1. Introduction

China is a large agricultural country. As the main by-product of agricultural production, the annual production of straw can reach approximately 800 million tons. However, due to factors such as utilization technology, collection method, and transportation cost, the utilization rate of straw in China is low in the early days, and the treatment methods are mainly incineration and discarding, which not only causes waste but also environmental pollution [

1,

2].

Converting wastes into production materials after simple physical or chemical treatment is an effective way to effectively reduce the pressure of waste treatment and achieve the sustainable development of the ecological economy [

3,

4,

5]. From this perspective, we propose a solution to prepare biomass-based nursery trays from straw. A biomass-based nursery tray is a container that can be used for seedling cultivation, which is prepared from crop straw, cow manure, and starch adhesive through a press molding process [

6]. It has the advantages of good degradation performance, ecological environmental protection, and a reduction in straw disposal pressure [

7,

8,

9]. At present, it has been widely used for transplanting production of field crops, economic crops, and forest tree seedlings. The field trials result showed that the biomass-based nursery trays have high seeding quality and a significant yield increase.

Related work has been carried out in the development of biomass-based nursery trays. Li D et al. prepared seedling bowls by a thermo-pressing process using oligo-xylose production waste residue as the main raw material, and the seedling bowl had good mechanical strength and water absorption [

10]. Zhang Z et al. prepared seedling pots that can be widely used for seedling transplanting of crops, vegetables, flowers and forest trees by simple chemical and physical modification with agricultural wastes such as wheat and maize by mechanical molding method [

11]. Ma Y et al. took maize straw as the main raw material prepares the maize homemade seedling-growing tray suitable for maize transplanting, and realize the maize bowl transplanting and the efficient utilization of straw [

12].

Postemsky et al. produced nursery containers from sunflower seed hulls and rice hulls, and the results of seedling trials showed that seedling growth traits of sunflower seed hull seedling containers were better than those of the rice hull seedling container group [

13]. Sun E H et al. prepared biodegradable ecological composite nursery containers using urea-formaldehyde modified rice hulls and maize starch as the main raw materials, resulting in a 108.9% increase in the dry strength of the nursery trays [

14]. Tian M. R. et al. mixed rice straw and cow dung with starch adhesive and designed different nursery container models according to the different proportions of raw materials. When the proportion of rice straw and cow dung is 1:15, the molding rate of the container can reach 98% and the moisture content of the container is approximately 15% [

6]. In the early stage, the research group developed six generations of biomass-based nursery trays and their supporting forming equipment from the perspective of efficient utilization of straw, using innovative technologies such as roller molding technology and hot pressing technology, according to the needs of rice seedling raising [

15,

16,

17]. In addition, rice production demonstration and application have been Carried out in 20 demonstration sites including Northeast Reclamation Area and Hainan Sanya Experimental Demonstration Base, with a total area of 3.2 million mu. The results show that the nursery trays have the advantages of no root damage, no regreening stage, biodegradability, self-supporting, good water preservation, and good air permeability, and can achieve approximately a 10~15% yield increase compared with traditional nursery trays [

18].

However, the above-mentioned nursery trays are prepared by a pressure molding process, which requires filling, mold closing, pressure holding, mold opening, mold removing, and other links. Sometimes the mold is heated to improve the molding effect, which is a tedious step and consumes more energy [

19]. At the same time, the molding process has high requirements on the uniformity and humidity of the raw material, and the molding rate of the product depends heavily on the physical and chemical properties of the raw material. For these reasons, the team innovatively proposed a method for producing biomass-based nursery trays from biomass slurry using pneumatic molding technology [

20]. Due to changes in the production of raw materials and forming methods, it is necessary to optimize and improve the structure of biomass-based nursery trays.

Based on the summary of previous research results, this study proposed the design scheme for biomass-based nursery trays. On the premise of meeting the agronomic requirements of rice seedling and machine transplanting, theoretical calculation and modification were carried out on the main dimension parameters such as transverse size, longitudinal size, pothole bowl structure, and thickness. Field trials were conducted to compare and analyze the improvement effect of biomass-based nursery trays in seedling and transplanting. The results of this study are significant for optimizing the structure of biomass-based nursery trays and cultivating robust seedlings.

