Five Guidelines for Adopting Smartwatches in Construction: A Novel Approach for Understanding Workers’ Efficiency Based on Travelled Distances and Locations

Abstract

:1. Introduction

- How can smartwatches be adopted to facilitate understanding workers’ travelled distances and job site location?

- How can the data gathered using smartwatches be helpful in measuring workers’ efficiency?

2. Literature Review

2.1. Smartwatches

2.2. Previous Studies That Used Wristworn Sensors in the Construction Sector

| # | Ref. | Field | Index Measured | Topic Evaluated | Sensors/ Tools Used | Goal | Type of Wearable | Testing Environment |

|---|---|---|---|---|---|---|---|---|

| 1 | [22] | AR | Heart rate (HR) | Four activities (hammering, sawing, sweeping, and drilling) | Accelerometer Gyrometer | To classify construction activities using accelerometer and gyrometer data | Samsung GearLive Smartwatch | Outdoor Job site |

| 2 | [34] | HS | HR | Workers’ physical strain | HR sensor ECG sensor | To monitor workers’ physical strain based on HR | Basis PeakTM fitness tracker | Job site |

| 3 | [30] | HS | HR | Energy Expenditure (EE) | Accelerometer | To estimate energy expenditure (EE) by monitoring HR | Basis PeakTM fitness tracker | Job site |

| 4 | [23] | AR | HR | Four activities (spreading mortar, bring and laying blocks, adjusting blocks, and removing remaining mortar) | Accelerometer | To recognise masonry actions | eZ430-Chronos sport watch | Indoor Masonry Training Centre |

| 5 | [35] | AR | Heart rate reserve (HRR) | Work patterns | HR sensor | To investigate the relationship between work patterns and heart rate reserve measurements | “off-the-shelf”-type | Job site |

| 6 | [13] | DS | Intention to adopt | Usefulness (PU), Social influence (SI), Perceived privacy risk (PR) | Questionnaire | To investigate workers’ intention to adopt a smart vest and a wristband | Basis PeakTM fitness tracker | Job site |

| 7 | [31] | HS | HR Number of steps | Level of stress: (1) Calm; (2) Stress; and (3) Sport status | HR sensor | To investigates the relationship between workers’ psychological status and physical data | Basis PeakTM smartwatch | Job site |

| 8 | [25] | HS | Electrodermal (EDA), Skin Temperature (ST), Photoplethysmogram (PPG) | Workers’ physical and mental state | Biosensor | To assess workers’ physical and mental state based on three bio signals. | Wristband sensor | Job site |

| 9 | [33] | DS | - | Predicting safety performance | Literature Review | To review the applications of wearable technology for personalised construction safety monitoring | - | - |

| 10 | [10] | AR | Hand activities | Four masonry activities (spreading mortar, bringing and laying blocks, adjustments blocks, and removing remaining mortar) | Accelerometer | To recognise actions of masonry work for automatic field data collection | eZ430-Chronos sport watch | Laboratory |

| 11 | [26] | HS | HR | Level of stress: (1) low; (2) medium, and (3) high | Biosensor | To measure workers’ stress with signals from a wristworn biosensor | Empatica E4 wristband biosensor | Job site |

| 12 | [27] | HS | HR | Physical demand: (1) low; (2) moderate, and (3) high | Biosensor | To measure workers’ physical demand levels from a wristworn biosensor | Empatica E4 wristband biosensor | Job site |

| 13 | [24] | HS | EDA | Workers’ perceived risk: (1) low; and (2) high | Biosensor | To understand workers’ perceived risk by monitoring physiological responses | Empatica E4 wristband biosensor | Job site |

| 14 | [32] | DS | - | Five applications to evaluate and prevent: (1) musculoskeletal disorders, (2) falls, (3) physical workload, (4) hazard-recognition abilities, and (5) workers’ mental status | Literature Review | State-of-the-art within applications of wearable kinematic and physiological sensors in construction safety and health | - | - |

| 15 | [7] | DS | - | Three categories: (1) audio-based, (2) kinematic-based, and (3) computer vision–based techniques | Literature Review | State-of-the-art of literature concerning technologies for automated performance monitoring of construction workers and equipment | - | - |

| 16 | [36] | HS | HR Sleep quality | Fatigue | Biosensor | To estimate fatigue based on monitoring HR and sleep quality of construction workers | Fitbit Charge 2 | Laboratory |

| 17 | [28] | HS | ST, PPG, EDA | Heat-related illnesses | Biosensor | To propose a predictive heat strain process based on workers’ physiological signals to address the risk of heat-related illnesses | Empatica E4 wristband biosensor | Laboratory |

| 18 | [37] | HS | HR | Workers’ perceived risk: (1) low; and (2) high | Biosensor | To develop an automatic method for identifying workers’ perceived risk level using a wristworn biosensor collecting physiological signals | Empatica E4 wristband biosensor | Job site |

| 19 | [4] | AR | Blood volume pulse (BVP), Respiration rate (RR), HR, Galvanic skin response (GSR), ST | Four activities (Oiling, moving, cleaning and opening stone moulds) | Biosensor Accelerometer | To recognise actions using labour physiological data | Empatica E4 wristband biosensor | Pre-fabrication factory |

