1. Introduction

A circular economy is an economic and industrial system that aims to eliminate waste through the restorative use of resources [

1]. The resources are retained in the system rather than being wasted by focusing on the product, component, and material reuse [

2,

3]. The recovery strategies are prioritised according to their capacity to preserve the embedded value, with product reuse being preferred over material recycling [

4]. The product design is regarded as a powerful contributor to establishing circular production and consumption processes [

1,

5], as the design determines to a large extent how the products are made, used, and processed at end of life.

Designing products for a circular economy can be challenging. The products need to be designed for multiple lifecycles [

6], including the complete system in which the product operates as well as prospective recovery activities [

7,

8]. Thus, time is an explicit factor in the design [

9]. The design is accompanied by the development of tailored circular business models to incentivise prolonged use and the return of products and to promote recovery [

10,

11]. These factors widen the scope of product development in terms of, for example, stakeholder interactions [

12,

13], requiring additional and altered competencies from the designer, such as designing for multiple use and recovery cycles, working with circular business models, and collaborating and engaging with stakeholders [

14,

15]. Additional challenges are found in specific industry sectors, such as when dealing with high end yet poorly recyclable materials such as composites [

16,

17,

18]. To date, the advantages and challenges of the materials have been widely acknowledged [

16,

17,

19], but the design of products using composite materials has not explicitly been considered in circular product design approaches.

To improve the design of composite products for a circular economy, we developed a circular composites design method based on the study by Joustra et al. (2021) [

16]. The design method consists of two parts: a product lifecycle exploration sheet and a product design framework. The product lifecycle exploration sheet is used to explore recovery loops, including for the stakeholders and their activities. The circular product design framework then relates the recovery strategies to design aspects that facilitate recovery. This novel method increases the product circularity by identifying recovery pathways and generating design solutions. As such, it supports designers when preparing products for reuse and recovery based on the design intent.

Industry insights were included when developing the circular composites design method; however, its application has not yet been tested in practice. Such testing is essential, since many developed design methods find limited uptake in industry and their actual impact remains unclear [

20,

21]. This is caused by many of the methods being developed out of context and without having the user in mind [

22,

23]. Design methods do not merely provide a formal description of the design process, they are part of the interaction between the designer, context, and design goal [

21,

22]. Failing to take these factors into account during method development leads to design methods having limited usability, unknown performance and ensuing poor acceptance in industry practice [

22,

23].

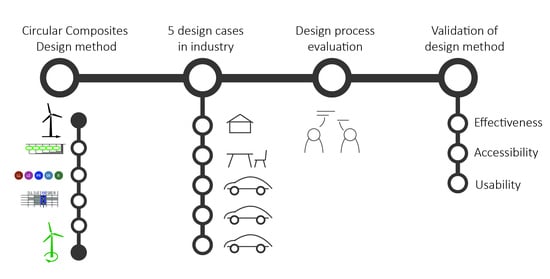

In this study, we describe and evaluate the circular composites design method through design case studies performed by expert designers. This approach takes the design method, its users, the industrial context, and the design goal explicitly into account. We focus on the circular design of products containing composite materials, most notably those containing fibre-reinforced thermoplastics. These materials represent the majority of the composite materials in the market today [

24], with the automotive industry being the largest consumer. The automotive sector is represented by three design cases, while the other cases in this study are taken from the construction and furniture industries to broaden the scope of the potential applications of the design method. All three are considered priority sectors for accelerating the transition to a circular economy in the European Union [

25]. As such, the evaluation of these cases provides an indication of the performance and demonstrates the use of the circular composites design method in realising a circular economy for composite products.

In this study, the designers learn about the circular composites design method and apply it in their respective cases. Afterwards, we reflect on the design case with the designers to evaluate the use of the method in the design process. In

Section 2, we outline the circular composites design method. In

Section 3, we introduce the design case studies in which it was used. This section also describes the data collection and analysis of the cases. In

Section 4, the design cases and the reflections of the designers on their method usage in the design process are described in detail. In

Section 5, we evaluate the method’s effectiveness, accessibility, and usability for composite product design for a circular economy. The main insights are then brought together in

Section 6.

2. Circular Composites Design Method

We describe the circular composites design method’s use in context by following the method content theory [

22]. The method’s goal is to support the designers of composite products when integrating circular economy strategies. As such, it facilitates product design

for a circular economy

with composite materials. The method includes an explorative lifecycle mapping worksheet and a circular product design framework.