2. Materials and Methods

2.1. Development of Biomass-Based Nursery Trays

2.1.1. Overall Structure of Biomass-Based Nursery Trays

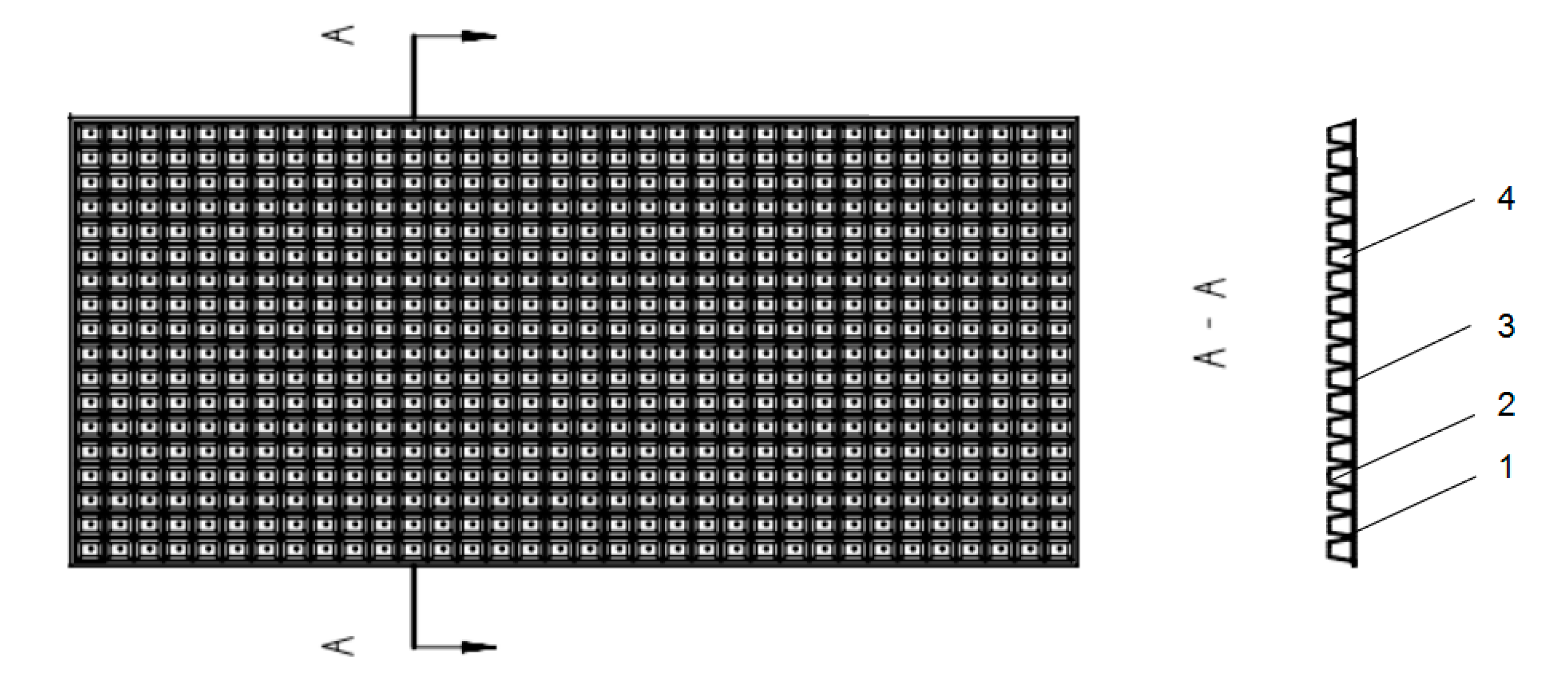

Biomass-based nursery trays are composed of pothole bowls, upright partitions, bottoms and vents, as shown in

Figure 1. The pothole bowl provides space for the growth of rice seedlings. The upright partition is the part that connects the adjacent pothole bowls and is used to separate them. The vent is used to ensure the circulation of air and nutrients in the bottom of the tray to promote root growth.

2.1.2. Horizontal Dimensions and Numbers of Pothole Bowls of Biomass-Based Nursery Trays

To ensure that the biomass-based nursery trays can be used with the general rice transplanter, the horizontal dimension of the biomass-based nursery trays should be smaller than the size of the seedling box of the transplanter, which is 285 mm [

21]. Therefore, in this study, 280 mm was determined as the horizontal dimension with an error of 5 mm [

22]. Biomass-based nursery trays are made of rice straw as the main raw material, which has strong water absorption and expansion. The expansion rate is an important index to evaluate the size change before and after water absorption. The water content will affect the structure dimensions of the biomass-based nursery trays.

Soak the biomass-based nursery trays in water to obtain the expansion rate. The structure dimensions were measured after water absorption saturation and the average value was taken after multiple tests. The expansion rate of the biomass-based nursery trays was calculated by Equation (1) to be 2.14%. Thus, the horizontal dimension of the nursery tray

= 275 mm.

where

is the horizontal dimension of nursery trays, mm;

is the size of a seedling box of rice transplanter, mm; δ is expansion rate, %.

Considering the commonly used rice transplanters have 18 transplanting times, the total number of horizontal pothole bows = 18 in order to meet the requirement of universality of nursery trays.

2.1.3. Pothole Bowl Structure

Cross-Sectional Shape of the Pothole Bowl

Generally, the pothole bowl shape of the nursery trays is rectangular or circular. It has been determined that in the same depth and hole diameter (side length) conditions, the rectangular pothole bowl capacity is 1.27-fold that of the circular [

23]. Further, because the upright partition thickness of the rectangular pothole bowl is more uniform than that of the circular one, the stress on the pothole bowl is more uniform during transplanting and the integrity rate of the pothole bowl after transplanting is higher. For the above reasons, the cross-sectional shape of the pothole bowl was determined to be rectangular. Since the overall shape of the nursery trays is rectangular, the cross-sectional shape of the pothole bowl was finally determined to be rectangular with short horizontal edge and long longitudinal edge, in order to arrange the pothole bowl evenly and make full use of the space of the biomass-based nursery trays.

Cross-Sectional Dimensions of the Pothole Bowl

The pothole bowl provides a suitable growth space for rice seeds to grow. Reasonable pothole bowl volume is crucial for seedling quality, and the cross-sectional dimension of the pothole bowl is an important factor affecting the pothole bowl volume. Experiments have shown that the optimal growth density of rice seed is 2.64 seeds/cm

2 [

24]. The precision seeding requirement of nursery trays is to ensure that 4 to 5 seeds are sown in each pothole bowl. The cross-sectional area of the pothole bowl was calculated by Equation (2) to be 1.52 cm

2 to 1.89 cm

2.

where

is the cross-sectional area of the pothole bowl, cm

2;

is the amount of seeds in a single pothole bowl.

According to the cross-sectional shape of the pothole bowl with short transverse and long longitudinal sides, the transverse side length of the upper surface of the pothole bowl = 12 mm, and the longitudinal side length = 14 mm. At this time, the cross-sectional area of the pothole bowl = 1.68 cm2, which is within the reasonable range of design.

