An Efficient Fault Detection Method for Induction Motors Using Thermal Imaging and Machine Vision

Abstract

:1. Introduction

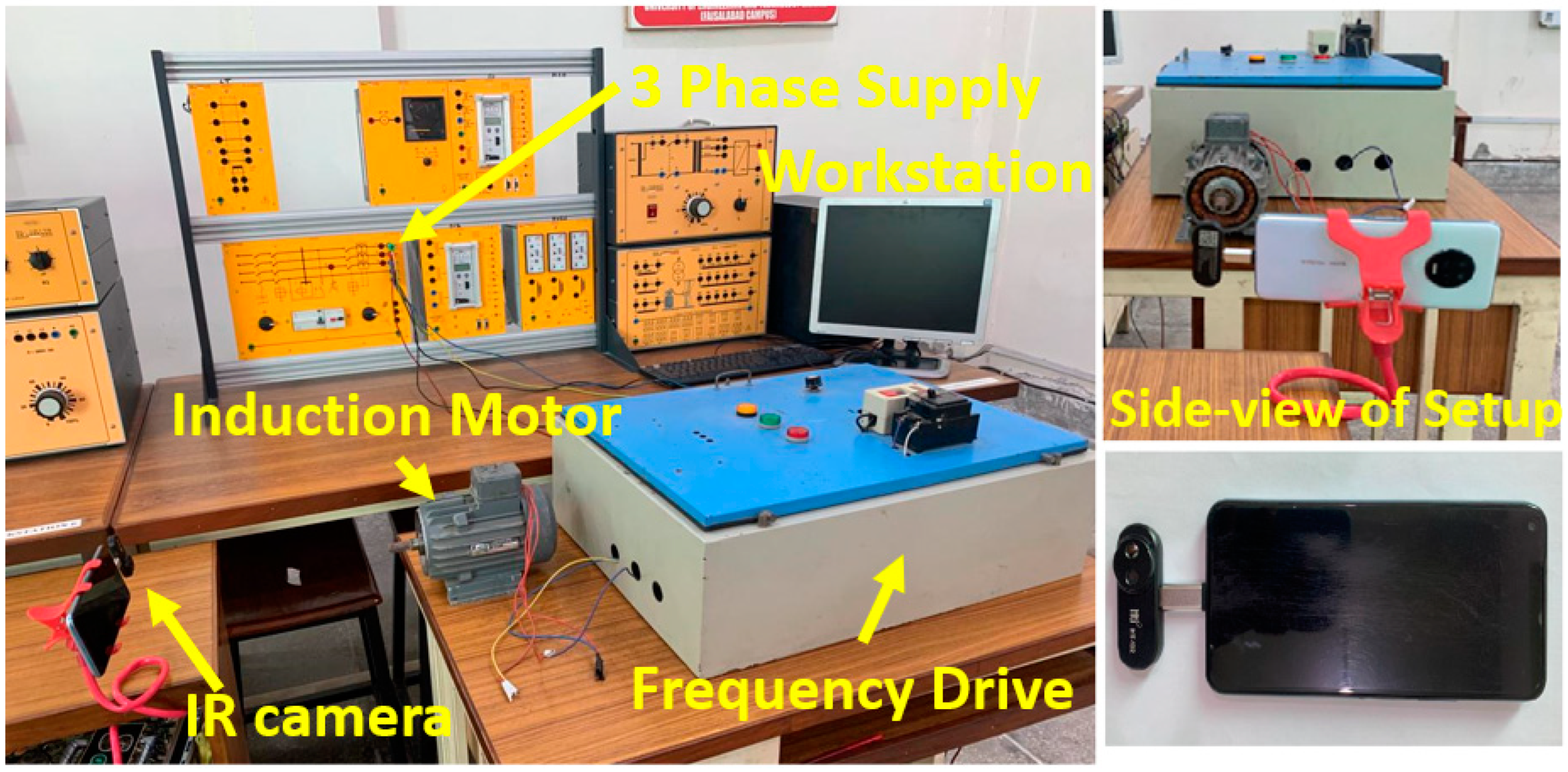

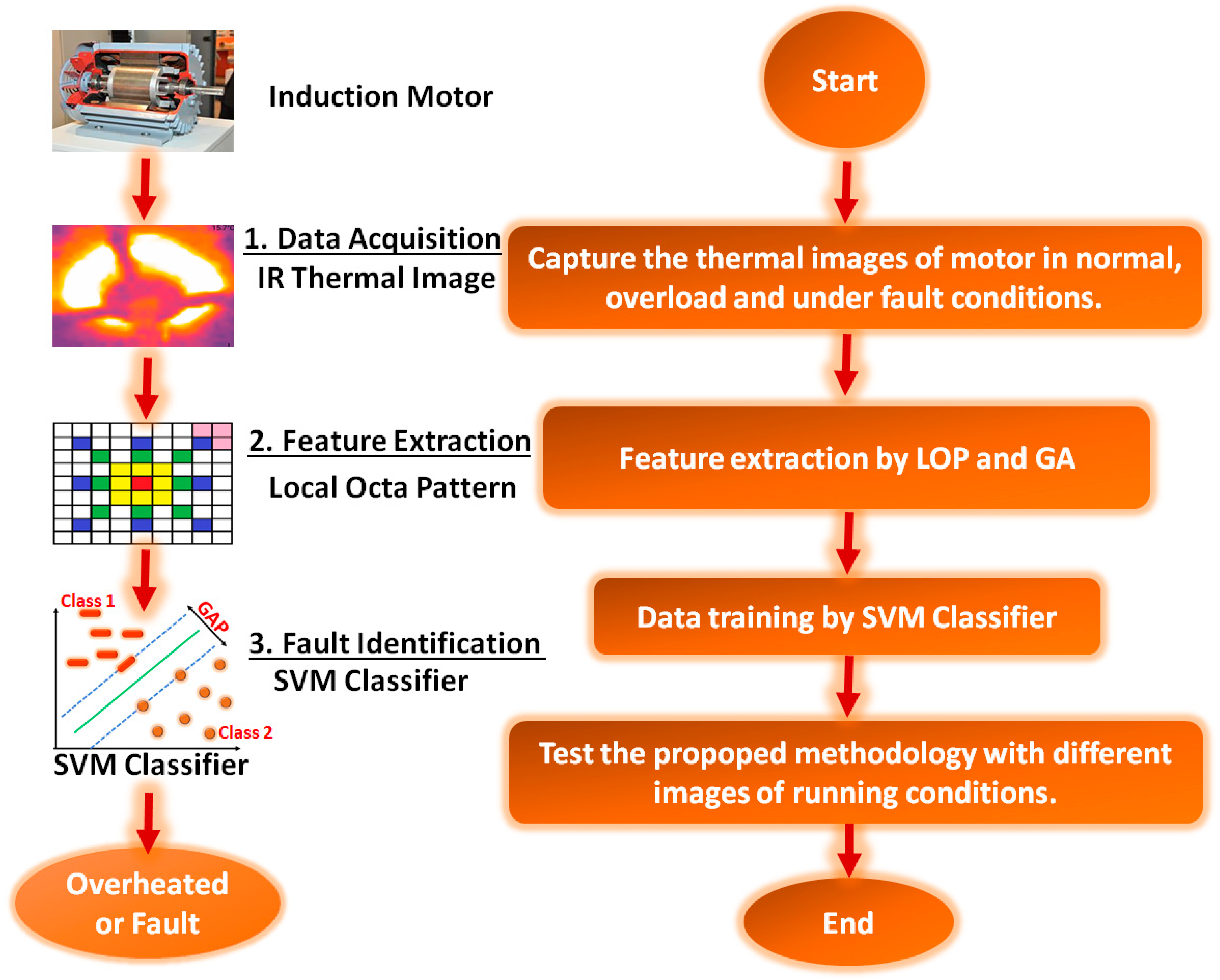

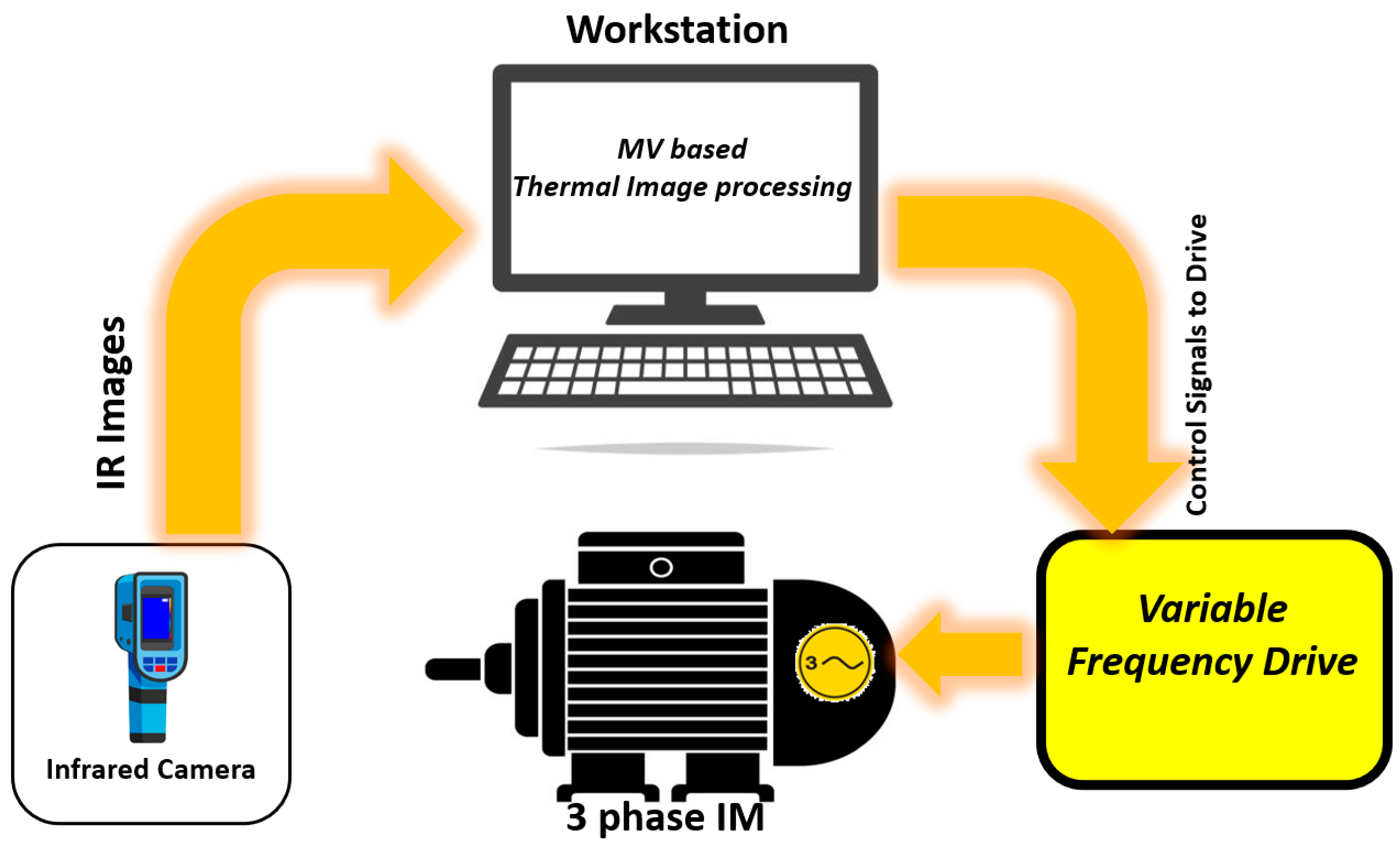