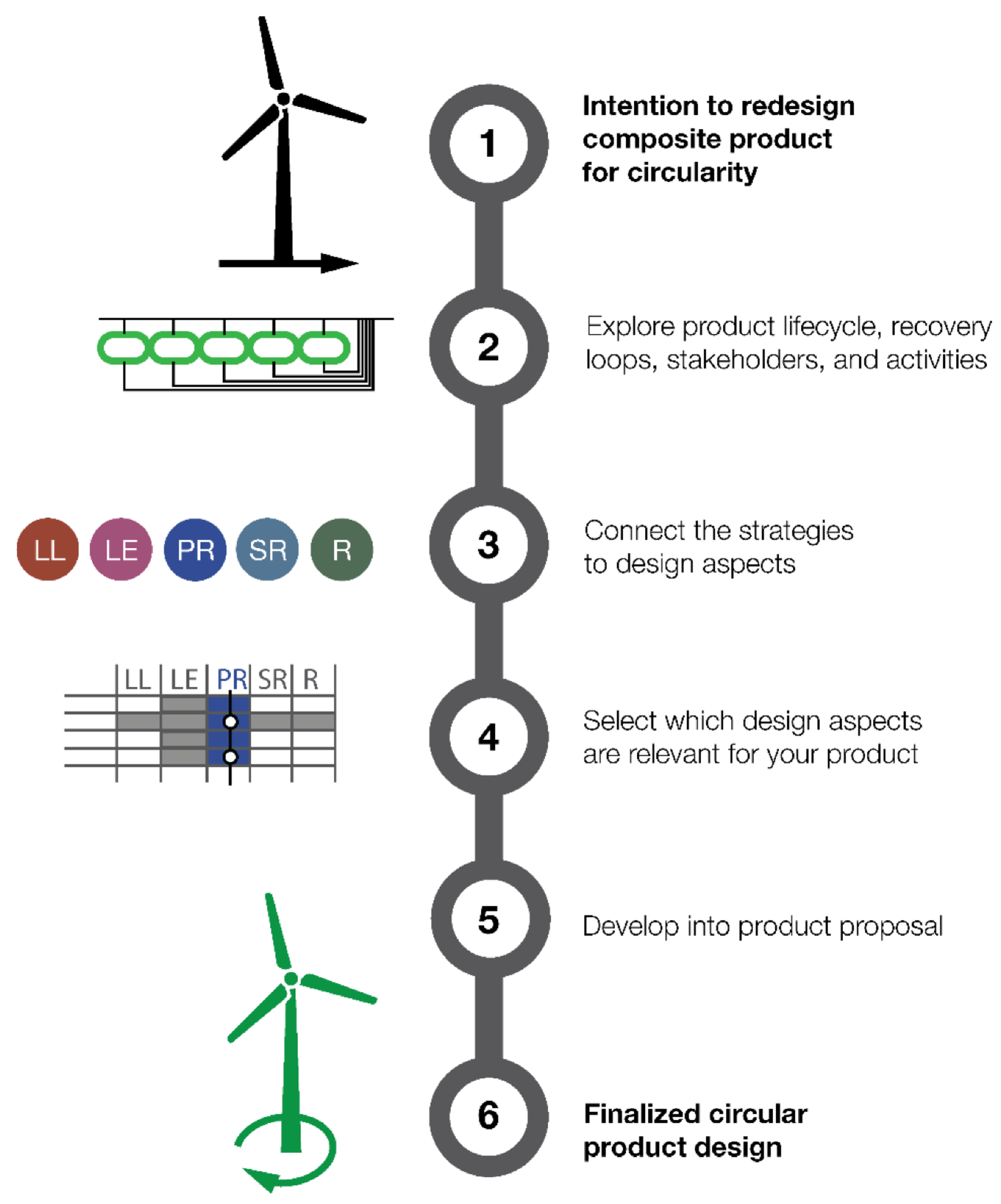

Figure 1 shows the method’s consecutive steps.

The circular composites design method process follows the numbered steps depicted in

Figure 1. The process starts with (1) the intent to (re)design a product containing composite materials for a circular economy, (2) then the designer uses the lifecycle exploration sheet shown in

Figure 2 to draw out and detail the product lifecycle. The mapping starts with a product description, followed by identifying stakeholders for each phase in the product value chain. Then, the recovery loops are explored, describing potential recovery actions to recover the product as an entity, parts, or materials at end of use. The sheet can be used in group sessions to stimulate discussion and create a shared understanding of the product lifecycle and circular opportunities. In the design cases in this study, the lifecycle exploration was done in stakeholder groups, facilitated by moderators.

