1. Introduction

Affordable and Clean Energy is the 7th goal of the United Nations’ Sustainable Development Goals (SDG 7). The daily life of the global population depends on reliable and affordable energy services such as heating and cooling, electricity supply, and transport systems. The United Nations states that the number of people with access to electricity increased by 1.7 billion between 1990 and 2010 [

1]. Still, with the rising energy prices, the over 1.2 billion of the world’s population who do not have access may as well increase. One of the main targets of the goal is to ensure universal access to affordable, reliable, and modern energy services by the year 2030. The energy sector in any nation is pivotal to the development of its economy and the general well-being of its citizens. The demand for energy for domestic cooking and other applications is ever increasing because of the growing population and industrial development.

In Nigeria, local energy demands are met using either electricity, liquefied petroleum gas (LPG), kerosene or charcoal, and firewood. However, more people, especially low-income rural dwellers, depend on charcoal and fuelwood for cooking and heating. The prices of electricity and LPG are high for many Nigerians and the supply is grossly insufficient even when they are available [

2]. The cost of energy in Nigeria has been on the rise for the past 20 years. For instance, the pump price of premium motor spirit (PMS) otherwise known as petrol moved from USD 0.07/L in 2002 to USD 0.25/L in 2012 [

3]. As projected, the electricity tariff rose from USD 0.02/kWh to USD 0.03/kWh within the same period [

4]. Just recently, the Federal Government of Nigeria (FGN), through its regulatory agencies, announced the increment in the pump price of petrol and electricity tariff again. The pump price of petrol was increased from USD 0.38/L to USD 0.40/L [

5] whereas the electricity tariff has been raised from USD 0.08/kWh to as much as USD 0.16/kWh [

6]. According to the National Bureau of Statistics, the current average price of LPG is USD 10.80 for a 12.5 kg gas cylinder whereas kerosene is USD 0.91 [

7]. Based on a market survey, current prices of charcoal and fuelwood are USD 0.52 and USD 0.26 per kg, respectively, and could be higher depending on location. Apart from petrol that has been subsidized until now, there is neither subsidy nor any incentive given for the consumption of energy from these sources.

The International Energy Agency reported that fuelwood and charcoal constitute about 73% of the cooking energy in Nigeria [

8]. Wood, which is generated mostly from the forest, is consumed either directly by burning in open fires or converted to charcoal before use. The indiscriminate harvesting of wood, open burning, and charcoal production are all inefficient and unsustainable. They lead to several environmental problems such as deforestation, soil erosion, land degradation, and air pollution from the emission of greenhouse gases. According to Shaaban and Petinrin [

9], about 350,000 hectares of forest and natural vegetation are lost annually with a much lower afforestation rate of 50,000 hectares per annum. The consequences of deforestation are so massive that between 1990 and 2005, Nigeria lost a staggering 79% of its old-growth forests [

10]. In addition, Bolaji [

11] reported that fuelwood, roots, agricultural residues, and animal dung all produce high emissions of carbon monoxide, hydrocarbons, and particulate matter. Women and children who are exposed to such are likely to suffer from elevated blood pressure which leads to an increased risk of stroke, kidney, and cardiovascular diseases [

12], including pneumonia amongst children less than five years of age [

13]. Recently, between 106,900 to <605,100 deaths were recorded due to indoor air pollution caused by cooking with biomass in Nigeria [

14].

The rising cost of petroleum products and erratic electricity supply has made the use of fuelwood inevitable and a significant source of energy for households and small to medium businesses [

15]. The need to replace these resources—especially fuelwood—with an alternative that is cheaper, cost-effective, and more environmentally friendly for rural dwellers will be a welcome idea. To articulate the sustainable development and application of all viable renewable energy resources, a National Energy Policy (NEP) was approved in 2003 by the Federal Government of Nigeria [

16]. Some of the key elements in the national policy are to de-emphasize and discourage the use of wood as fuel, and to promote efficient methods in the use of biomass energy resources, especially in rural areas. The briquetting technology is an appropriate means of converting biomass residue into solid fuel for domestic cooking in rural areas. The addition of briquettes to the energy mix will not only complement other fuel sources but reduce dependence on fuelwood and save some valuable time and money when preparing meals. However, the technology is not so popular in Nigeria, possibly due to the attendant apprehension placed on new technologies based on technical know-how and the cost of setting up. A cost analysis should be done to determine the financial viability of such a technology, as it is a critical consideration for any project, including a household briquette project. According to Eriksson and Prior [

17], the economic feasibility of incorporating briquetting technology anywhere will be subject to the relationship between the cost of production and the price of alternative fuels. Additionally, it is determined by the type of equipment used, biomass, skills of human resources, and investment capital [

18].

