Abstract

Design indicators can be used by companies to track circular design implementation, which can yield insights into their performance and opportunities for improvement. Yet, existing indicator methods either lack depth with regard to circular design, are incomplete, or do not use design semantics. This study explores product-level circularity indicators, with the aim of developing a comprehensive circularity indicator method specifically aimed at designers. The method development process follows a three step Design Science Research approach. It comprises a literature review and knowledge coproduction sessions with circular design experts on topics such as durability, repair, remanufacturing, and recycling. Furthermore, it includes company evaluations with two multinational corporations operating in the white goods and automotive industries. The study delivers the first indicator method for assessing circular product design on a broad range of aspects, including levels of readiness, company strengths, and opportunities for improvement. The method uses product design semantics to evaluate design aspects, takes a comprehensive view of the full life cycle, and has been specifically developed for industry use.

1. Introduction

In the drive towards greater circularity, companies can use design indicators to track their circular design readiness and implementation [1,2]. The literature on circularity indicator methods is diverse, with methods ranging from industry-level meso-approaches to product-level micro-approaches [2,3]. Product-level indicators tend to focus on resource circularity, commonly using material flow analysis models to derive indicators [2,3,4]. Specific product-related indicators have been collected, categorized, and reviewed in several academic studies that, for example, assess product performance in circular settings and the circularity of a product’s materials [5,6]. Other studies assess the performance of specific design aspects, usually expressed in quantitative units, such as longevity (expressed in time), recycling rate (expressed in percentage), or a re-manufacturability score (expressed as an aggregate of multiple variables) [7,8,9]. In a review of product-focused indicators, Linder et al. [6] concluded that the Material Circularity Indicator scheme by the Ellen MacArthur Foundation contains the most ambitious set of indicators [10]. This tool measures the effectiveness of a company’s transition based on material flows.

Despite the value of this approach and given that different sets of existing indicators contain information valuable for designers, none of these sets were specifically developed with the aim of guiding designers in their activities. In that context, the goal of this study was to develop a method to help designers to monitor the implementation level when designing a circular product or service. We assessed the efficacy of the newly developed method regarding its power to support strength–weakness analyses and design road mapping activities. Our findings can also be used to disseminate results to disciplines outside the field of design.

Design is an important factor in the transition from a linear to a circular economy. The way products are designed determines if and under what conditions products can be recovered. For example, design determines whether a product can be taken apart and put together again, maintained, repaired, or remanufactured. All desired events and behaviors a product experiences throughout its entire life cycle, from strategy to recovery, can be facilitated through design [11]. Having industry design professionals adopt circular product design contributes to achieving the economy’s potential to become circular. To design durable, reparable, and re-manufacturable products is a prominent part of the vision for circular product design, complemented by aspects such as having high-quality end-of-life recycling options.

The primary aim of circular product design is to maintain the largest part of a product’s value for as long as possible [12,13]. Yet, its fundamental differences with linear design make circular design hard to implement [14]. Designers have to choose between selling product functionality or performance as a core value rather than ownership, or whether they rate customer satisfaction higher than consumerism, and whether they think in terms of end-of-use products with potentially unlimited lifespans [15]. Circular products are designed for multiple use-cycles, and innovative multi-disciplinary solutions are needed to support this goal [16]. To achieve shifts such as these, strategic design can contribute to embedding circular design in existing processes [17].

The content of this paper is structured as follows: The background Section 2 analyzes existing indicator tools that assess circular product design, followed by the research design Section 3, which describes the different steps of the approach taken in this study. Section 4 then outlines the phases of development of the Circular Product Readiness (CPR) method, and Section 5 presents the results of the company evaluations. In Section 6 and Section 7 we discuss the results and draw final conclusions.

2. Background

In this section, we present an analysis of a selection of micro-level (product) indicator methods for circular product design, revealing gaps in the field. The methods were selected from both grey and academic literature on circular design and on method development. Inclusion criteria were the extent to which they address design and the extent to which they have been evaluated with companies. The analysis explores themes relating to circular design used by the indicator methods, for instance, life cycle stages or product characteristics, as well as the design indicators set to address these themes.

Five main criteria were identified:

- -

- The first concerns the method’s output, which is intended to help differentiate between readiness levels. Readiness can be defined as an “individual’s attitude toward a particular change”, which is influenced by dimensions—e.g., concerning the content, process, context, and people—relevant to the topic at hand [18]. For the method to reflect readiness, it needs to indicate the level of implementation of a circularity aspect, grading this at one of a set of appropriate predefined levels [18].

- -

- The second is that the method must show the strengths and areas for improvement at a granular level [5,6,19]. This informs designers not only about the current readiness level but also how this can be improved.

- -

- The third is to attune the method to designers. This can be addressed by using product design semantics to evaluate circular design, i.e., to evaluate design’s qualities expressed in product functions and the way it interacts with its (social) environment [20].

- -

- The fourth seeks method completeness; it has to cover a complete range of design factors, from strategy to recovery, in detail. The design process is sequential in nature and each phase carries important decisions that influence adjacent phases. This underpins the importance of front to end alignment and having clearly defined, distinctive phases, such as strategic design, embodiment design, service design, and recovery [16,21,22].

- -

- The fifth requires a method that can easily be applied to any industry, including in-company ease-of-communication, as well as communication with supply chain partners [23]. This requires a format which fits with the content and facilitates time-efficient use.

Table 1 shows the extent to which existing indicator methods meet the method criteria, marked as an ‘X’. All methods have individual strengths and contain valuable elements such as introducing opportunities for improvement, benchmarking performance, implementation progress, or addressing topics essential to circular design. None, however, encapsulate the full range of circular product design aspects.

Table 1.

Evaluation of existing indicator methods measuring circular design implementation.

In summary, additional research is required to find a comprehensive set of indicators that measure the readiness for the development of circular products and related service offerings. These can then be used to develop a dedicated method that focuses on circular product and service design. This method can be used by designers to monitor the implementation of circular design in their current offering, and it can serve as a guide in the transition to an improved circular offering. The next section outlines the design of the research undertaken to address this gap.

3. Research Design

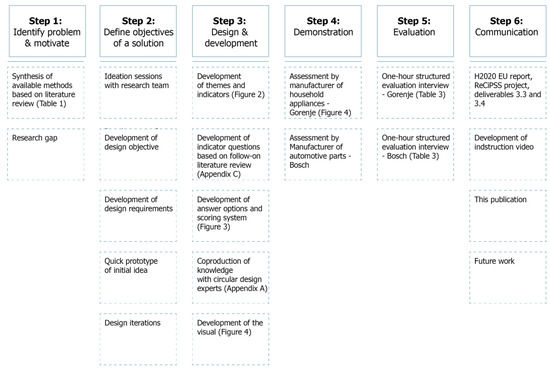

To develop the method, we conducted a literature review, organized knowledge coproduction sessions with circular design experts, and tested the findings with companies. We applied the Design Science Research approach, as our objective was to develop an artefact, in this case a method [26]. It provides a six-step framework that helps design researchers create a rigorous approach to arrive at the intended artefact (see top row Figure 1) [27]. Each step guides the researcher by detailing the required activities, attuned to the research objective. We completed all six steps, with an emphasis on steps 3 and 5.

Figure 1.

Method development process based on Design Science Research approach.

We compiled method criteria to guide the development process. The five main criteria were selected based on the analysis of existing methods and a literature review. The method content meets the requirements in Table 2.

We conducted a follow-on literature review to develop the basis for the questions of the Circular Product Readiness method. The findings guided the development of the themes, indicators, and assessment questions. The visual method was developed to match the content. The overall goal of the literature review was to find and select papers that (1) offer information about requirements to successfully apply (strategic) design resources and principles, (2) give an indication of how this can be influenced through (strategic) design decision making, and (3) contain validated micro-level indicators that measure circularity. Web of Science, Google Scholar, and Scopus were searched to find papers published between 2017 and 2021, using the search terms: circular, design, product, service, and indicators. A total of 110 articles were retrieved, of which 50 papers were analyzed in detail to develop a first draft of the themes, indicators, and questions. Snowballing was applied to find additional relevant articles.

To assess the validity of the information, we organized knowledge coproduction sessions [28]. Eight of these sessions were held with researchers specialized in different aspects of circular design working in the Design for Sustainability research group at the faculty of Industrial Design Engineering at the Delft University of Technology (Appendix A). A total of 11 experts were consulted during the sessions. Of the 20 design topics, 14 were evaluated through these knowledge coproduction sessions (Appendix A). The others were either sufficiently covered by the literature and did not require further input from experts or were added at a later stage of the design process.

The knowledge coproduction sessions took place in September 2021 and lasted 45 to 75 min (15 min introduction, 15 min discussion, 15 min brainstorming, and 10 min evaluation). Prior to the session, the participants received an overview of all themes and indicators as well as the assessment questions for their expertise. The sessions were structured using an online whiteboard on which the assessment questions could be rated based on significance. The experts’ input was collected through notetaking. The notes were analyzed after the sessions and served as input to sharpen and clarify the formulation of the questions, and to add or delete questions.

Table 2.

Content requirements.

Table 2.

Content requirements.

| Content Requirements | Explanation | References |

|---|---|---|

| Reliability | The method outcomes remain consistent for entries by different user within the same company. | [6,29] |

| Construct validity | The extent to which the indicator method actually measures circular design maturity as opposed to generic design management capabilities or circularity of material flows. | [19,29,30] |

| Content validity | The indicators fully cover all aspects that influence the maturity of circular design. | [29] |

| Comprehensibility | The indicators are understandable, meaningful, simple, and are easy to interpret for the representatives of designers and their wider team. | [19,30,31] |

| Operationability | The extent to which the indicator method is actionable and the outcomes controllable, by the way the format aligns with ongoing design activities and how the outcomes fit the decision structure. | [19] |

| Transversality | Applicability across different industries. | [3] |

We evaluated the method with two multinational corporations: Gorenje Gospodinjski Aparati D.D., assessing an AKSO washing machine made for pay-per-use application, and Robert Bosch GmbH, assessing a diesel injection system. The company representatives were asked to complete the Circular Product Readiness method independently and provide feedback during a one-hour evaluation interview. This interview addressed the content of the method, the wording and terminology used, and the readability of the visual method. An online whiteboard containing the full list of questions was used to structure the interview. During the interviews, notes were added to the whiteboard to capture the answers to specific questions. Based on an analysis of the notes, adaptations were made to the assessment questions and recommendations were made for further work. As a final step, we evaluated the method criteria to evaluate to what extent the final design meets these criteria.

4. Development of the Circular Product Readiness Method

In this section, we present the process that led to the final design of the method, corresponding to step 3 of the Design Science Research approach. The first activity was the development of the basic structure of the Circular Product Readiness method. This determined which design topics were to be addressed and how the design topics break down into indicators. This enabled us to develop the questions to be asked to assess the readiness level. Based on this, we developed the answer options. Following these activities, we created the visual method.