The recovery loops relate to circular strategies such as long life, lifetime extension, or material recycling. In the circular composites design method, the designer uses a circular product design framework to connect these strategies to design aspects (4). This framework, given in

Supplementary S1, contains 5 circular strategies and relates these to 24 design aspects [

16]. Three strategies aim to preserve the product integrity by ensuring long life, lifetime extension, and product recovery. The remaining two strategies aim to preserve the material integrity (maintaining material quality over time) via structural reuse and material recycling. While product integrity strategies are generally preferred to preserve performance and value, the material integrity remains necessary to reprocess products that have no next-use cycle [

5]. The related design aspects support designers in anticipating for recovery by design intent. The designer can use a subset of design aspects to conceptualise, embody, and detail the design proposal (5). Finally, the process results in a circular product design proposal (6).

3. Method

To evaluate the circular composites design method’s effectiveness, accessibility, and usability in the design process, we used a mixed methods approach to reflect on the design process with the designers. The approach consists of a questionnaire to elicit the method used in the successive stages of the design process and a semi-structured interview to elaborate on the designers’ reflections on the design process and the results achieved. These approaches were also used to evaluate the method used in the design process [

26,

27] and to gain insight into how experts approach circular product design in practice [

14]. The mixed methods approach allowed for systematic reflection, as well as the elaboration of the insights emerging in the design process.

The design case study and mixed methods reflection process were piloted in a student design course at Delft University of Technology. In the course, ten industrial design engineering students used the circular composites design method to develop circular products for a fictional case in the furniture industry. After the completion of the course, the students reflected on their design process with the researcher. The interviews were subsequently transcribed and analysed together with the questionnaire responses. This pilot study showed the feasibility of using the questionnaire and semi-structured interview to evaluate the effectiveness, accessibility, and usability of the design method.

3.1. Design Cases

Seven industry design experts used the circular composites design method to re-design a total of five case products. The designers developed their products within the context of a Horizon 2020 project on closing the loop of composite products in the automotive, furniture, and building sectors. The project ran from 2017 until 2021, of which three years were dedicated to product development [

28]. The consortium included stakeholders from all stages of the product lifecycle for each of the product sectors, such as material suppliers, original equipment manufacturers (OEMs), and recycling companies. The knowledge generated by TU Delft on circular product design was shared with the industrial partners through regular project meetings and intermediate reports. The prototypes were developed by designers from the industrial partner companies to demonstrate a circular composite product, evaluate the product’s performance in-use, and to simulate a closed-loop recovery action.

Five case products were developed for three sectors (

Table 1), namely the construction (

n = 1), furniture (

n = 1), and automotive (

n = 3) industries. In one case (E4), we interviewed three designers, while other cases were represented by one designer, which brought the total number of participants to seven. For the construction sector, a small-to-medium enterprise (SME) company developed an outdoor pavilion using extruded pillars and beams. The extrusion agglomerate was based on a recycled (shredded) glass fibre composite and polyethylene. For the furniture sector, a large manufacturer of interior furniture designed a modular bedroom set consisting of a bed, bookcase, chair, and desk, all made of particle board. For the automotive sector, three companies designed dashboard components using recycled or bio-based thermoplastic composite materials. The first company was a large manufacturer of automotive thermoplastics, the second was an SME developing hydrogen vehicles, and the third was a research and technology development (RTD) centre affiliated with a major car brand.

3.2. Design Process and Data Acquisition

The designers were asked to use the circular composites design method to develop prototype products. The prototype products were produced and exhibited at locations across Europe. These were then used to demonstrate and evaluate the circular product proposals in the final stage of the Ecobulk project. All designers reflected on their design process through a questionnaire and a semi-structured interview.

A baseline was established at the start of the design case study for case products as well as circular design expertise [

29]. The baseline consisted of a definition of the case product, the materials used, and the expected challenges to its uptake in a circular system. The current state of the art for the industry sectors was also established. The expertise of the designers in circular product design was evaluated by discussing to what extent recovery was already considered in the design stage and to what extent retrieved materials were used in ongoing product manufacturing.

At the end of the design process, we asked the designers to complete a questionnaire to reflect on their knowledge of the circular product design methods, and to identify how the circular composites design method was used in the design process. The questionnaire setup is provided in

Supplementary S2. To assess the prior knowledge, we offered several options such as “reading on the subject” and “courses” (including online open courseware), as well as options to add additional sources or simply state “none”. The responses allowed us to identify the means and types of sources the designers used to become acquainted with the topic of circular product design.