3. Research Methodology

3.1. Research Strategy

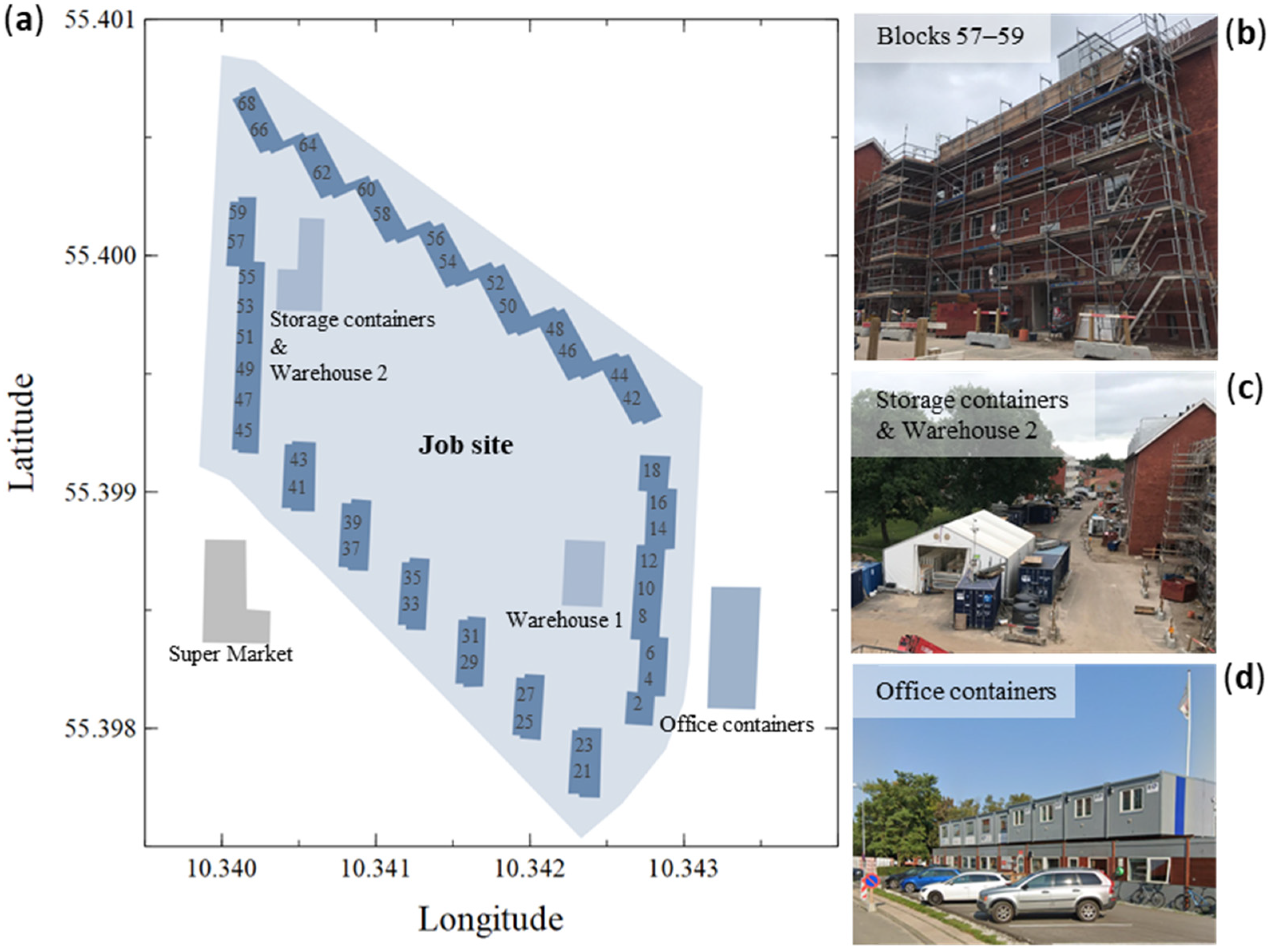

3.2. Case Study Description

3.3. Research Design

3.3.1. Study Preparation

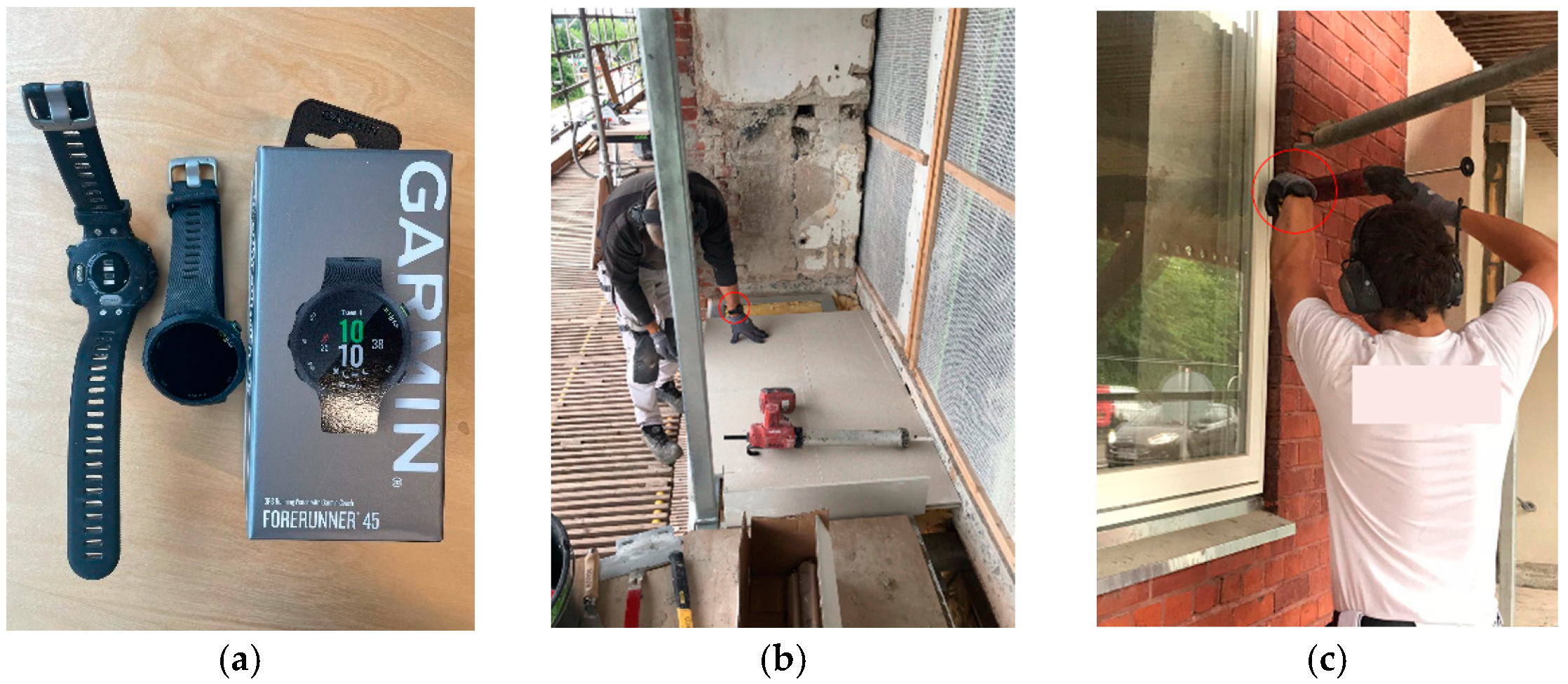

3.3.2. Setup of Smartwatches

3.3.3. Gathering Data

Smartwatches Delivered to Workers

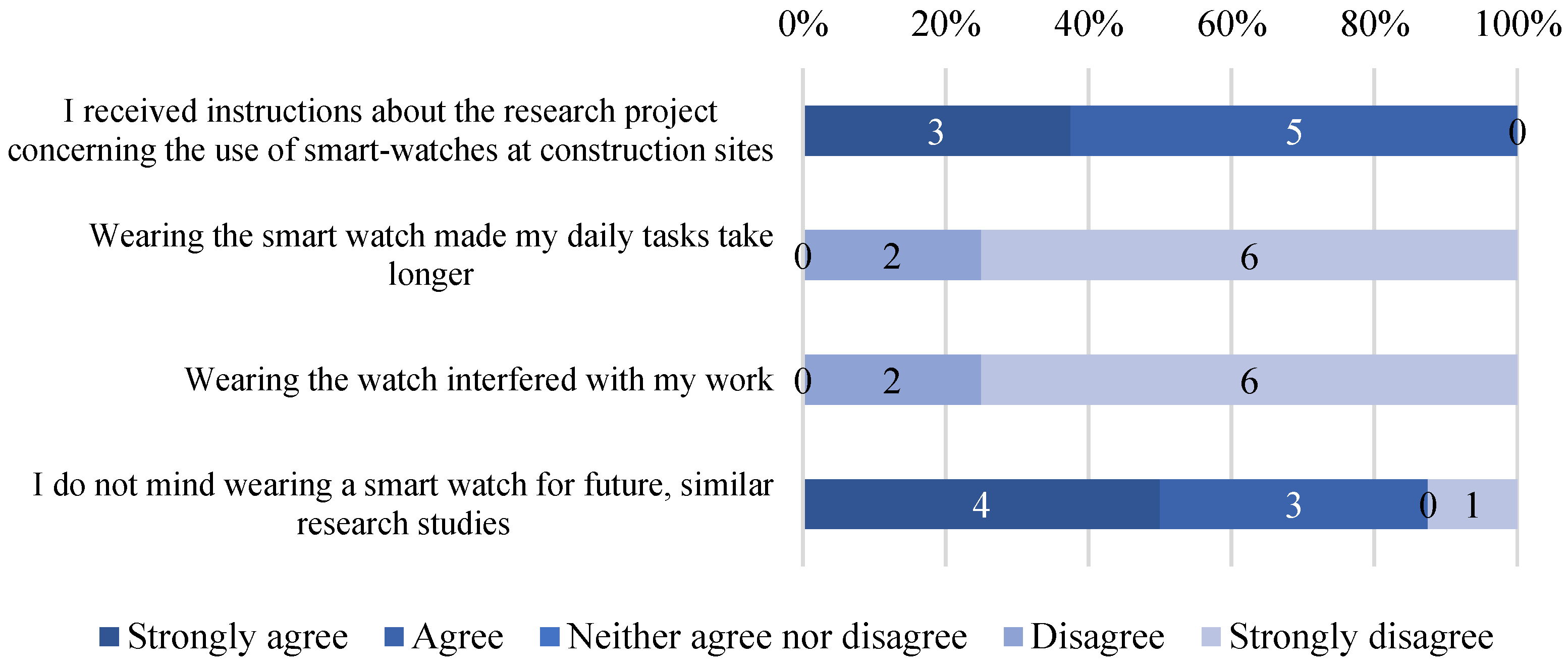

Workers’ Perception

3.3.4. Data Storing and Transformation

3.3.5. Data Aggregation and Cleaning

3.3.6. Data Analysis

4. Findings

4.1. Workers’ Travelled Distance

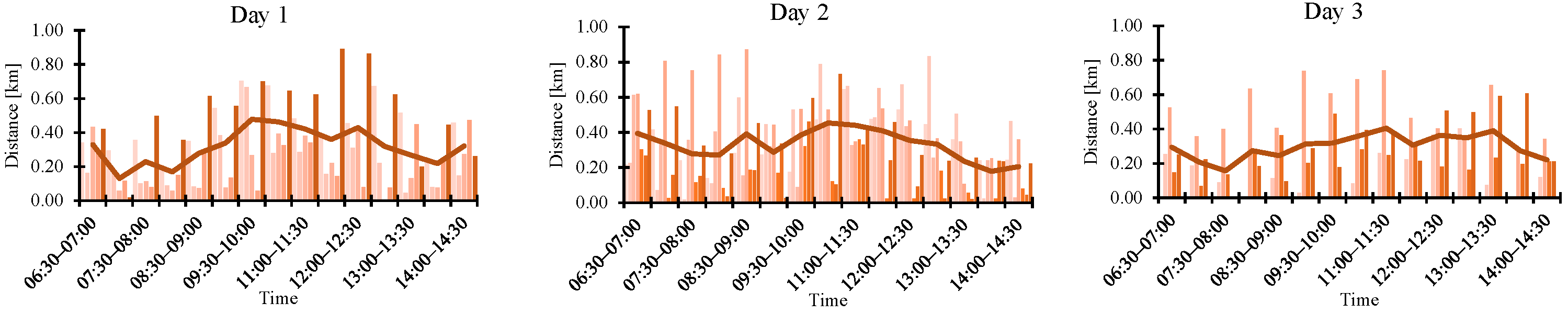

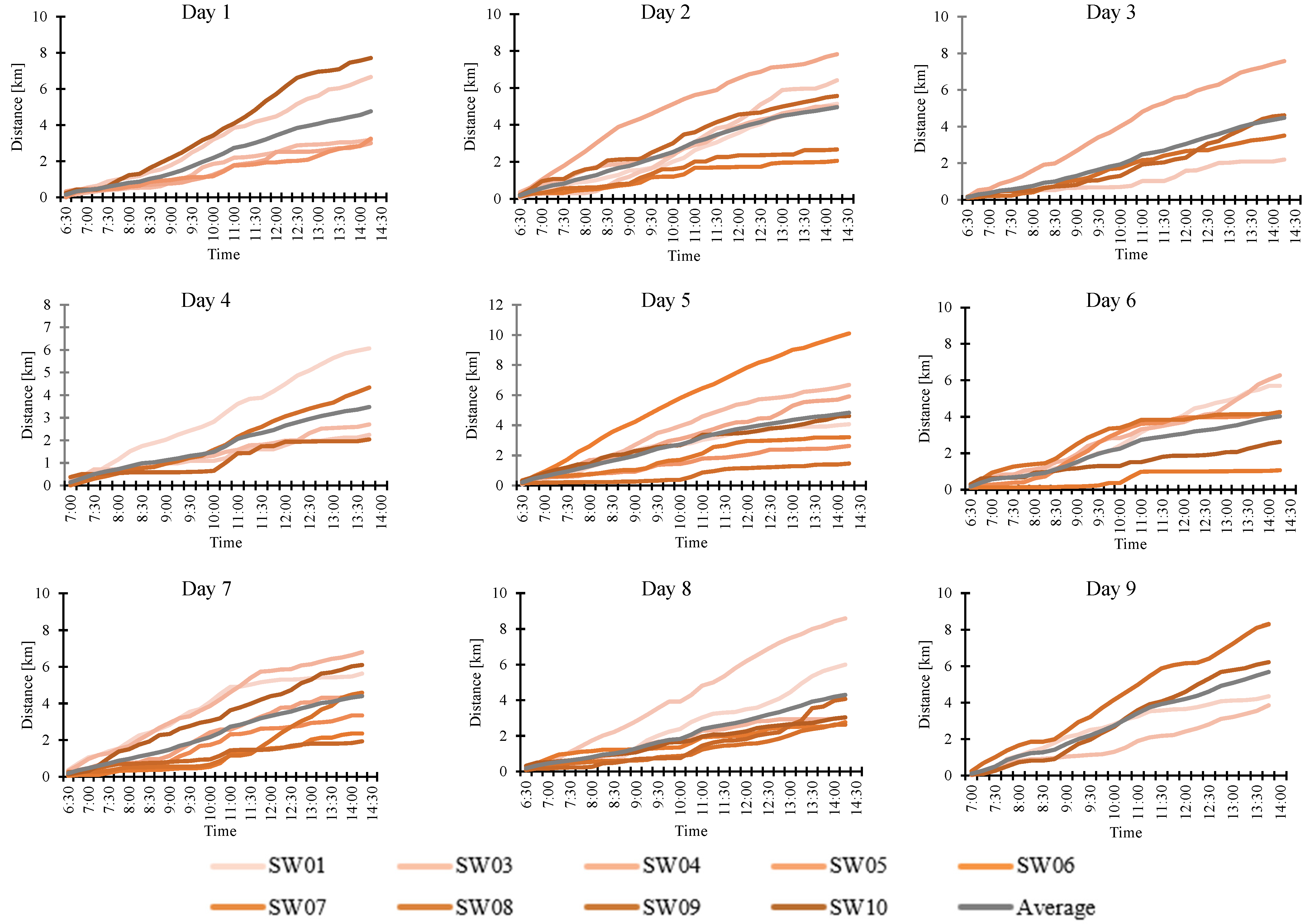

4.1.1. Total Travelled Distance (TTD) along the Day

4.1.2. Cumulative Travelled Distance

4.1.3. Average Travelled Distance [km]

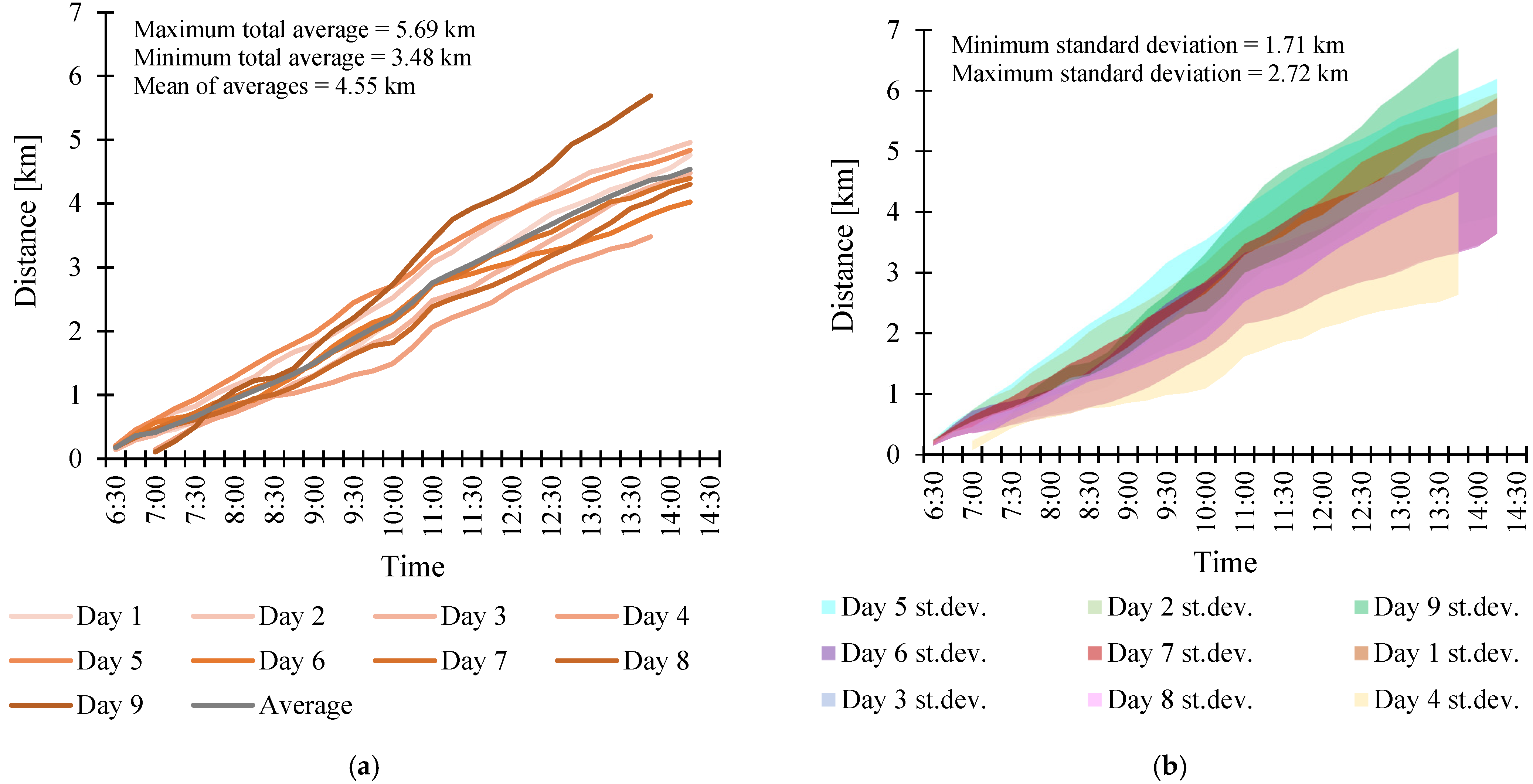

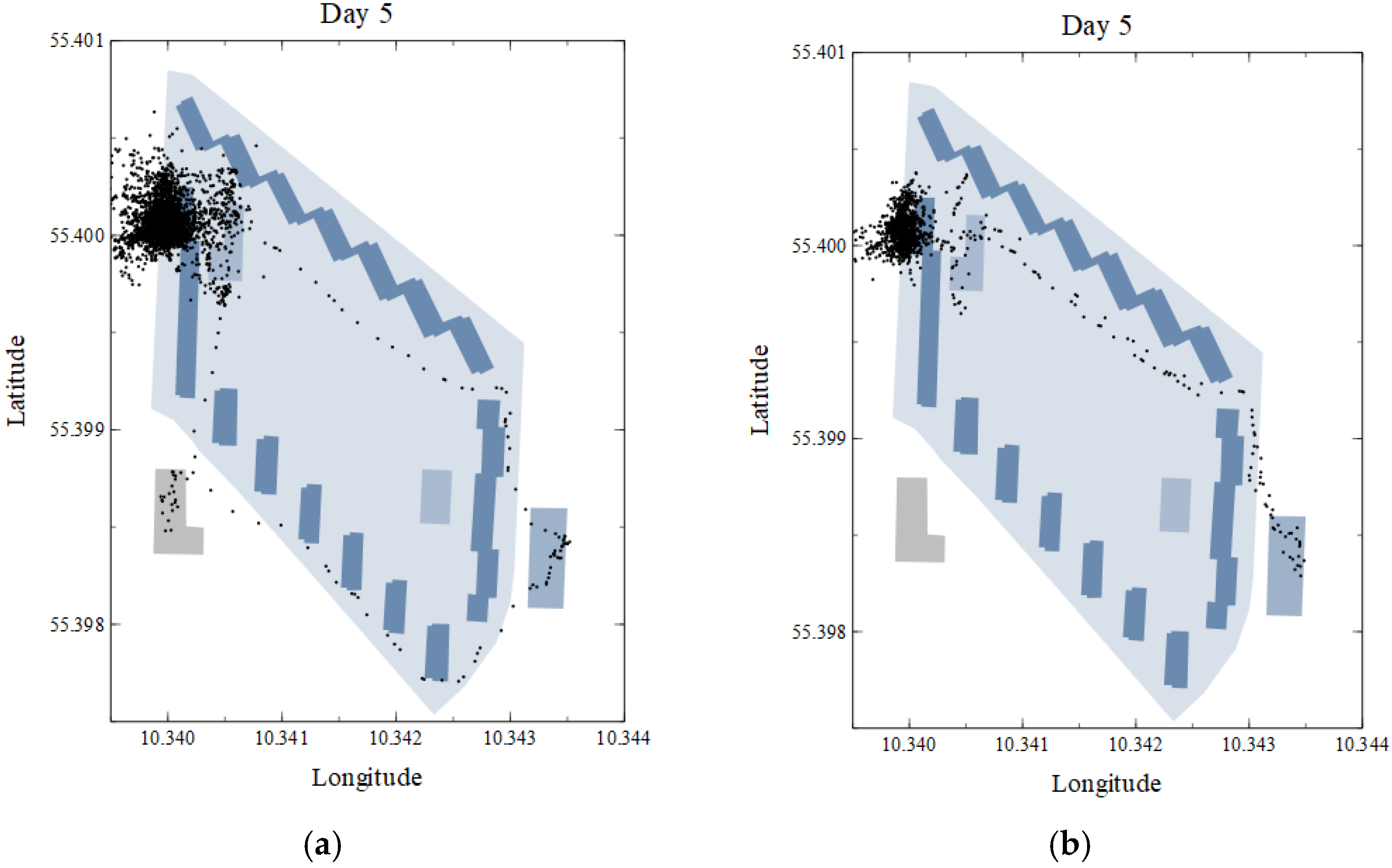

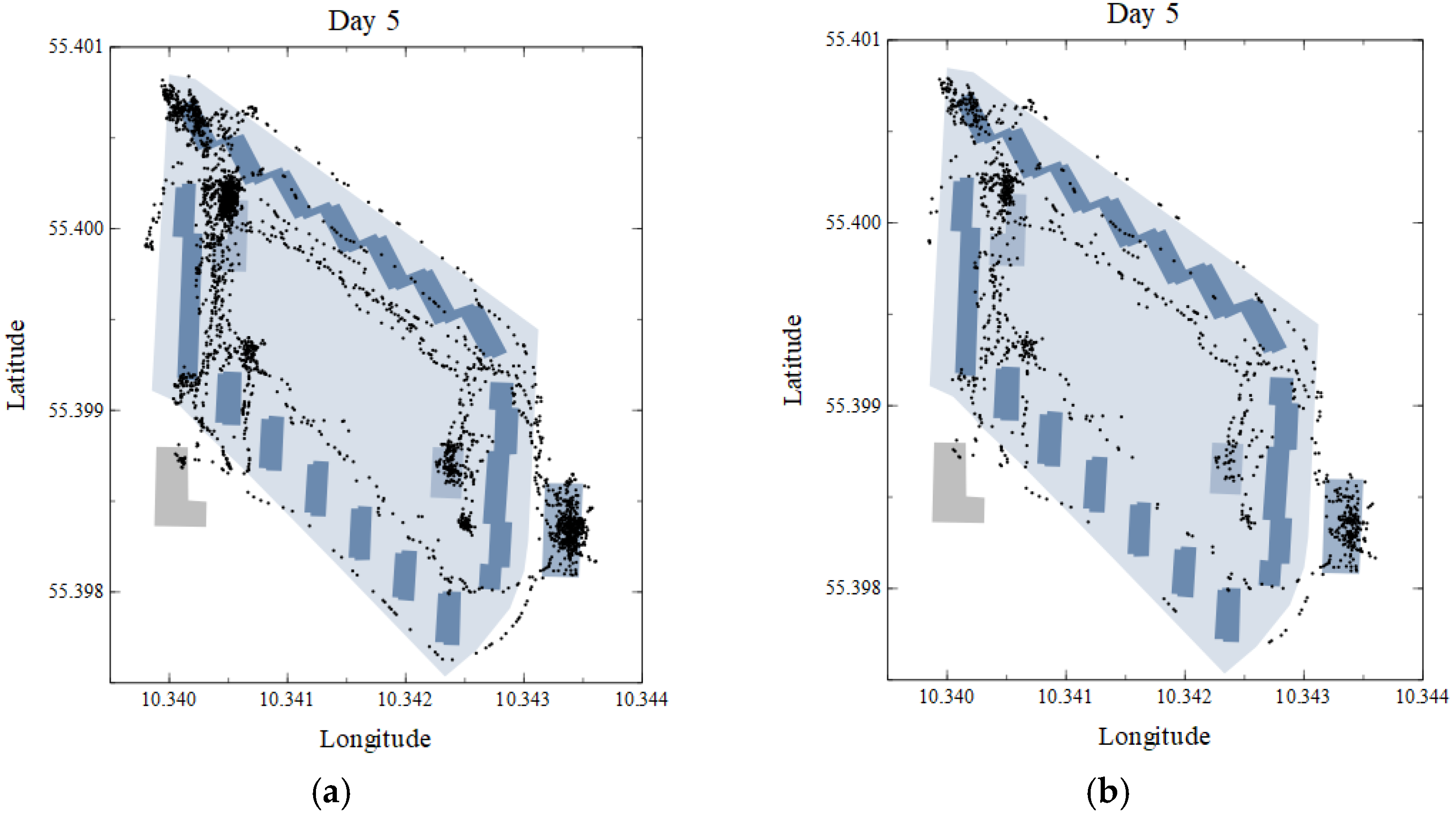

4.2. Workers’ Locations on the Job Site

4.3. Carpenters’ Perception

5. Guidelines for the Adoption of Smartwatches to Track Workers

5.1. Guideline 1: Adopt a Stratified Sampling Approach for Selecting the Workers Involved according to Their Tasks Conducted

- Guideline description: During the first step–selecting participants, the authors considered a stratified sampling the most suitable approach because knowing workers’ roles can provide helpful information for the analysis phase (e.g., workers in charge of installing windows; workers in charge of installing drywall). Stratified sampling is a method of sampling that involves dividing a population into sub-groups, called strata, based on shared characteristics [47]. Thus, one way to get a better assessment of the workers’ duties during the process would be to stratify the sample by type of task conducted.