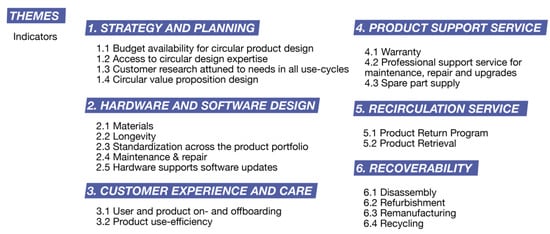

4.1. Development of Themes and Indicators

The final set of themes and indicators was obtained through 20 rounds of design iterations, the knowledge coproduction sessions, and the literature review. The first draft was created prior to the literature review and adjusted according to insights from the review. The final set of indicators was derived based on the knowledge coproduction sessions.

The circular indicator methods selected in the background section were analyzed in more detail for their use of design themes and indicators to learn which characteristics met the method criteria and were to be considered when developing the structure of the Circular Product Readiness method. The following characteristics (partially) met the method criteria. The Circulytics method takes a broad lifecycle focus by including strategic and human-centered design. This is important for linking design to the company strategy and optimizing a product for its context. MATChE also takes a broader focus, by considering the take-back services needed to ensure return rates. CEIP takes a designer-intuitive lifecycle perspective with a strong orientation on design aspects. The categorization of indicators benefits by adopting a practice-oriented structure over a theory-oriented structure like that of the C-Indicator Advisor. As a result of this analysis, the themes could be determined and a more advanced set of indicators was developed.

To further optimize the set of indicators, the circular design experts were asked to evaluate the preliminary selection of indicators in the knowledge coproduction sessions. This helped to determine the priority indicators and reach a set that covered all the essential circular design aspects. The final set of themes and indicators are presented in Figure 2.

Figure 2.

The final set of themes and indicators.

