Influence of Trust Relationships with Suppliers on Manufacturer Resilience in COVID-19 Era

Abstract

1. Introduction

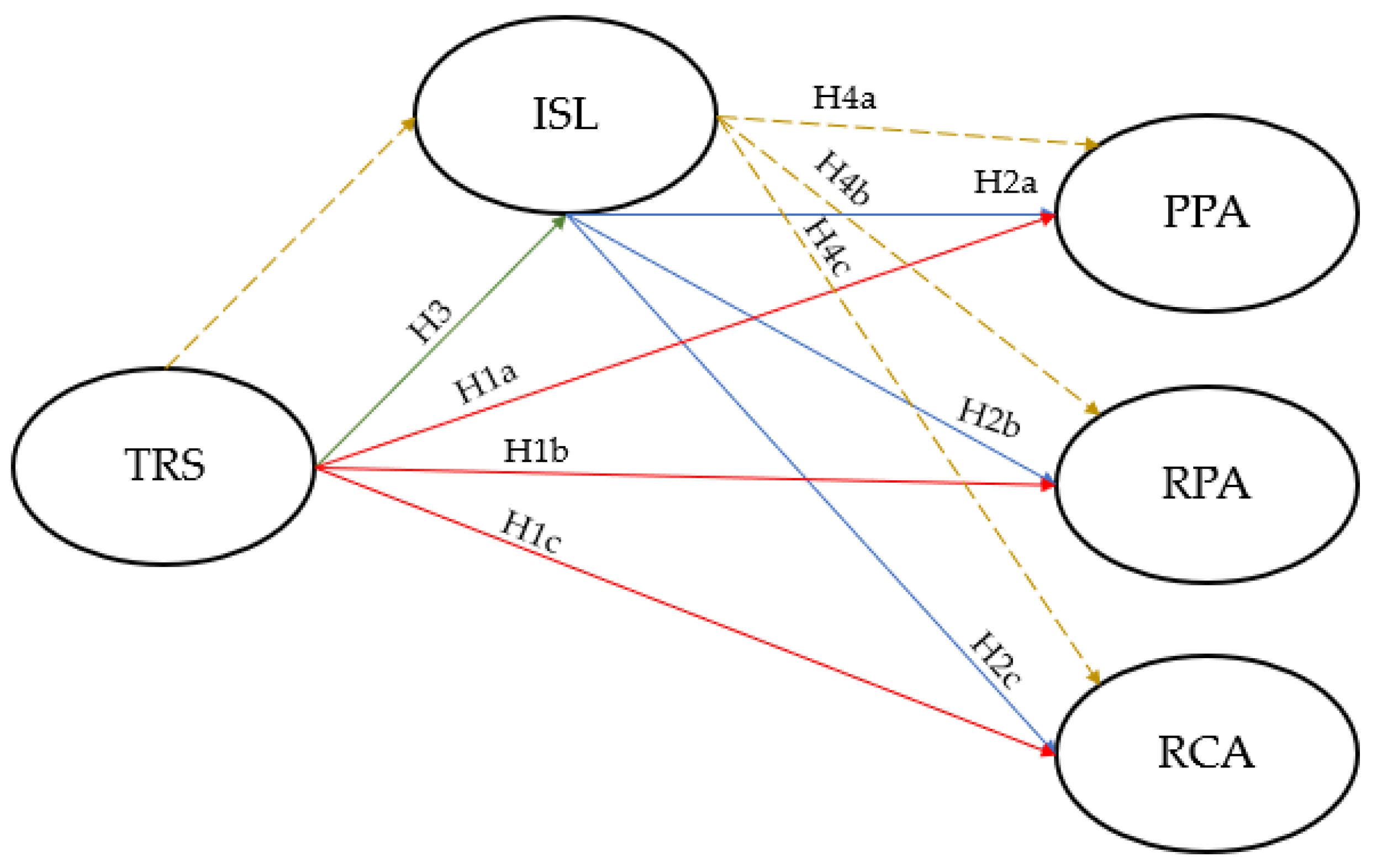

2. Literature Review and Research Hypotheses

2.1. Manufacturer Resilience

2.2. Trust Relationship with Suppliers and Manufacturer Resilience

2.3. Information-Sharing Level and Resilience

2.4. Mediating Role of Information-Sharing Level

2.5. Current Research Technicals

3. Methodology

3.1. Study Design

3.2. Sampling and Data Collection

3.3. Measures of Constructs

3.3.1. Trust Relationship with Suppliers

3.3.2. Manufacturer Resilience

3.3.3. Information-Sharing Level

3.4. Nonresponse Bias and Common Method Variance

3.5. Exploratory Factor Analysis

3.6. Validity and Reliability

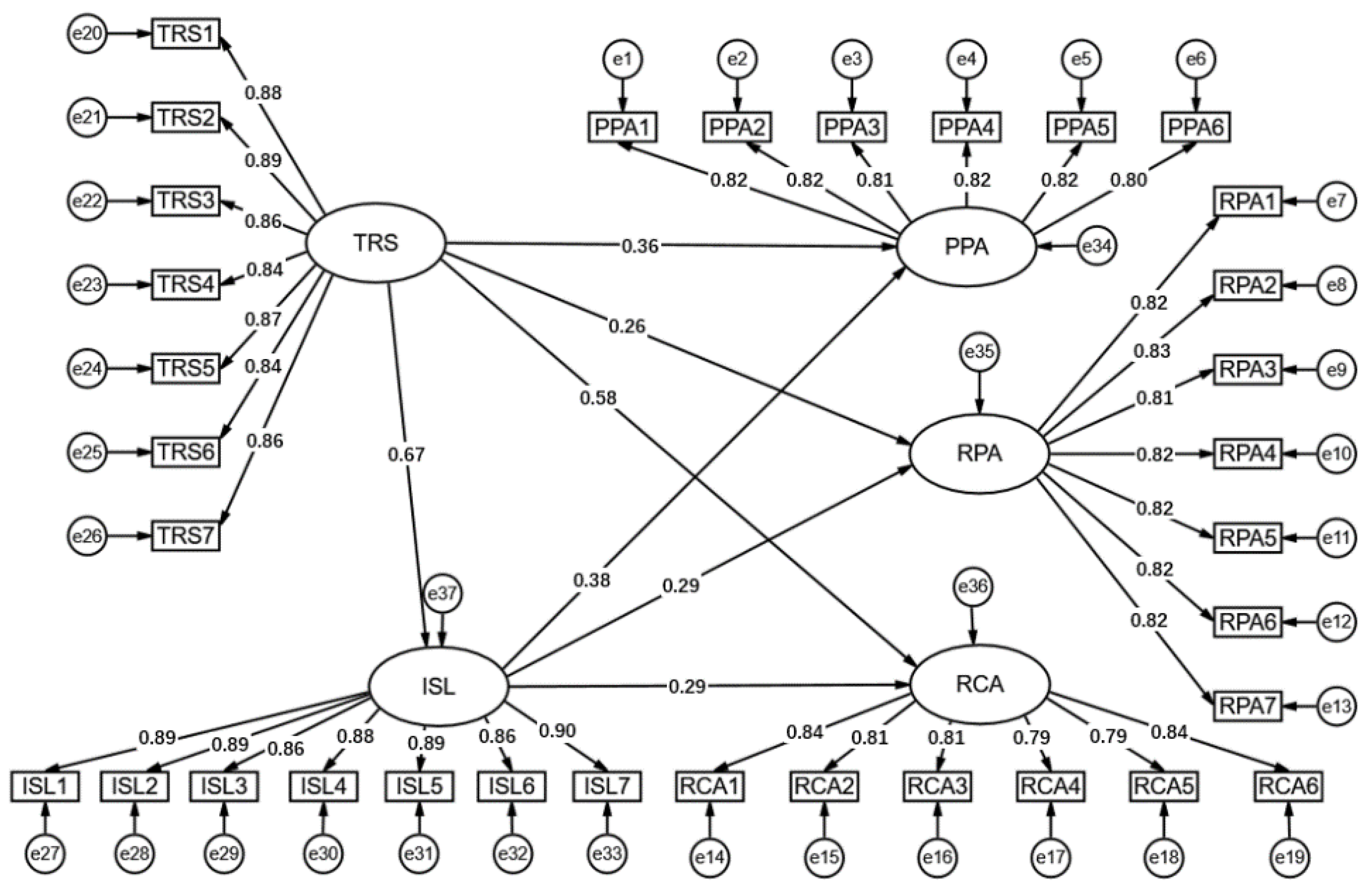

4. Structural Equation Model (SEM) Analysis

5. Discussion and Implications

5.1. Discussion

5.2. Contributions

5.3. Theoretical Implications

5.4. Practical Implications

6. Conclusions and Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Siagian, H.; Tarigan, Z.J.H.; Jie, F. Supply chain integration enables resilience, flexibility, and innovation to improve business performance in COVID-19 Era. Sustainability 2021, 13, 4669. [Google Scholar] [CrossRef]

- Lam, J.S.L.; Bai, X.A. Quality function deployment approach to improve maritime supply chain resilience. Transp. Res. E-Logist. 2016, 92, 16–27. [Google Scholar] [CrossRef]

- Rajesh, R. On Sustainability, resilience, and the sustainable–resilient supply networks. Sustain. Prod. Consump. 2018, 15, 74–88. [Google Scholar] [CrossRef]

- Majumdar, A.; Shaw, M.; Sinha, S.K. COVID-19 Debunks the myth of socially sustainable supply chain: A case of the clothing industry in south asian countries. Sustain. Prod. Consump. 2020, 24, 150–155. [Google Scholar] [CrossRef]

- Kazancoglu, Y.; Sezer, M.D.; Ozbiltekin-Pala, M.; Lafçı, Ç.; Sarma, P.R.S. Evaluating resilience in food supply chains during COVID-19. Int. J. Logist. Manag. 2021, 1–17, Ahead-of-print. [Google Scholar] [CrossRef]

- Blowfield, K.; Candogan, O.; Ehsani, S. Supply disruptions and optimal network structures. Manag. Sci. 2019, 65, 5504–5517. [Google Scholar] [CrossRef]