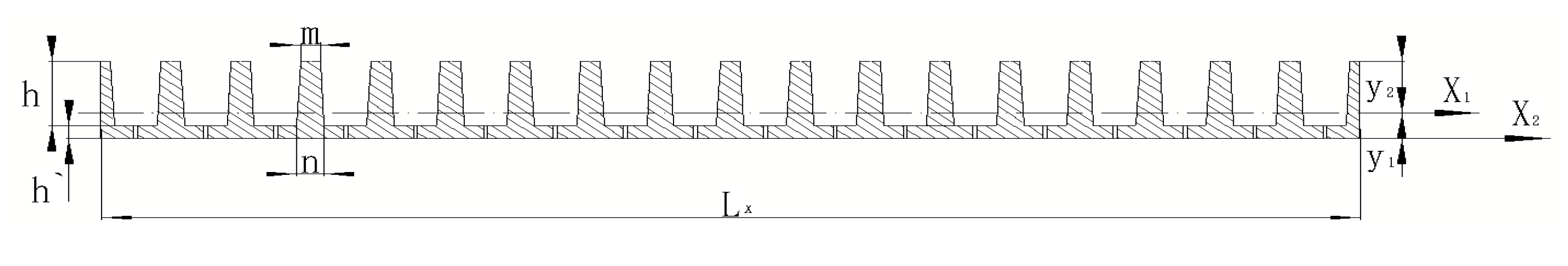

The demolding slope determines the demolding difficulty and molding effect. A large demolding slope is not only easy to demold, but also can improve the unevenness of the upright partition thickness. The commonly used slope range is 1~4°, and the slope is 4° in this study, as shown in

Figure 2. By calculation, the transverse side length of the bottom surface of the pothole bowl

= 10 mm, and the longitudinal side length of the bottom surface of the pothole bow

= 12 mm.

Depth of Pothole Bowl

The extension ratio is the ratio of the depth to the width of the molded part, the commonly used extension ranges from 0.5 to 1.5 [

25], and the extension ratio applied in this study is 1. Considering the longitudinal side length of the top surface of the pothole bowl

= 14 mm, the depth of the pothole bowl

h = 14 mm.

At this time, it is known that the pothole bowl is a truncated square cone structure with a mold slope of 4°. According to Equation (3), the volume of pothole bowl

= 365.57 mm

3.

where

v is the volume of the pothole bowl, mm

3;

is the transverse side length of the top surface of the pothole bow, mm;

is the longitudinal side length of the top surface of the pothole bow, mm;

is the transverse side length of the bottom surface of the pothole bow, mm;

is the longitudinal side length of the bottom surface of the pothole bow, mm;

h is the depth of the pothole bowl, mm.

Thickness of the Pothole Bowl

The transverse dimensions of the biomass-based nursery tray consist of the transverse side length of pothole bowl and upright partition thickness, and the number of single rows of pothole bowls has been determined as 18. From Equation (4), the thickness of the upper surface of the upright partition

m = 3 mm, and the bottom surface thickness

n = 5 mm according to the relationship between the pothole bowl and the biomass-based nursery tray.

where

m is the thickness of the top surface of the upright partition, mm;

is the transverse dimension of the nursery tray, mm;

is the transverse side length of the top surface of the pothole bow, mm.

When the rice grows to the three-leaf and one-bud stage, the nutrients stored in the seeds are not sufficient to sustain the continued growth of the seedlings. At this time, the seedlings transform from the autotrophic stage to the heterotrophic stage, relying on the generated root system to absorb nutrients for the seedlings. Therefore, it is required that the nursery tray can promote effective root coiling in the seedling autotrophic stage, ensure that the seedling taproot can absorb nutrients from the seedbed soil in the heterotrophic stage, and will not affect the subsequent growth of the seedling root system after transplanting seedlings to the field. The experimental results show that the bottom thickness of nursery trays = 2 mm can meet the above requirements.

2.1.4. Longitudinal Dimensions of Biomass-based Nursery Trays

The biomass-based nursery trays are subject to bending stress during lifting and transportation. In order to avoid excessive bending and fracture, the geometric centroid deflection of biomass-based nursery trays is required not to exceed the allowable deflection, as shown in Equation (5)

where

is geometric centroid deflection, mm;

is the allowable deflection at the geometric center point, 3.6 mm;

is the standard value of uniform load, KN/m;

is the longitudinal dimension, m;

is the modulus of elasticity, GPa;

is the moment of inertia of cross-section, cm

4.

Establish the transverse section of the biomass-based nursery trays, divided into two parts, the bottom cross-section (

) and upright partition cross-section (

), and establish the geometric centroid coordinate axis

and curved bottom coordinate axis

,

and

, respectively, represent the distances from the curved bottom surface and the top surface of the biomass-based nursery trays to the geometric centroid coordinate axis

, as shown in

Figure 3. Equation (6) is obtained from the geometric center calculation formula.

where

is the bottom cross-sectional area,

, mm

2;

is the upright cross-sectional area,

, mm

2;

is the distance from the center of the bottom cross-section to the curved bottom

,

, mm;

is the distance from the center of the upright cross-section to the curved bottom

,

, mm;

is the number of upright partitions in the transverse direction, 19.

Combining Equations (5) and (6), we get: = 8.18 mm and = 7.82 mm.

According to the moment of inertia calculation formula, we get Equation (8). By calculation, we can known

= 1.8 × 10

5 mm

4.

where

is the transverse dimensions of the biomass-based nursery tray, mm;

is the thickness of the upper surface of the upright partition, mm;

is the thickness of the bottom surface of the upright partition, mm;

is the depth of the pothole bowl, mm;

is the thickness of the bottom of the pothole bowl, mm.

