Operationalization of Critical Success Factors to Manage the Industry 4.0 Transformation of Manufacturing SMEs

Abstract

:1. Introduction

- Identify a list of actions associated with critical success factors to manage the digital transformation of manufacturing SMEs;

- Position these actions within the different phases of a manufacturing SME digital transformation process;

- Validate these actions with a panel of Industry 4.0 experts.

2. Literature Review

2.1. Management of Industry 4.0 Transformation within Manufacturing SMEs

2.2. Critical Success Factors for Industry 4.0 Transformation

2.3. Research Limitations

3. General Framework

- Industry 4.0 project post-mortem: The manufacturing SME reviews its Industry 4.0 projects by analyzing if their objectives were met, if issues happened during the project, how it solved them, what it could have done to prevent them, and what it should do better or differently on the following projects [21,78].

- Industry 4.0 management and project delivery approach revision: The manufacturing SME revises and implements changes to its management structure for Industry 4.0 transformation and its project delivery approach based on the project post-mortem analysis and the impact of the Industry 4.0 projects [21,38,50,76,77].

4. Research Methodology

4.1. The Delphi Methodology

4.2. The Abacus of Régnier

- Green: Completely agree with the statement;

- Light green: Somewhat agree with the statement;

- Yellow: Mixed opinion on the statement;

- Light red: Somewhat disagree with the statement;

- Red: Completely disagree with the statement;

- White: Cannot answer;

- Black: Do not want to answer.

4.3. Selection of Experts

- The experts’ experience;

- Their familiarity with the research subject;

- Their expertise in the research subject.

- Must have analyzed, managed, or executed digital transformation projects over the past three years;

- Must have worked for, or in collaboration, with manufacturing SMEs on digital transformation projects;

- Must have been involved in the starting phase of digital transformation within one or multiple manufacturing SMEs.

- Industrial Manager: Member of the high management or a project/program manager of a manufacturing SME;

- Academic: Researcher or university professor who has conducted research on the digital transformation of manufacturing SMEs;

- Independent Consultant: Consultant and expert in digital transformation who has supported manufacturing SMEs in managing their digital transformations.

4.4. Survey Creation

4.5. Iteration Structure

5. Findings and Discussion

- Steps and actions to manage the Industry 4.0 transformation;

- Dependence on the context of individual manufacturing SMEs;

- Managing the transformation through an iterative process.

5.1. Steps and Actions to Manage Industry 4.0 Transformation

5.1.1. Establishing a Strategic Vision for Industry 4.0 (Q1-1.1 to Q1-1.9, Q2-1.1 to Q2-1.13)

5.1.2. Current Situation Evaluation (Q1-2.1 to Q1-2.5, Q2-I2.1 to Q2-I2.5)

5.1.3. Industry 4.0 Projects/Opportunities Identification (Q1-I3.1 to Q1-I3.6)

5.1.4. Industry 4.0 Projects Prioritization (Q1-I4.1 to Q1-I4.6, Q2-I1.9, Q2-I2.6)

5.1.5. Implementing an Industry 4.0 Transformation Management Structure (Q1-I5.1 to Q1-I5.4, Q2-I1.10)

5.1.6. Implementing an Industry 4.0 Project Delivery Approach (Q1-I6.1 to Q1-I6.12)

5.1.7. Industry 4.0 Projects Execution and Management (Q1-I7.1 to Q1-I7.9)

5.1.8. Industry 4.0 Projects Post-Mortem (Q1-I8.1 to Q1-I8.3)

- The critical success factor of each Industry 4.0 project;

- The gap between the estimated and actual budget and schedule;

- The presence or absence of internal expertise needed for the project;

- The relationship with external partners and suppliers on the project;

- The performance of the project team members as per their roles and responsibilities.