To assess when the circular composites design method was used in the design process, we used a questionnaire setup developed by Person et al. (2013). This allowed us to relate the use of the design method to stages in the basic design cycle, which describes design as an iterative process of analysis, synthesis, simulation, evaluation, and decision making [

30]. It must be noted that the intention was not to quantify the extent to which the proposed design method was used, but rather to qualitatively assess

when and

how the method was used in the design process.

We then conducted semi-structured interviews with the designers to reflect on their design process. The questionnaire answers were used as inputs for the interview by questioning how the circular composites design method was used in the indicated design tasks. Reflecting on a design outcome can be difficult, and designers tend to prefer telling stories about the design process instead [

31]. We, therefore, invited the participants to bring intermediate results such as reports, drawings, and the final prototype to help them describe their process. The interviewer then asked about the specifics of the design and the decisions that underpinned these. The interviews took 30–60 min each; see

Supplementary S3 for the interview template.

The designers were interviewed online as they worked at companies across Europe. For the online interviews we used videoconferencing software and a shared web-based “whiteboard”. This whiteboard was prepared with pictures of the case product and drawings of the circular strategies and design aspects. Both the researcher and the participant could move and add pictures and notes. In addition, hand-written notes were taken by the researcher during the interviews. The interview was audio-recorded and the virtual workspace was exported and saved to capture notes and the selection of strategies and design aspects (

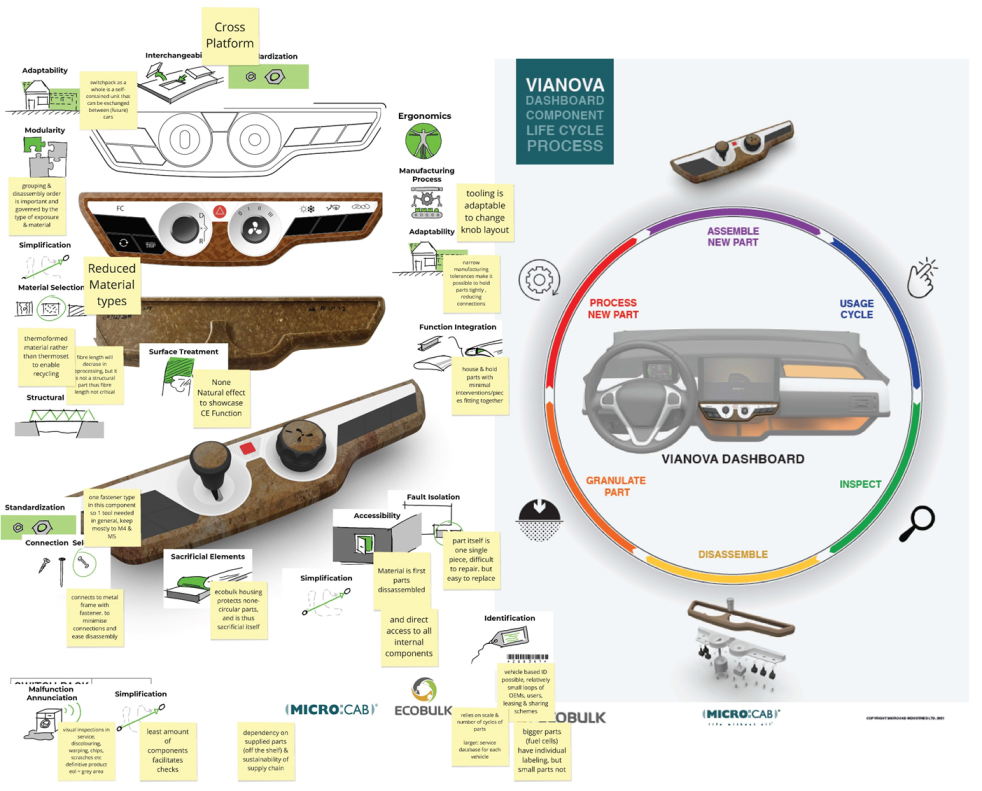

Figure 3).

3.3. Analysis

To evaluate the effectiveness, accessibility, and usability of the circular composites design method in practice, we analysed the questionnaire and interviews on their main aspects. In the questionnaire, the designers indicated the tasks for which the method had been used. The questionnaire setup was such that these tasks related to stages in the design process [

26]. Reviewing the questionnaire responses gave an immediate overview of when and how the designers used the design method in their design process.