- Xu, S.; Zhang, X.; Feng, L. Disruption risks in supply chain management: A literature review based on bibliometric analysis. Int. J. Prod. Res. 2020, 58, 3508–3526. [Google Scholar] [CrossRef]

- Yu, D.E.C.; Razon, L.F.; Tan, R.R. Can global pharmaceutical supply chains scale up sustainably for the COVID-19 crisis? Resour. Conserv. Recycl. 2020, 159, 104868. [Google Scholar] [CrossRef]

- Ambulkar, S.; Blackhurst, J.; Grawe, S. Firm’s resilience to supply chain disruptions: Scale development and empirical examination. J. Oper. Manag. 2015, 33, 111–122. [Google Scholar] [CrossRef]

- Parker, H.; Ameen, K. The role of resilience capabilities in shaping how firms respond to disruptions. J. Bus. Res. 2018, 88, 535–541. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. OR-methods for coping with the ripple effect in supply chains during COVID-19 pandemic: Managerial insights and research implications. Int. J. Prod. Econ. 2021, 232, 107921. [Google Scholar] [CrossRef]

- Heide, J.B. Interorganizational governance in marketing channels. J. Mark. 1994, 58, 71–85. [Google Scholar] [CrossRef]

- Christopher, M.; Peck, H. Building the resilient supply chain. Int. J. Logist. Manag. 2004, 15, 1–14. [Google Scholar] [CrossRef]

- Hohenstein, N.O.; Feisel, E.; Hartmann, E.; Giunipero, L. Research on the phenomenon of supply chain resilience: A systematic review and paths for further investigation. Int. J. Phys. Distr. Log. 2015, 45, 90–117. [Google Scholar] [CrossRef]

- Tukamuhabwa, B.R.; Stevenson, M.; Busby, J.; Zorzini, M. Supply chain resilience: Definition, review and theoretical foundations for further study. Int. J. Prod. Res. 2015, 53, 1–32. [Google Scholar] [CrossRef]

- Handfield, R.B.; Graham, G.; Burns, L. Corona virus, tariffs, trade wars and supply chain evolutionary design. Int. J. Oper. Prod. Manag. 2020, 40, 1649–1660. [Google Scholar] [CrossRef]

- Gao, Y.; Feng, Z.; Zhang, S.B. Managing supply chain resilience in the era of VUCA. Front. Eng. Manag. 2021, 8, 465–470. [Google Scholar] [CrossRef]

- Dubey, R.; Altay, N.; Gunasekaran, A.; Blome, C.; Papadopoulos, T.; Childe, S.J. Supply chain agility, adaptability and alignment: Empirical evidence from the Indian auto components industry. Int. J. Oper. Prod. Manag. 2018, 38, 129–148. [Google Scholar] [CrossRef]