5.1.9. Industry 4.0 Management and Project Delivery Approach Revision (Q1-I9.1 to Q1-I10.5)

5.2. Dependence on the Context of Individual Manufacturing SMEs

5.3. Managing the Transformation through an Iterative Process

6. Main Results and Limitations

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

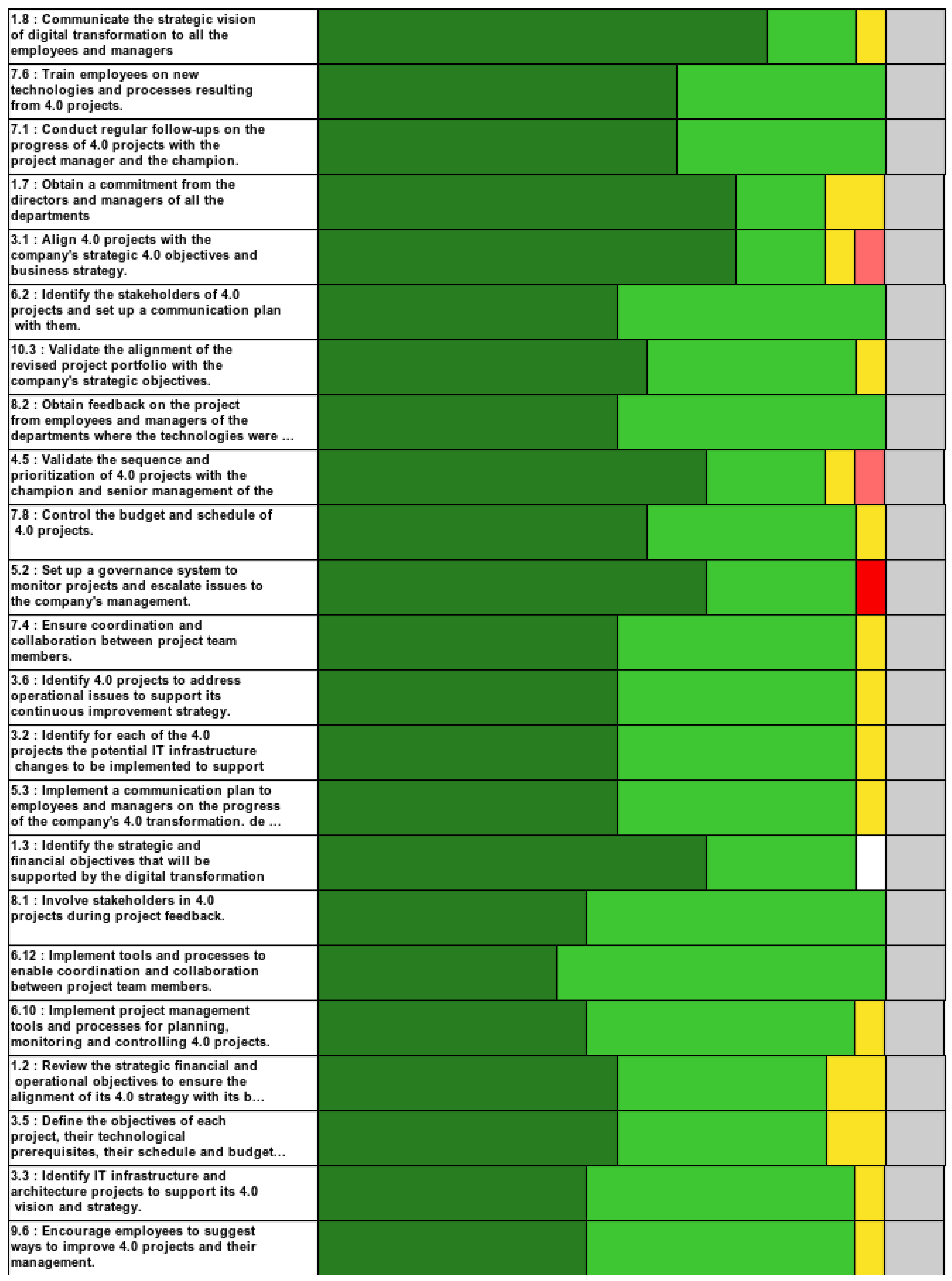

Appendix A. First Questionnaire Statements and Vote Distribution

- 1.

- When establishing a digital transformation strategy, the manufacturing SME must:

- 1.1.

- Revise the business strategy and business model to take into account digital technologies

- 1.2.

- Review the strategic financial and operational objectives to ensure the alignment of its 4.0 strategy with its business strategy.

- 1.3.

- Identify the strategic and financial objectives that will be supported by the digital transformation strategy

- 1.4.

- Appoint a digital transformation champion.

- 1.5.

- Ensure that the champion belongs to high management

- 1.6.

- Validate the digital transformation strategy with all the departments and business units

- 1.7.

- Obtain a commitment from the directors and managers of all the departments

- 1.8.

- Communicate the strategic vision of digital transformation to all the employees and managers

- 1.9.

- Define an IT architecture vision to support its digital transformation.

- 2.

- When assessing the current situation, the manufacturing SME must:

- 2.1.

- Perform a diagnostic on the performance of all its business processes and technologies

- 2.2.

- Analyze its infrastructure and its current IT and business architecture

- 2.3.

- Involve the company’s managers and employees in this step.

- 2.4.

- Assess the company’s ability to undertake 4.0 transformation projects

- 3.

- When identifying Industry 4.0 projects, the manufacturing SME must:

- 3.1.

- Align 4.0 projects with the company’s strategic 4.0 objectives and business strategy.

- 3.2.

- Identify for each of the 4.0 projects the potential IT infrastructure changes to be implemented to support them.

- 3.3.

- Identify IT infrastructure and architecture projects to support its 4.0 vision and strategy.

- 3.4.

- Conduct a needs analysis of resources and expertise for each 4.0 project.

- 3.5.

- Define the objectives of each project, their technological prerequisites, their schedule and budget, as well as the potential risks.

- 3.6.

- Identify 4.0 projects to address operational issues to support its continuous improvement strategy.

- 4.

- When prioritizing Industry 4.0 projects, the manufacturing SME must:

- 4.1.

- Prioritize its 4.0 projects by taking into account the priority of its strategic objectives.

- 4.2.

- Prioritize and sequence its 4.0 projects according to their technological requirements.es.

- 4.3.

- Prioritize and sequence 4.0 projects based on the company’s ability to successfully execute its projects.

- 4.4.

- Prioritize and sequence IT infrastructure projects that will support 4.0 projects.

- 4.5.

- Validate the sequence and prioritization of 4.0 projects with the champion and senior management of the company.

- 4.6.

- Communicate the prioritization and sequencing of 4.0 projects to the company’s managers and employees.

- 4.7.

- Train employees on general Industry 4.0 concepts to facilitate change management.

- 5.

- When setting up an Industry 4.0 transformation management structure, the manufacturing SME must:

- 5.1.

- Determine the level of authority the champion will have to manage the 4.0 transformation.

- 5.2.

- Set up a governance system to monitor projects and escalate issues to the company’s management.

- 5.3.

- Implement a communication plan to employees and managers on the progress of the company’s 4.0 transformation.

- 5.4.

- Implement a proactive change management plan and reactive change processes to facilitate change management during 4.0 transformation.

- 5.5.

- Allocate resources for solution 4.0 exploration and project review prior to implementation.

- 5.6.

- Align the structure and processes of Transformation 4.0 with the company’s existing internal structures and processes.

- 6.

- When implementing an Industry 4.0 project delivery approach, the manufacturing SME must:

- 6.1.