2. Experimental Setup

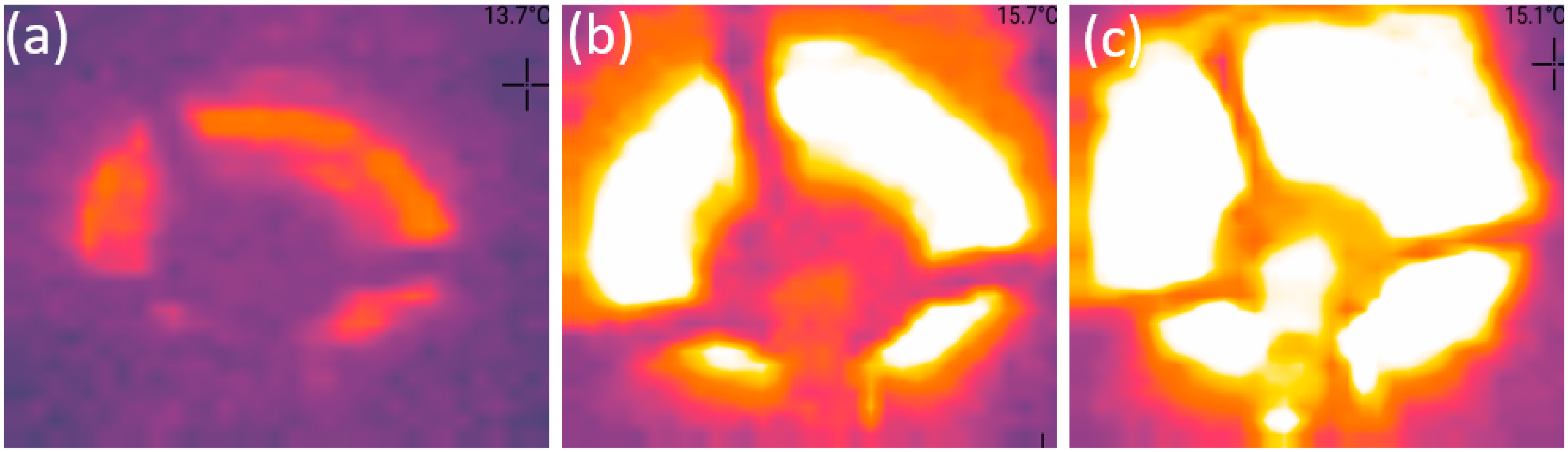

2.1. Data Acquisition

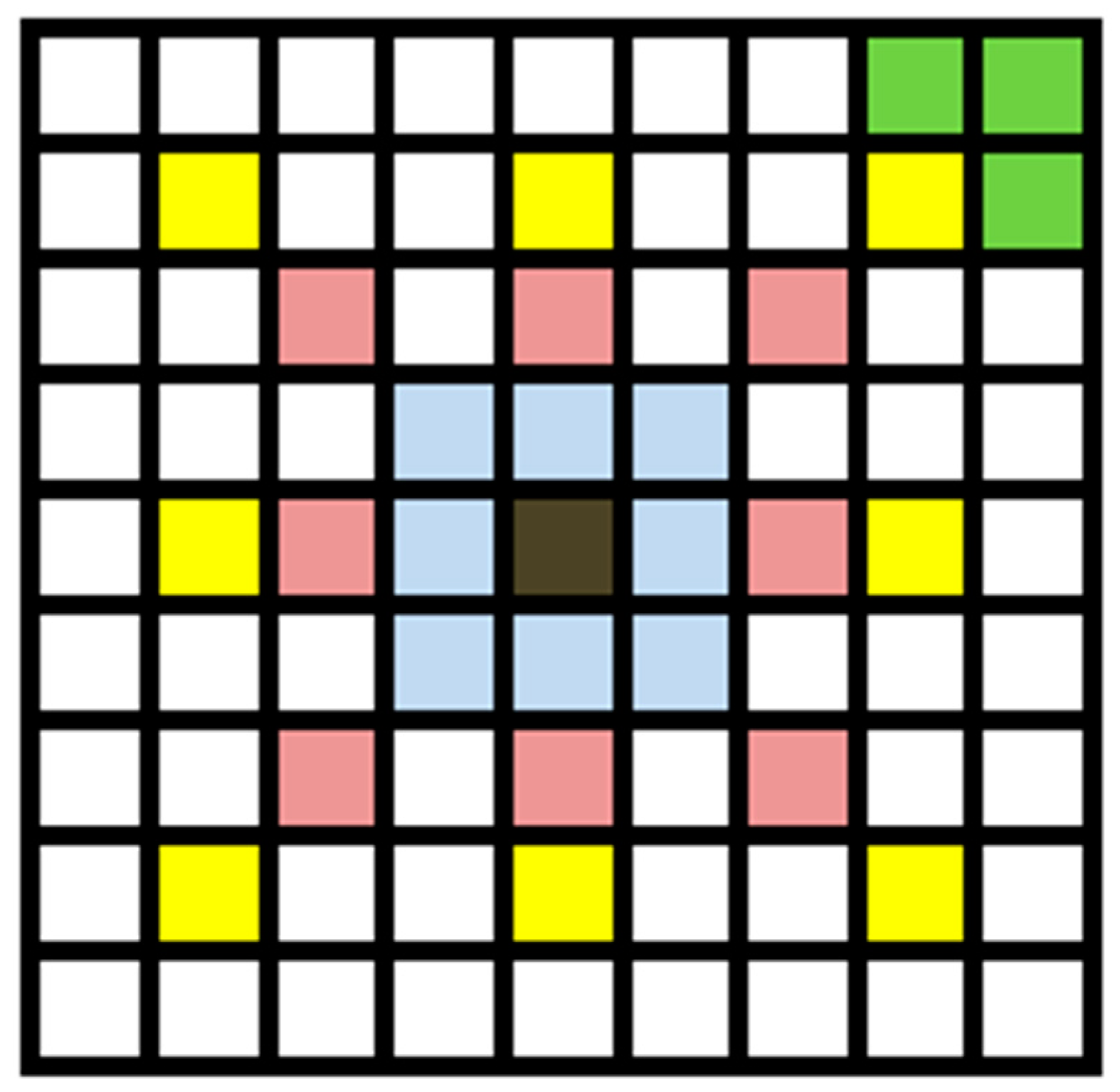

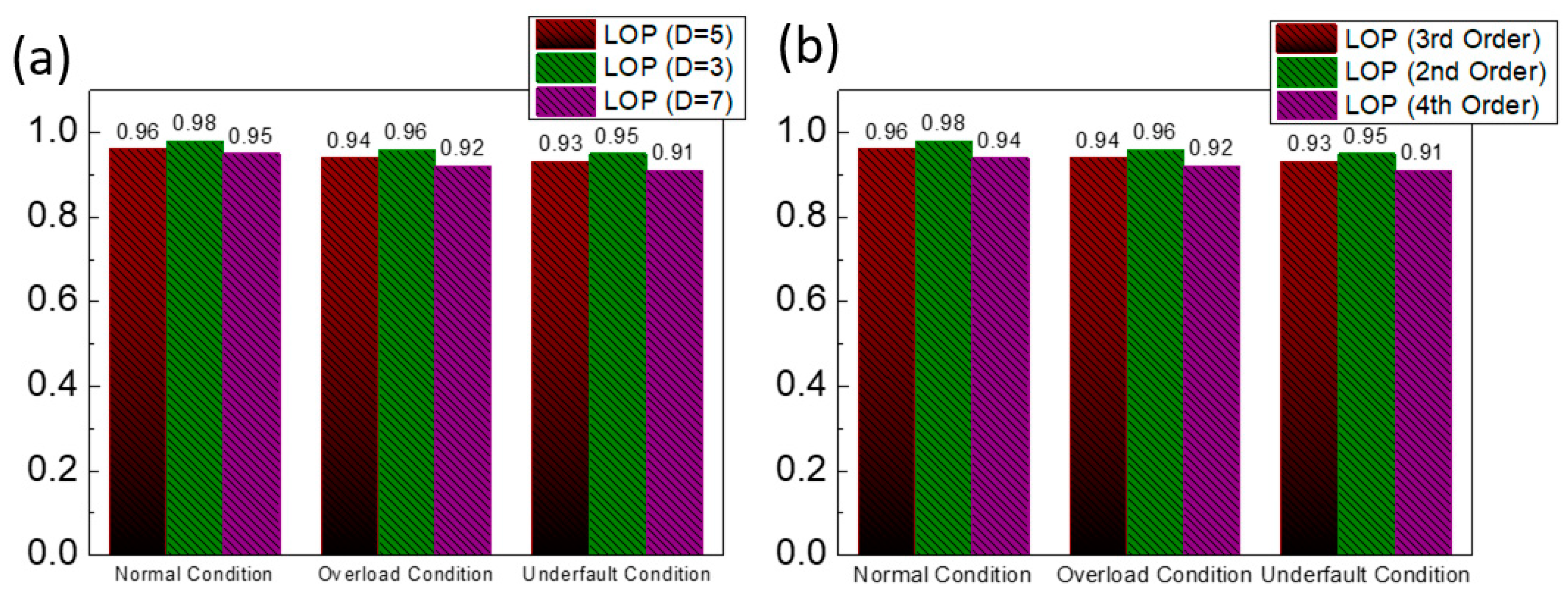

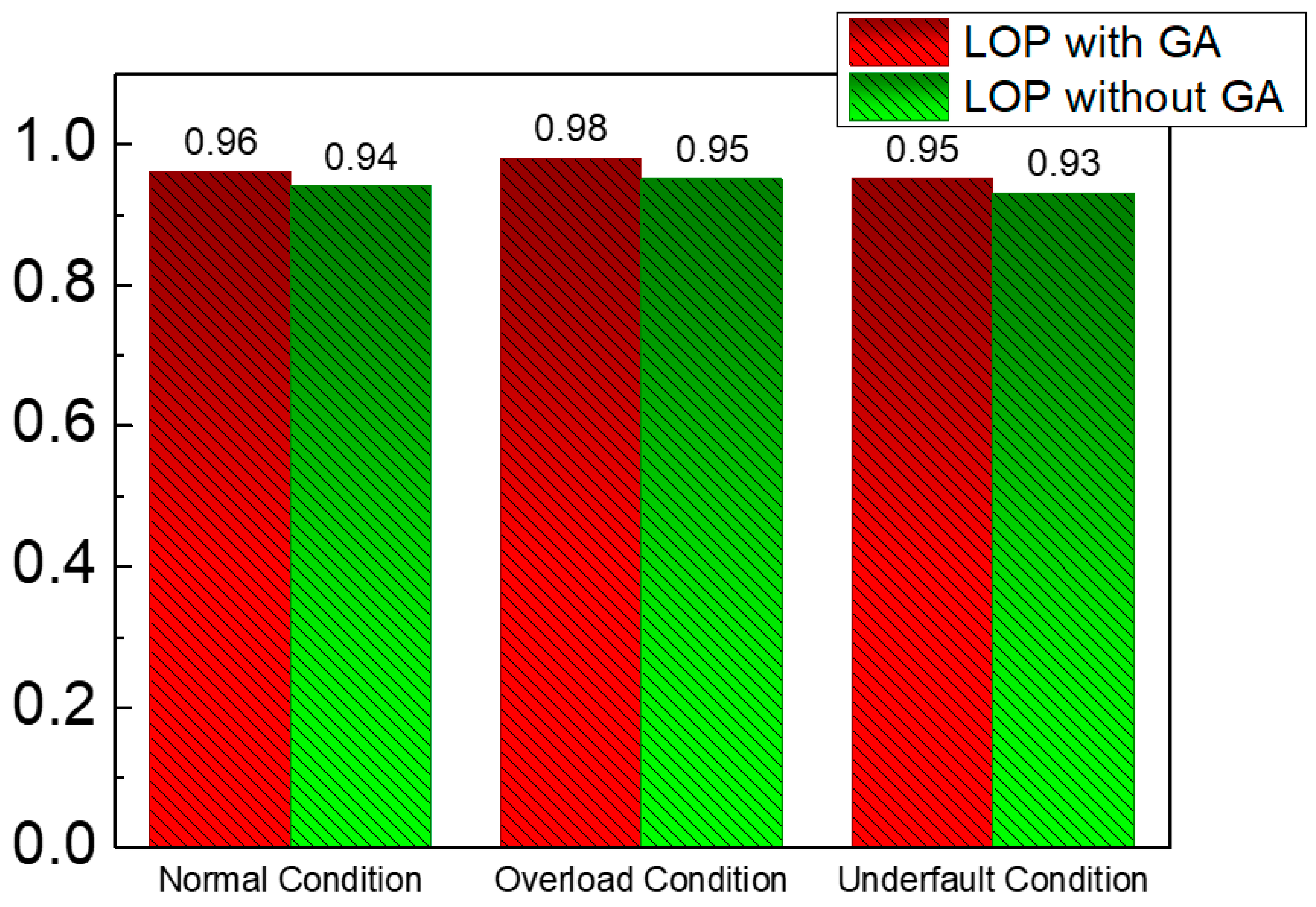

2.2. Feature Extraction through LOP

| Algorithm 1: Genetic algorithm (GA) |

| Input: positive image sample set ,images in database , β (number of generated populations), population size “PS”, genetic algorithm method “Gm” |

| 1. for j←1, β do |

| 2. |

| 3. for k←1, PS/2 do |

| 4. [p1, p2] ←rand (2) |

| 5. [C1, C2] ←rand (2) |

| 6. |

| 7. |

| 8. if Gm = elitism asymmetric, then |

| 9. compute |

| 10. else |

| 11. compute |

| 12. compute |

| 13. end if |

| 14. end for |

| 15. end for |

| Output: |

2.3. Data Training Using the SVM Classifier

- SVM works well when there is a clear margin of separation between classes;

- SVM is memory-efficient as compared to other classifiers;

- SVM has better computational complexity;

- The execution time of SVM is very short.