- Liu, L.; Gong, L.J.; Shi, W.Q. Three-stage supply chain coordination of emergency quantity discount contract. Comput. Integr. Manuf. 2016, 22, 1599–1607. [Google Scholar] [CrossRef]

- Chu, Z.F.; Lai, F.J.; Wang, L.L. Leveraging interfirm relationships in China: Western relational governance or guanxi? Domestic versus foreign firms. J. Int. Mark. 2020, 28, 58–74. [Google Scholar] [CrossRef]

- Bonatto, F.; Resende, L.M.M.; Pontes, J. Relational governance in supply chain: A systematic literature review. Benchmarking Int. J. 2020, 27, 1711–1741. [Google Scholar] [CrossRef]

- Li, Y.E.; Xie, H.; Teo, H.; Peng, M.W. Formal control and social control in domestic and international buyer-supplier relationships. J. Oper. Manag. 2010, 28, 333–344. [Google Scholar] [CrossRef]

- Wieland, A.; Marcus Wallenburg, C.M. The influence of relational competencies on supply chain resilience: A relational view. Int. J. Phys. Distr. Log. 2013, 43, 300–320. [Google Scholar] [CrossRef]

- Yu, W.; Jacobs, M.A.; Chavez, R.; Yang, J. Dynamism, disruption orientation, and resilience in the supply chain and the impacts on financial performance: A dynamic capabilities perspective. Int. J. Prod. Econ. 2019, 218, 352–362. [Google Scholar] [CrossRef]

- Ghosh, A.; Fedorowicz, J. The role of trust in supply chain governance. Bus. Process Manag. J. 2008, 14, 453–470. [Google Scholar] [CrossRef]

- Lu, H.E.; Potter, A.; Rodrigues, V.S.; Walker, H. Exploring sustainable supply chain management: A social network perspective. Supply Chain Manag. 2018, 23, 257–277. [Google Scholar] [CrossRef]

- Chiles, T.H.; McMackin, J.R. Integrating variable risk preferences, trust, and transaction cost economics. Acad. Manag. J. 1996, 21, 73–99. [Google Scholar] [CrossRef]

- Naghshineh, B.; Lotfi, M. Enhancing supply chain resilience: An empirical investigation. Contin. Resil. Rev. 2019, 1, 47–62. [Google Scholar] [CrossRef]

- Scholten, K.; Schilder, S. The role of collaboration in supply chain resilience. Supply Chain Manag. 2015, 20, 471–484. [Google Scholar] [CrossRef]

- Faruquee, M.; Paulraj, A.; Irawan, C.A. Strategic supplier relationships and supply chain resilience: Is digital transformation that precludes trust beneficial? Int. J. Oper. Prod. Manag. 2021, 41, 1192–1219. [Google Scholar] [CrossRef]

- Wu, I.L.; Chuang, C.H.; Hsu, C.H. Information sharing and collaborative behaviors in enabling supply chain performance: A social exchange perspective. Int. J. Prod. Econ. 2014, 148, 122–132. [Google Scholar] [CrossRef]

- Wang, Y.; Li, G.H.; Lu, H.L.; Huang, L. The impact of relational governance on b2b brand performance. Chin. J. Manag. 2021, 18, 1040–1048. [Google Scholar]

- Feng, H.; Liang, L.L. Research on the interaction between firm’s relationship capital and supply chain capability-based on the perspective of information sharing capability and supply chain flexibility. J. China Univ. Geosci. 2016, 16, 122–133. [Google Scholar] [CrossRef]

- Stephen, E.; Michael, D.H.; Christian, S. Supplier Relationship Management: How to Maximize Vendor Value and Opportunity; Apress LP: Berkeley, CA, USA, 2014; pp. 144–155. [Google Scholar]

- Villena, V.H.; Choi, T.Y.; Revilla, E. Revisiting interorganizational trust: Is more always better or could more be worse? J. Manag. 2019, 45, 752–785. [Google Scholar] [CrossRef]

- Diogo, C.; Fabrizio, S. Exploring the antecedents of organizational resilience practices–A transactive memory systems approach. Int. J. Oper. Prod. Manag. 2020, 40, 1531–1559. [Google Scholar] [CrossRef]

- Gligor, D.M.; Esmark, C.L.; Holcomb, M.C. Performance outcomes of supply chain agility: When should you be agile? J. Oper. Manag. 2015, 33, 71–82. [Google Scholar] [CrossRef]

- Sinha, P.C. Disaster Mitigation Preparedness, Recovery and Response; SBS Publishers and Distributors Pvt. Ltd.: New Delhi, India, 2006. [Google Scholar]

- Srinivasan, M.; Mukherjee, D.; Gaur, A.S. Buyer–supplier partnership quality and supply chain performance: Moderating role of risks, and environmental uncertainty. Eur. Manag. J. 2011, 29, 260–271. [Google Scholar] [CrossRef]

- Tarigan, Z.J.H.; Mochtar, J.; Basana, S.R.; Siagian, H. The effect of competency management on organizational performance through supply chain integration and quality. Uncertain Supply Chain Manag. 2021, 9, 283–294. [Google Scholar] [CrossRef]

- Liu, C.L.; Lee, Y.M. Integration, supply chain resilience, and service performance in third-party logistics providers. Int. J. Logist. Manag. 2018, 29, 5–21. [Google Scholar] [CrossRef]

- Brandon-Jones, E.; Squire, B.; Autry, C.W.; Petersen, K.J. A contingent resource-based perspective of supply chain resilience and robustness. J. Supply Chain Manag. 2014, 50, 55–73. [Google Scholar] [CrossRef]

- Juttner, U.; Maklan, S. Supply chain resilience in the global financial crisis: An empirical study. Supply Chain Manag. 2011, 16, 246–259. [Google Scholar] [CrossRef]

- Srinivasan, R.; Swink, M. An investigation of visibility and flexibility as complements to supply chain analytics: An organizational information processing theory perspective. Prod. Oper. Manag. 2018, 27, 1849–1867. [Google Scholar] [CrossRef]

- Manning, L.; Soon, J.M. Building strategic resilience in the food supply chain. Brit. Food J. 2016, 118, 1477–1493. [Google Scholar] [CrossRef]

- Liu, C.L.; Shang, K.C.; Lirn, T.C.; Lai, K.H.; Lun, Y.H. Supply chain resilience, firm performance, and management policies in the liner shipping industry. Transp. Res. Part A Policy Pract. 2018, 110, 202–219. [Google Scholar] [CrossRef]