- Designate a project manager reporting to the champion to manage 4.0 projects.

- 6.2.

- Identify the stakeholders of 4.0 projects and set up a communication plan with them.

- 6.3.

- Include a prototyping or proof-of-concept phase at the beginning of projects to test 4.0 solutions before deployment.

- 6.4.

- Create a validation process for 4.0 solutions before their deployment in the enterprise.

- 6.5.

- Designate and set up a team capable of carrying out 4.0 projects.

- 6.6.

- Hire or subcontract the missing resources identified for the various 4.0 projects.

- 6.7.

- Formally document the roles, authorities, responsibilities, and skills of all team members.

- 6.8.

- Include an employee training phase for each 4.0 project and for each 4.0 solution deployed.

- 6.9.

- Include a change management plan within each 4.0 project plan.

- 6.10.

- Implement project management tools and processes for planning, monitoring and controlling 4.0 projects.

- 6.11.

- Implement tools and processes to manage the risks identified for each project.

- 6.12.

- Implement tools and processes to enable coordination and collaboration between project team members.

- 7.

- When executing Industry 4.0 projects, the manufacturing SME must:

- 7.1.

- Conduct regular follow-ups on the progress of 4.0 projects with the project manager and the Champion.

- 7.2.

- Validate selected 4.0 technologies with 4.0 project stakeholders.

- 7.3.

- Document and communicate changes to the company’s IT infrastructure and architecture.

- 7.4.

- Ensure coordination and collaboration between project team members.

- 7.5.

- Create documentation and processes to support 4.0 technologies in deployment.

- 7.6.

- Train employees on new technologies and processes resulting from 4.0 projects.

- 7.7.

- Adjust the on-boarding process and documentation for new employees to reflect the changes implemented during the project.

- 7.8.

- Control the budget and schedule of 4.0 projects.

- 7.9.

- Involve employees in the validation and implementation of 4.0 technologies.

- 8.

- During the post-mortem of Industry 4.0 projects, the manufacturing SME must:

- 8.1.

- Involve stakeholders in 4.0 projects during project feedback.

- 8.2.

- Obtain feedback on the project from employees and managers of the departments where the technologies were implemented.

- 8.3.

- Identify elements of the management structure and delivery approach that negatively impacted the delivery of Project 4.0.

- 9.

- When reviewing the Industry 4.0 transformation structure, approach, and portfolio, the manufacturing SME must:

- 9.1.

- Revise the project portfolio according to the gains obtained from the projects carried out on the strategic objectives.

- 9.2.

- Revise the communication plan according to the changes that can be made to the stakeholders.

- 9.3.

- Review transformation governance based on changes to the project escalation and tracking process.

- 9.4.

- Review project management tools and processes to improve project planning, monitoring, and execution.

- 9.5.

- Identify the organizational changes required to support the implementation of 4.0 projects.

- 9.6.

- Encourage employees to suggest ways to improve 4.0 projects and their management.

- 10.

- When implementing revisions, the manufacturing SME must:

- 10.1.

- Validate revisions to the structure and delivery approaches of 4.0 projects with stakeholders.

- 10.2.

- Validate changes to the project portfolio by the company’s senior management.

- 10.3.

- Validate the alignment of the revised project portfolio with the company’s strategic objectives.

- 10.4.

- Train employees and managers on the revised elements.

- 10.5.

- Document revisions and organizational changes made.

