Redefining Quality in Food Supply Chains via the Natural Resource Based View and Convention Theory

Abstract

:1. Introduction

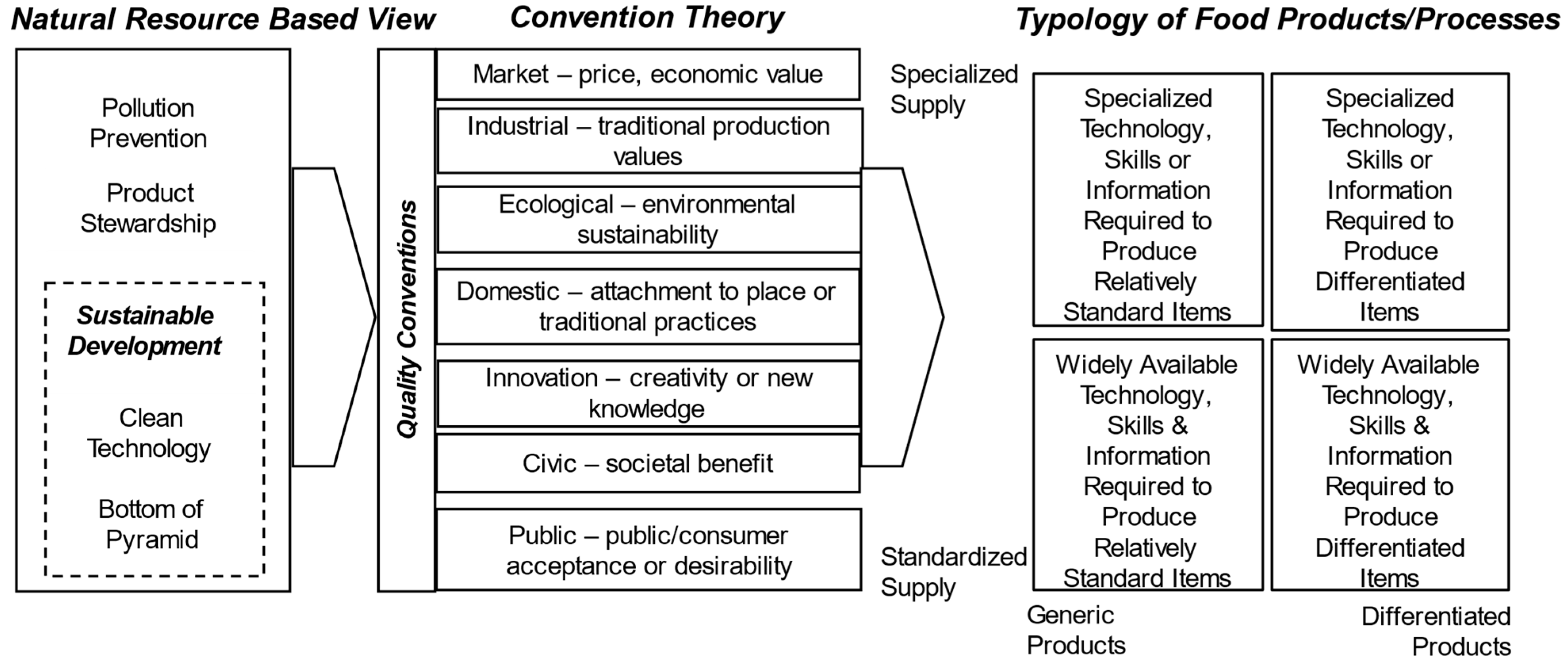

2. Literature Review and Theoretical Development

2.1. Natural Resource Based View

2.2. Convention Theory

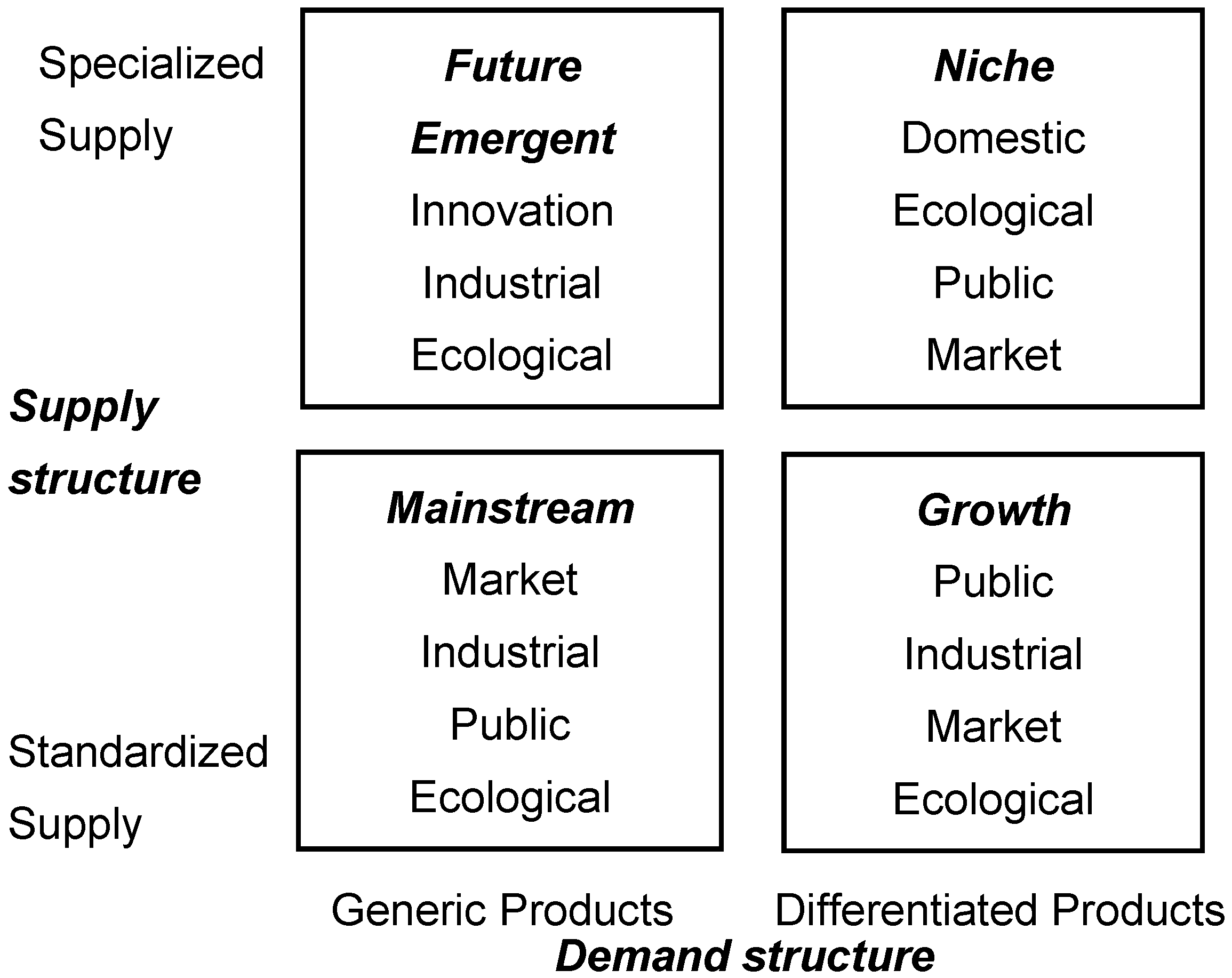

2.2.1. Quality Conventions

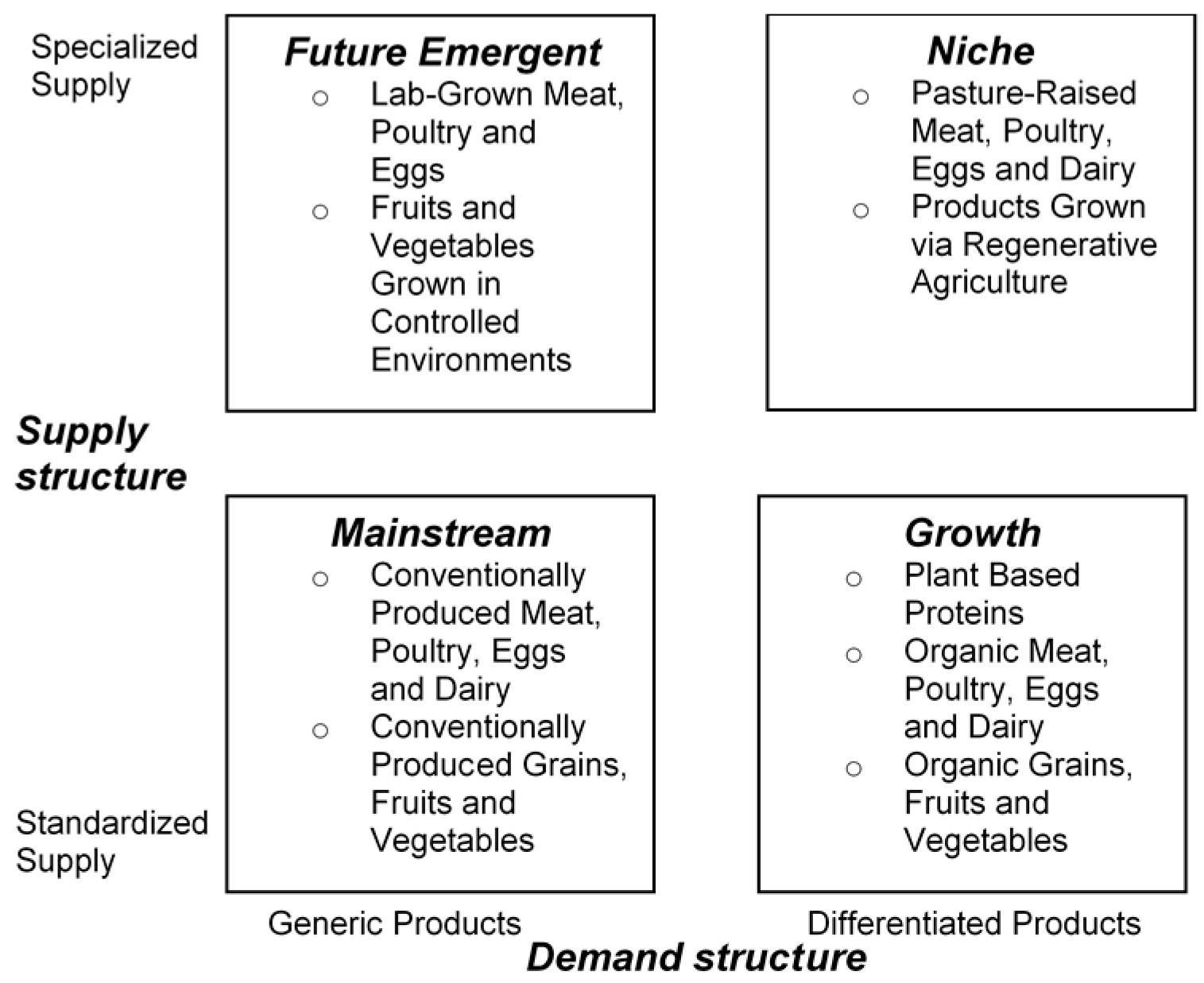

2.2.2. Worlds of Production and Quality Conventions in the FSC Context

3. Research Design and Methodology

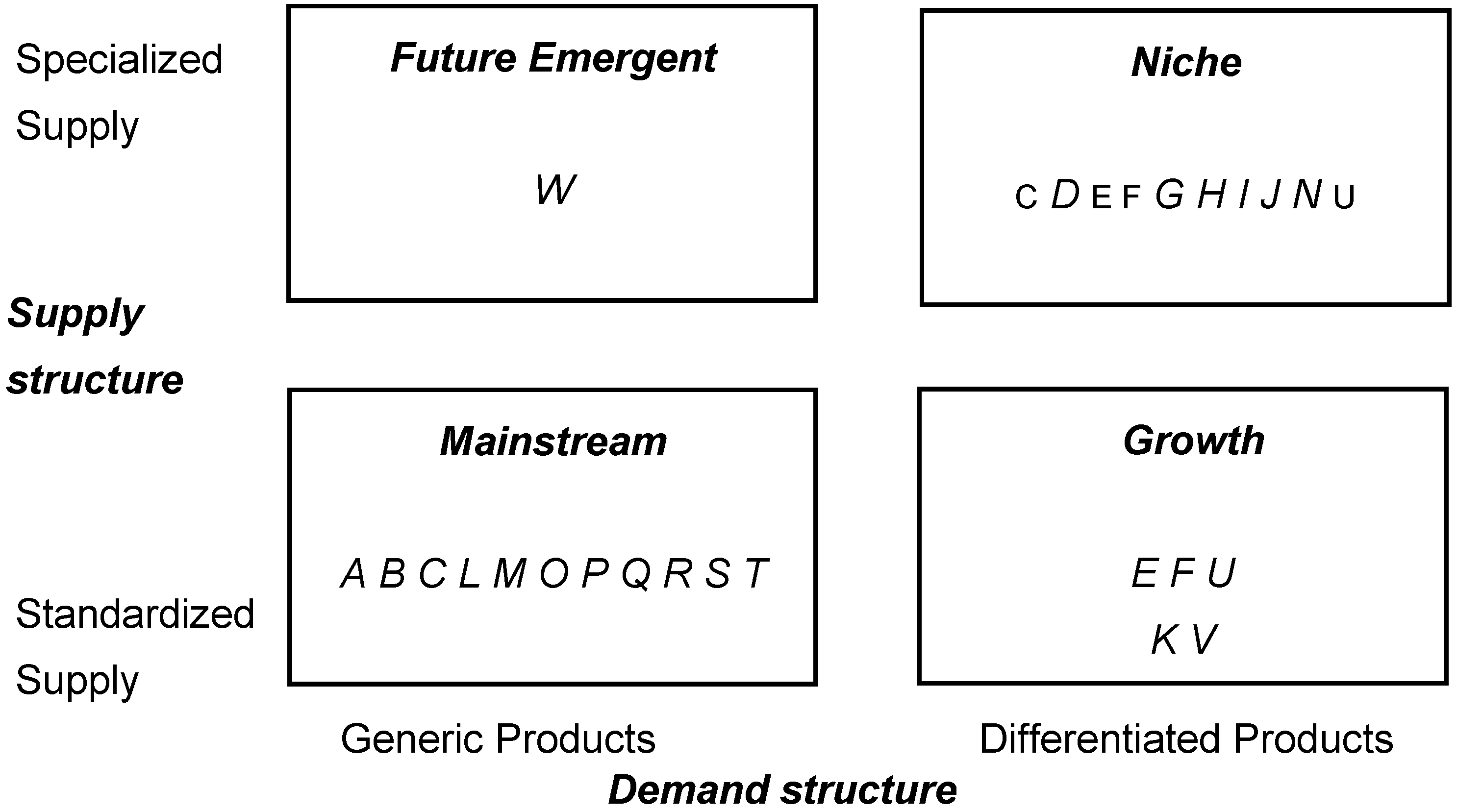

3.1. Case Selection

3.2. Data Collection and Analysis

4. Findings

4.1. Bundling of Quality Conventions and Competitive Advantage

4.1.1. Mainstream

4.1.2. Future Emergent

4.1.3. Growth

4.1.4. Niche

4.2. Cases Competing Based on a Single Quadrant

4.3. Cases Competing Based on Multiple Quadrants

4.4. Movement between Quadrants

5. Discussion and Conclusions

5.1. Research Contributions

5.2. Managerial Implications

5.3. Limitations, Future Research, and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Markman, G.; Krause, D. Theory building surrounding sustainable supply chain management: Assessing what we know, exploring where to go. J. Supply Chain Manag. 2016, 52, 3–10. [Google Scholar] [CrossRef]