Following this, the recorded interviews were transcribed and reviewed. We analysed the responses using predefined codes drawn from [

26] to identify tasks in the basic design cycle, from [

5] to identify the type of recovery loop, and from [

16] to identify the circular strategies and design aspects implemented in the product design. These were supplemented with codes that emerged from the interviews to capture additional method uses. The full list of codes is provided in

Supplementary S4. After coding, the transcripts were reviewed again through the lens of the research questions to capture insights that may have been overlooked through the granularity of coding. The design method’s effectiveness, accessibility, and usability were analysed as follows.

Effectiveness relates to “how well a method allows designers to achieve the desired effect in context” [

22]. In this design case study, we evaluated the extent to which the method invokes circularity in the design. We considered two aspects derived from [

5]: the considered level of integrity strategies, and the nature of the circular system. First, we classified a design as being circular if both product integrity and material-level integrity strategies were considered and a substantiated selection of a specific circular strategy was made. Second, reprocessing is generally considered most effective when done in a closed system, where control over and responsibility for the product recovery remains with the manufacturer.

The accessibility of a design method relates to “the ease with which (the method) can be accessed by a designer. This can refer to the method description as a whole or elements of it” [

23]. As learning builds on past knowledge and experience, we started by coding the questionnaire and project baseline report for prior knowledge on circular product design. We then coded the interview for prior experience and the means through which the designer learned and understood the method. Finally, we reviewed the interview for responses regarding the matching of the method with their design practice.

The usability of a design method relates to “the ease with which (the method) can be applied after it has been selected” [

23]. We, therefore, analysed when and how the method was used in various tasks of the individual design processes, referring to the basic design cycle. To evaluate the method use, we reviewed the questionnaire responses and coded the interviews for references to typical design tasks and method manifestations. The majority of the codes were drawn from [

26], supplemented by codes emerging from the interview. To evaluate the extent to which the design method could be used for each individual case, we mapped the product descriptions onto a template derived from the circular product design framework (

Supplementary S1).

4. Results

4.1. Case Results

We analysed five design case studies based on their use of the circular composites design method. An overview of the five cases (E1 to E5) is given in

Table 2.

We observed some notable similarities and differences in implementing circular strategies in the case designs.

Table 3 shows the selection of design aspects and strategies used in the development of each case. The combinations of the circular economy strategies and design aspects that were used by the participants are labelled E1, E2, etc., with E1 representing the first case in

Table 2. The green cells indicate design aspects that were identified in a previous study to be relevant to a particular design strategy [

16].

Mapping out the case results (

Table 3) shows that the majority of the identified design aspect implementations align with those suggested by the framework. All circular strategies except structural reuse were used, and the designers selected the design aspects they found relevant to achieve circularity for their case product. This also meant that not all of the suggested design aspect implementations (indicated in green in the table) found recurrence in the cases. On the other hand, additional design aspects were identified for the long life strategy. The use of circular strategies and design aspects in the cases is discussed further in this section.

At the product integrity level, the designers most often selected lifetime extension strategies, while long life and product recovery were addressed to a lesser extent. Long life builds on the resilience of composite materials, which generally grant a long product life. The cases leveraged these materials’ characteristics by facilitating lifetime extension.

At the material integrity level, none of the cases addressed structural reuse, but all addressed material recycling. The strategy of structural reuse aims to preserve the material integrity by repurposing parts or segments [

32]. Structural reuse has specific relevance to large-sized high-performance composite products such as wind turbine blades, which were not amongst the design cases in this study. Material recycling was mostly achieved by selecting appropriate materials and manufacturing techniques. With the exception of the modified particle board (E2), all cases used thermoplastic matrices to warrant recyclability.

The automotive cases focused on the interior components, which are part of a larger vehicle assembly process. The vehicle lifetime, thus, formed a boundary condition for that of individual components. In addition, in the automotive industry, the governing recycling directive [

33] has led to an industry model where vehicles are centrally reprocessed in bulk, for example by INDRA (France) and ARN (the Netherlands) [

34,

35]. E3 and E5, both of which are established players in the automotive sector, decided to focus on bulk recycling into plastic compounds. E4 on the other hand had the opportunity to design a complete vehicle, and planned for the maintenance and refurbishment of parts.

Several design aspects recurred across all projects. For example, dis- and reassembly, connection selection, standardisation, and material selection were used in all cases. The use of design aspects varied depending on the sector considered. For example, the automotive companies made extensive use of material selection, given their focus on recycling. They also all considered function integration through the inclusion of, among others, fasteners or keying during the injection moulding process. The furniture company considered modularity and fasteners as key design aspects. The construction company considered design aspects focused on materiality—namely material selection, cleanability, surface treatments, and manufacturing.