- Limitation: This paper adopted a random sampling approach for the selection of the participants. As previously described, in this study, all watches were handed out randomly to ensure anonymity, and thus it was not possible to associate the TTD and workers’ locations according to their tasks.

- Justification: A justification for the adoption of stratified random sampling can be explained based on the analysis of TTD of this study. It was observed that the foreman spent significantly more time walking than the other carpenters due to the different nature of his tasks. The foreman attended meetings and discussed with management in the office containers and then walked to the different teams of carpenters on site to deliver information and instructions. For this reason, including the foreman in the study when measuring travelled distance could have a distorting impact on the results.

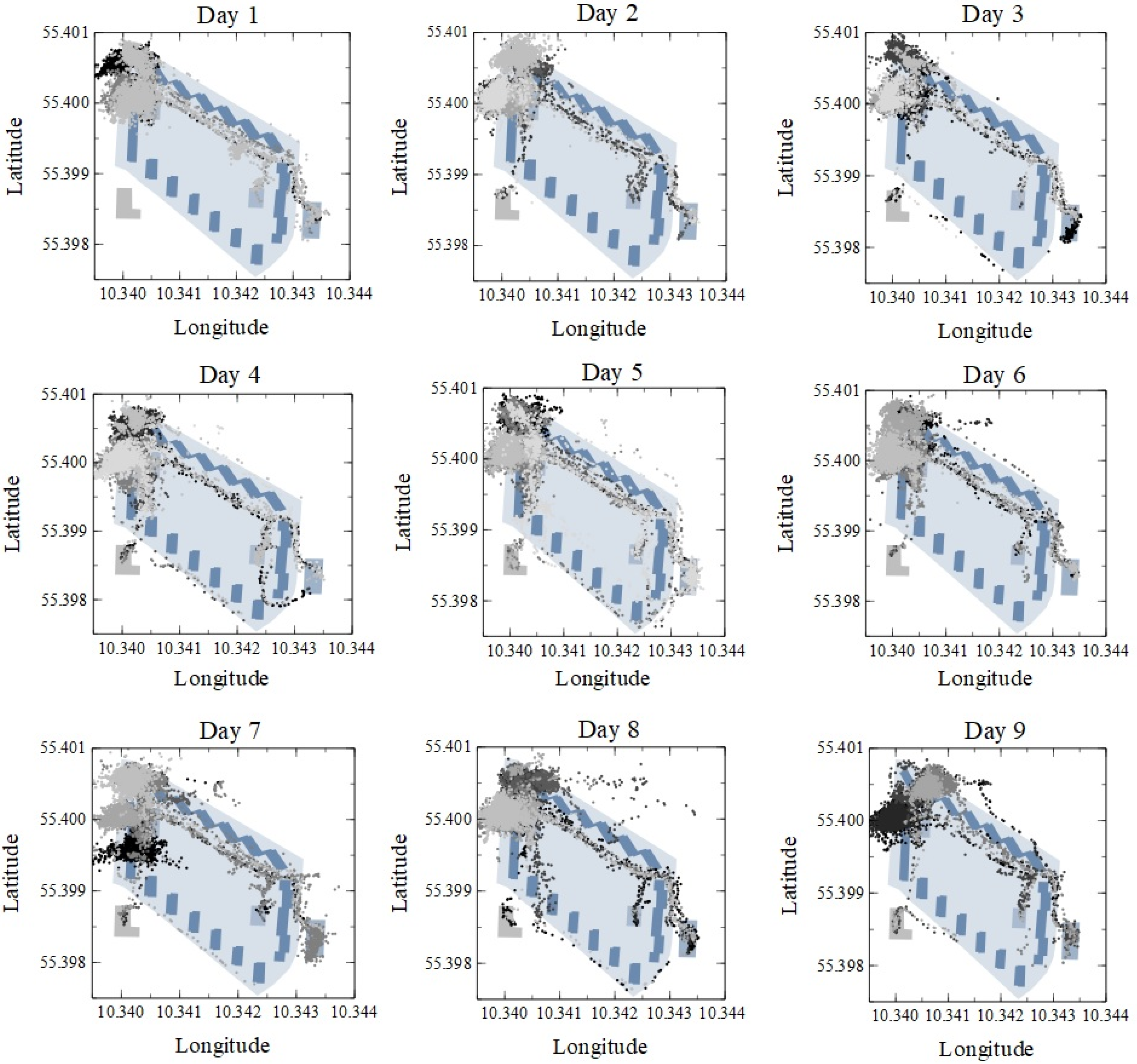

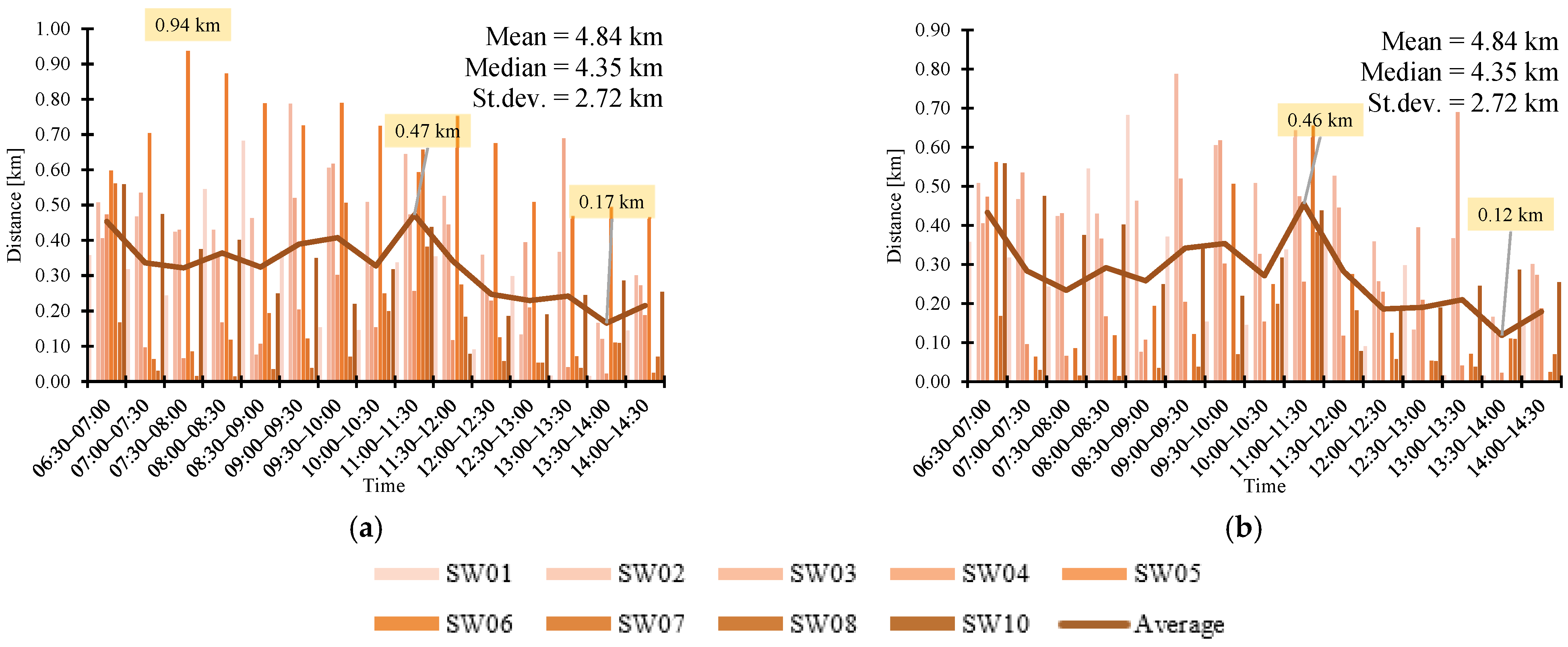

- Exemplifying the justification: To show the impact of including data from the foreman in the analyses, the data from the present study was cleaned of data from the assumed foreman on each day of data collection. Since the foreman was observed walking significantly more than the other participants in the study, in this example, he is assumed to be the one with the longest distance recorded each day. An example from Day 5 of data collection, including and excluding the assumed foreman, respectively, is depicted in Figure 8. The overall shape of the line showing the average distance does not change when excluding the foreman. The average and median distances decrease from 4.84 km to 4.09 km and from 4.35 km to 4.07 km, respectively, but the most significant change is in the standard deviation, σ, which is reduced from 2.72 km to 1.83 km.

5.2. Guideline 2: Set Up the Smartwatches Considering Workers’ Physical Features

- Guideline description: During the second step–set up smartwatches, as much as possible, the authors suggest collecting participants’ features (e.g., height, weight, gender and age) to add this information to the smartwatch profile, as this will influence the results.

- Limitation: This study adopted average data for a Danish male instead of the personal features of each worker to maintain the anonymity of the smartwatch user.

- Justification: Personal features have an impact on the accuracy of the recorded training data of smartwatches. Height impacts the stride length used to calculate the number of steps taken, and age affects the heart rate zones used to calculate the number of calories burned.

- Exemplifying the justification: The average male walking step length is 75 cm. However, the stride length varied from 63.5 cm for a male of 152 cm to 82.3 cm for a male of 198 cm.

5.3. Guideline 3: Carefully Consider the Job Site Location for Delivering and Collecting the Smartwatch to Workers

- Guideline description: During the third step–data collection process, the place to deliver and collect the smartwacthes should be always the same at the job site.