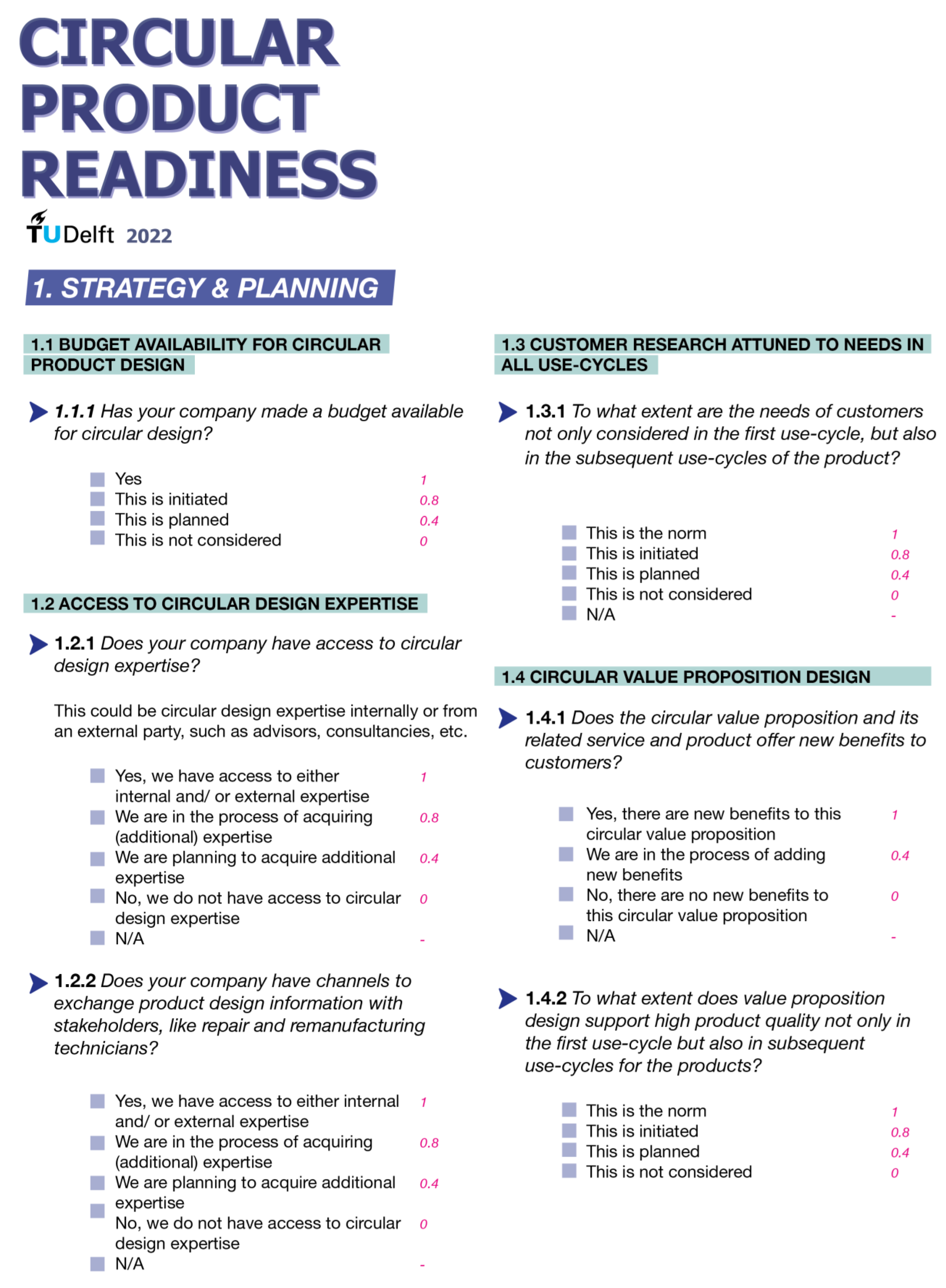

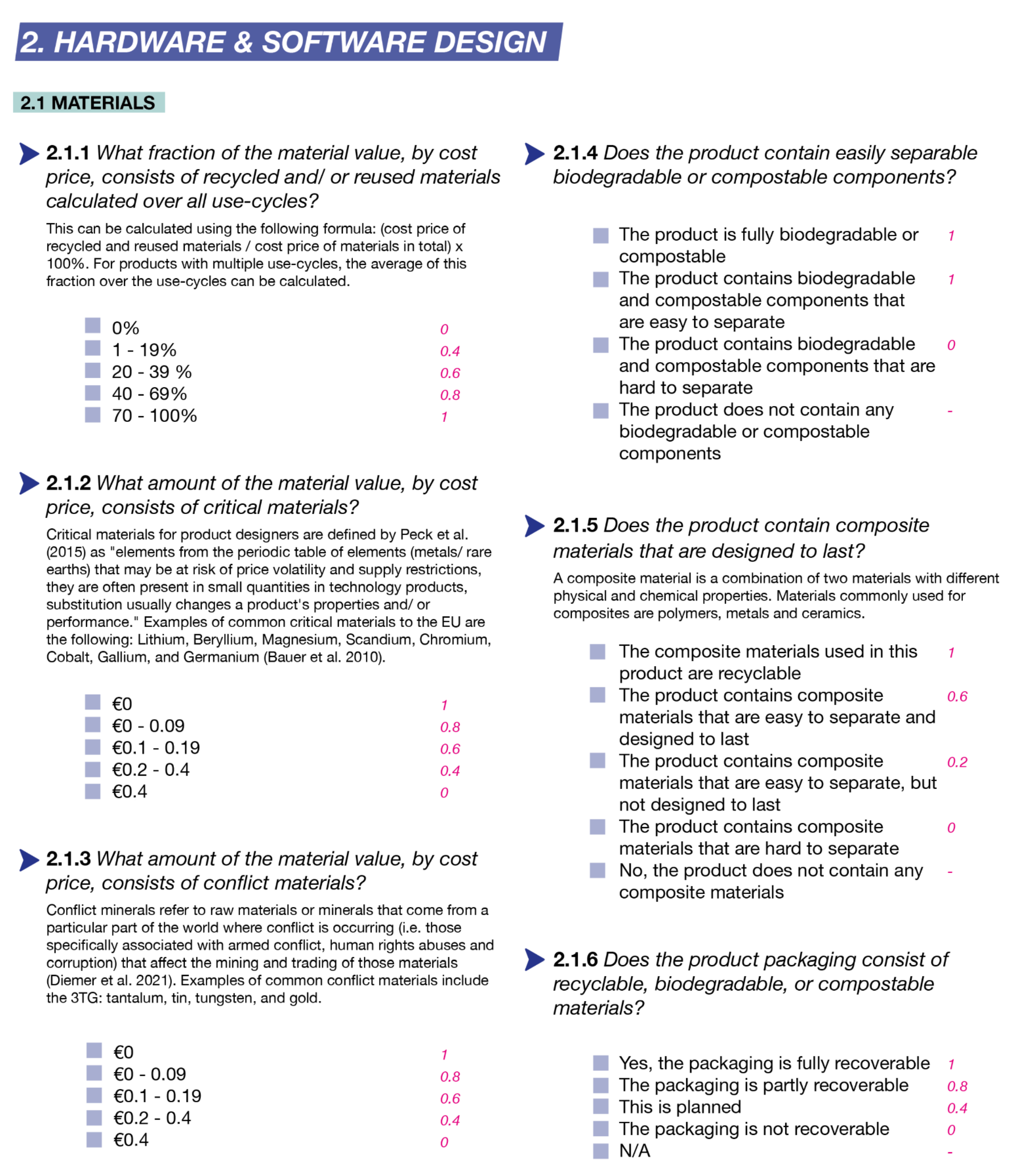

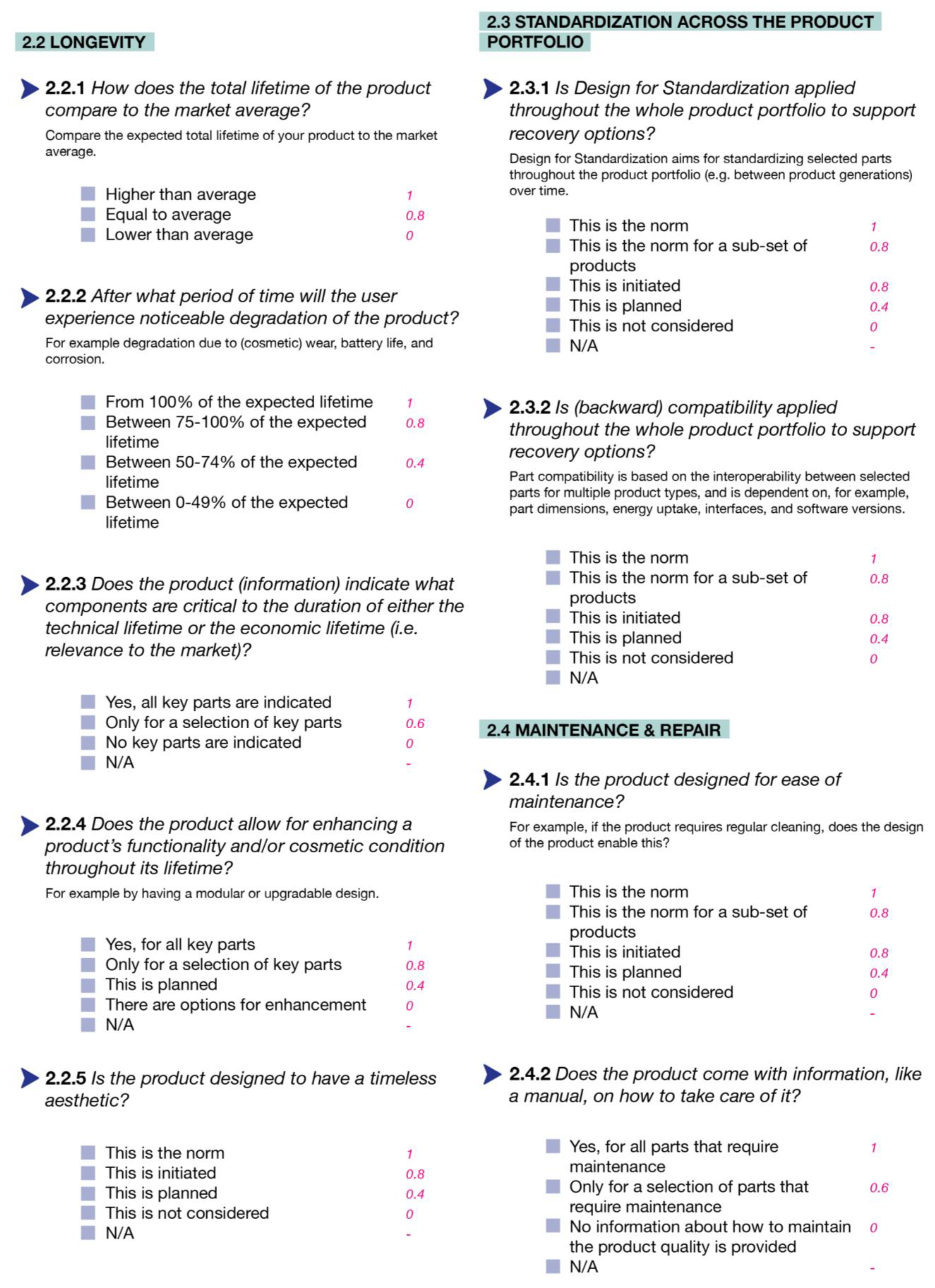

4.2. Development of the Assessment Questions

The literature review and design iterations formed the basis for the development of the assessment questions and the method visual. A first set of questions was developed based on the structure of themes and indicators as well as on the follow-on literature review. The set was then fine-tuned through iterations and feedback loops from this study’s TU Delft research team. In addition, knowledge coproduction sessions were organized to assess the questions’ significance and completeness. The complete set of questions resulting from these iterations can be found in Appendix B. The table in Appendix C contains the justification of the questions based on the literature and the co-creation sessions. The answer options were developed to reflect the readiness grades for the implementation of design activities. This was achieved by considering that design implementation can also be “planned” or “initiated”, if not yet fully implemented. Most questions had “not applicable” as an answer option to let companies tailor this method to their own product type and context, adding to the method’s transversality, as the appropriate strategies to design a product to be circular vary from product to product.

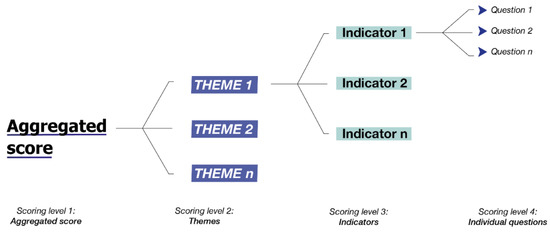

4.3. Development of the Scoring System

Scoring takes places at four levels: individual questions, indicators, themes, and aggregates of all scores into a single number (see Figure 3). A maximum of 1 point can be scored for each question. All the themes, indicators, and questions have equal weighting as the importance of the themes, indicators and questions is highly dependent on the type of product being assessed. The appropriate weighting can be determined by industry-experts. Adding up the score for a specific unit (theme, indicator, or question) and dividing this by the total score for that unit gives the average score (%) (Figure 3).

Figure 3.

Scoring system using four levels.

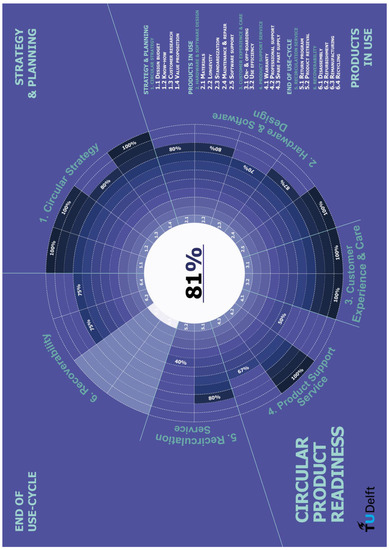

4.4. Developing the Visual

According to the method criteria, a visual allows for ease-of-communication of the results, fits the contents, and facilitates time-efficient use. Indicator visuals from literature were used as a reference for developing the final visual. These indicator visuals tend to use a radial structure to show the scores and the different axes of evaluation. Scores can be indicated by both lines and numbers. Colors were used to label different indicators.

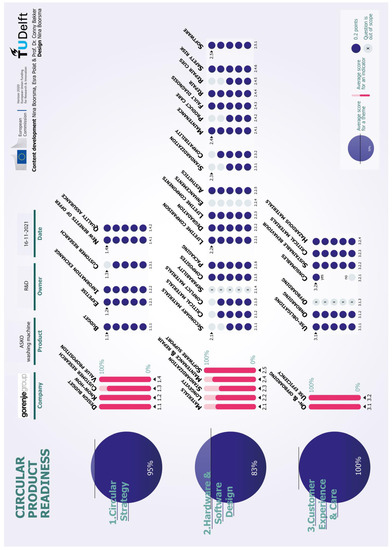

Based on insights from indicator visuals in the literature and design iterations, we created the first versions of the visual. This was updated along with progress in the theme and indicator development. Factors such as ease-of-communication of the results and having a coherent form language played an important role when developing the final visual (Figure 4). In addition, the visual shows grades of readiness divided over four levels: scores for the assessment questions, scores for the indicators, scores for the design themes, and an aggregated score. This helps to communicate the specific company strengths and shows opportunities for improvement, as it is easy to track which design aspects influence the higher-level scores.

Figure 4.

Final visual for the Circular Product Readiness method—results of Gorenje for themes 1, 2 and 3.

4.5. Application of the Method

The CPR method should be applied following a four-step process. The first step is to appoint two employees with prior knowledge and understanding of the circular economy and in-depth knowledge of the product under assessment. Appointing at least two employees, supports the accuracy and effectivity of the entry. The second step is to process the scores and translate them into percentages. The third step is to evaluate and interpret the scores by reflecting on the company’s mission and vision for circular product design. The outcomes are strengths and opportunities for improvement. The fourth step is to adjust the company design roadmap and (re)allocate design resources to fit the changes.

5. Evaluation

We evaluated the method by providing the companies with an online questionnaire and instructions that explain its use. For both companies, the method was completed in pairs. For Bosch, this included a Channel Manager and Product Marketing Manager and, for Gorenje, a Lead Engineer for R & D and a Project Manager. The results were translated into the visual by a TU Delft researcher (Figure 4). The method criteria and content requirements were evaluated with the respondents in a one-hour semi-structured interview.

Several valuable insights were collected during the evaluation and used to make final adjustments to the method. A question concerning the packaging material selection was added and the wording of several questions was adjusted. In addition, the answer options were evaluated to allow for additional differentiation of implementation levels. The insights from the evaluation are summarized in Table 3.

The application of the method at two different companies provided valuable insights. Gorenje scored 75% or higher for most of the design indicators and received its highest scores for theme 1 “Circular strategy”. Product retrieval (5.2) scored 40% due to the current return rate. Warranty (4.1) received a score of 50% since the average warranty period of all life cycles is significantly below that of the first use-cycle. This would only be relevant in the case of selling the product. Disassembly (6.1) and Refurbishment (6.2) were considered out of scope, since remanufacturing is the future aim. The scores indicate which areas the company excels in, but also points out opportunities for improvement of the circularity of their design. The main areas of improvement are the return rate and handling spare part supply. The indicators from the Recoverability theme (6) offer room for improvement once the company starts to adopt asset recovery.

Bosch received high scores on all design indicators that fall within the company’s range of influence. Materials (2.1) and Recycling (6.4) were the only indicators that scored below 90%. Standardization (2.3) and Software support (2.5) were marked out of scope, as most of the standardization is regulated by law and the product does not make use of software. The Use efficiency (3.2) received a score of 67%, as product design relies on other parts/products for the use efficiency of its consumables. The scores reflect the fact that the product is suitable for recovery operations from a design point-of-view.

Table 3.

Evaluation of the method criteria and content requirements.

Table 3.

Evaluation of the method criteria and content requirements.

| Method Criteria | Evaluation |

|---|---|

| Indicates levels of readiness | The readiness levels of the circular design aspects are reflected in the answer options. Higher levels of readiness receive more points than lower levels. The companies are also assigned points if the implementation is planned or initiated, if not yet fully implemented. Gorenje: For a number of questions, the company needed answer options that allowed for greater differentiation to more accurately reflect their progress. Having the visual use distinct colors to represent “planned implementation” and “readily implemented” would add to its usability. Overall, the results of the assessment helped Gorenje gain insights in their readiness level for circular design. Bosch: This method is expected to be useful as a quick scan for companies at the starting stages of implementing circular design. |

| Indicates company strengths and areas for improvement | The method’s visual makes it easy to interpret areas for improvement by showing scores on multiple levels. Four levels of dimensionality were distinguished: an aggregated score, scores for the design themes, scores for the indicators, and scores for the assessment questions. Having access to these scores helps pinpoint strengths and opportunities. Gorenje: From the visual, the company was able to spot opportunities to evolve further. The company sees the potential of the method to progress over time. The assessment helped evaluate the company’s goals and is expected to be of support when developing design road mapping activities. Bosch: The challenge for Bosch is to dive deeper into circular design and evaluate design decisions on sub-assembly, part and connector level. To monitor progress, the company goes into more detail with respect to experiences and costs. |

| Uses product design semantics | The accessibility of the method to designers was evaluated in the company tests. All questions that the companies considered in scope were answered. The link with design was clear. The wording was optimized in a final iteration to further improve accessibility. Gorenje: The choice of words of some questions needed to be adjusted to improve readability and make them easier to understand. The company representatives indicated that it took 30 to 45 min to complete the assessment. The ideal user is considered to be an employer working with marketing and branding, together with a project lead. Bosch: The user needs to be an expert in circular economy to complete the questionnaire successfully. The parts raising most discussion were those referring to the customer as what is meant by “customer” may differ per market (e.g., B2C or B2B). It took 60 min to complete the assessment. |