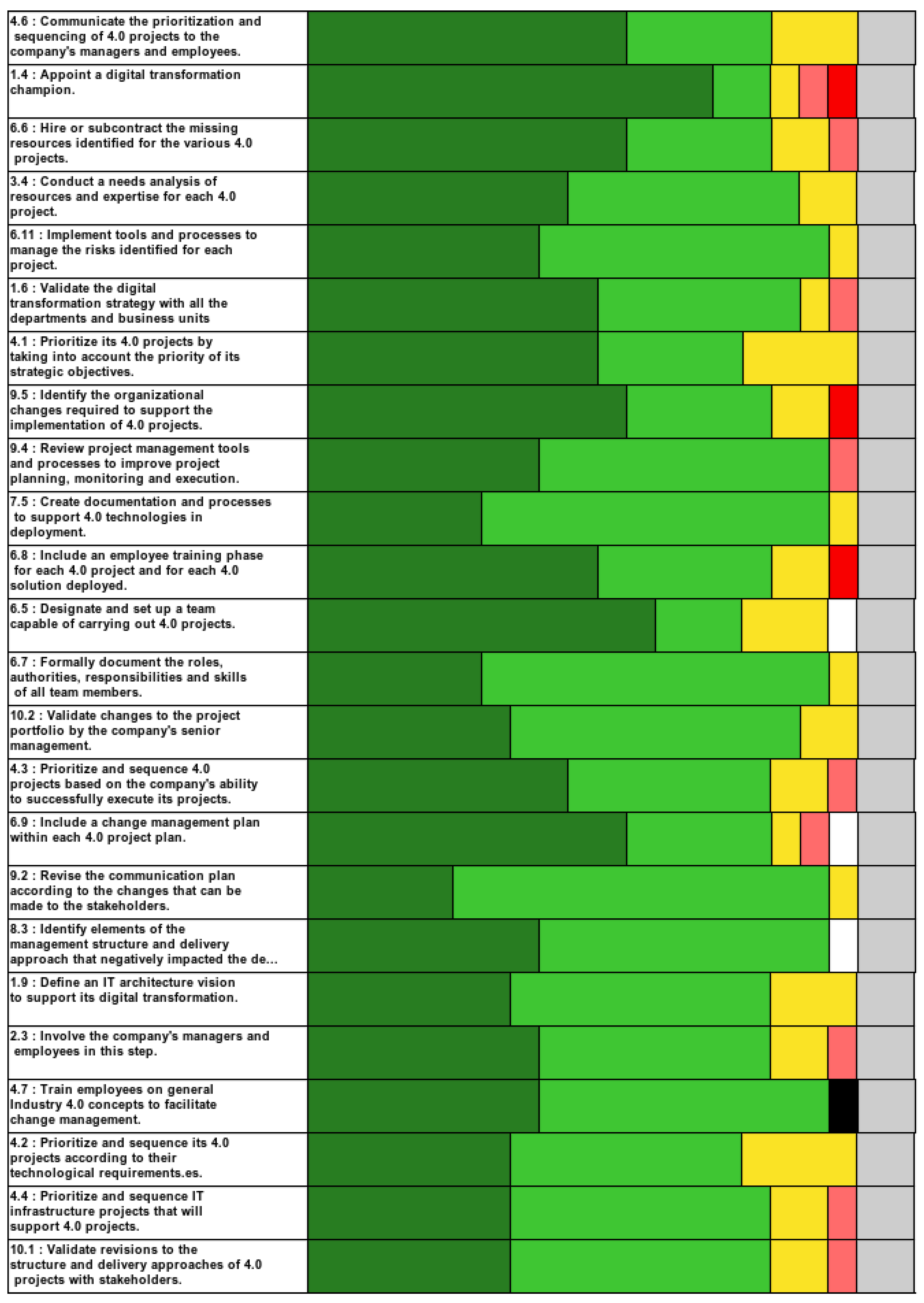

Appendix B. Second Questionnaire Statements and Vote Distribution

- 1.

- Characteristics of the Industry 4.0 champion

- 1.1.

- The Industry 4.0 transformation champion plays an informal role within the manufacturing SME

- 1.2.

- The Industry 4.0 transformation champion has a formal position within the manufacturing SME

- 1.3.

- The Industry 4.0 transformation champion within a manufacturing SME must be the company’s CEO

- 1.4.

- The Industry 4.0 transformation champion within the manufacturing SME should be a member of the company’s senior management, but not the CEO.

- 1.5.

- The Industry 4.0 transformation champion within the manufacturing SME should be a manager who reports to a member of the company’s senior management or CEO.

- 1.6.

- The Industry 4.0 transformation champion is directly responsible for ensuring the success of the manufacturing SME’s Transformation 4.0.

- 1.7.

- The Industry 4.0 transformation champion plays a communicator role responsible for educating the business on digital transformation as well as communicating the progress of Industry 4.0 projects.

- 1.8.

- The Industry 4.0 transformation champion is responsible for identifying Transformation 4.0 projects in the manufacturing SME.

- 1.9.

- The Industry 4.0 transformation champion is responsible for prioritizing Transformation 4.0 projects in the manufacturing SME.

- 1.10.

- The Industry 4.0 transformation champion is responsible for establishing a governance structure to track Industry 4.0 projects.

- 1.11.

- The Industry 4.0 transformation champion must assume the role of 4.0 project manager.

- 1.12.

- If they are not the same person, the 4.0 Project Manager must report hierarchically to the Industry 4.0 transformation champion.

- 1.13.

- The Industry 4.0 transformation champion must have prior experience in digital transformation.

- 2.

- Manufacturing SME’s capacity to realize its Industry 4.0 projects

- 2.1.

- When a manufacturing SME evaluates its capacity to carry out Industry 4.0 projects, it must assess its financial means and determine a budget to be allocated

- 2.2.

- When a manufacturing SME assesses its ability to carry out Industry 4.0 projects, it must assess the availability and skills of the company’s internal resources who will be responsible for implementing these projects

- 2.3.

- When a manufacturing SME assesses its ability to deliver Industry 4.0 projects, it should evaluate how its internal processes and practices can facilitate or hinder its Industry 4.0 projects

- 2.4.

- When a manufacturing SME evaluates its capacity to carry out Industry 4.0 projects, it must assess the level of openness and reluctance of its managers and employees towards the projects considered.

- 2.5.

- A manufacturing SME must consider all the potential external help available (grants, consultants, integrators, trainers, etc.) when evaluating its ability to undertake its Industry 4.0 transformation.

- 2.6.

- When a manufacturing SME assesses that its capacity to undertake Industry 4.0 projects is insufficient, it must identify projects (financing, hiring, organizational change) that will allow it to obtain the necessary capacity to carry out its Industry 4.0 projects.

Appendix C. Items Matrix of the First Questionnaire (First Round)

Appendix D. Items Matrix of the Second Questionnaire (Second Round)

References

- Statistique Canada. Registre des Entreprises. Available online: https://www.ic.gc.ca/eic/site/061.nsf/fra/h_03018.html (accessed on 31 May 2019).

- Institut de la Statistique du Québec. Statistiques Principales du Secteur de la Fabrication, pour L’activité Manufacturière et L’activité Totale, PME et Grandes Entreprises, par Sous-Secteur du SCIAN et Région Administrative, Québec, 2004–2012. Available online: http://www.stat.gouv.qc.ca/statistiques/secteur-manufacturier/pme/manuf-pme-fabrication-act-tot-2004-2012.html (accessed on 31 May 2019).