A few design aspects were not used in any of the cases. Functional packaging, malfunction signalling, and redundancy were not used because these were out of scope for the studied cases. We observed three additional design aspects being used for long life, whereby E1 and E5 implemented cleanability and E2 addressed ergonomics and fault isolation. These aspects were not previously identified as being relevant to the long life strategy, supplementing earlier findings [

16]. At the end, the selection and implementation of design aspects depend on multiple factors, such as the nature of the case and the achieved level of detail.

4.2. Evaluation of Method Effectiveness

To evaluate the circular composites design method’s effectiveness, we analysed the cases based on the integrity level (product or material) and the nature of the recovery system (open or closed) (

Table 4). All cases explored both material and product integrity strategies. Mapping out the value chain showed additional recovery pathways, which led to exploring various product integrity strategies. Most notably, lifetime extension through repairs was addressed in all cases. As such, the design method, applied under the guidance of the method developers, provided the designers with other strategies to those of a long lifecycle and recycling.

The designers considered both closed- and open-loop recovery strategies when developing the cases. The lifecycle mapping exploration connected the lifecycle stages, stakeholders, and recovery activities. These connections imply (additional) interactions. This led to E2 considering the inclusion of retailers in the collection and redistribution of used furniture, and E4 considering refurbishment and closed-loop recycling. E1, E3, and E5 considered closed-loop recovery, but found that this approach did not match their business model and industry setting. E1 developed a business model involving the licensing of (re-)processing technology to local vendors, and as such had no further activities in the product lifecycle after production. E3 and E5 were bound by recycling regulations for the automotive industry, and chose to conform to existing vehicle recycling infrastructure. Overall, we found that the method stimulated designers to make an informed choice on which circular strategy to choose and which model to pursue—either open- or closed-loop recovery.

To generate design solutions, the designers used both the strategies and the design aspects to generate ideas. The strategies relate to business models that facilitated the parallel development of business models and product design. The design aspects then relate these strategies to actionable design interventions. One designer (E4) used the design aspects as a guide while designing the case product. This helped to generate ideas outside of their focus on material recycling. E1, on the other hand, mentioned that the method “could have” led to specific design decisions, but ultimately did not apply it because the design was already too constrained prior to their knowledge of the method. This indicates that the circular composites design method facilitates circular product design, but that its effectiveness also relies on the context of the design project.

4.3. Evaluation of Method Accessibility

The accessibility of the design method was assessed by evaluating past theoretical knowledge of design for a circular economy, the practical knowledge or prior experience designers might have, and finally how the designers familiarised themselves with the method. The interview results are summarised in

Table 5 and discussed below.

The designers developed their knowledge and understanding in several ways. In general, they indicated that they relied more on face-to-face knowledge transfer rather than on reading. Courses were not mentioned at all. Of the five experts, three mentioned past professional experience as their only source of theoretical knowledge on CE, while two mentioned personal reading as a source of limited prior theoretical knowledge on CE. For E3 and E5, this was the first time they had engaged in circular economy design activities, and as such these designers had no practical knowledge or prior experience in circular product design.

During the project it was found that the circular design aspects connected to existing and well-known practices from general design and engineering, as well as to related design approaches. Three designers (E2, E3, E5) mentioned that they already had a practical understanding of parts of the method (from previous experience), and so it was easy to apply it in their work. Eco-design [

36] was, for example, mentioned as a related design approach. E3 noted that the technological concepts of eco-design are the same, but the circular economy method provided a different framing of the design goal. Thus, while the framing of the circular economy strategies was new, the design aspects were built on existing practices and technological background in the companies.

The circular product design method was considered well-structured by the experts. E2 commented that the left-to-right listing of circular strategies communicates a visual hierarchy, whereby product integrity strategies are favoured over material integrity. This also brings a clear distinction between strategies and design aspects. It was found that the connection to well-known design and engineering practices made it easy to understand what the design aspects entail and how they can be used. However, the terminology was sometimes found to be confusing. For example, some experts had different definitions of modularity, ranging from enabling parts exchange to reorganising subassemblies. Over the course of the design case studies, these definitions of terms and concepts were clarified and agreed upon by the stakeholders. Thus, the overall structure of the method is clear, but its contents need better descriptions to convey the underlying concepts and definitions.