- Bode, C.; Macdonald, J.R. Stages of supply chain disruption response: Direct, constraining, and mediating factors for impact mitigation. Decis. Sci. 2017, 48, 836–874. [Google Scholar] [CrossRef]

- Bowers, C.; Kreutzer, C.; Cannon-Bowers, J.; Lamb, J. Team resilience as a second-order emergent state: A theoretical model and research directions. Front. Psychol. 2017, 8, 1360. [Google Scholar] [CrossRef]

- Fattahi, M.; Govindan, K.; Keyvanshokooh, E. Responsive and resilient supply chain network design under operational and disruption risks with delivery lead-time sensitive customers. Logist. Transp. Rev. 2017, 101, 176–200. [Google Scholar] [CrossRef]

- Chiffoleau, Y.; Brit, A.C.; Monnier, M.; Akermann, G.; Lenormand, M.; Saucède, F. Coexistence of supply chains in a city’s food supply: A factor for resilience? Rev. Agric. Food Environ. Stud. 2020, 101, 391–414. [Google Scholar] [CrossRef]

- Stone, J.; Rahimifard, S. Resilience in Agri-Food supply chains: A critical analysis of the literature and synthesis of a novel framework. Supply Chain Manag. 2018, 23, 207–238. [Google Scholar] [CrossRef]

- Azadegan, A.; Parast, M.M.; Lucianetti, L.; Nishant, R.; Blackhurst, J. Supply chain disruptions and business continuity: An empirical assessment. Decis. Sci. 2020, 51, 38–73. [Google Scholar] [CrossRef]

- Li, X.; Wu, Q.; Holsapple, C.W.; Goldsby, T. An empirical examination of firm financial performance along dimensions of supply chain resilience. Manag. Res. Rev. 2017, 40, 254–269. [Google Scholar] [CrossRef]

- Zaheer, A.; Venkatraman, N. Relational governance as an interorganizational strategy: An empirical test of the role of trust in economic exchange. Strateg. Manag. J. 1995, 16, 373–392. [Google Scholar] [CrossRef]

- Rousseau, D.M.; Sitkin, S.B.; Burt, R.S.; Camerer, C. Not so different after all: A cross-discipline view of trust. Acad. Manag. Rev. 1998, 23, 393–404. [Google Scholar] [CrossRef]

- Lewicki, R.J.; Tomlinson, E.C.; Gillespie, N. Models of interpersonal trust development: Theoretical approaches, empirical evidence, and future directions. J. Manag. 2016, 32, 991–1022. [Google Scholar] [CrossRef]

- Li, T.; Qiao, C.L.; Yang, P. Function mechanism of supply chain inter-firm trust on supply chain enterprises organizational improvisation: Based on study of supply chain flexibility and transitive memory system. Nankai Bus. Rev. Nt. 2018, 21, 74–84. [Google Scholar]

- Poppo, L.; Zhou, K.Z.; Li, J.J. When can you trust ‘trust’? Calculative trust, relational trust, and supplier performance. Strateg. Manag. J. 2016, 37, 724–741. [Google Scholar] [CrossRef]

- Ye, F.; Xu, X.J. Impact of trust and relationship commitment among supply chain partners on information sharing and operational performance. Syst. Eng. Theory Pract. 2009, 29, 36–49. [Google Scholar]

- Zhang, X.M.; Chen, W. Trust, relationship commitment and cooperative performance in supply chain—An empirical study based on the perspective of knowledge trading. Stud. Sci. Sci. 2011, 29, 1865–1874. [Google Scholar] [CrossRef]

- Das, T.K.; Teng, B.S. Trust, control, and risk in strategic alliances: An integrated framework. Organ. Stud. 2001, 22, 251–283. [Google Scholar] [CrossRef]

- Fernandez, O.M. The moderating role of trust in contractual choice. Br. Food J. 2011, 113, 374–390. [Google Scholar] [CrossRef]

- He, Y.; Lai, K.K.; Sun, H.; Chen, Y. The impact of supplier integration on customer integration and new product performance: The mediating role of manufacturing flexibility under trust theory. Int. J. Prod. Econ. 2014, 147, 260–270. [Google Scholar] [CrossRef]

- Doney, P.M.; Cannon, J.P. An examination of the nature of trust in buyer–seller relationships. J. Mark. 1997, 61, 35–51. [Google Scholar] [CrossRef]

- Poppo, L.; Zhou, K.Z.; Kevin, Z.; Ryu, S. Alternative origins to interorganizational Trust: An interdependence perspective on the shadow of the past and the shadow of the Future. Organ. Sci. 2008, 19, 39–55. [Google Scholar] [CrossRef]

- Wang, Z.; Ye, F.; Tan, K.H. Effects of managerial ties and trust on supply chain information sharing and supplier opportunism. Int. J. Prod. Res. 2014, 52, 7046–7061. [Google Scholar] [CrossRef]

- Cadden, T.; Marshall, D.; Cao, G. Opposites Attract: Organisational Culture and Supply Chain Performance. Supply Chain Manag. 2013, 18, 86–103. [Google Scholar] [CrossRef]

- Vlachos, P.I.; Bourlakis, M. Supply chain collaboration between retailers and manufacturers, do they trust each other? Supply Chain Forum Int. J. 2006, 7, 70–80. [Google Scholar] [CrossRef]

- Hou, Y.Z.; Wang, X.L.; Wu, Y.C.; He, P.X. How does the trust affect the topology of supply chain network and its resilience? An agent-based approach. Transp. Res. E-Logist. 2018, 116, 229–241. [Google Scholar] [CrossRef]

- Dyer, J.H.; Singh, H. The relational view: Cooperative strategy and sources of inter-organisational competitive advantage. Acad. Manag. Rev. 1998, 23, 660–679. [Google Scholar] [CrossRef]

- McEvily, B.; Marcus, A. Embedded ties and the acquisition of competitive capabilities. Strateg. Manag. J. 2005, 26, 1033–1055. [Google Scholar] [CrossRef]

- Bode, C.; Wagner, S.M.; Petersen, K.; Ellram, L. Understanding responses to supply chain disruptions: Insights from information processing and resource dependence perspectives. Acad. Manag. J. 2011, 54, 833–856. [Google Scholar] [CrossRef]

- Cook, K. Trust in Society; Sage: New York, NY, USA, 2003. [Google Scholar]