- Montabon, F.; Pagell, M.; Wu, Z. Making sustainability sustainable. J. Supply Chain Manag. 2016, 52, 11–27. [Google Scholar] [CrossRef]

- Pagell, M.; Shevchenko, A. Why research in sustainable supply chain management should have no future. J. Supply Chain Manag. 2014, 50, 44–55. [Google Scholar] [CrossRef]

- Samson, D. Operations/supply chain management in a new world context. Oper. Manag. Res. 2020, 13, 1–3. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. The State of Food Security and Nutrition in the World 2018. Building Climate Resilience for Food Security and Nutrition; Food and Agriculture Organization of the United Nations: Rome, Italy, 2018. [Google Scholar]

- Food and Agriculture Organization of the United Nations. The Future of Food and Agriculture—Alternative Pathways to 2050; Food and Agriculture Organization of the United Nations: Rome, Italy, 2018. [Google Scholar]

- Food Marketing Institute. US Grocery Shopper Trends. 2017. Available online: https://www.fmi.org/our-research/research-reports/u-s-grocery-shopper-trends (accessed on 24 August 2020).

- Lappé, F.; Collins, J. World Hunger: Ten Myths; Grove Press: New York, NY, USA, 2015. [Google Scholar]

- Maloni, M.; Brown, M. Corporate social responsibility in the supply chain: An application in the food industry. J. Bus. Ethics 2006, 68, 35–52. [Google Scholar] [CrossRef]

- McWilliams, J. Just Food: Where Locavores Get It Wrong and How We Can Truly Eat Responsibly; Little, Brown and Company: New York, NY, USA, 2009. [Google Scholar]

- Norwood, F.; Calvo-Lorenzo, M.; Lancaster, S.; Oltenacu, P. Agricultural and Food Controversies: What Everyone Needs to Know; Oxford University Press: New York, NY, USA, 2015. [Google Scholar]

- Corbett, C.; Klassen, R. Extending the horizons: Environmental excellence as key to improving operations. Manuf. Serv. Oper. Manag. 2006, 8, 5–22. [Google Scholar] [CrossRef] [Green Version]

- Curkovic, S.; Melnyk, S.; Handfield, R.; Calantone, R. Investigating the linkage between total quality management and environmentally responsible manufacturing. IEEE Trans. Eng. Manag. 2000, 47, 444–464. [Google Scholar] [CrossRef]

- Curkovic, S.; Sroufe, R.; Landeros, R. Measuring TQEM returns from the application of quality frameworks. Bus. Strategy Environ. 2008, 17, 93–106. [Google Scholar] [CrossRef]

- Rusinko, C. Using quality management as a bridge to environmental sustainability in organizations. SAM Adv. Manag. J. 2005, 70, 54–61. [Google Scholar]