| Takes full lifecycle focus | The assessment method takes into consideration themes from the strategic design phase to the recoverability phase. Co-creation sessions and evaluation with companies helped assess the completeness of themes and indicators to cover the full lifecycle. Both companies felt that the method was complete regarding its topics. However, on some topics such as materials and reverse logistics, the method could go into more depth regarding the expectations of favorable conditions. Bosch: One example would be to add a question regarding material use about the level of fatigue strength, as this strongly impacts the reusability of parts. Another example would be to indicate the viability of setting up reverse logistics. Does the product form and size allow for transport through existing logistics channels? Does it require special packaging that protects the product from damage, such as scratches? How does the cost-size ratio of a product influence transportability? In the company’s experience, smaller sized, high-value products allow for most viable transport options. |

| Easy to apply in industry | The visual method was designed to allow ease of communication of the results on the level of an individual answer, as well as for aggregated scores such as that of an indicator, theme or the overall score. The method format was designed for ease-of-use, and for the ease-of-communication of the results. Gorenje: The method format was considered helpful in communicating the results visually to colleagues. Bosch: For the method to guide the company’s design process, it would have to become industry specific. |

| Reliability | The method was evaluated with two companies, each of which had two company representatives to apply the method, which resulted in a basic level of reliability. To further assess reliability, the outcomes of several representatives who independently apply the method on the same product should be compared for consistency. |

| Construct validity | The construct of the study is circular product design. Throughout the design process of the method, all questions were continuously evaluated for their relation to circular product design. This was carried out to make sure the questions referred to actions that can actually be influenced by design, and it helped steer away from questions about organization management, the business model, testing generic circular economy skills, or compliance. |

| Content validity | The construct validity was tested by asking the companies whether they missed relevant questions or found that certain questions were irrelevant. As a result, one new question was added (regarding the selection of packaging material) and none of the questions were removed. Gorenje: “The themes and indicators are highly relevant.” |

| Comprehensibility | During the evaluation interviews with the companies, all questions were evaluated one-by-one for their comprehensibility. This resulted in several small adjustments to the questions’ phrasing, as well as some adjustments to fit both professional contexts (i.e., business to consumer and business to business contexts). |

| Operationability | The operationability was assessed by looking at the time spent on completing the assessment and, again, the clarity of questions and answers. |

| Transversality | The method was applied by two companies operating in completely different industries: the white goods industry and the automotive industry. Both companies were able to fully complete the method successfully. In both instances, some of the questions turned out to be not relevant to their product. Including the option to answer questions with “Not Applicable” helped make the method more widely applicable. |

6. Discussion

The CPR method’s content is discussed in terms of the outcome of the evaluation with companies, the choice for equal weighting, and limitations of the design of the research. The method’s value is then discussed by appraising its alleged effectivity to measure design readiness, and possible drawbacks of the final design.

6.1. Method Contents

The CPR method has several contributions to make to the field of circular design assessment in terms of contents. The method contains 63 questions divided over 6 circular design themes, exceeding the number of questions asked in existing methods (e.g., 15 questions for the CEIP method). It helps companies to spot strengths and opportunities for improvement and allows comparison of several products. Having a report as the outcome with scores on four different levels creates a detailed overview of a company’s readiness level. This functionality is a significant step forward from existing indicator methods that either use a single score or lack reporting. Making it possible to mark questions as “not applicable” regarding a certain product allows users to create product-specific profiles, which meets the need for more context-specific product-level indicator methods [3].

The assessment questions determine the scope of what is assessed, but the answer options reflect the readiness level of designers. Accordingly, Gorenje expressed the need for additional answer options to some questions to reflect their current implementation status. With this improvement, the company expects the method to have the functionality to support their design road mapping activities in the longer term. Since Bosch has been specializing in remanufacturing for years, their breakdown of aspects to assess circular design would preferably go even deeper, aligning to their specific recovery requirements. This was outside the scope of this study but provides an interesting opportunity for further research. The wording of the questions was updated based on the input from both company evaluations to improve readability and to make the questions better fit companies that deal with other stakeholders, for example, in Business-to-Business contexts. Concluding from this, the method evaluation, step 5 of the Design Science Research (DSR) approach (Figure 1), led to new design iterations in step 3 of the DSR approach, design and development, a design route suggested by Peffers et al. [27]. Some comments require more extensive research and are discussed below.

In the current format, all indicators receive equal weighting, independent of the number of questions asked for that indicator. Yet, some indicators may have a stronger, more essential influence on a product’s circularity than others. Similarly, all questions that belong to one indicator receive equal weighting. For example, in the “Strategy and planning” theme “available budget for circular design” is evaluated together with “access to circular design expertise”. Yet, it can be argued that having budget available but no access to expertise is less favorable than having access to expertise and not having a dedicated budget. A weighting system can put additional emphasize to questions, indicators, or themes that are of higher priority. This point of prioritization was raised by Cayzer et al. [5], who, in addition, highlight the importance of pursuing tighter loops of the circular economy as a first option. Such aspects could also be considered for weighting. It is important to note that the value of having a scoring and weighting system is the discussions that they lead to among designers. Through these discussions, the next steps for implementation can be determined based on those which best align with the available resources.

The method was evaluated with two multinationals that produce high-value, durable goods. Once the method is applied to a broader range of companies, in terms of company size, industry, and product type, new insights can be collected concerning the applicability of the method. These insights can also lead to content optimization and provide an opportunity to further explore the method’s reliability.

6.2. Value of the Method

The CPR method makes several contributions related to its value for users. It can be used to monitor circular design readiness over time, informing designers about possible actions that support their ambitions of shifting towards a more circular practice. This, in turn, supports their design strategy and road mapping activities, using the method to make appropriate actions to stay on track. It meets the need for standardized methods for micro-level measurements, a point for further research noted by Kristensen et al. [2]. The method can also help inform design leads and design managers about the need for additional training or resources to strengthen or expand a team’s design capabilities. Finally, it can help companies determine priorities and focal points in the development of new products.

A drawback may be that it is not applicable to all industries; it currently targets designers developing durable goods. Moreover, the method requires prior knowledge and understanding of the circular economy and in-depth knowledge of the product under assessment. A central aim for artefacts developed through a DSR approach is the optimal usefulness of the method and should therefore be carefully considered [27].

7. Conclusions

In this study, we developed and evaluated the Circular Product Readiness method. This method assesses the readiness level of designers to design circular products by identifying strengths and areas for improvement. It responds to a gap found in the literature regarding circular indicators dedicated to assessing all aspects of design in depth.

This study delivers the first method which indicates levels of readiness considering all product lifecycle phases, uses product design semantics, and is easy to apply in a broad range of industries. The CPR method’s format not only makes it possible to compare scenarios, but also helps to guide and structure discussions about design. With that, it offers a framework to help develop design strategies and inform road mapping activities. The outcomes are accessible to the wider design team as well as to other company divisions; this can help inform expertise areas such as those of circular supply chains and circular business models to determine shared priorities and interlinkages.

The CPR method integrates the individual circular design strategies most prominently discussed in the current academic literature into one method. This is important since these strategies connect to and influence each other in a wider circular design approach. As a result, it yields a comprehensive overview which can help companies move towards circular ways of designing products and services.

We were able to develop a firm basis for the CPR method. It now offers opportunities for future research in the field of circular product design, adding topics to be addressed as well as their prioritization and weighting system. The latter can be achieved in an exercise where experts prioritize the indicators, which then can lead to a possible weighting system. In addition, further validation with experts from both academia and industry, followed by design iterations, can strengthen its transversality across industries. A database of outcomes would be valuable in creating industry reference points which help companies interpret their results. The method can be extended in several ways. Modules can deep-dive into industry-specific modules such as details of material fatigue strength, or the assessment of products that use multiple consumables. Another route would be to link the topics addressed in the CPR method with existing quantified indicators to enable companies to further quantify opportunities for improvement. As a final recommendation, the visual can be further developed to display the phases of implementation (planned, initiated, fully adopted) by, for example, using colors to strengthen and detail its guiding function, providing richer information.

Author Contributions

Conceptualization, N.B., E.P. and C.B.; methodology, N.B., E.P. and C.B.; software, N.B.; validation, N.B., E.P. and C.B.; formal analysis, N.B. and E.P.; investigation, N.B. and E.P.; resources, N.B. and E.P.; data curation, N.B. and E.P.; writing—original draft preparation, N.B.; writing—review and editing, N.B., C.B., R.B. and D.P.; visualization, N.B.; supervision, C.B., R.B. and D.P.; funding acquisition, C.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by H2020 EU project Resource-efficient Circular Product Service Systems (ReCiPSS) grant number 776577-2, project duration 2018 to 2022. The goal was to establish large-scale demonstrators of circular manufacturing systems. One of the three pillars of this project is product design, with the key objective to develop new circular design methodologies.

Institutional Review Board Statement

Ethical review and approval were waived for this study as all activities in the H2020 EU project ReCiPSS project comply to ethical and research integrity principles, stated and undersigned by all participants in the ReCiPSS grant agreement.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data presented in this study are openly available at https://zenodo.org/record/6411939#.YsRQsOxBxhF (accessed on 19 May 2022).

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Co-creation expert sessions—participants.

Table A1.

Co-creation expert sessions—participants.

| Indicator Number and Topic | Participant(s) |

|---|---|

| Session 1 1. Design budget (Strategy and Planning) 2. Know-how (Strategy and Planning) 3. Customer research (Strategy and Planning) 4. Value proposition (Strategy and Planning) | Assistant Professor—Scaling up the Circular Economy |

| Session 2 1. Design budget (Strategy and Planning) 2. Know-how (Strategy and Planning) 3. Customer research (Strategy and Planning) 4. Value proposition (Strategy and Planning) | PhD—Sustainable and Circular Product Development |

| Session 3 8. Maintenance and repair (Hardware and Software design) 13. Professional support (Product support Service) 17. Disassembly (Recoverability) | PhD Researcher—Design for Reparability and Longevity PhD—Fault Diagnosis for Repair |

| Session 4 10. On- and Off-boarding (Customer Experience and Care) | PhD—Design for Divestment Professor—Design Methodology for Sustainability and Circular Economy |

| Session 5 10. On- and Off-boarding (Customer Experience and Care) 11. Use efficiency (Customer Experience and Care) | PhD Researcher—Consumer Perception of Circular Products |

| Session 6 5. Materials (Hardware and Software Design) 20. Recycling (Recoverability) | PhD Researcher—Composites in a Circular Economy Professor—Circular Product Design |

| Session 7 14. Spare part supply (Product Support Service) 18. Refurbishment (Recoverability) 19. Remanufacturing (Recoverability) | Associate Professor—Critical Materials in a Circular Economy |

| Session 8 General: Social aspects of circular product design | PhD Researcher—Circular Medical Devices in Low Resource Settings |