- Faisal, M.; Banwet, D.; Shankar, R. Information risks management in supply chains: An assessment and mitigation framework. J. Enterp. Inf. Manag. 2007, 20, 677–699. [Google Scholar] [CrossRef]

- Mandal, S.; Sarathy, R.; Korasiga, V.R.; Bhattacharya, S.; Dastidar, S.G. Achieving supply chain resilience: The contribution of logistics and supply chain capabilities. Int. J. Disaster Resil. 2016, 7, 544–562. [Google Scholar] [CrossRef]

- Spekman, R.E.; Kamauff, J.W., Jr.; Myhr, N. An empirical investigation into supply chain management: A perspective on partnerships. Int. J. Phys. Distr. Logist. 1998, 28, 630–650. [Google Scholar] [CrossRef]

- Oliveira, N.; Lumineau, F. The dark side of interorganizational relationships: An integrative review and research agenda. J. Manag. 2019, 45, 231–261. [Google Scholar] [CrossRef]

- Dyer, J.H.; Singh, H.; Hesterly, W.S. The relational view revisited: A dynamic perspective on value creation and value capture. Strateg. Manag. J. 2018, 39, 3140–3162. [Google Scholar] [CrossRef]

- Kumar, P.; Kumar, S.R. Strategic framework for developing resilience in agri-food supply chains during COVID 19 pandemic. Int. J. Logist.-Res. Appl. 2021. [Google Scholar] [CrossRef]

- Sarkis, J.; Gonzalez-Torre, P.; Adenso-Diaz, B. Stakeholder pressure and the adoption of environmental practices: The mediating effect of training. J. Oper. R Manag. 2010, 28, 163–176. [Google Scholar] [CrossRef]

- Fan, Y.Y.; Stevenson, M.; Li, F. Supplier-initiating risk management behaviour and supply-side resilience: The effects of interpersonal relationships and dependence asymmetry in buyer-supplier relationships. Int. J. Oper. Prod. Manag. 2020, 40, 971–995. [Google Scholar] [CrossRef]

- Frohlich, M.T.E. Integration in the supply chain: Barriers and performance. Decis. Sci. 2002, 33, 537–556. [Google Scholar] [CrossRef]

- Kumar, S.; Raut, R.D.; Narwane, V.S.; Narkhede, B.E. Applications of industry 4.0 to overcome the COVID-19 operational challenges. Diabetes Metab. Syndr. Clin. Res. Rev. 2020, 14, 1283–1289. [Google Scholar] [CrossRef]

- Li, G.; Yang, H.; Sun, L. The impact of IT implementation on supply chain integration and performance. Int. J. Prod. Econ. 2009, 120, 125–138. [Google Scholar] [CrossRef]

- Philip, G.; Booth, M.E. A new six ‘S’ framework on the relationship between the role of information systems (IS) and competencies in ‘IS’ management. J. Bus. Res. 2001, 51, 233–247. [Google Scholar] [CrossRef]

- Daugherty, P.J. Review of logistics and supply chain relationship literature and suggested research agenda. Int. J. Phys. Distr. Logist. 2011, 41, 16–33. [Google Scholar] [CrossRef]

- Piprani, A.Z.; Mohezar, S.; Jaafar, N.I. Supply chain integration and supply chain performance: The mediating role of supply chain resilience. Int. J. Supply Chain Manag. 2020, 9, 58–73. [Google Scholar]

- Munir, M.; Sadiq, J.M.S.; Chatha, K.A.; Farooq, S. Supply chain risk management and operational performance: The enabling role of supply chain integration. Int. J. Prod. Econ. 2020, 227, 107667. [Google Scholar] [CrossRef]

- Ding, M.J.; Jie, F.; Parton, K.A.; Matanda, M.J. Relationships between quality of information sharing and supply chain food quality in the australian beef processing industry. Int. J. Logist. Manag. 2014, 25, 85–108. [Google Scholar] [CrossRef]

- Trivellas, P.; Malindretos, G.; Reklitis, P. Implications of green logistics management on sustainable business and supply chain performance: Evidence from a survey in the Greek Agri-Food sector. Sustainability 2020, 12, 10515. [Google Scholar] [CrossRef]

- Reklitis, P.; Sakas, D.P.; Trivellas, P.; Tsoulfas, G.T. Performance implications of aligning supply chain practices with competitive advantage: Empirical evidence from the Agri-Food sector. Sustainability 2021, 13, 8734. [Google Scholar] [CrossRef]

- Parashar, S.; Sood, G.; Agrawal, N. Modelling the enablers of food supply chain for reduction in carbon footprint. J. Clean Prod. 2020, 275, 122932. [Google Scholar] [CrossRef]

- Aslam, H.; Khan, A.Q.; Rashid, K.; Rehman, S.-U. Achieving supply chain resilience: The role of supply chain ambidexterity and supply chain agility. J. Manuf. Technol. Manag. 2020, 31, 1185–1204. [Google Scholar] [CrossRef]

- Prajogo, D.; Olhager, J. Supply chain integration and performance: The effects of long-term relationships, information technology and sharing, and logistics integration. Int. J. Prod. Econ. 2012, 135, 514–522. [Google Scholar] [CrossRef]

- Xu, K.; Dong, Y.; Evers, P.T. Towards better coordination of the supply chain. Transp. Res. E-Logist. 2001, 37, 35–54. [Google Scholar] [CrossRef]

- Pulkkinen, M.; Naumenko, A.; Luostarinen, K. Managing information security in a business network of machinery maintenance services business-enterprise architecture as a coordination tool. J. Syst. Softw. 2007, 80, 1607–1620. [Google Scholar] [CrossRef]

- Bharadwaj, A.S. A Resource-based perspective on information technology capability and firm performance: An empirical investigation. MIS Quart. 2000, 24, 169–196. [Google Scholar] [CrossRef]

- Müller, M.; Gaudig, S. An empirical investigation of antecedents to information exchange in supply chains. Int. J. Prod. Res. 2011, 49, 1531–1555. [Google Scholar] [CrossRef][Green Version]

- Sinha, P.R.; Whitman, L.E.; Malzahn, D. Methodology to mitigate supplier risk in an aerospace supply chain. Supply Chain Manag. 2004, 9, 154–168. [Google Scholar] [CrossRef]

- Zhang, Q.H.; Liu, Z.Y.; Yan, J. Information technology and relational governance: The moderating effect of special investment. Nankai Bus. Rev. Nt. 2010, 13, 125–133. [Google Scholar]