- Wiengarten, F.; Pagell, M. The importance of quality management for the success of environmental management initiatives. Int. J. Prod. Econ. 2012, 140, 407–415. [Google Scholar] [CrossRef]

- Roth, A.; Zheng, Y. A tale of two food chains: The duality of practices on well-being. Prod. Oper. Manag. 2021, 30, 783–801. [Google Scholar] [CrossRef]

- Craighead, C.W.; Ketchen, D.J., Jr.; Cheng, L. “Goldilocks” theorizing in supply chain research: Balancing scientific and practical utility via middle-range theory. Trans. J. 2016, 55, 241–257. [Google Scholar] [CrossRef]

- Wowak, K.D.; Craighead, C.W.; Ketchen, D.J., Jr.; Connelly, B.L. Food for thought: Recalls and outcomes. J. Bus. Logist. 2022, 43, 9–35. [Google Scholar] [CrossRef]

- Hart, S.; Dowell, G. A natural-resource-based-view of the firm: Fifteen years after. J. Manag. 2011, 37, 1464–1479. [Google Scholar]

- Granovetter, M. Economic action and social structure: The problem of embeddedness. Am. J. Soc. 1985, 91, 481–510. [Google Scholar] [CrossRef]

- Roth, A.; Tsay, A.; Pullman, M.; Gray, J. Unraveling the food supply chain: Strategic insights from China and the 2007 recalls. J. Supply Chain Manag. 2008, 44, 22–39. [Google Scholar] [CrossRef]

- Pullman, M.; Maloni, M.; Carter, C. Food for thought: Social versus environmental sustainability practices and performance outcomes. J. Supply Chain Manag. 2009, 45, 38–54. [Google Scholar] [CrossRef]

- Garvin, D. Competing on the eight dimensions of quality. Harvard Bus. Rev. 1987, 65, 101–109. [Google Scholar]

- Raynolds, L. Re-embedding global agriculture: The international organic and fair trade movements. Agric. Hum. Values 2000, 17, 297–309. [Google Scholar] [CrossRef]

- Hinrichs, C. Embeddedness and local food systems: Notes on two types of direct agricultural market. J. Rural. Stud. 2000, 16, 295–303. [Google Scholar] [CrossRef]

- Deloitte. Capitalizing on the Shifting Consumer Food Value Equation. 2016. Available online: https://www2.deloitte.com/content/dam/Deloitte/us/Documents/consumer-business/us-fmi-gma-report.pdf (accessed on 23 August 2020).

- Murdoch, J.; Marsden, T.; Banks, J. Quality, nature, and embeddedness: Some theoretical considerations in the context of the food sector. Econ. Geo. 2000, 76, 107–125. [Google Scholar] [CrossRef]

- Eisenhardt, K.M. Building theories from case study research. Acad. Manag. Rev. 1989, 14, 532–550. [Google Scholar] [CrossRef]

- Hart, S. A natural-resource-based-view of the firm. Acad. Manag. 1995, 20, 986–1014. [Google Scholar]

- Clarkson, P.; Li, Y.; Richardson, G.; Vasvari, F. Revisiting the relation between environmental performance and environmental disclosure: An empirical analysis. Account. Org. Soc. 2008, 33, 303–327. [Google Scholar] [CrossRef]

- Holder-Webb, L.; Cohen, J.; Nath, L.; Wood, D. The supply of corporate social responsibility disclosures among US firms. J. Bus. Ethics 2009, 84, 497–527. [Google Scholar] [CrossRef]

- Mueller, M.; Dos Santos, V.; Seuring, S. The contribution of environmental and social standards towards ensuring legitimacy in supply chain governance. J. Bus. Ethics 2009, 89, 509–523. [Google Scholar] [CrossRef]

- Ponte, S. Convention theory in the Anglophone agro-food literature: Past, present and future. J. Rural. Stud. 2016, 44, 12–23. [Google Scholar] [CrossRef] [Green Version]

- Boltanski, L.; Thévenot, L. De la Justification. Les Économies de la Grandeur. 2006 English Translation by C Porter: On Justification: Economies of Worth; Princeton University Press: Princeton, NJ, USA, 1991. [Google Scholar]

- Diaz-Bone, R. Convention theory, classification and quantification. Hist. Soc. Res. 2016, 42, 48–71. [Google Scholar]

- Murdoch, J.; Miele, M. Culinary networks and cultural connections: A conventions perspective. In Geographies of Commodity Chains; Hughes, A., Reimer, S., Eds.; Routledge: London, UK, 2004; pp. 102–119. [Google Scholar]

- Ponte, S. Governing through quality: Conventions and supply relations in the value chain for South African wine. Sociol. Rural. 2009, 49, 236–257. [Google Scholar] [CrossRef]

- Storper, M.; Salais, R. Worlds of Production: The Action Frameworks of the Economy; Harvard University Press: Cambridge, MA, USA, 1997. [Google Scholar]

- Trabalzi, F. Crossing conventions in localized food networks: Insights from southern Italy. Environ. Plan A 2007, 39, 283–300. [Google Scholar] [CrossRef]

- Gibbon, P.; Riisgaard, L. A new system of labour management in African large-scale agriculture? J. Agrar. Chang. 2014, 14, 94–128. [Google Scholar] [CrossRef]

- Feagan, R. The place of food: Mapping out the ‘local’ in local food systems. Prog. Hum. Geog. 2007, 31, 23–42. [Google Scholar] [CrossRef] [Green Version]

- Hinrichs, C. The practice and politics of food system localization. J. Rural. Stud. 2003, 19, 33–45. [Google Scholar] [CrossRef]

- Renting, H.; Marsden, T.; Banks, J. Understanding alternative food networks: Exploring the role of short food supply chains in rural development. Environ. Plan A 2003, 35, 393–411. [Google Scholar] [CrossRef] [Green Version]

- Winter, M. Embeddedness, the new food economy and defensive localism. J. Rural. Stud. 2003, 19, 23–32. [Google Scholar] [CrossRef]

- León-Bravo, V.; Caniato, F.; Caridi, M. Sustainability in multiple stages of the food supply chain in Italy: Practices, performance and reputation. Oper. Manag. Res. 2019, 12, 40–61. [Google Scholar] [CrossRef]