The elastic modulus test was conducted with the biomass-based nursery trays as the material. The load was added step by step to the biomass-based nursery trays using WES digital display hydraulic universal testing machine, and then unload it after the elastic deformation occurred. The average value of multiple tests was added to the elastic modulus calculation Equation (9) to obtain

= 0.05 GPa.

where

is the stress, GPa;

is the strain, m;

is the cross-sectional area of the biomass-based nursery tray, m

2;

is the force, KN;

is the deformation, m.

The uniformly distributed load is expressed as

q. The mass of biomass-based nursery trays itself is considered to be uniformly distributed on its bottom surface. The mass composition of a single biomass-based nursery tray before transplanting is: soil mass

= 3.5 g, seed mass

= 0.2 g, water mass

= 14.4 g and nursery trays mass

= 0.9 g. The equations for the uniformly distributed load are shown in Equations (10) and (11).

where

is the number of pothole bowls of nursery trays in the longitudinal direction, bowl;

is the longitudinal dimension of nursery trays, mm;

is the thickness of the top surface of the upright partition, mm.

Combining the above equations, it can be concluded that the longitudinal dimension of the biomass-based nursery tray = 585 mm and the number of pothole bowls on the longitudinal direction of the nursery tray = 34.

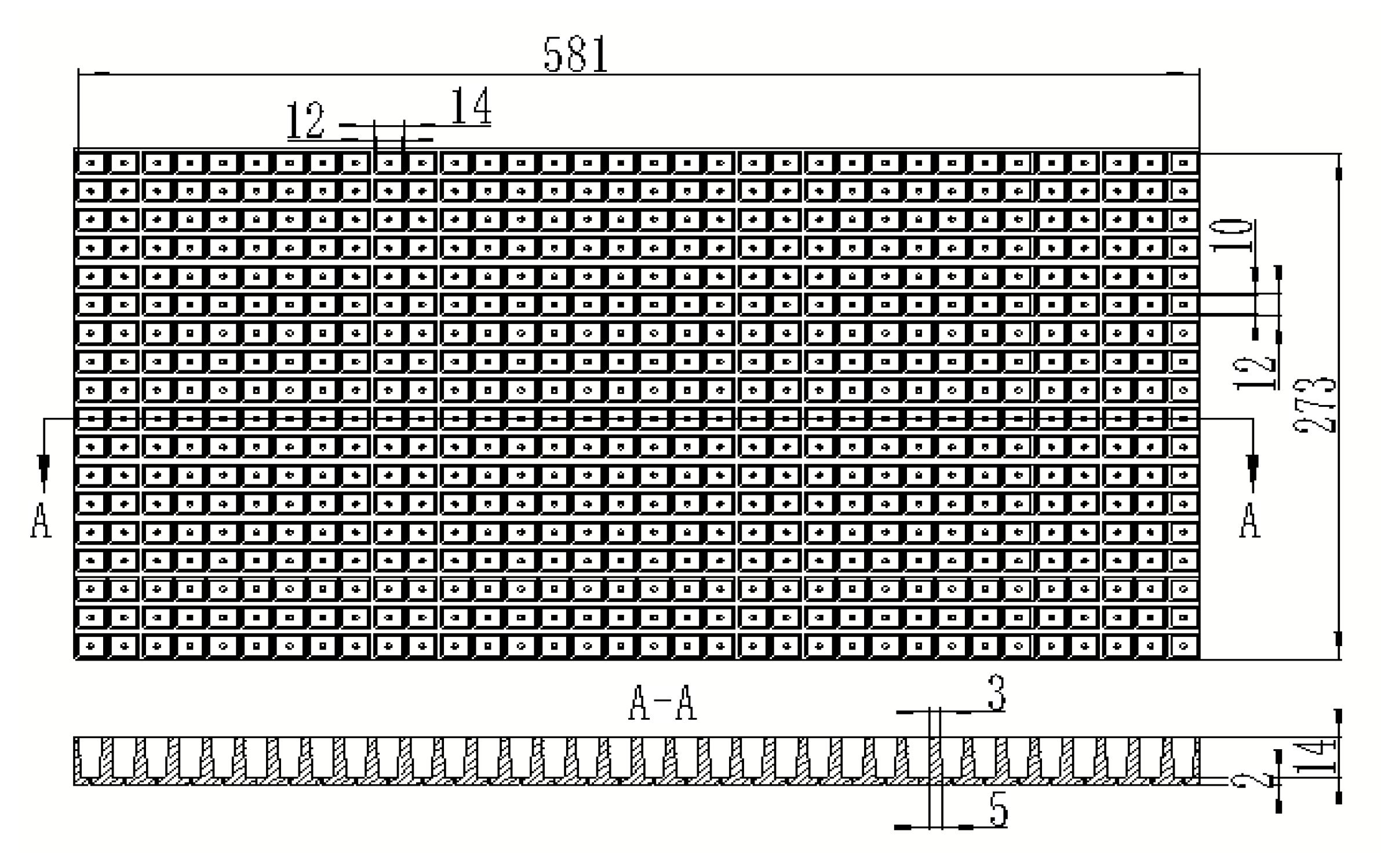

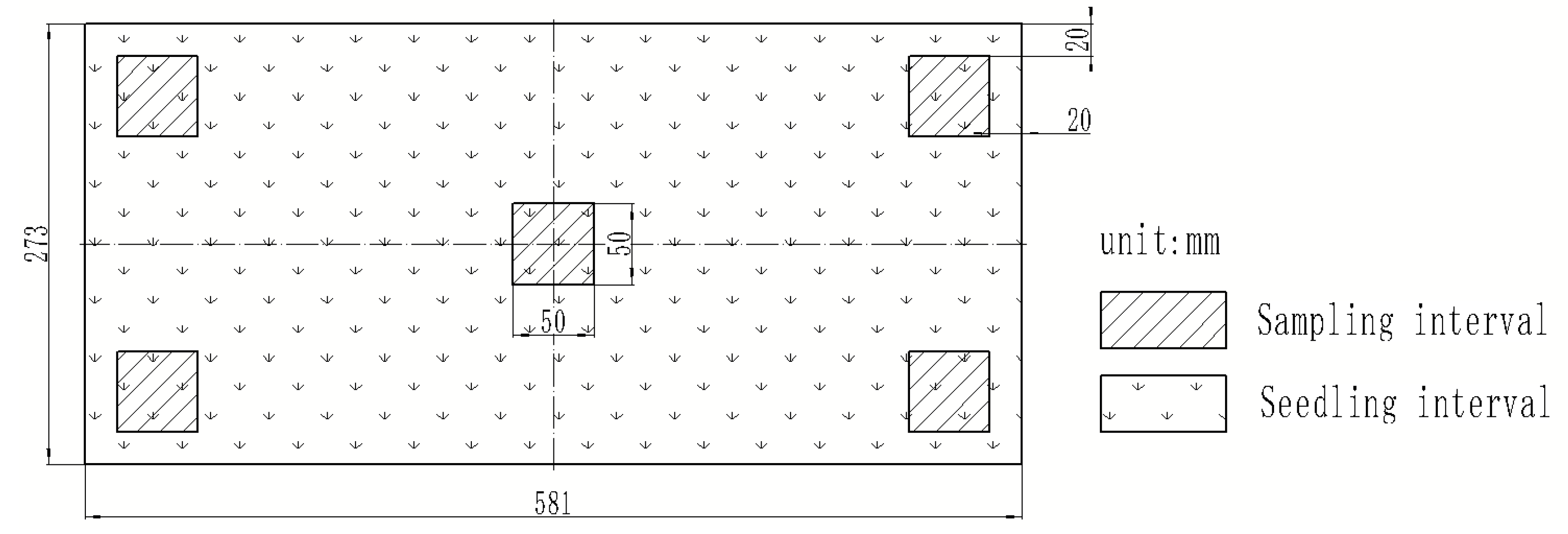

2.1.5. Dimensional Correction

In this study, the structure of biomass-based nursery trays was designed from the perspectives of seedling demand and structural strength, and the overall dimensions of the biomass-based nursery tray were revised by integrating the data based on the above research. According to the previous analysis, the number of pothole bowls of nursery trays in the transverse direction

= 18 holes, the transverse side length of the top surface of the pothole bow

= 12 mm, the thickness of the top surface of the upright partition

= 3 mm, and the transverse dimensions of the pothole bowl

= 273 mm. Similarly, the number of pothole bowls of the nursery tray in the longitudinal direction

= 34 holes, the longitudinal side length of the top surface of the pothole bow

= 14 mm, the thickness of the top surface of the upright partition

= 3 mm, and the longitudinal dimension of the nursery tray

= 581 mm. The structural parameters of nursery trays were finalized, as shown in

Figure 4 and

Table 1.

2.2. Study Site Description