- Limitation: The delivery and collection points for the smartwatches were not consistent, as previously described. This inconsistency had an impact on the recorded total travelled distance.

- Justification: All watches should be delivered and collected at the same place (e.g., the offices or the material storage workspace) to include all travelling necessary for the carpenters to perform their work.

- Exemplifying the justification: The TTDs previously presented in Figure 4 are presented again in Table 10, considering the hypothetical scenario of having delivered and collected the smartwatches at the same place. To understand how the delivery point could have impacted the findings, the distance between Warehouse 2 and the office room (300 m) was included in the cases where the delivered and collected points were different. With this information, the impact of not delivering and collecting the smartwatches by the changing rooms can be measured as the change in TTD. The change in TTD varies between a 4.31% increase and a 35.93% increase.

5.4. Guideline 4: Establish Assumptions for the Data Cleaning Process Regarding Construction Project Features and the Study’s Goal

- Guideline description: During the fourth step–data cleaning process, the authors suggest determining the necessary assumptions for each step to clean the data according to the construction project features. After deciding the best assumptions and steps, researchers should formalize the process for future studies.

- Limitation: The authors of this study adopted three assumptions during the data cleaning process: (1) removing short activities; (2) removing data outside the working hours; and (3) removing data according to the speed of the workers’ path. According to the analysis, the third assumption was the only one that did not help clean the data.

- Justification: Establishing and formalizing the premises can be used as a roadmap to follow. Researchers will work inconsistently without formalizing the assumptions adopted according to the construction project features.

- Exemplifying the justification: If the study’s goal in adopting smartwatches is to understand how the job site layout influences how much time workers travel, break times should be considered during the analysis. However, if the interest consists of understanding where workers spent their time during the working hours, the break times should be excluded from the study. The following sub-sections present how each of these assumptions could influence the findings.

5.4.1. Removing Activities with a Shorter Duration Than the Workday

5.4.2. Removing Data Outside Working Hours

5.4.3. Removing Data according to Workers’ Speed

5.5. Guideline 5: Use Individual Participant Data in the Analysis according to Each Participant’s Characteristics and Role

- Guideline description: During the fifth step–data analysis, the adoption of individual participant data (IPD) can provide a more appropriate analysis according to each participant’s characteristics and role. This approach requires the ability to identify which participant uses each smartwatch each day, preferably by delivering the same smartwatch to the same participant every day during the study period. For this, the product identification number of the smartwatch could be associated with the name or the role of each worker. This way, when the study ends, the names can be deleted to ensure the anonymity of the workers without the loss of data.

- Limitation: This study presented the results using an aggregated data approach based on the whole body of the collected data. The data aggregation process classified the data collected using the smartwatches according to the day of data collection and the smartwatch used (e.g., D1-SW01). The random delivery of each smartwatch to protect the anonymity of the workers prevented the adoption of an IPD approach.

- Justification: The major advantage of an IPD analysis compared to the adopted aggregated data approach is that it allows detailed participant-level exploration of effectiveness in relation to individual characteristics such as role (e.g., foreman, crew member) or construction task conducted (e.g., workers in charge of installing windows; workers in charge of installing drywall).

- Exemplifying the justification: The same example used in the Guideline 1 can be used for justifying the adoption of IPD. An IPD would have provided a better representation of the TTD and the locations on the job site according to the role of each worker.

6. Discussion

6.1. Future Steps

6.2. Limitations

6.3. Recommendations for Future Research

7. Conclusions

- How can smartwatches be adopted to facilitate understanding workers’ travelled distances and job site location?

- How can the data gathered using smartwatches be helpful in measuring workers’ efficiency?

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Sawnhey, A.; Riley, M.; Irizarry, J.; Pérez, C.T. A proposed framework for Construction 4.0 based on a Litrerature Review. In Proceedings of the Associated Schools of Construction Proceeding of the 56th Annual International Conference, Virtuall, 14–18 April 2020; pp. 301–309. [Google Scholar]

- Forcael, E.; Ferrari, I.; Opazo-Vega, A.; Pulido-Arcas, J.A. Construction 4.0: A literature review. Sustainability 2020, 12, 9755. [Google Scholar] [CrossRef]

- Črešnar, R.; Dabić, M.; Stojčić, N.; Nedelko, Z. It takes two to tango: Technological and non-technological factors of Industry 4.0 implementation in manufacturing firms. Rev. Manag. Sci. 2022. [Google Scholar] [CrossRef]

- Jassmi, H.A.; Ahmad, M.A.; Ahmed, S. Automatic recognition of labor activity: A machine learning approach to capture activity physiological patterns using wearable sensors. Constr. Innov. 2021, 21, 555–575. [Google Scholar]

- Cheng, T.; Teizer, J.; Migliaccio, G.C.; Gatti, U.C. Automated task-level activity analysis through fusion of real time location sensors and worker’s thoracic posture data. Autom. Constr. 2013, 29, 24–39. [Google Scholar] [CrossRef]

- Zhao, J.; Seppänen, O.; Peltokorpi, A.; Badihi, B.; Olivieiri, H. Real-time resource tracking for analyzing value-adding time in construction. Autom. Constr. 2019, 104, 52–65. [Google Scholar] [CrossRef]

- Sherafat, B.; Ahn, C.R.; Akhavian, R.; Behzadan, A.H.; Golparvar-Fard, M.; Kim, H.; Lee, Y.; Rashidi, A.; Azar, E.R. Automated Methods for Activity Recognition of Construction Workers and Equipment: State-of-the-Art Review. J. Constr. Eng. Manag. 2020, 146, 03120002-1–03120002-19. [Google Scholar] [CrossRef]

- Liu, K.J.; Golparvar-Fard, M. Crowdsourcing Construction Activity Analysis from Jobsite Video Streams. J. Constr. Eng. Manag. 2015, 141, 19. [Google Scholar] [CrossRef]

- Cheng, C.-F.; Rashidi, A.; Davenport, M.A.; Anderson, D.V. Activity analysis of construction equipment using audio signals and support vector machines. Autom. Constr. 2017, 81, 240–253. [Google Scholar] [CrossRef]

- Ryu, J.; Seo, J.; Jebelli, H.; Lee, S. Automated Action Recognition Using an Accelerometer-Embedded Wristband-Type Activity Tracker. J. Constr. Eng. Manag. 2018, 145, 04018114. [Google Scholar] [CrossRef]

- Joshua, L.; Varghese, K. Automated recognition of construction labour activity using accelerometers in field situations. Int. J. Product. Perform. Manag. 2014, 63, 841–862. [Google Scholar] [CrossRef]

- Shoaib, M.; Bosch, S.; Incel, O.; Scholten, H.; Havinga, P. A Survey of Online Activity Recognition Using Mobile Phones. Sensors 2015, 15, 2059–2085. [Google Scholar] [CrossRef]

- Choi, B.; Hwang, S.; Lee, S. What drives construction workers’ acceptance of wearable technologies in the workplace?: Indoor localization and wearable health devices for occupational safety and health. Autom. Constr. 2017, 84, 31–41. [Google Scholar] [CrossRef]

- Danova, T. Why the Smart Watch Market Is Poised to Explode as It Draws Millions of Consumers into Wearable Computing; Business Insider: New York, NY, USA, 2013; pp. 1–18. [Google Scholar]

- Herrera-Alcántara, O.; Barrera-Animas, A.Y.; González-Mendoza, M.; Castro-Espinoza, F. Monitoring Student Activities with Smartwatches: On the Academic Performance Enhancement. Sensors 2019, 19, 1605. [Google Scholar] [CrossRef] [Green Version]

- Kheirkhahan, M.; Nair, S.; Davoudi, A.; Rashidi, P.; Wanigatunga, A.A.; Corbett, D.B.; Mendoza, T.; Manini, T.M.; Ranka, S. A smartwatch-based framework for real-time and online assessment and mobility monitoring. J. Biomed. Inform. 2019, 89, 29–40. [Google Scholar] [CrossRef] [PubMed]

- Pérez, F.d.A.; Gago, J.M.S.; Rodríguez, M.C. Analytics of biometric data from wearable devices to support teaching and learning activities. J. Inf. Syst. Eng. Manag. 2016, 1, 41–54. [Google Scholar] [CrossRef] [Green Version]

- Johansson, R.E.; Adolph, S.T.; Swart, J.; Lambert, M.I. Accuracy of GPS sport watches in measuring distance in an ultramarathon running race. Int. J. Sports Sci. Coach. 2020, 15, 212–219. [Google Scholar] [CrossRef]

- Cummins, C.; Orr, R.; O’Connor, H.; West, C. Global Positioning Systems (GPS) and Microtechnology Sensors in Team Sports: A Systematic Review. Sports Med. 2013, 43, 1025–1042. [Google Scholar] [CrossRef]

- Jang, B.; Kim, H. Indoor Positioning Technologies Without Offline Fingerprinting Map: A Survey. IEEE Commun. Surv. Tutor. 2019, 21, 508–525. [Google Scholar] [CrossRef]

- Van Diggelen, F.; Enge, P. The World’s first GPS MOOC and Worldwide Laboratory using Smartphones. In Proceedings of the Proc. 28th International Technical Meeting of the Satellite Division of The Institute of Navigation (ION GNSS+ 2015), Tampa, FL, USA, 14–18 September 2015; pp. 361–369. [Google Scholar]

- Cezar, G. Activity Recognition in Construction Sites Using 3D Accelerometer and Gyrometer. Access 2012, 10, 2018. [Google Scholar]

- Ryu, S.; Seo, J.; Liu, M.; Lee, S.; Haas, C.T. Action Recognition Using a Wristband-Type Activity Tracker: Case Study of Masonry Work. In Proceedings of the Construction Research Congress, San Juan, Puerto Rico, 31 May–2 June 2016. [Google Scholar]

- Choi, B.; Jebelli, H.; Lee, S. Feasibility analysis of electrodermal activity (EDA) acquired from wearable sensors to assess construction workers’ perceived risk. Saf. Sci. 2019, 115, 110–120. [Google Scholar] [CrossRef]

- Jebelli, H.; Choi, B.; Kim, H.; Lee, S. Feasibility Study of a Wristband-Type Wearable Sensor to Understand Construction Workers’ Physical and Mental Status. In Proceedings of the Construction Research Congress 2018, New Orleans, LA, USA, 2–4 April 2018. [Google Scholar]

- Jebelli, H.; Choi, B.; Lee, S. Application of Wearable Biosensors to Construction Sites. I: Assessing Workers’ Stress. J. Constr. Eng. Manag. 2019, 145, 04019079. [Google Scholar] [CrossRef]

- Jebelli, H.; Choi, B.; Lee, S. Application of Wearable Biosensors to Construction Sites. II: Assessing Workers’ Physical Demand. J. Constr. Eng. Manag. 2019, 145, 04019080. [Google Scholar] [CrossRef]

- Shakerian, S.; Habibnezhad, M.; Ojha, A.; Lee, G.; Liu, Y.; Jebelli, H.; Lee, S. Assessing occupational risk of heat stress at construction: A worker-centric wearable sensor-based approach. Saf. Sci. 2021, 142, 105395. [Google Scholar] [CrossRef]

- iMotions. Empatica E4 EDA/GSR Wristband. Available online: https://imotions.com/hardware/empatica-e4-eda-gsr-wristband/ (accessed on 28 April 2022).