- Ghadge, A.; Kara, M.E.; Moradlou, H.; Goswami, M. The impact of Industry 4.0 implementation on supply chains. J. Manuf. Technol. Manag. 2020, 31, 669–686. [Google Scholar] [CrossRef]

- Xu, L.D.; Xu, E.L.; Li, L. Industry 4.0: State of the art and future trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef] [Green Version]

- Moeuf, A.; Pellerin, R.; Lamouri, S.; Tamayo-Giraldo, S.; Barbaray, R. The industrial management of SMEs in the era of Industry 4.0. Int. J. Prod. Res. 2018, 56, 1118–1136. [Google Scholar] [CrossRef] [Green Version]

- Barratt, M. Understanding the meaning of collaboration in the supply chain. Supply Chain. Manag. Int. J. 2004, 9, 30–42. [Google Scholar] [CrossRef]

- Manavalan, E.; Jayakrishna, K. A review of Internet of Things (IoT) embedded sustainable supply chain for industry 4.0 requirements. Comput. Ind. Eng. 2019, 127, 925–953. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Oztemel, E.; Gursev, S. Literature review of Industry 4.0 and related technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Piccarozzi, M.; Aquilani, B.; Gatti, C. Industry 4.0 in Management Studies: A Systematic Literature Review. Sustainability 2018, 10, 3821. [Google Scholar] [CrossRef] [Green Version]

- Agarwal, R.; Gao, G.; DesRoches, C.; Jha, A.K. Research Commentary—The Digital Transformation of Healthcare: Current Status and the Road Ahead. Inf. Syst. Res. 2010, 21, 796–809. [Google Scholar] [CrossRef] [Green Version]

- Majchrzak, A.; Markus, M.L.; Wareham, J. Designing for digital transformation: Lessons for information systems research from the study of ICT and societal challenges. MIS Q. 2016, 40, 267–277. [Google Scholar] [CrossRef]

- Vial, G. Understanding digital transformation: A review and a research agenda. J. Strateg. Inf. Syst. 2019, 28, 118–144. [Google Scholar] [CrossRef]

- Jones, M.D.; Hutcheson, S.; Camba, J.D. Past, present, and future barriers to digital transformation in manufacturing: A review. J. Manuf. Syst. 2021, 60, 936–948. [Google Scholar] [CrossRef]

- Fitzgerald, M.; Kruschwitz, N.; Bonnet, D.; Welch, M. Embracing digital technology: A new strategic imperative. MIT Sloan Manag. Rev. 2014, 55, 1. [Google Scholar]

- Gamache, S.; Abdulnour, G.; Baril, C. Toward industry 4.0: Studies and practices in Quebec SMES. In Proceedings of the 47th International Conference on Computers and Industrial Engineering: How Digital Platforms and Industrial Engineering are Transforming Industry and Services, CIE 2017, Lisbon, Portugal, 11–13 October 2017. [Google Scholar]

- Borangiu, T.; Trentesaux, D.; Thomas, A.; Leitão, P.; Barata, J. Digital transformation of manufacturing through cloud services and resource virtualization. Comput. Ind. 2019, 108, 150–162. [Google Scholar] [CrossRef]

- Xu, X.; He, Y. Blockchain application in modern logistics information sharing: A review and case study analysis. Prod. Plan. Control 2022, 1–15. [Google Scholar] [CrossRef]

- Arcidiacono, F.; Ancarani, A.; Mauro, C.D.; Schupp, F. Where the Rubber Meets the Road. Industry 4.0 Among SMEs in the Automotive Sector. IEEE Eng. Manag. Rev. 2019, 47, 86–93. [Google Scholar] [CrossRef]

- Wank, A.; Adolph, S.; Anokhin, O.; Arndt, A.; Anderl, R.; Metternich, J. Using a learning factory approach to transfer Industrie 4.0 approaches to small-and medium-sized enterprises. Procedia CIRP 2016, 54, 89–94. [Google Scholar] [CrossRef] [Green Version]

- Brodeur, J.; Pellerin, R.; Deschamps, I. Collaborative approach to digital transformation (CADT) model for manufacturing SMEs. J. Manuf. Technol. Manag. 2022, 33, 61–83. [Google Scholar] [CrossRef]

- Zangiacomi, A.; Pessot, E.; Fornasiero, R.; Bertetti, M.; Sacco, M. Moving towards digitalization: A multiple case study in manufacturing. Prod. Plan. Control 2020, 31, 143–157. [Google Scholar] [CrossRef]

- Ali, I.; Aboelmaged, M.G.S. Implementation of supply chain 4.0 in the food and beverage industry: Perceived drivers and barriers. Int. J. Product. Perform. Manag. 2021, 71, 1426–1443. [Google Scholar] [CrossRef]

- Zhou, K.L.; Liu, T.G.; Zhou, L.F. Industry 4.0: Towards future industrial opportunities and challenges. In Proceedings of the 2015 12th International Conference on Fuzzy Systems and Knowledge Discovery (FSKD), Zhangjiajie, China, 15–17 August 2015; pp. 2147–2152. [Google Scholar]

- Moeuf, A.; Lamouri, S.; Pellerin, R.; Tamayo-Giraldo, S.; Tobon-Valencia, E.; Eburdy, R. Identification of critical success factors, risks and opportunities of Industry 4.0 in SMEs. Int. J. Prod. Res. 2019, 58, 1384–1400. [Google Scholar] [CrossRef]

- Stentoft, J.; Jensen, K.W.; Philipsen, K.; Haug, A. Drivers and barriers for industry 4.0 readiness and practice: A SME perspective with empirical evidence. In Proceedings of the 52nd Hawaii International Conference on System Sciences, Maui, HI, USA, 8–11 January 2019. [Google Scholar]

- Singla, A.R. Challenges in Enterprise Information Systems Implementation. In Enterprise Information Systems and Implementing IT Infrastructures; Enterprise Information Systems and Implementing IT Infrastructures: Challenges and Issues; IGI Global: Hershey, PA, USA, 2010; pp. 195–209. [Google Scholar]