This experiment was conducted from April to October 2021 on farm 857 in Heilongjiang Province. The farm is located in Mishan City, Heilongjiang Province, which has a continental monsoon climate with an annual average temperature of 10 °C, a frost-free period of 132 days, an effective accumulated temperature of 2450~2650 °C, and an average annual precipitation of 500~550 mm. The soil of the test site is Baijiang soil. On 2 April 2021, foundation soil samples were collected to measure the physical and chemical indicators of the soil foundation. The results demonstrated that the thickness of the black soil layer was 15~20 cm, the average PH of the soil was 5.54, the average organic matter was 4.77%, nitrogen was 0.218%, phosphorus was 0.159%, and potassium was 4.09%. The soil conditions were suitable for rice growth and meet the test requirements.

2.3. Sample Preparation and Experimental Design

The pre-treated straw and cow dung were put into the pulping tank according to the mass ratio of 2:1, add water to make a 30% concentration of slurry, and mix evenly with 530 g of adhesive to get the prepared raw material. The blank biomass-based nursery trays were prepared by a TL-YPCX-01 Pneumatic Molding Machine (self-developed). The nursery tray was dried by a YHMW900-100 microwave hot wind coupled multi-function dryer (self-developed). The made biomass-based nursery trays are given in

Figure 5, and the technical indicators are listed in

Table 1. The BTR280-18 plastic flat nursery plates were commercially purchased with dimensions of 570 mm × 280 mm × 20 mm, as shown in

Figure 6. The barrier materials were the plastic film with a thickness of 0.05~0.08 mm (

Figure 7) and the non-woven fabric of 100 g/m

2 (

Figure 8). The experimental material was Suijing 18 with a fertility period of 134 days, a thousand-grain weight of 26 g, and approximately 108.8 grains per panicle.

On 8 April, nursery trays were used as the seedling carrier and a plastic film and a non-woven fabric were used as isolation materials to carry out the seedling raising test. Since the preliminary test determined that the plastic film laid under the plastic flat nursery plates affected water permeability and air permeability performance, and the effect of rice planting was not good, only three groups of tests were set up in this experiment. The details of the three groups are as follows: a non-woven fabric was laid under the plastic flat nursery plate (CK), a non-woven fabric was laid under the biomass-based nursery tray (CK

1), and a plastic film was laid under the biomass-based nursery tray (CK

2). To ensure uniform of test conditions and easy of management, all three sets of trials were conducted in the same seedling greenhouse. 20 trays are raised in each group and repeated three times. After arranging the seedbed and laying the specified isolation materials, nursery trays are placed flatly on it with 0.5 cm spacing between trays to prevent them from swelling and squeezing each other after absorbing water. Arrangements were made in groups according to the random areas, as shown in

Figure 9. After that, seeds were sown, mulched and watered. Proper temperature and humidity management was ensured during the seedling raising process.