- Bloemhof, J.; van der Vorst, J.; Bastl, M.; Allaoui, H. Sustainability assessment of food chain logistics. Int. J. Logist. 2015, 18, 101–117. [Google Scholar] [CrossRef]

- Miller, S.; Tait, P.; Saunders, C.; Dalziel, P.; Rutherford, P.; Abell, W. Estimation of consumer willingness-to-pay for social responsibility in fruit and vegetable products: A cross-country comparison using a choice experiment. J. Consum. Behav. 2017, 16, 13–25. [Google Scholar] [CrossRef]

- Tobi, R.C.; Harris, F.; Rana, R.; Brown, K.A.; Quaife, M.; Green, R. Sustainable diet dimensions. Comparing consumer preference for nutrition, environmental and social responsibility food labelling: A systematic review. Sustainability 2019, 11, 6575. [Google Scholar] [CrossRef] [Green Version]

- Voss, C.; Tsikriktsis, N.; Frohlich, M. Case research in operations management. Int. J. Oper. Prod. Manag. 2002, 22, 195–219. [Google Scholar] [CrossRef] [Green Version]

- Meredith, J. Building operations management theory through case and field research. J. Oper. Manag. 1998, 16, 441–454. [Google Scholar] [CrossRef]

- Hoffman, A.J.; Ocasio, W. Not all events are attended equally: Toward a middle-range theory of industry attention to external events. Org. Sci. 2001, 12, 414–434. [Google Scholar] [CrossRef] [Green Version]

- United States Department of Agriculture. ChooseMyPlate. 2010. Available online: https://www.myplate.gov/ (accessed on 29 August 2020).

- Feeding America. What Is a Food Bank? 2020. Available online: https://www.feedingamerica.org/our-work/food-bank-network (accessed on 27 August 2020).

- Marsden, T.; Flynn, A.; Harrison, M. Consuming Interests: The Social Provision of Foods; UCL Press: London, UK, 2000. [Google Scholar]

- March, J. Exploration and exploitation in organizational learning. Org. Sci. 1991, 2, 71–87. [Google Scholar] [CrossRef]

- Gupta, A.; Smith, K.; Shalley, C. The interplay between exploration and exploitation. Acad. Manag. J. 2006, 49, 693–706. [Google Scholar] [CrossRef]

- Zimmermann, A.; Raisch, S.; Cardinal, L. Managing persistent tensions on the frontline: A configurational perspective on ambidexterity. J. Manag. Stud. 2018, 55, 739–769. [Google Scholar] [CrossRef]

- Karsten, H.; Patterson, P.; Stout, R.; Crews, G. Vitamins A, E and fatty acid composition of the eggs of caged hens and pastured hens. Renew Agri. Food Sys. 2010, 25, 45–54. [Google Scholar] [CrossRef] [Green Version]

- Certified Humane. Our standards. 2020. Available online: https://certifiedhumane.org/how-we-work/our-standards/ (accessed on 20 August 2020).

- Chaudhuri, A.; Holbrook, M. The chain of effects from brand trust and brand affect to brand performance: The role of brand loyalty. J. Mark. 2001, 65, 81–93. [Google Scholar] [CrossRef] [Green Version]

- Cheshire, C.; Gerbasi, A.; Cook, K. Trust and transitions in modes of exchange. Soc. Psychol. Q. 2010, 73, 176–195. [Google Scholar] [CrossRef]

- Kirwan, J.; Maye, D.; Brunori, G. Acknowledging complexity in food supply chains when assessing their performance and sustainability. J. Rural. Stud. 2017, 52, 21–32. [Google Scholar] [CrossRef]

- Nielsen. Nielsen Global Health and Wellness Survey. 2015. Available online: https://www.nielsen.com/wp-content/uploads/sites/3/2019/04/Nielsen20Global20Health20and20Wellness20Report20-20January202015-1.pdf (accessed on 1 August 2022).

- Center for Food Integrity. Cracking the Code on Food Issues: Insights from Moms, Millennials and Foodies; Funded Research for the Foundation for Food Integrity: Gladstone, MO, USA, 2014. [Google Scholar]

- Whoriskey, P. Why your “organic” milk may not be organic. The Washington Post, 1 May 2017. [Google Scholar]

- Chung, I.; Park, I.; Yoon, J.Y.; Yang, Y.S.; Kim, S.H. Determination of organic milk authenticity using carbon and nitrogen natural isotopes. Food Chem. 2014, 160, 214–218. [Google Scholar] [CrossRef]

- Hoffman, M. The social foundation of sustainable agriculture in southeastern Vermont. In Remaking the North American Food System; Hinrichs, C., Lyson, T., Eds.; University of Nebraska Press: Lincoln, NE, USA, 2007; pp. 315–331. [Google Scholar]

- Tuomisto, H. Vertical farming and cultured meat: Immature technologies for urgent problems. One Earth 2019, 1, 275–277. [Google Scholar] [CrossRef] [Green Version]

- Osterholm, M. Foodborne disease in 2011: The rest of the story. N. Engl. J. Med. 2011, 364, 889–891. [Google Scholar] [CrossRef] [PubMed]

- Hall, D.; Johnson-Hall, T. The value of downstream traceability in food safety management systems: An empirical examination of product recalls. Oper. Manag. Res. 2021, 14, 61–77. [Google Scholar] [CrossRef]

- Roberts, P. The End of Food; First Mariner Books: New York, NY, USA, 2008. [Google Scholar]

- Russell, J.; Rychilik, J. Factors that alter rumen microbial ecology. Science 2001, 292, 1119–1122. [Google Scholar] [CrossRef]

- Patel, P.; Terjesen, S.; Li, D. Enhancing effects of manufacturing flexibility through operational absorptive capacity and operational ambidexterity. J. Oper. Manag. 2012, 30, 201–220. [Google Scholar] [CrossRef]

- Beske, P.; Seuring, S. Sustainable supply chain management practices and dynamic capabilities in the food industry: A critical analysis of the literature. Int. J. Prod. Econ. 2014, 152, 131–143. [Google Scholar] [CrossRef]

- Jansen, J.; Van Den Bosch, F.; Volberda, H. Exploratory innovation, exploitative innovation, and performance: Effects of organizational antecedents and environmental moderators. Manag. Sci. 2006, 52, 1661–1674. [Google Scholar] [CrossRef] [Green Version]

- Fassler, J. After Backing Out of Beyond Meat, Tyson Foods Announces a New Plant-Based Brand of Its Own. 2019. Available online: https://thecounter.org/after-backing-out-of-beyond-meat-tyson-foods-announces-a-new-plant-based-brand-of-its-own/ (accessed on 25 August 2020).