- Hwang, S.; Seo, J.; Ryu, J.; Lee, S. Challenges and Opportunities of Understanding Construction Workers’ Physical Demands through Field Energy Expenditure Measurements Using a Wearable Activity Tracker. In Proceedings of the Construction Research Congress 2016: Old and New Construction Technologies Converge in Historic San Juan, San Juan, Puerto Rico, 31 May–2 June 2016; pp. 2730–2739. [Google Scholar]

- Guo, H.; Yu, Y.; Xiang, T.; Li, H.; Zhang, D. The availability of wearable-device-based physical data for the measurement of construction workers’ psychological status on site: From the perspective of safety management. Autom. Constr. 2017, 82, 207–217. [Google Scholar] [CrossRef]

- Ahn, C.R.; Lee, S.; Sun, C.; Jebelli, H.; Yang, K.; Choi, B. Wearable Sensing Technology Applications in Construction Safety and Health. J. Constr. Eng. Manag. 2019, 145, 03119007. [Google Scholar] [CrossRef]

- Awolusi, I.; Marks, E.; Hallowell, M. Wearable technology for personalized construction safety monitoring and trending: Review of applicable devices. Autom. Constr. 2018, 85, 96–106. [Google Scholar] [CrossRef]

- Hwang, S.; Seo, J.; Jebelli, H.; Lee, S. Feasibility analysis of heart rate monitoring of construction workers using a photoplethysmography (PPG) sensor embedded in a wristband-type activity tracker. Autom. Constr. 2016, 71, 372–381. [Google Scholar] [CrossRef]

- Hwang, S.; Lee, S. Wristband-type wearable health devices to measure construction workers’ physical demands. Autom. Constr. 2017, 83, 330–340. [Google Scholar] [CrossRef]

- Garimella, S.A.; Senouci, A.; Kim, K. Monitoring Fatigue in Construction Workers Using Wearable Sensors. In Proceedings of the Construction Research Congress 2020, Tempe, AZ, USA, 8–10 March 2020. [Google Scholar]

- Lee, G.; Choi, B.; Jebelli, H.; Lee, S. Assessment of construction workers’ perceived risk using physiological data from wearable sensors: A machine learning approach. J. Build. Eng. 2021, 42, 102824. [Google Scholar] [CrossRef]

- Lukka, K. The Constructive Research Approach; Turku School of Economics and Business Administration: Turku, Finland, 2003; pp. 83–101. [Google Scholar]

- Yin, R.K. Case Study Research. Design and Methods; Sage Publications Inc.: Thousand Oaks, CA, USA, 2003. [Google Scholar]

- Beach, R.; Muhlemann, A.P.; Price, D.H.R.; Paterson, A.; Sharp, J.A. The role of qualitative methods in production management research. Int. J. Prod. Econ. 2001, 74, 201–212. [Google Scholar] [CrossRef]

- Regeringen. Strategi for Energirenovering af Bygninger; The Danish Government: Copenhagen, Denmark, 2014.

- Regeringen. National Strategi for Bæredygtigt Byggeri; The Danish Government: Copenhagen, Denmark, 2021.

- Worlddata.Info. Average Height and Weight by Country. Available online: https://www.worlddata.info/average-bodyheight.php (accessed on 28 April 2022).

- Python. A Computer Programming Language. Available online: https://www.python.org/ (accessed on 17 May 2022).

- Veusz. A Scientific Plotting Package. Available online: https://veusz.github.io/ (accessed on 4 May 2022).

- RouteConverter. A GPS Tool. Available online: https://www.routeconverter.com/home/en (accessed on 4 May 2022).

- Wiley, J. Wiley StatsRef: Statistics Reference Online; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Kim, K.J.; Shin, D.-H. An acceptance model for smart watches. Internet Res. 2014, 25, 527–541. [Google Scholar] [CrossRef]

- Anzaldo, D. Wearable sports technology—Market landscape and compute SoC trends. In Proceedings of the International SoC Design Conference, Gyungju, Korea, 2–5 November 2015; pp. 1–6. [Google Scholar]

| Sounds & Alerts | Activity Type | Activity Tracking | User Settings | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Activity Tracking | HR | Measurement Units | Height | Weight | Gender | Age | |||

| Setting | All off | Walking | On | Wrist | Metric | 182 cm | 86 kg | Male | 41 |

| SW01 | SW02 | SW03 | SW04 | SW05 | SW06 | SW07 | SW08 | SW09 | SW10 | Total | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Day 1 | No | Yes | Yes | Yes | Yes | NS | No | No | No | Yes | 5 |

| Day 2 | Yes | Yes | Yes | Yes | NS | No | Yes | Yes | Yes | NS | 7 |

| Day 3 | Yes | Yes | NS | Yes | No | No | No | Yes | Yes | Yes | 6 |

| Day 4 | Yes | Yes | Yes | Yes | No | Yes | No | Yes | Yes | Yes | 8 |

| Day 5 | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | No | Yes | 9 |

| Day 6 | No | Yes | NS | Yes | Yes | Yes | Yes | Yes | Yes | Yes | 8 |

| Day 7 | NS | Yes | No | Yes | Yes | Yes | Yes | Yes | Yes | Yes | 8 |

| Day 8 | No | Yes | Yes | Yes | Yes | No | Yes | Yes | Yes | Yes | 8 |

| Day 9 | No | NS | No | Yes | Yes | No | NS | Yes | Yes | Yes | 5 |

| Total | 4 | 8 | 5 | 9 | 6 | 4 | 5 | 8 | 7 | 8 | 64 |

| Device Name | Activity Duration | Starting Time | Ending Time | Device Name | Activity Duration | Starting Time | Ending Time |

|---|---|---|---|---|---|---|---|

| D1-SW02 | 08:01:07 | 06:38:06 | 14:39:13 | D6-SW02 | 07:38:01 | 06:37:06 | 14:15:07 |

| D1-SW03 | 07:53:01 | 06:36:30 | 14:29:32 | D6-SW04 | 07:46:01 | 06:38:40 | 14:24:41 |

| D1-SW04 | 08:00:44 | 06:27:25 | 14:28:09 | D6-SW05 | 07:21:57 | 06:36:23 | 13:58:20 |

| D1-SW05 | 07:48:51 | 06:44:57 | 14:33:48 | D6-SW06 | 07:48:04 | 06:35:07 | 14:23:11 |

| D1-SW10 | 07:57:09 | 06:32:14 | 14:29:23 | D6-SW07 | 07:54:38 | 06:35:03 | 14:29:41 |

| D2-SW01 | 07:44:44 | 06:37:00 | 14:21:44 | D6-SW08 | 07:49:07 | 06:35:36 | 14:24:43 |

| D2-SW02 | 07:54:16 | 06:33:44 | 14:28:00 | D6-SW09 | 05:05:22 | 06:36:51 | 11:42:13 |

| D2-SW03 | 07:44:26 | 06:31:29 | 14:15:55 | D6-SW10 | 07:54:37 | 06:35:18 | 14:29:55 |

| D2-SW04 | 07:50:07 | 06:33:20 | 14:23:27 | D7-SW02 | 07:57:35 | 06:29:39 | 14:27:14 |

| D2-SW07 | 07:55:37 | 06:31:41 | 14:27:18 | D7-SW04 | 07:52:20 | 06:30:06 | 14:22:26 |

| D2-SW08 | 08:00:23 | 06:27:18 | 14:27:41 | D7-SW05 | 07:37:31 | 06:35:16 | 14:12:47 |

| D2-SW09 | 07:49:57 | 06:31:53 | 14:21:50 | D7-SW06 | 07:33:31 | 06:35:41 | 14:09:12 |

| D3-SW01 | 07:02:06 | 07:19:45 | 14:21:51 | D7-SW07 | 07:32:51 | 06:35:28 | 14:08:19 |

| D3-SW02 | 07:51:41 | 06:33:07 | 14:24:48 | D7-SW08 | 07:49:33 | 06:29:27 | 14:19:00 |

| D3-SW04 | 07:49:02 | 06:32:40 | 14:21:42 | D7-SW09 | 07:45:46 | 06:35:27 | 14:21:13 |

| D3-SW08 | 07:50:52 | 06:31:25 | 14:22:17 | D7-SW10 | 07:56:09 | 06:33:10 | 14:29:19 |

| D3-SW09 | 07:49:43 | 06:31:50 | 14:21:33 | D8-SW02 | 07:49:01 | 06:34:37 | 14:23:38 |

| D3-SW10 | 06:56:01 | 06:32:52 | 13:28:53 | D8-SW03 | 07:47:59 | 06:36:01 | 14:24:00 |

| D4-SW01 | 06:41:21 | 07:09:48 | 13:51:09 | D8-SW04 | 07:55:24 | 06:30:45 | 14:26:09 |

| D4-SW02 | 06:59:07 | 07:00:20 | 13:59:27 | D8-SW05 | 07:17:38 | 07:05:49 | 14:23:27 |

| D4-SW03 | 06:38:58 | 07:15:49 | 13:54:47 | D8-SW07 | 07:47:51 | 06:40:12 | 14:28:03 |

| D4-SW04 | 03:44:52 | 07:07:40 | 10:52:32 | D8-SW08 | 07:39:13 | 06:34:37 | 14:13:50 |

| D4-SW06 | 06:21:34 | 07:33:21 | 13:54:55 | D8-SW09 | 07:45:17 | 06:34:45 | 14:20:02 |

| D4-SW08 | 06:49:59 | 07:14:18 | 14:04:17 | D8-SW10 | 07:45:13 | 06:34:53 | 14:20:06 |

| D4-SW09 | 06:57:29 | 07:00:09 | 13:57:38 | D9-SW04 | 06:48:53 | 07:08:57 | 13:57:50 |

| D4-SW10 | 06:59:12 | 07:00:20 | 13:59:32 | D9-SW05 | 06:57:13 | 07:08:30 | 14:05:43 |

| D5-SW01 | 07:49:11 | 06:34:39 | 14:23:50 | D9-SW08 | 06:29:32 | 07:27:46 | 13:57:18 |

| D5-SW02 | 07:27:49 | 06:37:53 | 14:05:42 | D9-SW09 | 06:44:14 | 07:06:06 | 13:50:20 |

| D5-SW03 | 07:47:44 | 06:37:10 | 14:24:54 | D9-SW10 | 06:45:42 | 07:04:32 | 13:50:14 |

| D5-SW04 | 07:47:25 | 06:38:19 | 14:25:44 | ||||

| D5-SW05 | 07:52:56 | 06:34:00 | 14:26:56 | ||||

| D5-SW06 | 07:52:38 | 06:33:45 | 14:26:23 | ||||

| D5-SW07 | 07:52:23 | 06:33:42 | 14:26:05 | ||||

| D5-SW08 | 07:50:21 | 06:33:47 | 14:24:08 | ||||

| D5-SW10 | 07:49:14 | 06:34:47 | 14:24:01 |

| Participants | Activities Analysed | Data Size of Csv Files | Total Duration [h] | Sample Size | Variables of Each Data Point |