Recently, studies have analyzed the techno-economic viability of briquette production from agricultural residues using evaluation models. For instance, Bot et al. [

19] focused on the conversion of coconut shells, rattan waste, sugarcane bagasse, and banana peels based on a small-scale production plant in Cameroon. Economic analysis was carried out for a 20-year span and sensitivity analysis was conducted to assess the feasibility of the business. Result showed that the net present value (NPV) was found to be between −44,932 E and 67,189 E. From sensitivity analysis, briquette production was sensitive to briquette market price, discount rate, and capital cost. Similarly, Ifa et al. [

20] researched the techno-economic analysis of bio-briquette from cashew nut shell waste in Indonesia. One of the study objectives was to examine the economic feasibility of cashew nutshell bio-briquette waste. The production of briquettes was investigated based on investment rate, pay out time, and break-even point. The authors reported that the total production cost was USD 842,304/year and a net profit of USD 147,402/year. The study concluded that the economic feasibility of briquette production as analyzed from the investment rate was 23.55%, 3.42 years payout time, and 50.09% as the break-even point.

In another study, Pradhan et al. [

21] assessed the economic feasibility of agricultural waste pelletization in rural India. The economic evaluation was made using indicators such as net present value (NPV), internal rate of return (IRR), and discounted payback period (DPBP). Results showed that the NPV, IRR, and DPBP were USD 0.13 million, 41%, and 2.8 years, respectively. The cash flow statement showed a strong debt paying ability for the project. Pellet price was the most sensitive factor followed by annual operating days on pellet plant economics. What is noteworthy in these studies is the analysis of briquette production at small and medium scales but clearly beyond the level of a household which is the interest of this study. The current research is an attempt to contribute to the feasibility study of a household scale briquette production in rural Nigeria. Its significance lies in the provision of a piece of baseline information on the economic viability of briquette production at that level.

As the economics of briquetting is site-specific and depends on the local conditions of regions with different outcomes, it becomes necessary to conduct this study in a Nigerian context. It has been noted that for biomass densification to expand, residue availability, adequate technologies, and the market for briquettes should not be uncertain [

17,

22]. Nigeria has varied and abundant agricultural residues generated from its vast agricultural activities and extensive landmass, some of which are shown in

Table 1. These could be potentially used for sustainable bioenergy production. Moreover, there are a plethora of studies that dealt with the technical viability of briquetted fuel [

2,

23,

24,

25] including the development of local technology [

26,

27,

28]. Similarly, the potential and existing market for it, due to the high cost of fossil fuels and dependence on fuelwood has been reported [

29,

30]. Nevertheless, there is hardly any empirical investigation into its economic viability, whether on a small, medium, or large scale. Insufficient data about the economic viability of briquette production could be a hindrance to potential investment and a reason for its low expansion in the country’s energy sector. The determination of such can be a valid measure of evaluating consumers’ ability to afford the briquetted fuels.

Therefore, this study is an attempt to analyze the technical and economic viability of a household scale composite briquette project for application in rural communities in Nigeria. The objectives were to assess the quality of briquettes, estimate the cost of production, and determine the feasibility of the project using specific economic indicators. As a strategy for reducing the cost of production, a comprehensive sensitivity analysis was performed on the essential input parameters that may affect the profitability of the household briquette project. This study hypothesized that household briquetting projects in rural communities have good profitability and therefore are financially viable. The outcome could be a guide for householders in Nigeria with a potential interest in investing in briquette technology.

4. Conclusions and Policy Recommendations

This study was carried out to analyze the techno-economic viability of producing briquettes from agricultural residues with specific reference to corncobs and OPTB. The objectives were to assess the quality of briquettes, estimate the cost of production, and determine the economic feasibility of the briquette project using specific economic indicators. Additionally, economic feasibility was limited to the level of a household scale briquette production in a Nigerian context where energy poverty is inherent, especially in rural communities. A composite briquette project is an alternative to fuelwood as an energy source that possesses indirect benefits including a reduction in deforestation and less carbon emission. These indirect benefits are the added values to the benefit of the composite briquette project; however, they are not estimated in this study due to the unavailability of their market prices. Based on the findings the following conclusion has been drawn:

The unit cost per kg of the briquette was USD0.16 and can sell for USD0.26, which makes it cheaper compared to the price of charcoal and fuelwood.

The NPV of USD6755.91 was positive and shows high profitability based on the annual net cash revenues the project will generate.

The highest interest rates a household should take in order to not make losses should be 49%. Anything beyond that will make the project unprofitable.