- Choi, T.; Dooley, K.; Rungtusanatham, M. Supply networks and complex adaptive systems: Control versus emergence. J. Oper. Manag. 2001, 19, 351–366. [Google Scholar] [CrossRef]

- Choi, T.; Krause, D. The supply base and its complexity: Implications for transaction costs, risks, responsiveness, and innovation. J. Oper. Manag. 2006, 24, 637–652. [Google Scholar] [CrossRef]

- McDonald’s. Sharing Progress on Our Cage-Free Egg Commitment. 2020. Available online: https://news.mcdonalds.com/stories/using-our-scale-for-good/cage-free-farmer (accessed on 29 August 2020).

- Walmart. Walmart 2017 Global Responsibility Report. 2016. Available online: https://corporate.walmart.com/media-library/document/wmt-2017-grr-report-pdf-download (accessed on 1 August 2022).

- Fassler, J. What Are “Pasture-Raised Eggs,” Really? 2016. Available online: https://thecounter.org/pasture-raised-eggs-part-one/ (accessed on 20 August 2020).

- Shelman, M.; McLoughlin, D.; Pagell, M. Origin green: When your brand is your supply chain. In Supply Chain Processes for Sustainable Innovation in the Agri-Food Industry; Cagliano, R., Caniato, F., Worley, C., Eds.; Emerald Publishing Group Limited: Bingley, UK, 2016. [Google Scholar]

| Quality Convention | Convention Attributes | Examples |

|---|---|---|

| Market [42,46,48] | Price | Competitive price for volume |

| Value-for-price | Competitive price for specific attribute (e.g., organic) | |

| Industrial [34,39] | Economies of scale | High volume production |

| Scaled processes | ||

| Economies of scope | Product variety | |

| Emphasis on improving productivity & efficiency | Traditional productivity measures | |

| High reliability, low variation production | Uniform size and appearance | |

| Ecological [46] | Resource conservation | Reduce use of water, refrigerants; land, energy, inputs |

| Reducing plastic/changing packaging materials | ||

| Eliminate use of sub-clinical antibiotics | ||

| Waste reduction | Inventory management to reduce discards of perishables | |

| Total life cycle management | Life cycle analysis | |

| Recycling | Recycling packaging | |

| Recovery | Pick up of close to sale date food for distribution | |

| Reclamation | Waste converted to soil amendment or energy | |

| Domestic [26,34,42,43,44,45] | Ties to traditional production methods or practices | Seasonal local produce |

| Wild-caught seafood | ||

| “Small batch” production | ||

| Heirloom varieties of produce or grains | ||

| Feeding or foraging methods (e.g., jamón Ibérico) | ||

| Ties to specific geographic region or location | Italian wine regions (e.g., DOCG) | |

| Washington apples | ||

| Gulf shrimp | ||

| Jamón Ibérico (Spain) or Texas Ibérico (Texas) | ||

| Relationship between producer and customer | Direct-to-consumer retailing | |

| Events that bring producer and customer together | ||

| Materials that share history, producer characteristics | ||

| Innovation [34,39] | Development of new categories of products and process technologies | New categories using plant-based protein |

| Lab-grown protein | ||

| Clean production technology [20] | ||

| Public [39] | Differentiated attribute that is either well-accepted by the public, or an order winner in the target market | Nutritional characteristics (protein, fiber, fat, etc.) |

| Taste characteristics | ||

| Convenience packaging | ||

| Certified Human® | ||

| Methods/conditions that promote natural behaviors | ||

| More humane slaughter methods | ||

| Civic [46,47] | Societal/community benefits | Products developed for bottom of pyramid markets |

| Charitable donations | ||

| Community projects | ||

| Working conditions/Supply chain practices | Workplace safety | |

| Worker’s rights | ||

| Living wage, competitive pay | ||

| Fair treatment of suppliers | ||

| Supplier codes of conduct |

| Case | Product Categories | Organization Type | FSC Stage | Downstream Supply Chain Reach | Sales ($) | Number of Employees |

|---|---|---|---|---|---|---|

| A | Various | For-profit | Retailer Processor | Multiple regions | >100 B | >200,000 |

| B | Various | For-profit | Retailer Processor | Regional | >2 B | >50,000 |

| C | Various | For-profit | Retailer | Local | ~80 MM | ~800 |

| D | Produce Meat Poultry Eggs | For-profit | Producer Processor Distributor Retailer | Local (~200 miles) | ~2 MM | ~10 |

| E | Eggs Dairy | For-profit | Producer Processor | Nationwide | ~140 MM | ~100 |

| F | Eggs | For-profit | Producer Processor | Multiple regions | ~2 MM | <20 |

| G | Dairy | For-profit | Producer Processor Distributor Retailer | Local (~60 miles) | <1 MM | <20 |

| H | Produce Meat Poultry Eggs | For-profit | Producer Processor Distributor | Local (~200 miles) | <1 MM | <10 |

| I | Produce | For-profit | Retailer Grower | Local | <2 MM | <10 |

| J | Various | Non-profit | Distributor | Regional | Not applicable | <50 |

| K | Produce | For-profit | Producer Processor | Regional | <10 MM | <500 |

| L | Various | Non-profit | Distributor | Local | Not applicable | Not applicable |

| M | Various | For-profit | Retailer | Regional | ~500 MM | ~3000 |

| N | Various | For-profit | Retailer | Local | <50 MM | ~300 |

| O | Produce Dairy | For-profit | Producer Processor | Nationwide | >2 B | >5000 |

| P | Various | Non-profit | Food bank | Regional | Not applicable | ~40 |

| Q | Various | Non-profit | Food bank | Regional | Not applicable | ~20 |

| R | Various | Non-profit | Food pantry | Local | Not applicable | ~30 |

| S | Various | Non-profit | Food pantry | Local | Not applicable | <20 |

| T | Various | Non-profit | Food pantry | Local | Not applicable | <5 |

| U | Eggs | For-profit | Producer Processor | Nationwide | ~200 MM | ~200 |

| V | Plant-based protein | For-profit | Producer Processor | Nationwide | ~300 MM | ~500 |