- Paulraj, A.; Lado, A.A.; Chen, I.J. Inter-organisational communication as a relational competency: Antecedents and performance outcomes in collaborative buyer–supplier relationships. J. Oper. Manag. 2008, 26, 45–64. [Google Scholar] [CrossRef]

- Kwon, I.W.G.; Suh, T. Factors affecting the level of trust and commitment in supply chain relationships. J. Supply Chain Manag. 2004, 40, 4–14. [Google Scholar] [CrossRef]

- Mohr, J.; Spekman, R. Characteristics of partnership success-partnership attributes, communication behavior, and conflict-resolution techniques. Strateg. Manag. J. 1994, 15, 135–152. [Google Scholar] [CrossRef]

- Moshtari, M. Inter-Organizational fit, relationship management capability, and collaborative performance within a humanitarian setting. Prod. Oper. Manag. 2016, 25, 1542–1557. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Roubaud, D.; Wamba, S.F.; Giannakis, M.; Foropon, C. Big Data analytics and organizational culture as complements to swift trust and collaborative performance in the humanitarian supply chain. Int. J. Prod. Econ. 2019, 210, 120–136. [Google Scholar] [CrossRef]

- Li, S.C.; Yang, G.Q. Research on the impact of IT capability and information sharing against the R&D collaboration between enterprises. Sci. Res. Manag. 2008, 29, 55–63. [Google Scholar] [CrossRef]

- Shan, S.; Luo, Y.; Zhou, Y.; Wei, Y. Big Data analysis adaptation and enterprises’ competitive advantages: The perspective of dynamic capability and resource-based theories. Technol. Anal. Strateg. 2019, 31, 406–420. [Google Scholar] [CrossRef]

- Nandi, M.L.; Nandi, S.; Moya, H.; Kaynak, H. Blockchain technology-enabled supply chain systems and supply chain performance: A resource-based view. Supply Chain Manag. 2020, 25, 841–862. [Google Scholar] [CrossRef]

- Chin, W.W. The Partial Least Squares Approach to Structural Equation Modeling. Modern Methods for Business Research; Marcoulides, G.A., Ed.; Erlbaum: Mahwah, NJ, USA, 1998; pp. 295–358. [Google Scholar]

- Nunnally, J. Psychometric Methods; McGraw-Hill: New York, NY, USA, 1978. [Google Scholar]

- Baron, R.M.; Kenny, D.A. The moderator-mediator variable distinction in social psychological research: Conceptual, strategic, and statistical considerations. J. Pers. Soc Psychol. 1986, 51, 1173–1182. [Google Scholar] [CrossRef]

- MacKinnon, D. Introduction to Statistical Mediation Analysis; Routledge: London, UK, 2008. [Google Scholar]

- Preacher, K.J.; Hayes, A.F. SPSS and SAS procedures for estimating indirect effects in simple mediation models. Behav. Res. Methods Instrum. Comput. 2004, 36, 717–731. [Google Scholar] [CrossRef]

- Kroes, J.R.; Ghosh, S. Outsourcing congruence with competitive priorities: Impact on supply chain and firm performance. J. Oper. Manag. 2010, 28, 124–143. [Google Scholar] [CrossRef]

- Riley, J.M.; Klein, R.; Miller, J.; Sridharan, V. How internal integration, information sharing, and training affect supply chain risk management capabilities. Int. J. Phys. Distr. Logist. 2016, 46, 953–980. [Google Scholar] [CrossRef]

- Feng, H.; Nie, L.; Hai, F. Research on the interaction between information sharing level and SC capability: A Mediating Effect of Social Control. Nankai Bus. Rev. Nt. 2018, 21, 85–92. [Google Scholar]

- Podsakoff, P.M.; Mackenzie, S.B.; Lee, J.Y.; Podsakoff, N.P. Common method biases in behavioral research: A critical review of the literature and recommended remedies. J. Appl. Psychol. 2003, 88, 879–903. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Giglio, R.; Dun, D.H. Industry 4.0 adoption as a moderator of the impact of lean production practices on operational performance improvement. Int. J. Oper. Prod. Manag. 2019, 39, 860–886. [Google Scholar] [CrossRef]

- Mitchell, T. An evaluation of the validity of correlational research conducted in organisations. Acad. Manag. Rev. 1985, 10, 192. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; Organ, D.W. Self-reports in organizational research-problems and prospects. J. Manag. 1986, 12, 531–544. [Google Scholar] [CrossRef]

- Williams, L.J.; Cote, J.A.; Buckley, M.R. Lack of method variance in self-reported affect and perceptions at work: Reality or artifact. J. Appl. Psychol. 1989, 74, 462–468. [Google Scholar] [CrossRef]

- Li, G.; Li, L.; Choi, T.M.; Sethi, S.P. Green supply chain management in Chinese firms: Innovative measures and the moderating role of quick response technology. J. Oper. Manag. 2020, 66, 958–988. [Google Scholar] [CrossRef]

- Kline, R. Methodology in the Social Sciences: Principles and Practice of Structural Equation Modeling, 2nd ed.; Guilford Press: New York, NY, USA, 2005. [Google Scholar]

- Fornell, C.; Larcker, D.F. Structural equation models with unobservable variables and measurement error: Algebra and statistics. J. Mark. Res. 1981, 18, 382–388. [Google Scholar] [CrossRef]

- Deng, Z.; Mo, X.; Liu, S. Comparison of the middle-aged and older users’ adoption of mobile health services in China. Int. J. Med. Inform. 2014, 83, 210–224. [Google Scholar] [CrossRef]

- Hu, L.T.; Bentler, P.M. Cutoff criteria for fit indexes in covariance structure analysis: Conventional criteria versus new alternatives. Struct. Equ. Modeling 1999, 6, 1–55. [Google Scholar] [CrossRef]

- Shrout, P.E.; Bolger, N. Mediation in experimental and non-experimental studies: New procedures and recommendations. Psychol. Methods 2002, 7, 422–445. [Google Scholar] [CrossRef]

- Datta, P.P.; Christopher, M.; Allen, P. Agent-based modelling of complex production/distribution systems to improve resilience. Int. J. Logist.-Res. Appl. 2007, 10, 187–203. [Google Scholar] [CrossRef]

- Pereira, J.V. The new supply chain’s frontier: Information management. Int. J. Inf. Manag. 2009, 29, 372–379. [Google Scholar] [CrossRef]