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Inductionmotor | IM |

| Infrared thermography | IRT |

| Local octa pattern | LOP |

| Support-vector machine | SVM |

| Run-to-failure | RTF |

| Artificial intelligence | AI |

| Artificial neural network | ANN |

| Multilayer perception | MLP |

| Local tetra pattern | LTP |

| Genetic algorithm | GA |

| Machine vision | MV |

References

- Malekpour, M.; Phung, B.; Ambikairajah, E. Online technique for insulation assessment of induction motor stator windings under different load conditions. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 349–358. [Google Scholar] [CrossRef]

- Huda, A.N.; Taib, S. Application of infrared thermography for predictive/preventive maintenance of thermal defect in electrical equipment. Appl. Therm. Eng. 2013, 61, 220–227. [Google Scholar] [CrossRef]

- Kim, Y.-H.; Youn, Y.-W.; Hwang, D.-H.; Sun, J.-H.; Kang, D.-S. High-Resolution Parameter Estimation Method to Identify Broken Rotor Bar Faults in Induction Motors. IEEE Trans. Ind. Electron. 2012, 60, 4103–4117. [Google Scholar] [CrossRef]

- Arkan, M.; Kostic-Perovic, D.; Unsworth, P. Modelling and simulation of induction motors with inter-turn faults for diagnostics. Electr. Power Syst. Res. 2005, 75, 57–66. [Google Scholar] [CrossRef]

- Hong, J.; Park, S.; Hyun, D.; Kang, T.J.; Lee, S.B.; Kral, C.; Haumer, A. Detection and classification of rotor demagnetization and eccentricity faults for PM synchronous motors. IEEE Trans. Ind. Appl. 2012, 48, 923–932. [Google Scholar] [CrossRef]

- Torkaman, H.; Afjei, E.; Yadegari, P. Static, Dynamic, and Mixed Eccentricity Faults Diagnosis in Switched Reluctance Motors Using Transient Finite Element Method and Experiments. IEEE Trans. Magn. 2012, 48, 2254–2264. [Google Scholar] [CrossRef]

- Leite, V.C.; Da Silva, J.G.B.; Veloso, G.F.C.; Da Silva, L.E.B.; Lambert-Torres, G.; Bonaldi, E.L.; De Lacerda De Oliveira, L.E. Detection of Localized Bearing Faults in Induction Machines by Spectral Kurtosis and Envelope Analysis of Stator Current. IEEE Trans. Ind. Electron. 2015, 62, 1855–1865. [Google Scholar] [CrossRef]

- Eftekhari, M.; Moallem, M.; Sadri, S.; Shojaei, A. Review of induction motor testing and monitoring methods for inter-turn stator winding faults. In Proceedings of the 2013 21st Iranian Conference on Electrical Engineering (ICEE), Mashhad, Iran, 14–16 March 2013; pp. 1–6. [Google Scholar]

- Gyftakis, K.N.; Drif, M.; Cardoso, A.J.M. Thorough investigation of the third current harmonic in delta-connected induction motors suffering from a stator inter-turn fault. In Proceedings of the 2015 IEEE 10th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives (SDEMPED), Guarda, Portugal, 1–4 September 2015; pp. 7–13. [Google Scholar]

- Kawady, T.A.; Afify, A.A.; Osheiba, A.M.; Taalab, A.I. Modeling and Experimental Investigation of Stator Winding Faults in Induction Motors. Electr. Power Compon. Syst. 2009, 37, 599–611. [Google Scholar] [CrossRef]

- Chen, B.; Wan, J.; Xia, M.; Zhang, Y. Exploring Equipment Electrocardiogram Mechanism for Performance Degradation Monitoring in Smart Manufacturing. IEEE/ASME Trans. Mechatron. 2020, 25, 2276–2286. [Google Scholar] [CrossRef]

- Ge, Z.; Du, X.; Yang, L.; Yang, Y.; Li, Y.; Jin, Y. Performance monitoring of direct air-cooled power generating unit with infrared thermography. Appl. Therm. Eng. 2011, 31, 418–424. [Google Scholar] [CrossRef]

- Lahiri, B.; Bagavathiappan, S.; Jayakumar, T.; Philip, J. Medical applications of infrared thermography: A review. Infrared Phys. Technol. 2012, 55, 221–235. [Google Scholar] [CrossRef] [PubMed]

- Royo, R.; Albertos-Arranz, M.A.; Cárcel-Cubas, J.A.; Payá, J. Thermographic study of the preheating plugs in diesel engines. Appl. Therm. Eng. 2012, 37, 412–419. [Google Scholar] [CrossRef]

- Manana, M.; Arroyo, A.; Ortiz, A.; Renedo, C.; Perez, S.; Delgado, F. Field winding fault diagnosis in DC motors during manufacturing using thermal monitoring. Appl. Therm. Eng. 2011, 31, 978–983. [Google Scholar] [CrossRef]

- Tsanakas, J.A.; Ha, L.; Buerhop, C. Faults and infrared thermographic diagnosis in operating c-Si photovoltaic modules: A review of research and future challenges. Renew. Sustain. Energy Rev. 2016, 62, 695–709. [Google Scholar] [CrossRef]