|---|---|---|---|---|---|

| 10 | 54 | 19.6 MB | 413.5 h | 63,145 points | 2 Identifiers (ID, timestamp) 3 Location (Latitude & longitude & altitude) 1 Distance (Accumulative distance) |

| Time | Maximum [km] | Minimum [km] | Mean, m [km] | St. dev., σ [km] |

|---|---|---|---|---|

| 06:30–07:00 | 0.45 | 0.29 | 0.36 | 0.05 |

| 07:00–07:30 | 0.34 | 0.13 | 0.26 | 0.07 |

| 07:30–08:00 | 0.58 | 0.10 | 0.27 | 0.14 |

| 08:00–08:30 | 0.38 | 0.17 | 0.26 | 0.07 |

| 08:30–09:00 | 0.39 | 0.17 | 0.26 | 0.08 |

| 09:00–09:30 | 0.59 | 0.17 | 0.36 | 0.12 |

| 09:30–10:00 | 0.48 | 0.18 | 0.36 | 0.09 |

| 10:00–10:30 | 0.63 | 0.28 | 0.41 | 0.10 |

| 11:00–11:30 | 0.66 | 0.33 | 0.46 | 0.09 |

| 11:30–12:00 | 0.41 | 0.17 | 0.30 | 0.08 |

| 12:00–12:30 | 0.43 | 0.20 | 0.31 | 0.07 |

| 12:30–13:00 | 0.55 | 0.14 | 0.31 | 0.11 |

| 13:00–13:30 | 0.39 | 0.20 | 0.28 | 0.07 |

| 13:30–14:00 | 0.42 | 0.17 | 0.25 | 0.09 |

| 14:00–14:30 | 0.32 | 0.19 | 0.23 | 0.05 |

| Day 1 | Day 2 | Day 3 | Day 4 | Day 5 | Day 6 | Day 7 | Day 8 | Day 9 | |

|---|---|---|---|---|---|---|---|---|---|

| SW01 | - | 5.15 | - | 6.08 | 4.07 | - | - | - | - |

| SW02 | 6.66 | 6.42 | 2.20 | 2.25 | - | 5.70 | 5.63 | 6.00 | - |

| SW03 | 3.18 | 5.00 | - | 2.71 | 6.69 | - | - | 8.58 | - |

| SW04 | 3.00 | 7.82 | 7.58 | - | 5.93 | 6.28 | 6.80 | 3.03 | 4.36 |

| SW05 | 3.25 | - | - | - | 2.63 | - | 4.43 | - | 3.86 |

| SW06 | - | - | - | - | 10.10 | 4.22 | 3.34 | - | - |

| SW07 | - | 2.06 | - | - | 3.21 | 1.07 | 2.36 | 2.77 | - |

| SW08 | - | 2.68 | 3.51 | 4.34 | 1.46 | 4.26 | 4.59 | 2.63 | - |

| SW09 | - | 5.57 | 4.62 | 2.04 | - | - | 1.93 | 4.07 | 8.31 |

| SW10 | 7.71 | - | - | - | 4.62 | 2.63 | 6.10 | 3.05 | 6.23 |

| Average | 4.76 | 4.96 | 4.48 | 3.48 | 4.84 | 4.03 | 4.40 | 4.30 | 5.69 |

| Maximum [km] | Minimum [km] | Mean, m [km] | St. dev., σ [km] | |

|---|---|---|---|---|

| Day 1 | 7.71 | 3.00 | 4.76 | 2.25 |

| Day 2 | 7.82 | 2.06 | 4.96 | 2.01 |

| Day 3 | 7.58 | 2.20 | 4.48 | 2.29 |

| Day 4 | 6.08 | 2.04 | 3.48 | 1.71 |

| Day 5 | 10.10 | 1.46 | 4.84 | 2.72 |

| Day 6 | 6.28 | 1.07 | 4.03 | 1.93 |

| Day 7 | 6.80 | 1.93 | 4.40 | 1.76 |

| Day 8 | 8.58 | 2.63 | 4.30 | 2.22 |

| Day 9 | 8.31 | 3.86 | 5.69 | 2.02 |

| Description | Maximum [km] | Minimum [km] | Mean, m [km] | St. dev., σ [km] | |

|---|---|---|---|---|---|

| Day 1 | All | 7.71 | 3.00 | 4.76 | 2.25 |

| Without foreman | 6.66 | 3.00 | 4.02 | 1.76 | |

| Delta | −13.62% | - | −15.55% | −21.78% | |

| Day 2 | All | 7.82 | 2.06 | 4.96 | 2.01 |

| Without foreman | 6.42 | 2.06 | 4.48 | 1.72 | |

| Delta | −17.90% | - | −9.68% | −14.43% | |

| Day 3 | All | 7.58 | 2.20 | 4.48 | 2.29 |

| Without foreman | 4.62 | 2.20 | 3.45 | 1.21 | |

| Delta | −39.05% | - | −22.99% | −47.16% | |

| Day 4 | All | 6.08 | 2.04 | 3.48 | 1.71 |

| Without foreman | 4.34 | 2.04 | 2.83 | 1.04 | |

| Delta | −28.62% | - | −18.68% | −39.18% | |

| Day 5 | All | 10.10 | 1.46 | 4.84 | 2.72 |

| Without foreman | 6.69 | 1.46 | 4.09 | 1.83 | |

| Delta | −33.86% | - | −15.50% | −32.72% | |

| Day 6 | All | 6.28 | 1.07 | 4.03 | 1.93 |

| Without foreman | 5.70 | 1.07 | 3.58 | 1.78 | |

| Delta | −9:24% | - | −11.17% | −7.77% | |

| Day 7 | All | 6.80 | 1.93 | 4.40 | 1.76 |

| Without foreman | 6.10 | 1.93 | 4.05 | 1.58 | |

| Delta | −10.29% | - | −7.95% | −10.23% | |

| Day 8 | All | 8.58 | 2.63 | 4.30 | 2.22 |

| Without foreman | 6.00 | 2.63 | 3.59 | 1.28 | |

| Delta | −30.07% | - | −16.51% | −42.34% | |

| Day 9 | All | 8.31 | 3.86 | 5.69 | 2.02 |

| Without foreman | 6.23 | 3.86 | 4.82 | 1.25 | |

| Delta | −25.03% | - | −15.29% | −38.12% | |

| Average change (delta) | −23.08% | −13.33% | −28.19% | ||

| Total averages | All | 5.69 | 3.48 | 4.55 | 0.62 |

| Without foreman | 4.82 | 2.83 | 3.88 | 0.59 | |

| Delta | −15.29% | −18.68% | −14.73% | −5.14% |

| Delivered | Collected | TTD [km] | TTD if at Office [km] | Δ TTD | Delivered | Collected | TTD [km] | TTD if at Office [km] | Δ TTD | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| D1-SW02 | Site | Office | 6.66 | 6.96 | 4.31% | D6-SW02 | Site | Site | 5.70 | 6.30 | 9.52% |

| D1-SW03 | Site | Site | 3.18 | 3.78 | 15.87% | D6-SW04 | Site | Site | 6.28 | 6.88 | 8.72% |

| D1-SW04 | Office | Site | 3.00 | 3.30 | 9.10% | D6-SW06 | Site | Site | 4.22 | 4.82 | 12.45% |

| D1-SW05 | Site | Office | 3.25 | 3.55 | 8.45% | D6-SW07 | Site | Site | 1.07 | 1.67 | 35.93% |

| D1-SW10 | Halfway | Site | 7.71 | 8.16 | 5.51% | D6-SW08 | Site | Site | 4.26 | 4.86 | 12.35% |

| D2-SW01 | Site | Site | 5.15 | 5.75 | 10.44% | D6-SW10 | Site | Site | 2.63 | 3.23 | 18.58% |

| D2-SW02 | Site | Site | 6.42 | 7.02 | 8.55% | D7-SW02 | Office | Site | 5.63 | 5.93 | 5.06% |

| D2-SW03 | Site | Site | 5.00 | 5.60 | 10.71% | D7-SW04 | Office | Site | 6.80 | 7.10 | 4.23% |

| D2-SW04 | Site | Site | 7.82 | 8.42 | 7.12% | D7-SW05 | Site | Site | 4.43 | 5.03 | 11.93% |

| D2-SW07 | Site | Site | 2.06 | 2.66 | 22.53% | D7-SW06 | Site | Site | 3.34 | 3.94 | 15.23% |

| D2-SW08 | Site | Site | 2.68 | 3.28 | 18.31% | D7-SW07 | Site | Site | 2.36 | 2.96 | 20.27% |

| D2-SW09 | Site | Site | 5.57 | 6.17 | 9.73% | D7-SW08 | Office | Site | 4.59 | 4.89 | 6.13% |

| D3-SW02 | Site | Site | 2.20 | 2.80 | 21.43% | D7-SW09 | Site | Site | 1.93 | 2.53 | 23.72% |

| D3-SW04 | Site | Site | 7.58 | 8.18 | 7.33% | D7-SW10 | Halfway | Site | 6.10 | 6.55 | 6.87% |

| D3-SW08 | Site | Site | 3.51 | 4.11 | 14.60% | D8-SW02 | Site | Site | 6.00 | 6.60 | 9.09% |

| D3-SW09 | Site | Site | 4.62 | 5.22 | 11.49% | D8-SW03 | Site | Site | 8.58 | 9.18 | 6.54% |

| D4-SW01 | Site | Site | 6.08 | 6.68 | 8.98% | D8-SW04 | Office | Site | 3.03 | 3.33 | 9.01% |

| D4-SW02 | Office | Site | 2.25 | 2.55 | 11.76% | D8-SW07 | Site | Site | 2.77 | 3.37 | 17.80% |

| D4-SW03 | Site | Site | 2.71 | 3.31 | 18.13% | D8-SW08 | Site | Site | 2.63 | 3.23 | 18.58% |

| D4-SW08 | Site | Office | 4.34 | 4.64 | 6.47% | D8-SW09 | Site | Site | 4.07 | 4.67 | 12.85% |

| D4-SW09 | Office | Site | 2.04 | 2.34 | 12.82% | D8-SW10 | Site | Site | 3.05 | 3.65 | 16.44% |

| D5-SW01 | Site | Site | 4.07 | 4.67 | 12.85% | D9-SW04 | Site | Site | 4.36 | 4.96 | 12.10% |