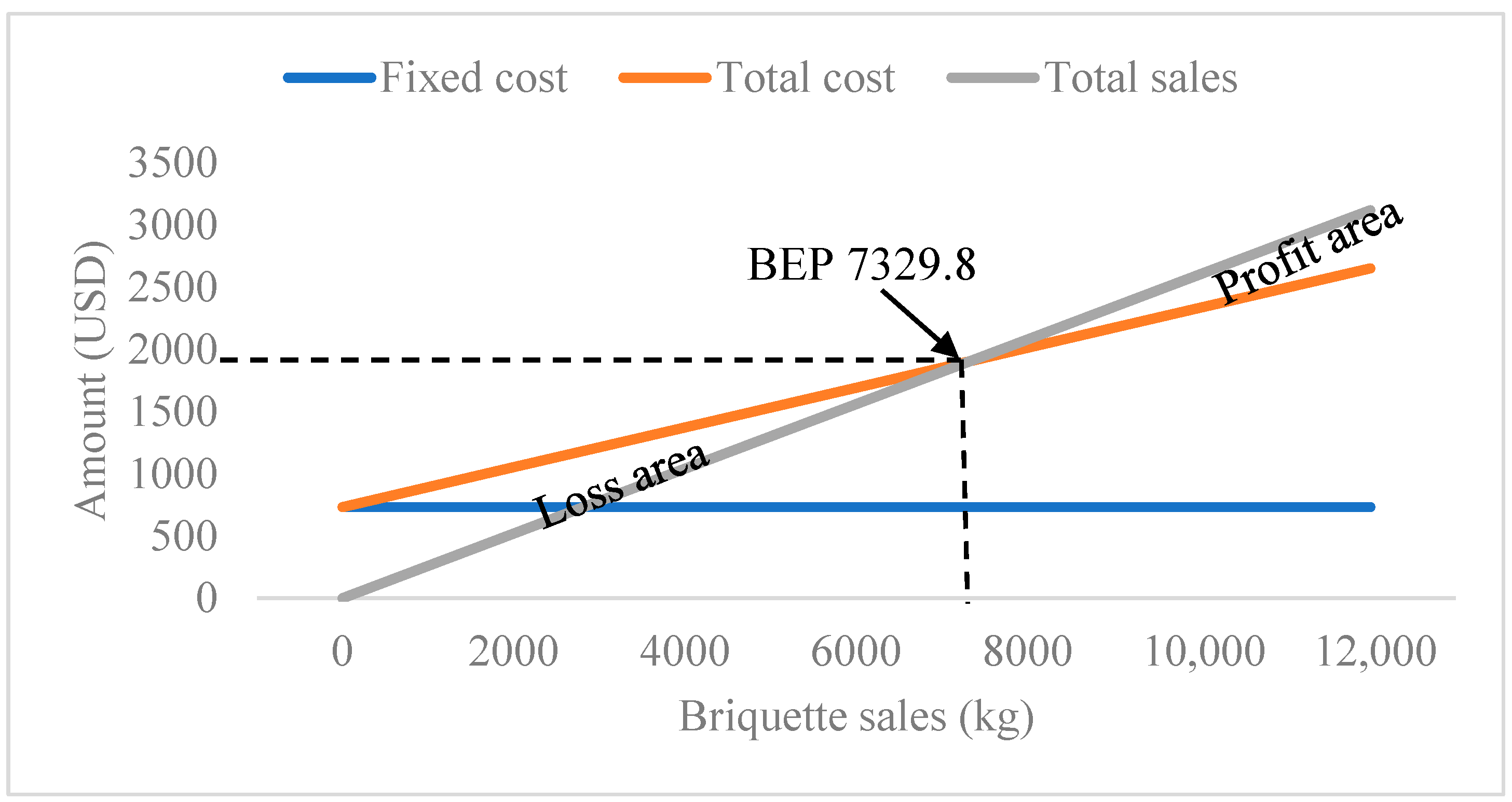

The PBP was less than 3 years which shows an immediate prospect of initial investment cost recovery and the project will make an accounting profit as long as briquette sales are above 7329.8 kg.

The NPV was more sensitive to the selling price of briquettes and a higher selling price of briquettes could lead to higher economic benefits. However, as a strategy to reduce the selling price of briquettes, the CAPEX and OPEX should be reduced.

Households could save about 25% from per-capita expenditure on fuelwood when briquettes are utilized.

Overall, the composite briquettes have adequate handling, transport, storage, and combustion characteristics. They are also environmentally friendly and cost efficient. Thus, developing composite briquettes from corncobs and OPTB is technically and economically viable even at the current interest rate (16%) obtained in Nigeria. The extraction of useful energy from a blend of corn cob and OPTB could bring significant environmental and socio-economic benefits to the rural communities of Nigeria.

The positive assessment of the technical and economic viability of the composite briquette project leads to a new direction for energy policy in Nigeria. Instead of solely depending on raw resources (e.g., fuelwood), the use of composite briquette promotes dependency on renewable resources. This will stimulate more innovations towards producing renewable energy sources and boost economic growth in Nigeria by increment in gross domestic product and creating more job opportunities for locals. Additionally, given the significant capital investment required to produce briquettes, government support is needed to guarantee that interest rates are as low as feasible for households looking to borrow money to invest in the technology. This calls for the establishment of microfinance institutions expressly for briquette and related technologies in order to promote the development of local briquette factories and, more crucially, to provide incentives for sustained operation.

In relation to the limitation of this study, future research can include the estimation of the indirect benefits of the composite briquette project into NPV estimation. For a comprehensive economic analysis, a cost-benefit analysis should be carried out to compare the economic indicators (NPV, IRR, and BCR) between composite briquette and fuelwood (the status quo of energy sources in rural Nigeria). The study also recommends that similar studies should be carried out to determine the economic viability of medium- and large-scale briquette projects.