | ||

| C | No. of refs in bins divided in 8 | 1464 | ||

| D | No. of refs in bins divided in 4 | 663 | ||

| E | No. of refs in bins divided in 2 | 1839 | ||

| F | No. of refs in bins without compartments | 595 | 485 | |

| G = C × 8 + D × 4 + E × 2 + F | Number of needed bins | 2349 | ||

| H = G − A | Number of references in surplus | 309 | ||

| I = B + H | Number of references to manage outside the automated system | 1004 | ||

| Nb. of Movements | 220 | 1099 | 1674 | 2197 | 3296 | 4394 | 5493 | 6592 | 8789 | 10,986 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Nb. of Amortization Years | |||||||||||

| 1 | 228.67 € | 46.34 € | 30.67 € | 23.55 € | 15.95 € | 12.15 € | 9.87 € | 8.35 € | 6.45 € | 5.31 € | |

| 2 | 123.89 € | 25.38 € | 16.92 € | 13.07 € | 8.97 € | 6.91 € | 5.68 € | 4.86 € | 3.83 € | 3.22 € | |

| 3 | 88.97 € | 18.40 € | 12.33 € | 9.58 € | 6.64 € | 5.17 € | 4.28 € | 3.70 € | 2.96 € | 2.52 € | |

| 4 | 71.51 € | 14.91 € | 10.04 € | 7.83 € | 5.47 € | 4.29 € | 3.59 € | 3.11 € | 2.53 € | 2.17 € | |

| 5 | 61.03 € | 12.81 € | 8.67 € | 6.78 € | 4.77 € | 3.77 € | 3.17 € | 2.77 € | 2.26 € | 1.96 € | |

| 6 | 54.05 € | 11.41 € | 7.75 € | 6.09 € | 4.31 € | 3.42 € | 2.89 € | 2.53 € | 2.09 € | 1.82 € | |

| 7 | 49.06 € | 10.42 € | 7.09 € | 5.59 € | 3.98 € | 3.17 € | 2.69 € | 2.37 € | 1.96 € | 1.72 € | |

| 8 | 45.32 € | 9.67 € | 6.60 € | 5.21 € | 3.73 € | 2.98 € | 2.54 € | 2.24 € | 1.87 € | 1.65 € | |

| 9 | 42.40 € | 9.09 € | 6.22 € | 4.92 € | 3.53 € | 2.84 € | 2.42 € | 2.14 € | 1.80 € | 1.59 € | |

| 10 | 40.08 € | 8.62 € | 5.92 € | 4.69 € | 3.38 € | 2.72 € | 2.33 € | 2.07 € | 1.74 € | 1.54 € | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Edouard, A.; Sallez, Y.; Fortineau, V.; Lamouri, S.; Berger, A. Automated Storage and Retrieval Systems: An Attractive Solution for an Urban Warehouse’s Sustainable Development. Sustainability 2022, 14, 9518. https://doi.org/10.3390/su14159518

Edouard A, Sallez Y, Fortineau V, Lamouri S, Berger A. Automated Storage and Retrieval Systems: An Attractive Solution for an Urban Warehouse’s Sustainable Development. Sustainability. 2022; 14(15):9518. https://doi.org/10.3390/su14159518

Chicago/Turabian StyleEdouard, Aurélie, Yves Sallez, Virginie Fortineau, Samir Lamouri, and Alexandre Berger. 2022. "Automated Storage and Retrieval Systems: An Attractive Solution for an Urban Warehouse’s Sustainable Development" Sustainability 14, no. 15: 9518. https://doi.org/10.3390/su14159518

APA StyleEdouard, A., Sallez, Y., Fortineau, V., Lamouri, S., & Berger, A. (2022). Automated Storage and Retrieval Systems: An Attractive Solution for an Urban Warehouse’s Sustainable Development. Sustainability, 14(15), 9518. https://doi.org/10.3390/su14159518