4.4. Evaluation of Method Usability

To assess the usability, we evaluated the method’s applicability to the design cases and its use (

Table 6). The method was used for different purposes in the various cases: to explore opportunities or challenges, as an idea generator, as an evaluation checklist, as a communication tool, and to detail product concepts.

Four designers (E2, E3, E4, E5) mentioned that they used the method to find opportunities within the design activity. E2 mentioned that the method was useful to help designers consider things they had not considered, “for example, surface treatment”, while E4 mentioned that “it helps the designer understand all the opportunities” presented to them. E3 noted that the method was helpful for understanding the challenges and barriers to creating a circular product: “Many of the strategies are pre-defined by the carmaker, besides recyclability”; as such, the method helped to frame the available design space and its boundary conditions.

The circular composites design method was used in all stages of the basic design cycle. In analysing the case, the lifecycle mapping sheet helped designers to better understand extended time horizons and multiple use cycles. When synthesising, the design aspects were used to generate ideas and develop concepts. In addition to the generative setup of the method, three of the designers (E2, E4, E5) used the framework as an evaluation checklist. The design aspects helped the designer to locate problems in the design and point to specific areas that needed further attention, highlighting missed opportunities for circular product design. In addition to checking the design, it also gave the designers the confidence that they had addressed relevant concerns for circular product design.

Interactions with internal and external stakeholders signalled the need for a common language and shared goals. The circular strategies listed in the method relate to business models and stakeholder actions. The experts further valued the circular composites design method as a communication tool to stimulate discussions between stakeholders and departments in the organisation and with external stakeholders along the product value chain. E1 stated that “the framework (works) more as a communication tool than a design tool”.

5. Discussion

In this study, we evaluated the effectiveness, accessibility, and usability of the circular composites design method in practice. The method was tested in five design case studies in an industry setting, giving insights into the prevailing boundary conditions and ways of working. The method aimed to increase product circularity by design intent through exploring circular strategies and generating associated product concepts.

As expected, there were differences in the method’s effectiveness and the way the designers accessed and used it for their design tasks. Some aspects of the method need further development to meet the demands of and approaches to design practice.

5.1. Validating the Circular Composites Design Method

The first aim, exploring the circular strategies, was achieved in all five design case studies. All cases explored circular strategies by mapping out their product lifecycles on the product lifecycle exploration sheet. The mapping exercise stimulated the designers’ discussions and their assessments of the various recovery routes. Two of the five cases generated circular product proposals. In implementing circular strategies in the design, both cases used design aspects suggested by the method. At the same time, the business models were co-developed to arrive at a circular product proposal. The other three cases explored and considered additional product-integrity-level recovery routes but experienced too many constraints to implement circular solutions. In one case, a strong technological focus contributed to a product development process that was already constrained at the start of the project. The other two cases were constrained in developing circular product solutions by their industry setting.

We recorded the unanticipated use of the design method. We also noticed that the designers tended to use the method to evaluate and communicate design choices, in addition to generating ideas. The method also encouraged iteratively expanding the scope in consecutive design cycles. Changes could be made in a controllable way, increasing the circularity of the product in question step-by-step without overwhelming the designer. Thus, the method allowed for some flexibility in use. Such flexibility in applying a method in the design process is likely to increase its effectiveness [

27].

Overall, we saw a number of strategies and design aspects not being selected in the cases. This was not unexpected, as the framework targets composite products in general [

16]. This means that it should be applicable for designers from various backgrounds and industry settings. On the other hand, this broad scope implies that not all content is relevant to each case. Both the method and the design framework could be adapted to meet specific demands; for example, by selecting design aspects based on a specific industry sector.

The company, policy, and industry contexts determined the implementation of the circular principles. The context in which a design method is used is an important but often overlooked factor for its success [

22]. By developing the design method in context, we have addressed some of these concerns, but still improvements can be made. The method could improve on the terminology, for example, by illustrating design aspects with examples to show its typical implementation in design.

5.2. Designing Products for a Circular Economy

The scope for redesign in our cases was large; they were developed in an industry innovation project that stimulated participants to experiment with circular product design and its associated business models and materials. However, the existing infrastructure for recovery and reprocessing creates a lock-in that is hard to break [

25], especially for the large companies—such as in automotive cases E3 and E5. These systems are typically set up in a linear rather than a circular fashion, and as such do not support circular design strategies [

13]. Thus, a broader perspective on the production and consumption system is necessary to actually make the shift to circular products. Such systems thinking has been the basic premise of transitioning to the circular economy [

1].