Appendix B

Appendix C

| Assessment Questions | Justification Based on the Literature Review and Co-Creation |

| 1. CIRCULAR STRATEGY | |

| 1.1 Design budget | |

| 1.1.1 Has your company made a budget available for circular design? | Allocating budget to circular design underpins the strategic value of circular design and their level of commitment to prioritizing the associated design requirements [16]. |

| 1.2 Know-how | |

| 1.2.1 Does your company have access to circular design expertise? | The development of or having access to circular design competencies is seen as a success factor to implement circular design, looking at the financial, operational and structural challenges [32]. The question was added as a result of Co-creation sessions 2, 7 and 8. |

| 1.2.2 Does your company have channels to exchange product design information with stakeholders, like repair and remanufacturing technicians? | The integration of circular design is strongly linked with the frequency and quality of data exchange between technicians who perform recovery operations and design engineers [33]. |

| 1.3 Customer research | |

| 1.3.1 To what extent are the needs of customers not only considered in the first use-cycle, but also in the subsequent use-cycles of the product? | Market demand is seen as the strongest incentive for companies to adjust design requirements, collecting data about customer needs with regard to circular design helps in building arguments to implement circular design [16]. The question was rephrased as a result of Co-creation session 1. |

| 1.4 Value proposition | |

| 1.4.1 Does the circular value proposition and its related service and product offer new benefits to customers? | Circular product offers are established in value networks and are effective when all partners gain value from the offer [34]. The fact that circular products are taken back and recovered can offer additional unique value and can be offered to customers, such as access to information and access to exclusive features (van Dam et al. 2021) [35]. The question was added as a result of Co-creation session 8. |

| 1.4.2 To what extent does value proposition design support high product quality not only in the first use-cycle but also in subsequent use-cycles for the products? | The brand and product identity help customers build trust in, and accept, products that serve multiple use-cycles [16]. Building this quality perception also helps in obtaining buy-in from employees [16]. The question was rephrased as a result of Co-creation session 1. |

| 2. HARDWARE AND SOFTWARE DESIGN | |

| 2.1 Materials | |

| 2.1.1 What fraction of the material value, by cost price, consists of recycled and/or reused materials calculated over all use-cycles? | Calculating the ratio of the recoverable share of a product denotes the progress towards the circularity potential of a product [5]. The question was rephrased as a result of Co-creation session 6. |

| 2.1.2 What amount of the material value, by cost price, consists of critical materials? | Critical materials, commonly used by design engineers, tend to have rare material characteristics, yet they are labelled critical, for instance, due to constraints in supply chains, volatile prices, or implications to the environment [36]. Circular design is seen as a promising solution to diminish risks and offer a more sustainable alternative to using these valuable resources [36]. |

| 2.1.3 What amount of the material value, by cost price, consists of conflict materials? | Mineral trade can be involved with inhumane activities such as forced labor, labor under harsh working conditions, or criminal activities [37]. The OECD recommends traceability systems to map upstream supply chain stakeholders in collaboration with industry bodies [38]. |

| 2.1.4 Does the product contain easily separable biodegradable or compostable components? | Following the “power of pure circles” principle of the Ellen MacArthur Foundation, product circularity increases through separating material streams to their purest possible form at the core, separating the bio- and the techno-cycles [39]. |

| 2.1.5 Does the product contain composite materials that are designed to last? | Closing the material loop for composites through recycling remains suboptimal because of the material use and structure [40]. Therefore, choosing long lasting application through careful designs consideration should be favored [40]. |

| 2.1.6 Does the product packaging consist of recyclable, biodegradable, or compostable materials? | Calculating the ratio of the recoverable share of a product denotes the progress towards the circularity potential of a product [5]. The question was added as a result of the company evaluation (Section 5). |

| 2.2 Longevity | |

| 2.2.1 How does the total lifetime of the product compare to the market average? | Comparing a product’s lifetime against the market average is considered a valuable indicator to measure utility [10]. |

| 2.2.2 After what period of time will the user experience noticeable degradation of the product? | Functional, emotional, and social values play a role in the attachment users experience towards their products [41]. |

| 2.2.3 Does the product (information) indicate what key components are critical to the duration of either the technical lifetime or the economic lifetime (i.e., relevance to the market)? | An aspect from circular design is to determine what components are expected to degrade first and, if these components are critical, look for design solutions to prevent this [42]. The question was rephrased as a result of the company evaluation (Section 5). |

| 2.2.4 Does the product allow for enhancing a product’s functionality and/or cosmetic condition throughout its lifetime? | Design strategies such as modularity can allow a product’s functionality or appearance to be enhanced during its lifetime [43]. |

| 2.2.5 Is the product designed to have a timeless aesthetic? | The selection of design style links with timelessness and can influence market acceptance of circular products significantly, which can increase longevity [44]. The question was rephrased as a result of Co-creation session 7. |

| 2.3 Standardization | |

| 2.3.1 Is Design for Standardization applied throughout the whole product portfolio to support recovery options? Design for Standardization aims for standardizing selected parts throughout the product portfolio (e.g., between product generations) over time. | Standardization of sub-assemblies and components across product platforms allow products to be used over multiple use-cycles as it prevents them from becoming obsolete by replacement [43]. The question was rephrased as a result of the company evaluation (Section 5). |

| 2.3.2 Is (backward) compatibility applied throughout the whole product portfolio to support recovery options? Part compatibility is based on the interoperability between selected parts for multiple product types, and is dependent on, for example, part dimensions, energy uptake, interfaces, and software versions. | (Backward) compatibility of sub-assemblies and components across product platforms allow parts to be exchanged between products generations, lines, and platforms, which increases reusability potential [43]. The question was rephrased as a result of the company evaluation (Section 5). |

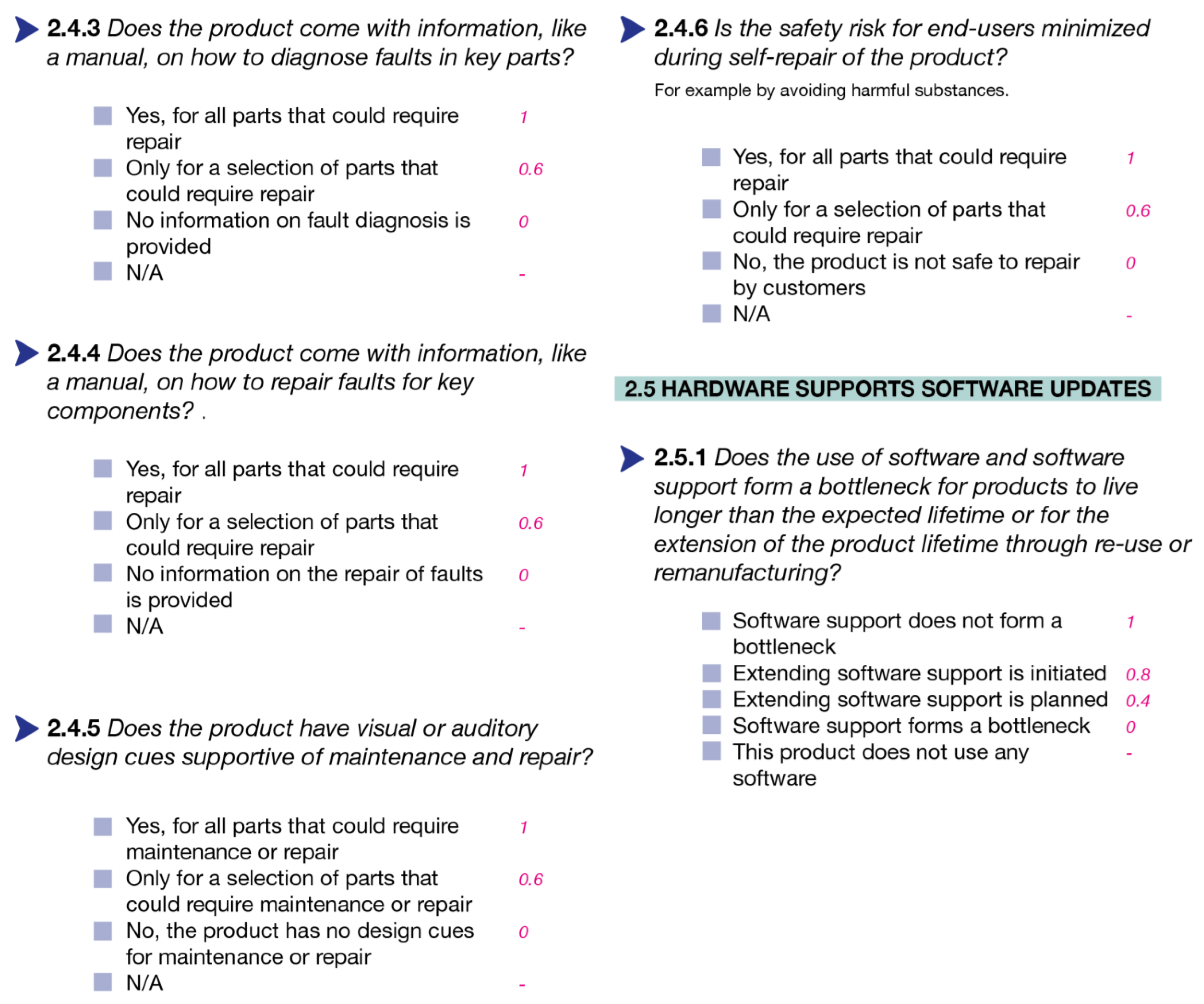

| 2.4 Maintenance and repair | |

| 2.4.1 Is the product designed for ease of maintenance? | If the product requires maintenance to preserve its performance, then it should allow for ease-of-maintenance (Co-creations session 3). In case maintenance cannot be “designed-out”, minimizing the time and effort to maintain a product is recommended to enhance simplicity, reliability, and supportability [45]. The implementation of Design for Maintenance has a positive effect on other recovery activities [46]. |

| 2.4.2 Does the product come with information, like a manual, on how to take care of it? | Informing a user about the possibilities for product care, makes the user aware of his or her influence on a product’s lifetime [47]. |

| 2.4.3 Does the product come with information, like a manual, on how to diagnose faults in key parts? | Providing information about fault diagnosis can help in restoring a product’s function in a time-efficient, safe, and cheap way [48]. |

| 2.4.4 Does the product come with information, like a manual, on how to repair faults for key components? | Providing information about repairing faults can help in restoring a product’s function in a time-efficient, safe, and cheap way [49]. |

| 2.4.5 Does the product have visual or auditory design cues supportive of maintenance and repair? | A product’s design can help navigate the user in following the simplest and time-efficient route for disassembly in order to maintain or repair a product [48]. |

| 2.4.6 Is the safety risk for end-users minimized during self-repair of the product? | A product’s design can be built facilitate safe maintenance, disassembly, and repair, not only by providing manuals, such as mandated by EU legislation, but also through the physical design features [48]. The question was rephrased as a result of the company evaluation (Section 5). |

| 2.5 Software support | |

| 2.5.1 Does the product make use of any software? | A product that uses software to operate (a part of) its functionality. |

| 2.5.2 Does software support form a bottleneck for products to live longer than the expected lifetime or for the extension of the product lifetime through re-use or remanufacturing? | Products that run software and serve for multiple use-cycles should have hardware to support continuous software updates and upgrades, as well as availability of new versions of this software [43]. |