On 10 May, the rice transplanting test was conducted in a standardized rice planting test field. The grouping was the same as that of the seedling raising test. Each group was repeated in three plots with a plot area of 30 m2. The 2zt-9356 rice transplanter was used for rice transplanting, and the row-column spacing is 30 cm × 18 cm. When transplanting seedlings by machine, the biomass-based nursery trays were inserted into the field together with the seedlings. As for plastic flat nursery plates, the blanket seedlings should be taken out first and then inserted into the field. The fields were arranged randomly with a protective rows around and drainage ditches in the middle. The application rate of nitrogen fertilizer (urea) is 180 kg/hm2, which is applied according to base fertilizer, tiller fertilizer and panicle fertilizer = 5:3:2. The application amount of phosphate fertilizer (calcium superphosphate) was 450 kg/hm2, which is applied as the base fertilizer in a single application. The application rate of potassium fertilizer (potassium chloride) is 112.5 kg/hm2, which is applied as panicle fertilizer at one time. Adhere to the principles of frequent irrigation in shallow water at the seedling stage, drainage, and drying at the end of the tillering stage. Other management measures should be implemented in accordance with the principles of high-yield cultivation to give full play to the yield potential of the crop.

2.4. Measurement and Analysis

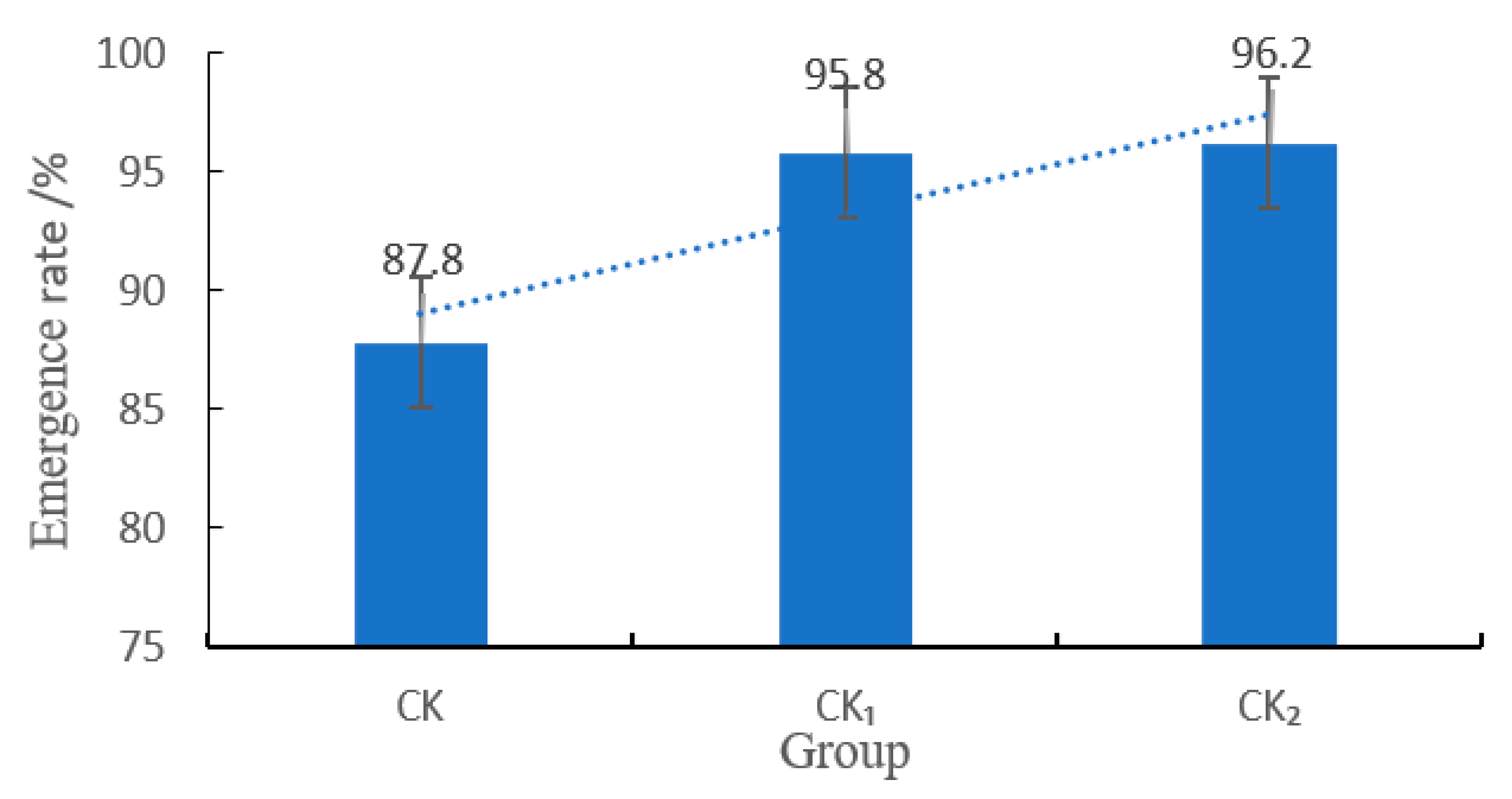

2.4.1. The Seedling Emergence Rate

The seedling emergence rate is the ratio of the number of seeds to the total number of seeds. On the 9th day after rice sowing, 5 regions were selected in the center of the nursery trays and 20 cm from the boundary in an area of 5 cm × 5 cm, as shown in

Figure 10. The number of emerging and unemerging seeds in each region was counted. The emergence rate was calculated as the emergence rate = number of emergence seeds/total number of seeds ×100%, and three samples were taken from each group and the average value was calculated [

26].