- Golgeci, I.; Ponomarov, S.Y. Does firm innovativeness enable effective responses to supply chain disruptions? An empirical study. Supply Chain Manag. 2013, 18, 604–617. [Google Scholar] [CrossRef]

- Pettit, T.J.; Croxton, K.L.; Fiksel, J. Ensuring supply chain resilience: Development and implementation of an assessment tool. J. Bus. Logist. 2013, 34, 46–76. [Google Scholar] [CrossRef]

- Poppo, L.; Zenger, T. Do formal contracts and relational governance function as substitutes or complements? Strateg. Manag. J. 2002, 23, 707–725. [Google Scholar] [CrossRef]

- Liu, Y.; Luo, Y.; Liu, T. Governing buyer–supplier relationships through transactional and relational mechanisms: Evidence from China. J. Oper. Manag. 2009, 27, 294–309. [Google Scholar] [CrossRef]

- Ryall, M.D.; Sampson, R.C. Formal contracts in the presence of relational enforcement mechanisms: Evidence from technology development projects. Manag. Sci. 2009, 55, 906–925. [Google Scholar] [CrossRef]

- Huber, T.; Fischer, T.A.; Dibbern, J.; Hirschheim, R. A process model of complementarity and substitution of contractual and relational governance in IS outsourcing. J. Manag. Inform. Syst. 2013, 30, 81–114. [Google Scholar] [CrossRef]

- Adobor, H. Supply chain resilience: A multi-level framework. Int. J. Logist. Manag. 2019, 22, 533–556. [Google Scholar] [CrossRef]

- Schmoltzi, C.; Wallenburg, C.M. Operational governance in horizontal cooperation of logistics service providers: Performance effects and the moderating role of cooperation complexity. J. Supply Chain Manag. 2012, 48, 53–74. [Google Scholar] [CrossRef]

| Description | Frequencies | Percentage | |

|---|---|---|---|

| Nature of enterprises | State-Owned or State-Owned Holding | 80 | 23% |

| Private Enterprise | 228 | 65% | |

| Foreign-Owned or Sino-Foreign Joint Ventures. | 10 | 3% | |

| Other | 33 | 9% | |

| Industry type | Food and Beverage | 73 | 21% |

| Metallurgical Manufacturing and Processing/Industry of Metal Products/Mechanical and Equipment | 51 | 15% | |

| Pharmaceutical/Chemical Raw Materials and Chemical Products | 62 | 18% | |

| Textile and Clothing | 41 | 12% | |

| Wood Furniture/Paper Printing/Sports Goods | 44 | 12% | |

| Communications Equipment, Computers and Other Electronic Equipment | 50 | 14% | |

| Others | 30 | 9% | |

| Enterprise size (Employee Number) | 1–50 | 25 | 7% |

| 51–300 | 45 | 13% | |

| 301–2000 | 138 | 39% | |

| >2001 | 143 | 41% |

| Constructs and Items | Coding | FL |

|---|---|---|

| Trust Relationship with Suppliers (CR = 0.9101, AVE = 0.5916, α = 0.953) | TRS | |

| Our company trusts our suppliers to understand us when we share issues with them. | TRS1 | 0.783 |

| We trust our suppliers to be honest and keep their promises. | TRS2 | 0.811 |

| We trust our suppliers to have adequate personnel and equipment. | TRS3 | 0.772 |

| We believe that the quality and quantity of products delivered by our suppliers meet the contract requirements. | TRS4 | 0.716 |

| We believe that our suppliers are always ready to help and support us. | TRS5 | 0.772 |

| Suppliers will consider our interests when making decisions. | TRS6 | 0.738 |

| Our suppliers share our goal to pursue successful cooperation. | TRS7 | 0.788 |

| Information-sharing level (CR = 0.9263, AVE = 0.6423, α = 0.961) | ISL | |

| The company uses information technology to process information. | ISL1 | 0.792 |

| We can exchange information electronically with our suppliers. | ISL2 | 0.799 |

| We have IT system troubleshooting procedures and performance evaluations. | ISL3 | 0.802 |

| Employees are familiar with the business processes of information systems. | ISL4 | 0.808 |

| We are willing to provide information to our suppliers that may be helpful to them. | ISL5 | 0.810 |

| We exchange information with our suppliers in a frequent and timely manner. | ISL6 | 0.774 |

| We exchange accurate and complete information with our suppliers. | ISL7 | 0.824 |

| Preparedness (CR = 0.9157, AVE = 0.6448, α = 0.922) | PPA | |

| We can pre-identify and eliminate potential risk that can be controlled. | PPA1 | 0.821 |

| Basic safety stocks and buffer stocks can be maintained. | PPA2 | 0.802 |

| The inventory level is visible. | PPA3 | 0.806 |

| We have set up personnel to monitor the operation process to prevent accidents. | PPA4 | 0.848 |

| Material preparedness and personnel training to face disruptions are in place. | PPA5 | 0.830 |

| There are contingency plans formed based on experience to deal with the disruption. | PPA6 | 0.703 |

| Responsiveness (CR = 0.9333, AVE = 0.6666, α = 0.935) | RPA | |

| The workflow between departments can be flexibly adjusted. | RPA1 | 0.834 |

| Contingency plans can be quickly carried out and executed. | RPA2 | 0.835 |

| We can respond quickly to unforeseen emergencies and realign resources. | RPA3 | 0.798 |

| We can keep our staff and production running steadily to meet the demand of orders. | RPA4 | 0.829 |

| We can increase or decrease the number of suppliers reasonably. | RPA5 | 0.810 |

| We can detect the root cause of supply or production disruptions. | RPA6 | 0.786 |

| We can identify opportunities and risks arising from emergencies quickly based on the knowledge. | RPA7 | 0.822 |

| Recovery Capability (CR = 0.8897, AVE = 0.5741, α = 0.922) | RCA | |

| After interruptions caused by unexpected events such as epidemics, our company can return to a new normal state. | RCA1 | 0.801 |

| Interruptions can be resolved quickly. | RCA2 | 0.796 |

| We will quickly restart production to respond to unexpected disruptions. | RCA3 | 0.771 |

| Basic normal operation of departments can be maintained after an interruption. | RCA4 | 0.731 |

| We will coordinate resources to reduce the negative impact of disruptions. | RCA5 | 0.739 |

| We can learn from our experience and integrate resources to cope with the changing environment in the future. | RCA6 | 0.703 |