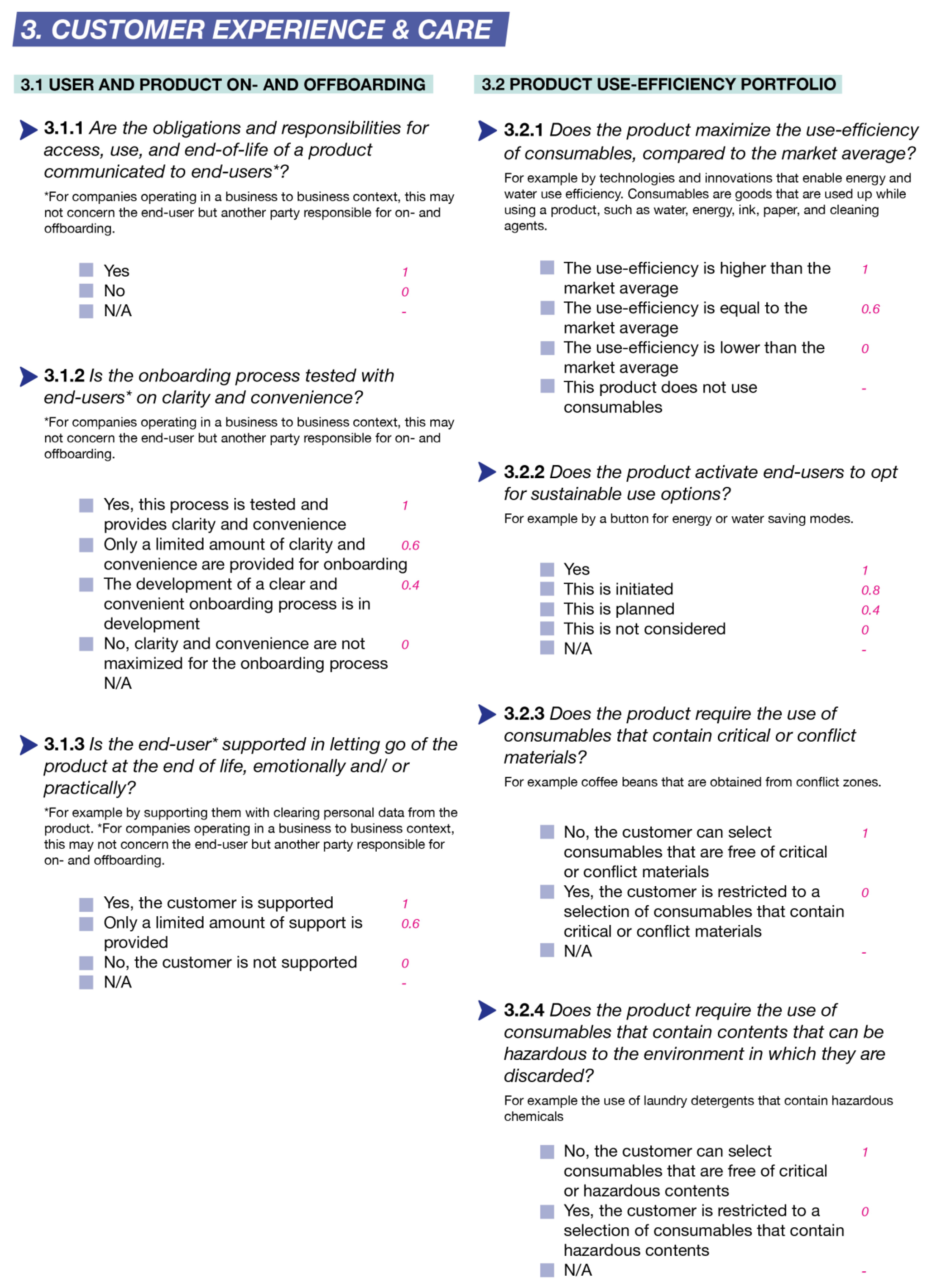

| 3. CUSTOMER EXPERIENCE AND CARE | |

| 3.1 On- and off-boarding | |

| 3.1.1 Are the obligations and responsibilities for access, use, and end-of-life of a product communicated to end-users *? * For companies operating in a business to business context, this may not concern the end-user but another party responsible for on- and offboarding. | A central design intervention in gaining acceptance of users in product-service-systems has to do with communicating a clear and consistent message [50]. The question was rephrased as a result of Co-creation session 4 and the company evaluation (Section 5). |

| 3.1.2 Is the onboarding process tested with end-users * on clarity and convenience? * For companies operating in a business to business context, this may not concern the end-user but another party responsible for on- and offboarding. | Major contributors to rejection of a product-service-system relate to a lack of understanding and lacking service quality, test and design iterations help prevent design flaws [50]. The question was rephrased as a result of Co-creation session 4 and the company evaluation (Section 5). |

| 3.1.3 Is the end-user * supported in letting go of the product at the end of life, either emotionally or practically? * For companies operating in a business to business context, this may not concern the end-user but another party responsible for on- and offboarding. | Design interventions focused on emotional support help increase the readiness level and willingness of end-users to return their product, through reducing uncertainty and confusion [51]. The question was rephrased as a result of Co-creation session 4 and the company evaluation (Section 5). |

| 3.2 Use efficiency | |

| 3.2.1 Does the product make use of consumables? This includes energy and water use. Consumables are goods that are used up while using a product, such as water, energy, ink, paper, and cleaning agents. | For certain products to fulfil a function, they require consumables which can be either dissipative (e.g., washing detergent) or disposable (e.g., razorblades) [52]. The question was rephrased as a result of Co-creation session 5. |

| 3.2.2 Does the product maximize the use-efficiency of consumables, compared to the market average? | Use efficiency that can be influenced by design relates to facilitating correct use, adjusted to the use context, as well as using appropriate products in the right quantities [52]. The question was rephrased as a result of Co-creation session 5. |

| 3.2.3 Does the product activate end-users to opt for sustainable use options? | Sustainable use can be promoted by complicating the more unsustainable options or simplifying the most sustainable option(s) [53]. The question was rephrased as a result of Co-creation session 5 and the company evaluation (Section 5). |

| 3.2.4 Does the product require the use of consumables that contain critical or conflict materials? | Critical or conflict materials can be avoided or minimized through careful material selection [52]. The question was rephrased as a result of Co-creation session 5. |

| 3.2.5 Does the product require the use of consumables that contain contents that can be hazardous to the environment in which they are discarded? | Hazardous materials can be avoided or minimized through careful material selection [52]. The question was rephrased as a result of Co-creation session 5. |

| 4. PRODUCT SUPPORT SERVICES | |

| 4.1 Warranty | |

| 4.1.1 Does the product’s warranty period last longer than what is legally required? | Warranty is provided for longer than the 2- or 5 years than mandatory from a legal perspective to guarantee a product’s durability [54]. |

| 4.1.2 Are products that are returned by the end-user * as part of warranty repaired, refurbished or remanufactured? * For companies that operate in a business to business context or offer products as a service, this may not concern the end-user but another party responsible for returning products. | Closing the loop for all of a product’s material streams adds to the circularity of a product and is a proven concept for companies to pursue remanufacturing operations [16,55]. The question was rephrased as a result of the company evaluation (Section 5). |

| 4.2 Professional support | |

| 4.2.1 Does your company, or partnered companies, offer in-warranty maintenance and repair services for the product? | In cases where a product stops functioning within the warranty period, the product should be replaced. Turing to repair to restate the function of the product is the preferred action from a circular economy point of view [54]. |

| 4.2.2 Does your company, or partnered companies, offer any paid maintenance and repair support service for the product? | The availability of professional repair services as a route to lifetime extension to meet the need for repair in cases where self-repair is impossible or not desired [56]. |

| 4.2.3 Is the end-user informed about the availability of a professional maintenance and repair service? | Awareness of the professional support services offered are necessary to close make such services truly operational [56]. The question was rephrased as a result of the company evaluation (Section 5). |

| 4.2.4 Does your company, or partnered companies, offer an upgrade service for your product? | Upgrade services allow customers to update and personalize product performance during a use-cycle [57]. |

| 4.2.5 Is the end-user informed about the possibility to upgrade the product? | The possibility for a customer to upgrade their product should be communicated through the accompanied service [57]. The question was rephrased as a result of the company evaluation (Section 5). |

| 4.3 Spare part supply | |

| 4.3.1 Are the spare parts to support self-repair by end-users affordable? | The availability of spare parts is essential to benefit from a product’s reparability [58]. Affordability of such spare parts is a key factor in motivating customers to invest in repair [59]. The question was rephrased as a result of the company evaluation (Section 5). |

| 4.3.2 Does your company produce extra spare parts for recovery, to enable refurbishment or remanufacturing? | The availability of spare parts is essential in performing recovery activities, including the required number of spare parts in the calculations for production is one of the ways to secure availability [16]. The question was rephrased as a result of Co-creation session 7. |

| 4.3.3 Can end-users * return their used parts, that they have replaced, to your company? * For companies that operate in a business to business context or offer products as a service, this may not concern the end-user but another party responsible for returning parts. | Taking back used parts that are released from product through, for example, repair, can be valuable for several reasons: they can help increase circularity though (1) recovery for spare part supply (2) dedicated material recovery [55,60]. The question was rephrased as a result of Co-creation session 7 and the company evaluation (Section 5). |

| 4.3.4 Are parts that are returned by the end-user * repaired, refurbished or remanufactured? * For companies that operate in a business to business context or offer products as a service, this may not concern the end-user but another party responsible for returning parts. | Closing the loop for all of a product’s material streams adds to the circularity of a product and is a proven concept for companies to pursue remanufacturing operations [16,55]. The question was rephrased as a result of Co-creation session 7 and the company evaluation (Section 5). |