- Buonanno, G.; Themistocleous, M.; Faverio, P.; Pigni, F.; Ravarini, A.; Sciuto, D.; Tagliavini, M. Factors affecting ERP system adoption. J. Enterp. Inf. Manag. 2005, 18, 384–426. [Google Scholar] [CrossRef]

- Schröder, C. The Challenges of Industry 4.0 for Small and Medium-Sized Enterprises; Friedrich-Ebert-Stiftung: Bonn, Germany, 2016. [Google Scholar]

- Müller, J.M.; Kiel, D.; Voigt, K.-I. What Drives the Implementation of Industry 4.0? The Role of Opportunities and Challenges in the Context of Sustainability. Sustainability 2018, 10, 247. [Google Scholar] [CrossRef] [Green Version]

- Amaral, A.; Peças, P. SMEs and Industry 4.0: Two case studies of digitalization for a smoother integration. Comput. Ind. 2021, 125, 103333. [Google Scholar] [CrossRef]

- Leyh, C.; Schaffer, T.; Bley, K.; Bay, L. The Application of the Maturity Model SIMMI 4.0 in Selected Enterprises. In Proceedings of the 23rd Americas Conference on Information Systems, Boston, MA, USA, 10–12 August 2017. [Google Scholar]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. A critical review of smart manufacturing & Industry 4.0 maturity models: Implications for small and medium-sized enterprises (SMEs). J. Manuf. Syst. 2018, 49, 194–214. [Google Scholar] [CrossRef]

- Schumacher, A.; Erol, S.; Sihn, W. A maturity model for assessing Industry 4.0 readiness and maturity of manufacturing enterprises. In Proceedings of the 6th International Conference on Changeable, Agile, Reconfigurable and Virtual Production (Carv2016), Bath, UK, 4–6 September 2016; Volume 52, pp. 161–166. [Google Scholar] [CrossRef]

- Amaral, A.; Peças, P. A Framework for Assessing Manufacturing SMEs Industry 4.0 Maturity. Appl. Sci. 2021, 11, 6127. [Google Scholar] [CrossRef]

- Ganzarain, J.; Errasti, N. Three stage maturity model in SME’s toward industry 4.0. J. Ind. Eng. Manag. (JIEM) 2016, 9, 1119–1128. [Google Scholar] [CrossRef]

- Pozzi, R.; Rossi, T.; Secchi, R. Industry 4.0 technologies: Critical success factors for implementation and improvements in manufacturing companies. Prod. Plan. Control 2021, 1–21. [Google Scholar] [CrossRef]

- Shinohara, A.C.; da Silva, E.H.D.R.; de Lima, E.P.; Deschamps, F.; da Costa, S.E.G. Critical Success Factors for Digital Manufacturing Implementation in the Context of Industry 4.0. In Proceedings of the 2017 Industrial and Systems Engineering Conference, Pittsburgh, PA, USA, 20–23 May 2017; pp. 199–204. [Google Scholar]

- Gupta, M.; Cawthon, G. Managerial implications of flexible manufacturing for small/mediumm-sized enterprises. Technovation 1996, 16, 77–94. [Google Scholar] [CrossRef]

- Brettel, M.; Klein, M.; Friederichsen, N. The relevance of manufacturing flexibility in the context of Industrie 4.0. Research and Innovation in Manufacturing: Key Enabling Technologies for the Factories of the Future. In Proceedings of the 48th Cirp Conference on Manufacturing Systems, Ischia, Italy, 24–26 June 2015; Volume 41, pp. 105–110. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.Y.; Vonderembse, M.A.; Lim, J.S. Manufacturing flexibility: Defining and analyzing relationships among competence, capability, and customer satisfaction. J. Oper. Manag. 2003, 21, 173–191. [Google Scholar] [CrossRef]

- Levy, M.; Powell, P. SME flexibility and the role of information systems. Small Bus. Econ. 1998, 11, 183–196. [Google Scholar] [CrossRef]

- Laforet, S.; Tann, J. Innovative characteristics of small manufacturing firms. J. Small Bus. Enterp. Dev. 2006, 13, 363–380. [Google Scholar] [CrossRef]

- Khan, A.; Turowski, K. A survey of current challenges in manufacturing industry and preparation for industry 4.0. In Proceedings of the First International Scientific Conference “Intelligent Information Technologies for Industry”(IITI’16), Sochi, Russia, 16–21 May 2016; pp. 15–26. [Google Scholar]

- Raymond, L.; Uwizeyemungu, S. A profile of ERP adoption in manufacturing SMEs. J. Enterp. Inf. Manag. 2007, 20, 487–502. [Google Scholar] [CrossRef]

- Stonehouse, G.; Pemberton, J. Strategic planning in SMEs—Some empirical findings. Manag. Decis. 2002, 40, 853–861. [Google Scholar] [CrossRef]

- Smallbone, D.; Leig, R.; North, D. The characteristics and strategies of high growth SMEs. Int. J. Entrep. Behav. Res. 1995, 1, 44–62. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent Manufacturing in the Context of Industry 4.0: A Review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Müller, J.M.; Buliga, O.; Voigt, K.-I. Fortune favors the prepared: How SMEs approach business model innovations in Industry 4.0. Technol. Forecast. Soc. Chang. 2018, 132, 2–17. [Google Scholar] [CrossRef]

- Brodeur, J.; Deschamps, I.; Pellerin, R. Organizational Changes during the Industry 4.0 Transformation of a Manufacturing SME: A Case Study. 2021; Manuscript submitted for publication. [Google Scholar]

- Ghobakhloo, M. The future of manufacturing industry: A strategic roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef] [Green Version]

- Dillinger, F.; Bernhard, O.; Kagerer, M.; Reinhart, G. Industry 4.0 implementation sequence for manufacturing companies. Prod. Eng. 2022, 1–14. [Google Scholar] [CrossRef]

- Liebrecht, C.; Kandler, M.; Lang, M.; Schaumann, S.; Stricker, N.; Wuest, T.; Lanza, G. Decision support for the implementation of Industry 4.0 methods: Toolbox, Assessment and Implementation Sequences for Industry 4.0. J. Manuf. Syst. 2021, 58, 412–430. [Google Scholar] [CrossRef]

- Labbe, M. Energy Consumption of AI Poses Environmental Problems. Available online: https://www.techtarget.com/searchenterpriseai/feature/Energy-consumption-of-AI-poses-environmental-problems (accessed on 7 July 2022).