- Roslidar, R.; Rahman, A.; Muharar, R.; Syahputra, M.R.; Arnia, F.; Syukri, M.; Pradhan, B.; Munadi, K. A Review on Recent Progress in Thermal Imaging and Deep Learning Approaches for Breast Cancer Detection. IEEE Access 2020, 8, 116176–116194. [Google Scholar] [CrossRef]

- Doshvarpassand, S.; Wu, C.; Wang, X. An overview of corrosion defect characterization using active infrared thermography. Infrared Phys. Technol. 2018, 96, 366–389. [Google Scholar] [CrossRef]

- Nardi, I.; Lucchi, E.; de Rubeis, T.; Ambrosini, D. Quantification of heat energy losses through the building envelope: A state-of-the-art analysis with critical and comprehensive review on infrared thermography. Build. Environ. 2018, 146, 190–205. [Google Scholar] [CrossRef] [Green Version]

- ElMasry, G.; ElGamal, R.; Mandour, N.; Gou, P.; Al-Rejaie, S.; Belin, E.; Rousseau, D. Emerging thermal imaging techniques for seed quality evaluation: Principles and applications. Food Res. Int. 2020, 131, 109025. [Google Scholar] [CrossRef]

- Glowacz, A. Ventilation Diagnosis of Angle Grinder Using Thermal Imaging. Sensors 2021, 21, 2853. [Google Scholar] [CrossRef]

- Chou, Y.-C.; Yao, L. Automatic Diagnostic System of Electrical Equipment Using Infrared Thermography. In Proceedings of the 2009 International Conference of Soft Computing and Pattern Recognition, Malacca, Malaysia, 4–7 December 2009; pp. 155–160. [Google Scholar]

- Singh, G.; Naikan, V. Infrared thermography based diagnosis of inter-turn fault and cooling system failure in three phase induction motor. Infrared Phys. Technol. 2017, 87, 134–138. [Google Scholar] [CrossRef]

- Manduchi, G.; Marinetti, S.; Bison, P.; Grinzato, E. Application of neural network computing to thermal non-destructive evaluation. Neural Comput. Appl. 1997, 6, 148–157. [Google Scholar] [CrossRef]

- Kumar, R.; Raj, L.G.C.; Abarna, J. Analysis of Fuzzy Logic Based Fault Detection for Three Phase Induction Motor Drive System. In Proceedings of the 2018 4th International Conference on Electrical Energy Systems (ICEES), Chennai, India, 7–9 February 2018; pp. 700–705. [Google Scholar]

- Hussan, U.; Majeed, M.A.; Asghar, F.; Waleed, A.; Khan, A.; Javed, M.R. Fuzzy logic-based voltage regulation of hybrid energy storage system in hybrid electric vehicles. Electr. Eng. 2021, 104, 485–495. [Google Scholar] [CrossRef]

- Javed, M.R.; Waleed, A.; Virk, U.S.; Hassan, S.Z.U. Comparison of the Adaptive Neural-Fuzzy Interface System (ANFIS) based Solar Maximum Power Point Tracking (MPPT) with other Solar MPPT Methods. In Proceedings of the 2020 IEEE 23rd International Multitopic Conference (INMIC), Bahawalpur, Pakistan, 5–7 November 2020; pp. 1–5. [Google Scholar]

- Idrees, M.; Riaz, M.T.; Waleed, A.; Paracha, Z.J.; Raza, H.A.; Khan, M.A.; Hashmi, W.S. Fuzzy Logic Based Calculation and Analysis of Health Index for Power Transformer Installed in Grid Stations. In Proceedings of the 2019 International Symposium on Recent Advances in Electrical Engineering (RAEE), Islamabad, Pakistan, 28–29 August 2019; Volume 4, pp. 1–6. [Google Scholar] [CrossRef]

- Darabi, A.; Maldague, X. Neural network based defect detection and depth estimation in TNDE. NDT E Int. 2002, 35, 165–175. [Google Scholar] [CrossRef]

- Almeida, C.A.L.; Braga, A.P.; Nascimento, S.; Paiva, V.; Martins, H.J.A.; Torres, R.; Caminhas, W.M. Intelligent Thermographic Diagnostic Applied to Surge Arresters: A New Approach. IEEE Trans. Power Deliv. 2009, 24, 751–757. [Google Scholar] [CrossRef]

- Kumar, P.; Hati, A.S. Review on Machine Learning Algorithm Based Fault Detection in Induction Motors. Arch. Comput. Methods Eng. 2020, 28, 1929–1940. [Google Scholar] [CrossRef]

- Jia, Z.; Liu, Z.; Vong, C.-M.; Pecht, M. A Rotating Machinery Fault Diagnosis Method Based on Feature Learning of Thermal Images. IEEE Access 2019, 7, 12348–12359. [Google Scholar] [CrossRef]

- Rao, P.N.; Kumar, N.M.; Padmanaban, S.; Subathra, M.S.P.; Chand, A.A. A Novel Sensorless Approach for Speed and Displacement Control of Bearingless Switched Reluctance Motor. Appl. Sci. 2020, 10, 4070. [Google Scholar] [CrossRef]

- Shafi’i, M.A.; Hamzah, N. Internal fault classification using artificial neural network. In Proceedings of the 2010 4th International Power Engineering and Optimization Conference (PEOCO), Shah Alam, Malaysia, 23–24 June 2010; pp. 352–357. [Google Scholar]