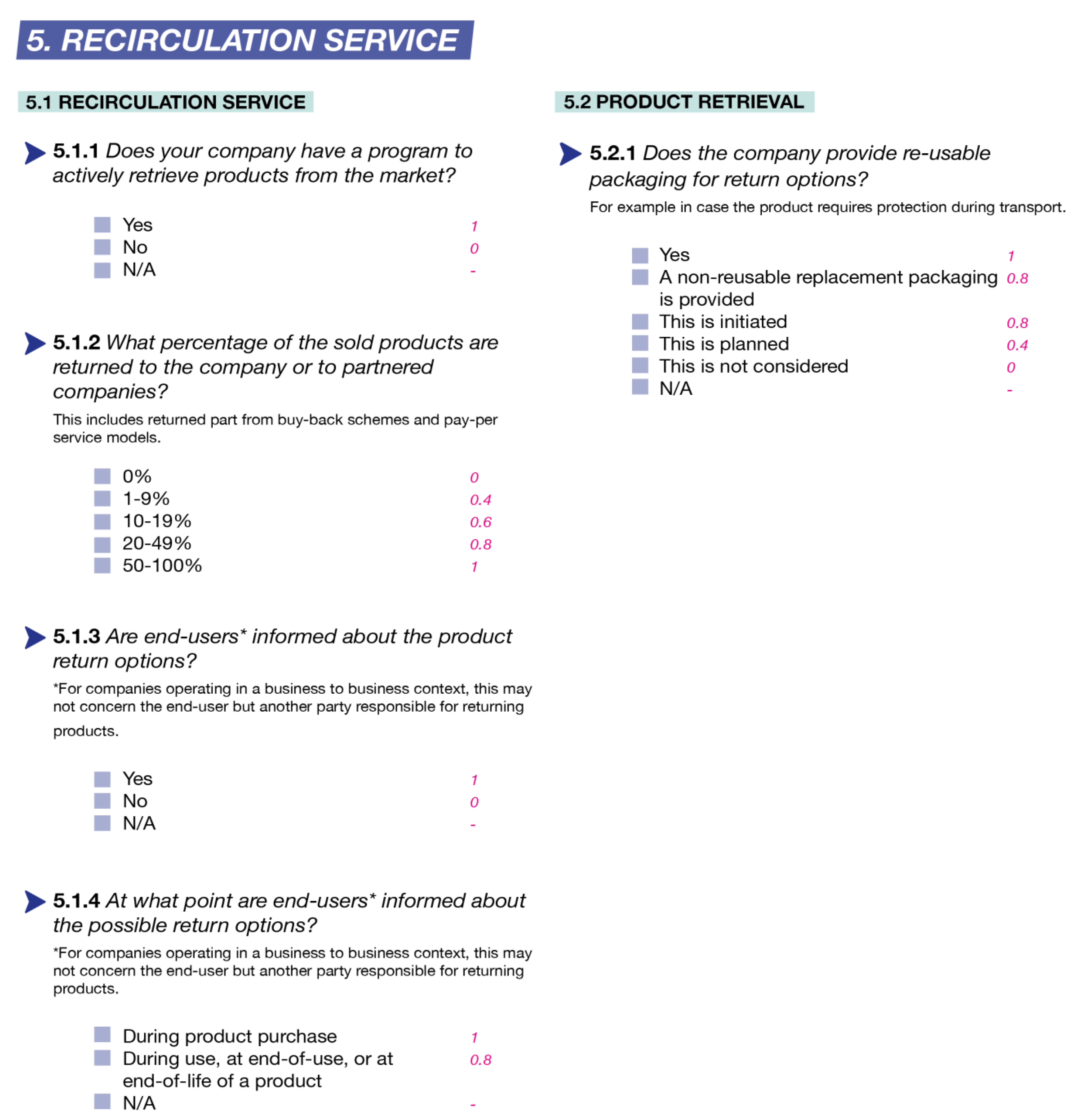

| 5. RECIRCULATION SERVICE | |

| 5.1 Return program | |

| 5.1.1 Does your company have a program to actively retrieve products from the market? | Products can be sold in combination with services, or as services, with the benefit of securing the return flow at end-of-use [61]. Having a return program prevents products to turn into waste or move into recycling before the product has reached its technical End-of-Life [62]. |

| 5.1.2 What percentage of the sold products are returned to the company or to partnered companies? | The number of products returning from the market has a significant influence on the effectiveness of a closed loop system [63]. |

| 5.1.3 Are end-users * informed about the product return options? *For companies operating in a business to business context, this may not concern the end-user but another party responsible for returning products. | Proactively marketing the options for customers to return products helps increase the awareness of the options and the likelihood of customers to engage with the options [64]. The question was rephrased as a result of the company evaluation (Section 5). |

| 5.1.4 At what point are end-users * informed about the possible return options? *For companies operating in a business to business context, this may not concern the end-user but another party responsible for returning products. | Circular design can be used to (emotionally) support customers in returning their products through design interventions at different moments in time to increase product returns [64]. The question was rephrased as a result of the company evaluation (Section 5). |

| 5.2 Product retrieval | |

| 5.2.1 Is the product designed for ease and efficiency of reverse logistics? The product can be designed to minimize the use of transportation volume, flatbed packaging, or to meet transportation conditions of existing logistical services | The question was rephrased as a result of the company evaluation (Section 5). |

| 5.2.2 Does the company provide re-usable packaging for return options? | Packaging materials typically have a short lifetime and generate a lot of waste, which can be reduced radically by replacing single use with reusable packaging [65]. |

| 6. RECOVERABILITY | |

| 6.1 Disassembly | |

| 6.1.1 Does your company list the key parts for disassembly? | Key components refer to those components in a product that are technically, economically, or environmentally valuable to the recovery activities to reach to enable maintenance, repair, replacement or parts harvesting [42,66]. The question was rephrased as a result of Co-creation session 3. |

| 6.1.2 Is product disassembly and reassembly optimized for time, cost efficiency, simplicity and tool availability? | Design for disassembly helps make the disassembly process of a product feasible, while minimizing damage caused to parts, optimizing part re-use, optimizing the disassembly route to access a key part, and reducing the disassembly complexity in terms of tools, knowledge and skill needed [66]. The question was rephrased as a result of Co-creation session 3. |

| 6.2 Refurbishment | |

| 6.2.1 Does your company list what parts make the refurbishment operations feasible and viable? | The parts or sub-assemblies of a product can contribute to recoverability in different ways, like through increasing viability or feasibility. Understanding their role can help in optimizing their added value through design [16]. The question was rephrased as a result of Co-creation session 7. |

| 6.2.2 Which fraction of the material value, by cost price, can be refurbished? | Calculating the ratio of the recoverable share of a product denotes the progress towards the circularity potential of a product [5]. |

| 6.2.3 Does your company provide refurbishment instructions and protocols to the relevant departments or third parties? | Having standardized instructions for recovery operations is the first recommendation towards lean production [67]. The question was rephrased as a result of Co-creation session 7. |

| 6.2.4 Does your company have a clear diagnosis procedure for products returning from the market? | Diagnostics is seen as the critical first, and potentially time-consuming step, of the recovery process [68,69]. Standardization of this process helps avoid deviations and avoid unnecessary time loss [67]. The question was rephrased as a result of Co-creation session 7. |

| 6.3 Remanufacturing | |

| 6.3.1 Does your company list what parts make the remanufacturing operations feasible and viable? | The parts or sub-assemblies of a product can contribute to recoverability in different ways, like through increasing viability or feasibility. Understanding their role can help in optimizing their added value through design [16]. The question was rephrased as a result of Co-creation session 7. |

| 6.3.2 Which fraction of the material value, by cost price, can be remanufactured? | Calculating the ratio of the recoverable share of a product denotes the progress towards the circularity potential of a product [5]. |

| 6.3.3 Does your company provide remanufacturing instructions and protocols to the relevant departments or third parties? | Having standardized instructions for recovery operations is the first recommendation towards lean production [67]. The question was rephrased as a result of Co-creation session 7. |

| 6.3.4 Does your company have a clear diagnosis procedure for products returning from the market? | Diagnostics is seen as the critical first, and potentially time-consuming step, of the recovery process [68,69]. Standardization of this process helps avoid deviations and avoid unnecessary time loss [67]. The question was rephrased as a result of Co-creation session 7. |

| 6.4 Recycling | |

| 6.4.1 Which fraction of the material value, by cost price, can be recycled? | Calculating the ratio of the recoverable share of a product denotes the progress towards the circularity potential of a product [5]. Expressing this ratio in value provides an inclusive image with respect to, for example, minor metals, that are often used in small quantities (Co-creation session 6; [70]). |

| 6.4.2 Does the product fall apart into separate homogeneous or compatible material fragments in the shredding process? | Separating the materials of a product into uncontaminated material streams is a key factor to high-quality recycling [40,70]. |

| 6.4.3 Are general recycling processes available for the materials in your product? | However, recyclable a material is, whether a material gets recycled in reality depends on the availability of formal recycling processes, technology, and infrastructure [71]. The more common a material is, in type and mass, the more likely it is that general recycling processes are available. The question was added as a result of Co-creation session 6. |

| 6.4.4 Is there an End-of-Use repurposing plan for the materials that are non-recyclable? | While their use is not uncommon, closing the loop for non-recyclable materials remains a challenge. Until recycling technology progresses, designers should turn to repurposing scenarios to extend the lifetime of such materials to make continued use of the value of these materials’ existing form and characteristics [9,40]. |

References

- EMF (Ellen MacArthur Foundation). Circulytics—Indicators; EMF: Cowes, UK, 2020. [Google Scholar]

- Kristensen, H.S.; Mosgaard, M.A. A review of micro level indicators for a circular economy–moving away from the three dimensions of sustainability? J. Clean. Prod. 2020, 243, 118531. [Google Scholar] [CrossRef]

- Saidani, M.; Yannou, B.; Leroy, Y.; Cluzel, F.; Kendall, A. A taxonomy of circular economy indicators. J. Clean. Prod. 2019, 207, 542–559. [Google Scholar] [CrossRef] [Green Version]

- Corona, B.; Shen, L.; Reike, D.; Carreón, J.R.; Worrell, E. Towards sustainable development through the circular economy—A review and critical assessment on current circularity metrics. Resour. Conserv. Recycl. 2019, 151, 104498. [Google Scholar] [CrossRef]

- Cayzer, S.; Griffiths, P.; Beghetto, V. Design of indicators for measuring product performance in the circular economy. Int. J. Sustain. Eng. 2017, 10, 289–298. [Google Scholar] [CrossRef] [Green Version]

- Linder, M.; Sarasini, S.; van Loon, P. A metric for quantifying product-level circularity. J. Ind. Ecol. 2017, 21, 545–558. [Google Scholar] [CrossRef] [Green Version]

- Figge, F.; Thorpe, A.S.; Givry, P.; Canning, L.; Franklin-Johnson, E. Longevity and circularity as indicators of eco-efficient resource use in the circular economy. Ecol. Econ. 2018, 150, 297–306. [Google Scholar] [CrossRef]

- Omwando, T.A.; Otieno, W.A.; Farahani, S.; Ross, A.D. A bi-level fuzzy analytical decision support tool for assessing product remanufacturability. J. Clean. Prod. 2018, 174, 1534–1549. [Google Scholar] [CrossRef]

- van Schaik, A.; Reuter, M.A. Recycling indices visualizing the performance of the circular economy. World Metall. Erzmetall 2016, 69, 201–216. [Google Scholar]

- Ellen MacArthur Foundation; Granta Design. Circularity Indicators. An Approach to Measuring Circularity. Methodology; EMF: Cowes, UK, 2015. [Google Scholar]

- Bakker, C.; den Hollander, M.; Van Hinte, E.; Zijlstra, Y. Products That Last: Product Design for Circular Business Models; TU Delft Library: Delft, The Netherlands, 2014. [Google Scholar]

- EMF (Ellen MacArthur Foundation). Towards the Circular Economy 3: Accelerating the Scale-Up across Global Supply Chains. 2014. Available online: https://ellenmacarthurfoundation.org/towards-the-circular-economy-vol-3-accelerating-the-scale-up-across-global (accessed on 12 January 2022).