| W | Lab-grown meat | For-profit | Producer Processor | Not applicable | Not applicable | <100 |

| Case | Product Categories | Organization Type | FSC Stage | Typology Quadrant 1 | Convention Practices |

|---|---|---|---|---|---|

| A | Various | For-profit | Retailer Processor | Mainstream Growth | (MKT/IND/PUB) Produces, distributes and retails food products created via industrialized processes at highly competitive prices. (MKT/IND/PUB/ECO) Produces, distributes and retails differentiated products created via industrialized processes at competitive prices (e.g., certified organic, Fair Trade). (ECO) Benchmarks, annual and long-term improvement targets for food waste recycling, recycling other types of waste and reducing packaging and making packaging more recyclable. Similar targets and planning for energy use reduction, water use reduction. (ECO) Benchmarks, annual and long-term improvement targets for responsible sourcing of seafood. (PUB/ECO) Animal welfare (e.g., transition to 100% cage-free eggs, elimination of gestation crates in pork production). (CIV) Sets targets for food and funds donated for hunger relief. (CIV) Donates close to sale date products (food recovery). |

| B | Various | For-profit | Retailer Processor | Mainstream Growth | (MKT/IND/PUB) Produces, distributes and retails food products created via industrialized processes at highly competitive prices. (MKT/IND/PUB/ECO) Produces, distributes and retails differentiated products created via industrialized processes at competitive prices (e.g., certified organic, Rainforest Alliance Certified®). (ECO) Benchmarks, annual and long-term improvement targets for food waste recycling, recycling other types of waste and reducing packaging and making packaging more recyclable. Similar targets and planning for energy use reduction (Energy Star Partner), water use reduction. (PUB/ECO) Animal welfare (e.g., transition to 100% cage-free eggs). (CIV) Donates close to sale date products (food recovery). |

| C | Various | For-profit | Retailer | Mainstream Growth Niche | (MKT/IND/PUB) Produces, distributes and retails food products created via industrialized processes at highly competitive prices. (MKT/IND/PUB/ECO) Produces, distributes and retails differentiated products created via industrialized processes at competitive prices (e.g., certified organic, Fair Trade). (MKT/DOM/PUB) Partners with specific local producers for seasonal items, conducts events with these producers, creates personalized advertising materials that tell the story of the producers. Direct-to-source relationships with suppliers for specific items and expedited shipping to increase freshness (e.g., seafood, which is air-freighted to stores). (DOM/PUB) Emphasis on trust developed with suppliers, customers. Marketing materials emphasize basis for trust, including supplier relationships and sourcing methods. (DOM/PUB) Holds cooking demonstrations for local/seasonal food and heavily promotes sale of limited stock of in-season items (e.g., Hatch chiles). (DOM/PUB) Emphasizes continuous family ownership, history, tradition, local (CIV) Donates close to sale date products (food recovery). (CIV) Charitable contributions to local organizations; includes customer participation. |

| D | Produce Meat Poultry Eggs | For-profit | Producer Processor Distributor Retailer | Niche | (DOM/MKT/PUB/ECO) Produces pastured meat, poultry, eggs. Regenerative agriculture. (ECO/DOM/MKT/PUB) Longstanding practice of organic production (uncertified). (DOM) Direct to consumer model connects producer with customer personally. (DOM) On farm store, events, visiting policy. (DOM) Widespread communication of production methods. (DOM/ECO) Limits distribution area, seasonal retailing (e.g., limits sales to growing season). (DOM/ECO) Promotes sale of whole chickens, older chickens. (PUB/ECO) Practices that promote natural animal behavior. (PUB) Humane slaughter methods. (CIV) Donates surplus products to food banks. |

| E | Eggs Dairy | For-profit | Producer Processor | Growth Niche | (DOM/MKT/PUB/ECO) Produces pastured eggs and dairy. (PUB/ECO) Humane Certified® production. (MKT/ECO/PUB) Certified organic production, certified non-GMO. (IND) Production at scale. (IND) Expansion of scope of products offered, expansion of processing methods. (IND) Process improvements to reduce labor requirements and maximize productivity. (DOM) Transparency regarding production methods, including culling of male chicks, euthanization of hens, and COVID-19 at its facilities. (DOM/CIV/MKT) Partners with small farm owners. (CIV) Donates products to food banks. (CIV) Pledges reasonable income to farm partners. |

| F | Eggs | For-profit | Producer Processor | Growth Niche | (DOM/MKT/PUB/ECO) Produces pastured eggs. (MKT/ECO/PUB) Certified organic production, certified non-GMO. (IND) Increasing scale of production. (CIV) Donates products to food banks. |

| G | Dairy | For-profit | Producer Processor Distributor | Niche | (DOM/MKT/PUB/ECO) Cow-to-consumer production of dairy products for local markets. (DOM) Home delivery. (DOM) On farm store, events, visiting policy. (CIV) Donates surplus products. |

| H | Produce Meat Poultry Eggs | For-profit | Producer Processor Distributor | Niche | (DOM/MKT/PUB/ECO) Coordinates production, processing, and distribution for consortium of local poultry, meat, eggs, produce. Alternative methods of agriculture. (MKT/PUB/CIV) Partners with local retailer to distribute local products from small producers. (ECO/MKT/PUB/CIV) Partnered with regulatory agency and small producers to pursue streamlined form of organic certification. Certification allows producers to earn a premium. (DOM/MKT/PUB) Partners with local producers to sell through local retailers. (CIV) Partners to provide seasonal produce to urban food deserts and schools. (CIV) Donates surplus products. |

| I | Produce | For-profit | Producer Retailer | Niche | (DOM) Sells personally via two farmers’ markets. (MKT/ECO/PUB) Longstanding use of organic methods to grow seasonal produce (uncertified). (CIV) Donates surplus products. |

| J | Various | Non-profit 2 | Distributor | Niche | (DOM/MKT/PUB/ECO) Distributes food from local sustainable producers. Provides processing capabilities to small producers. (DOM/MKT/ECO/PUB) Sets standards for sustainable production (certification not required). (DOM/CIV) Transparency regarding production methods. Emphasizes building community and trust, improving food security, access to fresh food, community health. (DOM/MKT/PUB/ECO) Connects small local producers to wholesalers and retailers. (CIV) Connects small local producers to institutions to improve access to nutritious food in vulnerable communities. (CIV) Discounts for qualifying non-profits. |