| χ2/df | RMSEA | SRMR | CFI | GFI | IFI | TLI | |

|---|---|---|---|---|---|---|---|

| Original Model | 1.509 | 0.038 | 0.041 | 0.976 | 0.892 | 0.976 | 0.974 |

| Single-Factor Model | 9.175 | 0.153 | 0.123 | 0.612 | 0.387 | 0.613 | 0.586 |

| Common Method Factor Model | 1.309 | 0.030 | 0.033 | 0.987 | 0.91 | 0.987 | 0.984 |

| Model Fit Variation | ΔRMSEA | ΔSRMR | ΔCFI | ΔGFI | ΔIFI | ΔTLI | |

| 0.008 | 0.008 | −0.011 | −0.018 | −0.011 | −0.01 | ||

| Criteria | <0.05 | <0.05 | <0.1 | <0.1 | <0.1 | <0.1 |

| Index | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| PPA1 | 0.782 | ||||

| PPA2 | 0.773 | ||||

| PPA3 | 0.784 | ||||

| PPA4 | 0.797 | ||||

| PPA5 | 0.789 | ||||

| PPA6 | 0.676 | ||||

| RPA1 | 0.820 | ||||

| RPA2 | 0.824 | ||||

| RPA3 | 0.790 | ||||

| RPA4 | 0.821 | ||||

| RPA5 | 0.801 | ||||

| RPA6 | 0.777 | ||||

| RPA7 | 0.825 | ||||

| RCA1 | 0.599 | ||||

| RCA2 | 0.711 | ||||

| RCA3 | 0.663 | ||||

| RCA4 | 0.698 | ||||

| RCA5 | 0.687 | ||||

| RCA6 | 0.629 | ||||

| TRS1 | 0.788 | ||||

| TRS2 | 0.814 | ||||

| TRS3 | 0.777 | ||||

| TRS4 | 0.721 | ||||

| TRS5 | 0.778 | ||||

| TRS6 | 0.744 | ||||

| TRS7 | 0.794 | ||||

| ISL1 | 0.788 | ||||

| ISL2 | 0.795 | ||||

| ISL3 | 0.799 | ||||

| ISL4 | 0.806 | ||||

| ISL5 | 0.802 | ||||

| ISL6 | 0.759 | ||||

| ISL7 | 0.822 |

| Construct | Mean | SD | TRS | ISL | PPA | RPA | RCA |

|---|---|---|---|---|---|---|---|

| TRS | 4.800 | 1.575 | 0.769 | ||||

| ISL | 4.924 | 1.668 | 0.645 ** | 0.801 | |||

| PPA | 3.318 | 1.340 | 0.568 ** | 0.578 ** | 0.803 | ||

| RPA | 5.931 | 1.058 | 0.425 ** | 0.439 ** | 0.313 ** | 0.816 | |

| RCA | 4.679 | 1.002 | 0.714 ** | 0.623 ** | 0.618 ** | 0.547 ** | 0.758 |

| Index | CMIN/DF | RMSEA | CFI | RFI | IFI | NFI | PNFI | PGFI | SRMR |

|---|---|---|---|---|---|---|---|---|---|

| Criteria | <3 | <0.1 | >0.9 | >0.9 | >0.9 | >0.9 | >0.5 | >0.5 | <0.08 |

| Result | 1.638 | 0.043 | 0.970 | 0.921 | 0.970 | 0.927 | 0.857 | 0.766 | 0.059 |

| Hypotheses | Path | β | SE | p | Results |

|---|---|---|---|---|---|

| H1a | TRS --> PPA | 0.353 | 0.051 | *** | Supported |

| H1b | TRS --> RPA | 0.254 | 0.046 | *** | Supported |

| H1c | TRS --> RCA | 0.574 | 0.036 | *** | Supported |

| H2a | ISL --> PPA | 0.382 | 0.050 | *** | Supported |

| H2b | ISL --> RPA | 0.300 | 0.045 | *** | Supported |

| H2c | ISL --> RCA | 0.296 | 0.032 | *** | Supported |

| H3 | TRS --> ISL | 0.676 | 0.052 | *** | Supported |

| Bootstrapping | ||||||||

|---|---|---|---|---|---|---|---|---|

| Bias-Corrected | Percentile | |||||||

| 95% CI | 95% CI | |||||||

| Path | Estimate | SE | Z | lower | upper | lower | upper | |

| TRS -> ISL -> PPA | Indirect effect | 0.202 | 0.036 | 5.611 | 0.135 | 0.275 | 0.134 | 0.274 |

| Direct effect | 0.288 | 0.051 | 5.647 | 0.195 | 0.393 | 0.195 | 0.393 | |

| Total effect | 0.49 | 0.038 | 12.895 | 0.409 | 0.571 | 0.411 | 0.576 | |

| TRS -> ISL -> RPA | Indirect effect | 0.126 | 0.038 | 3.316 | 0.056 | 0.206 | 0.055 | 0.205 |

| Direct effect | 0.171 | 0.052 | 3.288 | 0.072 | 0.278 | 0.072 | 0.278 | |

| Total effect | 0.297 | 0.043 | 6.907 | 0.22 | 0.386 | 0.217 | 0.383 | |

| TRS -> ISL -> RCA | Indirect effect | 0.118 | 0.035 | 3.371 | 0.057 | 0.193 | 0.054 | 0.187 |

| Direct effect | 0.358 | 0.048 | 7.458 | 0.269 | 0.454 | 0.269 | 0.455 | |

| Total effect | 0.476 | 0.033 | 14.424 | 0.414 | 0.544 | 0.412 | 0.543 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.; Liu, Y.; Jia, Y. Influence of Trust Relationships with Suppliers on Manufacturer Resilience in COVID-19 Era. Sustainability 2022, 14, 9235. https://doi.org/10.3390/su14159235

Yang J, Liu Y, Jia Y. Influence of Trust Relationships with Suppliers on Manufacturer Resilience in COVID-19 Era. Sustainability. 2022; 14(15):9235. https://doi.org/10.3390/su14159235

Chicago/Turabian StyleYang, Jianhua, Yuying Liu, and Yajun Jia. 2022. "Influence of Trust Relationships with Suppliers on Manufacturer Resilience in COVID-19 Era" Sustainability 14, no. 15: 9235. https://doi.org/10.3390/su14159235

APA StyleYang, J., Liu, Y., & Jia, Y. (2022). Influence of Trust Relationships with Suppliers on Manufacturer Resilience in COVID-19 Era. Sustainability, 14(15), 9235. https://doi.org/10.3390/su14159235