- Zhang, Q.; Yang, S. Evaluating the sustainability of big data centers using the analytic network process and fuzzy TOPSIS. Environ. Sci. Pollut. Res. 2021, 28, 17913–17927. [Google Scholar] [CrossRef] [PubMed]

- Stock, T.; Seliger, G. Opportunities of Sustainable Manufacturing in Industry 4.0. In Proceedings of the 13th Global Conference on Sustainable Manufacturing—Decoupling Growth from Resource Use, Binh Duong New City, Vietnam, 16–18 September 2015; Volume 40, pp. 536–541. [Google Scholar] [CrossRef] [Green Version]

- Richard, S.; Pellerin, R.; Bellemare, J.; Perrier, N. A business process and portfolio management approach for Industry 4.0 transformation. Bus. Process Manag. J. 2021, 27, 505–528. [Google Scholar] [CrossRef]

- Françoise, O.; Bourgault, M.; Pellerin, R. ERP implementation through critical success factors’ management. Bus. Process Manag. J. 2009, 15, 371–394. [Google Scholar] [CrossRef]

- Sony, M.; Naik, S. Critical factors for the successful implementation of Industry 4.0: A review and future research direction. Prod. Plan. Control 2019, 31, 799–815. [Google Scholar] [CrossRef]

- Vrchota, J.; Rehor, P.; Marikova, M.; Pech, M. Critical Success Factors of the Project Management in Relation to Industry 4.0 for Sustainability of Projects. Sustainability 2021, 13, 281. [Google Scholar] [CrossRef]

- Cimini, C.; Boffelli, A.; Lagorio, A.; Kalchschmidt, M.; Pinto, R. How do industry 4.0 technologies influence organisational change? An empirical analysis of Italian SMEs. J. Manuf. Technol. Manag. 2020, 32, 695–721. [Google Scholar] [CrossRef]

- Brettel, M.; Friederichsen, N.; Keller, M.; Rosenberg, M. How virtualization, decentralization and network building change the manufacturing landscape: An Industry 4.0 Perspective. Int. J. Inf. Commun. Eng. 2014, 8, 37–44. [Google Scholar]

- Elenkov, D.S.; Manev, I.M. Top management leadership and influence on innovation: The role of sociocultural context. J. Manag. 2005, 31, 381–402. [Google Scholar] [CrossRef]

- Müller, R.; Söderland, J.; Jugdev, K. Critical success factors in projects. Int. J. Manag. Proj. Bus. 2012, 5, 757–775. [Google Scholar] [CrossRef]

- Müller, R.; Turner, R. The Influence of Project Managers on Project Success Criteria and Project Success by Type of Project. Eur. Manag. J. 2007, 25, 298–309. [Google Scholar] [CrossRef]

- De Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Foropon, C.; Godinho Filho, M. When titans meet—Can industry 4.0 revolutionise the environmentally-sustainable manufacturing wave? The role of critical success factors. Technol. Forecast. Soc. Change 2018, 132, 18–25. [Google Scholar] [CrossRef]

- Sony, M. Industry 4.0 and lean management: A proposed integration model and research propositions. Prod. Manuf. Res. 2018, 6, 416–432. [Google Scholar] [CrossRef] [Green Version]

- Rojko, A. Industry 4.0 concept: Background and overview. Int. J. Interact. Mob. Technol. 2017, 11, 77–90. [Google Scholar] [CrossRef] [Green Version]

- Müller, J.M.; Veile, J.W.; Voigt, K.-I. Prerequisites and incentives for digital information sharing in Industry 4.0–An international comparison across data types. Comput. Ind. Eng. 2020, 148, 106733. [Google Scholar] [CrossRef]

- Nfuka, E.N.; Rusu, L. The effect of critical success factors on IT governance performance. Ind. Manag. Data Syst. 2011, 111, 1418–1448. [Google Scholar] [CrossRef]

- Denolf, J.M.; Trienekens, J.H.; Wognum, P.M.; van der Vorst, J.G.A.J.; Omta, S.W.F. Towards a framework of critical success factors for implementing supply chain information systems. Comput. Ind. 2015, 68, 16–26. [Google Scholar] [CrossRef]

- Demircan Keskin, F. A two-stage fuzzy approach for Industry 4.0 project portfolio selection within criteria and project interdependencies context. J. Multi-Criteria Decis. Anal. 2019, 27, 65–83. [Google Scholar] [CrossRef]

- Kaiser, M.G.; El Arbi, F.; Ahlemann, F. Successful project portfolio management beyond project selection techniques: Understanding the role of structural alignment. Int. J. Proj. Manag. 2015, 33, 126–139. [Google Scholar] [CrossRef]

- Isikli, E.; Yanik, S.; Cevikcan, E.; Ustundag, A. Project portfolio selection for the digital transformation era. In Industry 4.0: Managing The Digital Transformation; Springer Series in Advanced Manufacturing; Springer International Publishing: Cham, Switzerland, 2018; pp. 105–121. [Google Scholar]