| K | Produce | For-profit | Producer Processor | Growth | (MKT/IND/PUB/ECO) Produces differentiated products created via industrialized processes at competitive prices (e.g., certified organic). (IND) Traceability—barcoding to greenhouse & date of harvest. (IND/ECO) Closed loop water system with sterilization. (IND/ECO/PUB) Optimized climate control in greenhouse. (IND/ECO/PUB) Biomass hot water boilers used for heating greenhouses. (ECO/PUB) Greenhouse production with insulation to reduce heat loss. (ECO/PUB) Vertical growing. (ECO/PUB) Sustainable growth medium. (PUB/ECO) Non-GMO seeds. (ECO/PUB) Integrated pest management. (ECO/PUB) Limited use of plastic. (CIV) Donates surplus products. |

| L | Various | Non-profit 2 | Distributor | Mainstream Growth | (CIV) Provides technology to enable food recovery. (CIV) Connects food donors with volunteers and food pantry operations. |

| M | Various | For-profit | Distributor Retailer | Mainstream Growth Niche | (MKT/IND/PUB) Produces, distributes and retails food products created via industrialized processes at highly competitive prices. (MKT/IND/PUB/ECO) Produces, distributes and retails differentiated products created via industrialized processes at competitive prices (e.g., certified organic). (DOM) Partnership with local aggregator for local seasonal products. (DOM) Holds farmers market within/outside stores. (DOM) Holds events within store to meet local producers. (CIV) Donates close to sale date items (food recovery). |

| N | Various | For-profit | Retailer | Niche | (DOM/MKT/PUB/ECO) Emphasizes local production, small businesses, seasonal produce, freshness, and sustainable production methods including regenerative agriculture, renewable energy, and biodiversity. (MKT/PUB/ECO) Retails differentiated products created via smaller scale processes at premium prices (e.g., certified organic, fair trade). (MKT/PUB) Inventory systems allow customers to order products that are still at farms. (DOM/ECO/PUB) Sources the majority of produce within ~150 miles of service area. (DOM/PUB) Commits to transparency to customers regarding production methods and sources. (CIV/PUB) Supplier standards for working conditions and wages. (CIV) Donates close to sale date items. |

| O | Produce Dairy | For-profit | Producer Processor Distributor | Mainstream Growth | (MKT/IND/PUB) Produces, processes and distributes food products created via industrialized processes at highly competitive prices. (MKT/IND/PUB/ECO) Produces differentiated products created via industrialized processes at competitive prices (e.g., certified organic). (CIV) Donates products to food banks. |

| P | Various | Non-profit 2 | Food bank | Mainstream Growth | (CIV/ECO) Coordinates food recovery among participating donors and food pantries. (CIV) Warehouses and distributes food from USDA, corporate donors, and private donors to food pantries. |

| Q | Various | Non-profit 2 | Food bank | Mainstream Growth | (CIV/ECO) Coordinates food recovery among participating donors and food pantries (CIV) Warehouses and distributes food from USDA, corporate donors, and private donors to food pantries. |

| R | Various | Non-profit 2 | Food pantry | Mainstream Growth | (CIV/ECO) Conducts food recovery from local grocery stores to increase fresh content for pantry clients. (CIV) Stores and distributes food to pantry clients. |

| S | Various | Non-profit 2 | Food pantry | Mainstream Growth | (CIV/ECO) Conducts food recovery from local grocery stores to increase fresh content for pantry clients. (CIV) Stores and distributes food to pantry clients. |

| T | Various | Non-profit 2 | Food pantry | Mainstream Growth | (CIV/ECO) Conducts food recovery from local grocery stores to increase fresh content for pantry clients. (CIV) Stores and distributes food to pantry clients. |

| U | Eggs | For-profit | Producer Processor | Growth Niche | (DOM/MKT/PUB/ECO) Produces free-range eggs. (PUB/ECO) Humane Certified® production. (MKT/PUB/ECO) Certified organic production, certified non-GMO. (IND) Production at scale. (DOM) Transparent communication regarding production methods, including culling of male chicks, euthanization of hens. (PUB/ECO) Humane Certified® production. (CIV) Donates products to food banks. |

| V | Plant-based meat substitutes | For-profit | Producer Processor | Growth | (MKT/IND/PUB) Produces, distributes and retails food products created via industrialized processes at competitive prices. (MKT/ECO/PUB) Plant-based protein source (animal welfare, climate change, human health, natural resources). (MKT/CIV) Minimizes potential for safety issues as compared to animal-based proteins. (CIV) Donates products to food banks. |

| W | Lab grown beef and poultry | For-profit | Producer Processor | Future Emergent | (INN/MKT) Novel technology being developed to grow meat cells and to form those cells into products that look, feel, and taste like animal-based meat. (IND/INN) Actively pursuing manufacturing at scale; development of new process technology. (IND/INN) Expanding product scope. (ECO) Use of animal cells to create meat; (animal welfare, climate change, human health, natural resources). (MKT/CIV) Lab grown meat will have a favorable nutritional profile and minimizes food safety issues because the environment is controlled. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Johnson-Hall, T.D.; Hall, D.C. Redefining Quality in Food Supply Chains via the Natural Resource Based View and Convention Theory. Sustainability 2022, 14, 9456. https://doi.org/10.3390/su14159456

Johnson-Hall TD, Hall DC. Redefining Quality in Food Supply Chains via the Natural Resource Based View and Convention Theory. Sustainability. 2022; 14(15):9456. https://doi.org/10.3390/su14159456

Chicago/Turabian StyleJohnson-Hall, Tracy D., and David C. Hall. 2022. "Redefining Quality in Food Supply Chains via the Natural Resource Based View and Convention Theory" Sustainability 14, no. 15: 9456. https://doi.org/10.3390/su14159456

APA StyleJohnson-Hall, T. D., & Hall, D. C. (2022). Redefining Quality in Food Supply Chains via the Natural Resource Based View and Convention Theory. Sustainability, 14(15), 9456. https://doi.org/10.3390/su14159456