- Stahel, W.R. The Performance Economy, 2nd ed.; Palgrave Macmillan: London, UK, 2010. [Google Scholar]

- Kirchherr, J.; Piscicelli, L.; Bour, R.; Kostense-Smit, E.; Muller, J.; Huibrechtse-Truijens, A.; Hekkert, M. Barriers to the circular economy: Evidence from the European Union (EU). Ecol. Econ. 2018, 150, 264–272. [Google Scholar] [CrossRef] [Green Version]

- Boorsma, N.; Peck, D.; Bakker, T.; Bakker, C.; Balkenende, R. The Strategic Value of Design for Remanufacturing: A Case Study of Professional Imaging Equipment. J. Remanuf. 2022, 12, 187–212. [Google Scholar] [CrossRef]

- EEA (European Environment Agency). Circular by Design, Products in the Circular Economy; European Environment Agency: Copenhagen, Denmark, 2017. [Google Scholar]

- Boorsma, N.; Balkenende, R.; Bakker, C.; Tsui, T.; Peck, D. Incorporating design for remanufacturing in the early design stage: A design management perspective. J. Remanuf. 2020, 11, 25–48. [Google Scholar] [CrossRef]

- Holt, D.T.; Armenakis, A.A.; Harris, S.G.; Feild, H.S. Toward a comprehensive definition of readiness for change: A review of research and instrumentation. Res. Organ. Chang. Dev. 2007, 16, 289–336. [Google Scholar] [CrossRef]

- Drucker, P.F.; Maciariello, J.A. Management, Revised ed.; Collins: New York, NY, USA, 2008. [Google Scholar]

- Krippendorff, K.; Butter, R. Product semantics-exploring the symbolic qualities of form. Innovation 1984, 3, 4–9. [Google Scholar]

- Den Hollander, M.C.; Bakker, C.A.; Hultink, E.J. Product design in a circular economy: Development of a typology of key concepts and terms. J. Ind. Ecol. 2017, 21, 517–525. [Google Scholar] [CrossRef]

- Sumter, D.; De Koning, J.; Bakker, C.; Balkenende, R. Circular economy competencies for design. Sustainability 2020, 12, 1561. [Google Scholar] [CrossRef] [Green Version]

- Daalhuizen, J.J. Method Usage in Design: How Methods Function as Mental Tools for Designers. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2014. [Google Scholar]

- Pigosso, D.C.; McAloone, T.C. Making the transition to a circular economy within manufacturing companies: The development and implementation of a self-assessment readiness tool. Sustain. Prod. Consum. 2021, 28, 346–358. [Google Scholar] [CrossRef]

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain; PBL Publishers: The Hague, The Netherlands, 2017. [Google Scholar]

- Dresch, A.; Lacerda, D.P.; Antunes, J.A.V. Design science research. In Design Science Research; Springer: Cham, Switzerland, 2015; pp. 67–102. [Google Scholar]

- Peffers, K.; Tuunanen, T.; Rothenberger, M.A.; Chatterjee, S. A design science research methodology for information systems research. J. Manag. Inf. Syst. 2007, 24, 45–77. [Google Scholar] [CrossRef]

- Mielke, J.; Vermaßen, H.; Ellenbeck, S. Ideals, practices, and future prospects of stakeholder involvement in sustainability science. Proc. Natl. Acad. Sci. USA 2017, 114, E10648–E10657. [Google Scholar] [CrossRef] [Green Version]

- Bannigan, K.; Watson, R. Reliability and validity in a nutshell. J. Clin. Nurs. 2009, 18, 3237–3243. [Google Scholar] [CrossRef]

- Ente Nazionale Italiano di Unificazione (UNI). UNI 11097. Quality Management—Quality Indicators and Quality Management Synoptical Tables-General Guidelines; Ente Nazionale Italiano di Unificazione (UNI): Rome, Italy, 2003. [Google Scholar]

- Franceschini, F.; Galetto, M.; Maisano, D. Management by Measurement: Designing Key Indicators and Performance Measurement Systems; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Sumter, D.; de Koning, J.; Bakker, C.; Balkenende, R. Key Competencies for Design in a Circular Economy: Exploring Gaps in Design Knowledge and Skills for a Circular Economy. Sustainability 2021, 13, 776. [Google Scholar] [CrossRef]

- Hatcher, G.D.; Ijomah, W.L.; Windmill, J.F.C. Integrating design for remanufacture into the design process: The operational factors. J. Clean. Prod. 2013, 39, 200–208. [Google Scholar] [CrossRef]

- Bocken, N.; Short, S.; Rana, P.; Evans, S. A literature and practice review to develop sustainable business model archetypes. J. Clean. Prod. 2014, 65, 42–56. [Google Scholar] [CrossRef] [Green Version]

- van Dam, S.; Sleeswijk Visser, F.; Bakker, C. The impact of co-creation on the design of circular product-service systems: Learnings from a case study with washing machines. Des. J. 2021, 24, 25–45. [Google Scholar] [CrossRef]

- Peck, D.; Kandachar, P.; Tempelman, E. Critical materials from a product design perspective. Mater. Des. 2015, 65, 147–159. [Google Scholar] [CrossRef]

- EC (European Commission). The EU’s New Conflict Minerals Regulation: A Quick Guide if You’re Involved in the Trade in Tin Tungsten Tantalum or Gold. 2017. Available online: https://ec.europa.eu/trade/policy/in-focus/conflict-minerals-regulation/regulation-explained/ (accessed on 23 January 2022).

- OECD. OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas, 3rd ed.; OECD Publishing: Paris, France, 2016. [Google Scholar] [CrossRef]

- EMF (Ellen MacArthur Foundation). Towards the Circular Economy: Economic and Business Rationale for an Accelerated Transition. 2013. Available online: https://ellenmacarthurfoundation.org/towards-the-circular-economy-vol-1-an-economic-and-business-rationale-for-an (accessed on 10 January 2022).

- Joustra, J.; Flipsen, B.; Balkenende, R. Circular design of composite products: A framework based on insights from literature and industry. Sustainability 2021, 13, 7223. [Google Scholar] [CrossRef]

- van den Berge, R.; Magnier, L.; Mugge, R. Too good to go? Consumers’ replacement behaviour and potential strategies for stimulating product retention. Curr. Opin. Psychol. 2021, 39, 66–71. [Google Scholar] [CrossRef]

- Nasr, N.; Russell, J.; Bringezu, S.; Hellweg, S.; Hilton, B.; Kreiss, C.; von Gries, N. Re-Defining Value—The Manufacturing Revolution. Remanufacturing, Refurbishment, Repair and Direct Reuse in the Circular Economy; International Resource Panel, United Nations Environment Programme: Nairobi, Kenya, 2018; Available online: https://www.resourcepanel.org/reports/re-defining-value-manufacturing-revolution (accessed on 25 January 2022).

- Schischke, K.; Proske, M.; Nissen, N.F.; Schneider-Ramelow, M. Impact of modularity as a circular design strategy on materials use for smart mobile devices. MRS Energy Sustain. 2019, 6, E16. [Google Scholar] [CrossRef] [Green Version]

- Wallner, T.S.; Magnier, L.; Mugge, R. An exploration of the value of timeless design styles for the consumer acceptance of refurbished products. Sustainability 2020, 12, 1213. [Google Scholar] [CrossRef] [Green Version]

- Mulder, W.; Blok, J.; Hoekstra, S.; Kokkeler, F. Design for Maintenance—Guidelines to Enhance Maintainability, Reliability and Supportability of Industrial Products. 2021. Available online: https://research.utwente.nl/en/publications/design-for-maintenance-guidelines-to-enhance-maintainability-reli (accessed on 25 January 2022).

- Ingemarsdotter, E.; Kambanou, M.L.; Jamsin, E.; Sakao, T.; Balkenende, R. Challenges and solutions in condition-based maintenance implementation—A multiple case study. J. Clean. Prod. 2021, 296, 126420. [Google Scholar] [CrossRef]

- Ackermann, L. Design for Product Care. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2020. [Google Scholar]

- Arcos, B.P. Fault Diagnosis in Household Appliances: A Design Perspective. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2021. [Google Scholar]

- Dangal, S.; Faludi, J.; Balkenende, R. Reparability Scoring Systems: Comparing Their Objectivity and Completeness. 2022; manuscript in preparation. [Google Scholar]

- Poppelaars, F.A. Let It Go: Designing the Divestment of Mobile Phones in a Circular Economy from a User Perspective. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2020. [Google Scholar]

- Poppelaars, F.; Bakker, C.; van Engelen, J. Design for divestment in a circular economy: Stimulating voluntary return of smartphones through design. Sustainability 2020, 12, 1488. [Google Scholar] [CrossRef] [Green Version]

- Willskytt, S. Resource efficient products in a circular economy—The case of consumables. Ph.D. Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2020. [Google Scholar]

- Wever, R.; Van Kuijk, J.; Boks, C. User-centred design for sustainable behaviour. Int. J. Sustain. Eng. 2008, 1, 9–20. [Google Scholar] [CrossRef]

- Maitre-Ekern, E.; Dalhammar, C. Regulating planned obsolescence: A review of legal approaches to increase product durability and reparability in Europe. Rev. Eur. Comp. Int. Environ. Law 2016, 25, 378–394. [Google Scholar] [CrossRef]

- Inderfurth, K.; Mukherjee, K. Decision support for spare parts acquisition in post product life cycle. Cent. Eur. J. Oper. Res. 2008, 16, 17–42. [Google Scholar] [CrossRef]

- Niskanen, J.; McLaren, D. The Political Economy of Circular Economies: Lessons from Future Repair Scenario Deliberations in Sweden. Circ. Econ. Sustain. 2021, 1–25. [Google Scholar] [CrossRef] [PubMed]

- Poppelaars, F.A. Developing a Mobile Device for a Circular Economy. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2014. [Google Scholar]

- Repair Café IF (International Foundation). Repair Monitor—Analysis Results 2019. 2020. Available online: https://repaircafe.org/wp-content/uploads/2020/05/RepairMonitor_analysis_2019_05052020_ENGLISH-1.pdf (accessed on 25 January 2022).

- Sabbaghi, M.; Esmaeilian, B.; Cade, W.; Wiens, K.; Behdad, S. Business outcomes of product repairability: A survey-based study of consumer repair experiences. Resour. Conserv. Recycl. 2016, 109, 114–122. [Google Scholar] [CrossRef] [Green Version]

- De Giovanni, P.; Reddy, P.V.; Zaccour, G. Incentive strategies for an optimal recovery program in a closed-loop supply chain. Eur. J. Oper. Res. 2016, 249, 605–617. [Google Scholar] [CrossRef]

- Tukker, A. Eight types of product–service system: Eight ways to sustainability? Experiences from SusProNet. Bus. Strategy Environ. 2004, 13, 246–260. [Google Scholar] [CrossRef]

- Guide, V.D.R.; Souza, G.C.; Van Wassenhove, L.N.; Blackburn, J.D. Time value of commercial product returns. Manag. Sci. 2006, 52, 1200–1214. [Google Scholar] [CrossRef] [Green Version]