2.4.2. Seedling Quality

One day before transplanting, five biomass-based nursery trays were randomly selected from each group, and 50 plants with balanced growth were washed clean to measure their seedling quality, and the average value was taken. Measure the following indicators: plant height, measuring the distance from the highest leaf tip of the seedling to the base of the plant with a ruler. Stem base width: 50 plants were randomly selected, and every 10 plants were grouped close to each other, measure the base width that 1 cm away from the root, and the average value obtained was the stem base width of each plant. Fresh weight: 100 plants were randomly selected, dried after removing the soil from the roots, and weighed the stems, leaves and roots. Dry weight: 100 plants were randomly selected, dried at 105 °C for 1 h and 80 °C until constant weight, and measure their mass according to the above-ground and below-ground parts [

27].

2.4.3. Yield

At maturity, three points were selected according to the triangle sampling method, and 10 samples were selected from each point to investigate the number of pothole bowls per acre, the panicles per pothole bowl and the grains per panicle. The harvested rice grains were placed in a room until the grains were balanced with the humidity in the air, removed impurities and empty grains by the wind sorting and then weight the grains (using an accuracy of 0.01 g balance) [

28], and the maturity rate was calculated. After drying, the quality and moisture content of rice were measured, and then the yield was calculated according to the standard moisture content of 13.5%. Theoretical yield per acre = pothole bowls per acre × panicles per pothole bowl × grains per panicle × maturing rate × thousand seed weight.

2.5. Data Analysis

Statistical analyses were carried out by using SPSS 22.0 for Windows (SPSS Inc., IBM Inc., Armonk, NY, USA). OriginPro 2019b (OriginLab Inc., Northampton, MA, USA) was used for plotting. Least significant difference (LSD) analysis was performed for significant comparisons of seedling quality and yield. Comparative items included the emergence rate, plant height, stem base width, leaf age, number of tillers, root length, number of roots, the fresh weight of a hundred seedlings, the dry weight of a hundred seedlings and yield.

4. Discussion

4.1. Effect of Nursery Trays on the Seedling Emergence Rate

The experiment showed that different nursery carriers had a significant effect on the seedling emergence rate. Compared with the plastic flat nursery plates used in CK, the biomass-based nursery trays used in CK1 and CK2 do not need to form a blanket through the seedling root trays, thus allowing a reduction in the amount of seed sown. While sparse planting could improve the seedling emergence rate and optimize seedling morphology. In addition, the biomass-based nursery tray has good water absorption and water retention, which are conducive to absorb water form the soil and store it around the seeds to meet the needs of seed germination. At the same time, the biomass-based nursery tray has a good pore structure, which is beneficial to air circulation, ventilation and nutrient exchange, providing a suitable growth environment and natural conditions for seed germination, and the seedling emergence rate can be improved.

The experiment showed that different nursery carriers had a significant impact on the seedling emergence rate. In the CK group, seeds are sown at high density to ensure that seedling roots became blankets, and competition among seedlings is fierce, resulting in poor seedling quality. This result is consistent with previous studies that high planting density of blanket seedlings and weak seedlings are not conducive to the dominant development of strong stems and large panicles in hybrid rice [

29]. For hybrid rice, to make full use of strong tillering ability and large panicle advantage, it is necessary to plant sparsely and reduce the sowing rate when raising seedlings, but low sowing rate can lead to poor seedling blanket formation and high seedling leakage rate [

30]. Compared to the plastic flat nursery plates used in CK, the biomass-based nursery trays used in CK

1 and CK

2 do not require the formation of a blanket through the root system, so the seeding amount can be reduced. Sparse planting can improve the seedling emergence rate and optimize seedling morphology [

31].

In addition, the biomass-based nursery tray has good water absorption and water retention, which are conducive to absorb water from the soil and store it around the seeds to meet the needs of seed germination. At the same time, the biomass-based nursery tray has a good pore structure, which is conducive to air circulation, ventilation and nutrient exchange, providing suitable growth environment and natural conditions for seed germination, and can improve the seedling emergence rate.

4.2. Effect of Nursery Trays on Seedling Quality

Through the field trials, we know that the use of biomass-based nursery trays can improve seedling quality. The characteristics of strong seedlings are enhanced by using a non-woven fabric as a barrier material. Biomass-based nursery trays are sown in small quantities and planted at low densities, which are beneficial to increasing the root biomass of seedlings, expanding the nutrient absorption area of the root system, and ensuring sufficient nutrient supply. The biomass-based nursery trays contained sustained-release agent (0.2 g/tray) which provides nutrients for seedling growth and effectively promotes the growth of the rice and the accumulation of dry material, which is similar to the observation of Shi H et al. [

32]. Biomass-based nursery trays have good water holding and air permeability, which are conducive to improve soil temperature, enhance soil air flow and provide a good environment for seedling growth; Chen made the same conclusion [

33]. The seedling root system penetrates the bottom of the biomass-based nursery trays and the non-woven fabric, and takes root in the soil of the seedling bed with better nutrient, water and air circulation conditions. Ryouji S researched growing-season rice, and their results reflected similar changes [

34,

35]. However, the root system at the bottom of the nursery tray intertwines with the non-woven fabric, which affects the subsequent lifting effect.

4.3. Effect of Nursery Trays on Yield

The application of biomass-based nursery trays can increase the yield. The results showed that under different seedling raising methods, the contribution rate of grains per panicle was the largest, followed by pothole bowls per mu, panicles per pothole bowl and matching rate. Yang L pointed out that the panicle per pothole bowl and the thousand seed weight of bowl seedlings were less than those of blanket seedlings, but the number of grains per panicle and the mating rate were greater than those of blanket seedlings. This may be because Yang L used a plastic seedling pot, and the seedling carrier cannot self-degrading to provide nutrients for seedling growth. At the same time, the biomass-based nursery trays can be transplanted to the field together with the seedlings. The growing environment in the pots is similar to that in the field environment, so it does not need to recover.