- Ullah, I.; Yang, F.; Khan, R.; Liu, L.; Yang, H.; Gao, B.; Sun, K. Predictive Maintenance of Power Substation Equipment by Infrared Thermography Using a Machine-Learning Approach. Energies 2017, 10, 1987. [Google Scholar] [CrossRef] [Green Version]

- Rahmani, A.; Haddadnia, J.; Seryasat, O. Intelligent fault detection of electrical equipment in ground substations using thermo vision technique. In Proceedings of the 2010 2nd International Conference on Mechanical and Electronics Engineering, Kyoto, Japan, 1–3 August 2010; Volume 2, pp. V2-150–V2-154. [Google Scholar]

- Shabbir, Z.; Irtaza, A.; Javed, A.; Mahmood, M.T. Tetragonal Local Octa-Pattern (T-LOP) based image retrieval using genetically optimized support vector machines. Multimed. Tools Appl. 2019, 78, 23617–23638. [Google Scholar] [CrossRef]

- Murala, S.; Maheshwari, R.P.; Balasubramanian, R. Local Tetra Patterns: A New Feature Descriptor for Content-Based Image Retrieval. IEEE Trans. Image Process. 2012, 21, 2874–2886. [Google Scholar] [CrossRef]

- Asghar, F.; Talha, M.; Kim, S.H. Neural Network Based Fault Detection and Diagnosis System for Three-Phase Inverter in Variable Speed Drive with Induction Motor. J. Control Sci. Eng. 2016, 2016, 1286318. [Google Scholar] [CrossRef] [Green Version]

- Talha, M.; Asghar, F.; Kim, S.H. A Novel Three-Phase Inverter Fault Diagnosis System Using Three-dimensional Feature Extraction and Neural Network. Arab. J. Sci. Eng. 2018, 44, 1809–1822. [Google Scholar] [CrossRef]

- Irtaza, A.; Jaffar, M.A. Categorical image retrieval through genetically optimized support vector machines (GOSVM) and hybrid texture features. Signal Image Video Process. 2014, 9, 1503–1519. [Google Scholar] [CrossRef]

- Arevalillo-Herráez, M.; Ferri, F.J.; Moreno-Picot, S. Distance-based relevance feedback using a hybrid interactive genetic algorithm for image retrieval. Appl. Soft. Comput. 2011, 11, 1782–1791. [Google Scholar] [CrossRef]

- Herrera, F.; Lozano, M. Hybrid crossover operators for real-coded genetic algorithms: An experimental study. Soft Comput. 2004, 9, 280–298. [Google Scholar] [CrossRef]

- Hearst, M.A.; Dumais, S.T.; Osuna, E.; Platt, J.; Scholkopf, B. Support vector machines. IEEE Intell. Syst. Appl. 1998, 13, 18–28. [Google Scholar] [CrossRef] [Green Version]

| No. | Parameter | Specification (Value) |

|---|---|---|

| 1 | Rated Power | 2 kW |

| 2 | Rated Frequency | 50 Hz |

| 3 | Stator Resistance | 1.47 Ω |

| 4 | Rotor Resistance | 1.39 Ω |

| 5 | Magnetizing Reactance | 54.1 Ω |

| 6 | Rated Speed | 1410 RPM |

| 7 | Efficiency | 87% |

| No. | State of Motor | ΔT | Recommended Action |

|---|---|---|---|

| 1 | Normal Operating Condition | 30 < T < 45 | No Need for Action |

| 2 | Overloaded Condition | 45 < T < 63 | Wait for Some Time |

| 3 | Fault Condition | T > 65 | Shut Down |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Javed, M.R.; Shabbir, Z.; Asghar, F.; Amjad, W.; Mahmood, F.; Khan, M.O.; Virk, U.S.; Waleed, A.; Haider, Z.M. An Efficient Fault Detection Method for Induction Motors Using Thermal Imaging and Machine Vision. Sustainability 2022, 14, 9060. https://doi.org/10.3390/su14159060

Javed MR, Shabbir Z, Asghar F, Amjad W, Mahmood F, Khan MO, Virk US, Waleed A, Haider ZM. An Efficient Fault Detection Method for Induction Motors Using Thermal Imaging and Machine Vision. Sustainability. 2022; 14(15):9060. https://doi.org/10.3390/su14159060

Chicago/Turabian StyleJaved, Muhammad Rameez, Zain Shabbir, Furqan Asghar, Waseem Amjad, Faisal Mahmood, Muhammad Omer Khan, Umar Siddique Virk, Aashir Waleed, and Zunaib Maqsood Haider. 2022. "An Efficient Fault Detection Method for Induction Motors Using Thermal Imaging and Machine Vision" Sustainability 14, no. 15: 9060. https://doi.org/10.3390/su14159060

APA StyleJaved, M. R., Shabbir, Z., Asghar, F., Amjad, W., Mahmood, F., Khan, M. O., Virk, U. S., Waleed, A., & Haider, Z. M. (2022). An Efficient Fault Detection Method for Induction Motors Using Thermal Imaging and Machine Vision. Sustainability, 14(15), 9060. https://doi.org/10.3390/su14159060