| D5-SW03 | Site | Site | 6.69 | 7.28 | 8.24% | D9-SW05 | Site | Office | 3.86 | 4.16 | 7.21% |

| D5-SW04 | Site | Site | 5.93 | 6.53 | 9.19% | D9-SW09 | Site | Site | 8.31 | 8.91 | 6.73% |

| D5-SW05 | Site | Site | 2.63 | 3.23 | 18.58% | D9-SW10 | Site | Site | 6.23 | 6.83 | 8.78% |

| D5-SW06 | Site | Site | 10.10 | 10.70 | 5.61% | Distance from office to material storage area on site = 300 m. | |||||

| D5-SW07 | Site | Site | 3.21 | 3.81 | 15.75% | ||||||

| D5-SW08 | Site | Site | 1.46 | 2.06 | 29.13% | ||||||

| D5-SW10 | Site | Site | 4.62 | 5.22 | 11.49% | ||||||

| Description | Maximum [km] | Minimum [km] | Mean, m [km] | St. dev., σ [km] | |

|---|---|---|---|---|---|

| Day 1 | Without data from break | 7.71 | 3.00 | 4.76 | 2.25 |

| Including data from break | 7.94 | 3.03 | 4.89 | 2.32 | |

| Delta | −2.98% | −1.00% | −2.73% | −3.11% | |

| Day 2 | Without data from break | 7.82 | 2.06 | 4.96 | 2.01 |

| Including data from break | 7.96 | 2.30 | 5.09 | 1.98 | |

| Delta | −1.79% | −11.65% | −2.62% | 1.49% | |

| Day 3 | Without data from break | 7.58 | 2.2 | 4.48 | 2.29 |

| Including data from break | 7.6 | 2.31 | 4.55 | 2.24 | |

| Delta | −0.26% | −5.00% | −1.56% | 2.18% | |

| Day 4 | Without data from break | 6.08 | 2.04 | 3.48 | 1.71 |

| Including data from break | 6.09 | 2.15 | 3.57 | 1.68 | |

| Delta | −0.16% | −5.39% | −2.59% | 1.75% | |

| Day 5 | Without data from break | 10.1 | 1.46 | 4.84 | 2.72 |

| Including data from break | 10.25 | 1.65 | 4.97 | 2.69 | |

| Delta | −1.49% | −13.01% | −2.69% | 1.10% | |

| Day 6 | Without data from break | 6.28 | 1.07 | 4.03 | 1.93 |

| Including data from break | 6.46 | 1.09 | 4.13 | 1.97 | |

| Delta | −2.87% | −1.87% | −2.48% | −2.07% | |

| Day 7 | Without data from break | 6.8 | 1.93 | 4.4 | 1.76 |

| Including data from break | 6.91 | 2.08 | 4.54 | 1.72 | |

| Delta | −1.62% | −7.77% | −3.18% | 2.27% | |

| Day 8 | Without data from break | 8.58 | 2.63 | 4.3 | 2.22 |

| Including data from break | 8.64 | 2.72 | 4.34 | 2.22 | |

| Delta | −0.70% | −3.42% | −0.93% | 0.00% | |

| Day 9 | Without data from break | 8.31 | 3.86 | 5.69 | 2.02 |

| Including data from break | 8.38 | 3.95 | 5.79 | 1.99 | |

| Delta | −0.84% | −2.33% | −1.76% | 1.49% | |

| Total averages | Without data from break | 5.69 | 3.48 | 4.55 | 0.622 |

| Including data from break | 5.79 | 3.57 | 4.65 | 0.64 | |

| Delta | −1.76% | −2.59% | −2.20% | −2.89% |

| Number of Points Before | Number of Points After | Before [km] | After [km] | Δ [km] | Δ [%] | Number of Points Before | Number of Points After | Before [km] | After [km] | Δ [km] | Δ [Δ [%] | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D1-SW02 | 4465 | 1842 | 12.37 | 6.66 | 5.71 | −46.18 | D6-SW02 | 4184 | 1500 | 13.84 | 5.70 | 8.14 | −58.82 |

| D1-SW03 | 3375 | 862 | 8.35 | 3.18 | 5.17 | −61.91 | D6-SW04 | 4322 | 1558 | 15.33 | 6.28 | 9.06 | −59.07 |

| D1-SW04 | 2964 | 776 | 6.33 | 3.00 | 3.33 | −52.67 | D6-SW06 | 3715 | 1155 | 12.60 | 4.22 | 8.38 | −66.49 |

| D1-SW05 | 3645 | 897 | 7.05 | 3.25 | 3.80 | −53.90 | D6-SW07 | 2024 | 211 | 2.66 | 1.07 | 1.60 | −59.93 |

| D1-SW10 | 3546 | 1630 | 16.82 | 7.71 | 9.11 | −54.17 | D6-SW08 | 4060 | 1255 | 9.09 | 4.26 | 4.83 | −53.11 |

| D2-SW01 | 4081 | 1375 | 10.25 | 5.15 | 5.10 | −49.78 | D6-SW10 | 3461 | 678 | 6.14 | 2.63 | 3.52 | −57.26 |

| D2-SW02 | 4172 | 1612 | 14.19 | 6.42 | 7.77 | −54.76 | D7-SW02 | 3802 | 1418 | 13.41 | 5.63 | 7.77 | −57.99 |

| D2-SW03 | 4534 | 1290 | 9.60 | 5.00 | 4.60 | −47.89 | D7-SW04 | 4410 | 1743 | 12.96 | 6.80 | 6.16 | −47.55 |

| D2-SW04 | 4399 | 1824 | 17.32 | 7.82 | 9.49 | −54.82 | D7-SW05 | 3776 | 1139 | 11.50 | 4.43 | 7.08 | −61.52 |

| D2-SW07 | 2928 | 519 | 6.42 | 2.06 | 4.36 | −67.86 | D7-SW06 | 3221 | 870 | 7.93 | 3.34 | 4.58 | −57.82 |

| D2-SW08 | 2919 | 616 | 8.67 | 2.68 | 5.99 | −69.13 | D7-SW07 | 3211 | 644 | 5.92 | 2.36 | 3.56 | −60.19 |

| D2-SW09 | 3894 | 1457 | 12.56 | 5.57 | 6.99 | −55.68 | D7-SW08 | 2640 | 1196 | 11.54 | 4.59 | 6.95 | −60.22 |

| D3-SW02 | 2587 | 532 | 5.87 | 2.20 | 3.66 | −62.42 | D7-SW09 | 2539 | 484 | 4.38 | 1.93 | 2.45 | −55.94 |

| D3-SW04 | 4823 | 1972 | 14.67 | 7.58 | 7.09 | −48.35 | D7-SW10 | 3851 | 1421 | 15.47 | 6.10 | 9.37 | −60.57 |

| D3-SW08 | 3628 | 955 | 8.71 | 3.51 | 5.19 | −59.65 | D8-SW02 | 4122 | 1602 | 12.23 | 6.00 | 6.23 | −50.95 |

| D3-SW09 | 4336 | 1242 | 9.29 | 4.62 | 4.64 | −49.94 | D8-SW03 | 5247 | 2383 | 17.93 | 8.58 | 9.35 | −52.16 |

| D4-SW01 | 4233 | 1712 | 12.11 | 6.08 | 6.04 | −49.84 | D8-SW04 | 3691 | 877 | 7.32 | 3.03 | 4.29 | −58.60 |

| D4-SW02 | 1221 | 487 | 5.42 | 2.25 | 3.17 | −58.53 | D8-SW07 | 3025 | 650 | 6.22 | 2.77 | 3.45 | −55.48 |

| D4-SW03 | 3407 | 770 | 7.37 | 2.71 | 4.67 | −63.31 | D8-SW08 | 2982 | 725 | 7.22 | 2.63 | 4.58 | −63.49 |

| D4-SW08 | 3566 | 1158 | 8.77 | 4.34 | 4.43 | −50.50 | D8-SW09 | 3082 | 961 | 7.80 | 4.07 | 3.73 | −47.79 |

| D4-SW09 | 2324 | 434 | 4.36 | 2.04 | 2.32 | −53.20 | D8-SW10 | 3790 | 822 | 7.64 | 3.05 | 4.59 | −60.12 |

| D5-SW01 | 3920 | 1070 | 9.49 | 4.07 | 5.42 | −57.11 | D9-SW04 | 3281 | 1119 | 8.68 | 4.36 | 4.32 | −49.79 |

| D5-SW03 | 4821 | 1834 | 13.65 | 6.69 | 6.96 | −51.02 | D9-SW05 | 3484 | 1097 | 8.28 | 3.86 | 4.42 | −53.37 |

| D5-SW04 | 3385 | 1367 | 12.76 | 5.93 | 6.84 | −53.56 | D9-SW09 | 4266 | 2141 | 17.77 | 8.31 | 9.46 | −53.25 |

| D5-SW05 | 2874 | 640 | 7.35 | 2.63 | 4.73 | −64.26 | D9-SW10 | 3814 | 1627 | 13.76 | 6.23 | 7.53 | −54.73 |

| D5-SW06 | 5467 | 2629 | 20.01 | 10.10 | 9.91 | −49.52 | Total | 194,549 | 63,145 | 548.77 | 244.77 | ||

| D5-SW07 | 2930 | 862 | 8.47 | 3.21 | 5.25 | −62.05 | Average | 3603 | 1169 | 10.16 | 4.55 | 5.61 | −55.2 |

| D5-SW08 | 2282 | 339 | 3.58 | 1.46 | 2.11 | −59.12 | |||||||

| D5-SW10 | 3823 | 1166 | 9.34 | 4.62 | 5.71 | −46.18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pérez, C.T.; Salling, S.; Wandahl, S. Five Guidelines for Adopting Smartwatches in Construction: A Novel Approach for Understanding Workers’ Efficiency Based on Travelled Distances and Locations. Sustainability 2022, 14, 8875. https://doi.org/10.3390/su14148875

Pérez CT, Salling S, Wandahl S. Five Guidelines for Adopting Smartwatches in Construction: A Novel Approach for Understanding Workers’ Efficiency Based on Travelled Distances and Locations. Sustainability. 2022; 14(14):8875. https://doi.org/10.3390/su14148875

Chicago/Turabian StylePérez, Cristina Toca, Stephanie Salling, and Søren Wandahl. 2022. "Five Guidelines for Adopting Smartwatches in Construction: A Novel Approach for Understanding Workers’ Efficiency Based on Travelled Distances and Locations" Sustainability 14, no. 14: 8875. https://doi.org/10.3390/su14148875

APA StylePérez, C. T., Salling, S., & Wandahl, S. (2022). Five Guidelines for Adopting Smartwatches in Construction: A Novel Approach for Understanding Workers’ Efficiency Based on Travelled Distances and Locations. Sustainability, 14(14), 8875. https://doi.org/10.3390/su14148875