However, the root system of seedlings cultivated with plastic flat nursery plates forms a blanket that can be damaged during separation at transplanting and requires a regreening stage. Excessive recovery time can affect plant growth and development progress, reduce the average number of tillers and maturing rate, and restrict the increase in yield. This is the same as the conclusion reached by Liu Jun and he, H [

36,

37]. At the same time, when the biomass-based nursery trays are returned to the field, organic substances such as nitrogen, phosphorus and potassium are formed under the action of soil microorganisms, which can enhance soil fertility and improve soil structure.

The use of a non-woven fabric as a barrier material for seedling breeding has good seedling growth traits. However, the seedling roots penetrate the holes at the bottom of the nursery trays and intertwine in the non-woven fabric, even rooted in seeding bed soil. The separation of the nursery trays and the non-woven fabric during the lifting process will inevitably cause damage to the root system of the seedlings, which is the same damage to the root system when transplanting seedlings from plastic plates. This also explains why the seedling quality of CK1 is better than that of CK2, but the final yield is not as high as that of CK2.

5. Field Implications

This study shows that the use of crop straw to prepare biomass rice seedling nutrition trays meets the need of agricultural sustainable development. Rice is among the three major food crops in the world. It produces a large amount of rice straw every year. If not handled properly, it will cause serious environmental pollution. In recent years, many countries, including China, have committed to researching the comprehensive utilization of waste straw. The preparation of biomass-based nursery trays involves the utilization of straw. This is an effective way to achieve resourceful use of straw, which has many benefits. In China, for example, the rice planting area in 2021 is 450 million mu. According to the demand of 45 nursery plates per mu, a total of 20.25 billion nursery plates will be required. According to the actual production process, 0.6 kg of straw is required for the preparation of biomass-based nursery trays. Therefore, annual resource utilization of approximately 12 million tons of straw can be realized through the preparation of biomass-based nursery trays, and the white pollution caused by using plastic nursery plates can be avoided. Rice straw can be obtained from rice planting areas at a price of 100 RMB/ton, and with the cost of labor, utilities, and depreciation of instruments and equipment required to produce biomass-based nursery trays, the cost of producing 10,000 pieces of biomass-based nursery trays is 1121.1 RMB, which significantly reduces the investment in rice production [

38].

Straw is rich in nitrogen, phosphorus, potassium and other micronutrients, which are important sources of organic fertilizer. Straw return to the field can return the nutrients in crops to the soil, increase the content of soil organic matter, enhance soil microbial activity, improve soil physical and chemical properties, reduce chemical fertilizer use, and promote sustainable development of rice production [

39]. The preparation of biomass-based nursery tray requires converting crop straw into high-value-added agricultural products. Nursery trays can be transplanted to the field together with the seedlings and degraded by the biological action of soil to provide nutrients for crop growth and achieve the effect of straw return [

40]. It can be seen from this study that biomass-based nursery trays not only have good permeability and water retention performance, as well as easy to grow roots, but also easily degrade, providing sufficient nutrients for crop growth and laying the foundation for high-yield and high-quality rice. However, the collection, sorting and transportation of rice straw needs a lot of labor. The promotion and application of straw automatic harvesting and baling machines can greatly increase the level of straw resource utilization. In general, the preparation of biomass-based nursery trays from crop straw plays a positive role in sustainable development of agriculture and the mitigation of environmental pollution.

6. Conclusions

Straw return to the field is important for developing soil strength and improving crop quality and yield. The preparation of biomass-based nursery trays using straw and transplanting them to the field for seedlings are effective means to achieve sustainable agricultural development through straw materialization applications. In this paper, based on the results of previous studies, the design was optimized and improved for structural problems, the effectiveness of the nursery trays was verified through field trials, and the following conclusions can be made.

On the premise of meeting the agronomic requirements of bowl seedlings and transplanting, the overall structural dimensional parameters of the biomass-based nursery trays were determined by theoretical calculations from the perspective of reasonable planting density, taking into account the working characteristics of the transplanter. The key structural technical parameters are: the transverse dimensions of the nursery tray is 273 mm, the longitudinal dimension of the nursery tray is 581 mm, the shape of the pothole bowl is rectangular, the depth of pothole bowl is 14 mm, the thickness of the upright partition is 3 mm, and the total number of pothole bowls is 612.

The use of biomass-based nursery trays for seedlings, with low seedling planting density and a good crop growth environment, is conducive to the cultivation of strong seedlings. The root system of young seedlings is independent of the pothole bowl, so the root system is not damaged when transplanting and there is no recovery period after transplanting. The pothole bowl is reasonably designed with good water absorption and retention, which can save 30~50% of seedling soil and extend the watering interval by 1~2 days.

Compared with plastic flat nursery plates, the quality of young seedlings can be significantly improved by using biomass-based nursery trays as a carrier and a non-woven fabric as a barrier material. Specifically, the seedling emergence rate increased by 9.1%, plant height increased by 2.3 cm, stem base width increased by 0.3 cm, leaf age increased by 0.6, tiller number increased by 0.39, and average root number increased by 4.4. The fresh weight of the above-ground part of 100 seedlings, the fresh weight of below-ground part of 100 seedlings, the dry weight of the above-ground part of 100 seedlings, and the dry weight of the below-ground part of 100 seedlings increased by 1.23, 1.82, 1.43 and 0.37 g, respectively, and the yield increased by 2.1%.