- Yu, V.F.; Kuo, C.W.; Yeh, R.H. Decision Process Analysis on Project Priority Strategy: A Case Study of an ICT Design Firm. J. Appl. Math. 2014, 2014, 580851. [Google Scholar] [CrossRef]

- Mohelska, H.; Sokolova, M. Management Approaches for Industry 4.0-the Organizational Culture Perspective. Technol. Econ. Dev. Econ. 2018, 24, 2225–2240. [Google Scholar] [CrossRef] [Green Version]

- Hornstein, H.A. The integration of project management and organizational change management is now a necessity. Int. J. Proj. Manag. 2015, 33, 291–298. [Google Scholar] [CrossRef]

- Nelson, R.R. IT project management: Infamous failures, classic mistakes, and best practices. MIS Q. Exec. 2007, 6, 67–78. [Google Scholar]

- Linstone, H.A.; Turoff, M. The Delphi Method; Addison-Wesley Publishing: Reading, MA, USA, 1975. [Google Scholar]

- Rowe, G.; Wright, G. The Delphi technique as a forecasting tool: Issues and analysis. Int. J. Forecast. 1999, 15, 353–375. [Google Scholar] [CrossRef]

- Skulmoski, G.J.; Hartman, F.T.; Krahn, J. The Delphi method for graduate research. J. Inf. Technol. Educ. Res. 2007, 6, 1–21. [Google Scholar] [CrossRef]

- Rosin, F.; Forget, P.; Lamouri, S.; Pellerin, R. Enhancing the Decision-Making Process through Industry 4.0 Technologies. Sustainability 2022, 14, 461. [Google Scholar] [CrossRef]

- Maleki, K. Méthodes Quantitatives de Consultation D’experts: Delphi, Delphi Public, Abaque de Régnier et Impacts Croisés; Editions Publibook: Paris, France, 2009. [Google Scholar]

- Mitchell, V.W. The Delphi technique: An exposition and application. Technol. Anal. Strateg. Manag. 1991, 3, 333–358. [Google Scholar] [CrossRef]

- Ashton, R.H. Combining the judgments of experts: How many and which ones? Organ. Behav. Hum. Decis. Processes 1986, 38, 405–414. [Google Scholar] [CrossRef]

- Riemens, J.; Lemieux, A.A.; Lamouri, S.; Garnier, L. A Delphi-Regnier Study Addressing the Challenges of Textile Recycling in Europe for the Fashion and Apparel Industry. Sustainability 2021, 13, 11700. [Google Scholar] [CrossRef]

- Prifling, M. IT project portfolio management—A matter of organizational culture? In Proceedings of the 14th Pacific Asia Conference on Information Systems, PACIS 2010, Taipei, Taiwan, 9–12 July 2010; pp. 761–772. [Google Scholar]

| Identification Phase | Critical Success Factors | Actions |

|---|---|---|

| Establishing a strategic vision for Industry 4.0 | Align Industry 4.0 strategy to business strategy |

|

| Leadership |

| |

| Alignment along hierarchical line |

| |

| Communication management |

| |

| Current situation evaluation | Conduct a study prior to Industry 4.0 projects |

|

| Alignment along hierarchical line |

| |

| Communication management |

| |

| Industry 4.0 project/opportunity identification | Align Industry 4.0 strategy to business strategy |

|

| Alignment along hierarchical line |

| |

| Project management |

| |

| Continuous improvement strategy |

|

| Preparation Phase | Critical Success Factors | Actions |

|---|---|---|

| Industry 4.0 project prioritization | Align Industry 4.0 strategy to business strategy |

|

| Alignment along hierarchical line |

| |

| Communication management |

| |

| Implementing an Industry 4.0 transformation management structure | Alignment along hierarchical line |

|

| Communication management |

| |

| Continuous improvement strategy |

| |

| Organizational culture and change management |

| |

| Implementing an Industry 4.0 project delivery approach | Project management |

|

| Teamwork and team composition |

| |

| Communication management |

| |

| Employees’ training and knowledge management |

|

| Execution Phase | Critical Success Factors | Actions |

|---|---|---|

| Industry 4.0 project execution and management | Project management |

|

| Teamwork and team composition |

| |

| Communication management |

| |

| Employees’ training and knowledge management |

| |

| Industry 4.0 project post-mortem | Project management |

|

| Alignment along hierarchical line |

| |

| Teamwork and team composition |

| |

| Industry 4.0 management and project delivery approach revision | Align Industry 4.0 strategy to business strategy |

|

| Alignment along hierarchical line |

| |

| Communication management |

| |

| Project management |

| |

| Teamwork and team composition |

| |

| Organizational culture and change management |

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brodeur, J.; Pellerin, R.; Deschamps, I. Operationalization of Critical Success Factors to Manage the Industry 4.0 Transformation of Manufacturing SMEs. Sustainability 2022, 14, 8954. https://doi.org/10.3390/su14148954

Brodeur J, Pellerin R, Deschamps I. Operationalization of Critical Success Factors to Manage the Industry 4.0 Transformation of Manufacturing SMEs. Sustainability. 2022; 14(14):8954. https://doi.org/10.3390/su14148954

Chicago/Turabian StyleBrodeur, Jonathan, Robert Pellerin, and Isabelle Deschamps. 2022. "Operationalization of Critical Success Factors to Manage the Industry 4.0 Transformation of Manufacturing SMEs" Sustainability 14, no. 14: 8954. https://doi.org/10.3390/su14148954

APA StyleBrodeur, J., Pellerin, R., & Deschamps, I. (2022). Operationalization of Critical Success Factors to Manage the Industry 4.0 Transformation of Manufacturing SMEs. Sustainability, 14(14), 8954. https://doi.org/10.3390/su14148954