We noted a heavy focus on recycling as a key strategy for four of the five cases. Recycling has a low preference in the waste management hierarchy and R-frameworks [

37,

38], while it is a well-understood approach to circularity. It also is an easy approach to incorporate into existing business models, albeit with a need to comply to industry-specific regulation, such as the End-of-Life Vehicles Directive [

33]. Thus, the governing policy and existing industry structures create a lock-in, which may restrict the outcomes of a circular design processes.

5.3. Contributions

The findings in this study contribute to both the research and practice in the field of designing products containing composite materials for a circular economy. The design case analysis provides a further grounding of the circular strategies and design aspects identified for products containing composites in a circular economy. The developed design method supports designers in exploring, selecting, and realising circular strategies for their specific product case, and was validated here in five industry cases. This validation showed that the method is considered accessible, usable, and effective. It is expected that these validation results, together with the developed product demonstrators, will contribute to the further acceptance of the method in practice.

Earlier studies stressed the importance of collaboration along the product value chain to instill change and move towards a circular economy [

1,

12]. The circular composites method addresses this need, as it helps to keep stakeholders involved with the design activities and to broaden their view to other expertise areas, such as logistics and business models. On the other hand, the presented design case studies confirm the limitations posed by the existing policy and industry context [

13].

6. Limitations and Recommendations

The interview and questionnaire enabled reflection on the design results and process as a whole. The responses, however, may have been biased by the reflective nature of the method. Moreover, the expert’s confidence, combined with the high level of freedom in the design process, may have lowered the perceived impacts of the method on the design process [

27]. Such subjectivity in reflection was partially counteracted by inviting the participants to share intermediate results in the interview, anchoring their reflections to achieved results.

Throughout the interviews it appeared that the terminology related to composite design in a circular economy is yet to be fully developed. The strategy of structural reuse and several design aspects were not well understood by the designers. Some designers found the terminology too academic. On the other hand, academics argue that the concept of circular economy has been developed too much in practice and falls short on scientific grounding [

2,

3,

4]. We, therefore, recommend that the terminology be developed and agreed on within a stakeholder group to remove barriers to implementing the circular economy, including the circular composites design method. To improve the accessibility of the method to a broader audience, the strategies and design aspects require more elaborate clarification.

In this study, we analysed 5 design cases from 3 industry sectors. This number of cases limits the generalisation of the results to the composites industry at large. Nevertheless, the study provided interesting insights on using the design method in industry practice. We recommend performing similar design case studies in other industry sectors and product categories. These cases can also be used as examples to present and disseminate the method, an approach also taken for other design guidelines (see e.g., [

39]). Further case studies could also elicit and detail the implementation of circular strategies and design aspects, extending the relevance of the method to more sectors.

7. Conclusions

Despite the opportunities and challenges composites offer for designing products for a circular economy, this materials group was not yet explicitly addressed in circular design methods. To address this gap, we developed a novel design method. With this method, we aimed to increase product circularity by design intent through (1) exploring circular strategies using a lifecycle exploration sheet and (2) generating associated product concepts by indicating relevant design aspects based on a strategy-design aspect framework. In this study, we evaluated the effectiveness, accessibility, and usability of the circular composites design method in five design case studies.

The circular composites design method provided an entry point to approach the circular product design process. This starts with mapping out the product lifecycle and recovery opportunities. The method can be used to iteratively extend the scope of the design project to include additional lifecycle and reuse concerns. In addition to its direct use in exploring and generating design solutions, the method provides a framing of the circular design process that supports project organisation and communication.

The first aim, exploring circular strategies, was achieved in all five design case studies. The method seemed effective in exploring circular strategies in the product lifecycle. The lifecycle exploration sheet stimulated discussion among stakeholders and aligned business model development with product design. These interactions delivered explicit product design requirements and an initial selection of strategies to be considered in the design. The second aim, generating circular product concepts, was partially achieved. The method effectively supported designers in developing circular product design solutions; however, for some cases the implementation was restricted by the context in which they operated. Even though product-level recovery strategies were considered, three of the five cases remained within the existing material recycling pathways. The product recyclability relied heavily on the materials selection, with small adaptations made to other design aspects.

The design method was considered accessible. The method, with its underlying lifecycle mapping sheet and design framework, is well-structured and reflects the prioritisation of recovery strategies in a circular economy. The design aspects build on well-known industry approaches and practices, and support the designers in realising circular economy strategies in their product designs.

Composite materials present many opportunities and challenges for a circular economy, and specific attention has to be paid to material development, design, business models, and recovery processes. The method presented in this article supports designers in integrating these aspects in the design process for composite-containing products in a circular economy.